Comparison of Wet and Dry Grinding in Electromagnetic Mill

Abstract

:1. Introduction

- lower energy consumption per unit of mass,

- better efficiency of the mill,

- no dust,

- lower noise.

- the wear on the media and liners is usually considerably greater,

- less material in the range of the very small particle size is produced,

- drying the comminuted material usually needs more expensive dust collecting equipment than raw material drying,

- shut down and switching on procedures are more complex in the wet case therefore the wet process is less convenient for day or single shift operations.

- downstream (wet) processing requirements,

- higher energy efficiencies associated with wet grinding,

- requirement for a low moisture content feed (nominally less than 2% moisture) for dry milling is difficult to fulfill,

- fine sulphides tend to oxidize in the air,

- dry grinding often produces strong agglomerates and incrustation build-ups (depending on the fineness of the grind) which are difficult to subsequently disperse,

- the surface properties of dry ground minerals are different than the same minerals wet ground.

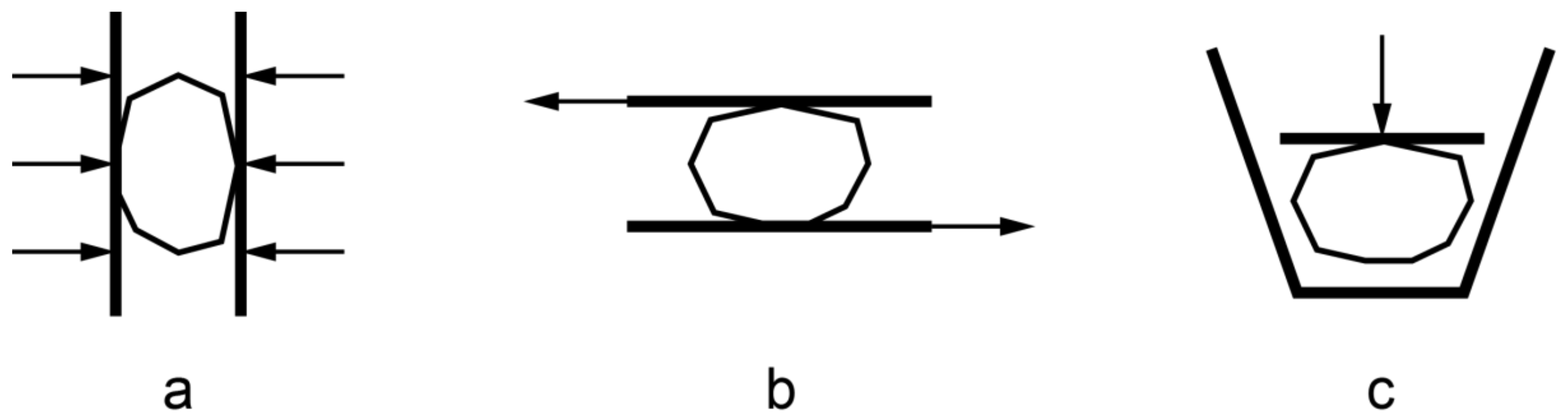

2. Electromagnetic Mill

2.1. Device Description

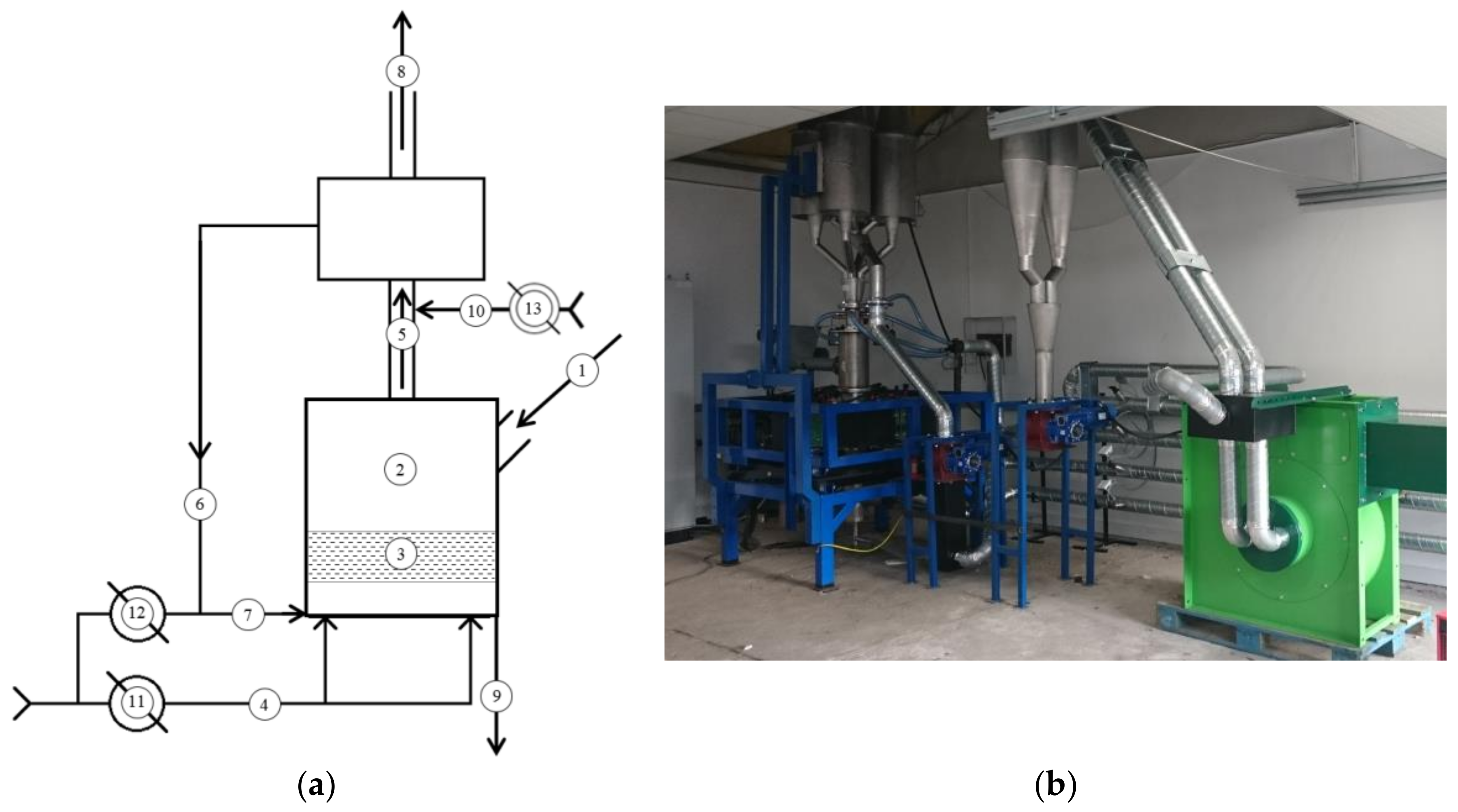

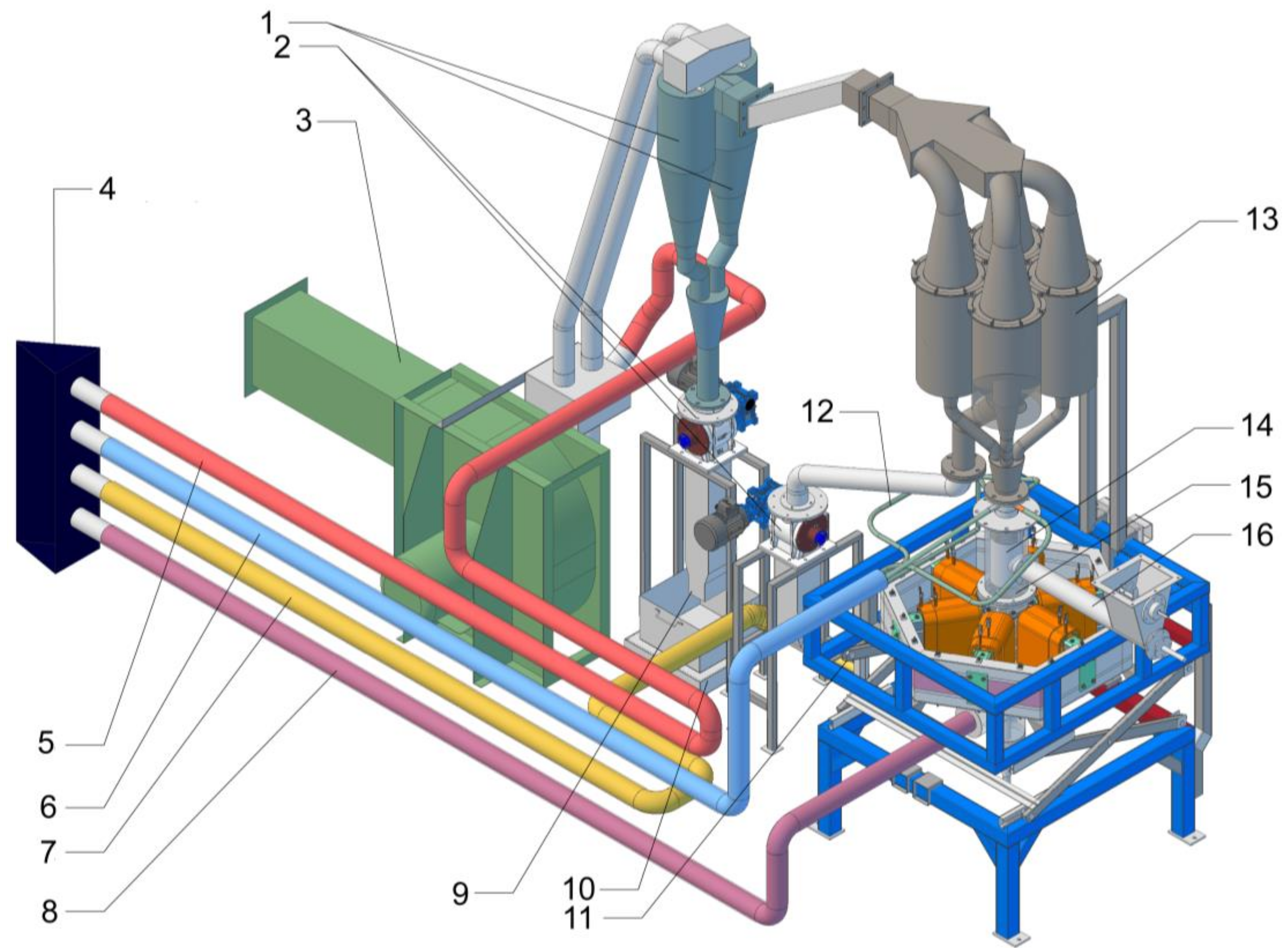

2.2. Grinding and Classification Circuit

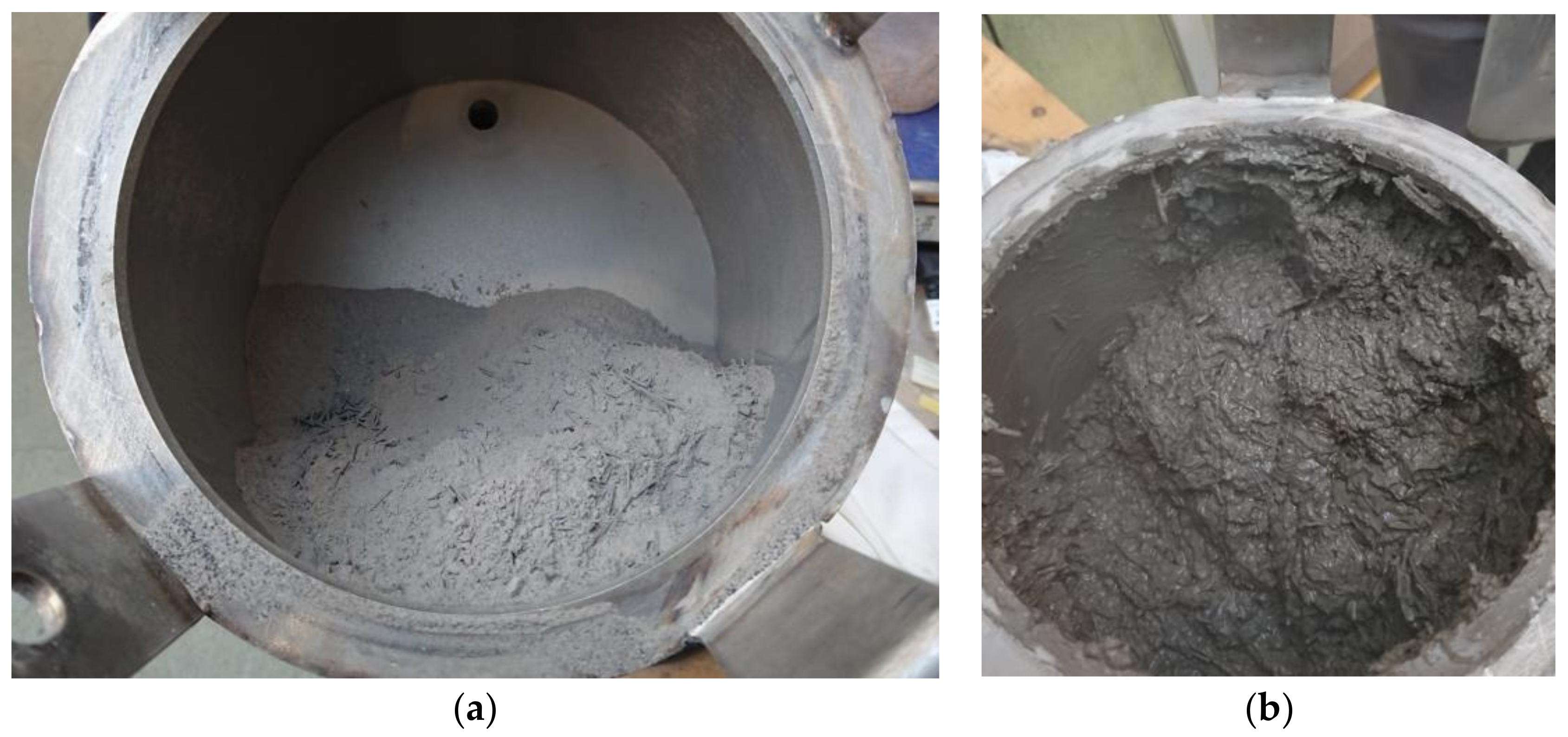

3. Wet and Dry Grinding Experiments

3.1. Laboratory Set-Up Description

3.2. Experiments Description

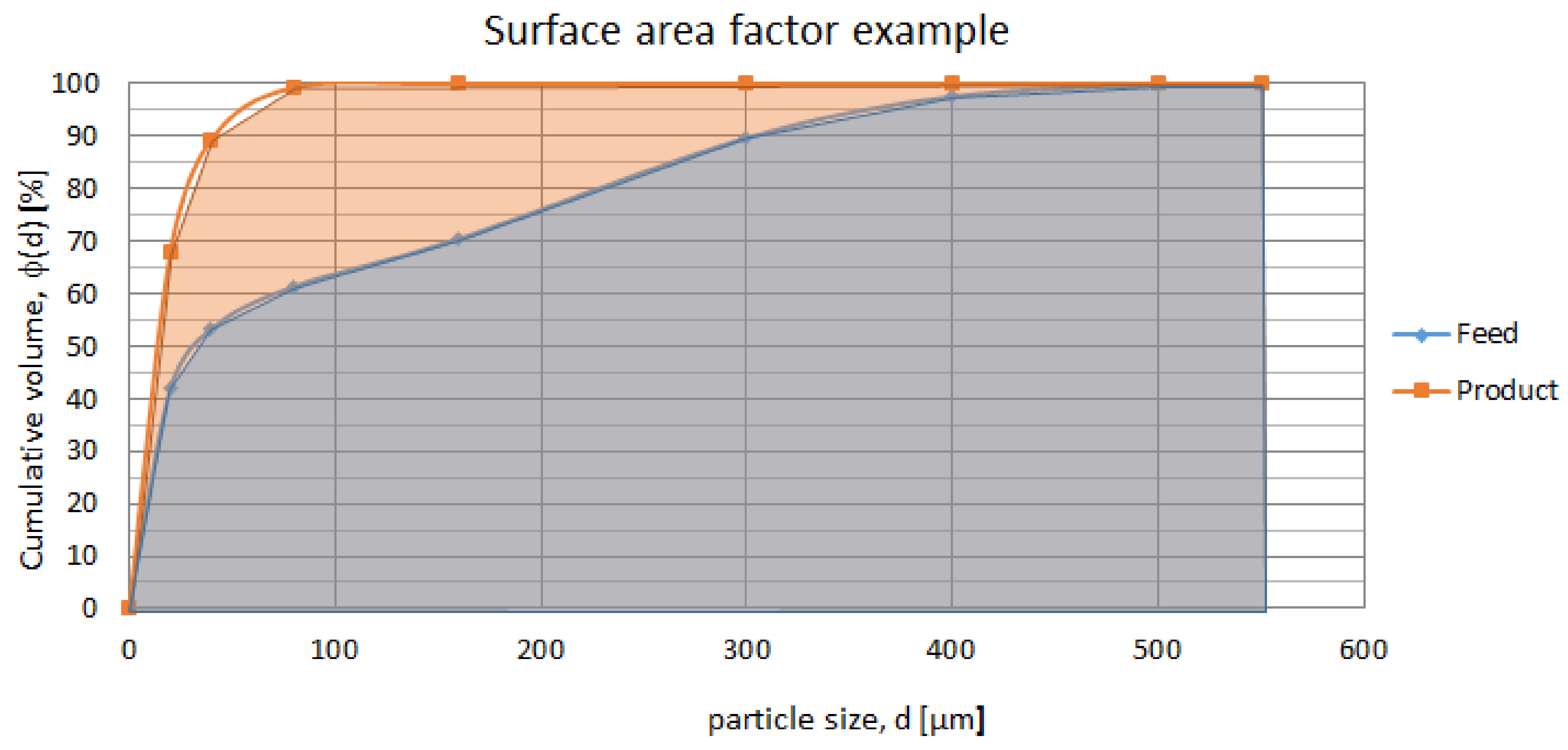

3.3. Factors and Indicators for Results Analysis

4. Experimental Results Analysis

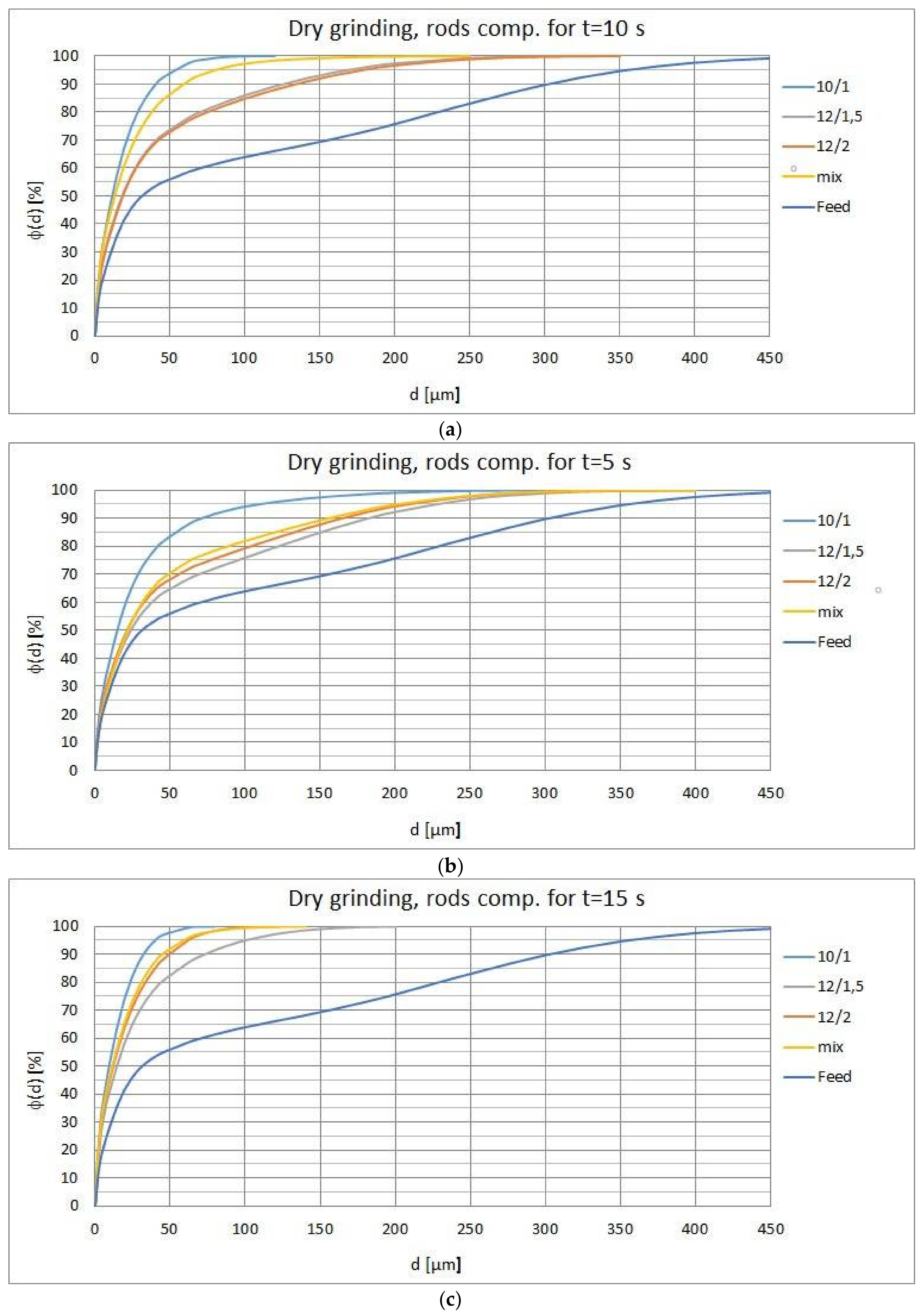

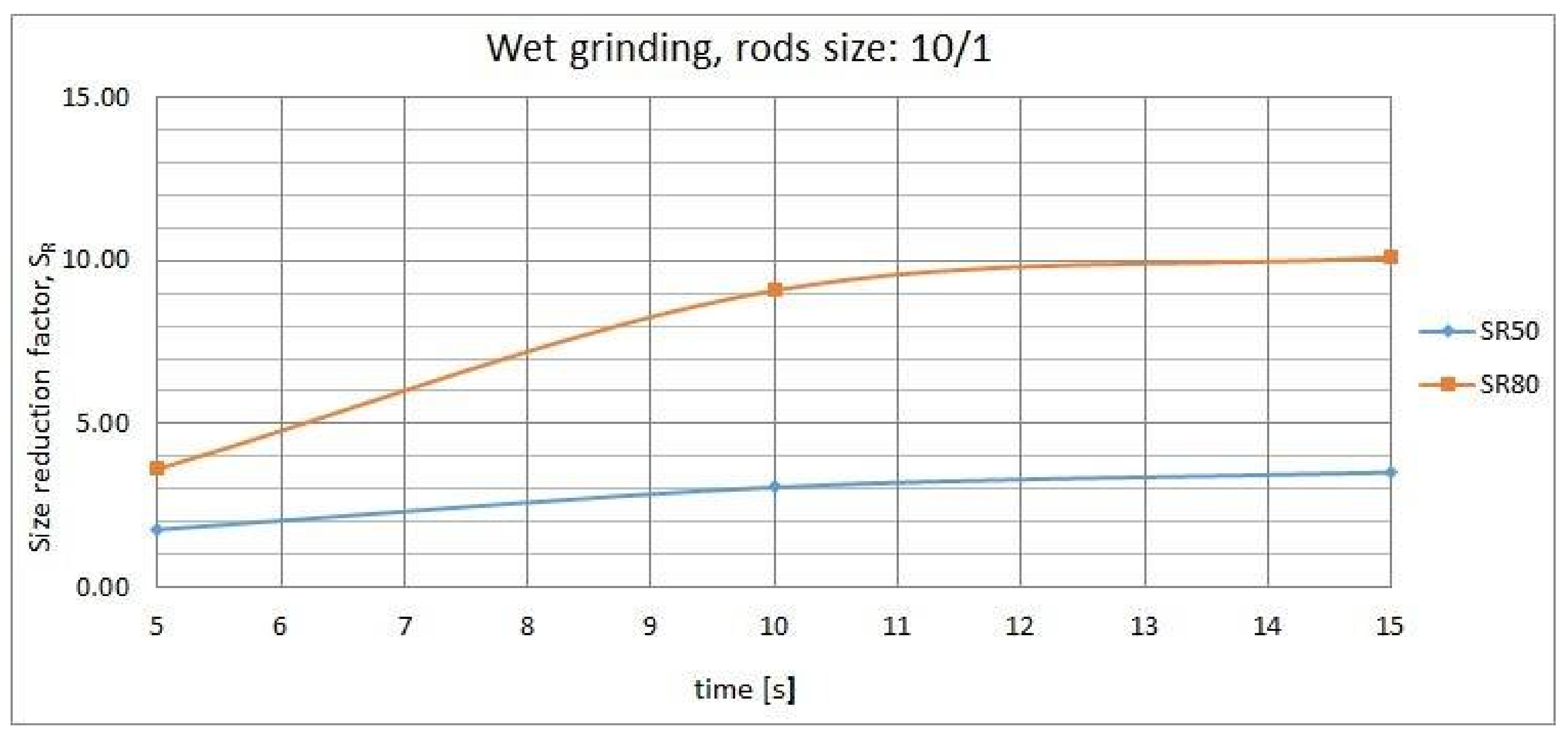

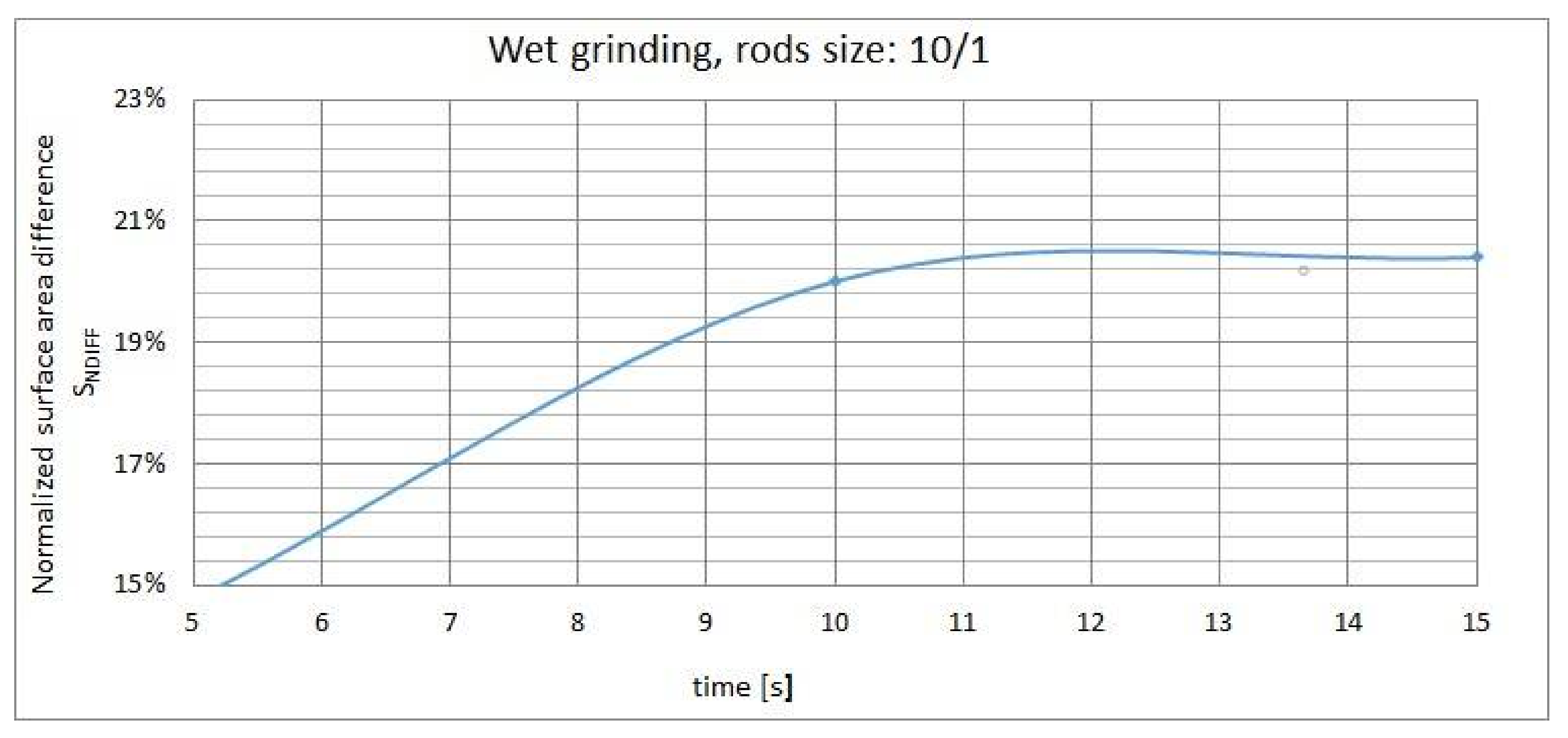

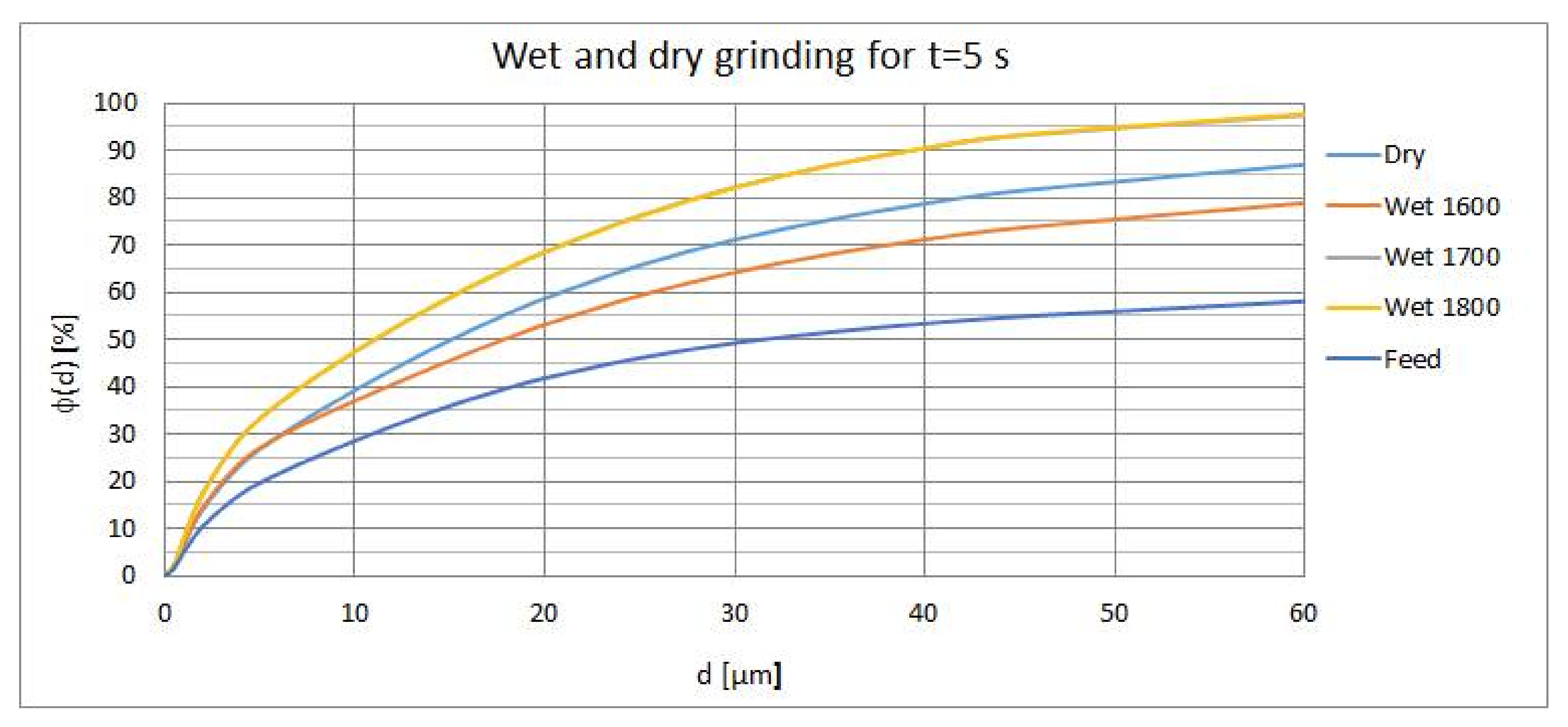

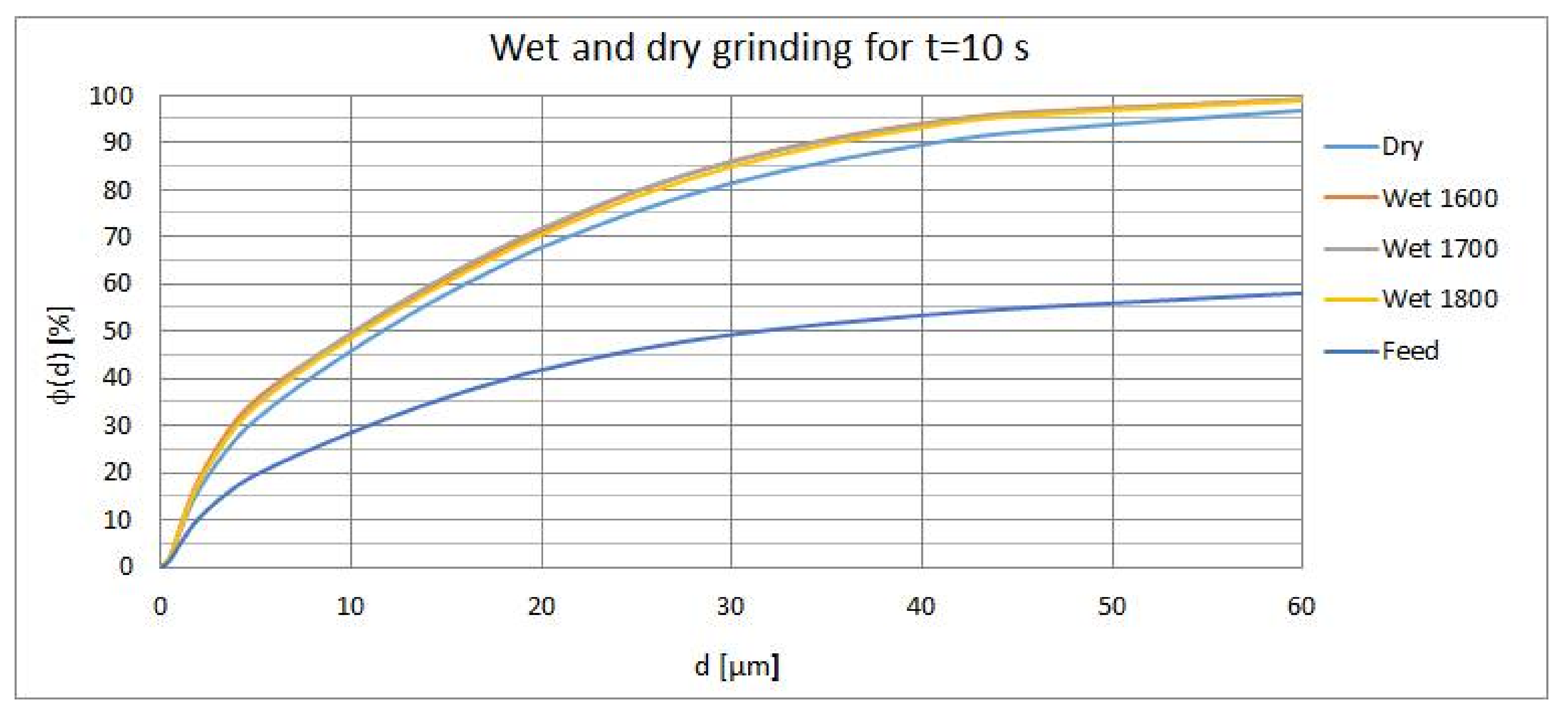

4.1. Product Parameters

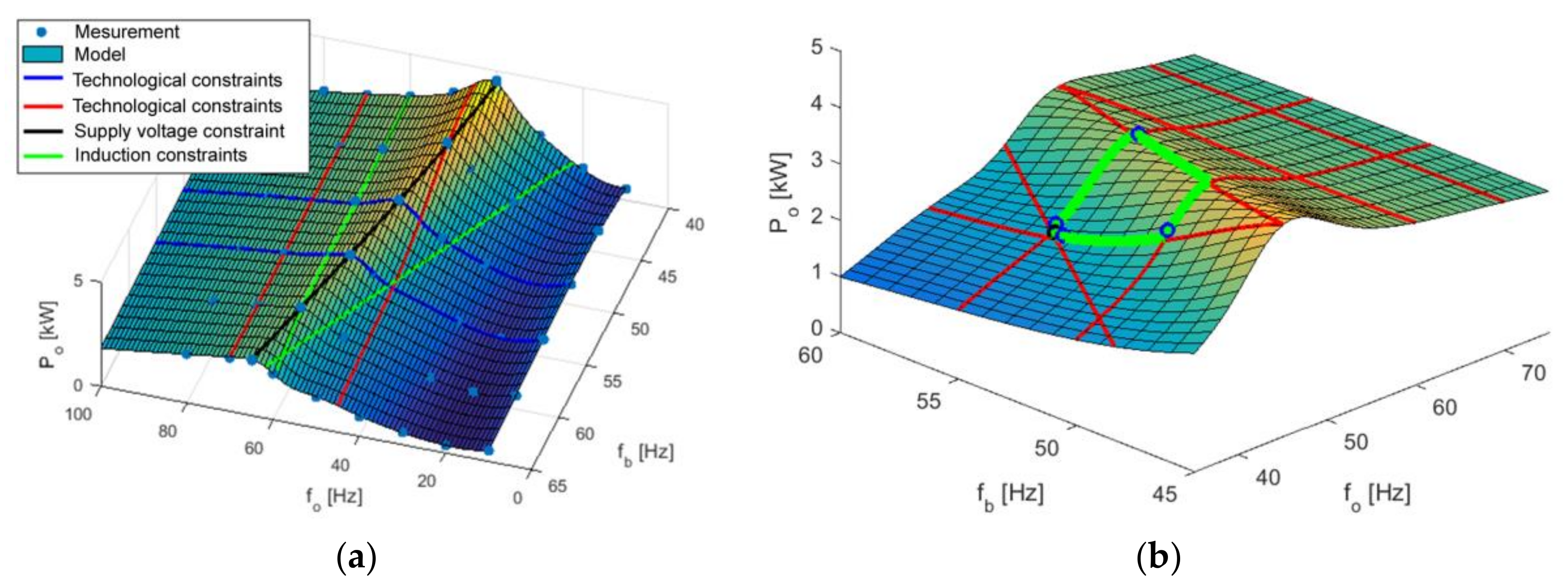

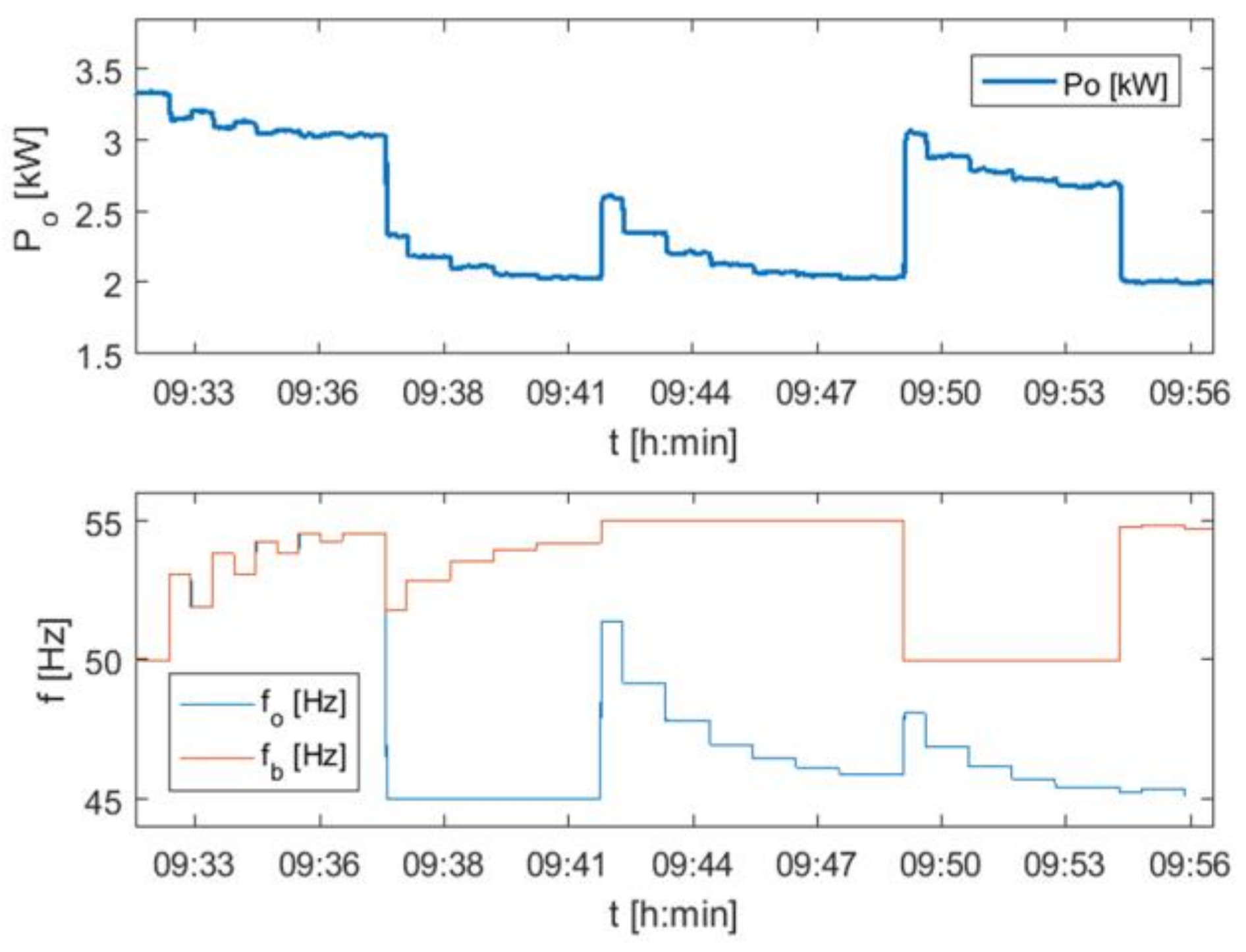

4.2. Energy Consumption Problems

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Blaschke, S. Mechanical Processing of Minerals, Part I; Wydawnictwo Śląsk: Katowice, Poland, 1982. (In Polish) [Google Scholar]

- Fuerstenau, D.W.; Abouzeid, A.-Z.M. The energy efficiency of ball milling in comminution. Int. J. Miner. Process. 2002, 67, 161–185. [Google Scholar] [CrossRef]

- Gawenda, T. Issues of crushing devices selection for mineral aggregates production circuits. Górnictwo i Geoinżynieria 2010, 34, 195–209. (In Polish) [Google Scholar]

- Malewski, J. Mineral Processing. Principles of Comminution and Classification; Wydawnictwo Politechniki Wrocławskiej: Wrocław, Poland, 1981. (In Polish) [Google Scholar]

- Laskowski, J.; Łuszczkiewicz, A. Mineral Processing. Enrichment of Mineral Resources; Skrypt Politechniki Wrocławskiej: Wrocław, Poland, 1989. (In Polish) [Google Scholar]

- Wills, B.; Napier-Munn, T. Mineral Processing Technology, 7th ed.; Pergamon Press: Oxford, UK, 2006; pp. 146–186. [Google Scholar]

- Clermont, B.; De Haas, B. Optimization of mill performance by using online ball and pulp measurements. J. S. Afr. Inst. Min. Metall. 2010, 110, 133–140. [Google Scholar]

- Wang, Y.M.; Forssberg, E. New Milling Technology; Technical Report; MinFo: Stockholm, Sweden, 2001. [Google Scholar]

- Mular, A.L.; Doug, N.H.; Derek, J.B. Mineral Processing Plant Design. Practice and Control Proceedings; SME: Chicago, IL, USA, 2002; pp. 537–669. [Google Scholar]

- Bruckard, W.J.; Sparrow, G.J.; Woodcock, J.T. A Review of the Effects of the Grinding Environment on the Flotation of Copper Sulphides. Int. J. Miner. Process. 2011, 100, 1–13. [Google Scholar] [CrossRef]

- Herbst, J.A.; Nordell, L.K. Emergence of HFS as a design tool in mineral processing. In Proceedings of the Mineral Processing Plant Design, Practice, and Control, Vancouver, BC, Canada, 20–24 October 2002; Mular, A.L., Halbe, D.N., Barratt, D.J., Eds.; Society for Mining, Metallurgy, and Exploration: Chicago, IL, USA, 2002; pp. 495–506, ISBN 0-87335-223-8. [Google Scholar]

- Morrison, R.D.; Richardson, J.M. JKSimMet: A simulator for analysis, optimization and design of comminution circuit. In Proceedings of the Mineral Processing Plant Design, Practice, and Control, Vancouver, BC, Canada, 20–24 October 2002; Mular, A.L., Halbe, D.N., Barratt, D.J., Eds.; Society for Mining, Metallurgy, and Exploration: Chicago, IL, USA, 2002; pp. 442–460, ISBN 0-87335-223-8. [Google Scholar]

- Wołosiewicz-Głąb, M.; Ogonowski, S.; Foszcz, D. Construction of the electromagnetic mill with the grinding system, classification of crushed minerals and the control system. IFAC-PapersOnLine 2016, 49, 67–71. [Google Scholar] [CrossRef]

- Wołosiewicz-Głąb, M.; Foszcz, D.; Ogonowski, S. Design of the electromagnetic mill and the air stream ratio model. IFAC-PapersOnLine 2017, 50, 14964–14969. [Google Scholar] [CrossRef]

- Pawełczyk, M.; Ogonowski, Z.; Ogonowski, S.; Foszcz, D.; Saramak, D.; Gawenda, T.; Krawczykowski, D. Method for Dry Grinding in Electromagnetic Mill. Patent PL413041, 6 July 2015. [Google Scholar]

- Ogonowski, Z.; Ogonowski, S. Estimation problems of pneumatic transport system for electromagnetic grinding. In Proceedings of the 22nd International Conference on Methods and Models in Automation and Robotics (MMAR 2017), Międzyzdroje, Poland, 28–31 August 2017. [Google Scholar] [CrossRef]

- Ogonowski, S.; Ogonowski, Z.; Pawelczyk, M. Model of the air stream ratio for an electromagnetic mill control system. In Proceedings of the 21st International Conference on Methods and Models in Automation and Robotics (MMAR 2016), Międzyzdroje, Poland, 29 August–1 September 2016; pp. 901–906. [Google Scholar] [CrossRef]

- Krauze, O.; Pawełczyk, M. Modelling dynamics of strongly coupled air paths in pneumatic transport system for milling product. In Proceedings of the 22nd International Conference on Methods and Models in Automation and Robotics (MMAR 2017), Międzyzdroje, Poland, 28–31 August 2017. [Google Scholar] [CrossRef]

- Wolosiewicz-Glab, M.; Ogonowski, S.; Foszcz, D.; Gawenda, T. Assessment of classification with variable air flow for inertial classifier in dry grinding circuit with electromagnetic mill using partition curves. Physicochem. Probl. Miner. Process. 2018, 54, 440–447. [Google Scholar] [CrossRef]

- Buchczik, D.; Wegehaupt, J.; Krauze, O. Indirect measurements of milling product quality in the classification system of electromagnetic mill. In Proceedings of the 22nd International Conference on Methods and Models in Automation and Robotics (MMAR 2017), Międzyzdroje, Poland, 28–31 August 2017. [Google Scholar] [CrossRef]

- Ogonowski, S.; Ogonowski, Z.; Swierzy, M.; Pawelczyk, M. Control System of Electromagnetic Mill Load. In Proceedings of the 2017 25th International Conference on Systems Engineering (ICSEng), Las Vegas, NV, USA, 22–24 August 2017; pp. 69–76. [Google Scholar] [CrossRef]

- Ogonowski, S.; Ogonowski, Z.; Swierzy, M. Power optimizing control of grinding process in electromagnetic mill. In Proceedings of the 2017 21st International Conference on Process Control (PC 2017), Strbske Pleso, Slovakia, 6–9 June 2017; pp. 370–375. [Google Scholar] [CrossRef]

- Ogonowski, S.; Ogonowski, Z.; Pawelczyk, M. Multi-objective and multi-rate control of the grinding and classification circuit with electromagnetic mill. Appl. Sci. 2018, 8, 506. [Google Scholar] [CrossRef]

- Sławiński, K.; Gandor, M.; Knaś, K.; Balt, B.; Nowak, W. Electromagnetic mill and its application for coal drying process. Rynek Energii 2014, 1, 140–150. [Google Scholar]

- Lynch, A.J. Mineral Crushing and Grinding Circuits: Their Simulation, Optimization, Design and Control; Elsevier Scientific: New York City, NY, USA, 1977; ISBN 978-0444415288. [Google Scholar]

- Krawczykowski, D. Application of Diffraction Laser Analysis to Monitor Granulation of Copper Ores Processing Products. Inżynieria Mineralna 2017, 1, 233–240. (In Polish) [Google Scholar]

- Kincaid, D.; Cheney, W. Numerical Analysis. Mathematics of Scientific Computing; Brooks/Cole Publishing: Pacific Grove, CA, USA, 2002; ISBN 0-534-13014-3. [Google Scholar]

- International Organization for Standardization. Particle Size Analysis—Laser Diffraction Methods; ISO13320; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Wegehaupt, J.; Buchczik, D.; Krauze, O. Preliminary studies on modelling the drying process in product classification and separation path in an electromagnetic mill installation. In Proceedings of the 22nd International Conference on Methods and Models in Automation and Robotics (MMAR 2017), Międzyzdroje, Poland, 28–31 August 2017. [Google Scholar] [CrossRef]

| Sample No. | Processing Time (s) | Rods Size l (mm)/d (mm) | Sample No. | Processing Time (s) | Rods Size l (mm)/d (mm) |

|---|---|---|---|---|---|

| 1 | 5 | 10/1 | 13 | 5 | 12/2 |

| 2 | 10 | 10/1 | 14 | 10 | 12/2 |

| 3 | 15 | 10/1 | 15 | 15 | 12/2 |

| 4 | 20 | 10/1 | 16 | 20 | 12/2 |

| 5 | 25 | 10/1 | 17 | 25 | 12/2 |

| 6 | 30 | 10/1 | 18 | 30 | 12/2 |

| 7 | 5 | 12/1.5 | 19 | 5 | mixture |

| 8 | 10 | 12/1.5 | 20 | 10 | mixture |

| 9 | 15 | 12/1.5 | 21 | 15 | mixture |

| 10 | 20 | 12/1.5 | 22 | 20 | mixture |

| 11 | 25 | 12/1.5 | 23 | 25 | mixture |

| 12 | 30 | 12/1.5 | 24 | 30 | mixture |

| Sample No. | Pulp Density (kg/m3) | Sample Volume (mL) | Water Volume (mL) | Sample WCV Ratio (%) | Processing Time (s) |

|---|---|---|---|---|---|

| 1 | 1600 | 506 | 330 | 10.1 | 5 |

| 2 | 1600 | 506 | 330 | 10.1 | 10 |

| 3 | 1600 | 506 | 330 | 10.1 | 15 |

| 4 | 1700 | 430 | 253 | 8.6 | 5 |

| 5 | 1700 | 430 | 253 | 8.6 | 10 |

| 6 | 1700 | 430 | 253 | 8.6 | 15 |

| 7 | 1800 | 375 | 198 | 7.5 | 5 |

| 8 | 1800 | 375 | 198 | 7.5 | 10 |

| 9 | 1800 | 375 | 198 | 7.5 | 15 |

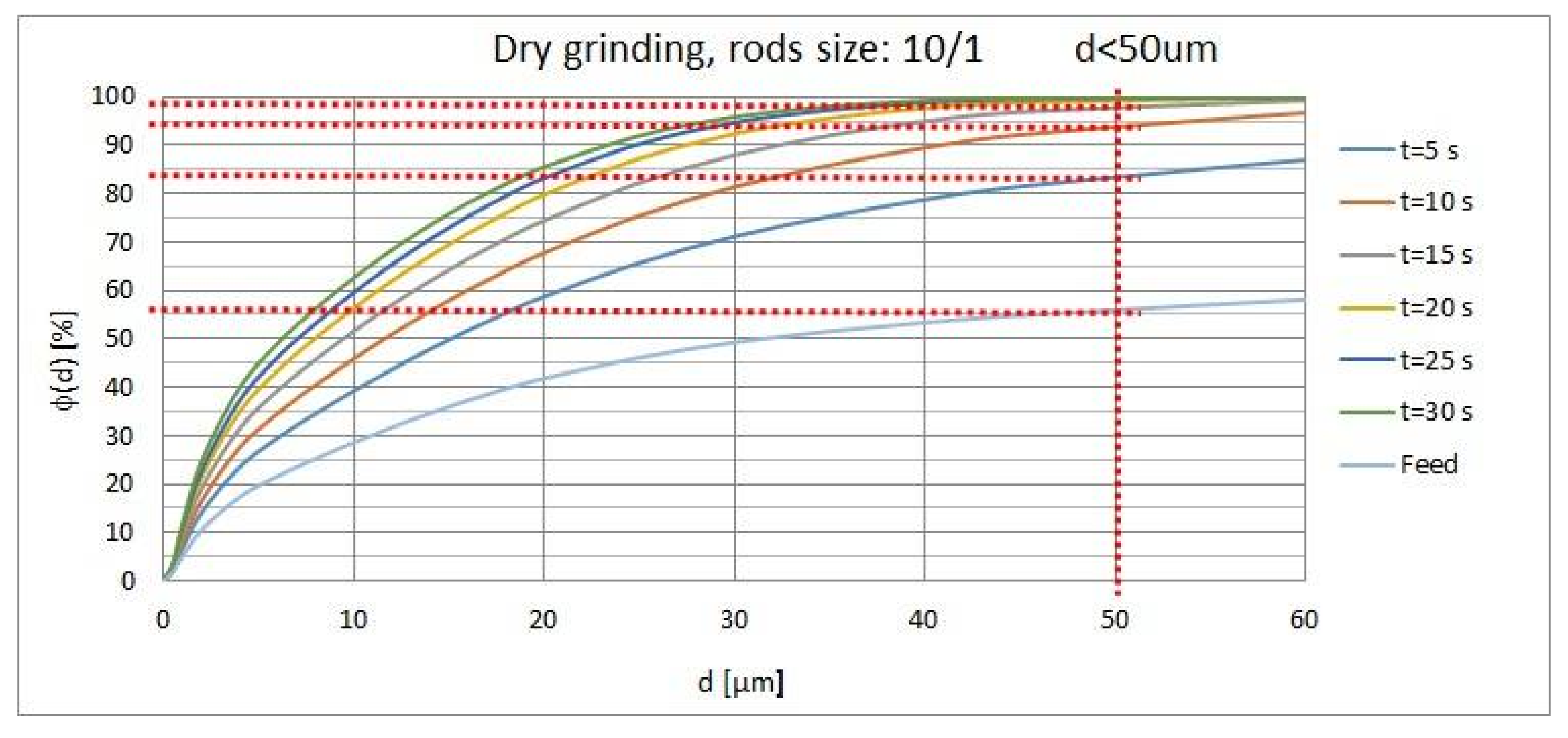

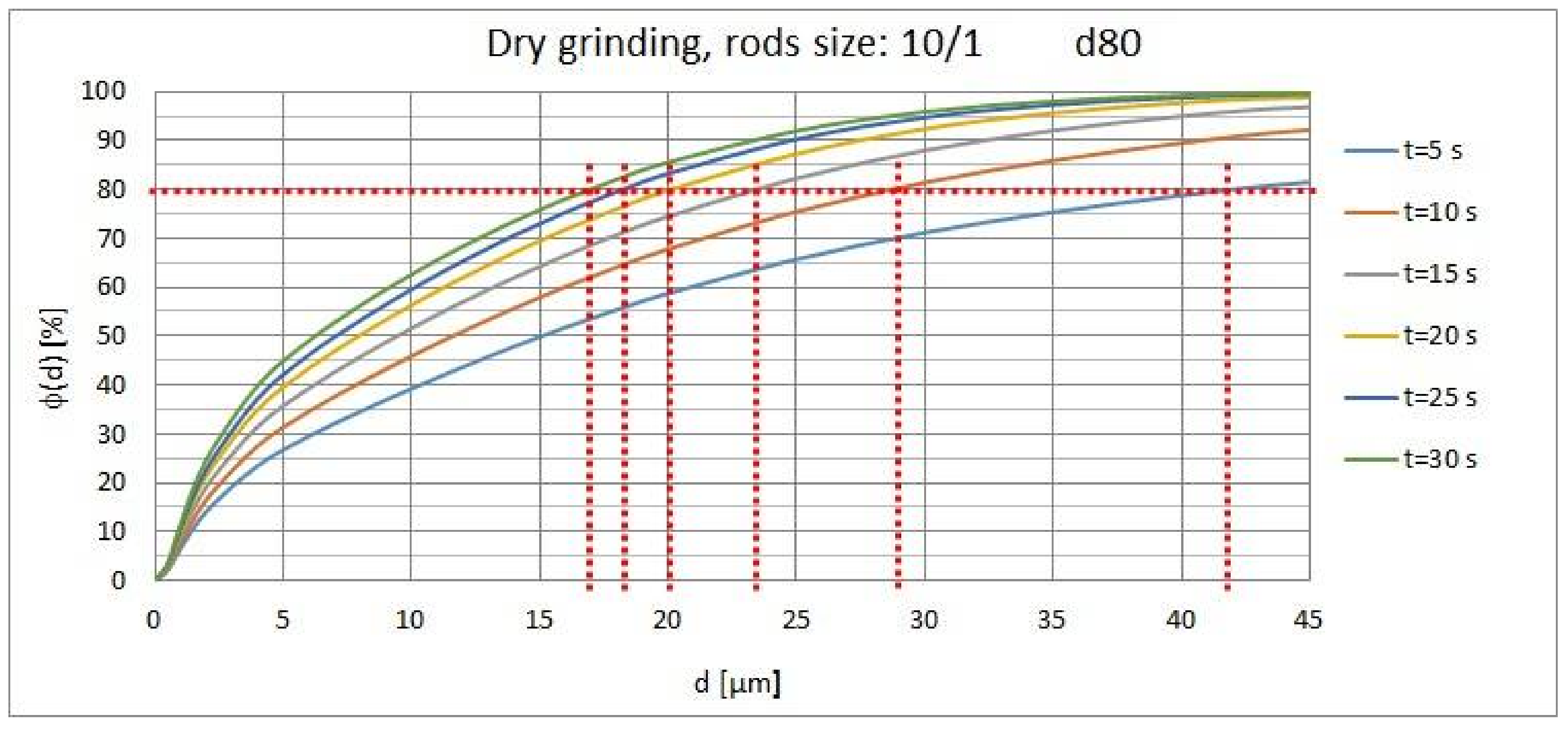

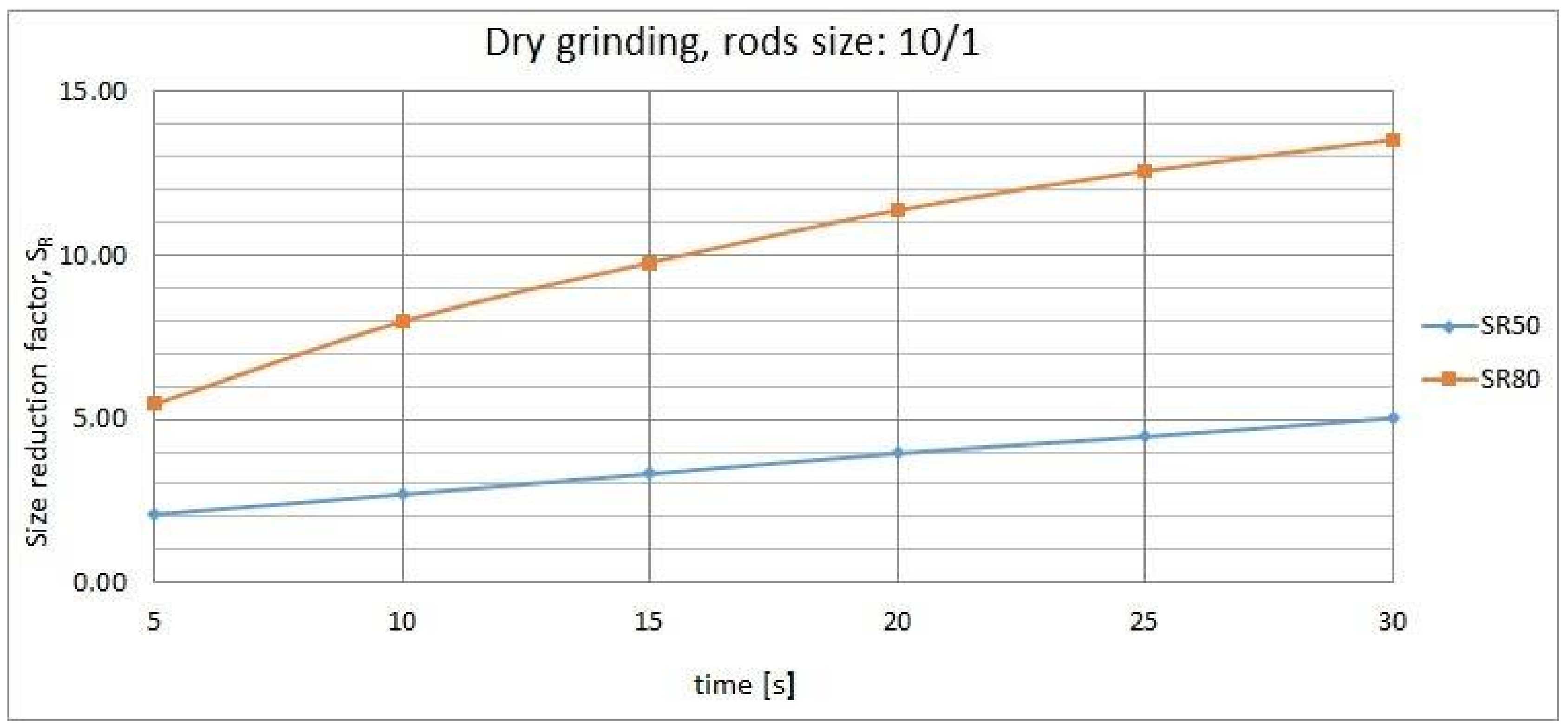

| Time (s) | Energy Consumption (kWh) | Specific Energy (kWh/t) | SDIFF ± RSD | SNDIFF ± RSD (%) | SR50 ± RSD | SR80 ± RSD |

|---|---|---|---|---|---|---|

| 5 | 0.025 | 50 | 7512.86 ± 744.42 | 16.84 ± 1.75 | 2.08 ± 0.31 | 5.46 ± 0.58 |

| 10 | 0.05 | 100 | 8676.44 ± 756.05 | 19.45 ± 1.79 | 2.71 ± 0.41 | 7.98 ± 0.85 |

| 15 | 0.075 | 150 | 9017.59 ± 759.47 | 20.21 ± 1.80 | 3.32 ± 0.50 | 9.78 ± 1.04 |

| 20 | 0.1 | 200 | 9217.12 ± 761.46 | 20.66 ± 1.81 | 3.96 ± 0.59 | 11.38 ± 1.22 |

| 25 | 0.125 | 250 | 9340.27 ± 762.69 | 20.93 ± 1.81 | 4.46 ± 0.67 | 12.58 ± 1.34 |

| 30 | 0.15 | 300 | 9420.22 ± 763.49 | 21.11 ± 1.82 | 5.04 ± 0.76 | 13.53 ± 1.45 |

| Time (s) | Energy Consumption (kWh) | Specific Energy (kWh/t) | SDIFF ± RSD | SNDIFF ± RSD (%) | SR50 ± RSD | SR80 ± RSD |

|---|---|---|---|---|---|---|

| 5 | 0.025 | 53 | 6584.10 ± 735.13 | 14.76 ± 1.72 | 1.76 ± 0.26 | 3.62 ± 0.39 |

| 10 | 0.05 | 106 | 8926.39 ± 758.55 | 20.01 ± 1.80 | 3.05 ± 0.46 | 9.08 ± 0.97 |

| 15 | 0.075 | 159 | 9100.61 ± 760.30 | 20.4 ± 1.81 | 3.51 ± 0.53 | 10.10 ± 1.08 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogonowski, S.; Wołosiewicz-Głąb, M.; Ogonowski, Z.; Foszcz, D.; Pawełczyk, M. Comparison of Wet and Dry Grinding in Electromagnetic Mill. Minerals 2018, 8, 138. https://doi.org/10.3390/min8040138

Ogonowski S, Wołosiewicz-Głąb M, Ogonowski Z, Foszcz D, Pawełczyk M. Comparison of Wet and Dry Grinding in Electromagnetic Mill. Minerals. 2018; 8(4):138. https://doi.org/10.3390/min8040138

Chicago/Turabian StyleOgonowski, Szymon, Marta Wołosiewicz-Głąb, Zbigniew Ogonowski, Dariusz Foszcz, and Marek Pawełczyk. 2018. "Comparison of Wet and Dry Grinding in Electromagnetic Mill" Minerals 8, no. 4: 138. https://doi.org/10.3390/min8040138

APA StyleOgonowski, S., Wołosiewicz-Głąb, M., Ogonowski, Z., Foszcz, D., & Pawełczyk, M. (2018). Comparison of Wet and Dry Grinding in Electromagnetic Mill. Minerals, 8(4), 138. https://doi.org/10.3390/min8040138