Subresolution Porosity Estimation of Porous Rocks from CT Images: Incorporating X-Ray Mass Attenuation Coefficients

Abstract

1. Introduction

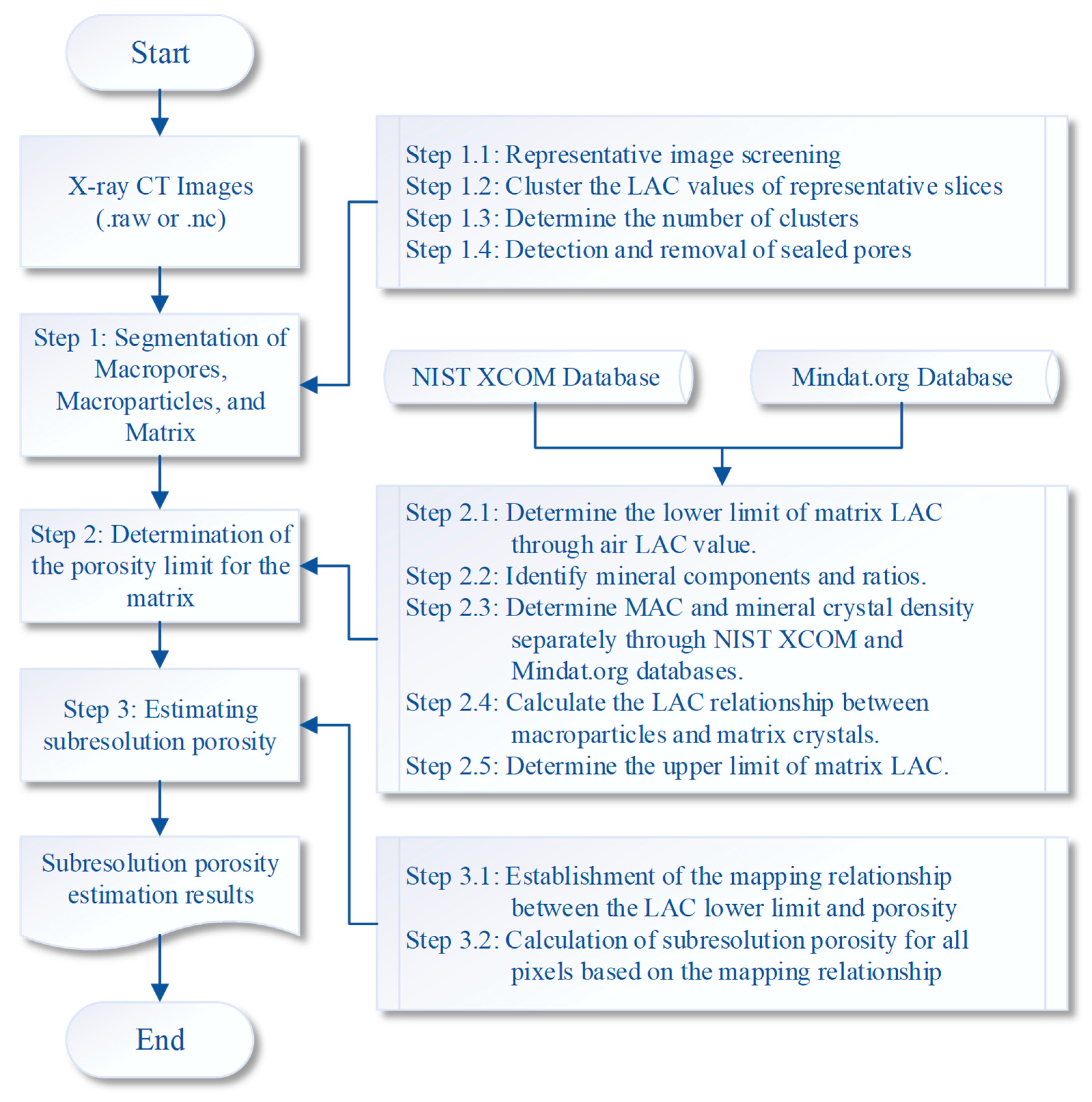

2. Methods

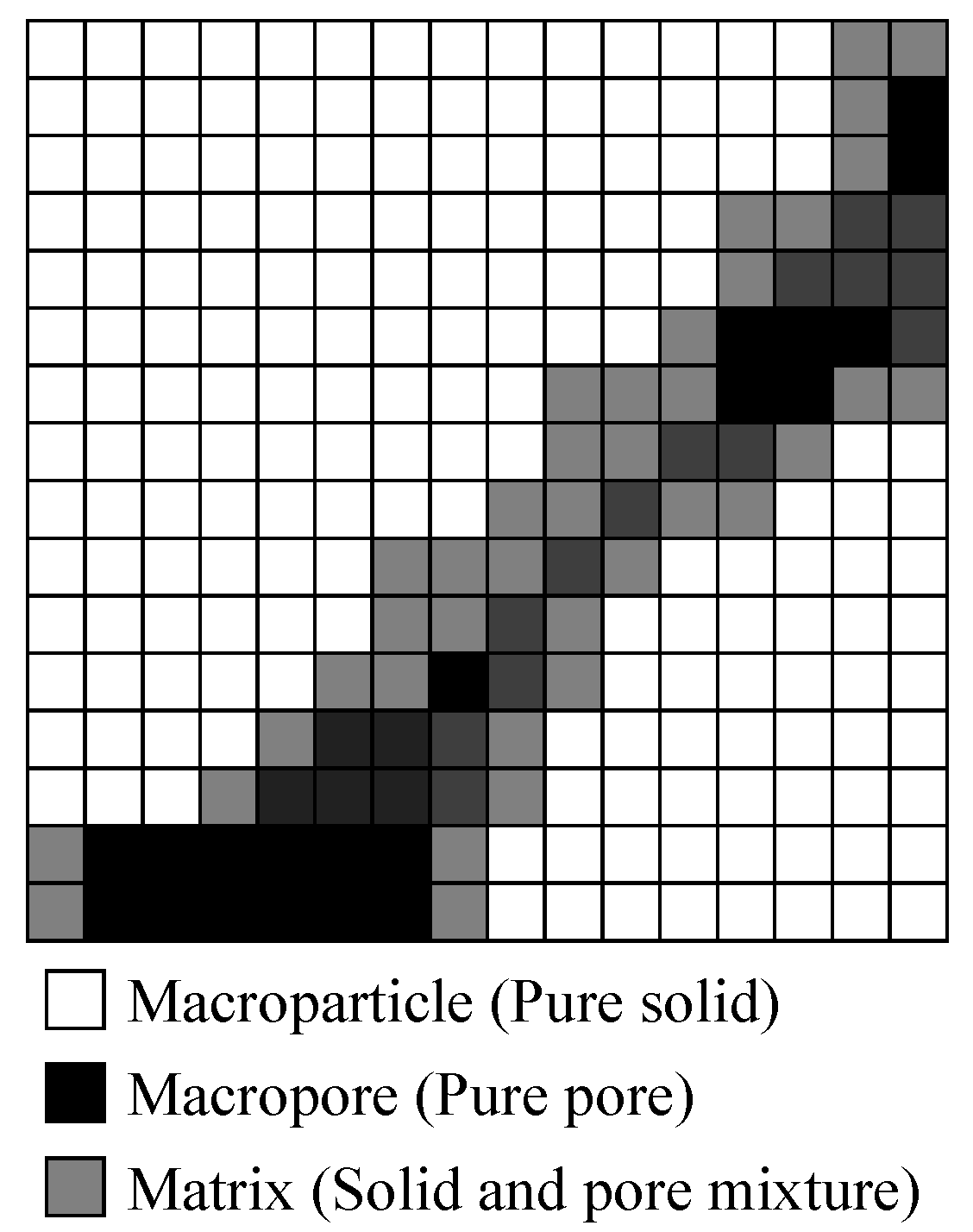

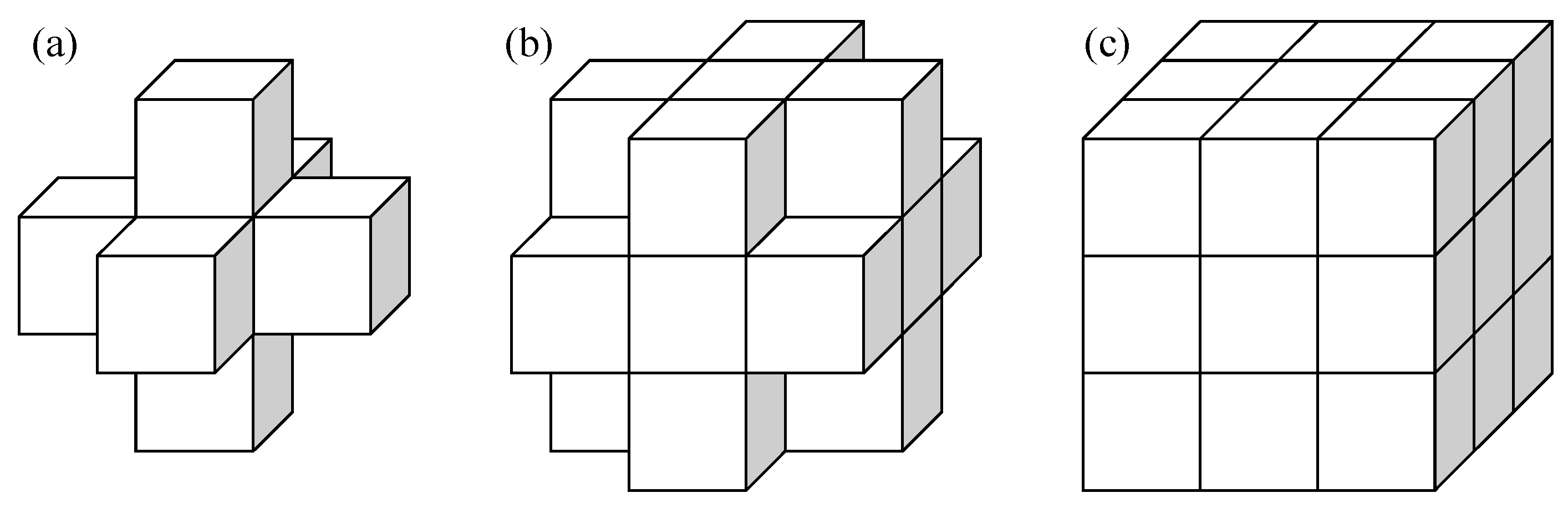

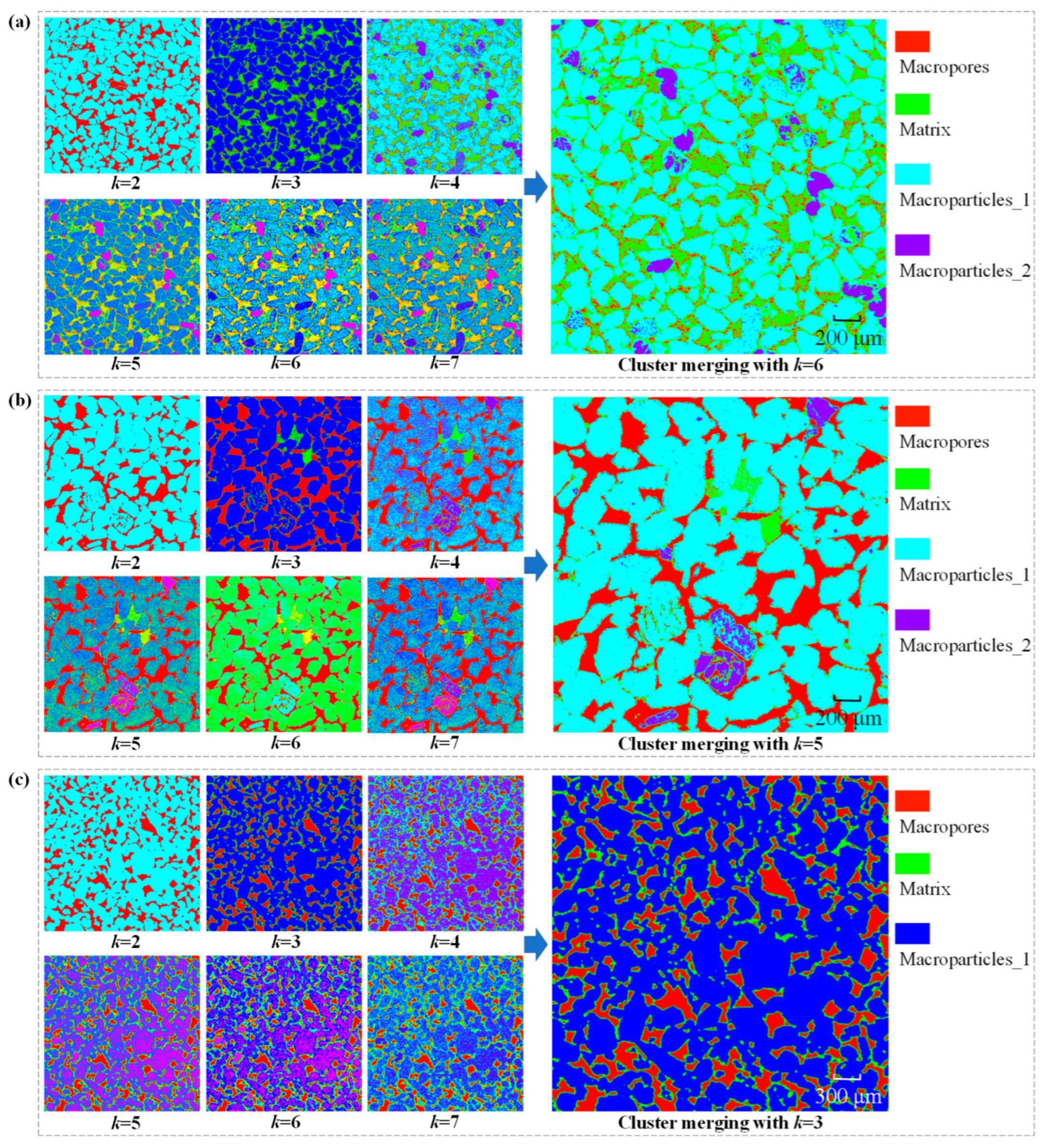

2.1. Component Segmentation

2.1.1. Linear Attenuation Coefficient (LAC) Clustering

| Algorithm 1. LAC-based clustering procedure for component segmentation |

| Input: 3D CT dataset V; candidate slices S; maximum number of clusters Kmax Output: Labels for macroparticles and matrix across V

|

2.1.2. Detection and Removal of Closed Pores

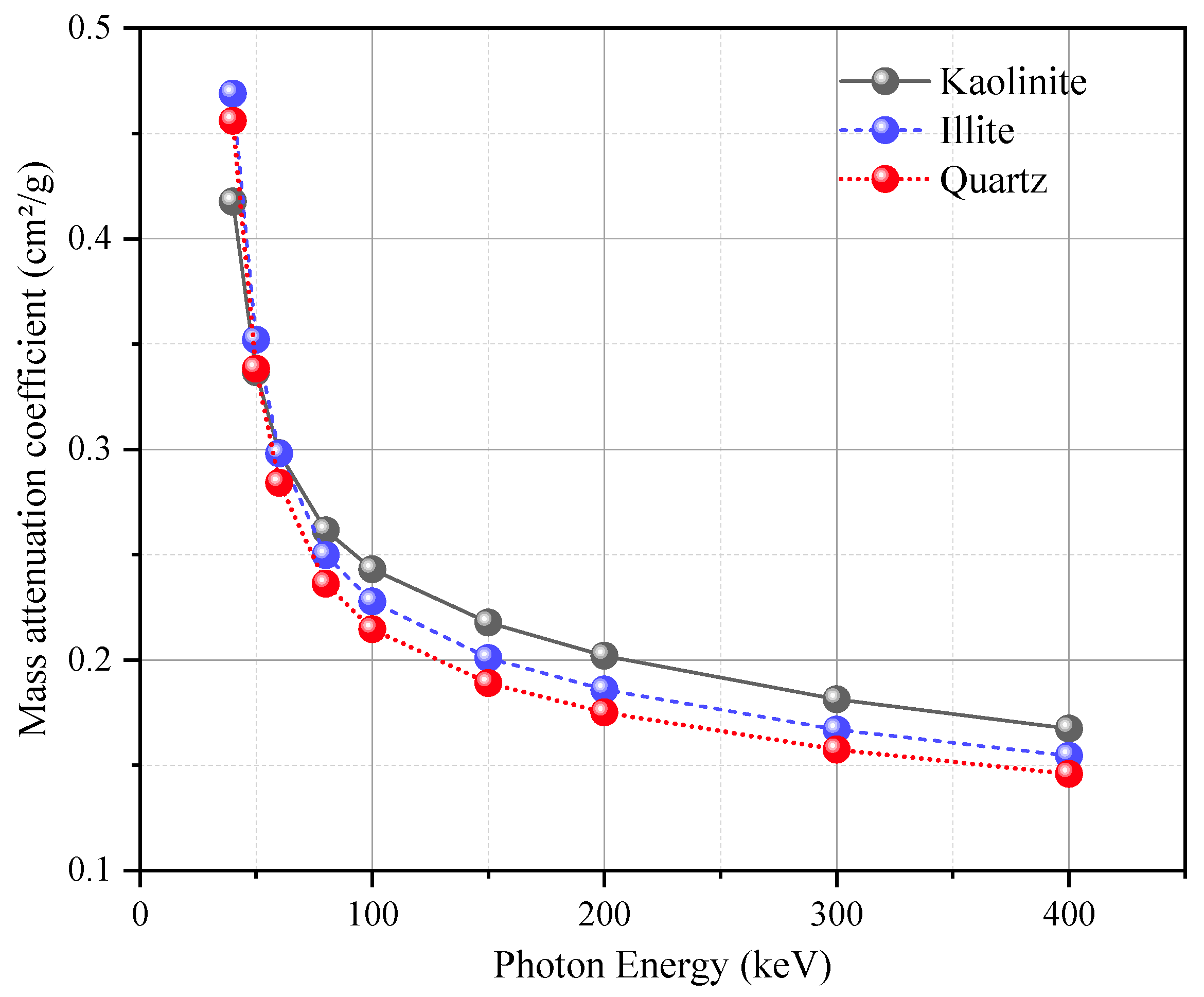

2.2. Determination of the LAC Limit for Matrix

2.3. Estimating Subresolution Porosity

3. Results

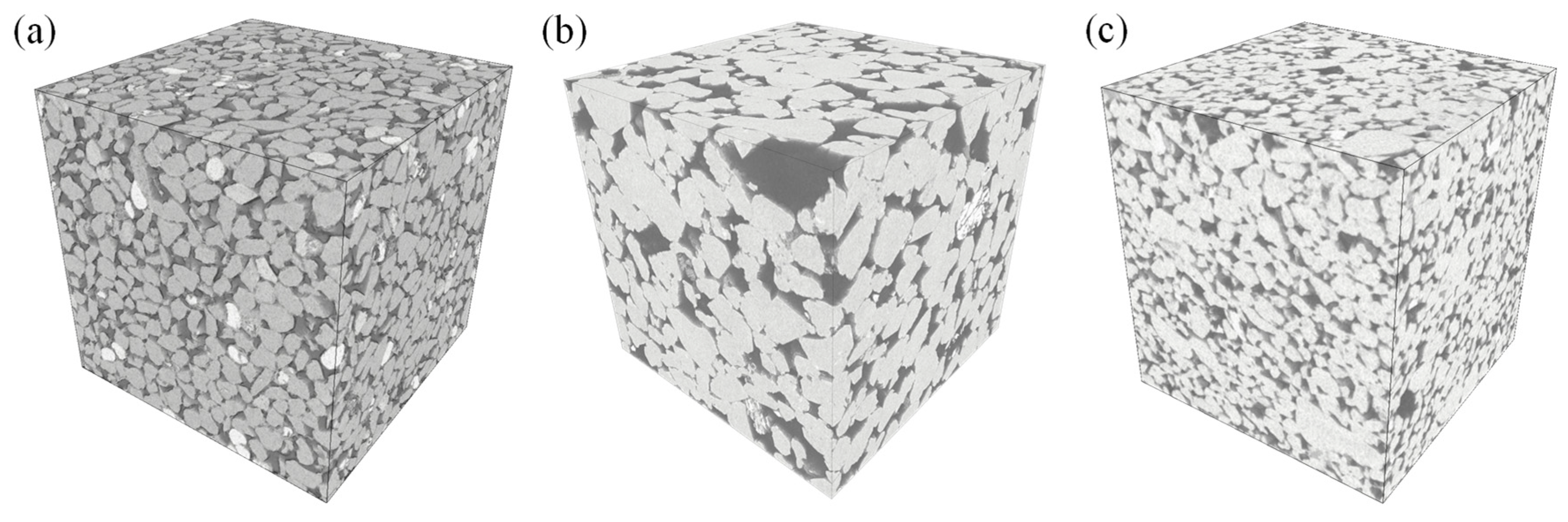

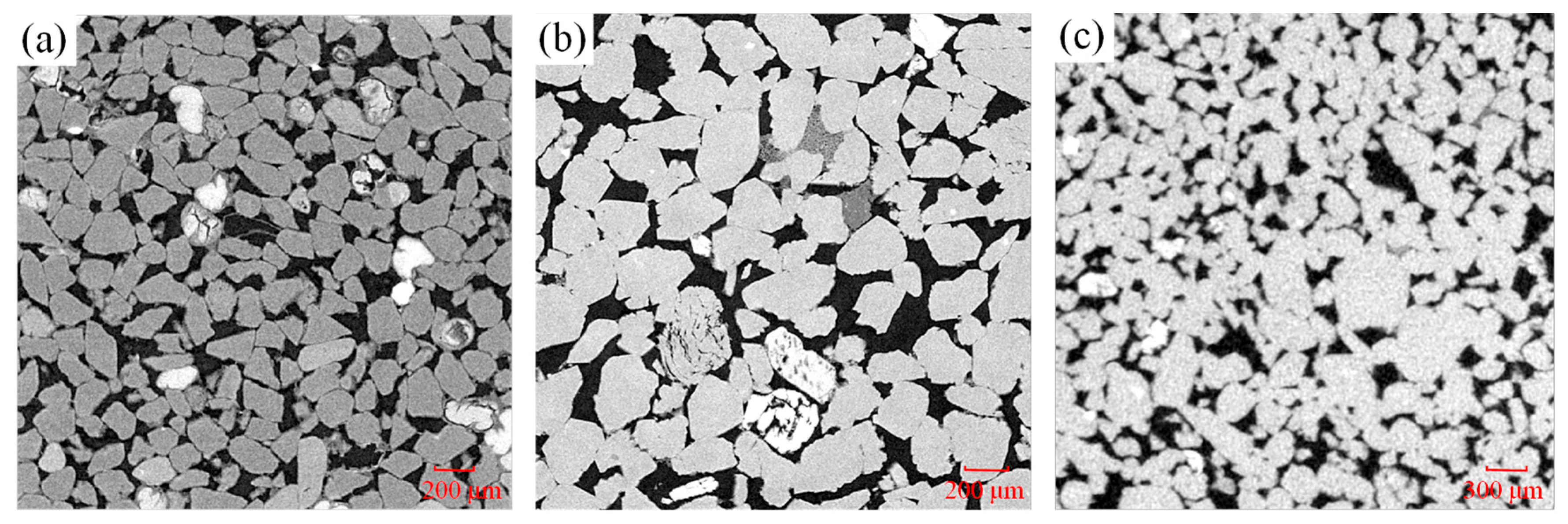

3.1. Data Sources

3.2. Component Segmentation Results

3.3. Determination of the Matrix LAC and Porosity Limits

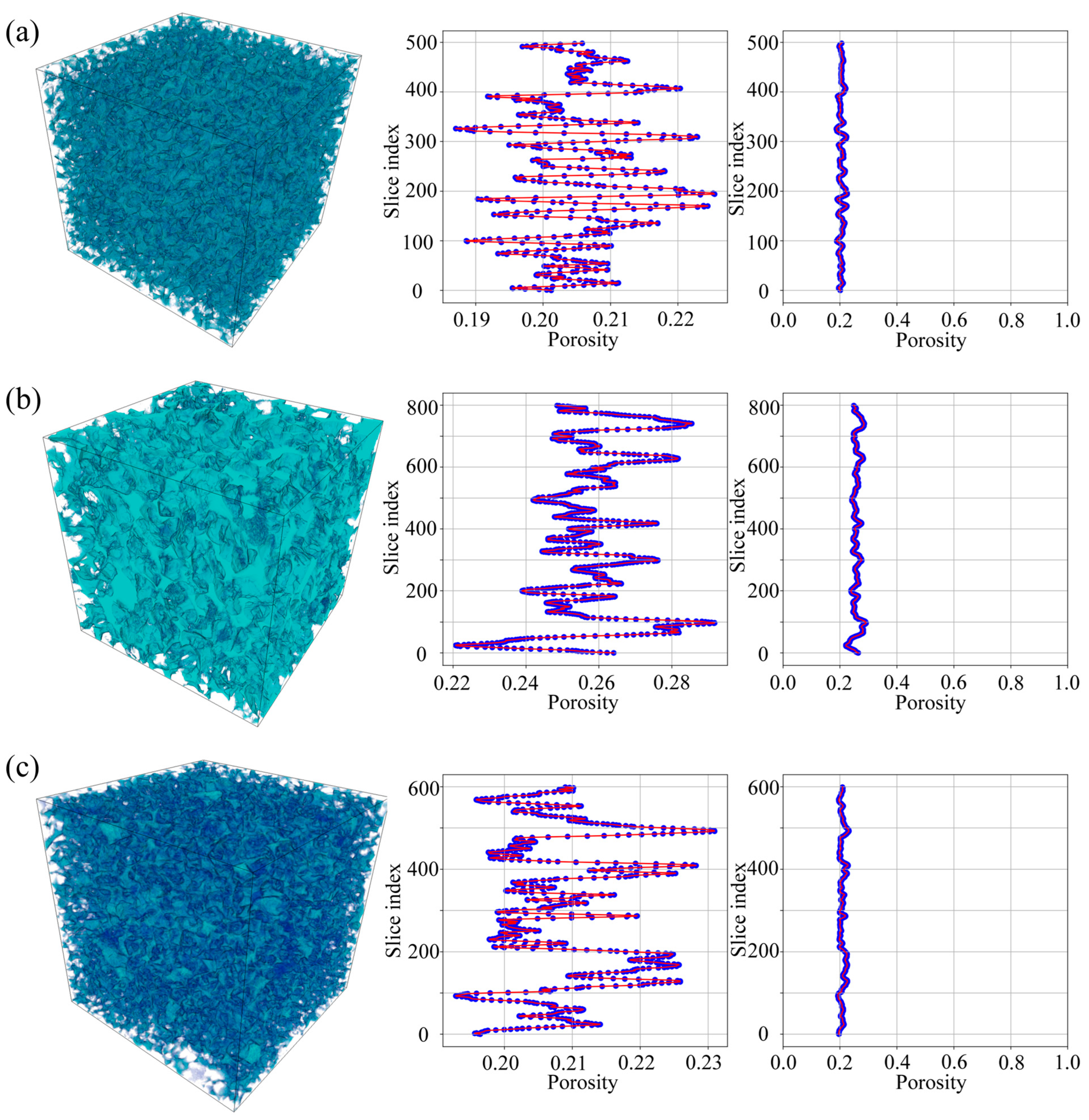

3.4. Subresolution Porosity Calculation Results

4. Discussion

4.1. Validation of Results

4.2. Limitations and Multisource Data Calibration

4.2.1. Correction of the Ratio of Macropores to the Matrix

4.2.2. Calibration of Total Porosity

4.3. Outlook

5. Conclusions

- (1)

- Compared with conventional binarised porosity estimation methods, the proposed approach enables the estimation of porosity values ranging between 0 and 1 for each voxel. Under the same conditions, the subresolution porosity estimation results exhibit greater connectivity.

- (2)

- Compared to the subresolution porosity estimation method, which does not take into account MAC and density, this method more accurately estimates the upper LAC limit of the matrix, bringing the porosity of the matrix closer to reality.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iraji, S.; Soltanmohammadi, R.; Munoz, E.R.; Basso, M.; Vidal, A.C. Core scale investigation of fluid flow in the heterogeneous porous media based on X-ray computed tomography images: Upscaling and history matching approaches. Geoenergy Sci. Eng. 2023, 225, 211716. [Google Scholar] [CrossRef]

- Frouté, L.; Guan, K.M.; Yun, W.; Lewis, S.J.Y.; Stripe, B.D.; Yang, X.; Lapene, A.; Kovscek, A.R.; Creux, P. Micro X-ray fluorescence reveals pore space details and spatially-resolved porosity of rock-based microfluidic devices. Lab Chip 2023, 23, 3978–3988. [Google Scholar] [CrossRef]

- Deng, W.; Fu, L.; Morozov, I.B.; Wang, Z. Macroscopic mechanical properties of fluid-saturated sandstone at variable temperatures. Geophysics 2023, 88, MR127–MR139. [Google Scholar] [CrossRef]

- Das, V.; Saxena, N.; Hofmann, R. Compressibility predictions using digital thin-section images of rocks. Comput. Geosci. 2020, 139, 104482. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Wang, L.; Qu, D.; Luo, Y.; Meng, F.; Pei, C.; Li, W. Study on the micro-mechanical behavior and pore structure evolution mechanism of coral reef limestone based on digital rock core. Comput. Geotech. 2025, 177, 106845. [Google Scholar] [CrossRef]

- Heidari, M.; Khanlari, G.R.; Torabi-Kaveh, M.; Kargarian, S.; Saneie, S. Effect of Porosity on Rock Brittleness. Rock Mech. Rock Eng. 2014, 47, 785–790. [Google Scholar] [CrossRef]

- Wang, H.L.; Xu, W.Y.; Cai, M.; Xiang, Z.P.; Kong, Q. Gas Permeability and Porosity Evolution of a Porous Sandstone Under Repeated Loading and Unloading Conditions. Rock Mech. Rock Eng. 2017, 50, 2071–2083. [Google Scholar] [CrossRef]

- Chen, L.; He, A.; Zhao, J.; Kang, Q.; Li, Z.; Carmeliet, J.; Shikazono, N.; Tao, W. Pore-scale modeling of complex transport phenomena in porous media. Prog. Energy Combust. Sci. 2022, 88, 100968. [Google Scholar] [CrossRef]

- Liu, H.; Kang, Q.; Leonardi, C.R.; Schmieschek, S.; Narváez, A.; Jones, B.D.; Williams, J.R.; Valocchi, A.J.; Harting, J. Multiphase lattice Boltzmann simulations for porous media applications. Comput. Geosci. 2016, 20, 777–805. [Google Scholar] [CrossRef]

- Nasir, M.; Kaito, K.; Patmonoaji, A.; Mahardika, M.A.; She, Y.; Matsushita, S.; Suekane, T. Three-dimensional pore-scale observation of drying process of porous media. Int. J. Heat Mass. Transf. 2022, 196, 123299. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, J.; Leung, A.K. Tracking spatial heterogeneity of local degree of saturation in unsaturated soils at different scales via X-ray computed tomography. J. Rock Mech. Geotech. Eng. 2025, 17, 3807–3818. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, X.; Chen, J. Pore-scale hydraulic properties of virtual sandstone microstructures: Spatial variations and voxel scale effects. Arch. Civ. Mech. Eng. 2022, 23, 22. [Google Scholar] [CrossRef]

- Zhou, X.; Xiao, N. Analyzing fracture properties of the 3D reconstructed model of porous rocks. Eng. Fract. Mech. 2018, 189, 175–193. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, G.; Zhou, H.; Wei, X.; Chen, Y. A CT-XRD-based thermo-mechanical coupling DLSM for quantitative analysis of extreme temperature-induced damage in rocks. Comput. Geotech. 2025, 179, 107056. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth-Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef]

- Inês Silva, M.; Malitckii, E.; Santos, T.G.; Vilaça, P. Review of conventional and advanced non-destructive testing techniques for detection and characterization of small-scale defects. Prog. Mater. Sci. 2023, 138, 101155. [Google Scholar] [CrossRef]

- Kim, J.; Chung, S.; Stephan, D.; Han, T. Issues on characterization of cement paste microstructures from μ-CT and virtual experiment framework for evaluating mechanical properties. Constr. Build. Mater. 2019, 202, 82–102. [Google Scholar] [CrossRef]

- Qsymah, A.; Sharma, R.; Yang, Z.; Margetts, L.; Mummery, P. Micro X-ray computed tomography image-based two-scale homogenisation of ultra high performance fibre reinforced concrete. Constr. Build. Mater. 2017, 130, 230–240. [Google Scholar] [CrossRef]

- Chung, S.; Han, T.; Kim, S.; Jay Kim, J.; Youm, K.S.; Lim, J. Evaluation of effect of glass beads on thermal conductivity of insulating concrete using micro CT images and probability functions. Cem. Concr. Compos. 2016, 65, 150–162. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, R.; Zhu, K.; Li, D.; Jin, Y.; Guo, W.; Liu, X.; Zhang, X.; Zhang, Q. Probing the Pore Structure of the Berea Sandstone by Using X-ray Micro-CT in Combination with ImageJ Software. Minerals 2023, 13, 360. [Google Scholar] [CrossRef]

- Shen, Z.; Meng, Z.; Liu, Y.; Lei, J.; Shen, W.; Ren, H.; Gao, T.; Zhang, K.; Wang, Y.; Tan, L. Relationship between multiscale nanopore structure and coal connectivity during coalification process. Microporous Mesoporous Mater. 2023, 360, 112717. [Google Scholar] [CrossRef]

- Tiberti, G.; Minelli, F.; Plizzari, G. Reinforcement optimization of fiber reinforced concrete linings for conventional tunnels. Compos. Part B Eng. 2014, 58, 199–207. [Google Scholar] [CrossRef]

- Duggal, P.; Tomar, R.K.; Kaushika, N.D. Design and application of concrete bricks using phase change materials. Int. J. Syst. Assur. Eng. Manag. 2024. [Google Scholar] [CrossRef]

- Hou, F.; Qu, G.; Yan, Z.; Zheng, M.; Ma, Y.; Li, J.; Fan, F.; Zhang, J. Properties and relationships of porous concrete based on Griffith’s theory: Compressive strength, permeability coefficient, and porosity. Mater. Struct. 2024, 57, 52. [Google Scholar] [CrossRef]

- Lin, X.; Li, Z.; Jiang, Z.; Miao, H.; Zhang, C. The Effects of Pore Wettability on the Adsorption and Flow Capacity of Shale Gas: New Insights from Molecular Dynamic Modeling. Energy Technol. 2023, 11, 2300004. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, C.; Ranjith, P.G. Behaviours of methane and water in heterogeneous shale nanopores: Effect of water saturation and pore size. Fuel 2023, 335, 126675. [Google Scholar] [CrossRef]

- Keller, L.M.; Schuetz, P.; Erni, R.; Rossell, M.D.; Lucas, F.; Gasser, P.; Holzer, L. Characterization of multi-scale microstructural features in Opalinus Clay. Microporous Mesoporous Mater. 2013, 170, 83–94. [Google Scholar] [CrossRef]

- Yin, S.; Chen, X.; Yan, R.; Wang, L. Pore Structure Characterization of Undisturbed Weathered Crust Elution-Deposited Rare Earth Ore Based on X-ray Micro-CT Scanning. Minerals 2021, 11, 236. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, M.; Sun, X.; Liu, B.; Ostadhassan, M.; Huang, W.; Chen, X.; Pan, Z. Pore network characterization of shale reservoirs through state-of-the-art X-ray computed tomography: A review. Gas Sci. Eng. 2023, 113, 204967. [Google Scholar] [CrossRef]

- Singh, A.; Regenauer Lieb, K.; Walsh, S.D.C.; Armstrong, R.T.; van Griethuysen, J.J.M.; Mostaghimi, P. On Representative Elementary Volumes of Grayscale Micro-CT Images of Porous Media. Geophys. Res. Lett. 2020, 47, e2020GL088594. [Google Scholar] [CrossRef]

- Smal, P.; Gouze, P.; Rodriguez, O. An automatic segmentation algorithm for retrieving sub-resolution porosity from X-ray tomography images. J. Pet. Sci. Eng. 2018, 166, 198–207. [Google Scholar] [CrossRef]

- Godoy, W.; Pontedeiro, E.M.; Barros, R.A.B.R.; de Vries, E.T.; Raoof, A.; van Genuchten, M.T.; Couto, P. Modeling sub-resolution porosity of a heterogeneous carbonate rock sample. Vadose Zone J. 2024, 23, e20348. [Google Scholar] [CrossRef]

- Zhuang, L.; Shin, H.; Yeom, S.; Pham, C.N.; Kim, Y. A novel method for estimating subresolution porosity from CT images and its application to homogeneity evaluation of porous media. Sci. Rep. 2022, 12, 16229. [Google Scholar] [CrossRef] [PubMed]

- Ghadiri, M.; Harrison, S.T.L.; Fagan-Endres, M.A. Quantitative X-ray µCT Measurement of the Effect of Ore Characteristics on Non-Surface Mineral Grain Leaching. Minerals 2020, 10, 746. [Google Scholar] [CrossRef]

- Qian, Y.H.; Humières, D.D.; Lallemand, P. Lattice BGK Models for Navier-Stokes Equation. Europhys. Lett. 1992, 17, 479. [Google Scholar] [CrossRef]

- Cui, Y.; Shikhov, I.; Li, R.; Liu, S.; Arns, C.H. A numerical study of field strength and clay morphology impact on NMR transverse relaxation in sandstones. J. Pet. Sci. Eng. 2021, 202, 108521. [Google Scholar] [CrossRef]

- Cui, Y.; Shikhov, I.; Arns, C.H. NMR Relaxation Modelling in Porous Media with Dual-Scale-Resolved Internal Magnetic Fields. Transp. Porous Media 2022, 142, 453–474. [Google Scholar] [CrossRef]

- De Boever, W.; Bultreys, T.; Derluyn, H.; Van Hoorebeke, L.; Cnudde, V. Comparison between traditional laboratory tests, permeability measurements and CT-based fluid flow modelling for cultural heritage applications. Sci. Total Environ. 2016, 554–555, 102–112. [Google Scholar] [CrossRef]

- Jackson, S.J.; Lin, Q.; Krevor, S. Representative Elementary Volumes, Hysteresis, and Heterogeneity in Multiphase Flow from the Pore to Continuum Scale. Water Resour. Res. 2020, 56, e2019WR026396. [Google Scholar] [CrossRef]

- Lv, P.; Liu, Y.; Liu, F.; Yang, W.; Liu, H.; Zhang, B.; Song, Y. Pore-based architecture and representative element volume evaluation in artificial sand packs and natural rock cores. Pet. Sci. 2022, 19, 1473–1482. [Google Scholar] [CrossRef]

- Huang, R.; Herring, A.L.; Sheppard, A. Effect of Saturation and Image Resolution on Representative Elementary Volume and Topological Quantification: An Experimental Study on Bentheimer Sandstone Using Micro-CT. Transp. Porous Media 2021, 137, 489–518. [Google Scholar] [CrossRef]

- Wang, C.; Yao, J.; Huang, Z.; Liu, F.; Yang, Y. Digital core reconstruction based on discrete element and Markov chain-Monte Carlo methods. Geoenergy Sci. Eng. 2024, 236, 212422. [Google Scholar] [CrossRef]

- Peksa, A.E.; Wolf, K.-H.A.A.; Zitha, P.L.J. Bentheimer sandstone revisited for experimental purposes. Mar. Pet. Geol. 2015, 67, 701–719. [Google Scholar] [CrossRef]

- Lucas Oliveira, E.; Araujo Ferreira, A.G.; Trevizan, W.A.; dos Santos, B.C.C.; Bonagamba, T.J. Sandstone surface relaxivity determined by NMR T2 distribution and digital rock simulation for permeability evaluation. J. Pet. Sci. Eng. 2020, 193, 107400. [Google Scholar] [CrossRef]

- Zhang, C.; Jia, S.; Huang, X.; Shi, X.; Zhang, T.; Zhang, L.; Wang, F. Accurate characterization method of pores and various minerals in coal based on CT scanning. Fuel 2024, 358, 130128. [Google Scholar] [CrossRef]

| Sample Name | CT Resolution (μm/Voxel) | X-Ray Energy (keV) | 3D Voxel Dimensions (Voxel) | Mineral Component and Content (wt%) | Total Porosity (%) |

|---|---|---|---|---|---|

| Belgian Fieldstone | 4.98 | 100 | 500 × 500 × 500 | Quartz, Chlorite | averaged 20 [42] |

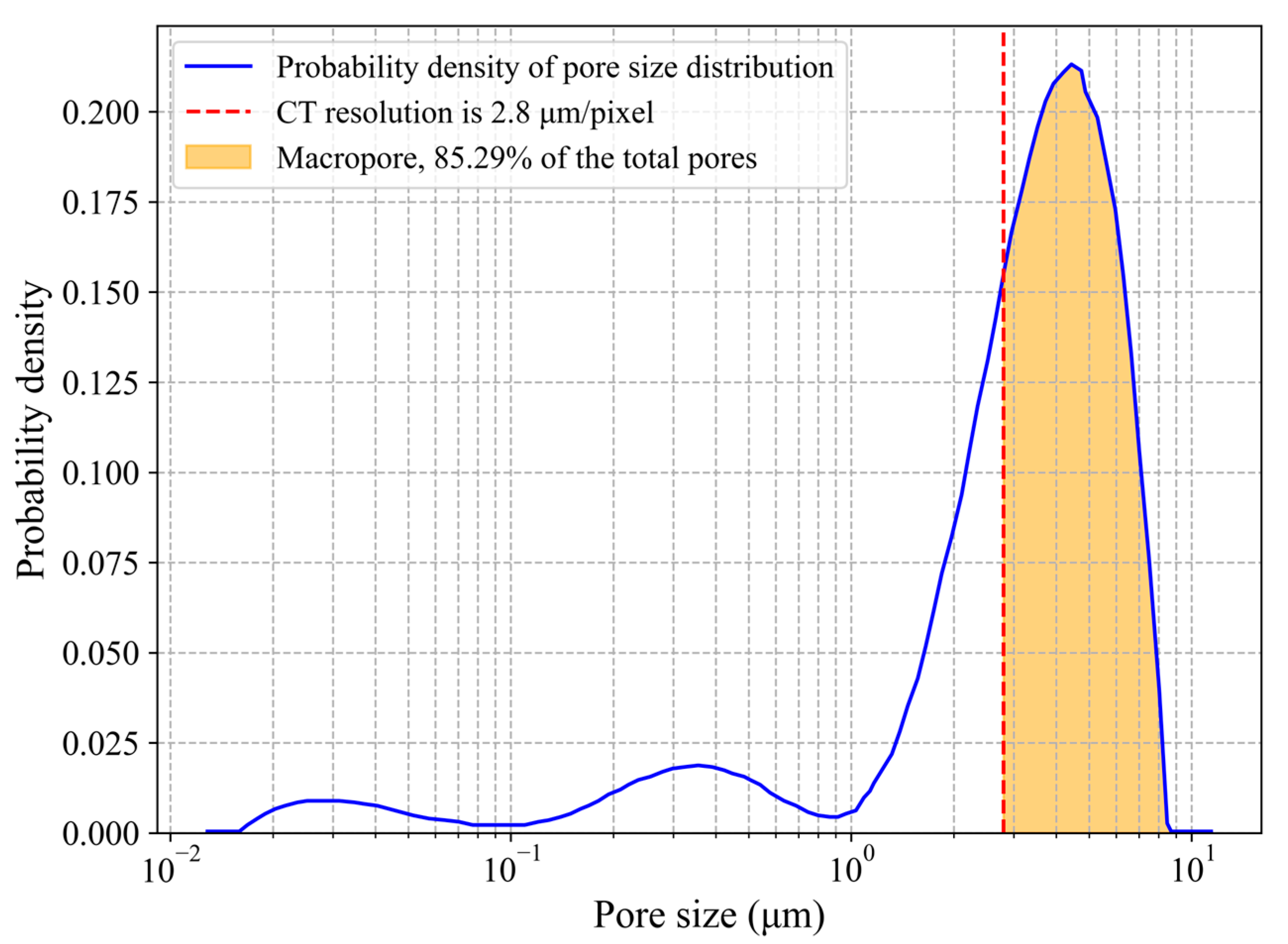

| Bentheimer_1 | 2.8 | 150 | 800 × 800 × 800 | Quartz (95.8), Feldspar (2.3), Kaolinite clay minerals (1.9) | 21~27 [43] |

| Bentheimer_2 | 6.0 | 100 | 600 × 600 × 600 | Quartz, Feldspar, Kaolinite clay minerals | 21~27 [43] |

| Sample Name | Number of Macroparticle Types (%) | Number of Matrix Types (%) | Number of Macroporosity Types (%) |

|---|---|---|---|

| Belgian Fieldstone | 2 (70.14%) | 1 (24.59%) | 1 (5.27%) |

| Bentheimer_1 | 2 (73.93%) | 1 (4.52%) | 1 (21.55%) |

| Bentheimer_2 | 1 (68.93%) | 1 (14.19%) | 1 (16.88%) |

| Sample Name | Component | Cluster Range | Cluster Centres |

|---|---|---|---|

| Belgian Fieldstone | Macroparticle 1 | 32,019~65,535 | 35,631.1 |

| Macroparticle 2 (Quartz) | 22,760~32,018 | 26,880.5 | |

| Matrix | 10,923~22,759 | 15,256.6 | |

| Macropore | 0~10,922 (Air) | - | |

| Bentheimer_1 | Macroparticle 1 | 14,173~32,765 | 14,602.3 |

| Macroparticle 2 (Quartz) | 12,721~14,172 | 13,550.8 | |

| Matrix | 11,373~12,720 | 12,160.0 | |

| Macropore | −32,715~11,372 | 10,584.3 | |

| Bentheimer_2 | Macroparticle (Quartz) | 8364~65,535 | 9948.8 |

| Matrix | 995~8363 | 6779.0 | |

| Macropore | 0~994 (Air) | - |

| Mineral Name | Chemical Formula | Crystal Density (g/cm3) | MACs (cm2/g) |

|---|---|---|---|

| Illite | K0.6–0.85(Al,Mg)2(Si,Al)4O10(OH)2 | 2.80 | 0.178 (100 keV) 0.151 (150 keV) |

| Kaolinite | Al2Si2O5(OH)4 | 2.68 | 0.193 (100 keV) 0.152 (150 keV) |

| Quartz | SiO2 | 2.65 | 0.165 (100 keV) 0.125 (150 keV) |

| Sample Name | X-Ray Energy (keV) | Main Components of the Matrix | Calibrated Mineral | |

|---|---|---|---|---|

| Belgian Fieldstone | 100 | Illite | Quartz | 1.14 |

| Bentheimer_1 | 150 | Kaolinite | Quartz | |

| Bentheimer_2 | 100 | Kaolinite | Quartz |

| A | B | Calculation Results of Total Porosity (%) | A1(%) | A2(%) | Reference range for Total Porosity (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| C | D | E | |||||||

| Matrix Content (%) | Macroporous Content (%) | Binarisation Method | and ρ. | and ρ. (This Paper) | (C-E)/100A E | (E-D)/A | |||

| Belgian Fieldstone | 24.59 | 5.27 | 29.86 | 21.52 | 23.45 | 1.11 (total 27.33) | 7.85 | averaged 20 [42] | |

| Bentheimer_1 | 4.52 | 21.55 | 26.07 | 25.68 | 25.98 | 0.08 (total 0.35) | 6.64 | 21~27 [43] | |

| Bentheimer_2 | 14.19 | 16.88 | 31.07 | 18.53 | 20.73 | 3.52 (total 49.88) | 15.5 | 21~27 [43] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zhang, Z.; Long, Z.; Zhang, Q.; Yue, Z. Subresolution Porosity Estimation of Porous Rocks from CT Images: Incorporating X-Ray Mass Attenuation Coefficients. Minerals 2025, 15, 966. https://doi.org/10.3390/min15090966

Chen J, Zhang Z, Long Z, Zhang Q, Yue Z. Subresolution Porosity Estimation of Porous Rocks from CT Images: Incorporating X-Ray Mass Attenuation Coefficients. Minerals. 2025; 15(9):966. https://doi.org/10.3390/min15090966

Chicago/Turabian StyleChen, Jianhuang, Zhongjian Zhang, Zhenyu Long, Qiong Zhang, and Zhongqi Yue. 2025. "Subresolution Porosity Estimation of Porous Rocks from CT Images: Incorporating X-Ray Mass Attenuation Coefficients" Minerals 15, no. 9: 966. https://doi.org/10.3390/min15090966

APA StyleChen, J., Zhang, Z., Long, Z., Zhang, Q., & Yue, Z. (2025). Subresolution Porosity Estimation of Porous Rocks from CT Images: Incorporating X-Ray Mass Attenuation Coefficients. Minerals, 15(9), 966. https://doi.org/10.3390/min15090966