Use of Fine Residues from Dimension Stone Processing as Stone Meal and Risk of Soil Salinization

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Physical, Chemical, and Mineralogical Analysis

2.3. Estimation of Exchangeable Sodium Percentage (ESP) and Sodium Adsorption Ratio (SAR)

3. Results

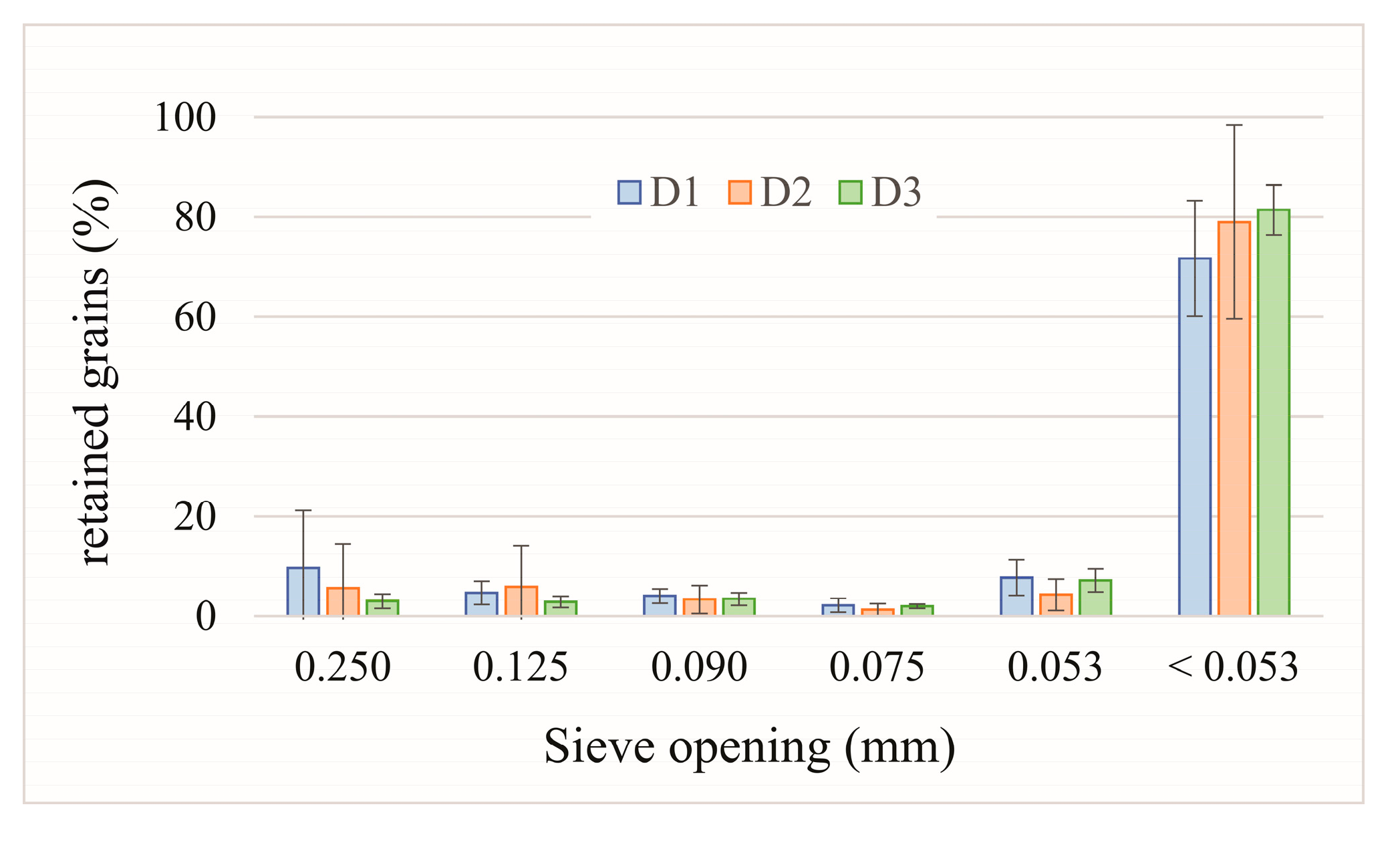

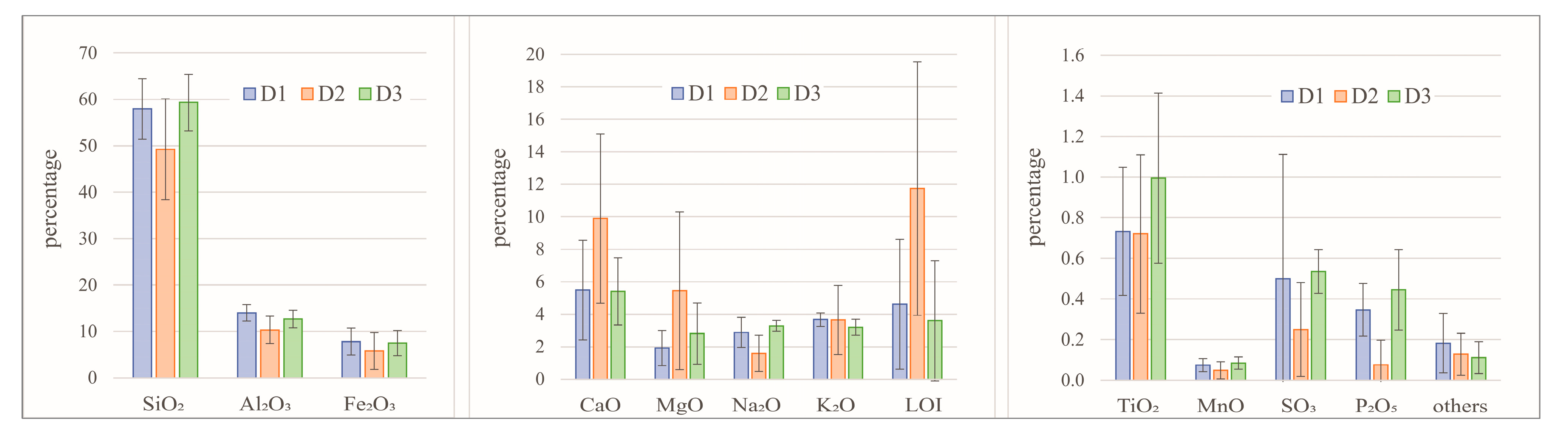

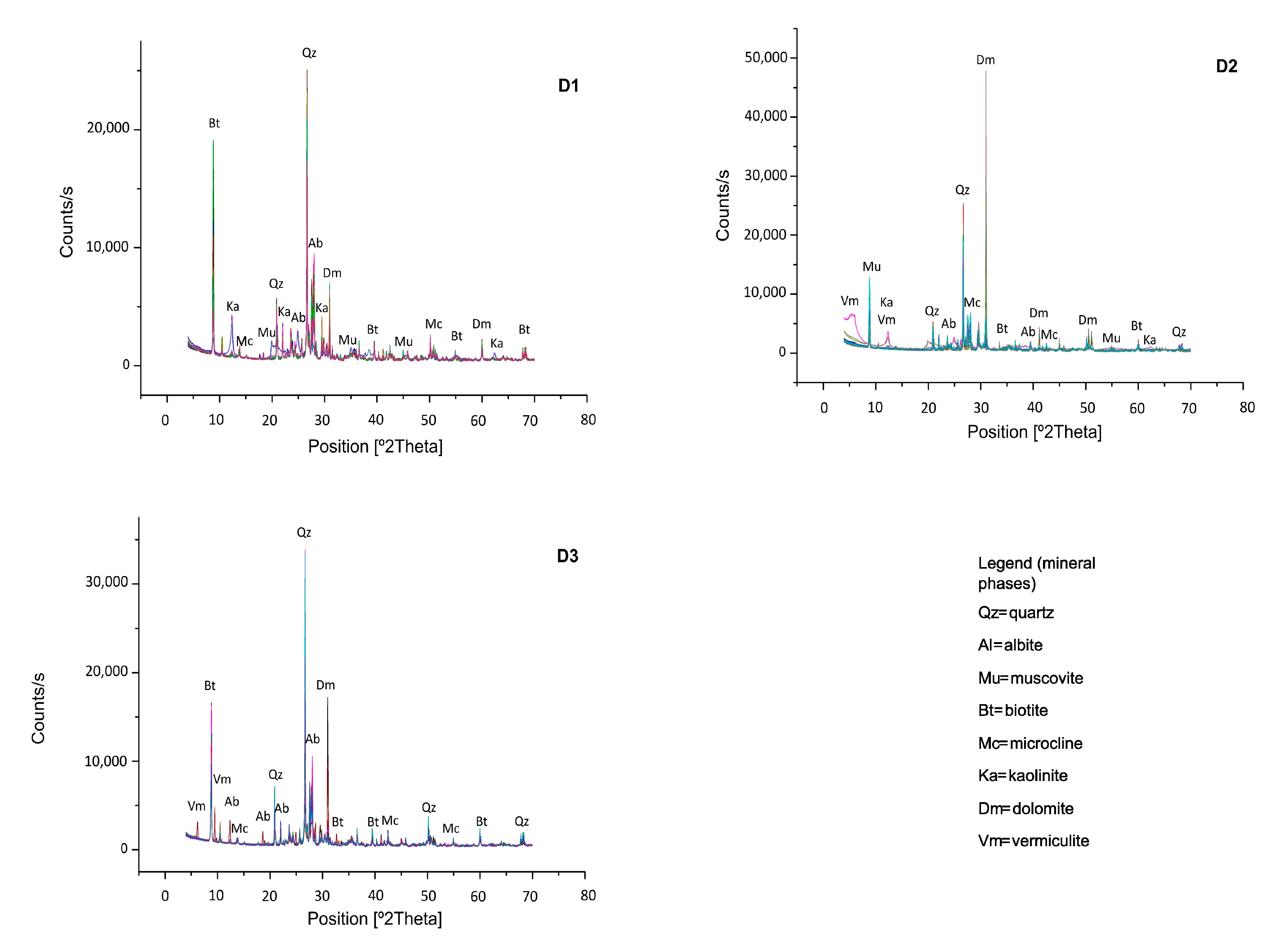

3.1. Granulometry and Composition of FDSP Residues

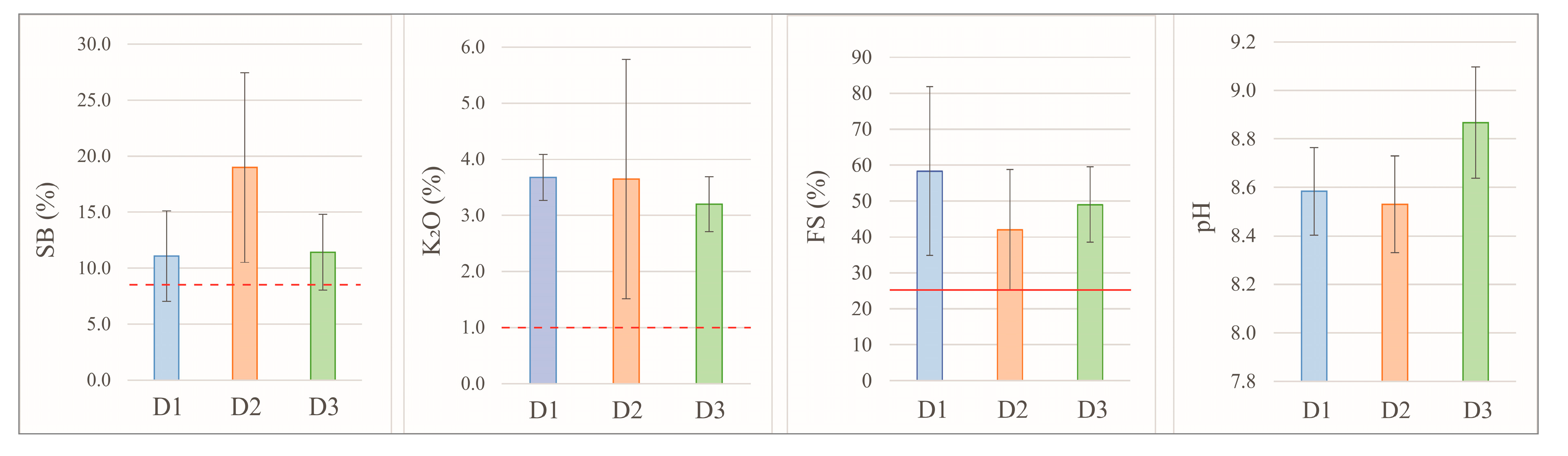

3.2. Comparison with the Requirements of Normative Instruction 05/2016 by the Brazilian Ministry of Agriculture, Livestock, and Supply (MAPA)

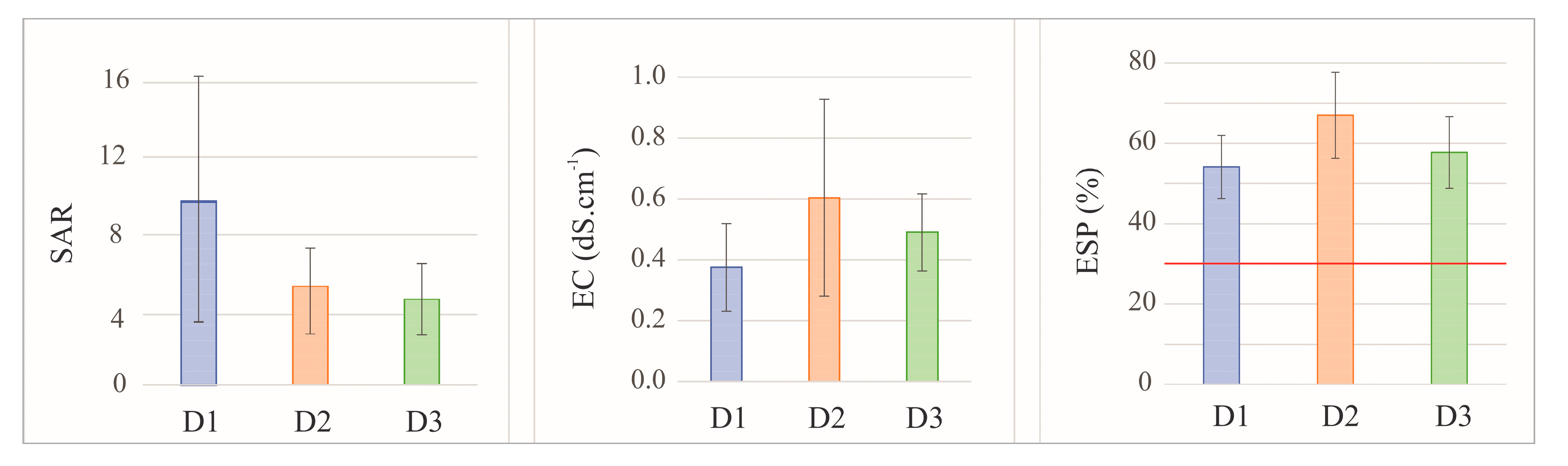

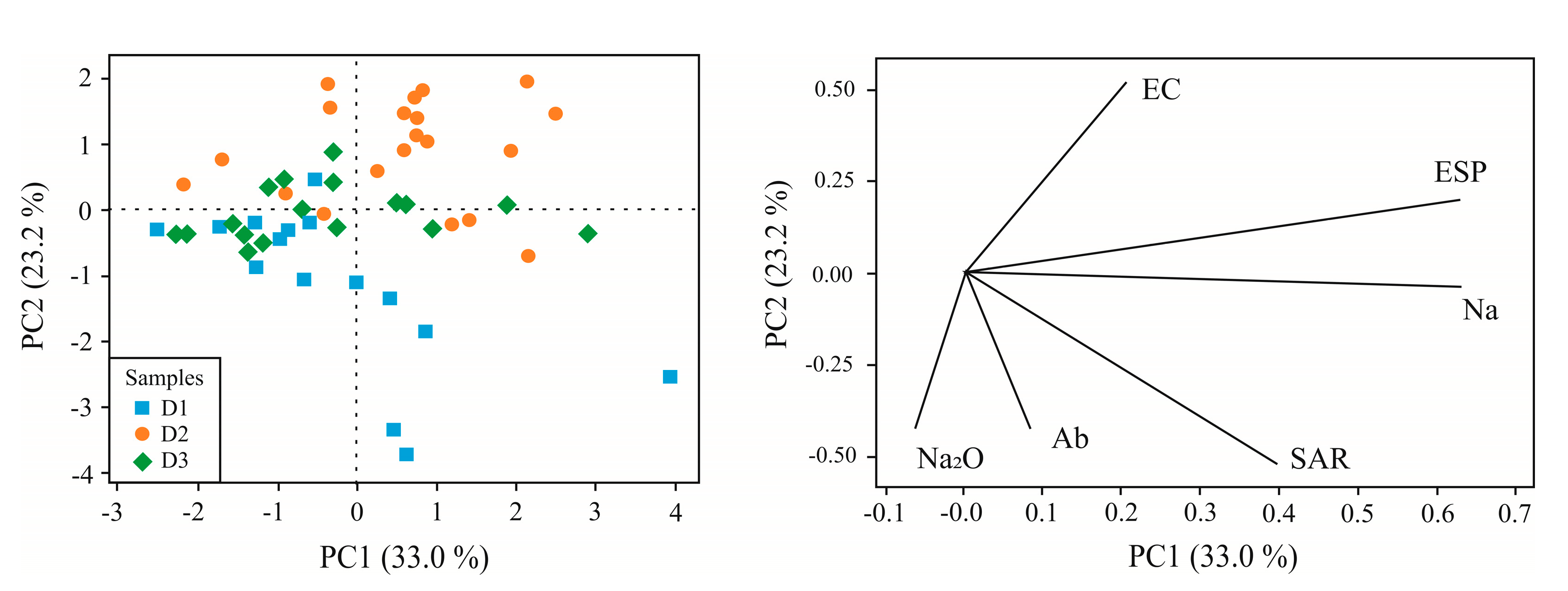

3.3. Restrictions Regarding Influence on Salinity, Infiltration of Water, and ESP

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Theodoro, S.; Medeiros, F.P.; Ianniruberto, M.; Jacobson, T.K.B. Soil remineralization and recovery of degraded areas: An experience in the tropical region. J. S. Am. Earth Sci. 2021, 107, 103014. [Google Scholar] [CrossRef]

- Santos, W.O.; Mattiello, E.M.; Costa, L.M.; Abrahão, W.A.P.; Novais, R.F.; Cantarutti, R.B. Thermal and chemical solubilization of verdete for use as potassium fertilizer. Int. J. Miner. Process. 2015, 140, 72–78. [Google Scholar] [CrossRef]

- Hendronursito, Y.; Barus, J.; Amin, M.; Muttaqii, M.A.; Rajagukguk, T.O.; Isnugroho, K.; Birawidha, D.C. The local mineral potential from East Lampung—Indonesia: The use of basalt rock as a stone meal for cassava plant. JDMLM 2019, 7, 1977–1985. [Google Scholar] [CrossRef]

- Wilpert, K.V.; Lukes, M. Ecochemical effects of phonolite rock powder, dolomite and potassium sulfate in a spruce stand on an acidified glacial loam. Nutr. Cycling Agroecosyst. 2003, 65, 115–127. [Google Scholar] [CrossRef]

- Abirochas—Associação Brasileira da Indústria de Rochas Ornamentais. Balanço do setor brasileiro de rochas ornamentais e de revestimento em 2024. Informe ABIROCHAS 2025, 1, 1–19. Available online: https://abirochas.com.br/wp-content/uploads/2025/03/Informe-01_2025-Exportacoes-2024-1.pdf (accessed on 17 April 2025).

- Espírito Santo. Secretaria do Meio Ambiente e Recursos Hídricos. Instituto Estadual de Meio Ambiente e Recursos Hídricos—IEMA. Instrução Normativa nº 012-N de 22 de agosto de 2023. Diário Oficial dos Poderes do Estado do Espírito Santo 2023, 39–42. [Google Scholar]

- Espírito Santo. Secretaria do Meio Ambiente e Recursos Hídricos. Instituto Estadual de Meio Ambiente e Recursos Hídricos—IEMA. Instrução Normativa nº 013-N de 22 de agosto de 2023. Diário Oficial dos Poderes do Estado do Espírito Santo 2023, 38–39. [Google Scholar]

- Espírito Santo. Secretaria do Meio Ambiente e Recursos Hídricos. Instituto Estadual de Meio Ambiente e Recursos Hídricos—IEMA. Instrução Normativa nº 11, de 11 de outubro de 2016. Diário Oficial dos Poderes do Estado do Espírito Santo 2016, 51. [Google Scholar]

- Barral Silva, M.T.; Hermo, B.S.; Garcia-Rodeja, E.; Freire, N.V. Reutilization of granite powder as an amendment and fertilizer for acid soils. Chemosphere 2005, 61, 993–1002. [Google Scholar] [CrossRef]

- Machado, R.V.; Andrade, F.V.; Passos, R.R.; Ribeiro, R.C.C.; Mendonça, E.S.; Mesquita, L.F. Characterization of ornamental rock residue and potassium liberation via organic acid application. RBCS 2016, 40, e0150153. [Google Scholar] [CrossRef][Green Version]

- Sivrikaya, O.; Koray, R.; Kiyildi, K.R.; Karaca, Z. Recycling waste from natural stone processing plants to stabilize clayey soil. Environ. Earth Sci. 2014, 71, 4397–4407. [Google Scholar] [CrossRef]

- Brasil. Presidência da República. Casa Civil. Subchefia para Assuntos Jurídicos. Lei Nº 12890, de 10 de dezembro de 2013. Altera a Lei Nº 6894, de 16 de dezembro de 1980, para incluir os remineralizadores como uma categoria de insumo destinado à agricultura, e dá outras providências. Casa Civil: Brasília, Brazil, 2013. Available online: https://www.planalto.gov.br/ccivil_03/_ato2011-2014/2013/lei/l12890.htm (accessed on 17 April 2025).

- Brasil. Presidência da República. Casa Civil. Subchefia para Assuntos Jurídicos. Lei Nº 6894, de 16 de dezembro de 1980. Dispõe sobre a inspeção e a fiscalização da produção e do comércio de fertilizantes, corretivos, inoculantes, estimulantes ou biofertilizantes, remineralizadores e substratos para plantas, destinados à agricultura, e dá outras providências. Casa Civil: Brasília, Brazil, 1980. Available online: https://www.planalto.gov.br/ccivil_03/leis/1980-1988/l6894.htm (accessed on 17 April 2025).

- Brasil. Ministério da Agricultura, Pecuária e Abastecimento—MAPA. Instrução Normativa Nº 5, de 10 de março de 2016. Estabelece as regras sobre definições, classificação, especificações e garantias, tolerâncias, registro, embalagem, rotulagem e propaganda dos remineralizadores e substratos para plantas, destinados à agricultura. MAPA: Brasília, Brazil, 2016. Available online: https://www.gov.br/agricultura/pt-br/assuntos/insumos-agropecuarios/insumos-agricolas/fertilizantes/legislacao/in-5-de-10-3-16-remineralizadores-e-substratos-para-plantas.pdf/view (accessed on 17 April 2025).

- Ayers, R.S.; Westcot, D.W. Water Quality for Agriculture; Food and Agriculture Organization of the United Nations—FAO: Rome, Italy, 1985; Available online: http://www.fao.org/DOCREP/003/T0234E/T0234E00.htm#TOC (accessed on 8 December 2024).

- Abrol, I.P.; Yadav, J.S.P.; Massoud, F.I. Salt-Affected Soils and Their Management; FAO—Food and Agriculture Organization of the United Nations: Rome, Italy, 1988; Available online: https://www.fao.org/4/x5871e/x5871e00.htm#Contents (accessed on 28 November 2024).

- Omuto, C.T.; Vargas, R.R.; El Mobarak, A.M.; Mohamed, N.; Viatkin, K.; Yigini, Y. Mapping of Salt-Affected Soils: Technical Manual; Food and Agriculture Organization of the United Nations—FAO: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- De Amorim, J.R.A.; Cruz, M.A.S.; Resende, R.S.; Bassoi, L.H.; Silva Filho, J.G. Espacialização da Porcentagem de Sódio Trocável do Solo no Perímetro Irrigado Califórnia, em Canindé de São Francisco, Sergipe; Embrapa Tabuleiros Costeiros: Aracaju, Brazil, 2010; p. 17. [Google Scholar]

- Teixeira, P.C.; Donagemma, G.K.; Fontana, A.; Teixeira, W.G. Manual de Métodos de Análise de Solo, 3rd ed.; Embrapa: Brasília, Brazil, 2017; p. 574. Available online: https://www.infoteca.cnptia.embrapa.br/handle/doc/1085209 (accessed on 12 February 2025).

- Sobral, L.F.; Barretto, M.C.V.; Silva, A.J.; Anjos, J.L. Guia Prático para Interpretação de Resultados de Análises de Solo; Embrapa Tabuleiros Costeiros: Aracaju, Brazil, 2015; p. 13. Available online: www.bdpa.cnptia.embrapa.br (accessed on 30 October 2024).

- Braga, F.S.; Buzzi, D.C.; Couto, M.C.L.; Lange, L.C. Caracterização ambiental de lamas de beneficiamento de rochas ornamentais. Eng. Sanit. Ambient. 2010, 5, 237–244. [Google Scholar] [CrossRef]

- Kawasaki, T.; Akiba, T.; Moritsugu, M. Effects of high concentrations of sodium chloride and polyethylene glycol on the growth and ion absorption in plants. I. Water culture experiments in a greenhouse. Plant Soil 1983, 75, 75–85. [Google Scholar] [CrossRef]

- Neves, M.A.; Nascimento, W.A.R.; Horn, A.H. Dimension stone processing sludge at different stages of production: Insights for waste management. Minerals 2025, 15, 39. [Google Scholar] [CrossRef]

- Neves, M.A.; Prado, A.C.A.; Marques, R.A.; Fonseca, A.B.; Machado, M.E.S. Lama de beneficiamento de rochas ornamentais processadas no Espírito Santo: Composição e aproveitamento. Geociências 2021, 40, 123–136. [Google Scholar] [CrossRef]

- Duarte, E.B.; Da Silva Nascimento, A.P.; Da Silva Gandine, S.M.; De Carvalho, J.R.; Burak, D.L.; Neves, M.A. Liberação de potássio e sódio a partir de resíduos do beneficiamento de rochas ornamentais. Pesqui. em Geocienc. 2021, 48, 101373. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas—ABNT. NBR 10004: Resíduos Sólidos—Classificação; ABNT: Rio de Janeiro, Brazil, 2004; pp. 1–71. [Google Scholar]

- Neves, M.A.; Nadai, C.P.; Fonseca, A.B.; Prado, A.C.A.; Giannotti, J.D.G.; Raymundo, V. pH e umidade dos resíduos finos de beneficiamento de rochas ornamentais. REM 2013, 66, 239–244. [Google Scholar] [CrossRef]

- Tozsin, G.; Oztas, T.; Arol, A.I.; Kalkan, E. Changes in the chemical composition of an acidic soil treated with marble quarry and marble cutting wastes. Chemosphere 2015, 138, 664–667. [Google Scholar] [CrossRef]

- Raymundo, V.; Neves, M.A.; Cardoso, M.S.N.; Bregonci, I.S.; Lima, J.S.S.; Fonseca, A.B. Resíduos de serragem de mármores como corretivo da acidez de solo. Rev. Bras. Eng. Agric. Ambient. 2013, 17, 47–53. [Google Scholar] [CrossRef]

- Pérez-Sirvent, C.; García-Lorenzo, M.L.; Martínez-Sánchez, M.J.; Navarro, M.C.; Marimón, J.; Bech, J. Metal-contaminated soil remediation by using sludges of the marble industry: Toxicological evaluation. Environ. Int. 2007, 33, 502–504. [Google Scholar] [CrossRef]

- Vital, A.F.M.; Santos, R.V.; Cavalcante, L.F.; Souto, J.S. Comportamento de atributos químicos de um solo salino-sódico tratado com gesso e fósforo. Rev. Bras. Eng. Agric. Ambient. 2005, 9, 30–36. [Google Scholar] [CrossRef]

- Chaves, E.; Pedron, F.A.; Melo, V.F.; Dalmolin, R.S.D. Reserva mineral de K por diferentes métodos em argissolos subtropicais. RBCS 2015, 39, 1088–1099. [Google Scholar] [CrossRef]

- Manhães, J.P.V.T.; Holanda, J.N.F. Caracterização e classificação de resíduo sólido “pó de rocha granítica” gerado na indústria de rochas ornamentais. Quim. Nova 2008, 31, 1301–1304. [Google Scholar] [CrossRef]

- Mosaferi, M.; Dianat, I.; Khatibi, M.S.; Mansour, S.N.; Fahiminia, M.; Hashemi, A.A. Review of environmental aspects and waste management of stone cutting and fabrication industries. J. Mater. Cycles Waste Manag. 2013, 16, 721–730. [Google Scholar] [CrossRef]

- Venturoti, G.P.; Boldrini-França, J.; Kiffer, W.P.; Francisco, A.P.; Gomes, A.S.; Gomes, L.C. Toxic effects of ornamental stone processing waste effluents on Geophagus brasiliensis (Teleostei: Cichlidae). Environ. Toxicol. Pharmacol. 2019, 72, 103268. [Google Scholar] [CrossRef]

- Zichella, L.; Dino, G.A.; Bellopede, R.; Marini, P.; Padoan, E.; Passarella, I. Environmental impacts, management and potential recovery of residual sludge from the stone industry: The piedmont case. Resour. Policy 2020, 65, 101562. [Google Scholar] [CrossRef]

| Class | ESP (%) |

|---|---|

| Non-sodic | <7 |

| Slightly sodic | 7–10 |

| Moderately sodic | 11–20 |

| Strongly sodic | 21–30 |

| Excessively sodic | >30 |

| Salinity | None | Moderate | Severe |

|---|---|---|---|

| EC | <0.7 | 0.7–3.0 | >3.0 |

| Infiltration | None | Moderate | Severe |

| SAR 0–3 and EC | >0.7 | 0.7–0.2 | <0.2 |

| SAR 3–6 and EC | >1.2 | 1.2–0.3 | <0.3 |

| SAR 6–12 and EC | >1.9 | 1.9–0.5 | <0.5 |

| SAR 12–20 and EC | >2.9 | 2.9–1.3 | <1.3 |

| SAR 20–40 and EC | >5.0 | 5.0–2.9 | <2.9 |

| Deposit | Qz | Ab | Mu | Bt | Mc | Ka | Dm | Cc | Mt | Vm | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | Mean | 58.3 | 15.1 | 4.2 | 6.0 | 2.4 | 2.1 | 9.0 | 0.0 | 2.9 | 0.0 |

| Median | 58.6 | 9.7 | 2.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| St.dev. | 23.5 | 20.5 | 4.6 | 11.2 | 4.8 | 4.7 | 17.8 | 0.0 | 10.9 | 0.0 | |

| Min. | 22.3 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Max. | 89.5 | 72.5 | 13.8 | 32.2 | 16.7 | 16.9 | 44.5 | 0.0 | 40.8 | 0.0 | |

| D2 | Mean | 42.0 | 8.9 | 1.8 | 13.0 | 2.3 | 0.9 | 22.6 | 5.1 | 1.5 | 2.1 |

| Median | 40.3 | 7.7 | 1.4 | 0.0 | 0.0 | 0.0 | 13.6 | 0.4 | 0.0 | 0.0 | |

| St.dev. | 16.8 | 7.5 | 2.7 | 16.2 | 4.4 | 2.3 | 23.9 | 8.2 | 7.0 | 9.9 | |

| Min. | 17.4 | 0.2 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Max. | 76.8 | 36.4 | 11.0 | 49.3 | 17.3 | 9.7 | 59.7 | 30.8 | 33.7 | 47.6 | |

| D3 | Mean | 49.0 | 5.4 | 1.2 | 29.1 | 8.8 | 1.1 | 3.5 | 0.0 | 0.0 | 1.8 |

| Median | 49.6 | 5.9 | 0.0 | 32.1 | 6.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| St.dev. | 10.5 | 4.2 | 4.8 | 12.1 | 8.4 | 4.5 | 9.9 | 0.2 | 0.0 | 7.3 | |

| Min. | 27.3 | 0.4 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Max. | 66.1 | 14.8 | 19.1 | 42.0 | 30.3 | 18.0 | 34.2 | 0.7 | 0.0 | 29.0 | |

| Deposit | n | Restriction on Salinity | Restriction on Infiltration | ESP | |||

|---|---|---|---|---|---|---|---|

| None | Moderate | None | Moderate | Severe | Excessive | ||

| D1 | 15 | 93% | 7% | 0% | 27% | 73% | 100% |

| D2 | 22 | 73% | 27% | 14% | 54% | 32% | 100% |

| D3 | 17 | 100% | 0% | 0% | 71% | 29% | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neves, M.A.; Mateus, G.T.; Duarte, E.B.; Burak, D.L. Use of Fine Residues from Dimension Stone Processing as Stone Meal and Risk of Soil Salinization. Minerals 2025, 15, 680. https://doi.org/10.3390/min15070680

Neves MA, Mateus GT, Duarte EB, Burak DL. Use of Fine Residues from Dimension Stone Processing as Stone Meal and Risk of Soil Salinization. Minerals. 2025; 15(7):680. https://doi.org/10.3390/min15070680

Chicago/Turabian StyleNeves, Mirna A., Gabriella T. Mateus, Eduardo B. Duarte, and Diego L. Burak. 2025. "Use of Fine Residues from Dimension Stone Processing as Stone Meal and Risk of Soil Salinization" Minerals 15, no. 7: 680. https://doi.org/10.3390/min15070680

APA StyleNeves, M. A., Mateus, G. T., Duarte, E. B., & Burak, D. L. (2025). Use of Fine Residues from Dimension Stone Processing as Stone Meal and Risk of Soil Salinization. Minerals, 15(7), 680. https://doi.org/10.3390/min15070680