Elasto-Dynamic Modeling of an Over-Constrained Parallel Kinematic Machine Using a Beam Model

Abstract

:1. Introduction

- Multi-body approaches: PKM legs can be modeled, for example, using beam theory and their joint behavior relies on Virtual Joint Method (VJM) [16,17]. In the literature, the simplest elasto-dynamic models are based on multi-body approaches. This method can only be applied for robot architectures whose hypotheses are valid. Other formulations are introduced to consider large deformations of flexible manipulators [18] or to decrease simulation time for complex mechanisms such as Matrix Structural Analysis (MSA) [19]. The decreasing of the time simulation is generally based on the development of a methodology to merge stiffness and mass matrices of all elements of the mechanism [19,20].

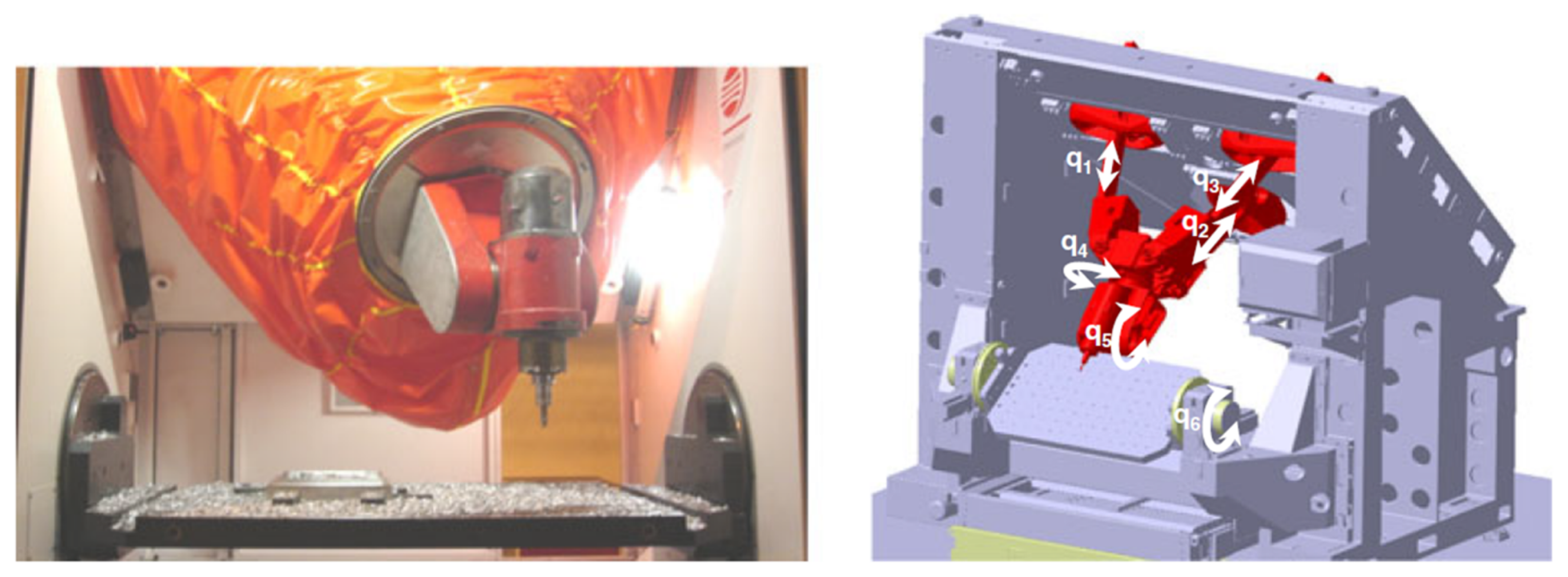

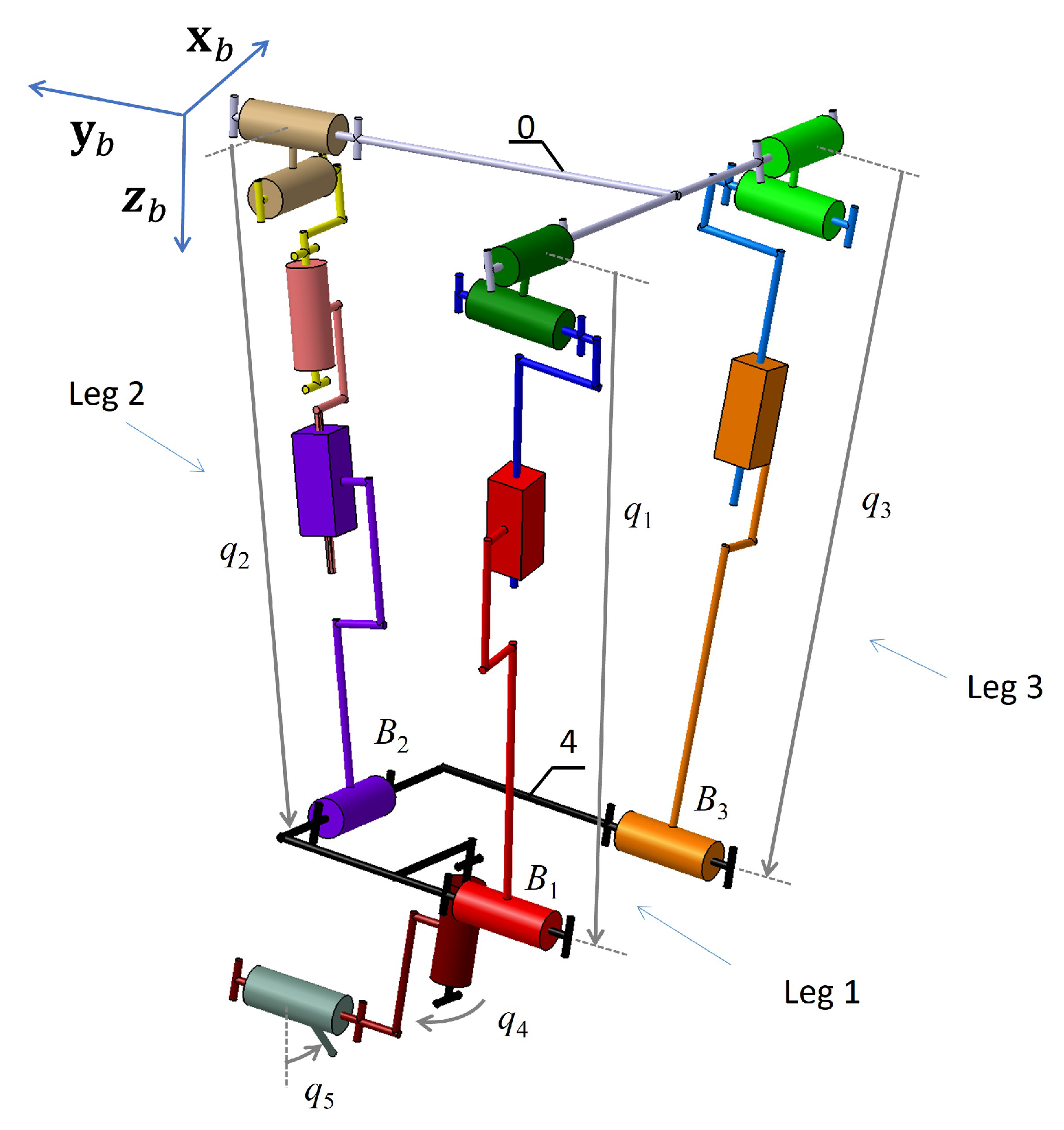

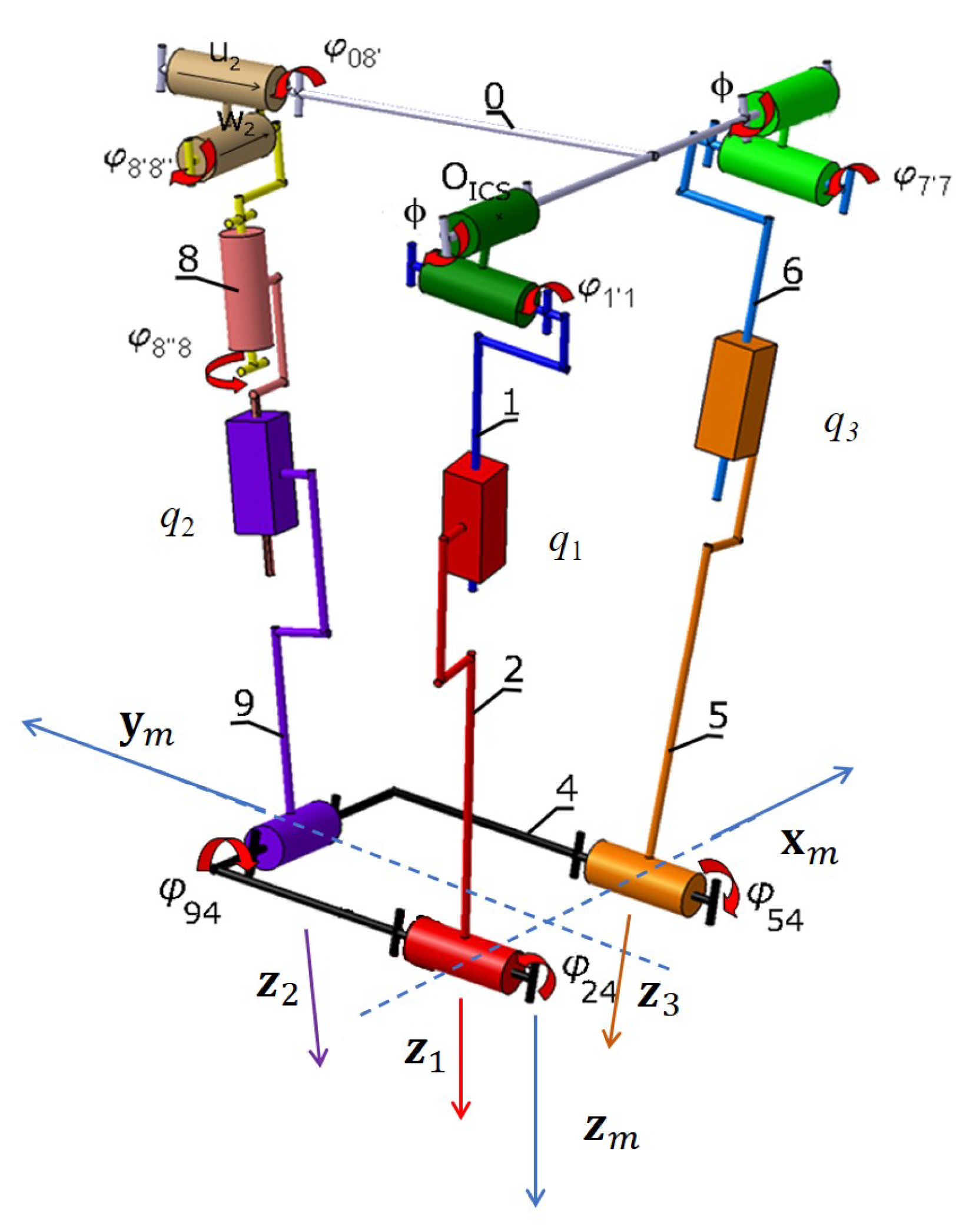

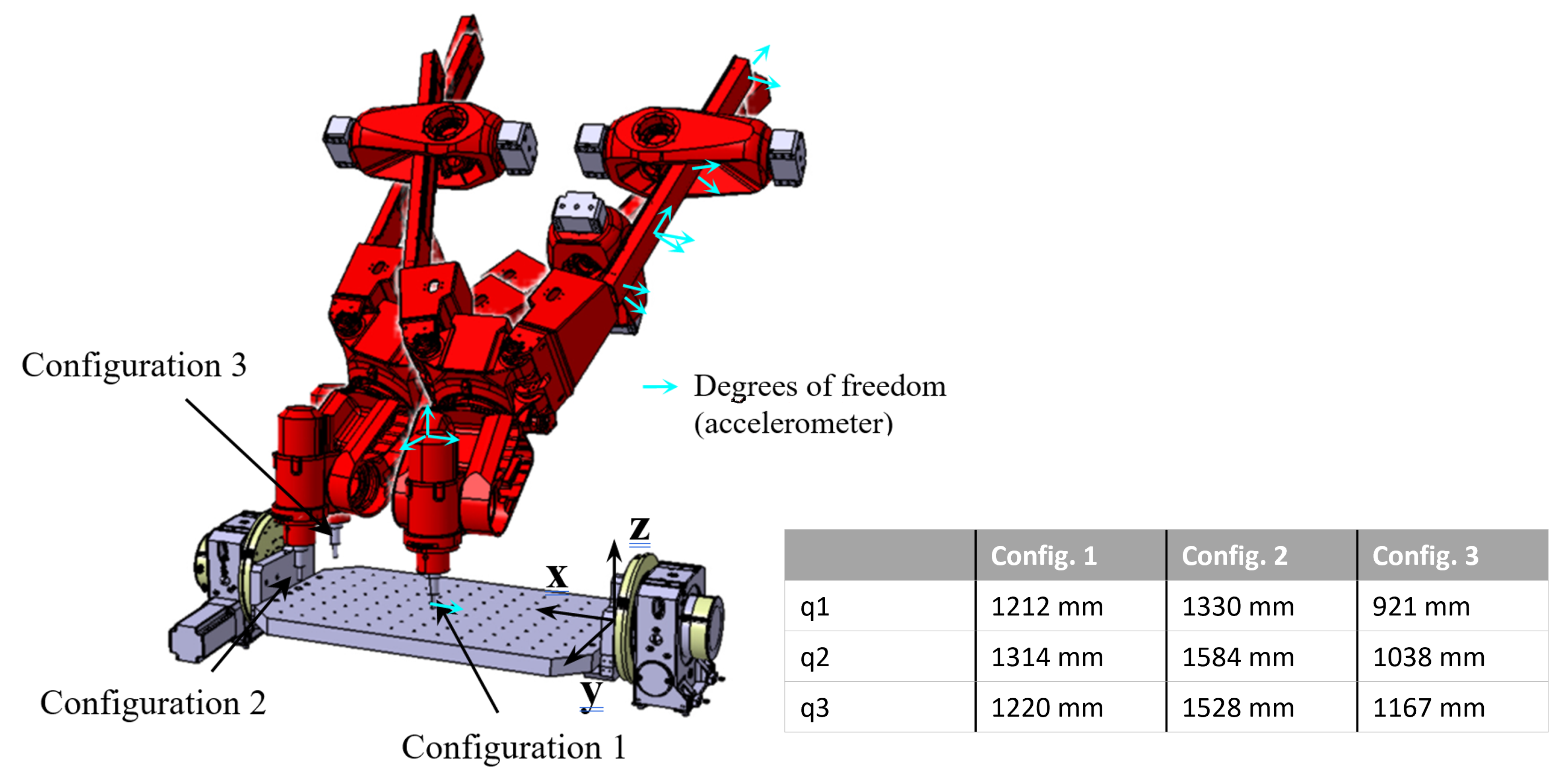

2. Tripteor X7 PKM

3. Elasto-Dynamic Modeling of PKMs

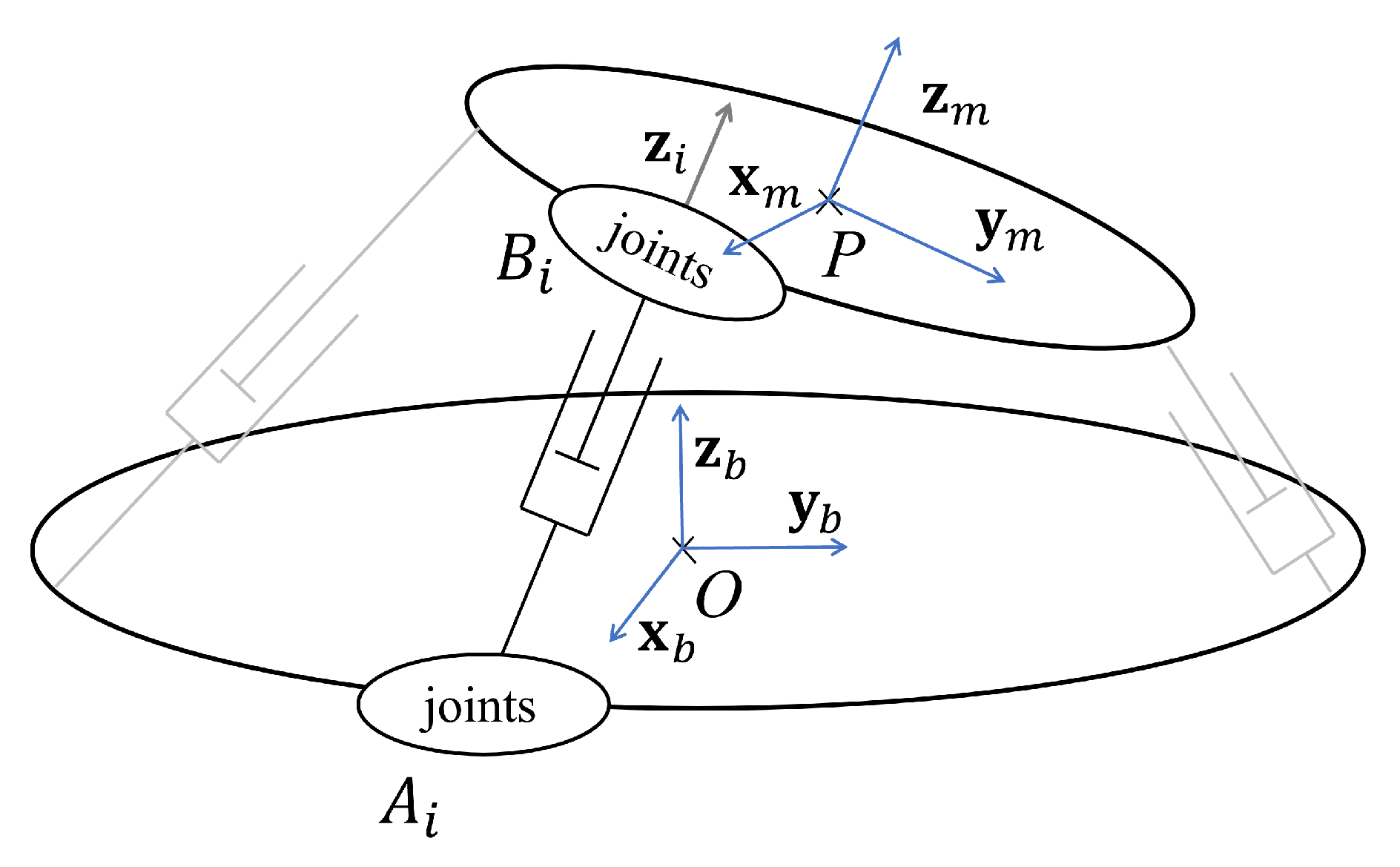

3.1. Local Modeling of PKM Leg

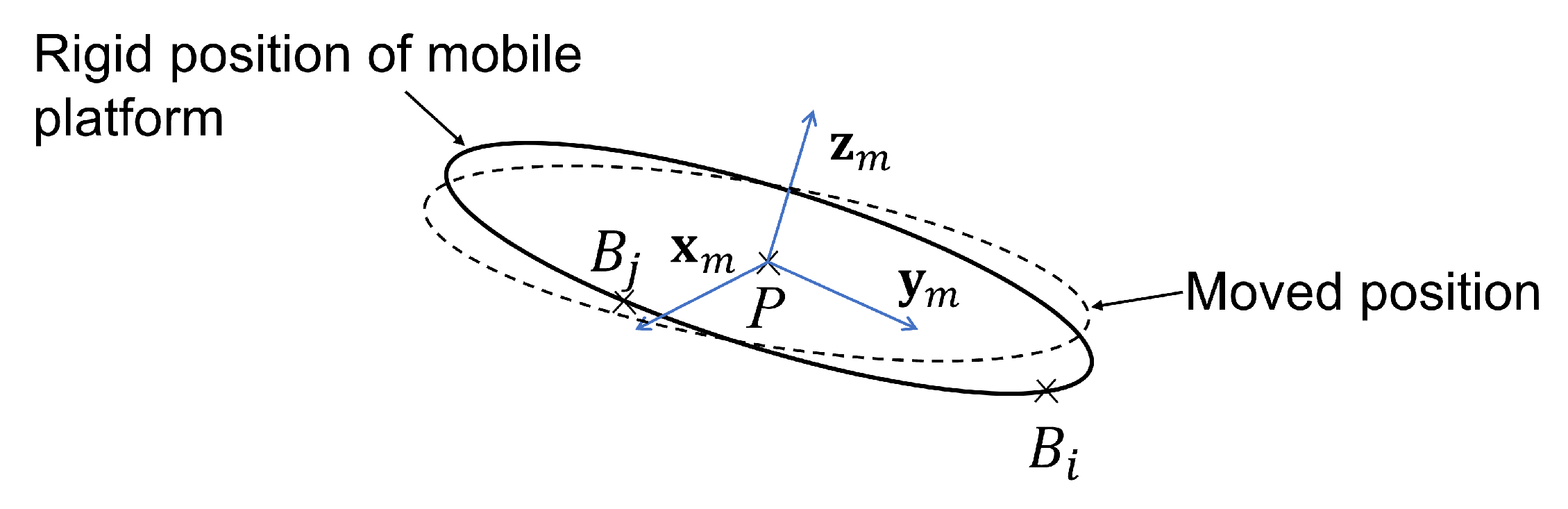

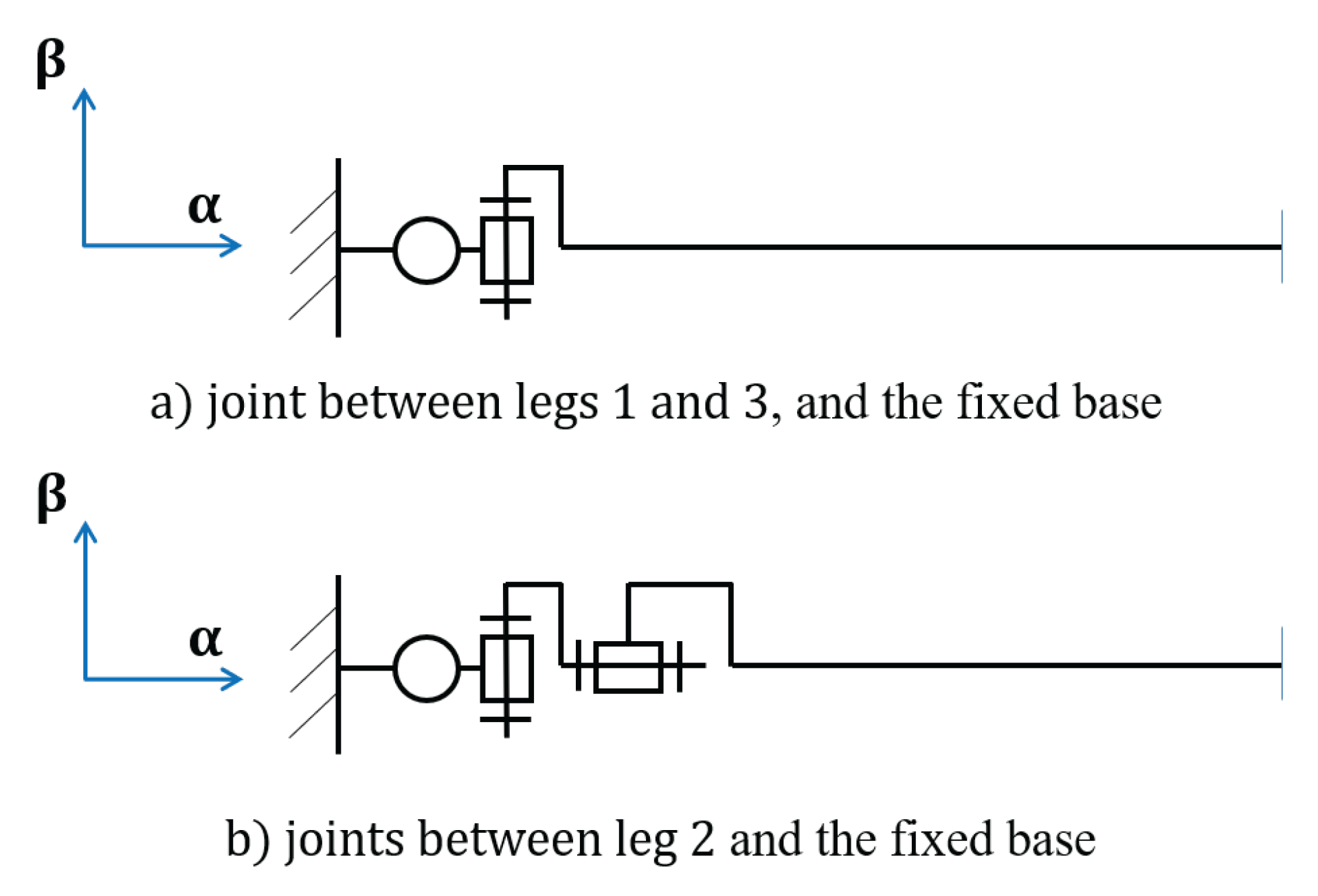

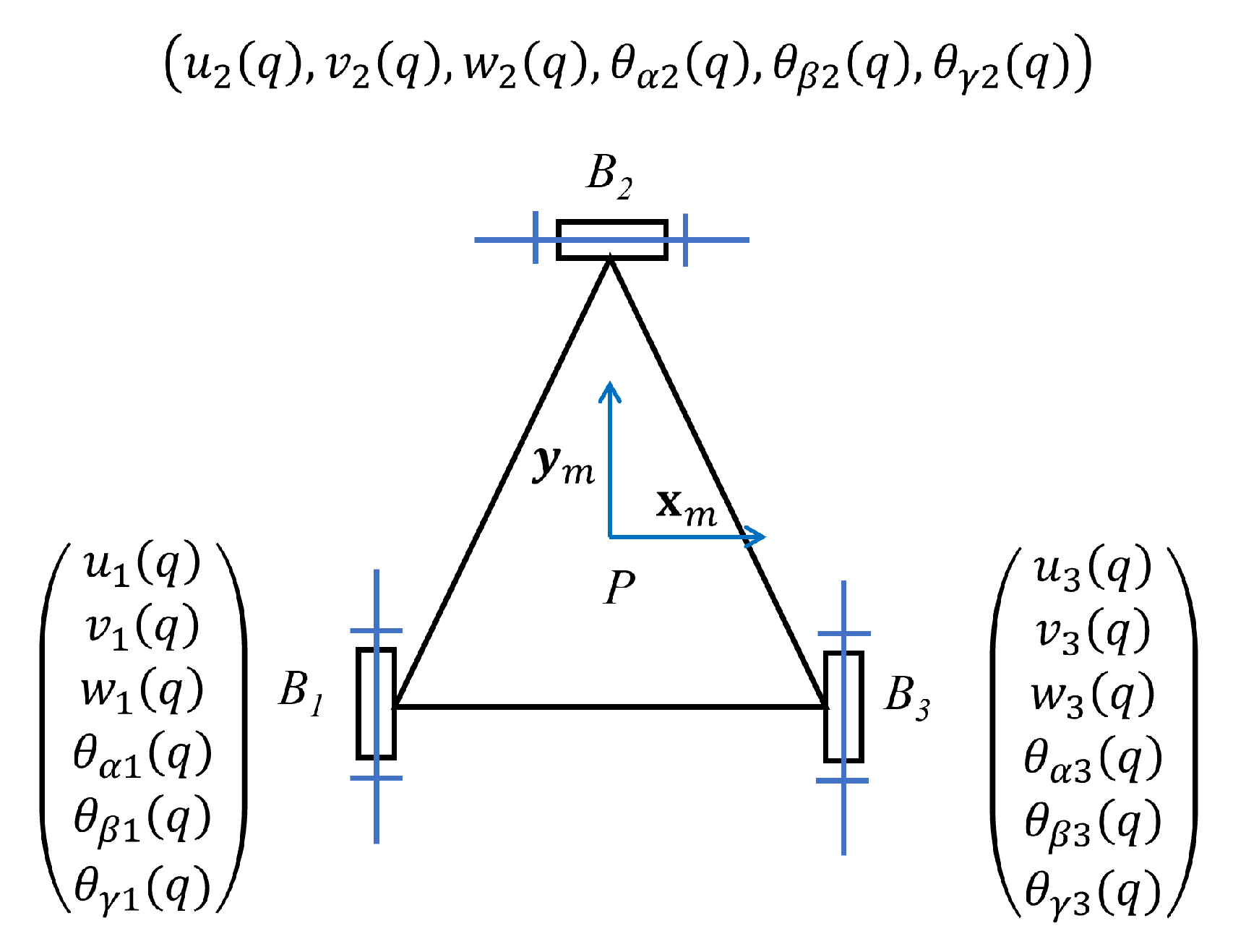

3.2. Constraint Equations

3.3. Mass Matrix Computation of Mobile Platform

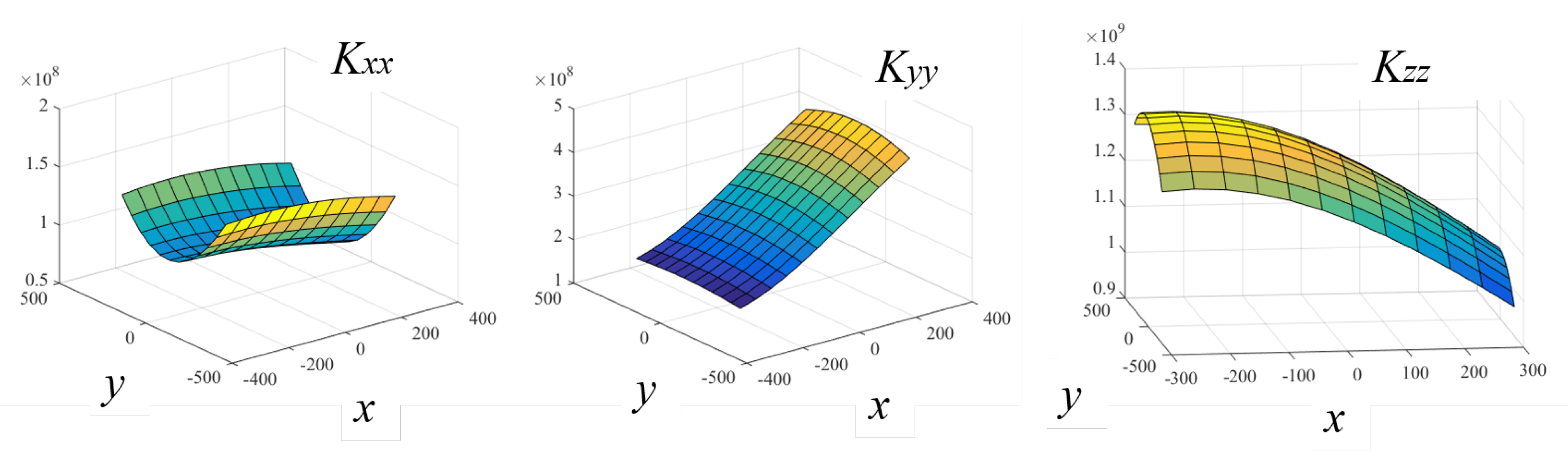

3.4. Cartesian Stiffness Computation

3.5. Natural Frequency Computation

4. Natural Frequencies and Modes of Tripteor X7

4.1. Identification of Null Legs Nodal Parameters

4.2. Constraint Equations

4.3. Cartesian Stiffness Matrix

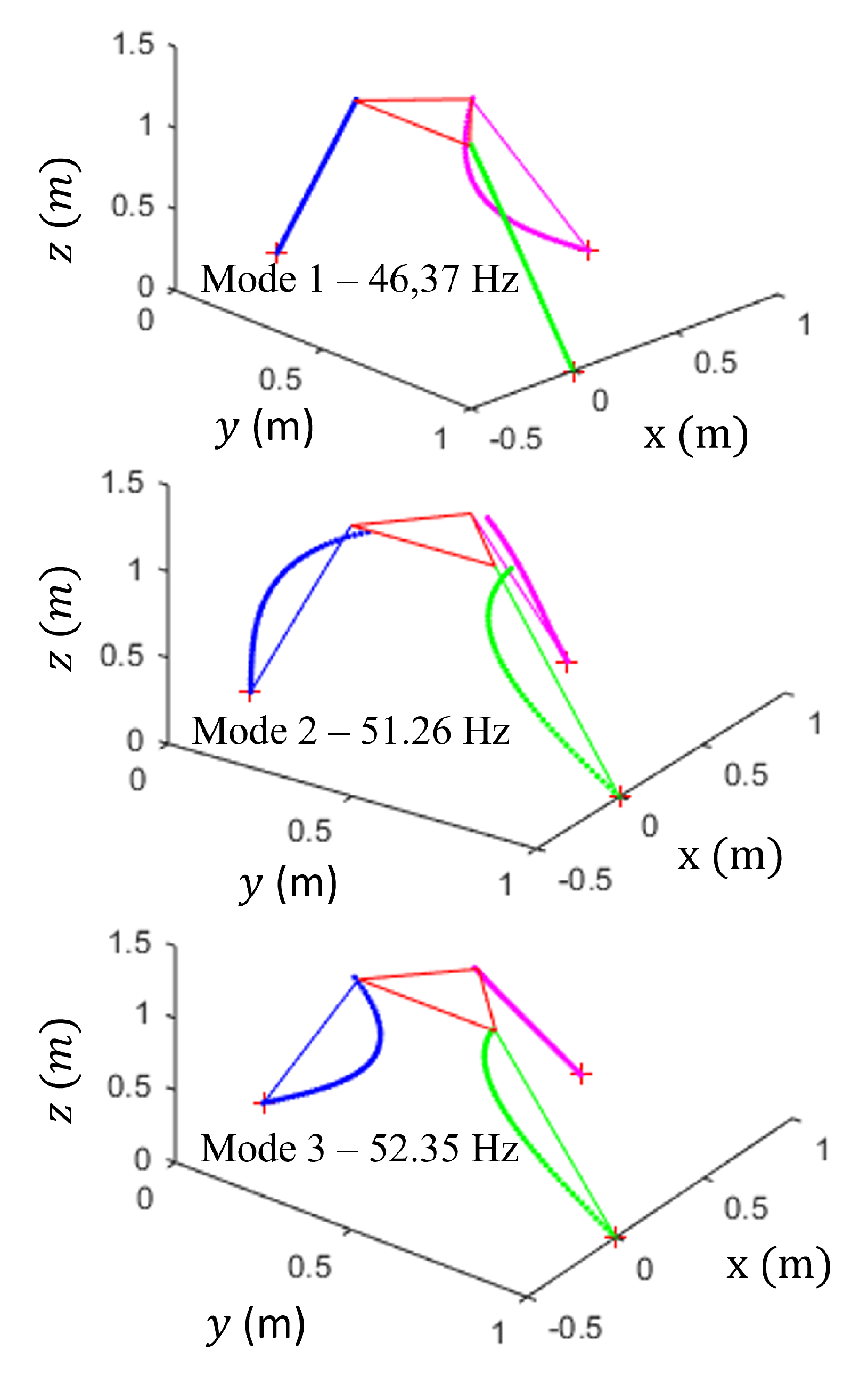

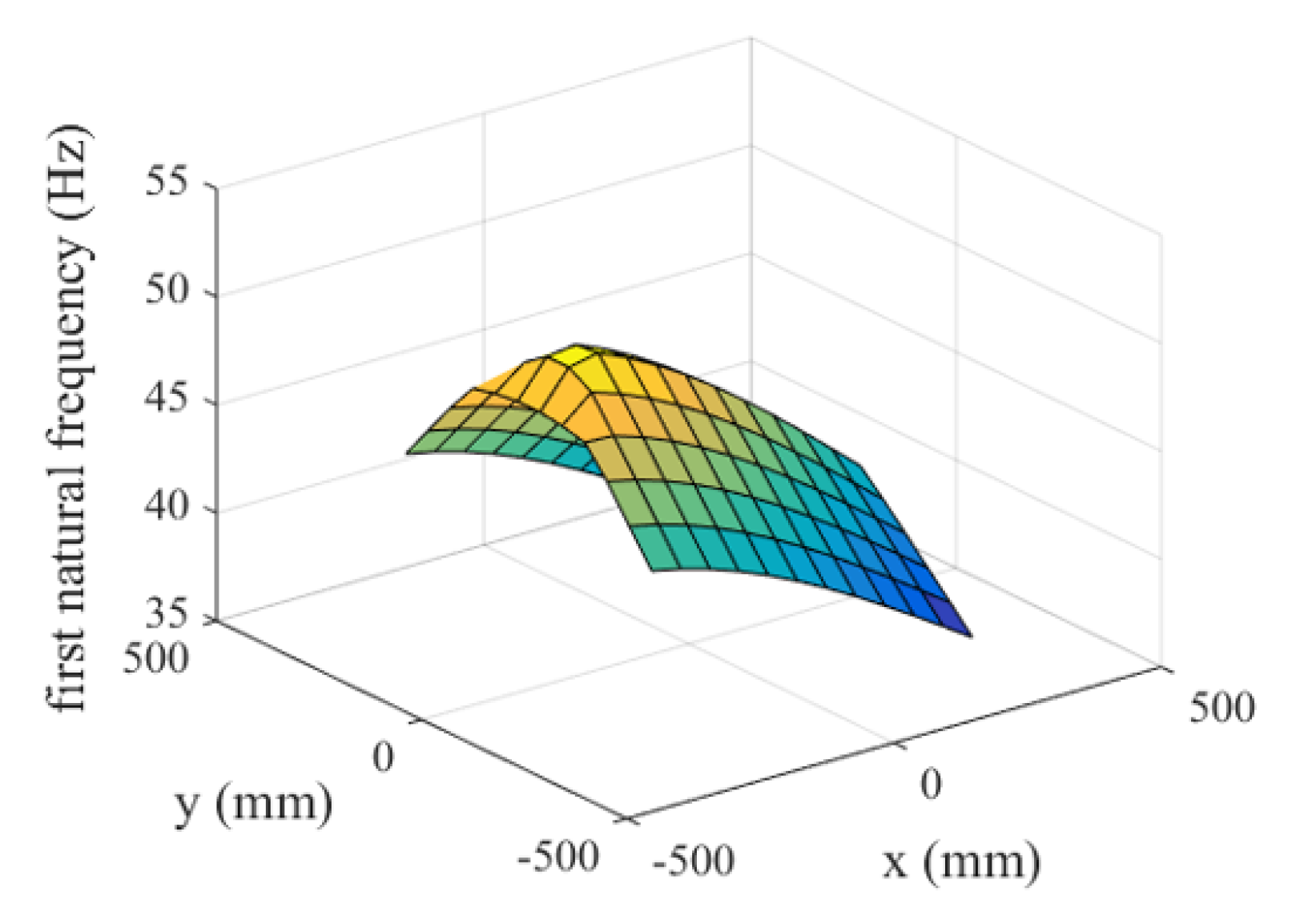

4.4. Natural Frequencies

4.5. Comparison with Experimental Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ith joint variable | |

| x | Beam abscissa |

| Displacement vector of the beam neutral axis | |

| Vector collecting the nodal values of the kinematic functions | |

| Beam displacement along the neutral axis | |

| Beam displacement along -axis | |

| Beam displacement along -axis | |

| Beam section rotation about neutral axis | |

| Beam section rotation about -axis | |

| Beam section rotation about -axis | |

| Beam force vector at a given abscissa | |

| Beam moment vector at a given abscissa | |

| Beam stiffness matrix | |

| Beam mass matrix | |

| Vector of small displacements of point | |

| Rotation vector of the mobile platform | |

| Vector of dependent parameters | |

| Vector of independent parameters | |

| Global stiffness matrix | |

| Global mass matrix | |

| First natural frequency vector |

References

- Patel, Y.; George, P. Parallel manipulators applications—A survey. Mod. Mech. Eng. 2012, 2, 57. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Ma, Y.; Liu, S.; Luo, Z.; Mei, J.; Huang, T.; Chetwynd, D. Integrated design of a 4-DOF high-speed pick-and-place parallel robot. CIRP Ann. 2014, 63, 185–188. [Google Scholar] [CrossRef]

- Chanal, H.; Duc, E.; Ray, P. A study of the impact of machine tool structure on machining processes. Int. J. Mach. Tools Manuf. 2006, 46, 98–106. [Google Scholar] [CrossRef]

- Terrier, M.; Dugas, A.; Hascoet, J.Y. Qualification of parallel kinematics machines in high-speed milling on free form surfaces. Int. J. Mach. Tools Manuf. 2004, 44, 865–877. [Google Scholar] [CrossRef]

- Pritschow, G.; Eppler, C.; Garber, T. Influence of the dynamic stiffness on the accuracy of PKM. In Proceedings of the Chemnitz Parallel Kinematic Seminar, Chemnitz, Germany, 23–25 April 2002; pp. 313–333. [Google Scholar]

- Pateloup, S.; Chanal, H.; Duc, E. Process parameter definition with respect to the behaviour of complex kinematic machine tools. Int. J. Adv. Manuf. Technol. 2013, 69, 1233–1248. [Google Scholar] [CrossRef]

- Neumann, K. Exechon concept-parallel kinematic machines in research and practice. In Proceedings of the Chemnitz Parallel Kinematics Seminar, Chemnitz, Germany, 25–26 April 2006. [Google Scholar]

- IFToMM. IFToMM Dictionnary—3. Dynamics. Available online: http://www.iftomm-terminology.antonkb.nl/2057_1036/frames.html (accessed on 6 March 2022).

- Liu, W.L.; Xu, Y.D.; Yao, J.T.; Zhao, Y.S. Methods for force analysis of overconstrained parallel mechanisms: A review. Chin. J. Mech. Eng. 2017, 30, 1460–1472. [Google Scholar] [CrossRef] [Green Version]

- Mei, B.; Xie, F.; Liu, X.J.; Yang, C. Elasto-geometrical error modeling and compensation of a five-axis parallel machining robot. Precis. Eng. 2021, 69, 48–61. [Google Scholar] [CrossRef]

- Benti, A.; Durieux, S.; Chanal, H. Mesure du Comportement Vibratoire D’une Machine-Outil à Structure Parallèle. 8ème Assises MUGV 2014. Available online: https://tel.archives-ouvertes.fr/tel-00451081/document (accessed on 9 March 2022).

- Pierrot, F.; Pierrot, F. Modelling and design issues of a 3-axis parallel machine-tool. Mech. Mach. Theory 2002, 11, 1325–1345. [Google Scholar]

- Yan, S.; Ong, S.; Nee, A. Stiffness analysis of parallelogram-type parallel manipulators using a strain energy method. Robot. Comput.-Integr. Manuf. 2016, 37, 13–22. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, T.; Zhao, X.; Mei, J.; Chetwynd, D.G.; Hu, S.J. Finite element analysis and comparison of two hybrid robots-the tricept and the trivariant. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–15 October 2006; pp. 490–495. [Google Scholar]

- Klimchik, A.; Pashkevich, A.; Chablat, D. CAD-based approach for identification of elasto-static parameters of robotic manipulators. Finite Elem. Anal. Des. 2013, 75, 19–30. [Google Scholar] [CrossRef] [Green Version]

- Germain, C.; Briot, S.; Caro, S.; Wenger, P. Natural frequency computation of parallel robots. J. Comput. Nonlinear Dyn. 2015, 10, 021004. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Y.Q.; Jin, Y. Elastodynamic modeling and analysis for an Exechon parallel kinematic machine. J. Manuf. Sci. Eng. 2016, 138, 031011. [Google Scholar] [CrossRef]

- Kermanian, A.; Kamali, A.; Taghvaeipour, A. Dynamic analysis of flexible parallel robots via enhanced co-rotational and rigid finite element formulations. Mech. Mach. Theory 2019, 139, 144–173. [Google Scholar] [CrossRef]

- Klimchik, A.; Pashkevich, A.; Chablat, D. Fundamentals of manipulator stiffness modeling using matrix structural analysis. Mech. Mach. Theory 2019, 133, 365–394. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, Y.; Chen, B.; Zhang, G.; Xu, Y.; Yao, J. Force Analysis of the Overconstrained Mechanisms Based on Equivalent Stiffness Considering Limb Axial Deformation. Res. Sq. 2021. Available online: https://www.researchsquare.com/article/rs-634709/v1 (accessed on 6 March 2022). [CrossRef]

- Yang, C.; Li, Q.; Chen, Q.; Xu, L. Elastostatic stiffness modeling of overconstrained parallel manipulators. Mech. Mach. Theory 2018, 122, 58–74. [Google Scholar] [CrossRef]

- Bi, Z. Kinetostatic modeling of Exechon parallel kinematic machine for stiffness analysis. Int. J. Adv. Manuf. Technol. 2014, 71, 325–335. [Google Scholar] [CrossRef]

- Bi, Z.M.; Jin, Y. Kinematic modeling of Exechon parallel kinematic machine. Robot. Comput.-Integr. Manuf. 2011, 27, 186–193. [Google Scholar] [CrossRef]

- Amine, S.; Caro, S.; Wenger, P. Constraint and singularity analysis of the Exechon. Appl. Mech. Mater. 2012, 162, 141–150. [Google Scholar] [CrossRef]

- Selig, J.; Ding, X. A screw theory of timoshenko beams. J. Appl. Mech. 2009, 76, 031003. [Google Scholar] [CrossRef]

- Bourdet, P.; Mathieu, L.; Lartigue, C.; Ballu, A. The concept of small displacement torsor in metrology. Ser. Adv. Math. Appl. Sci. 1996, 40, 110–122. [Google Scholar]

- Aydin, Y.; Kucuk, S. Quaternion based inverse kinematics for industrial robot manipulators with Euler wrist. In Proceedings of the 2006 IEEE International Conference on Mechatronics, Budapest, Hungary, 3–5 July 2006; pp. 581–586. [Google Scholar]

- Bonnemains, T.; Chanal, H.; Bouzgarrou, B.C.; Ray, P. Stiffness computation and identification of parallel kinematic machine tools. J. Manuf. Sci. Eng. 2009, 131, 041013. [Google Scholar] [CrossRef]

- Klimchik, A.; Pashkevich, A.; Caro, S.; Chablat, D. Stiffness modeling of robotic-manipulators under auxiliary loadings. International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Am. Soc. Mech. Eng. 2012, 45035, 469–476. [Google Scholar]

- Kucuk, S. Dexterous workspace optimization for a new hybrid parallel robot manipulator. J. Mech. Robot. 2018, 10, 064503. [Google Scholar] [CrossRef]

- Yoo, H.; Ryan, R.; Scott, R.A. Dynamic of flexible beams undergoing overall motions. J. Sound Vib. 1995, 181, 261–278. [Google Scholar] [CrossRef]

- Kong, X.; Gosselin, C.M. Type Synthesis of Parallel Mechanisms; Springer: Berlin/Heidelberg, Germany, 2007; Volume 33. [Google Scholar]

- Pateloup, S.; Chanal, H.; Duc, E. Geometric and kinematic modelling of a new Parallel Kinematic Machine Tool: The Tripteor X7 designed by PCI. Adv. Mater. Res. 2010, 112, 159–169. [Google Scholar] [CrossRef]

- Bonnemains, T.; Chanal, H.; Bouzgarrou, B.C.; Ray, P. Dynamic analysis of the Tripteor X7: Model and experiments. Robot. Comput.-Integr. Manuf. 2010, 29, 180–191. [Google Scholar] [CrossRef]

| Config. 1 | Config. 2 | Config. 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Beam Model | Measure | Error | Beam Model | Measure | Error | Beam Model | Measure | Error | |

| Mode 1 | 46.45 Hz | 46.2 Hz | 0.5% | 34.84 Hz | 39.6 Hz | 12% | 55.40 Hz | 49.4 Hz | 12.1% |

| Mode 2 | 50.98 Hz | 55.3 Hz | 7.8% | 36.51 Hz | 51.6 Hz | 29.2% | 66.66 Hz | 50.2 Hz | 32.8% |

| Mode 3 | 52.33 Hz | 71.3 Hz | 26.6% | 44.46 Hz | 58.4 Hz | 23.9% | 77.66 Hz | 71.3 Hz | 8.9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chanal, H.; Guichard, A.; Blaysat, B.; Caro, S. Elasto-Dynamic Modeling of an Over-Constrained Parallel Kinematic Machine Using a Beam Model. Machines 2022, 10, 200. https://doi.org/10.3390/machines10030200

Chanal H, Guichard A, Blaysat B, Caro S. Elasto-Dynamic Modeling of an Over-Constrained Parallel Kinematic Machine Using a Beam Model. Machines. 2022; 10(3):200. https://doi.org/10.3390/machines10030200

Chicago/Turabian StyleChanal, Hélène, Aurélie Guichard, Benoît Blaysat, and Stéphane Caro. 2022. "Elasto-Dynamic Modeling of an Over-Constrained Parallel Kinematic Machine Using a Beam Model" Machines 10, no. 3: 200. https://doi.org/10.3390/machines10030200

APA StyleChanal, H., Guichard, A., Blaysat, B., & Caro, S. (2022). Elasto-Dynamic Modeling of an Over-Constrained Parallel Kinematic Machine Using a Beam Model. Machines, 10(3), 200. https://doi.org/10.3390/machines10030200