A Review of Thermal Monitoring Techniques for Radial Permanent Magnet Machines

Abstract

1. Introduction

- Provide an introduction of the existing temperature monitoring techniques.

- Summarize the monitoring principles of these techniques.

- Identify the advantages and limitations.

- Discuss the challenges and opportunities for practical applications.

- The existing methods for temperature monitoring are categorized and introduced.

- The mechanisms of relevant failures caused by temperature rising is presented.

- The principles and implementation procedure of the existing methods are introduced.

- The advantages and limitations of these methods are summarized and analyzed.

- The challenges and opportunities for practical applications are discussed.

- The research trend is sketched and presented.

2. The Mechanism of Thermal-Caused Failures for the PM and Stator Windings

2.1. The heating Sources of PM and Stator Windings

2.2. Thermal-Caused Demagnetization of PM

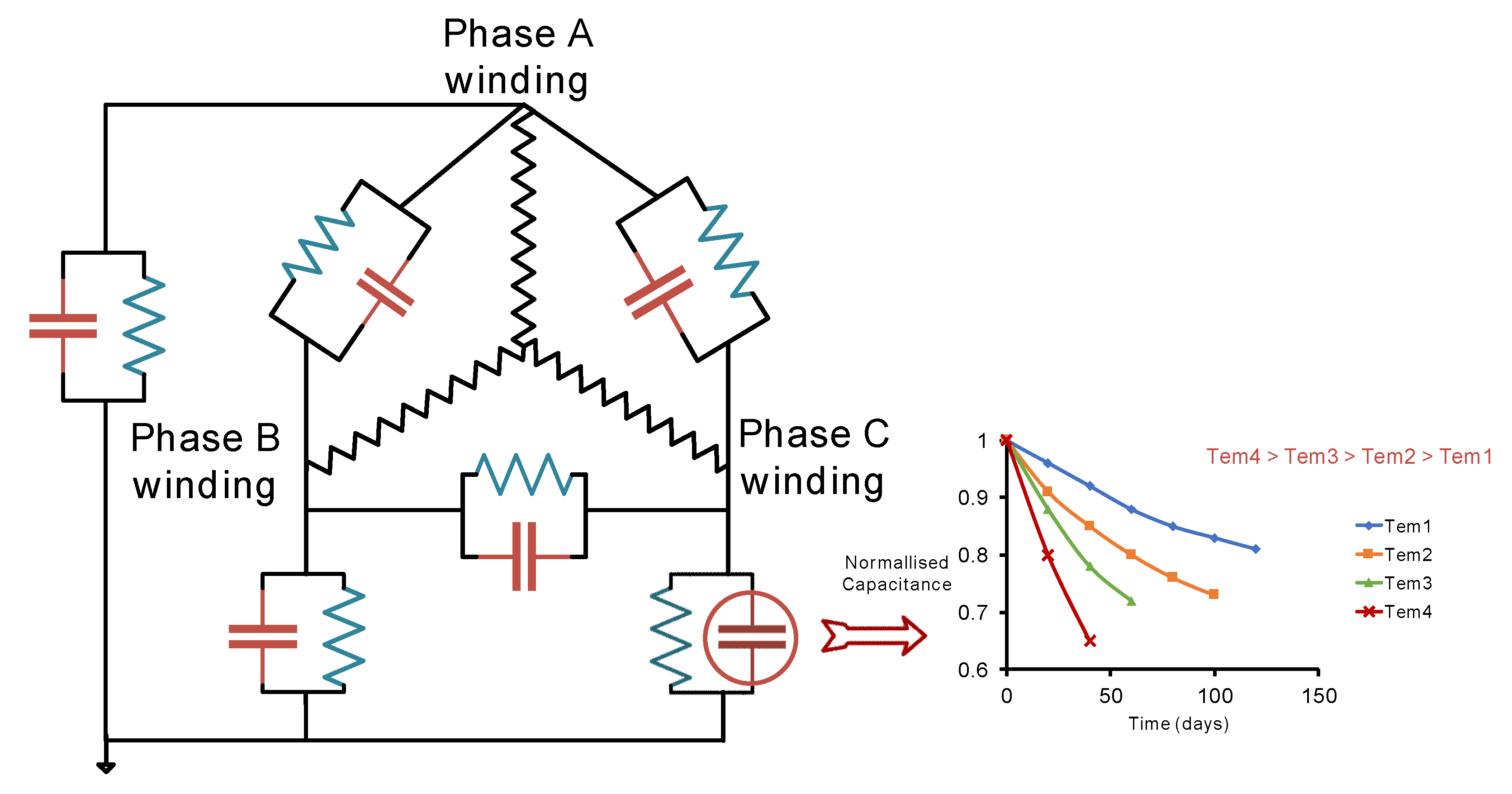

2.3. Stator Insulation Aging Caused by High Temperature

2.4. Sectional Discussion

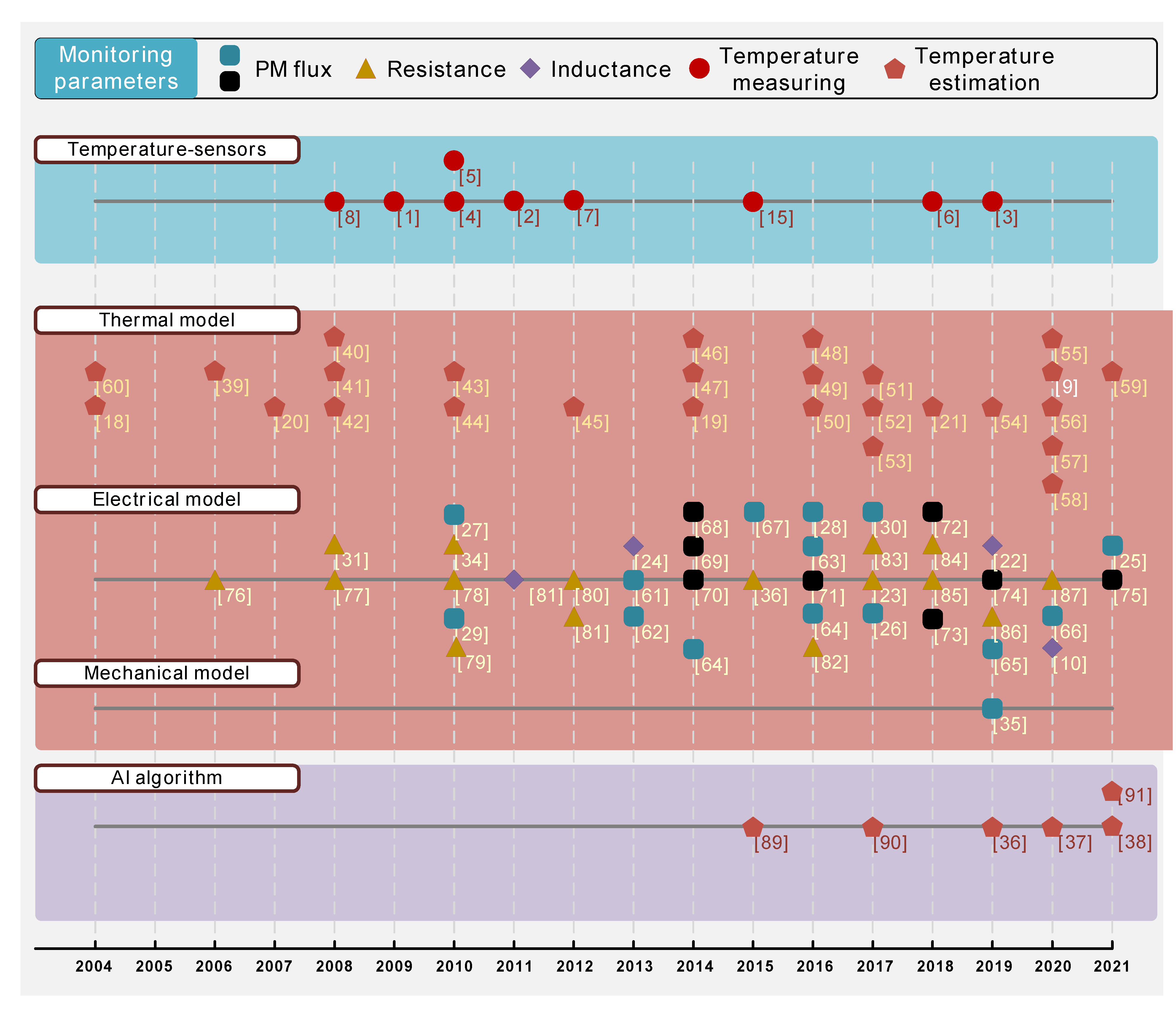

3. Sensor-Based Methods of Temperature Monitoring for PM Machines

Sectional Discussion

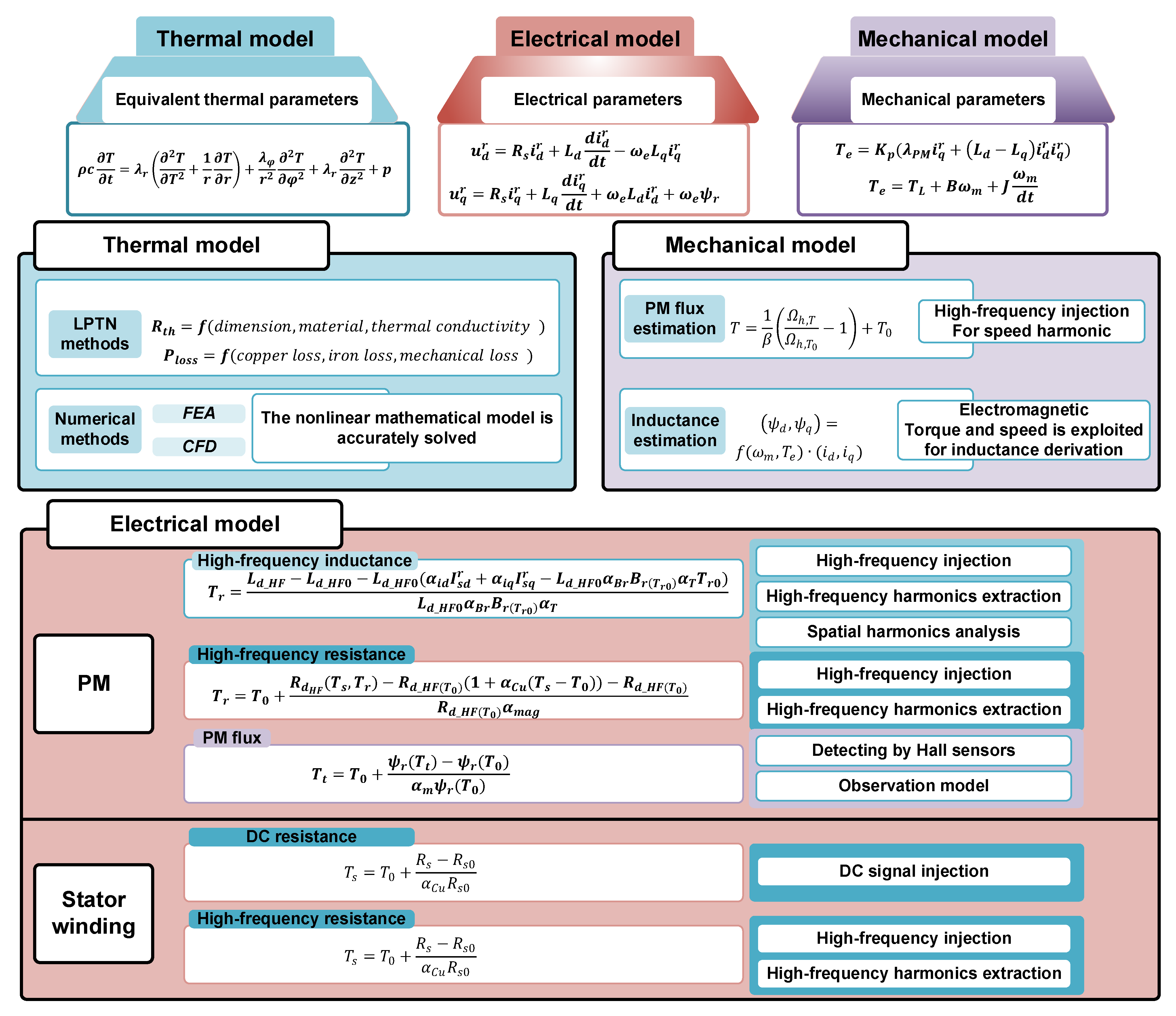

4. Model-Based Methods of Temperature Monitoring for PM Machines

4.1. Thermal Model-Based Methods for Temperature Monitoring

Sectional Discussion

4.2. Electrical Model-Based Methods for Temperature Monitoring

4.2.1. Monitoring Techniques for PM Temperature

- A.

- Signal injection-based methods for PM temperature estimation

- B.

- PM flux-based methods

4.2.2. Monitoring Techniques for Temperature of Stator Windings

- A.

- Noninvasive observer-based methods

- B.

- Invasive signal injection-based methods

4.2.3. Sectional Discussion

4.3. Mechanical Model-Based Methods for Temperature Monitoring

Sectional Discussion

4.4. Discussion for Model-Based Methods

5. AI algorithm-Based Methods of Temperature for PM Machines

Sectional Discussion

6. Discussion for Challenges and Opportunities

6.1. Challenges for Present works of Temperature Monitoring

6.1.1. The Non-Linearity of Thermal-Sensitive Parameters

6.1.2. The Conflict between Monitoring Accuracy and Technical Complexity

6.1.3. The Conflict between Anti-Interference Capability and Real-Time Capability

6.2. Opportunities for Future Works of Temperature Monitoring

6.2.1. Combination of Multi-Type Techniques for Temperature Monitoring

6.2.2. Prospects of System-Level Temperature Monitoring of PM Machines

7. Research Trend for Extensive Monitoring for PM Machines

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jianzhong, G.; Hui, G.; Zhe, H. Rotor temperature monitoring technology of direct-drive permanent magnet wind turbine, 2009. In Proceedings of the International Conference on Electrical Machines and Systems, Tokyo, Japan, 15–18 November 2009; pp. 1–4. [Google Scholar]

- Ganchev, M.; Umschaden, H.; Kappeler, H. Rotor temperature distribution measuring system. In Proceedings of the IECON 2011-37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, Australia, 7–10 November 2011; pp. 2006–2011. [Google Scholar]

- Kuppuswamy, R.; Rainey, S. Synthesis of Experiences using Resistive Temperature Detectors (RTD) as PD Sensors for Detecting and Locating Electrical Defects inside Generator Stator Windings. In Proceedings of the 2019 IEEE Electrical Insulation Conference (EIC), Calgary, AB, Canada, 16–19 June 2019; pp. 405–409. [Google Scholar]

- Ganchev, M.; Kubicek, B.; Kappeler, H. Rotor temperature monitoring system. In Proceedings of the XIX International Conference on Electrical Machines-ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–5. [Google Scholar]

- Kovačić, M.; Vražić, M.; Gašparac, I. Bluetooth wireless communication and 1-wire digital temperature sensors in synchronous machine rotor temperature measurement. In Proceedings of the 14th International Power Electronics and Motion Control Conference EPE-PEMC 2010, Ohrid, Macedonia, 6–8 September 2010; pp. T7-25–T7-28. [Google Scholar]

- Park, D.; Jung, H.; Cho, H.; Sul, S. Design of Wireless Temperature Monitoring System for Measurement of Magnet Temperature of IPMSM. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 656–661. [Google Scholar]

- Stipetic, S.; Kovacic, M.; Hanic, Z.; Vrazic, M. Measurement of Excitation Winding Temperature on Synchronous Generator in Rotation Using Infrared Thermography. IEEE Trans. Ind. Electron. 2012, 59, 2288–2298. [Google Scholar] [CrossRef]

- Mori, M.; Novak, L.; Sekavčnik, M.; Kuštrin, I. Application of IR thermography as a measuring method to study heat transfer on rotating surface. Forsch. Ing. 2008, 72, 1–10. [Google Scholar] [CrossRef]

- Burke, R.; Giedymin, A.; Wu, Z.; Chuan, H.; Bourne, N.; Hawley, J.G. A Lumped Parameter Thermal Model for Single-Sided AFPM Machines with Experimental Validation. IEEE Trans. Transp. Electrif. 2020, 6, 1065–1083. [Google Scholar] [CrossRef]

- Erazo, D.E.G.; Wallscheid, O.; Böcker, J. Improved Fusion of Permanent Magnet Temperature Estimation Techniques for Synchronous Motors Using a Kalman Filter. IEEE Trans. Ind. Electron. 2020, 67, 1708–1717. [Google Scholar] [CrossRef]

- Wallscheid, O.; Huber, T.; Peters, W.; Böcker, J. A critical review of techniques to determine the magnet temperature of permanent magnet synchronous motors under real-time conditions. EPE J. 2016, 26, 11–20. [Google Scholar] [CrossRef]

- Chiodetto, N.; Bianchi, N.; Alberti, L. Improved Analytical Estimation of Rotor Losses in High-Speed Surface-Mounted PM Synchronous Machines. IEEE Trans. Ind. Appl. 2017, 53, 3548–3556. [Google Scholar] [CrossRef]

- Tong, W.; Sun, L.; Wu, S.; Hou, M.; Tang, R. Analytical Model and Experimental Verification of Permanent Magnet Eddy Current Loss in Permanent Magnet Machines with Non-Concentric Magnetic Poles. IEEE Trans. Ind. Electron. 2021, early access. [CrossRef]

- Zheng, D.; Zhang, P. An Online Groundwall and Phase-to-Phase Stator Insulation Monitoring Method for Inverter-Fed Machine. IEEE Trans. Ind. Electron. 2021, 68, 5303–5313. [Google Scholar] [CrossRef]

- Fernandez, D.; Reigosa, D.; Tanimoto, T.; Kato, T.; Briz, F. Wireless permanent magnet temperature & field distribution measurement system for IPMSMs. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 3996–4003. [Google Scholar]

- Martiny, W.T.; McCoy, R.M.; Margolis, H.B. Thermal Relationships in an Induction Motor under Normal and Abnormal Operation, in Transactions of the American Institute of Electrical Engineers. Trans. Am. Inst. Electr. Engineers. Part III Power Appar. Syst. 1961, 80, 66–76. [Google Scholar]

- Zhu, Z.Q.; Liang, D.; Liu, K. Online Parameter Estimation for Permanent Magnet Synchronous Machines: An Overview. IEEE Access 2021, 9, 59059–59084. [Google Scholar] [CrossRef]

- L-Refaie, A.M.E.; Harris, N.C.; Jahns, T.M.; Rahman, K.M. Thermal analysis of multibarrier interior PM synchronous Machine using lumped parameter model. IEEE Trans. Energy Convers. 2004, 19, 303–309. [Google Scholar] [CrossRef]

- Kral, C.; Haumer, A.; Lee, S.B. A Practical Thermal Model for the Estimation of Permanent Magnet and Stator Winding Temperatures. IEEE Trans. Power Electron. 2014, 29, 455–464. [Google Scholar] [CrossRef]

- Kamiya, M.; Kawase, Y.; Kosaka, T.; Matsui, N. Temperature distribution analysis of permanent magnet in interior permanent magnet synchronous motor considering pwm carrier harmonics. In Proceedings of the 2007 International Conference on Electrical Machines and Systems (ICEMS), Seoul, Korea, 8–11 October 2007; pp. 2023–2027. [Google Scholar]

- Soualmi, A.; Zidat, F.; Lombard, P.; Mokhtari, N. Thermal Study Comparison of Permanent Magnets Machines Using Finite Element Method (FEM) Electric Vehicles Application. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Korea, 7–10 October 2018; pp. 59–64. [Google Scholar]

- Reigosa, D.; Fernández, D.; Martínez, M.; Guerrero, J.M.; Diez, A.B.; Briz, F. Magnet Temperature Estimation in Permanent Magnet Synchronous Machines Using the High Frequency Inductance. IEEE Trans. Ind. Appl. 2019, 55, 2750–2757. [Google Scholar] [CrossRef]

- Reigosa, D.; Fernandez, D.; Tanimoto, T.; Kato, T.; Briz, F. Comparative analysis of BEMF and pulsating high frequency current injection methods for PM temperature estimation in PMSMs. IEEE Trans. Power Elect. 2017, 32, 3691–3699. [Google Scholar] [CrossRef]

- Ganchev, M.; Kral, C.; Wolbank, T.M. Compensation of Speed Dependence in Sensorless Rotor Temperature Estimation for Permanent-Magnet Synchronous Motor. IEEE Trans. Ind. Appl. 2013, 49, 2487–2495. [Google Scholar] [CrossRef]

- Jung, H.-S.; Kim, H.; Sul, S.-K.; Berry, D.J. Magnet Temperature Estimation of Traction Motor in Standstill with Considering Spatial Harmonics. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Korea, 7–10 October 2018; pp. 59–64. [Google Scholar]

- Fernandez, D.; Hyun, D.; Park, Y.; Reigosa, D.D.; Lee, S.B.; Lee, D.M.; Briz, F. Permanent Magnet Temperature Estimation in PM Synchronous Motors Using Low-Cost Hall Effect Sensors. IEEE Trans. Ind. Appl. 2017, 53, 4515–4525. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, C.; Zhang, M. Dynamic Permanent Magnet Flux Estimation of Permanent Magnet Synchronous Machines. IEEE Trans. Appl. Supercond. 2010, 20, 1085–1088. [Google Scholar] [CrossRef]

- Dang, D.Q.; Rafaq, M.S.; Choi, H.H.; Jung, J. Online Parameter Estimation Technique for Adaptive Control Applications of Interior PM Synchronous Motor Drives. IEEE Trans. Ind. Electron. 2016, 63, 1438–1449. [Google Scholar] [CrossRef]

- Underwood, S.J.; Husain, I. Online Parameter Estimation and Adaptive Control of Permanent-Magnet Synchronous Machines. IEEE Trans. Ind. Electron. 2010, 57, 2435–2443. [Google Scholar] [CrossRef]

- Wallscheid, O.; Specht, A.; Böcker, J. Observing the Permanent-Magnet Temperature of Synchronous Motors Based on Electrical Fundamental Wave Model Quantities. IEEE Trans. Ind. Electron. 2017, 64, 3921–3929. [Google Scholar] [CrossRef]

- Briz, F.; Degner, M.W.; Guerrero, J.M.; Diez, A.B. Temperature Estimation in Inverter-Fed Machines Using High-Frequency Carrier Signal Injection. IEEE Trans. Ind. Appl. 2008, 44, 799–808. [Google Scholar] [CrossRef]

- Hamida, M.A.; de Leon, J.; Glumineau, A.; Boisliveau, R. An Adaptive Interconnected Observer for Sensorless Control of PM Synchronous Motors with Online Parameter Identification. IEEE Trans. Ind. Electron. 2013, 60, 739–748. [Google Scholar] [CrossRef]

- Bariša, T.; Erceg, I.; Marković, I. Estimation of stator resistance and rotor speed for IPMSG using model reference adaptive system. In Proceedings of the 2016 IEEE International Energy Conference (ENERGYCON), Leuven, Belgium, 4–8 April 2016; pp. 1–7. [Google Scholar]

- Wilson, S.D.; Stewart, P.; Taylor, B.P. Methods of Resistance Estimation in Permanent Magnet Synchronous Motors for Real-Time Thermal Management. IEEE Trans. Energy Convers 2010, 25, 698–707. [Google Scholar] [CrossRef]

- Feng, G.; Lai, C.; Kar, N.C. Speed Harmonic Based Modeling and Estimation of Permanent Magnet Temperature for PMSM Drive Using Kalman Filter. IEEE Trans. Ind. Inform. 2019, 15, 1372–1382. [Google Scholar] [CrossRef]

- Kirchgässner, W.; Wallscheid, O.; Böcker, J. Deep Residual Convolutional and Recurrent Neural Networks for Temperature Estimation in Permanent Magnet Synchronous Motors. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 1439–1446. [Google Scholar]

- Lee, J.; Ha, J. Temperature Estimation of PMSM Using a Difference-Estimating Feedforward Neural Network. IEEE Access 2020, 8, 130855–130865. [Google Scholar] [CrossRef]

- Kirchgässner, W.; Wallscheid, O.; Böcker, J. Data-Driven Permanent Magnet Temperature Estimation in Synchronous Motors with Supervised Machine Learning: A Benchmark. IEEE Trans. Energy Convers. 2021, 36, 2059–2067. [Google Scholar] [CrossRef]

- Boglietti, A.; Cavagnino, A.; Parvis, M.; Vallan, A. Evaluation of radiation thermal resistances in industrial motors. IEEE Trans. Ind. Appl. 2006, 42, .688–693. [Google Scholar] [CrossRef]

- Mejuto, C.; Mueller, M.; Shanel, M.; Mebarki, A.; Reekie, M.; Staton, D. Improved synchronous machine thermal modelling. In Proceedings of the 2008 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2008; pp. 1–6. [Google Scholar]

- Staton, D.A.; Cavagnino, A. Convection Heat Transfer and Flow Calculations Suitable for Electric Machines Thermal Models. IEEE Trans. Ind. Electron. 2008, 55, 3509–3516. [Google Scholar] [CrossRef]

- Tenconi, A.; Profumo, F.; Bauer, S.E.; Hennen, M.D. Temperatures Evaluation in an Integrated Motor Drive for Traction Applications. IEEE Trans. Ind. Electron. 2008, 55, 3619–3626. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, C.; Wang, Z.; Dong, Y.; Nino, C.E.; Tariq, A.R.; Strangas, E.G. Thermal Analysis of Permanent Magnet Motor for the Electric Vehicle Application Considering Driving Duty Cycle. IEEE Trans. Magn. 2010, 46, 2493–2496. [Google Scholar] [CrossRef]

- Wrobel, R.; Mellor, P.H. A General Cuboidal Element for Three-Dimensional Thermal Modelling. IEEE Trans. Magn. 2010, 46, 3197–3200. [Google Scholar] [CrossRef]

- Li, G.; Ojeda, J.; Hoang, E.; Gabsi, M.; Lecrivain, M. Thermal–Electromagnetic Analysis for Driving Cycles of Embedded Flux-Switching Permanent-Magnet Motors. IEEE Trans. Veh. Technol. 2012, 61, 140–151. [Google Scholar] [CrossRef]

- Boseniuk, F.; Ponick, B. Parameterization of transient thermal models for permanent magnet synchronous machines exclusively based on measurements. In Proceedings of the 2014 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 18–20 June 2014; pp. 295–301. [Google Scholar]

- Huber, T.; Peters, W.; Böcker, J. A low-order thermal model for monitoring critical temperatures in permanent magnet synchronous motors. In Proceedings of the 7th IET International Conference on Power Electronics, Machines and Drives (PEMD 2014), Manchester, UK, 8–10 April 2014; pp. 1–6. [Google Scholar]

- Boglietti, A.; Carpaneto, E.; Cossale, M.; Vaschetto, S. Stator-Winding Thermal Models for Short-Time Thermal Transients: Definition and Validation. IEEE Trans. Ind. Electron. 2016, 63, 2713–2721. [Google Scholar] [CrossRef]

- Hey, J.; Malloy, A.C.; Martinez-Botas, R.; Lampérth, M. Online Monitoring of Electromagnetic Losses in an Electric Motor Indirectly Through Temperature Measurement. IEEE Trans. Energy Convers 2016, 31, 1347–1355. [Google Scholar] [CrossRef]

- Wallscheid, O.; Böcker, J. Global Identification of a Low-Order Lumped-Parameter Thermal Network for Permanent Magnet Synchronous Motors. IEEE Trans. Energy Convers. 2016, 31, 354–365. [Google Scholar] [CrossRef]

- Maulidi, A.R.; Purwadi, A. Modeling and analysis of cooling system permanent magnet synchronous motor 30 kW for city EV with FEM. In Proceedings of the 2017 4th International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 2–5 October 2017; pp. 36–41. [Google Scholar]

- Sciascera, C.; Giangrande, P.; Papini, L.; Gerada, C.; Galea, M. Analytical Thermal Model for Fast Stator Winding Temperature Prediction. IEEE Trans. Ind. Electron. 2017, 64, 6116–6126. [Google Scholar] [CrossRef]

- Gaona, D.; Wallscheid, O.; Böcker, J. Fusion of a lumped-parameter thermal network and speed-dependent flux observer for PM temperature estimation in synchronous machines. In Proceedings of the 2017 IEEE Southern Power Electronics Conference (SPEC), Puerto Varas, Chile, 4–7 December 2017; pp. 1–6. [Google Scholar]

- Kirchgässner, W.; Wallscheid, O.; Böcker, J. Empirical Evaluation of Exponentially Weighted Moving Averages for Simple Linear Thermal Modeling of Permanent Magnet Synchronous Machines. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 318–323. [Google Scholar]

- Sun, T.; Yang, R.; Li, H.; Zhang, X.; Xu, T. Active Motor Rotor Temperature Management Based on One-Node Thermal Network Model Predictive Control. IEEE Trans. Power Electron. 2020, 35, 11213–11221. [Google Scholar] [CrossRef]

- Liu, G.; Liu, M.; Zhang, Y.; Wang, H.; Gerada, C. High-Speed Permanent Magnet Synchronous Motor Iron Loss Calculation Method Considering Multiphysics Factors. IEEE Trans. Ind. Electron. 2020, 67, 5360–5368. [Google Scholar] [CrossRef]

- Zhao, W.; Cao, D.; Ji, J.; Huang, L.; Liu, T. A Generalized Mesh-Based Thermal Network Model for SPM Machines Combining Coupled Winding Solution. IEEE Trans. Ind. Electron. 2020, 68, 116–127. [Google Scholar] [CrossRef]

- Chen, B.; Wulff, C.; Etzold, K.; Manns, P.; Birmes, G.; Andert, J.; Pischinger, S. A Comprehensive Thermal Model for System-Level Electric Drivetrain Simulation with Respect to Heat Exchange between Components. In Proceedings of the 2020 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 21–23 July 2020; pp. 558–567. [Google Scholar]

- Tovar-Barranco, A.; López-de-Heredia, A.; Villar, I.; Briz, F. Modeling of End-Space Convection Heat-Transfer for Internal and External Rotor PMSMs With Fractional-Slot Concentrated Windings. IEEE Trans. Ind. Electron. 2021, 68, 1928–1937. [Google Scholar] [CrossRef]

- Kral, C.; Habetler, T.G.; Harley, R.G.; Pirker, F.; Pascoli, G.; Oberguggenberger, H.; Fenz, C.J. Rotor temperature estimation of squirrel-cage induction motors by means of a combined scheme of parameter estimation and a thermal equivalent model. IEEE Trans. Ind. Appl. 2004, 40, 1049–1057. [Google Scholar] [CrossRef]

- Liu, K.; Zhu, Z.Q.; Stone, D.A. Parameter Estimation for Condition Monitoring of PMSM Stator Winding and Rotor Permanent Magnets. IEEE Trans. Ind. Electron. 2013, 60, 5902–5913. [Google Scholar] [CrossRef]

- Seilmeier, M.; Ebersberger, S.; Piepenbreier, B. Identification of high frequency resistances and inductances for sensorless control of PMSM. In Proceedings of the 2013 IEEE International Symposium on Sensorless Control for Electrical Drives and Predictive Control of Electrical Drives and Power Electronics (SLED/PRECEDE), Munich, Germany, 17–19 October 2013; pp. 1–8. [Google Scholar]

- Feng, G.; Lai, C.; Kar, N.C. A Novel Current Injection-Based Online Parameter Estimation Method for PMSMs Considering Magnetic Saturation. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Reigosa, D.D.; Fernandez, D.; Tanimoto, T.; Kato, T.; Briz, F. Permanent-Magnet Temperature Distribution Estimation in Permanent-Magnet Synchronous Machines Using Back Electromotive Force Harmonics. IEEE Trans. Ind. Appl. 2016, 52, 3093–3103. [Google Scholar] [CrossRef][Green Version]

- Feng, G.; Lai, C.; Li, W.; Li, Z.; Kar, N.C. Efficient Permanent Magnet Temperature Modeling and Estimation for Dual Three-Phase PMSM Considering Inverter Nonlinearity. IEEE Trans. Power Electron. 2019, 35, 7328–7340. [Google Scholar] [CrossRef]

- Xiao, S.; Griffo, A. PWM-Based Flux Linkage and Rotor Temperature Estimations for Permanent Magnet Synchronous Machines. IEEE Trans. Power Electron. 2020, 35, 6061–6069. [Google Scholar] [CrossRef]

- Reigosa, D.D.; Fernandez, D.; Yoshida, H.; Kato, T.; Briz, F. Permanent-Magnet Temperature Estimation in PMSMs Using Pulsating High-Frequency Current Injection. IEEE Trans. Ind. Appl. 2015, 51, 3159–3168. [Google Scholar] [CrossRef]

- Specht, A.; Wallscheid, O.; Böcker, J. Determination of rotor temperature for an interior permanent magnet synchronous machine using a precise flux observer. In Proceedings of the 2014 International Power Electronics Conference (IPEC-Hiroshima 2014-ECCE ASIA), Hiroshima, Japan, 18–21 May 2014; pp. 1501–1507. [Google Scholar]

- Liu, K.; Zhu, Z.Q. Online Estimation of the Rotor Flux Linkage and Voltage-Source Inverter Nonlinearity in Permanent Magnet Synchronous Machine Drives. IEEE Trans. Power Electron. 2014, 29, 418–427. [Google Scholar] [CrossRef]

- Qiu, T.; Wen, X.; Zhao, F.; Wang, Y. Permanent magnet flux linkage adaptive observer for permanent magnet synchronous motor. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–4. [Google Scholar]

- Uddin, M.N.; Zou, H.; Azevedo, F. Online Loss-Minimization-Based Adaptive Flux Observer for Direct Torque and Flux Control of PMSM Drive. IEEE Trans. Ind. Appl. 2016, 52, 425–431. [Google Scholar] [CrossRef]

- Feng, G.; Lai, C.; Tjong, J.; Kar, N.C. Noninvasive Kalman Filter Based Permanent Magnet Temperature Estimation for Permanent Magnet Synchronous Machines. IEEE Trans. Power Electron. 2018, 33, 10673–10682. [Google Scholar] [CrossRef]

- Feng, G.; Lai, C.; Li, W.; Kelly, M.; Kar, N.C. Simultaneous Stator Winding and Permanent Magnet Temperature Estimation for Permanent Magnet Synchronous Machines. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1945–1951. [Google Scholar]

- Min, Y.; Huang, W.; Yang, J.; Zhao, Y. On-line Estimation of Permanent-magnet Flux and Temperature Rise in Stator Winding for PMSM. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Jung, H.-S.; Kim, H.; Sul, S.-K.; Berry, D.J. Temperature Estimation of IPMSM by Using Fundamental Reactive Energy Considering Variation of Inductances. IEEE Trans. Power Electron. 2021, 36, 5771–5783. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, H. Induction-motor stator and rotor winding temperature estimation using signal injection method. IEEE Trans. Ind. Appl. 2006, 42, 1038–1044. [Google Scholar]

- Zhang, P.; Lu, B.; Habetler, T.G. A Remote and Sensorless Stator Winding Resistance Estimation Method for Thermal Protection of Soft-Starter-Connected Induction Machines. IEEE Trans. Ind. Electron. 2008, 55, 3611–3618. [Google Scholar] [CrossRef]

- Sonnaillon, M.O.; Bisheimer, G.; de Angelo, C.; García, G.O. Online Sensorless Induction Motor Temperature Monitoring. IEEE Trans. Energy Convers. 2010, 25, 273–280. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, B.; Habetler, T.G. An Active Stator Temperature Estimation Technique for Thermal Protection of Inverter-Fed Induction Motors with Considerations of Impaired Cooling Detection. IEEE Trans. Ind. Appl. 2010, 46, 1873–1881. [Google Scholar] [CrossRef]

- Reigosa, D.D.; Briz, F.; Degner, M.W.; Garcia, P.; Guerrero, J.M. Magnet Temperature Estimation in Surface PM Machines During Six-Step Operation. IEEE Trans. Ind. Appl. 2012, 48, 2353–2361. [Google Scholar] [CrossRef]

- Cheng, S.; Du, Y.; Restrepo, J.A.; Zhang, P.; Habetler, T.G. A Nonintrusive Thermal Monitoring Method for Induction Motors Fed by Closed-Loop Inverter Drives. IEEE Trans. Power Electron. 2012, 27, 4122–4131. [Google Scholar] [CrossRef]

- Baneira, F.; Yepes, A.G.; López, Ó.; Doval-Gandoy, J. Estimation Method of Stator Winding Temperature for Dual Three-Phase Machines Based on DC-Signal Injection. IEEE Trans. Power Electron. 2016, 31, 5141–5148. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Jiang, C.; He, L.; Harley, R.G. An enhanced active DC-flux injection based approach for thermal monitoring of induction machines with direct torque control schemes. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 3537–3544. [Google Scholar]

- Feng, G.; Lai, C.; Iyer, K.L.V.; Kar, N.C. Improved High-Frequency Voltage Injection Based Permanent Magnet Temperature Estimation for PMSM Condition Monitoring for EV Applications. IEEE Trans. Veh. Technol. 2018, 67, 216–225. [Google Scholar] [CrossRef]

- Fernandez, D.; Martínez, M.; Reigosa, D.D.; Guerrero, J.M.; Alvarez, C.M.S.; Briz, F. Influence of Magnetoresistance and Temperature on Permanent Magnet Condition Estimation Methods Using High-Frequency Signal Injection. IEEE Trans. Ind. Appl. 2018, 54, 4218–4226. [Google Scholar] [CrossRef]

- Baneira, F.; Asiminoaei, L.; Doval-Gandoy, J.; Delpino, H.A.M.; Yepes, A.G.; Godbersen, J. Estimation Method of Stator Winding Resistance for Induction Motor Drives Based on DC-Signal Injection Suitable for Low Inertia. IEEE Trans. Power Electron. 2019, 34, 5646–5654. [Google Scholar] [CrossRef]

- Fernández, D.; Martínez, M.; Reigosa, D.; Diez, A.B.; Guerrero, J.M.; Briz, F. Comparative Analysis of Magnet Thermal and Magnetization State Monitoring in PMSMs Based on High-Frequency Signal Injection. IEEE Trans. Ind. Appl. 2020, 56, 344–357. [Google Scholar] [CrossRef]

- Lee, S.B.; Habetler, T.G.; Harley, R.G.; Gritter, D.J. An evaluation of model-based stator resistance estimation for induction motor stator winding temperature monitoring. IEEE Trans. Energy Convers. 2002, 17, 7–15. [Google Scholar] [CrossRef]

- Ganchev, M.; Kral, C.; Oberguggenberger, H.; Wolbank, T. Sensorless rotor temperature estimation of permanent magnet synchronous motor. In Proceedings of the IECON 2011-37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, Australia, 7–10 November 2011; pp. 2018–2023. [Google Scholar]

- Liu, Z.; Li, X.; Wu, L.; Zhou, S.; Liu, K. GPU-Accelerated Parallel Coevolutionary Algorithm for Parameters Identification and Temperature Monitoring in Permanent Magnet Synchronous Machines. IEEE Trans. Ind. Inform. 2015, 11, 1220–1230. [Google Scholar] [CrossRef]

- Wallscheid, O.; Kirchgässner, W.; Böcker, J. Investigation of long short-term memory networks to temperature prediction for permanent magnet synchronous motors. In Proceedings of the 2017 International Joint Conference on Neural Networks (IJCNN), Anchorage, AK, USA, 14–19 May 2017; pp. 1940–1947. [Google Scholar]

- Kirchgässner, W.; Wallscheid, O.; Böcker, J. Estimating Electric Motor Temperatures with Deep Residual Machine Learning. IEEE Trans. Power Electron. 2021, 36, 7480–7488. [Google Scholar] [CrossRef]

- Available online: https://www.arnoldmagnetics.com/ (accessed on 25 July 2021).

- Calin, M.; Helerea, E. Temperature influence on magnetic characteristics of NdFeB permanent magnets. In Proceedings of the 2011 7th international symposium on advanced topics in electrical engineering (ATEE), Bucharest, Romania, 12–14 May 2011; pp. 1–6. [Google Scholar]

- Chen, L.; Hopkinson, D.; Wang, J.; Cockburn, A.; Sparkes, M.; O’Neill, W. Reduced Dysprosium Permanent Magnets and Their Applications in Electric Vehicle Traction Motors. IEEE Trans. Magn. 2015, 51, 8109004. [Google Scholar] [CrossRef]

- Liu, S.; Kuhl, G.E. Temperature coefficients of rare earth permanent magnets. IEEE Trans. Magn. 1999, 35, 3271–3273. [Google Scholar] [CrossRef]

- Takezawa, M.; Ikeda, S.; Morimoto, Y.; Kabashima, H. Analysis of thermal demagnetization behavior of Nd–Fe–B sintered magnets using magnetic domain observation. AIP Adv. 2016, 6, 056021. [Google Scholar] [CrossRef]

- Ruoho, S.; Haavisto, M.; Takala, E.; Santa-Nokki, T.; Paju, M. Temperature Dependence of Resistivity of Sintered Rare-Earth Permanent-Magnet Materials. IEEE Trans. Magn. 2010, 46, 15–20. [Google Scholar] [CrossRef]

- Fabian, K.; Shcherbakov, V.P.; Mcenroe, S.A. Measuring the Curie temperature. Geochemistry. Geophys. Geosystems 2015, 14, 947–961. [Google Scholar]

- Tsyokhla, I.; Griffo, A.; Wang, J. Online Condition Monitoring for Diagnosis and Prognosis of Insulation Degradation of Inverter-Fed Machines. IEEE Trans. Ind. Electron. 2019, 66, 8126–8135. [Google Scholar] [CrossRef]

- Howey, D.A.; Childs, P.R.N.; Holmes, A.S. Air-Gap Convection in Rotating Electrical Machines. IEEE Trans. Ind. Electron. 2012, 59, 1367–1375. [Google Scholar] [CrossRef]

- Li, Y.S.; Li, C.B.; Garg, A.; Gao, L.; Li, W. Heat dissipation analysis and multi-objective optimization of a permanent magnet synchronous motor using surrogate assisted method. Case Stud. Therm. Eng. 2021, 27, 101203. [Google Scholar] [CrossRef]

- North, D.; Collins, S.; Simpson, N.; Mellor, P. Electrical Machine Loss Distribution and Thermal Parameter Identification through Experimentally Informed Virtual Prototyping. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 4853–4859. [Google Scholar]

- North, D.; Simpson, N.; Mellor, P. Identifying AC Loss Distributions in Electrical Machines through Experimentally Informed Virtual Prototyping. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 3642–3648. [Google Scholar]

- Tami, R.; Boutat, D.; Zheng, G.; Kratz, F.; El Gouri, R. Rotor speed, load torque and parameters estimations of a permanent magnet synchronous motor using extended observer forms. IET Control Theory Appl. 2017, 11, 1485–1492. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, Q.; Chen, J.; Zhu, Z.Q.; Zhang, J. Online Multiparameter Estimation of Nonsalient-Pole PM Synchronous Machines with Temperature Variation Tracking. IEEE Trans. Ind. Electron. 2011, 58, 1776–1788. [Google Scholar] [CrossRef]

- Morimoto, S.; Sanada, M.; Takeda, Y. Mechanical Sensorless Drives of IPMSM with Online Parameter Identification. IEEE Trans. Ind. Appl. 2006, 42, 1241–1248. [Google Scholar] [CrossRef]

- Wallscheid, O.; Huber, T.; Peters, W.; Böcker, J. Real-time capable methods to determine the magnet temperature of permanent magnet synchronous motors—A review. In Proceedings of the IECON 2014-40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October-1 November 2014; pp. 811–818. [Google Scholar]

- Wallscheid, O. Thermal Monitoring of Electric Motors: State-of-the-Art Review and Future Challenges. IEEE Open J. Ind. Appl. 2021, 2, 204–223. [Google Scholar] [CrossRef]

- Gieras, J.F.; Wing, M. Permanent Magnet Motor Technology, 2nd ed.; Marcel Dekker: New York, NY, USA, 2002. [Google Scholar]

- Bonnett, A.H.; Soukup, G.C. Cause and analysis of stator and rotor failures in three-phase squirrel-cage induction motors. IEEE Trans. Ind. Appl. 1992, 28, 921–937. [Google Scholar] [CrossRef]

- Rothe, R.; Hameyer, K. Life expectancy calculation for electric vehicle traction motors regarding dynamic temperature and driving cycles. In Proceedings of the 2011 IEEE International Electric Machines & Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011; pp. 1306–1309. [Google Scholar]

- Huger, D.; Gerling, D. An advanced lifetime prediction method for permanent magnet synchronous machines. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; pp. 686–691. [Google Scholar]

- Chu, W.Q.; Zhu, Z.Q.; Chen, J.T. Simplified Analytical Optimization and Comparison of Torque Densities Between Electrically Excited and Permanent-Magnet Machines. IEEE Trans. Ind. Electron. 2014, 61, 5000–5011. [Google Scholar] [CrossRef]

| PM Material | (%/°C) | Curie Temperature | |

|---|---|---|---|

| Alnico_5 | −0.02 | 1.25 | °C |

| Alnico_9 | −0.02 | 1.05 | °C |

| Sr-Ferrite | −0.2 | 0.3 | °C |

| Ferrite_9 | −0.18 | 0.45 | °C |

| _35E | −0.035 | 1.19 | °C |

| _18 | −0.045 | 0.87 | °C |

| NdFeB_33EH | −0.11 | 1.15 | °C |

| NdFeB_N55 | −0.12 | 1.49 | °C |

| NdFeB_45UH | −0.12 | 1.35 | °C |

| Target | Monitoring Techniques | Computational Complexity | Precision | Additional Devices/ Invasiveness | Dependence on Motor Specifications | Signal Sampling Rate | Training Data Requirement | |

|---|---|---|---|---|---|---|---|---|

| PM | Sensor-based | Low | Very High 1.5 °C [6] | Yes/Mechanical modification | Low | Low | No | |

| Model-based | Thermal models | High | High 3.3 °C [19] | No | High | Medium | No | |

| Electrical models | Medium | High 2 °C [87] | No/Signal injection | Medium | High | No | ||

| Mechanical models | Medium | Medium 4 °C [35] | No/Signal injection | Medium | High | No | ||

| AI algorithm-based | High | High 1.5 °C [37] | No | Low | Medium | Yes | ||

| Stator Winding | Sensor-based | Low | Very High 2 °C [7] | Yes/Mechanical modification | Low | Low | No | |

| Model-based | Thermal models | High | High 2.3 °C [52] | No | High | Medium | No | |

| Electrical models | Medium | Medium 4 °C [86] | No/signal injection | Medium | High | No | ||

| AI algorithm-based | High | Medium 4.5 °C [37] | No | Low | Medium | Yes | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, T.; Zhang, P. A Review of Thermal Monitoring Techniques for Radial Permanent Magnet Machines. Machines 2022, 10, 18. https://doi.org/10.3390/machines10010018

Meng T, Zhang P. A Review of Thermal Monitoring Techniques for Radial Permanent Magnet Machines. Machines. 2022; 10(1):18. https://doi.org/10.3390/machines10010018

Chicago/Turabian StyleMeng, Tianze, and Pinjia Zhang. 2022. "A Review of Thermal Monitoring Techniques for Radial Permanent Magnet Machines" Machines 10, no. 1: 18. https://doi.org/10.3390/machines10010018

APA StyleMeng, T., & Zhang, P. (2022). A Review of Thermal Monitoring Techniques for Radial Permanent Magnet Machines. Machines, 10(1), 18. https://doi.org/10.3390/machines10010018