Abstract

Advancing material efficiency in the steel and cement industry is essential for achieving climate goals. One approach to addressing this is to increase the provisioning of alternative reactive binder materials from residues, in this case, from the steel industry. Different mixtures of identified residues are evaluated for metal recovery and suitability as supplementary cementitious material. For this purpose, suitable combinations are modeled according to specified quality requirements from the cement industry. These mixtures are heated up to 1600 °C for a targeted reduction of predominantly transition metal oxides and a separation into a mineral fraction. Subsequently, controlled cooling of the molten material is implemented through water granulation. The produced granulate is crushed and sieved, and finally, the metallic and mineral fractions are magnetically separated. The chemical modification, reduction, and phase modification are tested to prevent landfilling and provide alternative secondary resources for the steel and cement industry. According to the results, it is possible to recover metals from metallurgical residues and simultaneously separate the modified mineral fraction as an alternative cement constituent. These findings will be further investigated through additional research to identify the variables that influence and impact/affect the reduction efficiency.

1. Introduction

Cement and steel are two of the most used materials globally [1]. Their energy-and resource-intensive production requires 1202 million tonnes of oil equivalent. In 2019, they were responsible for 4.94 gigatonnes of carbon dioxide (CO2) emissions [1]. This contribution corresponds to 68% of the global industrial energy use and 31% of the global industrial CO2 emissions [1].

Improving material and energy efficiency in the cement and steel industry is essential to achieving climate goals. One possibility is to substitute clinker as a supplementary cementitious material (SCM) from metallurgical residues. Fly ash from coal combustion and ground granulated blast furnace slag (GGBFS) from hot metal production are used preferentially. However, the availability of GGBFS and fly ash will decrease due to the phase-out of coal-fired power plants and the transformation of the steel industry from the blast furnace route to scrap-based electric arc furnaces [1,2]. The expected share of GGBFS in global cement production is supposed to decrease by 2050 [2]. This situation necessitates alternative cement constituents to reduce the global clinker-to-cement ratio from 0.72 in 2019 to 0.61 by 2070 [2,3,4].

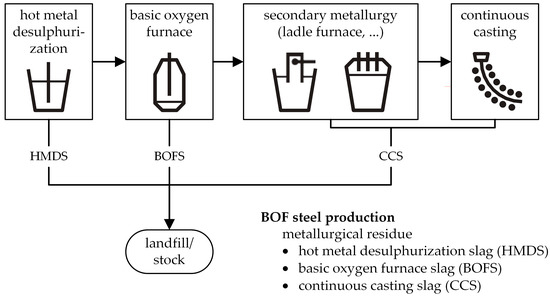

In 2022, global crude steel production was split into 71.1% basic oxygen furnace (BOF) steel and 28.6% electric arc furnace steel [2]. During these production steps, various residues are produced [3]. As shown in Scheme 1, three residues with a high transition metal content are identified for metal recovery in the BOF steel production of the voestalpine plant in Donawitz, Austria [4].

Scheme 1.

A scheme of the identified materials for treatment, with the process of their generation along the basic oxygen furnace steel production line of the voestalpine plant in Donawitz, Austria [4].

The residues can be differentiated according to the corresponding place of occurrence: hot metal desulphurization (HMD), BOF, and secondary metallurgy/continuous casting (CC). For this work, HMD and CC are the primary residues for simultaneous treatment, with a production ratio of three to one. Both residual material streams are magnetically separated and screened. The magnetic fractions of both residue streams are combined to separate iron for internal use. Both residual fractions, HMD slag (HMDS) and CC slag (CCS), are deposited in the company-owned landfill [4]. Internal or external recycling is not feasible due to the existing material properties (grain size distribution, impurity concentration). Furthermore, the voestalpine site in Donawitz is unsuited for such input material. Pilz et al. [5] presented a theoretical approach for the internal recycling of HMD fraction for the voestalpine site in Linz, Austria [5,6]. As mentioned, both residuals should be treated simultaneously in the current recycling approach.

The recycling potential of HMDS and CCS is determined based on previous findings on removing phosphorus and generating metal- and phosphorus-free slag from sewage sludge ash and BOFS [7,8]. On the one hand, the residues still contain metal oxides for recovery [9,10,11,12]. On the other hand, the remaining mineral fraction may serve as a reactive binder component for the cement industry after suitable chemical and phase modifications [13]. In the future, appropriate forms of alternative cement constituents from residues will gain importance as a component of composite cement with a low clinker content, especially in a three-component system consisting of clinker, limestone powder, and reactive SCMs [14,15,16].

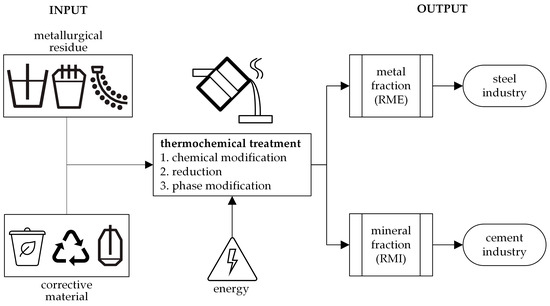

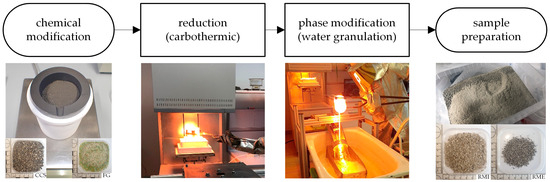

The treatment is divided into three steps, as shown in Scheme 2. First, the metallurgical residues are chemically modified with so-called corrective materials, like fine glass (FG) as silica-rich residue from glass recycling or eggshell (ES) as a calcium-rich residue from agriculture, to meet the cement industry’s requirements. Second, a thermochemical treatment is applied to reduce the transition metal oxide content and separate the remaining mineral fraction. Finally, these mineral fractions undergo phase modification through rapid cooling by water granulation of the molten material.

Scheme 2.

A scheme for treating iron-rich metallurgical residues to generate a metal fraction for the steel industry and a mineral fraction for the cement industry.

The operating range of the current treatment is limited by the residue ratio from the production and the cement industry’s requirements for the mineral fraction. For the calculation of the mixtures, a fixed ratio of HMDS and CCS is assumed according to the annual production ratio. Under these general conditions, the degree of metal reduction is determined by various corrective materials. After passing through the processing stages, the recovered metal fraction is available for internal use in the steel industry. Furthermore, the mineral fraction can be used as an alternative cement constituent [8].

The approaches mentioned above are in line with proposals by experts from the United Nations Environment Programme for Sustainable Construction and Climate [1,4] and the International Energy Agency (IEA) Program for Energy Technology Perspectives 2020 [2,5]. Several strategies were recommended to decarbonize the steel and cement industry and keep the global temperature increase below 1.5 °C through measures taken in the next 20 to 30 years [4]. In addition to long-term and costly processes such as carbon capture and storage [2,4], these strategies comprise the following:

- Regional and local optimization of material flows and cycles.

- Increased use of alternative cement constituents such as SCMs as a partial substitute for Portland cement clinker.

2. Materials and Methods

This section describes the metallurgical residues, corrective materials, treatment steps, and analysis methods. The main aim is to reduce the transition metal oxides based on carbothermic reduction to generate a metal fraction. Simultaneously, a mineral fraction suitable for the cement industry is also desired.

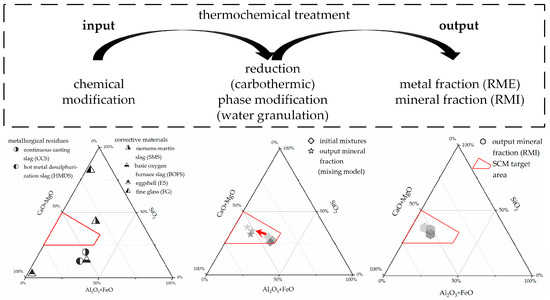

The treatment steps are illustrated in Scheme 3, which includes ternary phase diagrams in which the red area marks the target composition of the mineral fraction for meeting the required properties required of an alternative cement constituent, which includes, for example, a mass fraction (w) of magnesia oxide of less than 18% and a basicity (B3), defined as , that is greater than one, according to EN-15167-1.

Scheme 3.

The thermochemical treatment steps’ scheme, divided into chemical modification, reduction, and phase modification, is shown in a ternary phase diagram. The red target area is based on the limiting requirements for supplementary cementitious materials (SCMs) in the cement industry.

At the beginning of the investigation, an appropriate sample quantity was taken and homogenized to prevent the influence of product fluctuations because the residue composition varies depending on the input raw material and desired product qualities [17]. Before the chemical manipulation started, the metallurgical residues and corrective materials were analyzed. After the thermochemical treatment, the mixture is expected to be within the red target area, as shown in Scheme 3. For that step, a mixing model (MM) was used based on boundary conditions imposed by the requirements for GGBFS when used as a cement addition [18,19]. Additionally, the stoichiometric minimum of carbon needed as a reducing agent for the carbothermic reduction was calculated depending on the reduceable transition metal content. Then, the final sample was heated up to 1600 °C. After the thermal treatment, the reduced and molten material was cooled via water granulation. Finally, sample preparation for subsequent analyses was carried out by separating the mineral and metal fractions.

2.1. Metallurgical Residues/Corrective Material Description

The following input materials were considered for the chemical modification, reduction, and phase alteration of metallurgical residues aimed at metal recovery and slag utilization, as shown in Table 1.

Table 1.

An overview of the input materials for the treatment, divided into input materials (metallurgical residues) and corrective materials from different industries.

2.2. Material Characterization

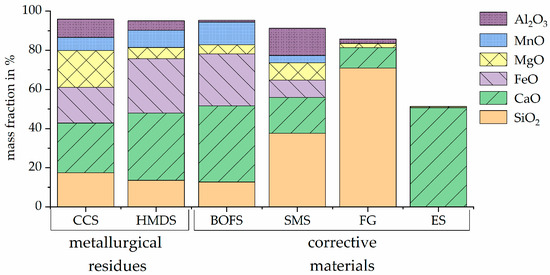

Quantitative chemical analysis of the input materials and output materials was performed by X-ray fluorescence (XRF) spectroscopy. The loss on ignition (LOI) was assessed on ~2 g portions of powdered samples at a temperature of 950 °C for one hour. Glass pellets were prepared from 0.6 g to 1 g of the calcined sample, and a mixture of lithium tetraborate (Li2B4O7) and lithium metaborate (LiBO2). The XRF measurements were performed on a Bruker Tiger S8 spectrometer (Bruker AXS GmbH, Karlsruhe, Germany) for input and output materials and a Malvern Panalytical Epsilon 4 instrument (Malvern Panalytical PLC, Malvern, Worcestershire, UK) for output mineral fractions after thermochemical treatment. Figure 1 shows the chemical composition of the input materials.

Figure 1.

The main oxide content of the metallurgical residues and corrective materials as mass fraction in percent (%). Differences to 100% correspond to minor components and the loss on ignition (LOI).

The chemical analyses revealed calcium (Ca), magnesium (Mg), aluminum (Al), and silicon (Si) as oxides as the main elements in the input materials. Furthermore, high Fe and Mn contents were detected. The corrective materials SMS, FG, and ES exhibit a significant loss on ignition (LOI) due to considerable amounts of carbonate, bound water, and likely some organic compounds (for ES), with only minor contributions to the LOI from sulfur and alkalis, as shown in Table 2.

Table 2.

Selected chemical composition and loss on ignition (LOI) of corrective materials.

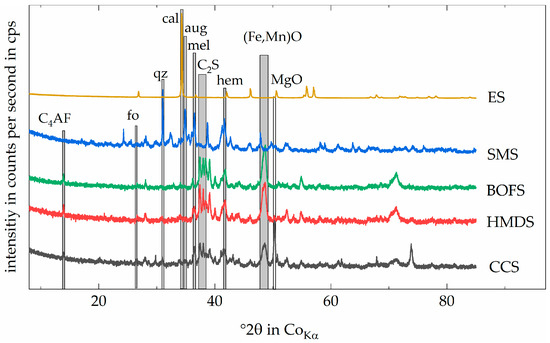

The mineralogical composition of input materials (see Figure 2) and the treated mineral fractions were analyzed by powder X-ray diffraction (PXRD) using a PANalytical X’Pert PRO diffractometer (Malvern Panalytical PLC, Malvern, Worcestershire, UK) with Co-Kα radiation. Finely powdered material was prepared using the back-loading technique and examined at 40 kV and 40 mA from 4 to 85° 2θ with a step size of 0.008° 2θ and 45 s count time per step. The recorded diffractograms were analyzed with the software Highscore Plus 3.0.5. The mineralogical examinations showed that the residues primarily consisted of various typical oxide compounds (e.g., MgO, FeMnO, Fe3O4, Ca4Al2Fe2O10) and silicates (e.g., Ca2SiO4 = belite, Ca2Mg0.5AlSi1.5O7 = melilite, Fe0.2Mg1.8SiO4 = forsterite) and small amorphous (=non-crystalline) proportions. The amorphous content was determined by the external standard method (using NIST 676a corundum powder as standard). Depending on their composition, the corrective materials either contained a majority of crystalline components (SMS, ES) (see Figure 2) or were predominantly amorphous (FG).

Figure 2.

Diffractograms of metallurgical residues and crystalline corrective materials. Representative peaks of crystalline phases have been labeled (C4AF = Ca4Al2Fe2O10, fo = forsterite, qz = quartz, cal = calcite, aug = augite, mel = melilite, C2S = belite, hem = hematite). The amorphous FG is not displayed for clarity purposes.

The melting behavior of the input material was determined via thermo-optical analysis with a heating microscope of type EM201 with EMI II software version 2.3 (Hesse Instruments GmbH, Osterode am Harz, Germany). The so-called characteristic temperatures are described based on the melting behavior of ash according to the standard DIN 51730 [20]. The characteristic temperatures relate to the geometric shapes of the input test object while it is heated [21]. Therefore, a small amount of sample is used to form a cylinder, placed on a ceramic plate made of 99.7% Al2O3 and put into the tube furnace. The input materials were measured twice, initially heated to 1350 °C at a rate of 80 °C per minute, followed by an increased heating rate of 50 °C per minute up to 1450 °C, while the tube furnace was continuously purged with 120 L of argon per hour. During heating, images of the sample silhouette are taken with a camera at a particular time interval. Sample deformation is detected through an area change, which indicates melting behavior. Based on these results in Table 3, the treatment temperature of 1600 °C was targeted.

Table 3.

The flow temperature of the input materials from the steel industry in °C.

The gained metal fraction was analyzed using various analytical methods to determine the concentrations of certain elements (see 3.3). Iron (Fe) was quantified by titration, while manganese (Mn) and phosphorus (P) were analyzed using aqua regia digestion followed by Inductively Coupled Plasma (ICP) spectroscopy. The carbon (C) content was determined using a combustion analyzer CHN628 (Leco Corporation, Michigan, USA), and chromium (Cr) was measured using ICP analysis after microwave digestion.

2.3. Experimental Setup

Scheme 4 shows the experimental procedure. First, a jaw crusher BB50 (Retsch GmbH, Haan, Deutschland) was used for crushing the input material with a gap width setting of one millimeter at 650 revolutions per minute. Then, the input materials were dried at 105 °C in a drying oven for 24 h. After mixing all components to achieve a one-kilogram output of mineral fraction, the sample mixture was filled in a cylindrical graphite crucible (diameter × height × wall thickness = 8 cm × 16.5 cm × 1.5 cm) and placed in an elevator resistance furnace ELHT 16/18 (Thermconcept GmbH, Bremen, Germany), equipped with a temperature controller and programmer (Eurotherm 3508), coupled with two type-B thermocouples placed in the middle of the furnace chamber wall at an 80 and 100 mm distance from the furnace chamber roof. Then, the furnace was heated to 1600 °C with an argon input of three liters per minute to achieve carbothermic reduction and protect the graphite crucible. After reaching the desired temperature and a holding time of 1.5 h, the load was vertically moved out of the furnace chamber and the melt was tapped into the water granulation unit, which consists of the granulation basin, a pump to realize the water jet (80 L per minute) and a netted cage to catch the granulate. Subsequently, the granulate was put into a drying oven at 110 °C for 24 h. After that, a jaw crusher (Retsch BB50) was implemented to grind the material with a gap width setting of 0.1 mm at 650 revolutions per minute for sample preparation. Then, a sieve tower (Retsch AS2002) was used to agglomerate the metal fraction at the top screens as it was not as easily crushed as the mineral fraction. With the aid of a magnet, the metal was finally separated and analyzed—see Section 2.2.

Scheme 4.

Experimental procedure of thermochemical treatment.

2.3.1. Chemical Modification

In the current case, the mixing model (MM) [18] was used to calculate four different initial mixture compositions (M-001–M-004) and the corresponding compositions of the mineral fractions (RMI) after treatment. The aim is to mix these input materials so that the resulting mineral fraction fulfills the assumed chemical and physical requirements.

Therefore, the chemical composition of each input material is first stored in a database for mixture modeling. A summation procedure is conducted at this step, followed by normalization to a default mass fraction value of 100%. The loss on ignition (LOI), which considers the compounds lost during carbothermal reduction, is subtracted. Then, a mathematical carbothermic reduction is performed in which the assumed reduction degrees for Fe, Mn, and Cr are applied.

The parameters of the RMI are then compared with the limit values specified by the cement industry. If the composition does not meet these requirements, the MM adjusts the ratio of the input materials until a suitable mixture is achieved, if possible. A summary of the parameters used in the MM can be found in Table 4.

Table 4.

Minimum and maximum requirements of the mixing model (MM), reduction, and phase modification.

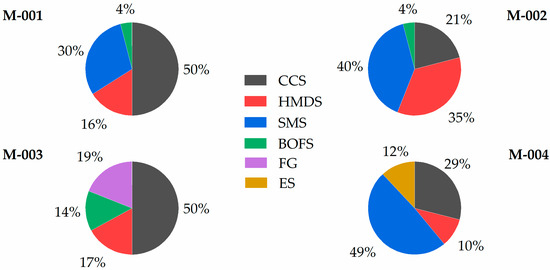

Corrective materials are required to adjust the silicon oxide and calcium oxide content based on the input material characterization and the specified requirements for the MM. Figure 3 shows the composition of the different mixtures (M-001 to M-004) depending on the variation in the input material.

Figure 3.

The initial mixture composition (M-001–M-004) of metallurgical residues and corrective materials as mass fraction in %.

2.3.2. Reduction

The carbothermic reduction of transition metal oxides (MO) is necessary to recover transition metals from metallurgical residues. Wang et al. [28] divided the carbothermic reduction into direct reduction of solid (s) and liquid (l) metal oxide (MO) with carbon (C) to metal (M) and carbon monoxide (CO)—see Equations (1) and (2)—and in indirect reduction of MO with CO to M and CO2, as shown in Equation (3).

(s)—solid; (l)—liquid; (g)—gaseous.

The carbon consumption due to the reduction of metal oxides can be estimated using Equations (1) to (3) [29,30]. Gatschlhofer [31] summarized the minimum temperatures for direct reduction of the respective oxides of the input materials. At an assumed target treatment of 1600 °C, Al2O3, MgO, and CaO cannot be reduced in the elevator resistance furnace. The occurrence of temperature peaks can theoretically lead to a partial reduction of SiO2. All other species, including Fe, Cr, and Mn oxides, are reduced according to thermodynamic considerations [31].

2.3.3. Phase Modification

The state-of-the-art technique for the blast furnace slag treatment is known as water granulation or quenching, in which the slag is directly poured into cooling water. The slag flow is fragmented into granules and cooled down rapidly. The resulting high cooling rates enable solidification as a glassy phase [32,33]. Transforming the molten slag into this amorphous state is a crucial prerequisite for utilization as an SCM similar to GGBFS because high amorphous contents typically enhance the high hydraulic reactivity of slags [34,35]. This study used a water granulation unit with a water-to-slag ratio of ten to achieve the desired cooling rates, as mentioned before [36].

3. Results and Discussion

This section outlines the experiment’s results. The findings are organized into several key sections, each focusing on different study aspects. These include the degree of reduction of transition metal oxides, the composition of the resulting metal and mineral fractions, and an exemplary material flow analysis.

3.1. Reduction Agent—Carbon

The necessary carbon mass for the carbothermic reduction of samples M-001 to M-004 was calculated with a ten percent surplus. The results, depending on the different input materials, are shown in Table 5. In general, the carbon mass increases with the transition metal oxide content of the mixture.

Table 5.

Carbon mass in gram (g) with surplus of ten percent for samples M-001 to M-004.

The results indicate a direct correlation between the carbon mass required and the transition metal oxide content in the samples. M-004 has the lowest metal input content in this case—see Figure 6.

3.2. Output Mineral Fraction—RMI

Table 6 presents the oxide content of the output mineral fraction (RMI) after thermochemical treatment. The results show that the oxide content is within the desired range for the mixing model, indicating successful calculation and mixing of input materials within the given boundary conditions.

Table 6.

The main oxide content of the output mineral fraction after thermochemical treatment as mass fraction (w) in percent (%) and basicity.

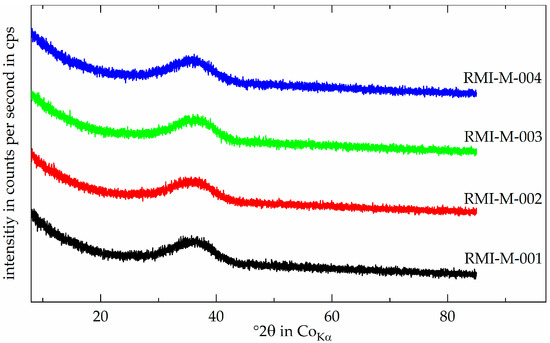

The treated RMI fractions were completely X-ray amorphous, as no discernible peaks could be found in the recorded diffractograms, shown in Figure 4. This confirms the desired amorphous nature of the output mineral fraction yielded by a successful water granulation process.

Figure 4.

Diffractograms of the output mineral fraction after thermochemical treatment. Note the absence of any X-ray reflections, indicating a completely amorphous composition.

This significant outcome indicates that the mineral fraction produced can potentially be used as an SCM [13]. Further research should focus on the mineral fraction’s long-term performance, durability, and leaching effects to fully understand its potential benefits and limitations. For example, open questions remain regarding the possible adverse effects of unreduced Mn species present in the mineral fraction (see Section 3.4) on reactivity [37,38,39,40].

3.3. Output Metal Fraction—RME

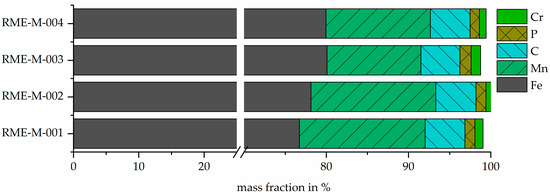

Figure 5 shows the main element contents of the output metal fractions after thermochemical treatment (RME). The results indicate that the iron content is around 80% for all mixtures, while manganese content varies between 12% and 15%. The remaining fraction primarily consists of carbon, about 4.8%; phosphorus, less than 1.4%; and chromium, less than 1.2%.

Figure 5.

The main element content of the output metal fraction after thermochemical treatment (RME) as mass fractions in % [41].

Based on the BOFS and electric arc furnace (EAF) slag investigations, the phosphorus and heavy metal contents have already been identified as a limiting factor for metal recovery. Under the intended process conditions of carbothermic reduction, phosphorus and heavy metals accumulate in the metal fraction. On the one hand, keeping the phosphorus content as low as possible is essential to ensure compliance with the production quality standards. On the other hand, the acceptable levels of heavy metals depend on the product’s specific requirements. Based on the desired substitution of scrap for the BOFS or EAF steel production, a possible strategy is to mix low-phosphorus scrap materials to achieve these quality criteria. This blending approach can also be applied to manage the heavy metal content [29,42].

3.4. Reduction Degree

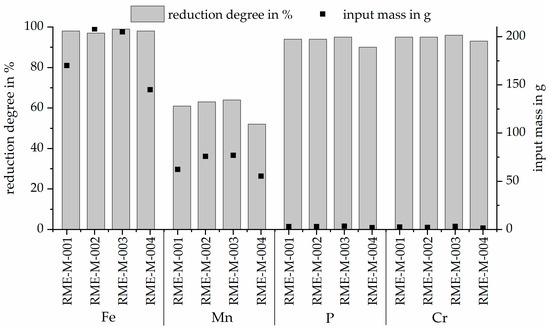

Figure 6 shows the reduction degree of Fe, Mn, P, and Cr of the metal fraction after thermochemical treatment, expressed as a percentage compared to their input mass.

Figure 6.

Reduction degree of Fe, Mn, P, and Cr after treatment in % compared to their input mass in gram (g) [41].

The average reduction degree for iron is above 97%, whereas the manganese reduction degree at approximately 60% is more inconsistent and lower than expected. The remaining Mn is presumably bound in the glass matrix of the mineral fraction, as no discernible peaks for Mn oxides or Mn-containing alloys could be found by X-ray diffraction see Figure 4. The lower reduction degree for manganese, particularly in sample M-004, may be attributed to using ES and SMS as corrective materials and the associated change in the chemical composition towards lower basicity. ES has a high LOI, affecting the mixing model’s input mass and reducing agent quantity. Additionally, SMS provides sulfur that could bind the reduced Mn in the slag matrix, reducing the overall manganese recovery. These results are consistent with previous studies by Ponak et al. [7], which also observed similar trends in manganese reduction. The reduction rates for iron and the challenges in manganese reduction highlight the need to optimize the reduction process further. Future research should focus on identifying and mitigating factors contributing to the variability in manganese reduction, such as the composition of corrective materials and their interactions during the reduction process.

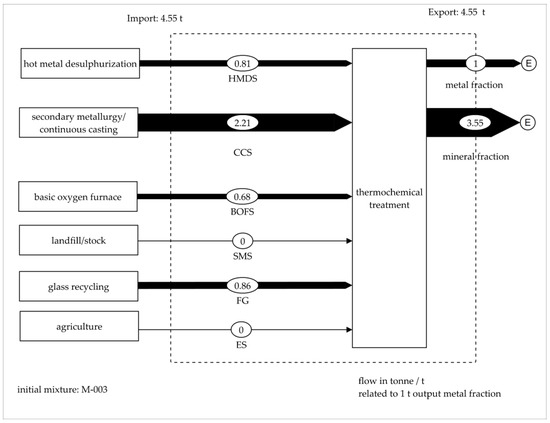

3.5. Material Flow Analysis

Based on the analysis results of M-003, a material flow diagram was created using the freeware program STAN 2.7 (subSTance flow ANalysis) [43]. The diagram, shown in Figure 7, illustrates the input materials (HMDS, CCS, BOFS, and FG) required to generate one ton of metal fraction output material. It is important to note that the carbon needed as a reducing agent was not considered as an input material. Additionally, the current analysis did not include gaseous emissions and processing losses.

Figure 7.

The material flow diagram of the thermochemical treatment of initial mixture M-003 related to one tonne of output metal fraction.

The material flow diagram in Figure 7 shows that for each tonne of output metal fraction, 4.55 tonnes of residues are recycled and diverted from landfills. This recycling process recovers valuable transition metals and produces a mineral fraction that can be utilized in the cement industry. Integrating these recycled materials into the steel and cement production processes supports the circular economy and enhances resource efficiency. The result generally represents a first approximation of the quantities and the substitution potential. For a detailed evaluation, such as a life cycle assessment (LCA), the amount of carbon, energy, emissions, and losses must be considered.

Future research should explore alternative treatment processes, such as hydrogen plasma smelt reduction, to improve the consistency of metal recovery rates. This innovative and sustainable approach could offer enhanced efficiency and environmental benefits in treating metal-rich residues [44]. On the other hand, improving the chemical modification during the process should be evaluated, focusing on the shift towards electric arc furnace steel production in Europe [45]. Therefore, understanding the interaction between process parameters and the variability of the chemical and mineralogical characteristics of the different residues is essential.

Regarding the mineral fraction, further studies are needed to explore the long-term performance and durability of binders containing cement and residue-based alternative SCMs. Additionally, the thermal history of the slag, as discussed by Ehrenberg et al. [46], and the chemical composition and cooling rate significantly influence the reactivity of the materials in cementitious systems. Understanding and controlling these parameters can enhance the material performance (e.g., reactivity and durability) and help balance product and process requirements, highlighting a pathway for slag valorization in the future.

4. Conclusions

This study demonstrates the potential of thermochemical treatment of metallurgical residues, including the carbothermic reduction of transition metal oxide and subsequent phase modification through water granulation, to recover a metal fraction and mineral fraction as secondary raw materials. These findings align with the targeted decarbonization and defossilisation of the steel and cement industry, enhancing material efficiency and supporting the transformation to a circular economy [47,48].

Future research should concentrate on optimizing the thermochemical treatment, investigating the long-term performance of the reactive binder component, and identifying potential limitations of the desired secondary raw materials.

Author Contributions

Conceptualization, K.D.-H. and A.C.K.; methodology, K.D.-H. and C.G.; validation, K.D.-H., A.C.K. and F.R.S.; formal analysis, D.W. and Z.R.; investigation, F.R.S. and D.W.; writing—original draft preparation, K.D.-H.; writing—review and editing, A.C.K.; visualization, K.D.-H. and A.C.K.; project administration, K.D.-H.; funding acquisition, K.D.-H. All authors have read and agreed to the published version of the manuscript.

Funding

The research project ‘UpcycSlag-Binder—US-B’ (PN 1316) was funded by the Styrian Future Fund and the Climate Protection Fund of the City of Graz and carried out as part of the ‘Green Tech 100-1 Earth, 0 Carbon, 0 Waste’ program.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

Grammarly (v1.2.141.1617) was used to revise the article’s language, including orthographic, grammatical, and stylistic improvements. We are grateful for the material supply and metal analysis by voestalpine Stahl Donawitz GmbH.

Conflicts of Interest

Author D.W. was employed by the company voestalpine Stahl Donawitz GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BOFS | basic oxygen furnace slag |

| CC | secondary metallurgy/continuous casting |

| CCS | continuous casting slag |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| ES | eggshell |

| FG | fine glass |

| GGBFS | ground granulated blast furnace slag |

| Gt | gigatonne |

| HMD | hot metal desulphurization |

| HMDS | hot metal desulphurization slag |

| LOI | loss on ignition |

| M | metal |

| MO | metal oxide |

| MM | mixing model |

| SCM | supplementary cementitious material |

| SMS | siemens-martin-slag/open-hearth furnace slag |

| t | tonne |

References

- International Energy Agency. Energy Technology Perspectives. 2020. Available online: https://iea.blob.core.windows.net/assets/7f8aed40-89af-4348-be19-c8a67df0b9ea/Energy_Technology_Perspectives_2020_PDF.pdf (accessed on 18 May 2022).

- Basson, E. World Steel in Figures. 2024. Available online: https://worldsteel.org/wp-content/uploads/World-Steel-in-Figures-2024.pdf (accessed on 9 March 2025).

- Chandel, S.S.; Singh, P.K.; Katiyar, P.K.; Randhawa, N.S. A Review on Environmental Concerns and Technological Innovations for the Valorization of Steel Industry Slag. Min. Metall. Explor. 2023, 40, 2059–2086. [Google Scholar] [CrossRef]

- voestalpine Stahl Donawitz GmbH. Umwelterklärung. 2018. Available online: https://www.voestalpine.com/stahldonawitz/static/sites/stahldonawitz/.downloads/de/VASD-Umwelterklaerung-2018_validiert_19.09.2018.pdf (accessed on 18 May 2020).

- Pilz, K.; Bertram, F.; Antrekowitsch, J.; Schneeberger, G. Verfahren zum Bearbeiten von Entschwefelungsschlacke. Available online: https://data.epo.org/publication-server/rest/v1.1/patents/EP3074540NWB1/document.html (accessed on 27 November 2014).

- Pichler, C.; Antrekowitsch, H.; Pilz, K. Thermische Behandlung von Entschwefelungsschlacke aus der Eisen- und Stahlindustrie. In Mineralische Nebenprodukte und Abfälle: Aschen, Schlacken, Stäube und Baurestmassen; Thomé-Kozmiensky, K.J., Thiel, S., Thomé-Kozmiensky, E., Friedrich, B., Pretz, T., Quicker, P., Senk, D.G., Wotruba, H., Eds.; TK: Neuruppin, Germany, 2017; pp. 223–237. ISBN 978-3-944310-35-0. [Google Scholar]

- Ponak, C.; Mally, V.; Windisch, S.; Holzer, A.; Raupenstrauch, H. Phosphorus Gasification during the Reduction of basic Oxygen Furnace Slags in a Novel Reactor Concept. Adv. Mater. Lett. 2020, 11, 20071535. [Google Scholar] [CrossRef]

- Windisch, S.; Ponak, C.; Mally, V.; Raupenstrauch, H. Phosphorrückgewinnung aus Klärschlammaschen mit dem RecoPhos-Prozess. Österr Wasser Abfallw 2020, 72, 421–428. [Google Scholar] [CrossRef]

- Bogala, M.R.; Zhang, M.; Reddy, R.G. Characterization of Steelmaking Desulfurization Slag. In Characterization of Minerals, Metals, and Materials 2015; Carpenter, J.S., Bai, C., Escobedo, J.P., Hwang, J.-Y., Ikhmayies, S., Li, B., Li, J., Monteiro, S.N., Peng, Z., Zhang, M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 193–200. ISBN 978-3-319-48601-7. [Google Scholar]

- Schrama, F.N.H.; Ji, F.; Hunt, A.; Beunder, E.M.; Woolf, R.; Tuling, A.; Warren, P.; Sietsma, J.; Boom, R.; Yang, Y. Lowering iron losses during slag removal in hot metal desulphurisation without using fluoride. Ironmak. Steelmak. 2020, 47, 464–472. [Google Scholar] [CrossRef]

- Schrama, F.N.H.; Beunder, E.M.; Panda, S.K.; Visser, H.-J.; Moosavi-Khoonsari, E.; Hunt, A.; Sietsma, J.; Boom, R.; Yang, Y. Optimal hot metal desulphurisation slag considering iron loss and sulphur removal capacity part II: Evaluation. Ironmak. Steelmak. 2021, 48, 14–24. [Google Scholar] [CrossRef]

- Mensah, M.; Das, A. Metallurgical resource recovery from waste steelmaking slag from electric arc furnace. Environ. Technol. 2023, 44, 260–277. [Google Scholar] [CrossRef]

- Krammer, A.C.; Doschek-Held, K.; Steindl, F.R.; Weisser, K.; Gatschlhofer, C.; Juhart, J.; Wohlmuth, D.; Sorger, C. Valorisation of metallurgical residues via carbothermal reduction: A circular economy approach in the cement and iron and steel industry. Waste Manag. Res. 2024, 42, 797–805. [Google Scholar] [CrossRef]

- Proske, T.; Rezvani, M.; Palm, S.; Müller, C.; Graubner, C.-A. Concretes made of efficient multi-composite cements with slag and limestone. Cem. Concr. Compos. 2018, 89, 107–119. [Google Scholar] [CrossRef]

- Neufert, W.; Reuken, I.; Müller, C.; Palm, S.; Graubner, C.-A.; Proske, T.; Rezvani, M. Performance of clinker-efficient cements containing granulated blast furnace slag and limestone. Cem. Int. 2018, 16, 58–66. [Google Scholar]

- Palm, S.; Müller, C.; Proske, T.; Rezvani, M.; Graubner, C.-A. Concrete application of clinker-efficient cements. Adv. Cem. Res. 2019, 31, 225–234. [Google Scholar] [CrossRef]

- International Energy Agency. Iron and Steel Technology Roadmap. Available online: https://iea.blob.core.windows.net/assets/35cef3fa-e77d-47c8-9ed3-e1ccd2c8b5f9/Iron-Steel-Roadmap-Presentation.pdf (accessed on 17 May 2022).

- Eisner, P. Stoffliche Verwertung von Eisenhütten- und Stahlwerksschlacken als Bindemittelkomponenten—Entwicklung Eines Mischungsrechners (Recycling of Iron and Steel Slags as a Supplementary Cementitious Material (SCM)—Development of a Mixing Calculator). Bachelor’s Thesis, Montanuniversität, Leoben, Austria, 2023. [Google Scholar]

- Frey, D. Working Title—Vergleich von Berechnungsmodellen der Dynamischen Viskosität—Entwicklung Einer Toolbox zur Stofflichen Verwertung von Reststoffkombinationen (Comparison of Calculation Models for Dynamic Viscosity-Development of a Toolbox for the Utilisation of Residue Combinations). Bachelor‘s Thesis, Montanuniversität Leoben, Leoben, Austria, 2025. [Google Scholar]

- DIN 51730; Testing of Solid Fuels—Determination of Fusibility of Fuel Ash. Beuth Verlag GmbH: Berlin, Germany, 1998.

- Hesse Instruments. Brochure EM301—The Heating Microscope and EMI III Software. Available online: https://www.hesse-instruments.de/wp-content/uploads/2023/12/BRO_EM301_EN_160608.pdf (accessed on 9 March 2025).

- Wang, S.; Wen, Z.; Dou, R.; Xiao, Y.; Guan, Y.; Liu, X. Numerical study on the mixing process of hot desulfurization slag and converter steel slag. Case Stud. Therm. Eng. 2022, 40, 102561. [Google Scholar] [CrossRef]

- Kovtun, O.; Korobeinikov, I.; Shukla, A.K.; Volkova, O. Viscosity of BOF Slag. Metals 2020, 10, 982. [Google Scholar] [CrossRef]

- Durdán, M.; Terpák, J.; Laciak, M.; Kačur, J.; Flegner, P.; Tréfa, G. Hot Metal Temperature Prediction During Desulfurization in the Ladle. Metals 2024, 14, 1394. [Google Scholar] [CrossRef]

- Brooks, G.A.; Hasan, M.M.; Rhamdhani, M.A. Slag Basicity: What Does It Mean? In 10th International Symposium on High-Temperature Metallurgical Processing; Jiang, T., Hwang, J.-Y., Gregurek, D., Peng, Z., Downey, J.P., Zhao, B., Yücel, O., Keskinkilic, E., Padilla, R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 297–308. ISBN 978-3-030-05954-5. [Google Scholar]

- Ehrenberg, A. Hüttensand—Ein leistungsfähiger Baustoff mit Tradition und Zukunft—Teil 2. Beton Inf. 2006, 46, 67–95. [Google Scholar]

- Austrian Standards Institute. Hüttensandmehl zur Verwendung in Beton, Mörtel und Einpressmörtel (Ground Granulated Blast Furnace Slag for Use in Concrete, Mortar and Grout)—Teil 1: Definition, Anforderungen und Konformatiätskriterien (Part 1: Definitions, Specifications and Conformity Criteria); Austrian Standards Institute: Vienna, Austria, 2006. [Google Scholar]

- Wang, G.; Zhang, H.; Wang, J.; Xue, Q. Improvement of Carbothermic Reduction of Copper Smelting Slag and Valuable Constituents Recovery. ISIJ Int. 2022, 62, 1–11. [Google Scholar] [CrossRef]

- Liu, C.; Huang, S.; Wollants, P.; Blanpain, B.; Guo, M. Valorization of BOF Steel Slag by Reduction and Phase Modification: Metal Recovery and Slag Valorization. Met. Mater. Trans. B 2017, 48, 1602–1612. [Google Scholar] [CrossRef]

- Yu, H.; Miki, T.; Sasaki, Y.; Nagasaka, T. Simultaneous Reduction of P2O5 and FeO from CaO–SiO2–FeO–P2O5 Synthesized Slag by Carbothermic Reduction. Met. Mater. Trans. B 2022, 53, 1806–1815. [Google Scholar] [CrossRef]

- Gatschlhofer, C. Phosphorus Behaviour During Carbothermal Reduction of Iron-, Chromium-, and Manganese-Rich Slags. Master’s Thesis, Montanuniversität Leoben, Leoben, Austria, 2022. [Google Scholar]

- Lin, B.; Wang, H.; Zhu, X.; Liao, Q.; Ding, B. Crystallization properties of molten blast furnace slag at different cooling rates. Appl. Therm. Eng. 2016, 96, 432–440. [Google Scholar] [CrossRef]

- Remus, R.; Roudier, S.; Aguado-Monsonet, M.A.; Delgado Sancho, L. Best Available Techniques (BAT) Reference Document for Iron and Steel Production: Industrial Emissions Directive 2010/75/EU: Integrated Pollution Prevention and Control; Publications Office: Luxembourg, 2013; ISBN 9279264753. [Google Scholar]

- Li, D.; Wu, X.; Shen, J.; Wang, Y. The influence of compound admixtures on the properties of high-content slag cement. Cem. Concr. Res. 2000, 30, 45–50. [Google Scholar] [CrossRef]

- Fu, X.; Hou, W.; Yang, C.; Li, D.; Wu, X. Studies on Portland cement with large amount of slag. Cem. Concr. Res. 2000, 30, 645–649. [Google Scholar] [CrossRef]

- Doschek-Held, K.; Raupenstrauch, H. Hochtemperaturprozesstechnik. Berg Hüttenmännische Monatshefte 2020, 165, 289–296. [Google Scholar] [CrossRef]

- Taylor, H. Cement Chemistry; Thomas Telford Publishing: London, UK, 1997; ISBN 0-7277-3945-X. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer: Dordrecht, The Netherlands, 2014; ISBN 978-94-007-7944-0. [Google Scholar]

- Blotevogel, S.; Steger, L.; Hart, D.; Doussang, L.; Kaknics, J.; Poirier, M.; Bornhöft, H.; Deubener, J.; Patapy, C.; Cyr, M. Effect of TiO2 and 11 minor elements on the reactivity of ground-granulated blast-furnace slag in blended cements. J. Am. Ceram. Soc. 2021, 104, 128–139. [Google Scholar] [CrossRef]

- Péra, J.; Ambroise, J.; Chabannet, M. Properties of blast-furnace slags containing high amounts of manganese. Cem. Concr. Res. 1999, 29, 171–177. [Google Scholar] [CrossRef]

- Krammer, A. Thermal Treatment and Cooling of Metallurgical Residues for Use as a Supplementary Cementitious Material. Master‘s Thesis, Montanuniversität, Leoben, Austria, 2022. [Google Scholar]

- Tossavainen, M.; Engstrom, F.; Yang, Q.; Menad, N.; Lidstrom Larsson, M.; Bjorkman, B. Characteristics of steel slag under different cooling conditions. Waste Manag. 2007, 27, 1335–1344. [Google Scholar] [CrossRef] [PubMed]

- Cencic, O.; Rechberger, H. Material Flow Analysis with Software STAN. J. Environ. Eng. Manag. 2008, 18, 3–7. [Google Scholar]

- Jovičević-Klug, M.; Souza Filho, I.R.; Springer, H.; Adam, C.; Raabe, D. Green steel from red mud through climate-neutral hydrogen plasma reduction. Nature 2024, 625, 703–709. [Google Scholar] [CrossRef] [PubMed]

- Ehrenberg, A. The steel production transformation process in Europe: New slag types will substitute granulated blast furnace slag. Zem.-Kalk-Gips 2023, 76, 86–97. [Google Scholar]

- Ehrenberg, A.; Romero Sarcos, N.; Hart, D.; Bornhöft, H.; Deubener, J. Influence of the Thermal History of Granulated Blast Furnace Slags on Their Latent Hydraulic Reactivity in Cementitious Systems. J. Sustain. Metall. 2020, 6, 207–215. [Google Scholar] [CrossRef]

- Steindl, F.R.; Doschek-Held, K.; Weisser, K.; Juhart, J.; Grengg, C.; Wohlmuth, D.; Mittermayr, F. Mineral Residues and By-Products Upcycled into Reactive Binder Components for Cementitious Materials. In International RILEM Conference on Synergising Expertise Towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures: SynerCrete’23—Volume 2, 1st ed.; Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D., Eds.; Springer: Cham, Switzerland, 2023; pp. 153–164. ISBN 978-3-031-33186-2. [Google Scholar]

- Steindl, F.R.; Radinger, S.; Hassan, A.; Rudic, O.; Weisser, K.; Krammer, A.; Doschek-Held, K.; Ratz, B.; Zögl, I.; Raič, S.; et al. Thermally Treated Residues and By-Products as Components of Waste-Based Alkali-Activated Materials. In Proceedings of the RILEM Spring Convention and Conference 2024, Milan, Italy, 7–12 April 2024; Ferrara, L., Muciaccia, G., Trochoutsou, N., Eds.; Springer: Cham, Switzerland, 2025; pp. 53–61, ISBN 978-3-031-70276-1. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).