Integrating Screening and Particle Sorting for the Beneficiation of Low-Grade Gold and Nickel Ores

Abstract

1. Introduction

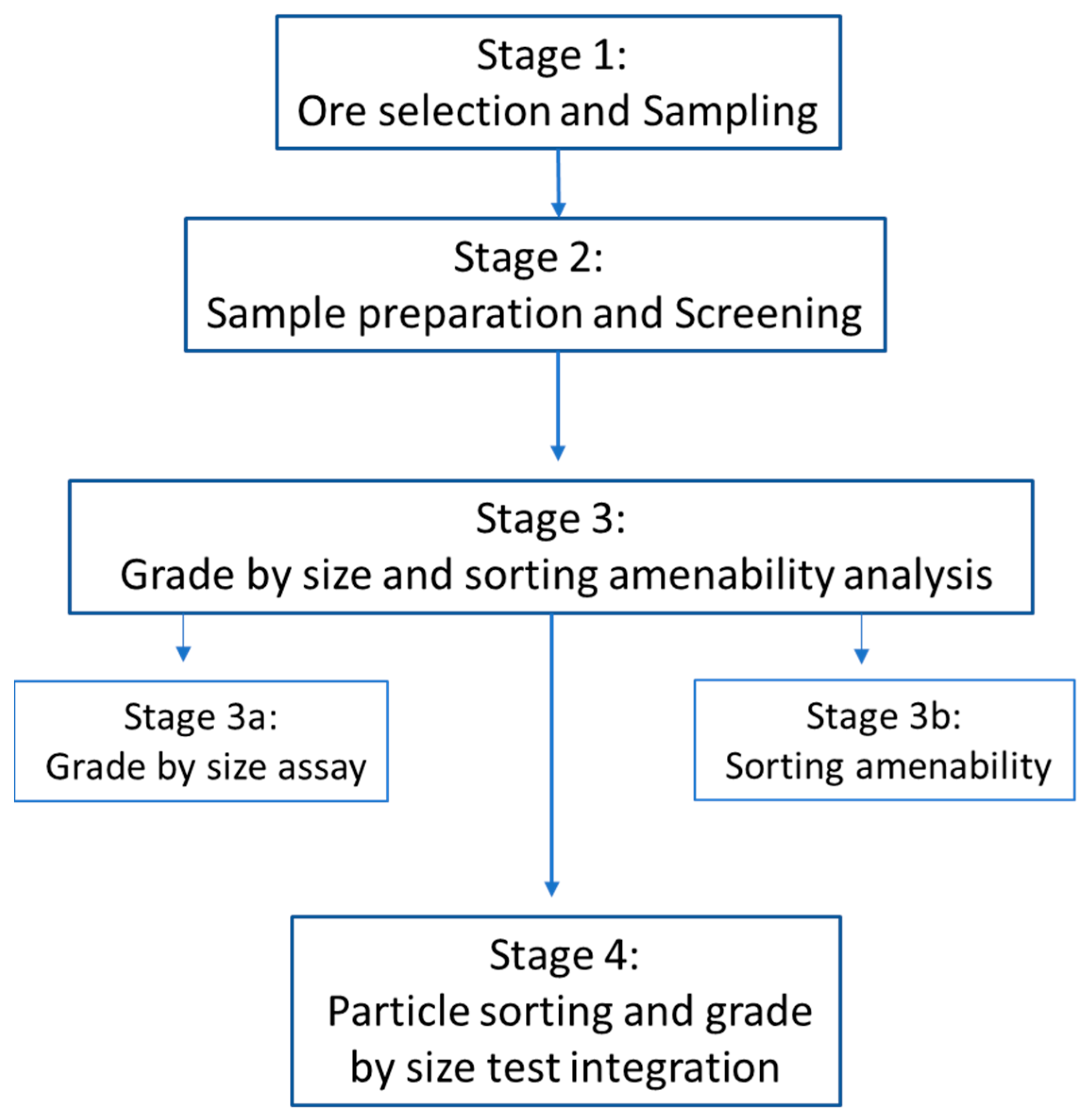

2. Methodology

2.1. Sampling Procedure

2.2. Grade-by-Size Assay

2.3. Quantitative X-Ray Diffraction Analysis (XRD) Analysis

2.4. Measured Particle Sorting Yield Method

2.5. Individual Particle (Actual) Sorting Procedure

- X-ray Transmission (XRT): evaluates variations in atomic density.

- 3D Laser: assesses particle dimensions and morphology, along with laser diffraction and brightness characteristics.

- Induction: detects and quantifies the electrical conductivity of metallic components.

- Color Camera: identifies and records differences in particle color.

- Ore samples from 5 different domains for each site were sized and 100 particles per size fraction for each domain were cleaned, photographed, weighed, and labeled.

- Each rock was scanned once through our High Resolution KSS FLI XT sensor sorting machine (see schematic in Figure 3) to record the data from the sensors.

- After scanning, all 100 rocks from −26 + 9.5 mm, −45 + 26 mm, −70 + 45 mm, and −110 + 70 mm rocks were sent for assays to confirm the grades of Au and Ni.

- Assay results were received and analyzed to complete the full evaluation using scans and their corresponding grades.

3. Results and Discussion

3.1. Particle Size Distribution (PSD) Analysis

3.2. Main Mineral Phases

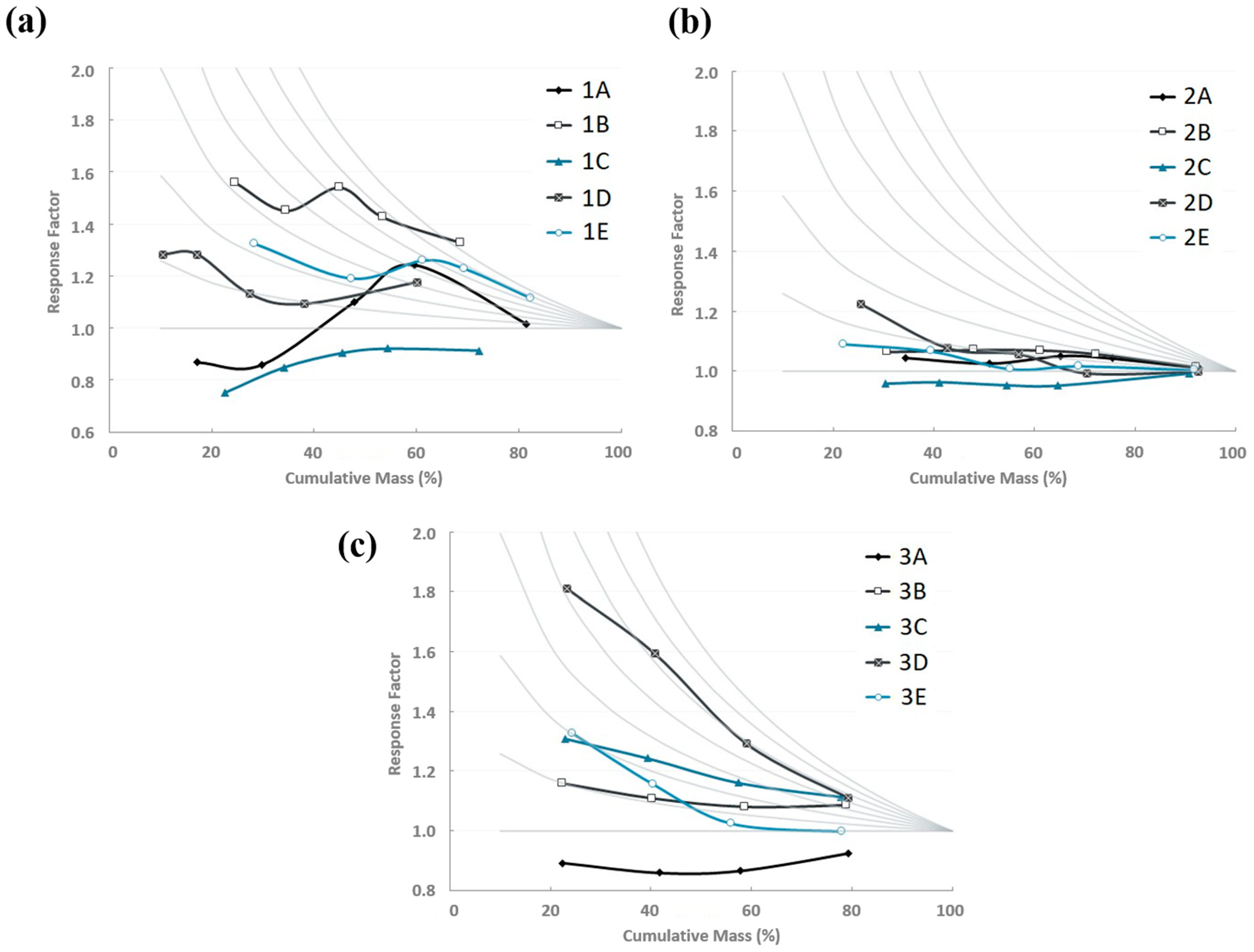

3.3. Grade-by-Size Analysis

3.4. Individual Particle Sorting

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abbadi, A.; Mucsi, G. A review on complex utilization of mine tailings: Recovery of rare earth elements and residue valorization. J. Environ. Chem. Eng. 2024, 12, 113118. [Google Scholar] [CrossRef]

- Larona, S.T.; Tsuyoshi, A. Future availability of mineral resources: Ultimate reserves and total material requirement. Miner. Econ. 2023, 36, 189–206. [Google Scholar]

- Rodríguez, J.E.; Razo, I.; Lazaro, I. Water footprint for mining process: A proposed method to improve water management in mining operations. Clean. Responsible Consum. 2023, 8, 100094. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Tromans, D. Mineral comminution: Energy efficiency considerations. Miner. Eng. 2008, 21, 613–620. [Google Scholar] [CrossRef]

- Bearman, R.A. Step change in the context of comminution. Miner. Eng. 2013, 44, 2–11. [Google Scholar] [CrossRef]

- Howe, P. Australian Water Commission, Framework for Assessing Local and Cumulative Effects of Mining on Groundwater Resources; Report 7; National Water Commission: Canberra, Australia, 2010. [Google Scholar]

- Bowman, D.J.; Bearman, R.A. Coarse waste rejection through size-based separation. Miner. Eng. 2014, 62, 102–110. [Google Scholar] [CrossRef]

- Siong, J.; Duffy, K.; Valery, W.; Tabosa, E.; Pyle, L. Integrating pre-concentration technologies to maximise resource and eco-efficiency. In Proceedings of the 63rd Conference of Metallurgists, COM 2024; Springer: Cham, Switzerland, 2024. [Google Scholar]

- Ballantyne, G.; Hilden, M.; Powell, M. Early rejection of gangue—How much energy will it cost to save energy? In Comminution ’12; Wills, B., Ed.; Mineral Engineering: Cape Town, South Africa, 2012. [Google Scholar]

- Salter, J.D.; Wyatt, N.P.G. Sorting in the minerals industry: Past, present and future. Miner. Eng. 1991, 4, 779–796. [Google Scholar] [CrossRef]

- Wills, B.A.; Napier-Munn, T. Chapter 14—Ore sorting. In Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery; Napier-Munn, B.A.W., Ed.; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Wotruba, H.; Harbeck, H. Sensor-based sorting. In Ullmans Encyclopedia of Industrial Chemistry; Wiley: Weinheim, Germany, 2010. [Google Scholar]

- Burns, R.; Grimes, A. The application of pre-concentration by screening at Bougainville copper limited. In Proceedings of the AusIMM Mineral Development Symposium, Madang, Papua New Guinea, 3–13 November 1986. [Google Scholar]

- McGrath, T.D.H.; Eksteen, J.J.; Bode, P. Assessing the amenability of a free milling gold ore to coarse particle gangue rejection. Miner. Eng. 2018, 120, 110–117. [Google Scholar] [CrossRef]

- Carrasco, C. Revision of the current methodology for characterizing grade by size responses. In CRC ORE Technical Report TR22; CRC for Optimizing Resource Extraction: Brisbane, Australia, 2015. [Google Scholar]

- Bellusci, N.; Taylor, P.R.; Spiller, D.R.; Braman, V. Coarse beneficiation of Trona ore by sensor-based sorting. Min. Metall. Explor. 2022, 39, 2179–2185. [Google Scholar] [CrossRef]

- Chen, X.; Kroell, N.; Feil, A.; Greiff, K. Sensor-based sorting. In Handbook of Recycling; Elsevier: Amsterdam, The Netherlands, 2024; pp. 145–159. [Google Scholar]

- Wikedzi, A.; Saquran, S.; Leißner, T.; Peuker, U.A.; Mutze, T. Breakage characterization of gold ore components. Miner. Eng. 2020, 151, 106314. [Google Scholar] [CrossRef]

- Dominy, S.C. Predicting the unpredictable—Evaluating high-nugget effect gold deposits. In Mineral Resource and Ore Reserve Estimation; The AusIMM: Carlton South, Australia, 2014; pp. 659–678. [Google Scholar]

- Walters, S.G. Driving Productivity by Increasing Feed Quality Through Application of Innovative Grade Engineering® Technologies; Cooperative Research Centre for Optimising Resource Extraction (CRC ORE): Brisbane, QLD, Australia, 2016. [Google Scholar]

| Site | Sample | Particle Size (mm) | |||||

|---|---|---|---|---|---|---|---|

| +110 | −110 + 70 | −70 + 45 | −45 + 26.5 | −26.5 + 9.5 | −9.5 | ||

| 1 (Au in ppm) | A | 1.10 | 0.47 | 2.16 | 1.77 | 1.00 | 1.03 |

| B | 0.22 | 0.75 | 0.62 | 1.39 | 0.90 | 1.18 | |

| C | 1.18 | 1.28 | 0.97 | 1.03 | 1.00 | 0.72 | |

| D | 0.41 | 0.74 | 0.56 | 0.49 | 0.72 | 0.72 | |

| E | 0.08 | 0.08 | 0.16 | 0.24 | 0.16 | 0.21 | |

| 2 (Ni in wt%) | A | 0.448 | 0.43 | 0.51 | 0.587 | 0.509 | 0.541 |

| B | 0.447 | 0.50 | 0.523 | 0.556 | 0.572 | 0.563 | |

| C | 1.81 | 1.68 | 1.57 | 1.53 | 1.62 | 1.59 | |

| D | 0.450 | 0.63 | 0.322 | 0.437 | 0.38 | 0.538 | |

| E | 0.540 | 0.51 | 0.594 | 0.479 | 0.576 | 0.608 | |

| 3 (Au in ppm) | A | - | 1.45 | 1.21 | 0.99 | 0.92 | 1.00 |

| B | - | 0.49 | 0.79 | 0.73 | 0.75 | 0.83 | |

| C | - | 0.42 | 0.69 | 0.69 | 0.81 | 0.92 | |

| E | - | 0.61 | 0.59 | 0.41 | 0.54 | 0.80 | |

| D | - | 0.48 | 0.48 | 0.51 | 1.08 | 5.93 | |

| Site | Sample | RR (Grade × Size Samples) | RR (100 Rocks) |

|---|---|---|---|

| 1 | A | 17 | 23 |

| B | 101 | 98 | |

| C | −36 | −60 | |

| D | 30 | 13 | |

| E | 81 | 88 | |

| 2 | A | 10 | 11 |

| B | 17 | 16 | |

| C | 15 | 15 | |

| D | 16 | −5 | |

| E | 12 | 19 | |

| 3 | A | −43 | −40 |

| B | 35 | 41 | |

| C | 56 | 51 | |

| D | 158 | 138 | |

| E | 19.3 | 36 |

| Site | Sample | Size Fraction (mm) | Measured Sorting | Actual Sorting | ||

|---|---|---|---|---|---|---|

| Au Recovery (%) | Mass Pull (%) | Au Recovery (%) | Mass Pull (%) | |||

| 1 | A | −110 + 70 | 92 | 14 | 67 | 30 |

| −70 + 45 | 96 | 12 | 87 | 21 | ||

| −45 + 26.5 | 90 | 16 | 81 | 31 | ||

| −26.5 + 9.5 | 95 | 24 | 83 | 30 | ||

| B | −110 + 70 | 91 | 16 | 67 | 30 | |

| −70 + 45 | 87 | 14 | 70 | 35 | ||

| −45 + 26.5 | 97 | 16 | 90 | 37 | ||

| −26.5 + 9.5 | 76 | 7 | 90 | 32 | ||

| C | −110 + 70 | 90 | 28 | 65 | 30 | |

| −70 + 45 | 95 | 30 | 74 | 30 | ||

| −45 + 26.5 | 90 | 26 | 75 | 42 | ||

| −26.5 + 9.5 | 89 | 12 | 73 | 23 | ||

| D | −110 + 70 | 88 | 13 | 80 | 30 | |

| −70 + 45 | 82 | 12 | 67 | 40 | ||

| −45 + 26.5 | 74 | 6 | 62 | 30 | ||

| −26.5 + 9.5 | 75 | 9 | 75 | 43 | ||

| E | −110 + 70 | 67 | 4 | 80 | 30 | |

| −70 + 45 | 55 | 3 | 75 | 40 | ||

| −45 + 26.5 | 75 | 3 | 80 | 30 | ||

| −26.5 + 9.5 | 70 | 2 | 77 | 30 | ||

| Site | Sample | Size Fraction (mm) | Measured Sorting | Actual Sorting | ||

|---|---|---|---|---|---|---|

| Ni Recovery (%) | Mass Pull (%) | Ni Recovery (%) | Mass Pull (%) | |||

| 2 | A | −110 + 70 | 56 | 24 | 58 | 30 |

| −70 + 45 | 65 | 22 | 64 | 24 | ||

| −45 + 26.5 | 49 | 15 | 55 | 24 | ||

| −26.5 + 9.5 | 54 | 20 | 62 | 28 | ||

| B | −110 + 70 | 65 | 26 | 60 | 30 | |

| −70 + 45 | 58 | 21 | 64 | 30 | ||

| −45 + 26.5 | 63 | 20 | 68 | 28 | ||

| −26.5 + 9.5 | 68 | 22 | 72 | 31 | ||

| C | −110 + 70 | 91 | 48 | 84 | 39 | |

| −70 + 45 | 88 | 41 | 89 | 42 | ||

| −45 + 26.5 | 90 | 45 | 90 | 47 | ||

| −26.5 + 9.5 | 89 | 47 | 84 | 44 | ||

| D | −110 + 70 | 67 | 19 | 75 | 35 | |

| −70 + 45 | 46 | 10 | 74 | 32 | ||

| −45 + 26.5 | 46 | 11 | 74 | 27 | ||

| −26.5 + 9.5 | 37 | 8 | 75 | 42 | ||

| E | −110 + 70 | 77 | 26 | 97 | 57 | |

| −70 + 45 | 43 | 11 | 73 | 31 | ||

| −45 + 26.5 | 86 | 35 | 80 | 34 | ||

| −26.5 + 9.5 | 76 | 27 | 75 | 34 | ||

| Site | Sample | Size Fraction (mm) | Measured Sorting | Actual Sorting | ||

|---|---|---|---|---|---|---|

| Au Recovery (%) | Mass Pull (%) | Au Recovery (%) | Mass Pull (%) | |||

| 3 | A | −110 + 70 | 89 | 28 | - | - |

| −70 + 45 | 90 | 30 | - | - | ||

| −45 + 26.5 | 86 | 23 | - | - | ||

| −26.5 + 9.5 | 85 | 11 | - | - | ||

| B | −110 + 70 | 89 | 11 | - | - | |

| −70 + 45 | 93 | 26 | 68 | 74 | ||

| −45 + 26.5 | 95 | 24 | 92 | 77 | ||

| −26.5 + 9.5 | 94 | 11 | - | - | ||

| C | −110 + 70 | 77 | 17 | - | - | |

| −70 + 45 | 85 | 13 | - | - | ||

| −45 + 26.5 | 78 | 22 | - | - | ||

| −26.5 + 9.5 | 77 | 13 | - | - | ||

| D | −110 + 70 | 78 | 13 | - | - | |

| −70 + 45 | 86 | 13 | - | - | ||

| −45 + 26.5 | 83 | 18 | - | - | ||

| −26.5 + 9.5 | 84 | 22 | - | - | ||

| E | −110 + 70 | 95 | 13 | - | - | |

| −70 + 45 | 94 | 11 | 98 | 95 | ||

| −45 + 26.5 | 91 | 19 | 96 | 74 | ||

| −26.5 + 9.5 | 93 | 22 | - | - | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Tadesse, B.; Saeed, G.; Dyer, L. Integrating Screening and Particle Sorting for the Beneficiation of Low-Grade Gold and Nickel Ores. Minerals 2026, 16, 13. https://doi.org/10.3390/min16010013

Tadesse B, Saeed G, Dyer L. Integrating Screening and Particle Sorting for the Beneficiation of Low-Grade Gold and Nickel Ores. Minerals. 2026; 16(1):13. https://doi.org/10.3390/min16010013

Chicago/Turabian StyleTadesse, Bogale, Ghuzanfar Saeed, and Laurence Dyer. 2026. "Integrating Screening and Particle Sorting for the Beneficiation of Low-Grade Gold and Nickel Ores" Minerals 16, no. 1: 13. https://doi.org/10.3390/min16010013

APA StyleTadesse, B., Saeed, G., & Dyer, L. (2026). Integrating Screening and Particle Sorting for the Beneficiation of Low-Grade Gold and Nickel Ores. Minerals, 16(1), 13. https://doi.org/10.3390/min16010013