Mechanical and Microstructural Behavior of Mine Gold Tailings Stabilized with Non-Conventional Binders

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Materials Characterization

2.3. Optimal Composition and Preparation of Alkali-Activated Binder

- SCBA and HEL were weighed, and sodium hydroxide pellets were dissolved in distilled water to prepare alkaline solutions at concentrations of 0.5, 1, 2, and 3 mol·L−1. The required volume of alkaline solution for each mixture was determined based on selected water-to-binder (w/b = 0.7, 0.8, 0.9, 1.0, 1.2) and SCBA-to-HEL (90/10, 80/20, 70/30, 60/40 by mass) ratios. The total binder mass was computed as the sum of SCBA and HEL, subtracting the solution mass.

- The dry components were homogenized, and the alkaline solution was gradually added while mixing until a uniform paste was obtained.

- The mixture was placed into molds and compacted by vibration.

- Specimens were cured for 7 days before demolding to ensure sufficient strength. All samples were stored in sealed plastic bags inside a humid chamber maintained at 23 °C and 95% relative humidity to prevent moisture loss.

2.4. Stabilized GMT Sample Preparation

2.5. Triaxial Tests

2.6. SEM/EDS for Microstructure Characterization

3. Results and Discussion

3.1. Triaxial Test Results

3.2. Microstructural Changes

4. Conclusions

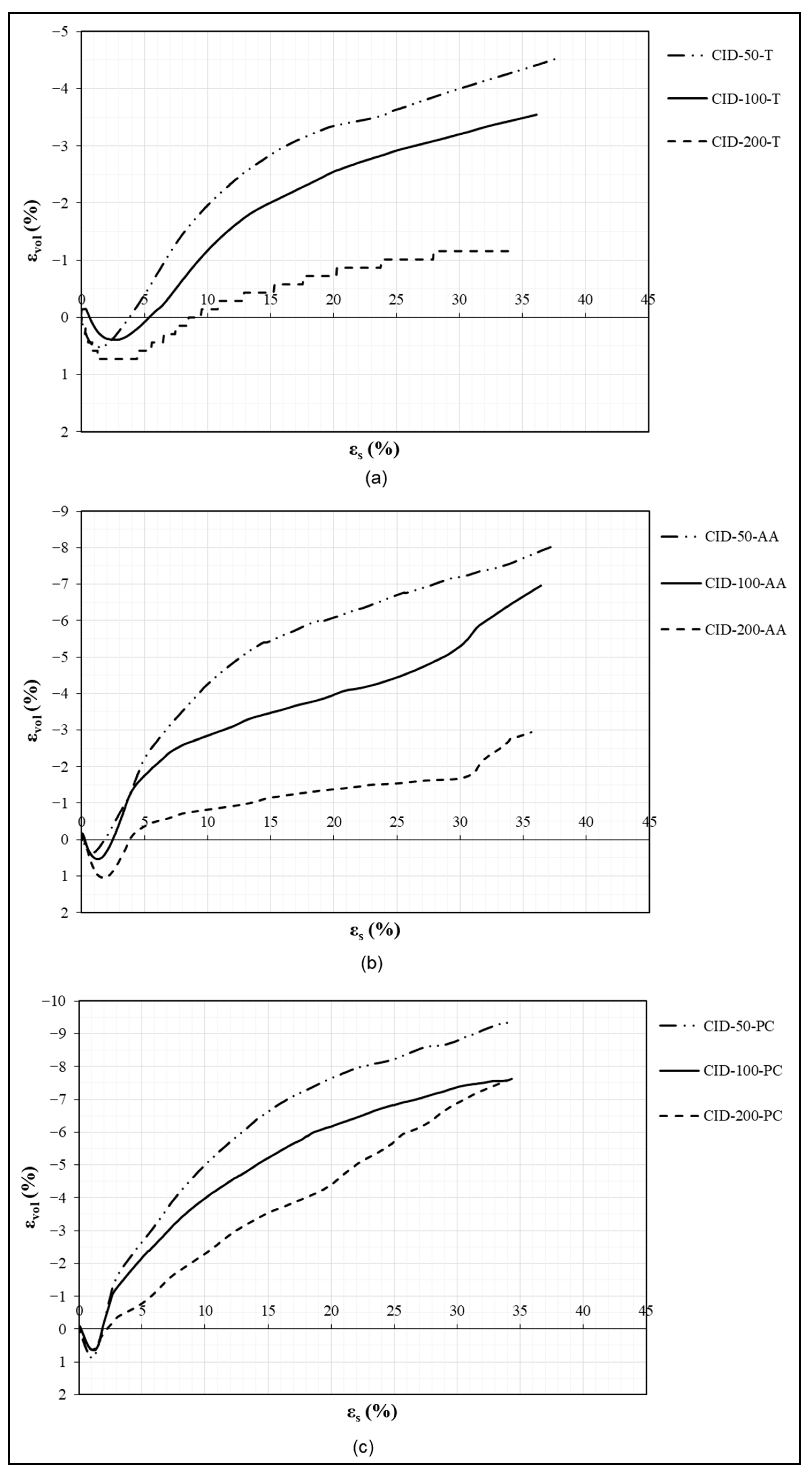

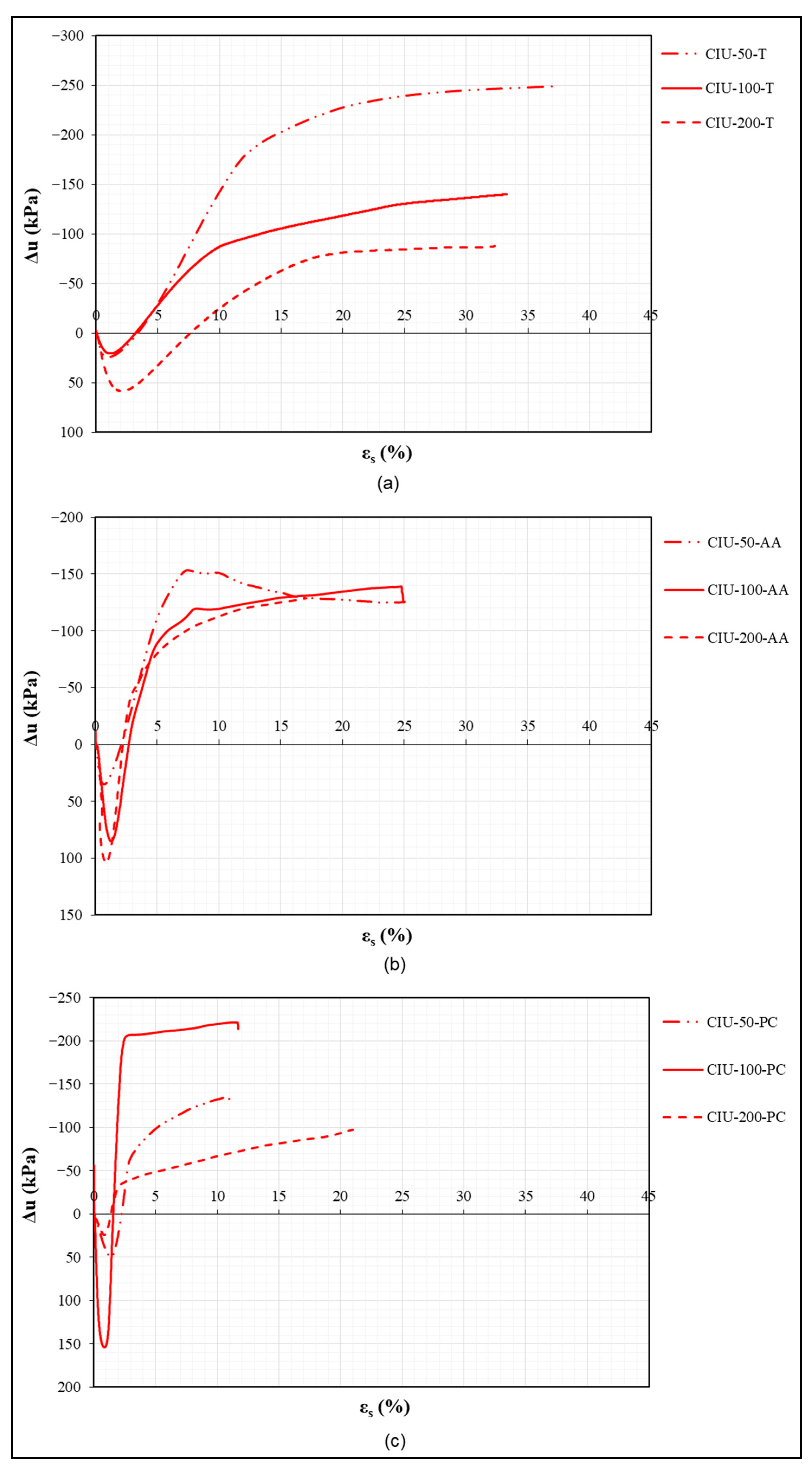

- Initially, all specimens exhibited positive pore pressure and volumetric strain, followed by the development of highly negative pore pressures at larger strains. The addition of binder increased the generation of positive pore pressure and reduced the extent of negative pore pressure development.

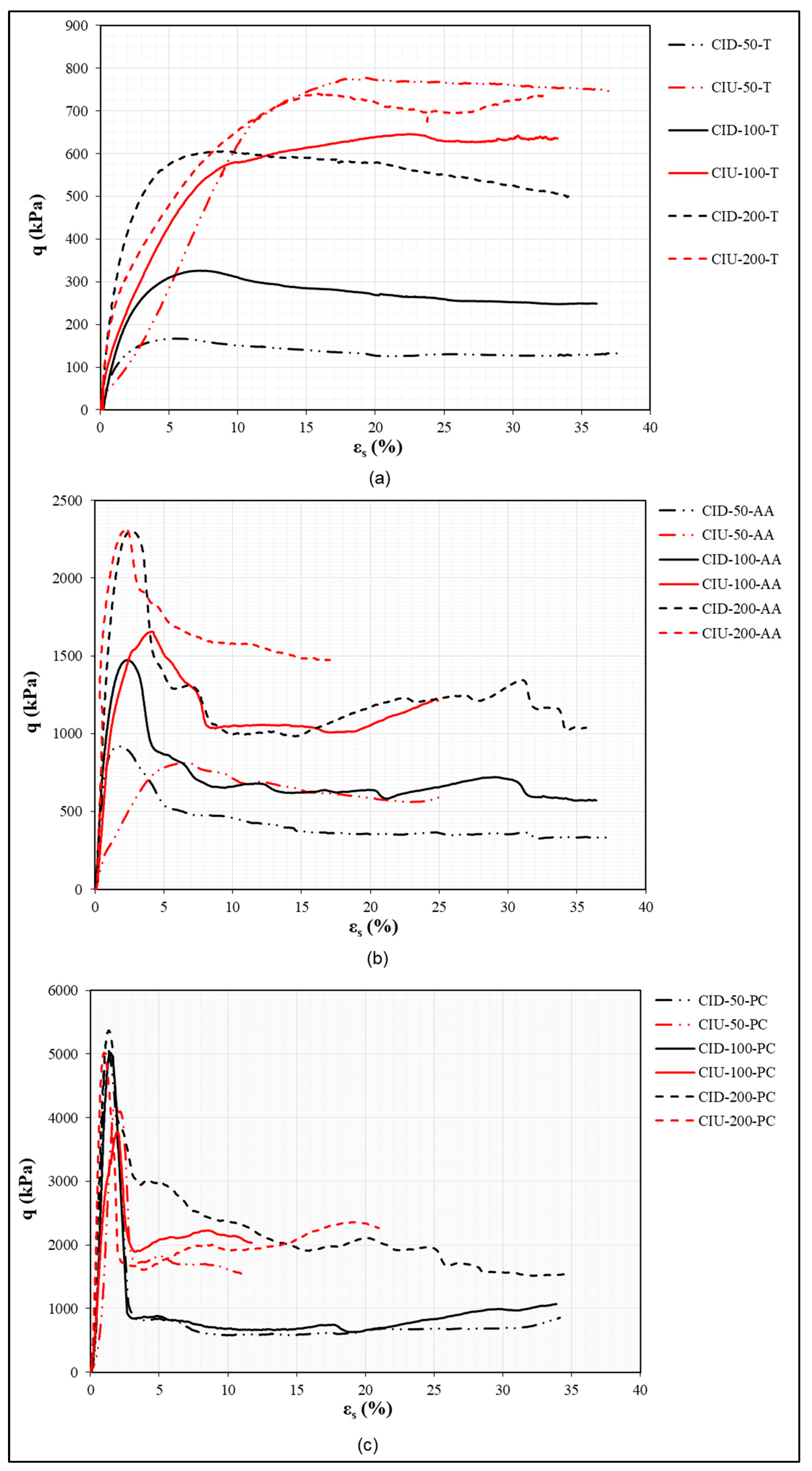

- CIU tests on non-stabilized GMTs exhibited a strain-hardening response, consistent with the generation of negative pore pressures. In contrast, CID tests showed mild strain-softening behavior. Specimens stabilized with the alkali-activated binder and Portland cement demonstrated pronounced strain-softening responses in both CID and CIU tests.

- The GMT–Portland cement specimens exhibited pronounced strain-softening behavior and the highest strength, reaching 5.3 MPa at 200 kPa confining pressure, compared to 2.3 MPa for GMT–alkali-activated specimens and 740 kPa for non-stabilized GMT specimens under the same confining pressure.

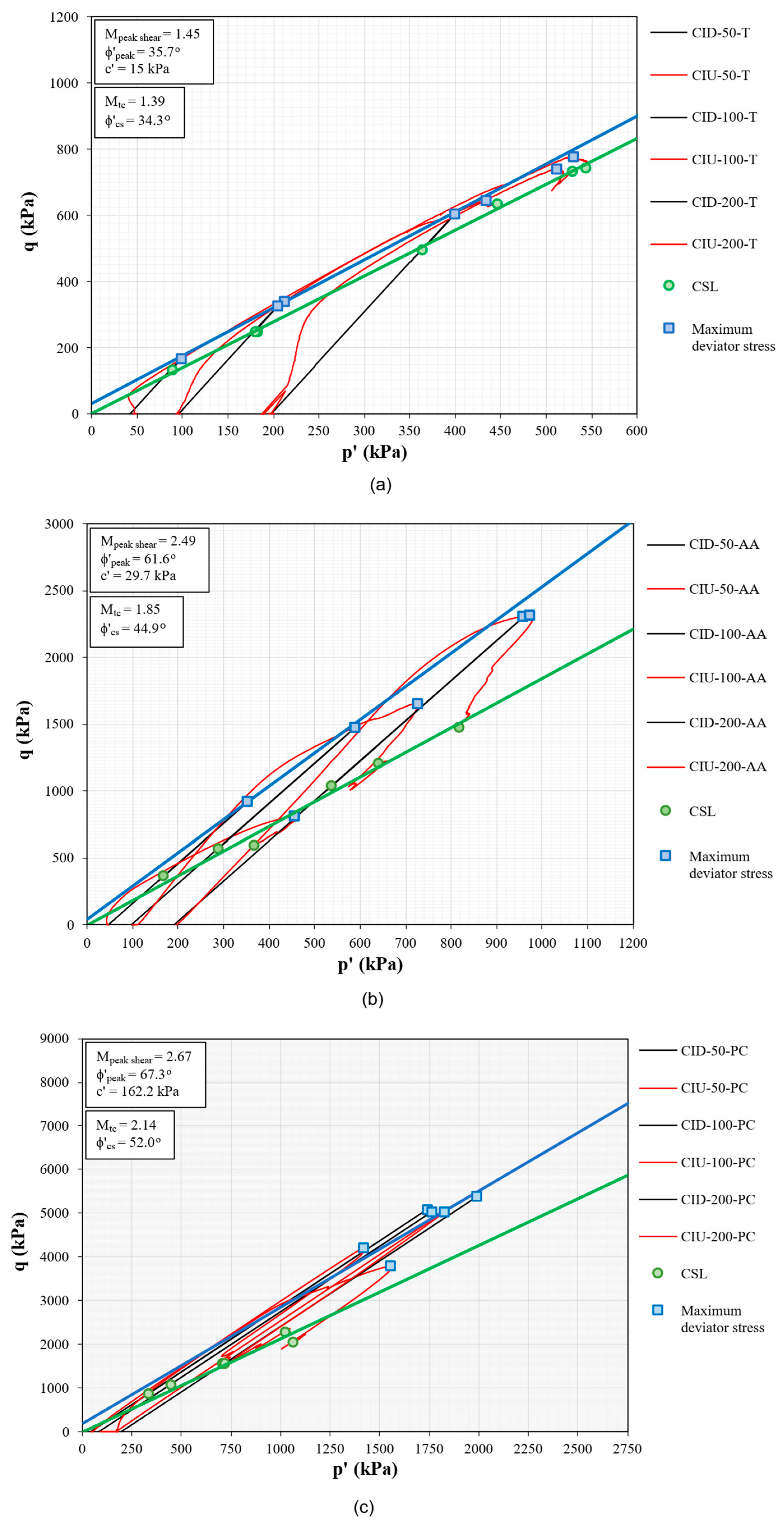

- The peak angle of shearing resistance at effective stresses was higher for the GMT–Portland cement samples (ϕ′peak = 67.3º), followed by GMT–alkali-activated samples (ϕ′peak = 61.6º) and non-stabilized GMT samples (ϕ′peak = 35.7º).

- The critical state line (CSL) stress ratio (Mtc), critical state friction angle (ϕ′cs), and cohesion intercept (c′) all increased with binder addition: for non-stabilized GMT, Mtc = 1.39, ϕ′cs = 34.3°, and c′ = 0 kPa; for GMT–alkali-activated specimens, Mtc = 1.78, ϕ′cs = 43.4°, and c′ = 19.7 kPa; and for GMT–Portland cement specimens, Mtc = 1.80, ϕ′cs = 43.8°, and c′ = 145.1 kPa.

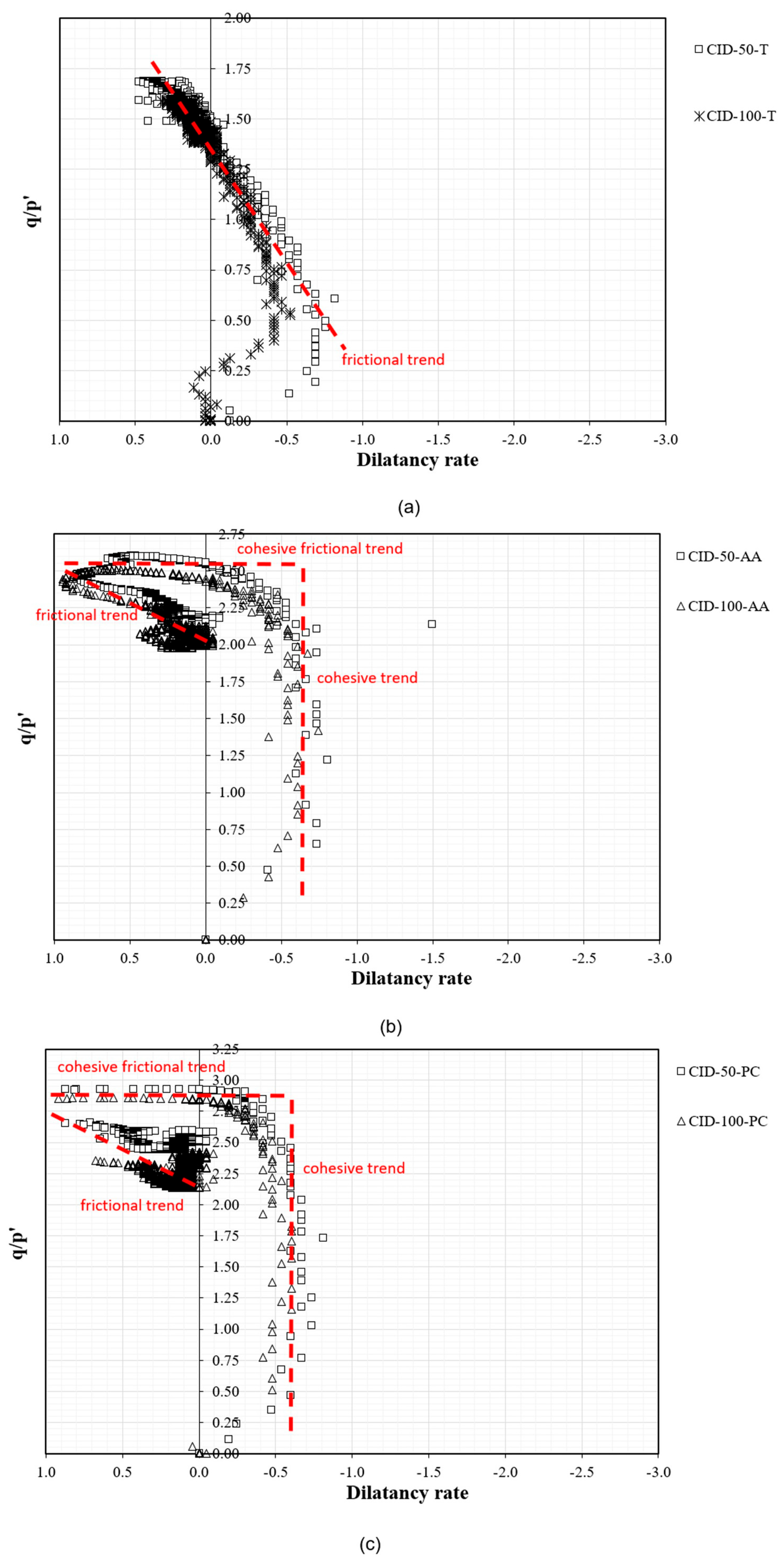

- The GMT–alkali-activated and GMT–Portland cement specimens exhibited higher dilation rates than the non-stabilized tailings, as interparticle bonding in cemented tailings initially suppresses dilatancy. Additionally, the greater shear resistance of the cemented specimens contributes to a more pronounced “cemented trend”.

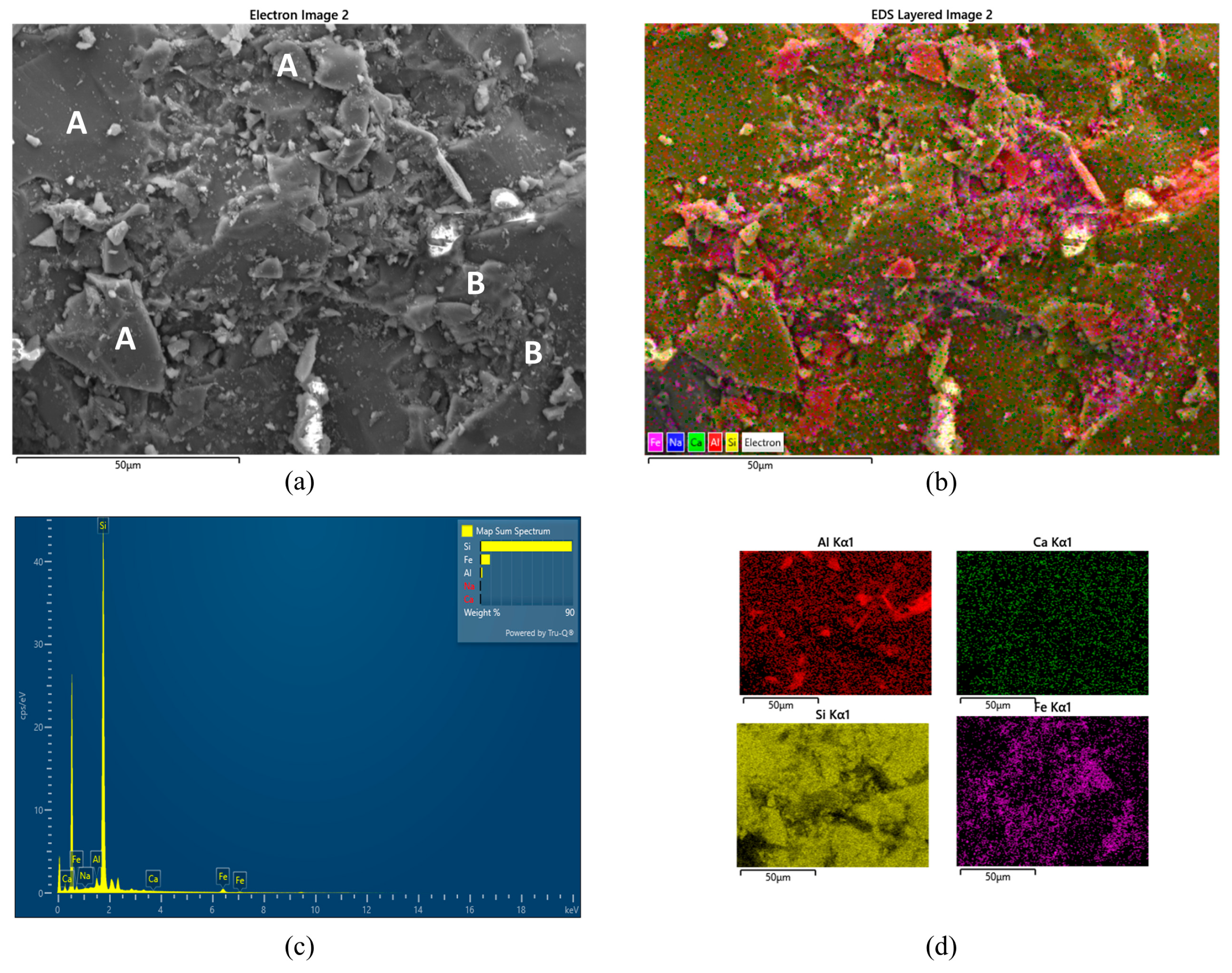

- SEM imaging reveals that the tailings’ morphological structure consists of minerals with irregularly shaped grains, which occur in two typical forms: smooth-surfaced grains primarily composed of SiO2 and Al2O3, and rough-surfaced grains dominated by Fe2O3.

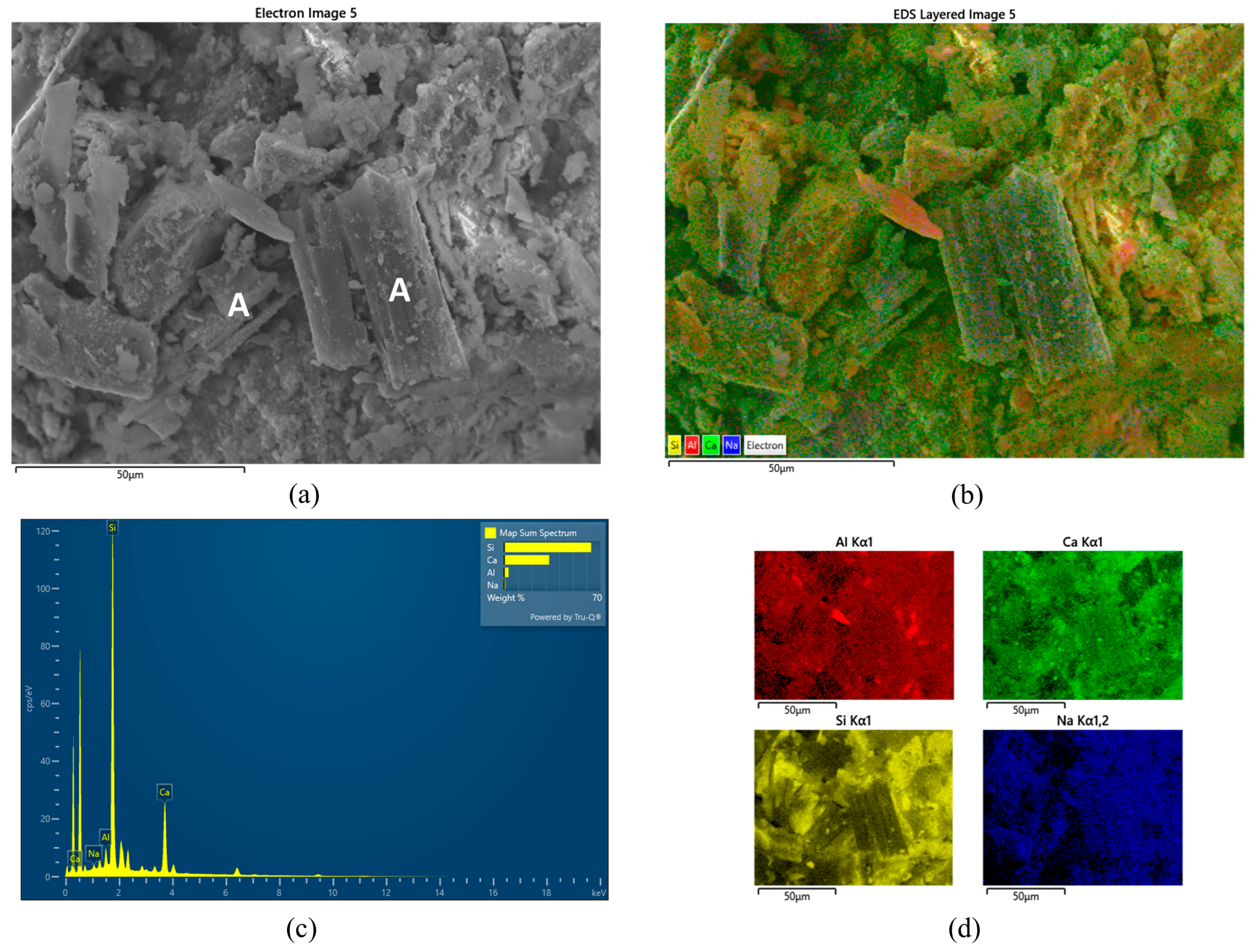

- For the GMT–alkali-activated sample, SEM imaging shows tailings particles embedded within a cementitious matrix formed by reaction products exhibiting significant compositional heterogeneity and an amorphous structure. The chemical map indicates the coexistence of C–S–H and (C,N)–A–S–H gels, with the latter incorporating sodium cations from the alkaline activator.

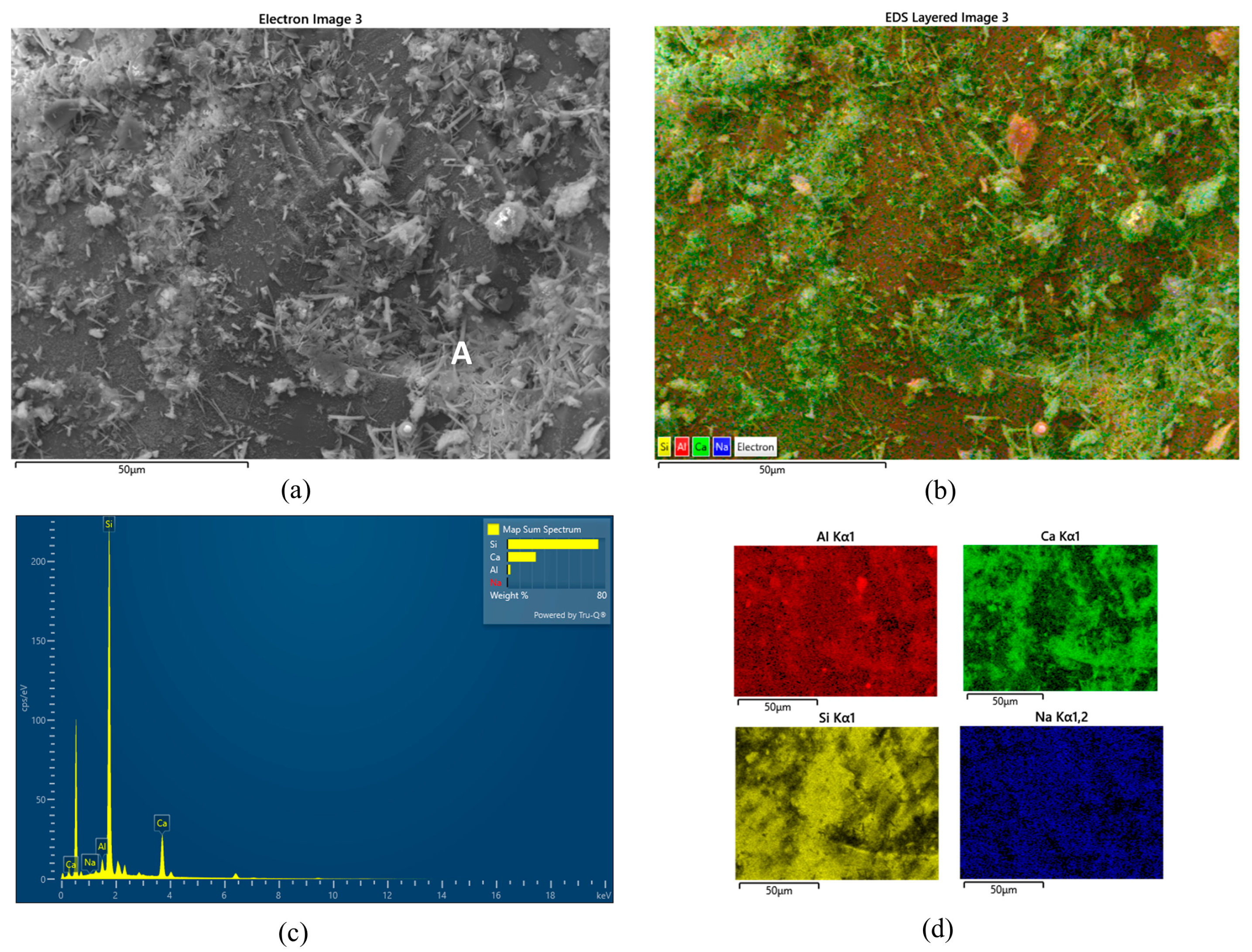

- The SEM image of the GMT–Portland cement sample reveals a smoother and more homogeneous surface compared to the alkali-activated sample. The tailings are embedded within a cementitious matrix composed of needle-like and reticular C–S–H phases, along with calcium hydroxide crystals.

- The higher peak angle of the GMT–alkali-activated and GMT–Portland cement samples compared to non-stabilized samples shows that binder addition increases the safety of stackings. The cementitious reaction products seen in the SEM-EDS analysis explain the higher shear resistance of the stabilized samples.

- The selection of a 7-day curing period was based on the material’s observed rapid strength development, which meets the minimum requirements for practical applications. The results demonstrate that the stabilized tailings achieve a compressive strength of 2.39 MPa within this timeframe, exceeding the 2.1 MPa minimum for soil–cement bases as stipulated by DNIT [28]. This finding validates the material’s viability for field-level applications in a shorter period. However, the study’s limitations, such as the short curing period and the absence of cyclic loading tests, are acknowledged. These factors are critical for evaluating the material’s long-term durability and resistance to liquefaction under dynamic conditions. Therefore, future work should focus on assessing these aspects and conducting field-scale validation to further translate these laboratory findings into practical engineering solutions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Notation

| AAC | alkali-activated cement |

| c′ | effective cohesion intercept |

| EDS | energy-dispersive X-ray spectroscopy |

| e | void ratio |

| emin | minimum void ratio |

| emax | maximum void ratio |

| GMT | gold mine tailing |

| HEL | hydrated eggshell lime |

| IOTs | iron ore tailings |

| Mtc | gradient of CSL at triaxial compression |

| OMC | optimum moisture content |

| SCBA | sugarcane bagasse ash |

| SEM | scanning electron microscopy |

| UCS | unconfined compressive strength |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

| p′ | mean effective stress (Cambridge notation) |

| q | deviatoric stress (Cambridge notation) |

| Δu | excess of pore pressure |

| εvol | volumetric strain |

| εs | rotational strain |

| ϕ′cs | angle of shearing resistance at critical state |

| ϕ′peak | peak angle of shearing resistance at effective stresses |

| δεv/δεs | dilatancy rate |

References

- Wang, L.; Ji, B.; Hu, Y.; Liu, R.; Sun, W. A review on in situ phytoremediation of mine tailings. Chemosphere 2017, 184, 594–600. [Google Scholar] [CrossRef]

- do Carmo, F.F.; Kamino, L.H.Y.; Tobias Junior, R.; de Campos, I.C.; do Carmo, F.F.; Silvino, G.; da Silva Xavier de Castro, K.J.; Mauro, M.L.; Uchoa Alonso Rodrigues, N.U.A.; de Souza Miranda, M.P.; et al. Fundão tailings dam failures: The environment tragedy of the largest technological disaster of Brazilian mining in global context. Perspect. Ecol. Conserv. 2017, 15, 145–151. [Google Scholar] [CrossRef]

- de Almeida, I.M.; Jackson Filho, J.M.; de Vilela, R.A.G. Razões para investigar a dimensão organizacional nas origens da catástrofe industrial da Vale em Brumadinho, Minas Gerais, Brasil. Cad. Saúde Pública 2019, 35, e00027319. [Google Scholar] [CrossRef]

- Robertson, P.K.; de Melo, L.; Williams, D.J.; Wilson, G.W. Report of the Expert Panel on the Technical Causes of the Failure of Feijão Dam I; Expert Panel: Vancouver, BC, Canada, 2019. [Google Scholar]

- Consoli, N.C.; Vogt, J.C.; Silva, J.P.S.; Chaves, H.M.; Filho, H.C.S.; Moreira, E.B.; Lotero, A. Behaviour of compacted filtered iron ore tailings–Portland cement blends: New Brazilian trend for tailings disposal by stacking. Appl. Sci. 2022, 12, 836. [Google Scholar] [CrossRef]

- Consoli, N.C.; Tomasi, L.F.; Veloso Marques, S.F. Cement-enhancing mechanical behavior of tailings behind upstream tailings dam for safe decommissioning. J. Mater. Civ. Eng. 2023, 35, 04023253. [Google Scholar] [CrossRef]

- Festugato, L.; Fourie, A.; Consoli, N.C. Cyclic shear response of fibre-reinforced cemented paste backfill. Géotech. Lett. 2013, 3, 5–12. [Google Scholar] [CrossRef]

- Festugato, L.; Consoli, N.C.; Fourie, A. Cyclic shear behaviour of fibre-reinforced mine tailings. Geosynth. Int. 2015, 22, 196–206. [Google Scholar] [CrossRef]

- da Silva, A.; Miguel, G.D.; Daronco, J.V.L.; dos Passos Coelho, P.O.; Festugato, L. Influence of curing under stress on the geomechanical response of cemented iron ore mining tailings subjected to distinct effective stress paths. Int. J. Geomech. 2024, 24, 04024056. [Google Scholar] [CrossRef]

- Kiventerä, J.; Piekkari, K.; Isteri, V.; Ohenoja, K.; Tanskanen, P.; Illikainen, M. Solidification/stabilization of gold mine tailings using calcium sulfoaluminate-belite cement. J. Clean. Prod. 2019, 239, 118008. [Google Scholar] [CrossRef]

- Servi, S.; Lotero, A.; Silva, J.P.S.; Bastos, C.; Consoli, N.C. Mechanical response of filtered and compacted iron ore tailings with different cementing agents: Focus on tailings-binder mixtures disposal by stacking. Constr. Build. Mater. 2022, 349, 128770. [Google Scholar] [CrossRef]

- Portela Farenzena, H.; Bruschi, G.J.; Schmitt Medina, G.; de Sousa Silva, J.P.; Lotero, A.; Consoli, N.C. Iron ore tailings stabilization with alternative alkali-activated cement for dry stacking: Mechanical and microstructural insights. Can. Geotech. J. 2024; ahead of print. [Google Scholar] [CrossRef]

- da Cunha, J.T.; Ferreira, I.C.; Campos, L.J.F.; Galery, R.; Mazzinghy, D.B. Geopolymer as an alternative stabilizer of waste and tailings from iron mining. Tecnol. Metal. Mater. Min. 2025, 22, e3201. [Google Scholar] [CrossRef]

- Diosdado-Aragón, A.J.; Dávila, J.M.; Caraballo, M.A. Chemical stability and environmental characterization of alkali-activated mine tailings generated using a MgCO3/MgO industrial residue. J. Geochem. Explor. 2026, 280, 107886. [Google Scholar] [CrossRef]

- Carneiro, A.A.; Alelvan, G.M.; Pierozan, R.C.; Casagrande, M.D.T. Improvement of iron ore tailings through polymeric solution stabilization and polypropylene fiber reinforcement. J. Mater. Civ. Eng. 2025, 37, 04025392. [Google Scholar] [CrossRef]

- Tonini de Araújo, M.; Tonatto Ferrazzo, S.; Mansur Chaves, H.; Gravina da Rocha, C.; Consoli, N.C. Mechanical behavior, mineralogy, and microstructure of alkali-activated wastes-based binder for a clayey soil stabilization. Constr. Build. Mater. 2023, 362, 129757. [Google Scholar] [CrossRef]

- C150/C150M; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Consoli, N.C.; Caicedo, A.M.L.; Beck Saldanha, R.; Scheuermann Filho, H.C.; Acosta, C.J.M. Eggshell produced limes: Innovative materials for soil stabilization. J. Mater. Civ. Eng. 2020, 32, 06020018. [Google Scholar] [CrossRef]

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014; ISBN 978-0-8031-8794-7. [CrossRef]

- NBR 16605; Cimento Portland e Outros Materiais em Pó–Determinação da Massa Específica. ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- ASTM D4318-17; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- ASTM D4254-16; Standard Test Methods for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- NBR 7181; Solo–Análise Granulométrica. ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018.

- NBR 6502; Solos e Rochas–Terminologia. ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2022.

- NBR 15895; Materiais Pozolânicos–Determinação do Teor de Hidróxido de Cálcio Fixado–Método Chapelle Modificado. ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2010.

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- DNIT–Departamento Nacional de Infraestrutura de Transportes. Manual de Pavimentação, 3rd ed.; Instituto de Pesquisas Rodoviárias: Rio de Janeiro, Brazil, 2006; 274p.

- NBR 6457; Amostras de Solo–Preparação Para Ensaios de Compactação e Ensaios de Caracterização. ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2016.

- Bedin, J.; Schnaid, F.; da Fonseca, A.V.; Costa Filho, L.D.M. Gold tailings liquefaction under critical state soil mechanics. Géotechnique 2012, 62, 263–267. [Google Scholar] [CrossRef]

- Adajar, M.A.Q.; Zarco, M.A.H. Predicting the stress–strain behavior of mine tailing using modified hyperbolic model. Int. J. GEOMATE 2016, 10, 1834–1841. [Google Scholar] [CrossRef]

- Ferrazzo, S.T.; de Araújo, M.T.; Bruschi, G.J.; Chaves, H.M.; Korf, E.P.; Consoli, N.C. Mechanical and environmental behavior of waste foundry sand stabilized with alkali-activated sugar cane bagasse ash-eggshell lime binder. Constr. Build. Mater. 2023, 383, 131313. [Google Scholar] [CrossRef]

- Ferrazzo, S.T.; de Araújo, M.T.; Bruschi, G.J.; Korf, E.P.; Levandoski, W.M.K.; dos Santos, C.P.; Consoli, N.C. Metal encapsulation of waste foundry sand stabilized with alkali-activated binder: Batch and column leaching tests. J. Environ. Manag. 2023, 348, 119287. [Google Scholar] [CrossRef]

- Ladd, R. Preparing test specimens using undercompaction. Geotech. Test. J. 1978, 1, 16–23. [Google Scholar] [CrossRef]

- ASTM D4767-20; Standard Test Method for Consolidated Undrained Triaxial Compression Test for Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D7181-20; Standard Test Method for Consolidated Drained Triaxial Compression Test for Soils. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- da Fonseca, A.V.; Cordeiro, D.; Molina-Gómez, F. Recommended procedures to assess critical state locus from triaxial tests in cohesionless remoulded samples. Geotechnics 2021, 1, 95–127. [Google Scholar] [CrossRef]

- Skempton, A.W. The pore-pressure coefficients A and B. Géotechnique 1954, 4, 143–147. [Google Scholar] [CrossRef]

- Wissa, A.E.Z.; Ladd, C.C.; Lambe, T.W. Effective stress strength parameters of stabilized soils. In Proceedings of the 6th International Conference on Soil Mechanics and Foundation Engineering, Montréal, QC, Canada, 8–15 September 1965. Soil Properties—Shear Strength and Consolidation. [Google Scholar]

- Lee, K.L.; Morrison, R.A.; Haley, S.C. A note on the pore pressure parameter B. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 29 August–4 September 1969. Stress–Deformation and Strength Characteristics, Including Time Effects.. [Google Scholar]

- La Rochelle, P.; Leroueil, S.; Trak, B.; Blais-Leroux, L.; Tavenas, F. Observational approach to membrane and area corrections in triaxial tests. In Advanced Triaxial Testing of Soil and Rock; ASTM International: West Conshohocken, PA, USA, 1988; pp. 715–717. [Google Scholar] [CrossRef]

- Fourie, A.; Verdugo, R.; Bjelkevik, A.; Torrez-Cruz, L.A.; Znidarcic, D. Geotechnics of mine tailings: A 2022 state of the art. In Proceedings of the 20th International Conference on Soil Mechanics and Geotechnical Engineering, Sydney, Australia, 1–5 May 2022; pp. 121–183. [Google Scholar]

- de A. Carvalho, J.V.; Wagner, A.C.; Scheuermann Filho, H.C.; Chaves, H.M.; Silva, J.P.S.; Delgado, B.G.; Consoli, N.C. Evaluation of strength parameters for application in cemented iron ore tailings stacks. Indian Geotech. J. 2023, 53, 775–788. [Google Scholar] [CrossRef]

- Coop, M.R.; Willson, S.M. Behavior of hydrocarbon reservoir sands and sandstones. J. Geotech. Geoenviron. Eng. 2003, 129, 1010–1019. [Google Scholar] [CrossRef]

- Scheuermann Filho, H.C. Adjusted Porosity/Cement Index: Mechanical Behavior and Microstructure over a Wide Range of Dosages; Universidade Federal do Rio Grande do Sul: Porto Alegre, Brazil, 2022. [Google Scholar]

- Robertson, P.K. Evaluation of flow liquefaction: Influence of high stresses. In Proceedings of the 3rd International Conference on Performance-Based Design in Earthquake Geotechnical Engineering, Vancouver, BC, Canada, 16–18 July 2017. [Google Scholar]

- de Araújo, M.T.; Ferrazzo, S.T.; Consoli, N.C.; da Rocha, C.G. Environmental, economic, and social impacts of sugar cane bagasse and eggshell wastes for soil stabilization. Environ. Sci. Pollut. Res. 2024, 31, 15973–15985. [Google Scholar] [CrossRef] [PubMed]

- NBR 10005; Procedimento para Obtenção de Extrato Lixiviado de Resíduis Sólidos. ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2004.

- ASTM D4874-95; Standard Test Method for Leaching Solid Material in a Column Apparatus. ASTM International: West Conshohocken, PA, USA, 2014.

- Qin, H.; Guo, X.; Tian, Q.; Zhang, L. Pyrite enhanced chlorination roasting and its efficacy in gold and silver recovery from gold tailing. Sep. Purif. Technol. 2020, 250, 117168. [Google Scholar] [CrossRef]

- Cizer, Ö.; Van Balen, K.; Van Gemert, D.; Elsen, J. Carbonation and hydration of mortars with calcium hydroxide and calcium silicate binders. In Proceedings of the International Conference on Sustainable Construction Materials and Technologies, Coventry, UK, 11–13 June 2007; pp. 611–621. [Google Scholar]

| Physical Properties | Materials | Standards | ||

|---|---|---|---|---|

| GMT | SCBA | HEL | ||

| Unit weight of solids (g.cm−3) | 2.71 | 2.08 | 2.24 | ASTM D854 [19] NBR 16605 [20] |

| Liquid limit, LL (%) | - | - | - | ASTM D4318 [21] |

| Plastic limit, PL (%) | - | - | - | |

| Plasticity index, PI (%) | non-plastic | non-plastic | non-plastic | |

| Minimum void ratio | 0.69 | - | - | ASTM D698 [22] |

| Maximum void ratio | 1.17 | - | - | ASTM D4254 [23] |

| Uniformity coefficient | 6.47 | - | - | NBR 7181 [24], NBR 6502 [25] |

| Coefficient of curvature | 1.39 | - | - | |

| % of coarse sand (0.6 < diameter < 2.0 mm) | 64 | - | - | |

| % of medium sand (0.2 < diameter < 0.6 mm) | 0 | - | - | |

| % of fine sand (0.06 < diameter < 0.2 mm) | 0 | - | - | |

| % of silt (0.002 < diameter < 0.06 mm) | 35 | - | - | |

| % of clay (diameter < 0.002 mm) | 1 | - | - | |

| Mean particle diameter, D50 (µm) | 91 | 31.01 | 7.43 | - |

| 90% finer particle diameter, D90 (µm) | - | 55.85 | 23.37 | - |

| 10% finer particle diameter, D10 (µm) | 15 | 9.18 | 2.53 | - |

| Specific surface area (m2·g−1) | - | 125.15 | 4.18 | - |

| Pozzolanic activity index (mg Ca(OH)2/g of pozzolan) | - | 817.6 | - | NBR 15895 [26] |

| USCS classification | SM | - | - | NBR D2487 [27] |

| Material | Sample | P0′ (kPa) |

|---|---|---|

| Non-stabilized gold mine tailings | CIU-50-T | 50 |

| CID-50-T | ||

| CIU-100-T | 100 | |

| CID-100-T | ||

| CIU-200-T | 200 | |

| CID-200-T | ||

| Gold mine tailings + alkali-activated binder | CIU-50-AA | 50 |

| CID-50-AA | ||

| CIU-100-AA | 100 | |

| CID-100-AA | ||

| CIU-200-AA | 200 | |

| CID-200-AA | ||

| Gold mine tailings + Portland cement | CIU-50-PC | 50 |

| CID-50-PC | ||

| CIU-100-PC | 100 | |

| CID-100-PC | ||

| CIU-200-PC | 200 | |

| CID-200-PC |

| Type of Binder | Name | qpeak (kPa) | qcs (kPa) | Difference Between Peak and Critical State (qpeak − qcs)/qpeak | Average (qpeak − qcs)/qpeak |

|---|---|---|---|---|---|

| GMT | CID-50-T | 167.03 | 133.36 | 20% | 21% |

| CID-100-T | 326.13 | 248.82 | 24% | ||

| CID-200-T | 606.11 | 497.66 | 18% | ||

| CIU-50-T | 777.70 | 744.73 | 4% | 2% | |

| CIU-100-T | 646.05 | 635.15 | 2% | ||

| CIU-200-T | 739.88 | 733.28 | 1% | ||

| GMT stabilized with the alkali-activated binder | CID-50-AA | 919.12 | 364.45 | 60% | 59% |

| CID-100-AA | 1473.68 | 572.10 | 61% | ||

| CID-200-AA | 2304.95 | 1037.80 | 55% | ||

| CIU-50-AA | 813.58 | 594.19 | 27% | 30% | |

| CIU-100-AA | 1656.04 | 1211.24 | 27% | ||

| CIU-200-AA | 2319.33 | 1472.86 | 36% | ||

| GMT stabilized with Portland cement | CID-50-PC | 5084.54 | 859.41 | 83% | 78% |

| CID-100-PC | 5022.77 | 1072.13 | 79% | ||

| CID-200-PC | 5372.07 | 1542.08 | 71% | ||

| CIU-50-PC | 4186.61 | 1549.67 | 63% | 55% | |

| CIU-100-PC | 3782.79 | 2031.38 | 46% | ||

| CIU-200-PC | 5022.44 | 2266.80 | 55% |

| Dosage | Abiotic Depletion | Global Warming | Ozone Layer | Human Toxicity | Fresh Water | Marine Aquatic | Terrestrial Ecotoxicity | Photochemical Oxidation | Acidification | Eutrophication |

|---|---|---|---|---|---|---|---|---|---|---|

| AA-LDHB | 0.951 | 0.625 | 1 | 0.937 | 0.704 | 0.673 | 0.293 | 1 | 1 | 1 |

| AA-HDLB | 0.745 | 0.478 | 0.762 | 0.716 | 0.546 | 0.527 | 0.224 | 0.761 | 0.746 | 0.748 |

| PC-LDHB | 1 | 1 | 0.25 | 1 | 1 | 1 | 1 | 0.627 | 0.556 | 0.587 |

| PC-HDLB | 0.737 | 0.737 | 0.186 | 0.738 | 0.737 | 0.737 | 0.736 | 0.463 | 0.411 | 0.434 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zakharia Hoch, B.; Tonini de Araújo, M.; Festugato, L.; Consoli, N.C.; Reddy, K.R. Mechanical and Microstructural Behavior of Mine Gold Tailings Stabilized with Non-Conventional Binders. Minerals 2025, 15, 995. https://doi.org/10.3390/min15090995

Zakharia Hoch B, Tonini de Araújo M, Festugato L, Consoli NC, Reddy KR. Mechanical and Microstructural Behavior of Mine Gold Tailings Stabilized with Non-Conventional Binders. Minerals. 2025; 15(9):995. https://doi.org/10.3390/min15090995

Chicago/Turabian StyleZakharia Hoch, Bruna, Mariana Tonini de Araújo, Lucas Festugato, Nilo Cesar Consoli, and Krishna R. Reddy. 2025. "Mechanical and Microstructural Behavior of Mine Gold Tailings Stabilized with Non-Conventional Binders" Minerals 15, no. 9: 995. https://doi.org/10.3390/min15090995

APA StyleZakharia Hoch, B., Tonini de Araújo, M., Festugato, L., Consoli, N. C., & Reddy, K. R. (2025). Mechanical and Microstructural Behavior of Mine Gold Tailings Stabilized with Non-Conventional Binders. Minerals, 15(9), 995. https://doi.org/10.3390/min15090995