Figure 1.

The photos of samples: (a) calcite; (b) chalcopyrite; (c) sphalerite.

Figure 1.

The photos of samples: (a) calcite; (b) chalcopyrite; (c) sphalerite.

Figure 2.

JK drop weight test equipment: (a) drop weight machine body diagram; (b) drop weight machine operation settings.

Figure 2.

JK drop weight test equipment: (a) drop weight machine body diagram; (b) drop weight machine operation settings.

Figure 3.

The equipment of Φ240 × 90 ball mill.

Figure 3.

The equipment of Φ240 × 90 ball mill.

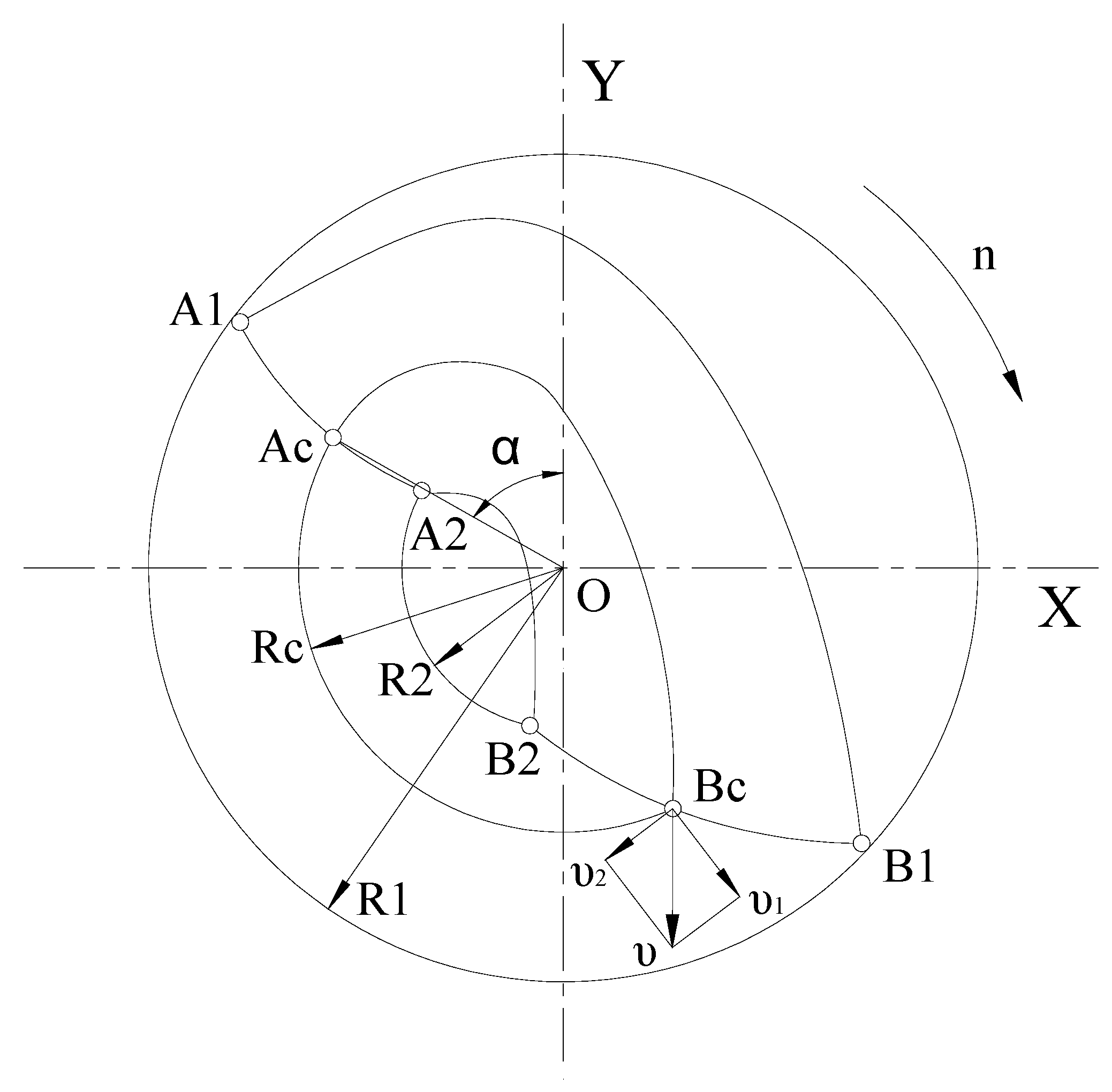

Figure 4.

The motion trajectory of the medium.

Figure 4.

The motion trajectory of the medium.

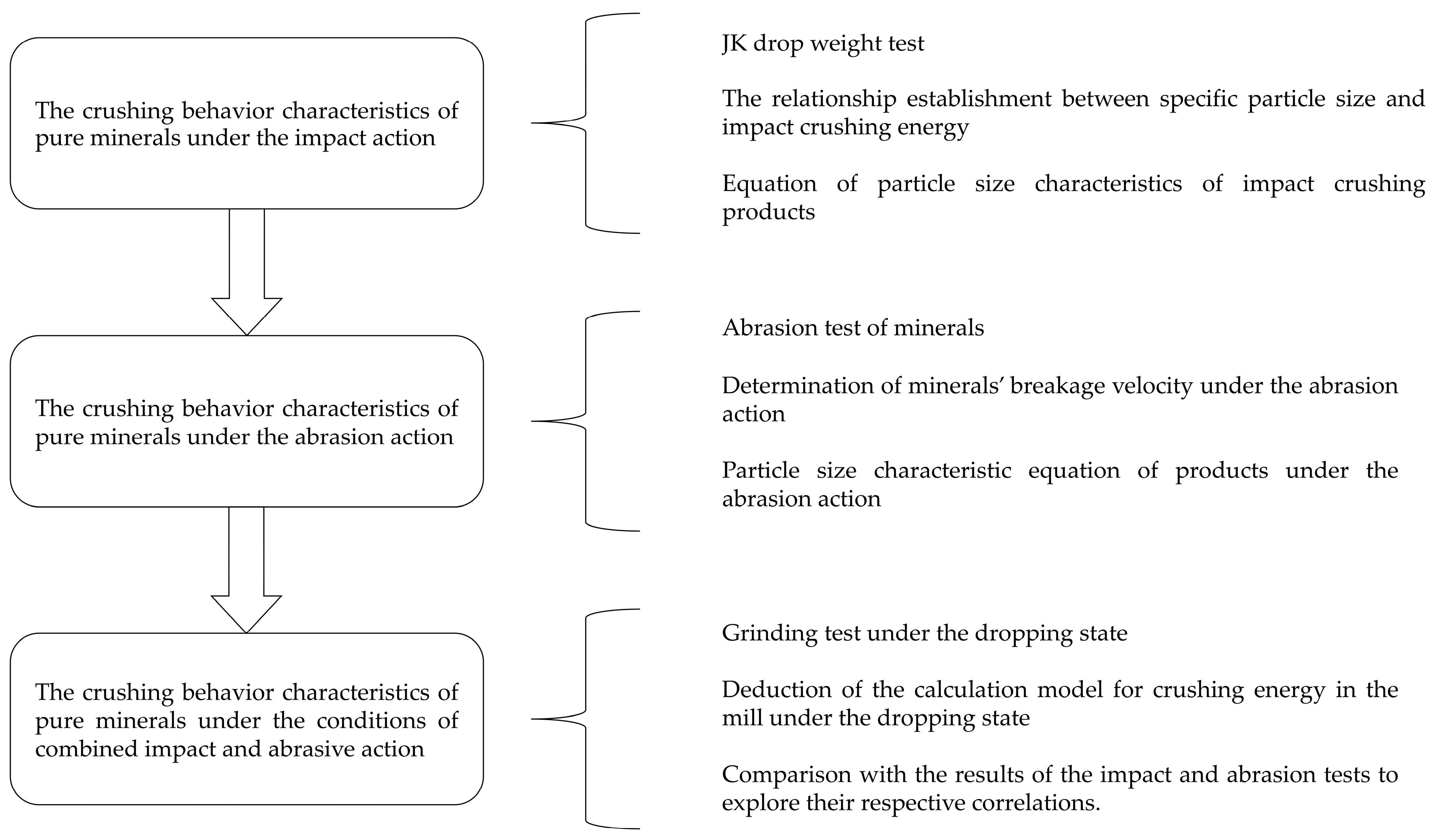

Figure 5.

Technology roadmap for this paper.

Figure 5.

Technology roadmap for this paper.

Figure 6.

Particle size distribution curve of impact crushing products under each particle size of calcite.

Figure 6.

Particle size distribution curve of impact crushing products under each particle size of calcite.

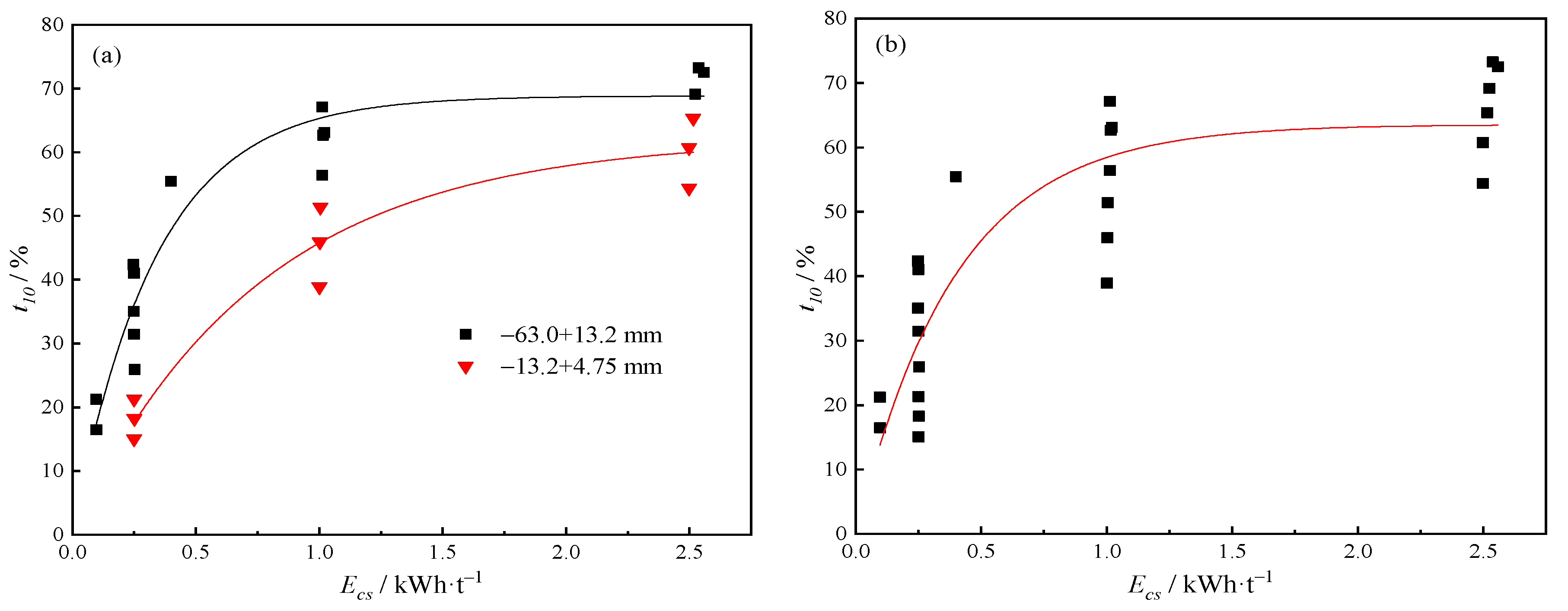

Figure 7.

Ecs-t10 relationship curve of calcite impact comminution tests: (a) comparison of two grain-level Ecs-t10; (b) full size range Ecs-t10 relationship.

Figure 7.

Ecs-t10 relationship curve of calcite impact comminution tests: (a) comparison of two grain-level Ecs-t10; (b) full size range Ecs-t10 relationship.

Figure 8.

Particle size distribution curve of impact crushing products under each particle size of chalcopyrite.

Figure 8.

Particle size distribution curve of impact crushing products under each particle size of chalcopyrite.

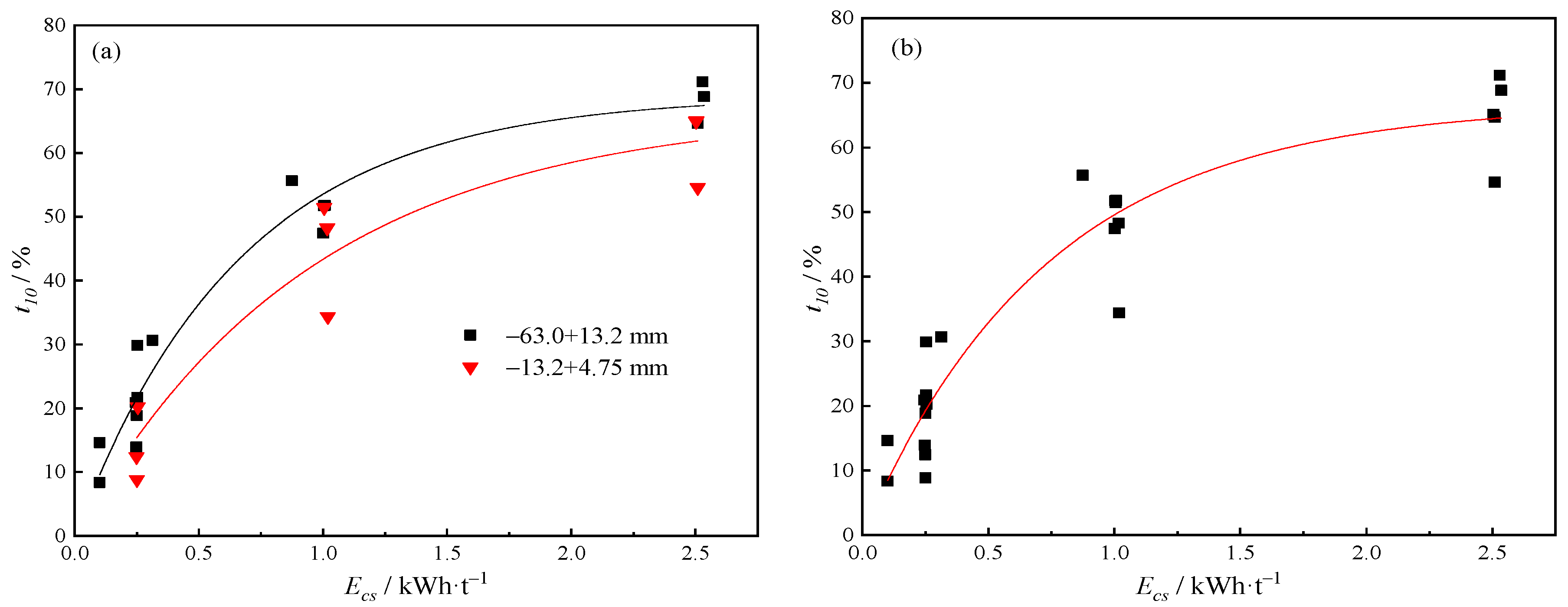

Figure 9.

Ecs-t10 relationship curve of chalcopyrite impact comminution tests: (a) comparison of two grain-level Ecs-t10; (b) full size range Ecs-t10 relationship.

Figure 9.

Ecs-t10 relationship curve of chalcopyrite impact comminution tests: (a) comparison of two grain-level Ecs-t10; (b) full size range Ecs-t10 relationship.

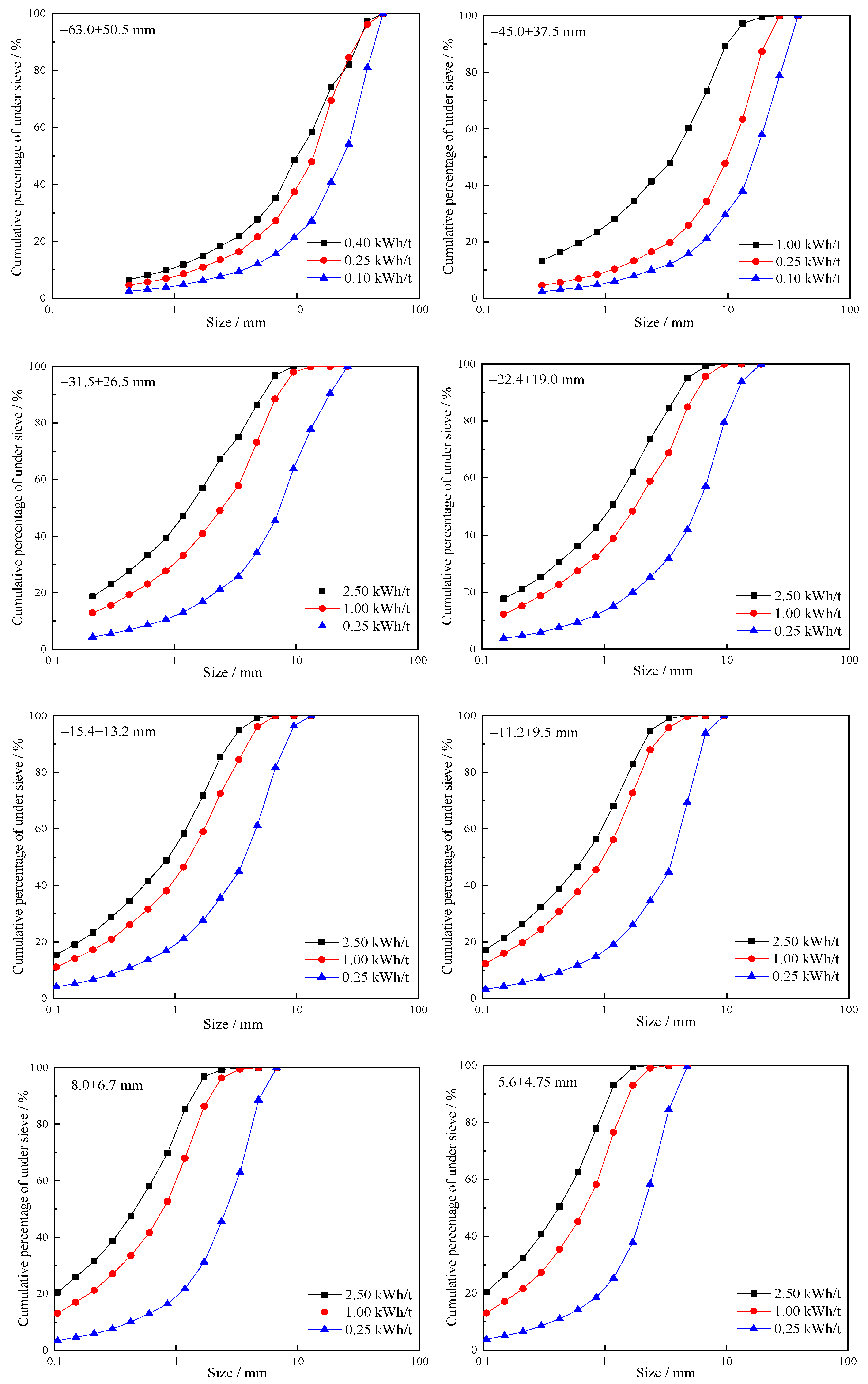

Figure 10.

Particle size distribution curve of impact crushing products under each particle size of sphalerite.

Figure 10.

Particle size distribution curve of impact crushing products under each particle size of sphalerite.

Figure 11.

Ecs-t10 relationship curve of sphalerite impact comminution tests: (a) comparison of two grain-level Ecs-t10; (b) full size range Ecs-t10 relationship.

Figure 11.

Ecs-t10 relationship curve of sphalerite impact comminution tests: (a) comparison of two grain-level Ecs-t10; (b) full size range Ecs-t10 relationship.

Figure 12.

Comparison of A × b values of three mineral ores under different particle sizes.

Figure 12.

Comparison of A × b values of three mineral ores under different particle sizes.

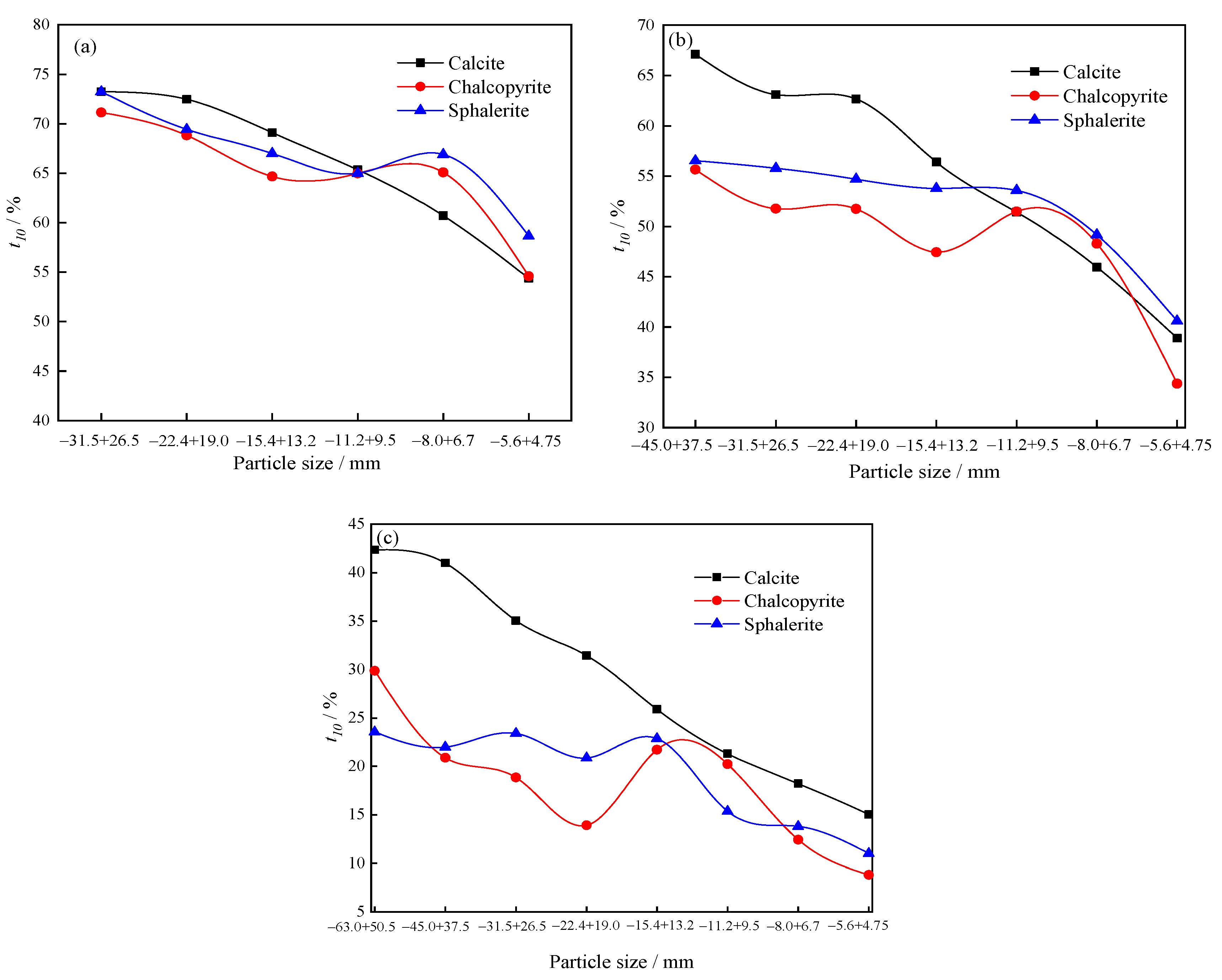

Figure 13.

Variation diagram of t10 in impact crushing products with different particle sizes: (a) Ecs = 2.50 kWh/t; (b) Ecs = 1.0 kWh/t; (c) Ecs = 0.25 kWh/t.

Figure 13.

Variation diagram of t10 in impact crushing products with different particle sizes: (a) Ecs = 2.50 kWh/t; (b) Ecs = 1.0 kWh/t; (c) Ecs = 0.25 kWh/t.

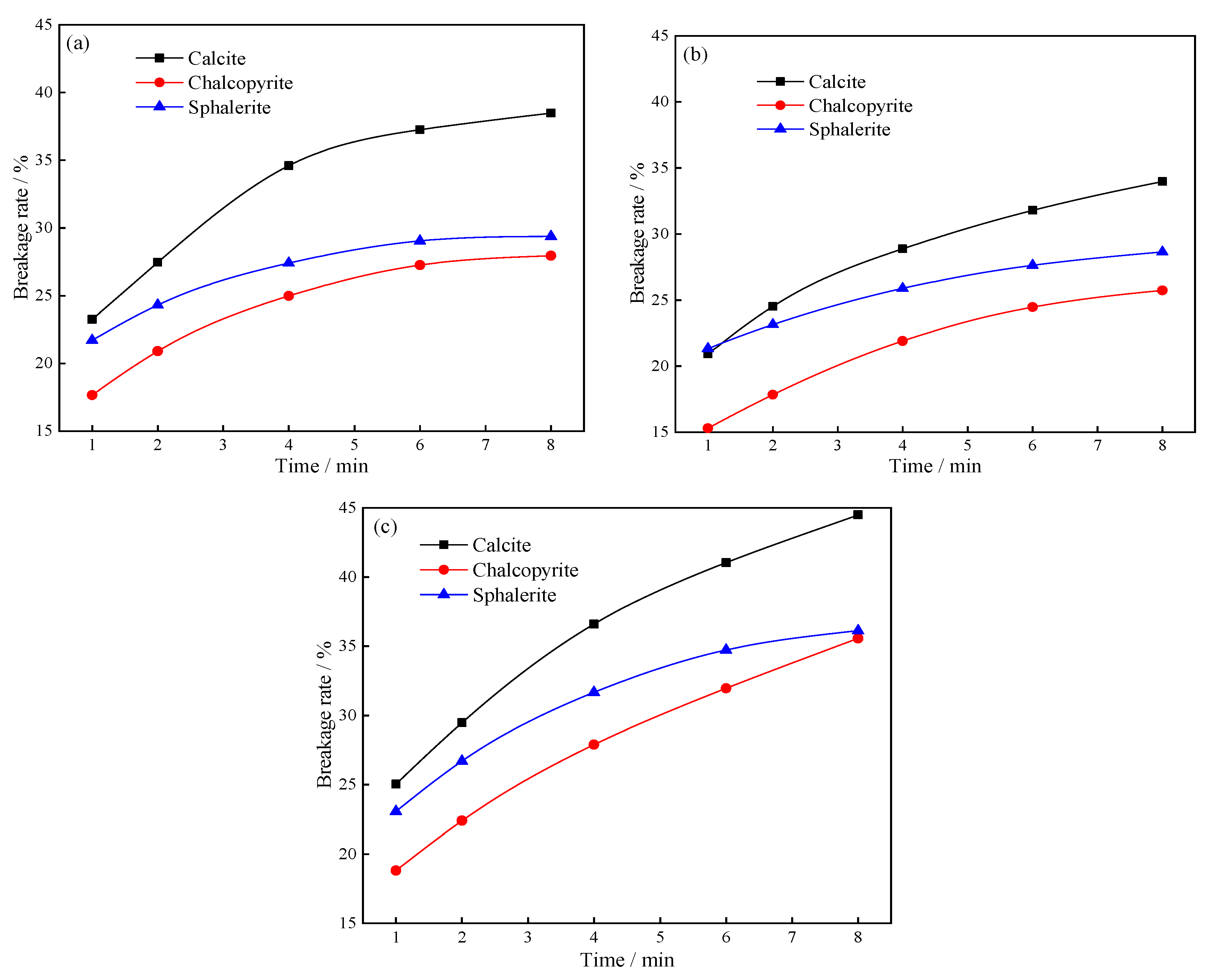

Figure 14.

Effect of grinding time on the breakage rate of three mineral ores: (a) calcite; (b) chalcopyrite; (c) sphalerite.

Figure 14.

Effect of grinding time on the breakage rate of three mineral ores: (a) calcite; (b) chalcopyrite; (c) sphalerite.

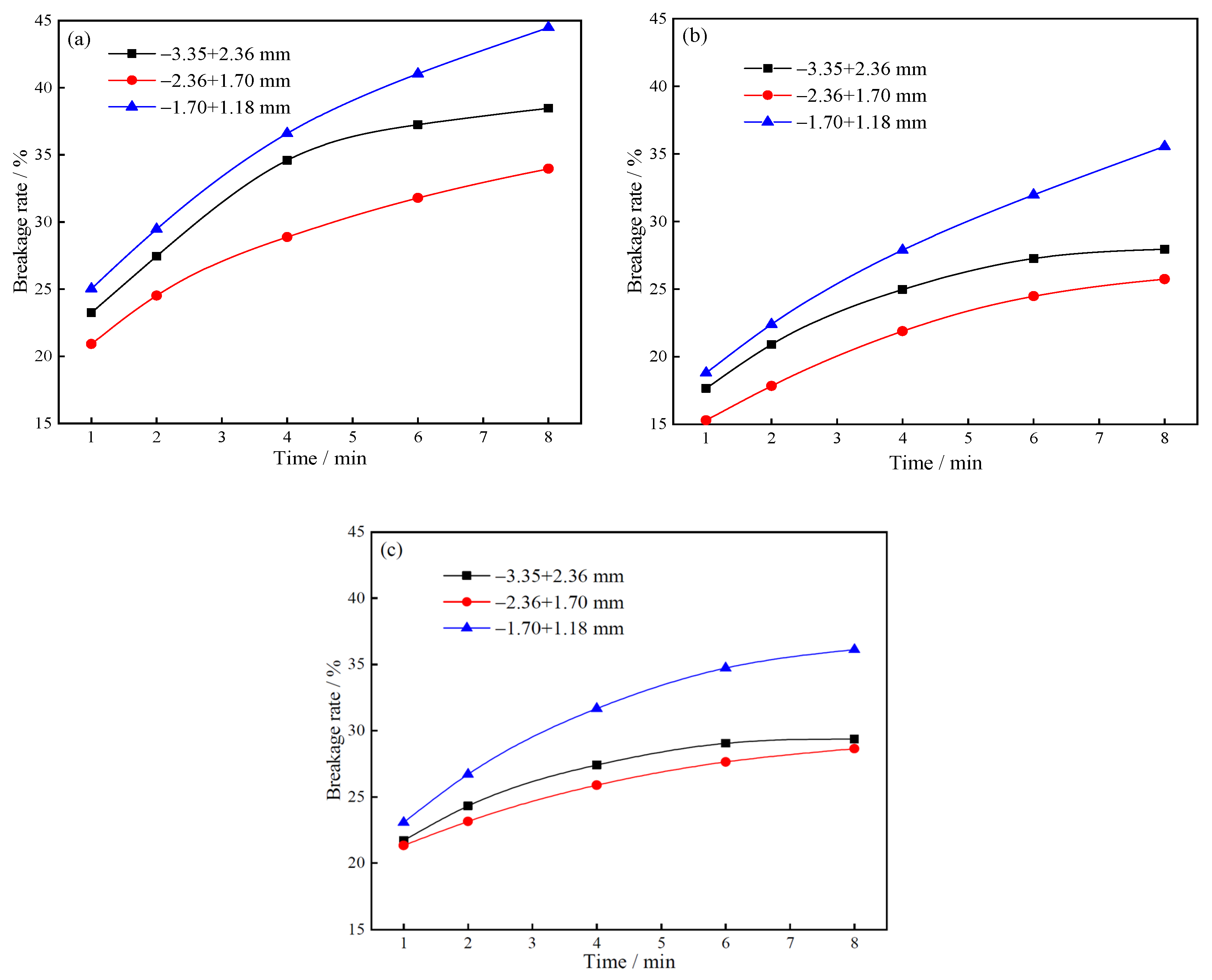

Figure 15.

Effect of grinding time on the breakage rate of different particle sizes: (a) −3.35 + 2.36 mm; (b) −2.36 + 1.70 mm; (c) −1.70 + 1.18 mm.

Figure 15.

Effect of grinding time on the breakage rate of different particle sizes: (a) −3.35 + 2.36 mm; (b) −2.36 + 1.70 mm; (c) −1.70 + 1.18 mm.

Figure 16.

Effect of grinding time on t10 of three mineral ores grinding products: (a) calcite; (b) chalcopyrite; (c) sphalerite.

Figure 16.

Effect of grinding time on t10 of three mineral ores grinding products: (a) calcite; (b) chalcopyrite; (c) sphalerite.

Figure 17.

Effect of grinding time on the t10 crushed products of different particle sizes: (a) −3.35 + 2.36 mm; (b) −2.36 + 1.70 mm; (c) −1.70 + 1.18 mm.

Figure 17.

Effect of grinding time on the t10 crushed products of different particle sizes: (a) −3.35 + 2.36 mm; (b) −2.36 + 1.70 mm; (c) −1.70 + 1.18 mm.

Figure 18.

Kinetic fitting of grinding products of three mineral ores: (a) calcite; (b) chalcopyrite; (c) sphalerite.

Figure 18.

Kinetic fitting of grinding products of three mineral ores: (a) calcite; (b) chalcopyrite; (c) sphalerite.

Figure 19.

Kinetic fitting of grinding products with different particle sizes: (a) −3.35 + 2.36 mm; (b) −2.36 + 1.70 mm; (c) −1.70 + 1.18 mm.

Figure 19.

Kinetic fitting of grinding products with different particle sizes: (a) −3.35 + 2.36 mm; (b) −2.36 + 1.70 mm; (c) −1.70 + 1.18 mm.

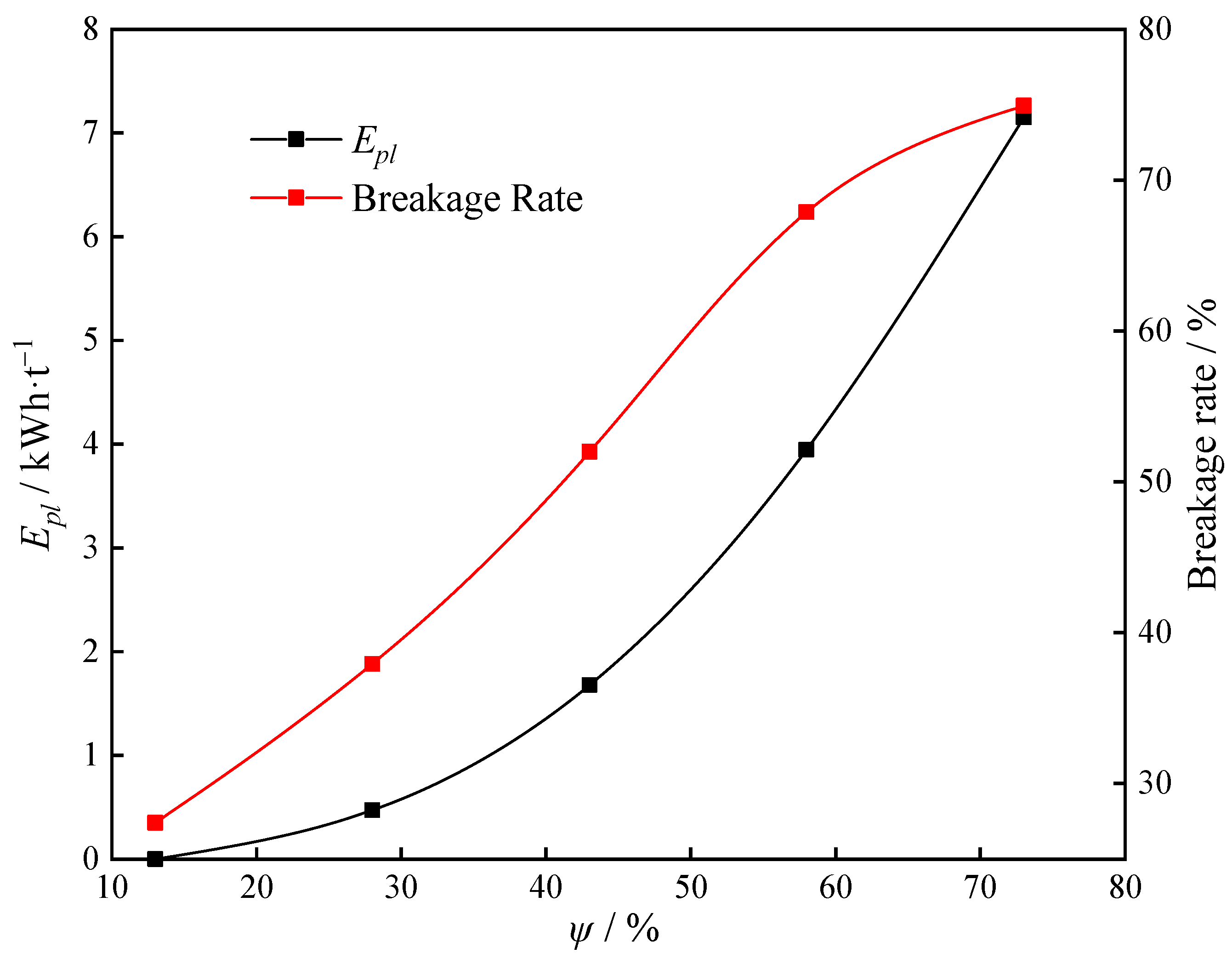

Figure 20.

The throwing-specific energy and breakage rate of calcite under different rotational rates.

Figure 20.

The throwing-specific energy and breakage rate of calcite under different rotational rates.

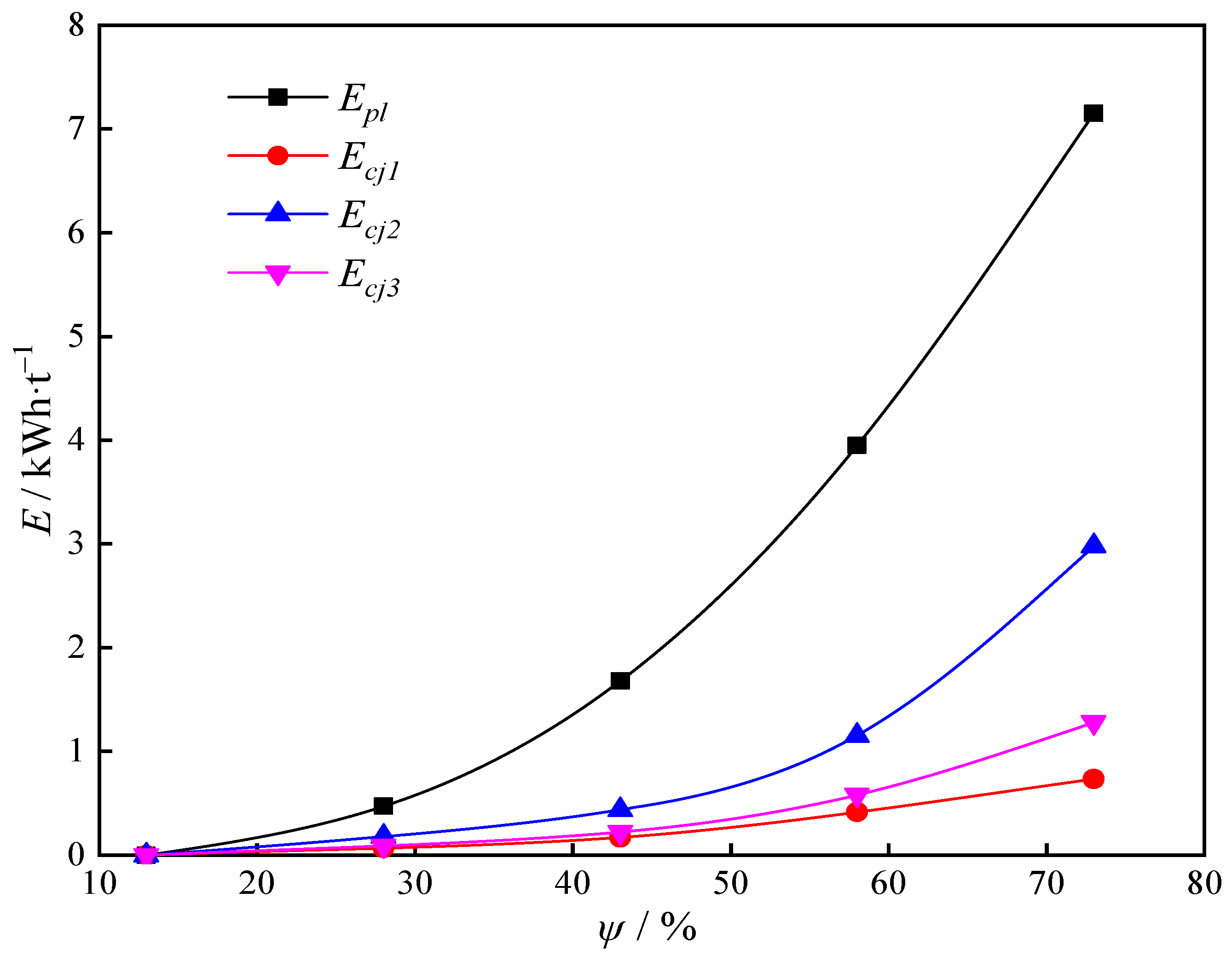

Figure 21.

Effects of different rotational rates on the throwing-specific energy and impact-specific energy of calcite.

Figure 21.

Effects of different rotational rates on the throwing-specific energy and impact-specific energy of calcite.

Figure 22.

The throwing-specific energy and breakage rate of chalcopyrite under different rotational rates.

Figure 22.

The throwing-specific energy and breakage rate of chalcopyrite under different rotational rates.

Figure 23.

Effects of different rotational rates on the throwing-specific energy and impact-specific energy of chalcopyrite.

Figure 23.

Effects of different rotational rates on the throwing-specific energy and impact-specific energy of chalcopyrite.

Figure 24.

The throwing-specific energy and breakage rate of sphalerite under different rotational rates.

Figure 24.

The throwing-specific energy and breakage rate of sphalerite under different rotational rates.

Figure 25.

Effects of different rotational rates on the throwing-specific energy and impact-specific energy of sphalerite.

Figure 25.

Effects of different rotational rates on the throwing-specific energy and impact-specific energy of sphalerite.

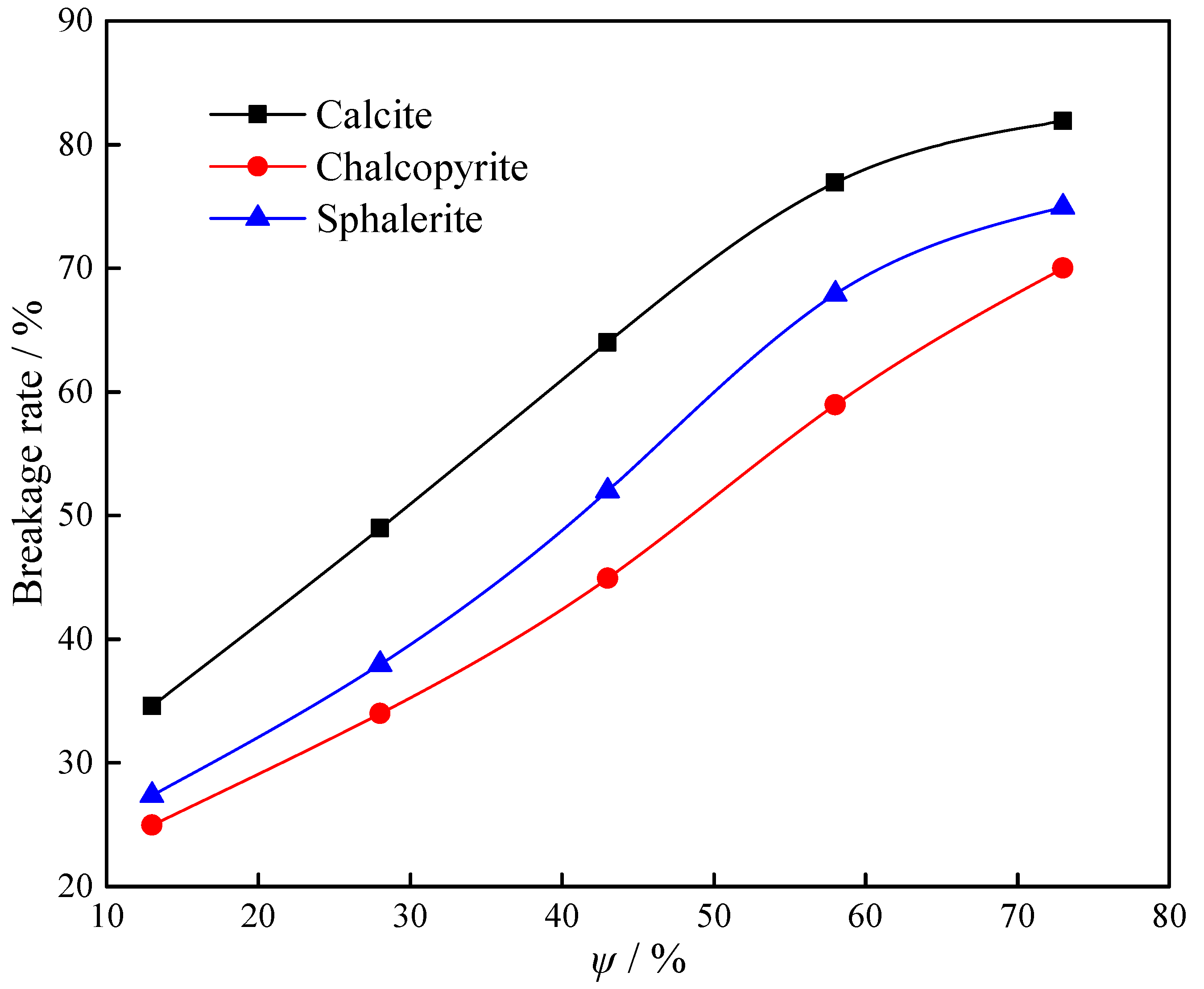

Figure 26.

Variation in three mineral ores’ breakage rates with grinding time.

Figure 26.

Variation in three mineral ores’ breakage rates with grinding time.

Figure 27.

Variation in t10 grinding products of three mineral ores with grinding time.

Figure 27.

Variation in t10 grinding products of three mineral ores with grinding time.

Table 1.

Classification of ore resistance to impact breakage based on A x b parameter.

Table 1.

Classification of ore resistance to impact breakage based on A x b parameter.

| Class of Hardness | Extremely Soft | Soft | Medium Soft | Medium | Medium Hard | Hard | Extremely Hard |

|---|

| A × b | >127 | 67~127 | 56~67 | 43~56 | 38~43 | 30~38 | <30 |

Table 2.

Design of drop weight test.

Table 2.

Design of drop weight test.

| Particle Size/mm | Calcite | Chalcopyrite | Sphalerite |

|---|

| Ecs/(kWh/t) | Number of Particles per Group | Number of Particles per Cycle | Ecs/(kWh/t) | Number of Particles per Group | Number of Particles per Cycle | Ecs/(kWh/t) | Number Of Particles per Group | Number of Particles per Cycle |

|---|

| −63.0 + 50.5 | 0.4 | 15 | 1 | 0.4 | 15 | 1 | 0.4 | 15 | 1 |

| 0.25 | 15 | 1 | 0.25 | 15 | 1 | 0.25 | 15 | 1 |

| 0.1 | 15 | 1 | 0.1 | 15 | 1 | 0.1 | 15 | 1 |

| −45.0 + 37.5 | 1.0 | 20 | 1 | 1.0 | 20 | 1 | 1.0 | 20 | 1 |

| 0.25 | 20 | 1 | 0.25 | 20 | 1 | 0.25 | 20 | 1 |

| 0.1 | 20 | 1 | 0.1 | 20 | 1 | 0.1 | 20 | 1 |

| −31.5 + 26.5 | 2.5 | 30 | 1 | 2.5 | 30 | 1 | 2.5 | 30 | 1 |

| 1.0 | 30 | 1 | 1.0 | 30 | 1 | 1.0 | 30 | 1 |

| 0.25 | 30 | 1 | 0.25 | 30 | 1 | 0.25 | 30 | 1 |

| −22.4 + 19.0 | 2.5 | 30 | 1 | 2.5 | 30 | 1 | 2.5 | 30 | 1 |

| 1.0 | 30 | 1 | 1.0 | 30 | 1 | 1.0 | 30 | 1 |

| 0.25 | 30 | 1 | 0.25 | 30 | 1 | 0.25 | 30 | 1 |

| −15.4 + 13.2 | 2.5 | 30 | 1 | 2.5 | 30 | 1 | 2.5 | 30 | 1 |

| 1.0 | 30 | 1 | 1.0 | 30 | 1 | 1.0 | 30 | 1 |

| 0.25 | 30 | 1 | 0.25 | 30 | 1 | 0.25 | 30 | 1 |

| −11.2 + 9.5 | 2.5 | 60 | 2 | 2.5 | 60 | 2 | 2.5 | 60 | 2 |

| 1.0 | 60 | 2 | 1.0 | 60 | 2 | 1.0 | 60 | 2 |

| 0.25 | 60 | 2 | 0.25 | 60 | 2 | 0.25 | 60 | 2 |

| −8.0 + 6.7 | 2.5 | 120 | 4 | 2.5 | 120 | 4 | 2.5 | 120 | 4 |

| 1.0 | 120 | 4 | 1.0 | 120 | 4 | 1.0 | 120 | 4 |

| 0.25 | 120 | 4 | 0.25 | 120 | 4 | 0.25 | 120 | 4 |

| −5.6 + 4.75 | 2.5 | 180 | 6 | 2.5 | 180 | 6 | 2.5 | 180 | 6 |

| 1.0 | 180 | 6 | 1.0 | 180 | 6 | 1.0 | 180 | 6 |

| 0.25 | 180 | 6 | 0.25 | 180 | 6 | 0.25 | 180 | 6 |

Table 3.

Specific testing conditions to study abrasion behavior.

Table 3.

Specific testing conditions to study abrasion behavior.

| Rotational Rate | Slurry Solid Concentration | Filling Rate | Grinding Times |

|---|

| 13% of the critical speed | 70% w/w | 35% | 1, 2, 4, 6, and 8 min |

Table 4.

Specific testing conditions to study the coexistence of impact and abrasion behavior.

Table 4.

Specific testing conditions to study the coexistence of impact and abrasion behavior.

| Rotational Rate | Slurry Solid Concentration | Grinding Concentration | Filling Rate | Grinding Time |

|---|

| 13%, 28%, 43%, 58%, and 73% of the critical speed | 70% w/w | 70% | 35% | 4 min |

Table 5.

Fitting results of calcite crushing parameters.

Table 5.

Fitting results of calcite crushing parameters.

| Particle Size/mm | A | B | A × b | Fitting Equation |

|---|

| −63.0 + 13.2 | 68.86 | 2.97 | 204.51 | t10 = 68.86 × (1 − exp(−2.97ECS)) |

| −13.2 + 4.75 | 62.22 | 1.33 | 82.75 | t10 = 62.22 × (1 − exp(−1.33ECS)) |

| −63.0 + 4.75 | 63.56 | 2.52 | 160.17 | t10 = 63.56 × (1 − exp(−2.52ECS)) |

Table 6.

Fitting results of chalcopyrite crushing parameters.

Table 6.

Fitting results of chalcopyrite crushing parameters.

| Particle Size/mm | A | b | A × b | Fitting Equation |

|---|

| −63.0 + 13.2 | 68.99 | 1.50 | 103.49 | t10 = 68.99 × (1 − exp(−1.50ECS)) |

| −13.2 + 4.75 | 66.67 | 1.05 | 70.00 | t10 = 66.67 × (1 − exp(−1.05ECS)) |

| −63.0 + 4.75 | 66.64 | 1.36 | 90.63 | t10 = 66.64 × (1 − exp(−1.36ECS)) |

Table 7.

Fitting results of sphalerite crushing parameters.

Table 7.

Fitting results of sphalerite crushing parameters.

| Particle Size/mm | A | b | A × b | Fitting Equation |

|---|

| −63.0 + 13.2 | 70.51 | 1.62 | 114.23 | t10 = 70.51 × (1 − exp(−1.62ECS)) |

| −13.2 + 4.75 | 68.67 | 1.09 | 74.85 | t10 = 68.67 × (1 − exp(−1.09ECS)) |

| −63.0 + 4.75 | 68.37 | 1.45 | 99.14 | t10 = 68.37 × (1 − exp(−1.45ECS)) |

Table 8.

Fitting results of grinding dynamics.

Table 8.

Fitting results of grinding dynamics.

| Feed Particle Size | Mineral Species | Fitting Equation | Goodness of Fit (R2) |

|---|

| −3.35 + 2.36 mm | Calcite | y = 0.01427 + 0.00211x | 0.986 |

| Chalcopyrite | y = 0.02069 + 0.00177x | 0.995 |

| Sphalerite | y = 0.00523 + 0.00431x | 0.996 |

| −2.36 + 1.70 mm | Calcite | y = 0.01024 + 0.00365x | 0.998 |

| Chalcopyrite | y = 0.0123 + 0.00299x | 0.997 |

| Sphalerite | y = 0.01863 + 0.00254x | 0.993 |

| −1.70 + 1.18 mm | Calcite | y = 0.01559 + 0.00435x | 0.990 |

| Chalcopyrite | y = 0.01792 + 0.0038x | 0.993 |

| Sphalerite | y = 0.02841 + 0.00356x | 0.998 |