Abstract

Hybrid hydrophobic coatings (HHCs), which combine organic and inorganic materials, have demonstrated superior weathering resistance compared to conventional organic coatings in conserving stone heritage structures. Among the inorganic components of HHCs, nanosilica is especially promising because of its ability to form durable, weathering-resistant and hydrophobic silane-based structures. This overview examined recent studies, advances, and emerging trends about nanosilica-based HHCs from 2020 to 2024 using the “Boolean strategy” and search terms “stone”, “heritage”, “hydrophobic”, and “coating”, capturing 5244 articles. After screening for titles containing “nanosilica” (470 items remained), excluding works related to “consolidants” and “cement” (171 items remained), and requiring quantitative data on formulations, methods, and performance of nanosilica-based HHCs in stone heritage structures, 16 relevant works were identified. China and Italy dominated research works on nanosilica-based HHC development, which was applied to stone heritage structures composed of carbonate materials (e.g., limestone, dolomite, and Palazzolo carbonates) and silica-rich materials (e.g., Qingshi stone, Hedishi stone, and red sandstone). Key evaluation metrics reported by multiple authors to evaluate HHC efficacy included water contact angle (WCA), total color difference (TCD), and solution pH. Moreover, ultraviolet light (UV) durability, thermomechanical stability, biocidal efficiency, and graffiti protection were achieved when nanosilica was combined with other nanomaterials. Integrating emerging technologies, such as artificial intelligence (AI), internet-of-things (IoT), and smartphones with colorimeter apps could improve accessibility, real-time monitoring and reliability of HHC testing, while adherence to standardized testing protocols would further enhance comparability and practical application across studies. Overall, this overview provides valuable insights into nanosilica-based HHCs for researchers and restorers/conservators of stone heritage structures.

1. Introduction

Heritage structures hold special historical significance and cultural importance to human society; however, many of these structures, especially those made of stone, have been continuously degrading over time due to natural weathering. In recent years, the rate of degradation of these cultural treasures have accelerated due to pollution, acid rain, vandalism, tourism and the changing climate (Figure 1) [1,2,3]. For example, Trajan’s Column in Rome has suffered significant damage from acid rain, where sulfur dioxide (SO2) and nitrogen oxides (NOx) react with calcium carbonate in the stone to form gypsum (CaSO4·2H2O), which is more soluble and easily washed away, leading to surface erosion [4,5,6]. Similarly, the Taj Mahal of India has faced rapid deterioration, including surface erosion and the accumulation of surface deposits, mainly from carbonaceous and dust particles linked to tourism and pollution [7]. Meanwhile, rising sea levels and increased storm intensity linked to climate change continue to threaten coastal heritage sites like Venice, where frequent flooding has been shown to accelerate structural damage [8]. Because heritage structures are priceless treasures, their degradation should be controlled and suppressed, and strategies for their protection must be employed [9]. Several conservation techniques have been developed in conserving cultural heritage, including water-repellent products (e.g., hydrophobic coatings), biocide treatments, surface cleaning, and desalination [10,11,12,13,14,15]. However, the majority of these strategies suffer from compatibility issues; that is, their effectiveness is largely dependent on the type of material used in the heritage structure [16].

Figure 1.

Photographs of damaged stone heritage structures: gargoyle (left) from Barbieri [17] and weathered statue (right) from Rafferty [18].

Hydrophobic coatings (HCs) are water-repellent products that are among the most popular surface protection employed to heritage preservation. Polymers, including acrylic copolymers, epoxy, polyurethane, and vinyl acetate copolymers, are the commonly used substances for HCs and serve as protective barriers against moisture, environmental pollutants and weathering agents [19]. The primary mechanism of HCs is the reaction of molecular alkyl chains with the substrate, resulting in a layer of hydrophobic molecules physically or chemically sorbed to the substrate surface, lowering its surface energy while increasing hydrophobicity (i.e., water hating characteristic) [20]. Because of this, the surface properties of heritage materials are altered, making them less prone to wetting and absorption of water while promoting fluid runoff instead of adsorption [21].

Although considered an effective protection method for heritage structures, pure organic coatings, such as acrylic-based polymers, are highly susceptible to photooxidative reactions. These reactions lead to the formation of oxidized species like γ-lactones, which cause the “yellowing” of polymer coating on stone surfaces [22]. In addition, pure organic coatings cause not only significant discoloration (i.e., high ΔE*) but are also prone to surface cracking after application [23,24]. To address these drawbacks, various additives have been explored to improve the physical properties and protective performance of HCs, resulting in the development of hybrid hydrophobic coatings (HHCs).

Among inorganic additives, nanoparticles are particularly interesting because they promote the synergistic interactions between organic components of HHCs and inorganic compounds on heritage substrate materials, improving protective capabilities and enhancing coating performance [25]. Nanosilica (n-SiO2), nano-titanium dioxide (n-TiO2), nano-zinc oxide (n-ZnO), carbon nanotubes (CNTs), graphene oxide, and nano-aluminum oxide (n-Al2O3) are the most popular (see Table 1), and HHCs containing one or combinations of these nanomaterials have been used for stones in heritage structures [26,27,28,29]. Shu et al. [27], for example, applied a TiO2-modified sol coating material (TSCM) onto a stone surface, which increased its acid resistance by 1.75 times compared with traditional coating materials such as polymerized siloxane and TiO2 pure-sol. Additionally, Mahmoud et al. [29] demonstrated a 74.6% reduction in water absorption rate by incorporating n-SiO2 and n-Al2O3 into a sol–gel system dispersed in a tetraethoxysilane (TEOS) polymer solution. The results reported by these authors were promising, achieving super-hydrophobicity with a maximum reported contact angle (CA) of 135°.

Table 1.

Properties imparted by nanomaterials on hybrid hydrophobic coatings (HHCs).

Nanomaterials have enhanced the protective capabilities of HHCs, and each additive provided distinct benefits in terms of cost-effectiveness, stability, and efficiency (Table 1). Among them, nanosilica (n-SiO2) is considered the most promising due to its affordability, wide availability, and broad applications in various sectors, including coatings, composites, energy generation, environmental remediation, cosmetics, food, agriculture, and cement fillers [32,52,53,54,55]. In particular, nanosilica is widely recognized for its effectiveness as an additive in coatings and paints for metals, wood, and stone. Although its use in stone conservation has been less common compared to other substrates, recent studies have highlighted its growing potential for protecting materials and substrates used in heritage structures.

The growing popularity of nanosilica-based coatings could be attributed to its versatility; that is, it has the ability to be functionalized to exhibit hydrophobic or even superhydrophobic behavior [16]. As reported by Artesani et al. [16], the advantage of using nanosilica is that it can be modified to bond with organosilanes or fluorinated compounds, which makes surfaces that repel water while maintaining transparency and minimal visual impact.

However, nanosilica has limitations, the most significant of which is its lack of intrinsic photocatalytic and antimicrobial properties (Table 1). This makes it less suitable as a standalone coating in environments where active degradation of organic pollutants or retardation of microbial growth is required. Additionally, pure nanosilica coatings showed lower durability under prolonged exposure against ultraviolet (UV) light without further reinforcements (e.g., addition of co-nanomaterials like Al2O3) [29]. Despite these challenges, nanosilica remains useful in heritage conservation due to its chemical inertness, high surface area, cost-effectiveness, and its ability to enhance the stability and dispersion of functional additives in HHC formulations [31,32,40,42,50,51,56].

To date, the bulk of review articles on nanosilica has been focused on cement, mortar and other cementitious materials (Table 2). For coatings, previous review papers published on nanomaterial-based coatings have focused on the antimicrobial or bactericidal properties of n-silver, n-copper, n-CuO, n-TiO2 and n-ZnO but did not include detailed discussion on nanosilica-based coatings (Table 2). To the best of our knowledge, this is the first review paper exploring the use of nanosilica-based HHCs for stone heritage structures. This significant gap presents an opportunity for further exploration, particularly in developing nanosilica-based HHCs tailored specifically to protect stone-type heritage structures.

Table 2.

A comparison of previous nanosilica review articles and the present work.

This review seeks to address the research question, “how is nanosilica-based coatings utilized in the conservation of stone heritage structures from 2020 to 2024?”. Specifically, the objectives of this review are to (i) examine the recent advances and formulations of nanosilica-based coatings for stone heritage structures, (ii) investigate the regional trends and recent applications of nanosilica-based coatings across various cultural, environmental, and geological contexts, and (iii) determine the performance of different nanosilica-based coatings based on experimental formulations and key parameters, such as pH stability, water contact angle, colorimetric changes, and other relevant physical and chemical properties.

These objectives were achieved through a systematic selection and analysis of peer-reviewed articles, focusing on studies that evaluated nanosilica-based coating formulations, methods of application (e.g., sol–gel, spraying and brushing), and performance outcomes on natural stone substrates. The findings of this work provide insights into both the versatility and current limitations of nanosilica-based coatings, helping researchers and practitioners for not only future research but also practical implementation in and strategies for stone heritage conservation.

2. Literature Review and Conceptual Background

This paper reviewed different materials and mixing procedures to formulate nanosilica-based HHCs, including their performance when applied to stone heritage substrates. Evaluation protocols, degradation factors, and performance indicators, including cracking resistance, adhesion and color changes (assessed via colorimetry), were analyzed to understand the coating performance of nanosilica-based HHCs on stone substrates.

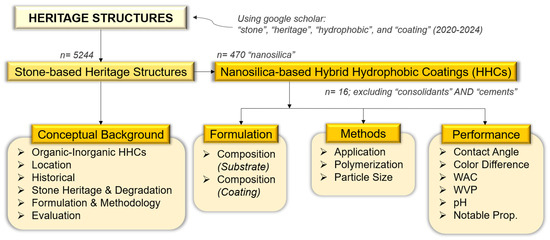

Using Google scholar as the database, a search technique called “Boolean strategy” was employed involving the use of search terms “stone”, “heritage”, “hydrophobic”, and “coating”. By setting its advanced search function to “find articles with all of the words” and limiting the date of publication between 2020 and 2024, 5244 articles were retrieved. The number of articles were narrowed down to 470 by excluding those without “nanosilica” in the title. A manual filtering of the title using Microsoft Excel further reduced the total to 131 by excluding documents related to “consolidants” and “cement”. Finally, the abstracts of the remaining articles were carefully screened for quantitative data helpful in explaining the formulations, methods, and performance of nanosilica-based HHCs in stone heritage structures, a criterion that yielded 16 eligible articles. Although “consolidants” are important in heritage conservation, we excluded them because consolidant-based studies focused on strengthening bricks or cementitious materials rather than protective coatings.

The overall discussion flow outline of this review is presented in Figure 2, showing the progression from stone degradation factors to trends in formulation, methods, and coating performance.

Figure 2.

Discussion flow outline of this review paper.

2.1. Brief Background on Organic-Inorganic Framework of Hybrid Hydrophobic Coatings

Hybrid hydrophobic coatings (HHCs) are innovative protective layers applied in the conservation of heritage stone structures. They combine inorganic nanomaterials with organic compounds, creating an integrated framework that enhances water repellency, durability, and resistance against environmental degradation [25]. This dual composition leverages the mechanical strength and chemical stability of inorganic particles with the flexibility and hydrophobicity of organic molecules [19].

One of the most commonly used inorganic nanomaterials in HHCs is nanosilica (n-SiO2). Nanosilica typically has particle sizes below 100 nanometers and is synthesized primarily via the sol–gel method [46]. This process involves the hydrolysis and condensation of silica precursors like tetraethyl orthosilicate (TEOS) under controlled pH and temperature, allowing precise control over particle size and surface functionality [61]. The surface hydroxyl groups on nanosilica facilitate strong chemical bonding with organic components, improving coating stability and adhesion [62].

Organic components typically paired with nanosilica in HHCs include alkylalkoxysilanes and methyltrimethoxysilane (MTMOS). These silanes provide hydrophobic alkyl groups that reduce surface energy and improve water repellency [63]. In addition, polydimethylsiloxane (PDMS) is frequently used due to its flexibility, excellent UV resistance, and ability to form crosslinked networks with nanosilica particles [64]. Together, these organic molecules form a continuous, flexible matrix binding the nanosilica chemical surface groups, improving not only the mechanical strength of the coating but also its thermal properties [32].

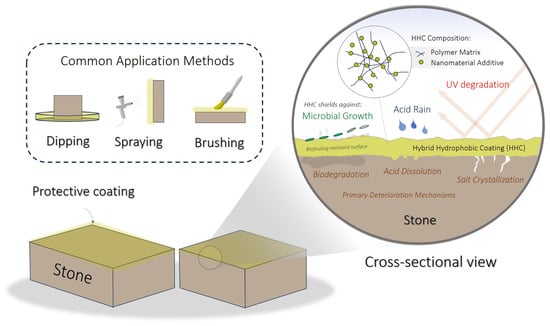

One protective property of HHCs is hydrophobicity (i.e., high WCA), which effectively prevent moisture absorption of stone materials. HHCs also offer resistance against microbial colonization, and protection from acid rain [39,40,41,42] and UV degradation [36,37,38], which are critical factors in slowing the deterioration and weathering of heritage structures. The choice of application method—such as spraying, brushing, or immersion—will be discussed in more detail in Section 2.6.

Figure 3 presents a schematic diagram of common application methods, basic composition, and key protective capabilities of HHCs. This figure illustrates the synergy between the organic and inorganic phases in creating multifunctional coatings tailored for heritage conservation.

Figure 3.

Common application methods, protective capabilities, and compositions of hybrid hydrophobic coatings (HHCs).

2.2. Trends in Nanosilica-Based Hybrid Hydrophobic Coatings for Stone Heritage Structures

The data from the Boolean search results was further analyzed for its country index using a choropleth map created with Datawrapper (https://www.datawrapper.de, accessed on 1 October 2025) (Figure 4). Different stones were treated with nanosilica-based HHCs in China, including sandstones, Hedishi stones, Qingshi stones, and Zhouqiao stones in Xi’an, Yunnan, and Henan, respectively. In Europe, nanosilica-based HHCs were applied on Comiso Stone, Lecce Stone, Trani Stone, and Carrara Marble in Spain, Portugal, and Italy. This map highlights the geographical distribution and diversity of research efforts focusing on nanosilica-based HHCs for stone conservation using the data from 2020 to 2024.

Figure 4.

Choropleth map of published journal articles on nanosilica-based hybrid hydrophobic coatings (HHCs) for stone heritage structures (2020–2024).

2.3. Historical Background of Stone Structures and Extent of Damage

In Italy, heritage structures for religious and imperial use built during the Roman Empire, especially in the cities of Rome, Venice, and Florence, are composed of various types of stones [65,66,67]. A well-known example is the Colosseum in Rome, constructed primarily from travertine limestone, which has undergone significant degradation due to historical air pollution (e.g., NOx and SOx) and acid rain [4,5,6]. Similarly, China’s long history of dynasties, including the Qin, Han, Tang, and Ming, influenced the development of enormous stone structures. One prominent example is the Yungang Grottoes, a series of Buddhist cave temples excavated along the silk road [68]. These grottoes are currently suffering from severe salt weathering and accelerated deterioration of sandstone walls, characterized by the formation of epsomite (MgSO4·7H2O), which was promoted by historical air pollution and mineral weathering [68]. These cases highlighted how ancient stone heritage structures in both China and Italy have suffered from long-term degradation, and the urgent need for protective measures to ensure their conservation and preservation.

2.4. Stones in Heritage Structures, Degradation and Conservation Strategies

Stone heritage structures are valued not only for their cultural and historical importance but also for the natural stone materials from which they were built, which reflect the geological richness of their regions. Italy, for example, is rich in high-quality stone materials, such as marble, which has been quarried for centuries to build some of the world’s most renowned ancient stone heritage structures. Famous quarries in Carrara, Tuscany, and other regions have provided marble, limestone, and stones for these monumental constructions [56,69]. For instance, the Trajan’s Column in Rome was built using 29 blocks of Luna marble sourced from Carrara, each weighing from 25 to 77 tons [70,71]. Similarly, the Florence Cathedral (Cathedral of Santa Maria del Fiore) featured green serpentine, red marly limestones, and white Carrara marble, reflecting the complex geological diversity of central Italy [72]. Meanwhile, China has vast deposits of granite, limestone, sandstone, and marble, which were used in the construction of temples, tombs, and other important historical structures [73,74,75]. The Forbidden City in Beijing, for example, was built mainly of two kinds of stones: white marble (Hanbaiyu stone) and bluish white stone (Qingbai stone) [70,71]. Similarly, the Leshan Giant Buddha, carved directly into a cliff of red sandstone in Sichuan Province, highlighted the regional geological characteristics that shaped cultural and architectural expressions in ancient China [76]. These previous works demonstrated how the availability and diversity of natural stone resources significantly influenced the construction, aesthetics, and conservation needs of stone heritage structures around the world.

Stone heritage structures are continually threatened by various environmental and biological factors, including rain-promoted dissolution, biodegradation, and salt crystallization, all of which contribute to their progressive deterioration. For example, acid rain, generated by the atmospheric interaction of water vapor and gaseous sulfur oxides (SOx), carbon dioxide (CO2) or nitrogen oxides (NOx) from industries and fossil fuel-fired powerplants [77,78], has severely degraded the travertine limestone of the Colosseum in Rome, causing surface erosion and loss of material [4,5,6]. In recent years, better air pollution regulations have reduced the impacts of acid rain to stone heritage structures. However, rainwater is naturally acidic with a pH of 5.8 [79,80], which means that prolonged exposure to rain of stone heritage structures, especially those made from carbonate minerals, could enhance acid-promoted dissolution.

Meanwhile, biodegradation was evident in the Leshan Giant Buddha in China, where the sandstone surface and surrounding mountains have been colonized by algae bacterial symbionts, lichens, bryophytes, and vascular plants [81]. Chen et al. [81] reported that nitrogen-containing pollutants enhance this microbial colonization by providing nutrients on the stone surface, accelerating biodeterioration. This is consistent with the observed bacterial community shifts highlighted by these authors, where dominant phyla, such as Cyanobacteria, Proteobacteria, Actinobacteria, and Firmicutes respond strongly to nitrogen input, suggesting a strong link between environmental nitrogen and microbially induced stone decay. Meanwhile, salt crystallization has accelerated the weathering of sandstone walls in the Yungang Grottoes in China due to the formation of salts like epsomite [68]. To mitigate these impacts, a range of conservation methods have been developed, including surface cleaning, protective coatings, biocidal treatments, and other non-destructive techniques.

Acid-promoted dissolution can be minimized by protective coatings (e.g., HHCs) on the surface of the substrate, maintaining the natural aesthetics of stone heritage structures while preventing surface deterioration even under harsh environmental conditions [82]. Meanwhile, biodegradation is controlled by utilizing biochemicals or biocides (e.g., carvacrol and curcumin [83]) that kill microorganisms present on stone surfaces [84]. Finally, salt crystallization is mitigated by applying consolidants such as alkoxysilanes [85] to macro-cracks that form due to freeze–thaw cycles, thereby reinforcing the structure and limiting further damage [86]. Overall, these techniques present potential mitigation strategies to limit and retard the degradation of stone heritage structures. This review, however, will only focus on nanosilica-based HHCs developed or adopted in studies published from 2020 to 2024, including their formulations, methods, and performance.

2.5. Formulation of Nanosilica-Based Hybrid Hydrophobic Coatings

Table 3 summarizes different protective coatings using nanosilica, with each formulation tailored for specific stone types and environmental conditions. For instance, Xu et al. [87] used dodecafluoroheptyl methacrylate (DFMA) and acrylates with nanosilica for protective applications, while specialized nanoparticles like n-ZnO and nanosilica were combined by Yumei et al. [88] to impart additional protective qualities.

In Italy, Sbardella et al. [89] adapted colloidal nanosilica as coatings for local carbonate substrates, such as Lecce stone and Carrara marble, to strengthen and protect their carbonate-based surface structure. In China, innovations include coatings developed by Xie et al. [63] using n-Al2O3 and perfluoroalkyl polyether (PFPE) to protect calcium carbonate-rich Yunnan marble. Another formulation, developed by Lettieri et al. [90], used fluororesin and nanosilica on two porous and compact calcarenite stones (Leece and Trani stones). Each formulation enhanced the durability of stone substrate and promoted the conservation of stone heritage structures by utilizing functionalized nanosilica coatings and applied by varying methods (Table 3). Depending on the type and size of nanoparticles, a specific mode of application like brushing, spraying, and dipping is required to enhance dispersion and layering of the coating [91].

Table 3.

Applications of nanosilica-based HHCs in stone heritage structures published from 2020 to 2024.

Table 3.

Applications of nanosilica-based HHCs in stone heritage structures published from 2020 to 2024.

| Ref. | Substrate Source | Substrate | Stone Composition | Coating Formulation |

|---|---|---|---|---|

| [26] | Xi’an, China | Red sandstone | Quartz, calcite, feldspar | DTMS, n-SiO2, n-TiO2, Iso-Propanol |

| [63] | Dali Prefecture, Yunnan Province, China | Yunnan marble | Calcium carbonate | Perfluoroalkylpolyether (PFPE), n-Al2O3, n-SiO2 |

| Qingshi stone | Quartz, graphite, ferric oxides | |||

| Hedishi stone | ||||

| [83] | Rosales Quarry, Albacete, Spain | Albamiel mediterranean Calcarenite stone | Calcium carbonate (CaCO3) | ISO-DGE (n-SiO2), APTS, GPTMS, IBuTMS, Carvacrol/Curcumin, TEOS |

| [87] | Zhenjiang, Jiangsu, China | Jiaoshan Stones | Not Indicated | Dodecafluoroheptyl methacrylate (DFMA), acrylates, Nanosilica (TEOS-based) |

| [88] | Not Indicated | Glass | GB a | Nanoparticles (n-ZnO) and SiO2 nanoparticles (n-SiO2) |

| [89] | Apulia, Italy | Leece stone | Calcite limestone | Colloidal n-SiO2 |

| Tuscany, Italy | Carrara marble | Limestone and dolostone minor (CaCO3 > 90%) | ||

| [90] | Apulia Region, Italy | Leece stone | Porous calcarenite | Fluorine Resin, n-SiO2 |

| Trani stone | Compact calcarenite | |||

| [92] | Portugal | Natural Portuguese stones | Calcium carbonate, quartz, plagioclase, alkali feldspar | FAKOLITH FK-7, CN2-SiO2 |

| [93] | Tuscany, Italy | Carrara marble | Calcium carbonate (CaCO3) | NanoEstel (n-SiO2), Estel 1000, TEOS |

| [94] | Henan Province, China | Zhouqiao stone | Illite, diopside, and albite | Potassium methyl silicate + n-SiO2 MTH + n-SiO2 MTI-2080 + n-SiO2 |

| [95] | Rome, Italy | Sperone stone | Volcanic scoriae | Silo N7 (functionalized n-SiO2) |

| [96] | Not indicated | Glass | GB a | Epoxy-silica Hybrid nanocomposite |

| [97] | Not indicated | Glass | GB a | Trichloromethylsilane (TCMS), n-SiO2 |

| [98] | Villa Vela, Italy | White Noto | Middle—Late Miocene Palazzolo carbonate | Fluoline HY, Wacker 290, n-SiO2 |

| Contrada Petraro, Italy | Comiso | Late OligoceneLate Miocene carbonate |

a GB: Glass-based substrates are considered non-ideal in this study, as the coating is intended for application on real stone materials.

2.6. Evaluation and Methodologies of Nanosilica-Based Hybrid Hydrophobic Coatings

The range of application methods, including brushing, spraying, and dipping, are selected based on the stone’s characteristics and the specific formulation as presented in Table 4. For instance, Yumei et al. [88] and Armal et al. [92] applied nanosilica with average size of around 12 nm through spraying, providing a uniform layer of protection ideal for delicate surfaces. In comparison, Jokilehto et al. [67] used the brushing method to ensure a uniform application to the substrate of HHCs composed of water-based or methanol-based nanosilica (15 nm) solutions, as shown in Table 4.

Table 4.

Nanosilica particle sizes, polymerization processes, and application methods used in HHCs applied to stone heritage structures.

For larger nanosilica particles (40–50 nm), brushing is preferred to form a durable, water-based coating. Emulsifier-based formulations applied through immersion offered full coverage for stones that can handle extended liquid contact, as reported with Yunnan marble [63]. Generally, the method of application strongly controls coating homogeneity. Spraying, for example, can effectively spread out and produce a uniform layer; however, according to Antonini et al. [99], the disadvantage of spraying was the production of respiratory hazards. Spraying requires the atomization of particles, inadvertently dispersing and suspending nanosilica and organic compounds in the air, which when inhaled could lead to serious health hazards, such as respiratory irritation and lung cancer [93]. Most importantly, since application methods strongly influence the results of property testing, values obtained from different approaches should not be directly compared but rather interpreted within the context of their respective methodologies.

To evaluate HHC performance systematically, several European Norm (EN) standards are commonly employed. These standards provide quantitative measures of water repellency, water absorption by capillarity, and aesthetic compatibility of treated substrates. Table 5 summarizes the key EN standards used for stone protection.

Table 5.

EN Standards for the Evaluation of Nanosilica-Based Hybrid Hydrophobic Coatings on Stone.

These standards collectively provide a comprehensive framework for assessing HHC effectiveness, ensuring that coatings impart sufficient water repellency, limit water ab-sorption, maintain substrate breathability, and preserve visual appearance. By following these standardized tests, researchers can systematically compare different formulations and application methods, supporting the selection of the most suitable treatments for heritage stone conservation. Unfortunately, many studies do not follow these standardized methods, therefore limiting comparability and reproducibility of results.

3. Performance Evaluation of Nanosilica-Based Hybrid Hydrophobic Coatings

The effectiveness of nanosilica-based hybrid hydrophobic coatings (HHCs) is commonly assessed through a range of measurable properties that reflect their protective performance on stone heritage materials. These include surface wettability, chemical stability, color difference, water uptake, and vapor permeability, as well as other relevant physical and chemical characteristics. The following subsections present these evaluation methods to determine coating efficiency and suitability for long-term conservation applications. It should be noted, however, that some presented studies do not follow standardized EN protocols; limiting comparability and reproducibility of result.

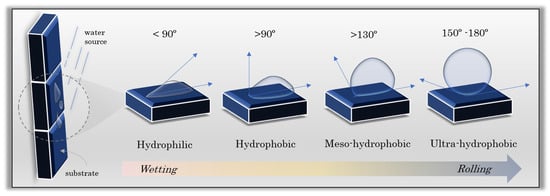

3.1. Water Contact Angle

The impacts of protective coatings on the water contact angle (WCA), color, and other properties across various substrates are summarized in Table 6. WCA is determined by placing a droplet of water on the coated surface and measuring the angle formed between the droplet’s edge and the surface using a contact angle goniometer [105]. Higher WCA, often above 90° (Figure 5), indicate strong hydrophobicity, a key criterion for minimizing water adsorption on stone substrates. For instance, the WCA for treated Lecce stone in the study of Sbardella et al. [92] reached 94.6° using nanosilica modified in methanol, enhancing its drying behavior, reducing water absorption coefficient by capillary action, and increasing water absorption resistance. In comparison, in the same study, the treated Carrara marbles with SiO2-free formulation achieved the lowest WCA of 55.0°. Note that in Table 6, SCA refers to static contact angle, which is measured at equilibrium. It is similar to WCA, but WCA specifically uses water as the test liquid, while SCA can use various liquids depending on the study.

Table 6.

Material properties, pH levels, and performance characteristics of nanosilica-based HHCs published from 2020 to 2024.

Figure 5.

Different levels of surface hydrophobicity based on water contact angles (WCA).

In China, nanosilica-based treatments (PFPE + nanosilica) on Yunnan, Qingshi, and Hedishi stones by Xie et al. [63] achieved SCAs between 165.4° and 169.6°, with additional details that reported the effectivity of the formulation against surface thermal stress, essential for stability under fluctuating temperatures due to seasonal changes. In addition, the protection of Trani stone using nanoF (a water-based fluorine resin with 10% nanosilica) proposed by Lettieri et al. [90] demonstrated strong anti-graffiti properties and resilience against surface contaminants with a WCA of 139°. The highest WCA found in this review was achieved by Peng et al. [26], who utilized Silo N7 (functionalized nanosilica) to protect red sandstone in Xi’an, China, and the coating exhibited improved protective properties like UV shielding. It is also interesting to note that other authors have induced hydrophobic behavior on stone substrates like Luci et al. [93] using Estel1000 (CTS srl, Altavilla Vicentina, Italy) on Carrara marbles and Irizar et al. [83] using amino-functionalized mesoporous nanosilica mixed with biocidal chemicals like Carvacrol and Curcumin applied on Mediterranean calcarenite stone, that resulted to WCA of 101° and 105°, respectively.

The total color difference (TCD) test is a fundamental method used to assess surface changes in the conservation of heritage structures. Generally, the threshold of color difference in the conservation of cultural heritage is 5.0 [86]. Multiple countries have adopted this criterion and are pushing efforts to maintain and standardize the usage of non-destructive methods, promoting conservation while maintaining the natural aesthetics of structures.

In this test, the color difference is measured by a fluorescent whiteness meter wherein the CIE L*a*b* color space is used, and color changes are evaluated by total color difference (∆E*). The ∆E* between the samples is calculated using Equation (1)

where coordinates of the uncoated sample and [106].

As listed in Table 6, Renda et al. [98] applied Fluoline HY, Wacker 290, and nanosilica to the white Noto of Villa Vela, Italy, and Comiso stone of Contrada Petraro, Italy, yielding a value of 7.0 for white Noto and 6.0 for Comiso stone. The lowest TCD was reported with the formulation developed by Lettieri et al. [90] where the value was 0.54. This was lower than the highest TCD value of 11.0 reported by Armal et al. [92], who noted that high TCD values made the appearance of the substrate very different from its original state. In consideration of the threshold limit of TCD value (TCD < 5.0), only the studies of Peng et al. [26], Sbardella et al. [89], Luci et al. [93], Zhang et al. [94], Lettieri et al. [90], and Pelosi et al. [95] reported color changes within acceptable limits, each using functionalized nanosilica in combination with different materials, such as water-based fluorine, DTMS, carvacrol, or curcumin, resulting in changes below the level perceptible to the human eye.

3.2. Water Absorption by Capillarity

Water absorption by capillarity is an important parameter for evaluating the effectiveness of protective treatments on porous stone. It reflects a coating’s ability to limit the penetration of water through the stone’s pores, which is crucial for preventing moisture-related deterioration such as salt crystallization, freeze–thaw damage, and biological growth [11,68,87].

Among the studies reviewed, Sbardella et al. [89] reported quantitative water absorption for Leece stone and Carrara marble, with values of 15,840 g/m2 and 1160 g/m2, respectively (Table 6). Zhang et al. [94] reported absorption as percentages for different formulations—potassium methyl silicate, waterborne acrylic emulsion, and nano-titanium dioxide sol (MTI-2080)—with 17.83%, 19.44%, and 19.87%, respectively, without providing mass per area data. Meanwhile, all formulations reported by Xu et al. [87] demonstrated promising properties, such as effective salt resistance and waterproof performance; however, they showed a 23% reduction in air permeability compared to the untreated sample and exhibited high light transmittance with limited radiation shielding capability. Other studies, including Armal et al. [92], Renda et al. [98], and Pelosi et al. [95], presented changes in capillary water absorption (CWA) graphically but did not report numerical values. These findings highlight the variability in reporting practices and emphasize the need for standardized measurements, such as EN 15801 [102], to enable consistent comparison of coating performance across different stone types and formulations. Overall, while many coatings exhibit strong hydrophobicity, a balance between water resistance, vapor permeability, and optical performance remains essential for long-term stone conservation.

3.3. Water Vapor Permeability

Water vapor permeability (WVP) is a key property in evaluating protective coatings for porous stone. It reflects the ability of a treated substrate to allow water vapor to pass through while preventing liquid water penetration, ensuring the stone can “breathe”, reducing the risk of moisture accumulation.

In this test, the mass of water vapor transmitted through a coated specimen is measured over time, and WVP is calculated using the formula:

where ΔM is the mass of water vapor transmitted (g), t is the test duration (24 h), and A is the exposed surface area of the specimen (m2) [107].

Among the studies reviewed, only Xie et al. [63] evaluated water vapor permeability (transpirability) on marble, Qingshi, and Hedishi stones treated with 101S, a clear and transparent liquid coating mainly composed of perfluoroalkylpolyether (PFPE). Different nanoparticle dispersions were incorporated, including 1.5 mg/mL Al2O3 and 0.1–1.0 mg/mL SiO2 [63]. The results showed that the reduction in water vapor permeability was slightly higher for Qingshi stone, with 53.1% and 50.5% reduction when treated with 1.5 mg/mL Al2O3 and 1.0 mg/mL SiO2, respectively, while Hedishi exhibited reductions of 55.5% and 40.2% for 0.5 mg/mL Al2O3 and 1.0 mg/mL SiO2. Marble treated with the nanosilica colloidal suspension showed a 26% reduction in WVP. These findings indicate that the addition of nanoparticles enhances the barrier properties of 101S coatings while maintaining some breathability, ensuring effective protection of stone substrates without completely restricting moisture transfer.

3.4. pH

The effectiveness of surfactants used in coatings is influenced by the acidity or basicity of the working environment. Sayan et al. [108] demonstrated that pH significantly affected the adhesion behavior of sodium oleate on calcium carbonate surfaces. Moreover, these authors reported improved adsorption of sodium oleate at the pH range of 9 to 11. However, at pH values higher than 11, the adsorption of sodium oleate decreased sharply, along with its concentration. As summarized in Table 6, only Zhang et al. [94] reported the pH of the coating used in treating stone heritage structures. This previous work conducted experiments at three different pH levels (2, 7, and 10) using various mixtures of nanosilica and applied to Zhouqiao stones in Henan Province, China. The resulting WCA values at each pH level was not presented; however, the total color difference showed that the mixture at pH 7 had the lowest color difference of 1.39. In contrast, HHC at pH 10 exhibited the highest total color difference of 8.80 (Table 6).

3.5. Other Notable Properties

Different formulations exhibited distinct protective properties depending on the additives used alongside nanosilica. These properties include UV resistance, chemical resistance, thermal stability, and antimicrobial activity, which are essential for ensuring the long-term performance of protective coatings on stone heritage substrates. It should be noted, however, that the studies do not follow a standardized testing procedure, and the methods used to evaluate each property vary between articles.

UV resistance refers to a coating’s ability to withstand degradation from prolonged exposure to UV radiation, thus, preserving surface integrity and appearance [36,37,38]. Chemical resistance is the capacity of the coating to resist deterioration or reaction when exposed to aggressive substances such as acids, alkalis, environmental pollutants or salts [39,40,41,42]. Meanwhile, thermal stability is the ability of a material to maintain its structural and functional integrity under elevated temperatures [32,43,44,45]. Finally, antimicrobial activity refers to the inhibition or reduction of microbial growth, which is particularly important in preventing biodeterioration of porous stone materials [48,49].

As summarized in Table 1, the incorporation of nanosilica with various functional materials has been shown to impart one or more of these advantageous properties. The specific characteristics achieved by each formulation are detailed in Table 4. Notably, UV durability was significantly enhanced when nanosilica was combined with nanoparticles, such as ZnO, nano-Al2O3, and nano-TiO2, as demonstrated in the studies of Yumei et al. [88], Xie et al. [63], and Peng et al. [26]. Thermomechanical properties were reported in the studies of Sbardella et al. [89], Xie et al. [63], and Irizar et al. [83], showing similar protective stability to UV-resistant coatings but with the added capability of withstanding significantly higher temperatures without cracking, delamination, or structural failure. In addition, Lettieri et al. [90] developed a formulation combining fluorine resin with nanosilica that achieved anti-graffiti performance, effectively protecting compact calcarenite (Trani stone) in the Apulia region of Italy by preventing pigment penetration and allowing for easy surface cleaning.

Overall, the nanomaterials determining the unique characteristics of the formulations emphasized the importance of tailored protective strategies to match stone types and environmental needs. Previous works have highlighted the effectiveness of nanosilica-based HHCs and confirmed their efficacy through WCA measurements and specific property tests like biocidal efficiency and colorimetry. It should be noted, however, that most studies do not follow standardized EU protocols (e.g., EN 15802 [101], EN 15801 [102], and EN 15803 [103]), limiting comparability and reproducibility of results. Adopting these standards would enable more consistent evaluation and provide clearer guidance for practical conservation applications. Taken together, these findings demonstrate that nanosilica-based HHCs offer versatile, durable, and effective protection, making them potentially effective tools for the preservation of stone heritage structures.

4. Future Research Directions

Conserving heritage structures is a complex process because the variable compositions and types of heritage materials require specific and tailored strategies. Multiple methods are currently available, most of which are designed to be non-destructive, minimizing physical or chemical damage while addressing environmental and anthropogenic degradation of stone substrates. For stone heritage conservation, strict criteria and protocols regarding the property testing should be implemented. These protocols may need to be adapted for each type of stone (e.g., tuff, coral rock, limestone, sandstone, and marble) because differences in composition, mineralogy, porosity, and microstructure influence how coatings interact with the substrate and how water, vapors, and other environmental factors penetrate the stone.

Although advanced materials, such as nanomaterials offer significant benefits, they also pose potential risks to human health. Therefore, future research should prioritize safety regulations and comprehensive risk assessments related to their formulation and application. For instance, the atomization of nanosilica-based HHCs when applied by spraying may generate airborne particles that pose respiratory hazards, potentially leading to illnesses like silicosis [109]. In addition, future research on stone heritage conservation should explore emerging technologies, such as the integration of artificial intelligence (AI) and internet-of-things (IoT) for analyzing patterns and trends in risk management and environmental monitoring of cultural heritage sites [110]. The use of smartphone-based colorimeter applications also showed promising potential for on-site monitoring of surface color changes. Recent studies have demonstrated that apps like Color Grab can provide accurate CIELAB values comparable to those obtained from portable colorimeters, offering a cost-effective and accessible tool for field conservation work [111]. These insights highlight the importance of pursuing future research directions that integrate innovation, technological advancements, and health safety toward developing next-generation heritage conservation techniques.

5. Summary

This paper reviewed published journals from 2020 to 2024 utilizing nanosilica as an additive to formulate hybrid hydrophobic coatings (HHCs). Here are the findings of this study:

- Research articles related to nanosilica-based hybrid hydrophobic coatings (HHCs) are increasing annually from 2014 to 2024.

- The majority of research articles on stone heritage structure conservation came from China and Italy, which could be attributed to the large number of ancient stone heritage structures in these countries.

- Materials used in stone heritage structures are geological materials available locally, such as carbonate materials (e.g., limestone, dolomite, and Palazzolo carbonates) and silica-rich materials (e.g., Qingshi stone, Hedishi stone, and red sandstone).

- The highest water contact angle (WCA) of 150.7° with a low total color difference (TCD) of 3.07 was achieved using Silo N7, a functionalized nanosilica coating applied to red sandstone.

- Using a combination of nanosilica and fluororesin, the Lecce stone achieved a high WCA of 142° and a low total color difference (TCD) value of 1.39, indicating the formulation’s suitability for coating calcareous stones.

- Different pH levels in the coating affected the TCD values, with pH 10 yielding a TCD of 8.80 and pH 2 resulting in a lower TCD of 3.64.

- Color difference analysis is essential in heritage protection to ensure aesthetic preservation, and coatings should maintain a TCD below the perceptible threshold for the human eye (TCD < 5).

- Notable properties achieved with nanosilica, in combination with other nanomaterials, include UV durability, thermomechanical stability, biocidal efficiency, and graffiti protection.

- Future research on HHC for heritage structure conservation should address potential physical and environmental hazards, while integrating emerging technologies such as AI, IoT, and smartphones to enable accessible heritage conservation testing.

- It should also be emphasized that despite the promising results reported by previous studies on stone heritage conservation, the lack of standardized testing protocols limited comparability and reproducibility. Establishing and following standardized methodologies would enable more consistent evaluation and provide clearer guidance for practical conservation applications.

Author Contributions

Conceptualization, R.L.J., A.A. and C.B.T.; validation, R.O., K.B.S. and A.B.; investigation, A.B. and M.S.; resources, T.P., M.S. and R.O.; data curation, M.S. and K.B.S.; writing—original draft preparation, R.L.J. and A.B.; writing—review and editing, C.B.T., M.V.-T. and A.A.; visualization, R.L.J., K.B.S., M.V.-T. and R.O.; supervision, C.B.T., A.A. and T.P.; project administration, C.B.T. and R.L.J.; funding acquisition, C.B.T., M.V.-T. and T.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Department of Science and Technology–Philippine Council for Industry, Energy, and Emerging Technology Research and Development (DOST-PCIEERD) through EPOCH Project 2 (Grant Number: 1212387) and the Department of Research of Mindanao State University-Iligan Institute of Technology (MSU-IIT), Iligan City, Philippines (SO#00228-IIT).

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors express sincere appreciation to the editors and anonymous reviewers for their valuable comments and to the journal’s editorial team for their professional assistance. Gratitude is also extended to colleagues from Mindanao State University–Iligan Institute of Technology (MSU-IIT) for their support, and to the Department of Science and Technology–Engineering Research and Development for Technology (DOST-ERDT) program for the graduate scholarship of R.L.J.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CNT | Carbon Nanotubes |

| DFMA | Dodecafluoroheptyl Methacrylate |

| DTMS | Dodecyltrimethoxysilane |

| HC | Hydrophobic Coating |

| HHC | Hybrid Hydrophobic Coating |

| MTH | Methyltrimethoxysilane |

| NP | Nanoparticles |

| PFPE | Perfluoroalkyl polyether |

| SA | Surface Area |

| SCA | Static Contact Angle |

| TCD | Total Color Difference |

| TEOS | Tetraethoxysilane |

| UV | Ultraviolet |

| WCA | Water Contact Angle |

References

- Patil, S.M.; Kasthurba, A.K. Weathering of stone monuments: Damage assessment of basalt and laterite. Mater. Today Proc. 2020, 43, 1647–1658. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, R.; Ahuja, I.P.S.; Hashmi, M.S.J. On technological solutions for repair and rehabilitation of heritage sites: A review. Adv. Mater. Process. Technol. 2020, 6, 146–166. [Google Scholar] [CrossRef]

- Blavier, C.L.S.; Huerto-Cardenas, H.E.; Aste, N.; Del Pero, C.; Leonforte, F.; Della Torre, S. Adaptive measures for preserving heritage buildings in the face of climate change: A review. Build. Environ. 2023, 245, 110832. [Google Scholar] [CrossRef]

- Mehta, P. A conceptual understanding of scientific and legal perspective of acid precipitation and its impacts: A review. J. Appl. Sci. Res. 2015, 3, 54–75. [Google Scholar]

- Columbu, S.; Lisci, C.; Sitzia, F.; Lorenzetti, G.; Lezzerini, M.; Pagnotta, S.; Raneri, S.; Legnaioli, S.; Palleschi, V.; Gallello, G.; et al. Mineralogical, petrographic and physical-mechanical study of Roman construction materials from the Maritime Theatre of Hadrian’s Villa (Rome, Italy). Measurement 2018, 127, 264–276. [Google Scholar] [CrossRef]

- Columbu, S.; Gaviano, E.; Costamagna, L.G.; Fancello, D. Mineralogical-Petrographic and Physical-Mechanical Features of the Construction Stones in Punic and Roman Temples of Antas (SW Sardinia, Italy): Provenance of the Raw Materials and Conservation State. Minerals 2021, 11, 964. [Google Scholar] [CrossRef]

- Bergin, M.H.; Tripathi, S.N.; Jai Devi, J.; Gupta, T.; Mckenzie, M.; Rana, K.S.; Shafer, M.M.; Villalobos, A.M.; Schauer, J.J. The discoloration of the Taj Mahal due to particulate carbon and dust deposition. Environ. Sci. Technol. 2015, 49, 808–812. [Google Scholar] [CrossRef]

- Berto, L.; Talledo, D.A.; Bruschi, G.; Zamboni, I.; Lazzarini, E.; Zofrea, C.; Faccio, P.; Saetta, A. A Multidisciplinary Approach for the Vulnerability Assessment of a Venetian Historic Palace: High Water Phenomena and Climate Change Effects. Buildings 2022, 12, 431. [Google Scholar] [CrossRef]

- Sardaro, R.; La Sala, P.; De Pascale, G.; Faccilongo, N. The conservation of cultural heritage in rural areas: Stakeholder preferences regarding historical rural buildings in Apulia, southern Italy. Land Use Policy 2021, 109, 105662. [Google Scholar] [CrossRef]

- La Russa, M.F.; Rovella, N.; Alvarez de Buergo, M.; Belfiore, C.M.; Pezzino, A.; Crisci, G.M.; Ruffolo, S.A. Nano-TiO2 coatings for cultural heritage protection: The role of the binder on hydrophobic and self-cleaning efficacy. Prog. Org. Coat. 2016, 91, 1–8. [Google Scholar] [CrossRef]

- Young, M.E.; Alakomi, H.-L.; Fortune, I.; Gorbushina, A.A.; Krumbein, W.E.; Maxwell, I.; McCullagh, C.; Robertson, P.; Saarela, M.; Valero, J.; et al. Development of a biocidal treatment regime to inhibit biological growths on cultural heritage: BIODAM. Environ. Geol. 2008, 56, 631–641. [Google Scholar] [CrossRef]

- Aragoni, M.C.; Giacopetti, L.; Arca, M.; Carcangiu, G.; Columbu, S.; Gimeno, D.; Isaia, F.; Lippolis, V.; Meloni, P.; Ezquerra, A.N.; et al. Ammonium monoethyloxalate (AmEtOx): A new agent for the conservation of carbonate stone substrates. New J. Chem. 2021, 45, 5327–5339. [Google Scholar] [CrossRef]

- Columbu, S.; Lisci, C.; Sitzia, F.; Buccellato, G. Physical–mechanical consolidation and protection of Miocenic limestone used on Mediterranean historical monuments: The case study of Pietra Cantone (southern Sardinia, Italy). Environ. Earth Sci. 2017, 76, 148. [Google Scholar] [CrossRef]

- Baglioni, M.; Poggi, G.; Chelazzi, D.; Baglioni, P. Advanced Materials in Cultural Heritage Conservation. Molecules 2021, 26, 3967. [Google Scholar] [CrossRef] [PubMed]

- Macleod, I.D. Analysis of poultice-based desalination of a nineteenth century brick and stone cathedral after the event; a longitudinal study of surface chloride readings. AICCM Bull. 2021, 42, 82–90. [Google Scholar] [CrossRef]

- Artesani, A.; Di Turo, F.; Zucchelli, M.; Traviglia, A. Recent Advances in Protective Coatings for Cultural Heritage–An Overview. Coatings 2020, 10, 217. [Google Scholar] [CrossRef]

- Barbieri, N. Acid Rain Damaged Gargoyle. Available online: https://commons.wikimedia.org/wiki/File:-_Acid_rain_damaged_gargoyle_-.jpg (accessed on 8 December 2024).

- Rafferty, J. What Happened to Acid Rain? Britannica. Available online: https://www.britannica.com/story/what-happened-to-acid-rain (accessed on 8 December 2024).

- Azadi, N.; Parsimehr, H.; Ershad-Langroudi, A. Cultural heritage protection via hybrid nanocomposite coating. Plast. Rubber Compos. 2020, 49, 414–424. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nižetić, S.; Duong, X.Q.; Rowinski, L.; Nguyen, X.P. Advanced super-hydrophobic polymer-based porous absorbents for the treatment of oil-polluted water. Chemosphere 2021, 277, 130274. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, X.; Chen, S.; Lin, H.; Li, Z.; Lin, X. Hydrophobic or superhydrophobic modification of cement-based materials: A systematic review. Compos. B Eng. 2022, 243, 110104. [Google Scholar] [CrossRef]

- Pagnin, L.; Guarnieri, N.; Izzo, F.C.; Goidanich, S.; Toniolo, L. Protecting Street Art from Outdoor Environmental Threats: What Are the Challenges? Coatings 2023, 13, 2044. [Google Scholar] [CrossRef]

- Lettieri, M.; Masieri, M.; Aquaro, M.; Dilorenzo, D.; Frigione, M. Eco-Friendly Protective Coating to Extend the Life of Art-Works and Structures Made in Porous Stone Materials. Coatings 2021, 11, 1270. [Google Scholar] [CrossRef]

- Torabi-Kaveh, M.; Moshrefyfar, M.; Shirzaei, S.; Moosavizadeh, S.M.A.; Ménendez, B.; Maleki, S. Application of resin-TiO2 nanoparticle hybrid coatings on travertine stones to investigate their durability under artificial aging tests. Constr. Build. Mater. 2022, 322, 126511. [Google Scholar] [CrossRef]

- Liu, F.; Liu, A.; Tao, W.; Yang, Y. Preparation of UV curable organic/inorganic hybrid coatings-a review. Prog. Org. Coat. 2020, 145, 105685. [Google Scholar] [CrossRef]

- Peng, M.; Wang, L.; Guo, L.; Guo, J.; Zheng, L.; Yang, F.; Ma, Z.; Zhao, X. A Durable Nano-SiO2-TiO2/Dodecyltrimethoxysilane Superhydrophobic Coating for Stone Protection. Coatings 2022, 12, 1397. [Google Scholar] [CrossRef]

- Shu, H.; Yang, M.; Liu, Q.; Luo, M. Study of TiO2-Modified Sol Coating Material in the Protection of Stone-Built Cultural Heritage. Coatings 2020, 10, 179. [Google Scholar] [CrossRef]

- Otilia Cinteză, L.; Antonia Tănase, M. Multifunctional ZnO Nanoparticle: Based Coatings for Cultural Heritage Preventive Conservation. In Thin Films; IntechOpen: London, UK, 2021. [Google Scholar]

- Marey Mahmoud, H. An effective polymer nanocomposite based on tetraethoxysilane (TEOS) and SiO2-Al2O3 nanoparticles for super protection of damaged ancient Egyptian wall paintings. Pigment. Resin Technol. 2022, 51, 344–353. [Google Scholar] [CrossRef]

- Liu, Q.; Lv, Y.; Li, J.; Xu, W. Study on Application of Nanosilica in Paper Coating. Adv. Mat. Res. 2011, 311–313, 502–506. [Google Scholar] [CrossRef]

- Ranjbar, Z.; Rastegar, S. The influence of surface chemistry of nano-silica on microstructure, optical and mechanical properties of the nano-silica containing clear-coats. Prog. Org. Coat. 2009, 65, 125–130. [Google Scholar] [CrossRef]

- Allahverdi, A.; Ehsani, M.; Janpour, H.; Ahmadi, S. The effect of nanosilica on mechanical, thermal and morphological properties of epoxy coating. Prog. Org. Coat. 2012, 75, 543–548. [Google Scholar] [CrossRef]

- Puchy, V.; Hvizdos, P.; Dusza, J.; Kovac, F.; Inam, F.; Reece, M.J. Wear resistance of Al2O3–CNT ceramic nanocomposites at room and high temperatures. Ceram. Int. 2013, 39, 5821–5826. [Google Scholar] [CrossRef]

- Ahmad, I.; Kennedy, A.; Zhu, Y.Q. Wear resistant properties of multi-walled carbon nanotubes reinforced Al2O3 nanocomposites. Wear 2010, 269, 71–78. [Google Scholar] [CrossRef]

- Lee, K.-S.; Jang, B.-K.; Sakka, Y. Damage and wear resistance of Al2O3–CNT nanocomposites fabricated by spark plasma sintering. J. Ceram. Soc. Jpn. 2013, 121, 867–872. [Google Scholar] [CrossRef][Green Version]

- Zhu, S.; Chen, Y.; Tang, Y.; Li, Q.; Zhong, B.; Zeng, X.; Xie, D.; Jia, Z.; Jia, D. A novel nanosilica-supported ultraviolet absorber for the preparation of robust biodegradable plastic film with high ultraviolet aging resistance. Polym. Compos. 2019, 40, 4154–4161. [Google Scholar] [CrossRef]

- Jašková, V.; Hochmannová, L.; Vytřasová, J. TiO2 and ZnO Nanoparticles in Photocatalytic and Hygienic Coatings. Int. J. Photoenergy 2013, 2013, 795060. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Dao, P.H.; Duong, K.L.; Duong, Q.H.; Vu, Q.T.; Nguyen, A.H.; Mac, V.P.; Le, T.L. Effect of R-TiO2 and ZnO nanoparticles on the UV-shielding efficiency of water-borne acrylic coating. Prog. Org. Coat. 2017, 110, 114–121. [Google Scholar] [CrossRef]

- Adebanjo, A.U.; Abbas, Y.M.; Shafiq, N.; Khan, M.I.; Farhan, S.A.; Masmoudi, R. Optimizing nano-TiO2 and ZnO integration in silica-based high-performance concrete: Mechanical, durability, and photocatalysis insights for sustainable self-cleaning systems. Constr. Build. Mater. 2024, 446, 138038. [Google Scholar] [CrossRef]

- Alam, M.A.; Samad, U.A.; Anis, A.; Alam, M.; Ubaidullah, M.; Al-Zahrani, S.M. Effects of SiO2 and ZnO Nanoparticles on Epoxy Coatings and Its Performance Investigation Using Thermal and Nanoindentation Technique. Polymers 2021, 13, 1490. [Google Scholar] [CrossRef]

- Dhoke, S.K.; Bhandari, R.; Khanna, A.S. Effect of nano-ZnO addition on the silicone-modified alkyd-based waterborne coatings on its mechanical and heat-resistance properties. Prog. Org. Coat. 2009, 64, 39–46. [Google Scholar] [CrossRef]

- Parimalam, M.; Islam, M.R.; Yunus, R.M. Effects of nanosilica, zinc oxide, titatinum oxide on the performance of epoxy hybrid nanocoating in presence of rubber latex. Polym. Test. 2018, 70, 197–207. [Google Scholar] [CrossRef]

- Zheng, C.-F.; Yang, Z.-F.; Lv, C.-C.; Zhou, X.-P.; Xie, X.-L. Thermal stability and abrasion resistance of polyacrylate/nano-silica hybrid coatings. Iran. Polym. J. 2013, 22, 465–471. [Google Scholar] [CrossRef]

- Yang, H.; Cheng, Y.; Xiao, F. Thermal stable superhydrophobic polyphenylsilsesquioxane/nanosilica composite coatings. Appl. Surf. Sci. 2011, 258, 1572–1580. [Google Scholar] [CrossRef]

- Palraj, S.; Selvaraj, M.; Maruthan, K.; Rajagopal, G. Corrosion and wear resistance behavior of nano-silica epoxy composite coatings. Prog. Org. Coat. 2015, 81, 132–139. [Google Scholar] [CrossRef]

- Langroudi, A.E.; Rahimi, A. Synthesis and characterisation of nano silica-based coatings for protection of antique articles. Int. J. Nanotechnol. 2009, 6, 915. [Google Scholar] [CrossRef]

- Yan, L.; Xu, Z.; Wang, X. Influence of nano-silica on the flame retardancy and smoke suppression properties of transparent intumescent fire-retardant coatings. Prog. Org. Coat. 2017, 112, 319–329. [Google Scholar] [CrossRef]

- Roguska, A.; Pisarek, M.; Andrzejczuk, M.; Lewandowska, M. Synthesis and characterization of ZnO and Ag nanoparticle-loaded TiO2 nanotube composite layers intended for antibacterial coatings. Thin Solid Films 2014, 553, 173–178. [Google Scholar] [CrossRef]

- Nguyen, V.; Vu, V.; Nguyen, T.; Nguyen, T.; Tran, V.; Nguyen-Tri, P. Antibacterial Activity of TiO2- and ZnO-Decorated with Silver Nanoparticles. J. Compos. Sci. 2019, 3, 61. [Google Scholar] [CrossRef]

- Phoohinkong, W.; Kitthawee, U. Low-Cost and Fast Production of Nano-Silica from Rice Husk Ash. Adv. Mat. Res. 2014, 979, 216–219. [Google Scholar] [CrossRef]

- Ibrahim, S.; Sultan, M. Superhydrophobic Coating Polymer/Silica Nanocomposites: Part I Synthesis and Characterization as Eco-Friendly Coating. Silicon 2020, 12, 805–811. [Google Scholar] [CrossRef]

- Sprenger, S. Nanosilica-Toughened Epoxy Resins. Polymers 2020, 12, 1777. [Google Scholar] [CrossRef]

- Barbhuiya, G.H.; Moiz, M.A.; Hasan, S.D.; Zaheer, M.M. Effects of the nanosilica addition on cement concrete: A review. Mater. Today Proc. 2020, 32, 560–566. [Google Scholar] [CrossRef]

- Singh, P.; Srivastava, S.; Singh, S.K. Nanosilica: Recent Progress in Synthesis, Functionalization, Biocompatibility, and Biomedical Applications. ACS Biomater. Sci. Eng. 2019, 5, 4882–4898. [Google Scholar] [CrossRef]

- Fytianos, G.; Rahdar, A.; Kyzas, G.Z. Nanomaterials in Cosmetics: Recent Updates. Nanomaterials 2020, 10, 979. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Zeng, K.; Yang, F.; Zhu, H.; Liu, Q. Advanced design of Chinese traditional materials for the conservation of historic stone buildings. J. Archaeol. Sci. 2011, 38, 1896–1900. [Google Scholar] [CrossRef]

- Gherardi, F.; Maravelaki, P.N. Advances in the application of nanomaterials for natural stone conservation. RILEM Tech. Lett. 2022, 7, 20–29. [Google Scholar] [CrossRef]

- Fernández, A.S.; Gomez, L.S.; Rabanal, M.E.; González, R.F. New nanomaterials for applications in conservation and restoration of stony materials: A review. Mater. Construcción 2017, 67, 325. [Google Scholar]

- Tariq, L.R.; & Jafaar, A.M.; Jafaar, A.M. A Review of Nanotechnology in Self-Healing of Ancient and Heritage Buildings: Heritage buildings, Nanomaterial, Nano architecture, Nanotechnology in construction. Int. J. Nanoelectron. Mater. 2024, 17, 153–163. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. Nano-Silica-Modified Concrete: A Bibliographic Analysis and Comprehensive Review of Material Properties. Nanomaterials 2022, 12, 1989. [Google Scholar] [CrossRef] [PubMed]

- Kaur, H.; Chaudhary, S.; Kaur, H.; Chaudhary, M.; Jena, K.C. Hydrolysis and Condensation of Tetraethyl Orthosilicate at the Air–Aqueous Interface: Implications for Silica Nanoparticle Formation. ACS Appl. Nano Mater. 2022, 5, 411–422. [Google Scholar] [CrossRef]

- Yuan, J.; Zhou, S.; Gu, G.; Wu, L. Effect of the particle size of nanosilica on the performance of epoxy/silica composite coatings. J. Mater. Sci. 2005, 40, 3927–3932. [Google Scholar] [CrossRef]

- Xie, Z.; Duan, Z.; Zhao, Z.; Li, R.; Zhou, B.; Yang, D.; Hu, Y. Nano-materials enhanced protectants for natural stone surfaces. Herit. Sci. 2021, 9, 122. [Google Scholar] [CrossRef]

- Kongchan, S.; Pacaphol, K.; Aht-Ong, D. Waterborne Silane/Polysiloxane Hydrophobic Coating for Stone-Built Cultural Heritage Conservation. SIAM Sci. Innov. Adv. Mater. 2023, 3, 66001. [Google Scholar]

- Vale, L. Architecture, Power and National Identity; Routledge: New York, NY, USA, 2014. [Google Scholar]

- Henneberg, K.V. Monuments, Public Space, and the Memory of Empire in Modern Italy. Hist. Mem. 2004, 16, 37. [Google Scholar] [CrossRef]

- Jokilehto, J. A History of Architectural Conservation, 2nd ed.; Routledge: New York, NY, USA, 2017. [Google Scholar]

- Yang, X.; Jiang, X.W.; Ouyang, K.G.; Ji, T.T.; Gao, Y.F.; Geng, X.H.; Niu, R.; Huang, J.Z.; Yan, H.B.; Wan, L. The mechanisms of salt weathering responsible for sandstone deterioration in the Yungang Grottoes, China. Eng. Geol. 2025, 350, 107989. [Google Scholar] [CrossRef]

- Primavori, P. Carrara Marble: A Nomination for ‘Global Heritage Stone Resource’ from Italy; Special Publications; Geological Society: London, UK, 2015; Volume 407, pp. 137–154. [Google Scholar] [CrossRef]

- Qin, T.; Yu, H.; Dai, S.; Zhang, P. Study on deterioration of historic masonry in the forbidden city in Beijing aided by gis. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2021, 46, 585–591. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, B.; Zhang, J.; Zhai, K.; Luo, L. Weathering Characteristics of White Marble Relics Around the Hall of Supreme Harmony (Taihe Dian) in the Forbidden City. KSCE J. Civ. Eng. 2023, 27, 794–804. [Google Scholar] [CrossRef]

- Malesani, P.; Pecchioni, E.; Cantisani, E.; Fratini, F. Geolithology and provenance of materials of some historical buildings and monuments in the centre of Florence (Italy). Epis. J. Int. Geosci. 2003, 26, 250–255. [Google Scholar] [CrossRef]

- Collins, G. The Geology and Tectonic Settings of China’s Mineral Deposits. Econ. Geol. 2013, 108, 909–910. [Google Scholar] [CrossRef]

- Zhao, W.W.; Zhou, M.-F.; Li, Y.H.M.; Zhao, Z.; Gao, J.-F. Genetic types, mineralization styles, and geodynamic settings of Mesozoic tungsten deposits in South China. J. Asian Earth Sci. 2017, 137, 109–140. [Google Scholar] [CrossRef]

- Zaw, K.; Peters, S.G.; Cromie, P.; Burrett, C.; Hou, Z. Nature, diversity of deposit types and metallogenic relations of South China. Ore Geol. Rev. 2007, 31, 3–47. [Google Scholar] [CrossRef]

- Yang, Y.; Song, L.; Wang, J.; Yue, L.; Shi, E.; Wang, Z.; Yang, T. Impact of Acid, Salt, and Wetting-Drying Cycles on Weathering Deterioration of the Red Sandstone Used for Leshan Giant Buddha China. Int. J. Archit. Herit. 2025, 19, 457–484. [Google Scholar] [CrossRef]

- Phengsaart, T.; Srichonphaisan, P.; Kertbundit, C.; Soonthornwiphat, N.; Sinthugoot, S.; Phumkokrux, N.; Juntarasakul, O.; Maneeintr, K.; Numprasanthai, A.; Park, I.; et al. Conventional and recent advances in gravity separation technologies for coal cleaning: A systematic and critical review. Heliyon 2023, 9, e13083. [Google Scholar] [CrossRef]

- Tabelin, C.B.; Park, I.; Phengsaart, T.; Jeon, S.; Villacorte-Tabelin, M.; Alonzo, D.; Yoo, K.; Ito, M.; Hiroyoshi, N. Copper and critical metals production from porphyry ores and E-wastes: A review of resource availability, processing/recycling challenges, socio-environmental aspects, and sustainability issues. Resour. Conserv. Recycl. 2021, 170, 105610. [Google Scholar] [CrossRef]

- Eang, K.E.; Igarashi, T.; Kondo, M.; Nakatani, T.; Tabelin, C.B.; Fujinaga, R. Groundwater monitoring of an open-pit limestone quarry: Water-rock interaction and mixing estimation within the rock layers by geochemical and statistical analyses. Int. J. Min. Sci. Technol. 2018, 28, 849–857. [Google Scholar] [CrossRef]

- Eang, K.E.; Igarashi, T.; Fujinaga, R.; Kondo, M.; Tabelin, C.B. Groundwater monitoring of an open-pit limestone quarry: Groundwater characteristics, evolution and their connections to rock slopes. Environ. Monit. Assess. 2018, 190, 193. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Song, H.; Sun, B.; Yang, T. Effects of simulated atmospheric nitrogen deposition on the bacterial community structure and diversity of four distinct biocolonization types on stone monuments: A case study of the Leshan Giant Buddha, a world heritage site. Herit. Sci. 2024, 12, 23. [Google Scholar] [CrossRef]

- Dong, Q.; Sun, X.; Sheng, J.; Lei, N. An experimental investigation on the damage mechanisms of red glutenite in the Mount Wuyi cultural and natural heritage site subject to acid rain and wet-dry cycles: A macro-to-micro approach. Herit. Sci. 2024, 12, 273. [Google Scholar] [CrossRef]

- Irizar, P.; Pintor-Rial, A.; Maguregui, M.; Martinez-Arkarazo, I.; Cardiano, P.; Gómez-Laserna, O. Synergies of sugar-derived epoxy-silica hybrids and amino-functionalized silica NPs for advanced stone conservation. Prog. Org. Coat. 2024, 196, 108735. [Google Scholar] [CrossRef]

- Rosado, T.; Silva, M.; Galvão, A.; Mirão, J.; Candeias, A.; Caldeira, A.T. A first insight on the biodegradation of limestone: The case of the World Heritage Convent of Christ. Appl. Phys. A 2016, 122, 1012. [Google Scholar] [CrossRef]

- Mariani, A.; Malucelli, G. Consolidation of Stone Materials by Organic and Hybrid Polymers: An Overview. Macromol. Chem. Phys. 2023, 224, 2300053. [Google Scholar] [CrossRef]

- Abdi, Y.; Sabzi, M. The Effect of Salt Crystallization on Degradation of Limestones Used as Heritage Building Stone in Lorestan, Iran. Geoheritage 2024, 16, 118. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, T.; Jiang, Y.; Qiu, S.; Li, P.; Yang, D.; Qiu, F. Nano-silica/fluorinated polyacrylate composites as surface protective coatings for simulated stone cultural relic protection. J. Appl. Polym. Sci. 2022, 139, e52953. [Google Scholar] [CrossRef]

- Yumei, C.; Gang, W.; Pei, S.; Luo, H.; Xichen, Z.; Biao, Z.; Zhu, J. Nanosized ZnO/SiO2-Based Amphiphobic Coatings for Stone Heritage Protection. ACS Appl. Nano Mater. 2022, 5, 18708–18717. [Google Scholar] [CrossRef]

- Sbardella, F.; Bracciale, M.P.; Santarelli, M.L.; Asua, J.M. Waterborne modified-silica/acrylates hybrid nanocomposites as surface protective coatings for stone monuments. Prog. Org. Coat. 2020, 149, 105897. [Google Scholar] [CrossRef]

- Lettieri, M.; Masieri, M.; Frigione, M. Novel Nano-Filled Coatings for the Protection of Built Heritage Stone Surfaces. Nanomaterials 2021, 11, 301. [Google Scholar] [CrossRef]

- Mishra, R.; Militky, J.; Baheti, V.; Huang, J.; Kale, B.; Venkataraman, M.; Bele, V.; Arumugam, V.; Zhu, G.; Wang, Y. The production, characterization and applications of nanoparticles in the textile industry. Text. Prog. 2014, 46, 133–226. [Google Scholar] [CrossRef]

- Armal, F.; Dias, L.; Mirão, J.; Pires, V.; Sitzia, F.; Martins, S.; Costa, M.; Barrulas, P. Chemical Composition of Hydrophobic Coating Solutions and Its Impact on Carbonate Stones Protection and Preservation. Sustainability 2023, 15, 16135. [Google Scholar] [CrossRef]

- Luci, M.; De Leo, F.; De Pascale, D.; Galasso, C.; La Russa, M.F.; Lo Schiavo, S.; Ricca, M.; Ruffolo, S.A.; Ruocco, N.; Urzì, C. Surface-Active Ionic-Liquid-Based Coatings as Anti-Biofilms for Stone: An Evaluation of Their Physical Properties. Coatings 2023, 13, 1669. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, Q.; Zheng, X.; Cheng, K.; Lang, R. Study on Anti-Weathering Protection of Excavated Ancient Stone Arch Bridge with Nano-Composites. Coatings 2023, 13, 1898. [Google Scholar] [CrossRef]

- Pelosi, C.; Lanteri, L.; Agresti, G.; Rubino, G.; Persia, F.; Bonifazi, G.; Serranti, S.; Capobianco, G. Experimental tests for evaluating the stability of a new nano-silica based protective for Sperone stone in comparison to traditional products. In AIP Conference Proceedings; Publishing LLC: Melville, NY, USA, 2020. [Google Scholar]

- Irizar, P.; Irto, A.; Martinez-Arkarazo, I.; Olazabal, M.Á.; Cardiano, P.; Gomez-Laserna, O. Sugar-derived bio-based resins as platforms for the development of multifunctional hybrids with potential application for stone conservation. Mater Today Commun. 2022, 31, 103662. [Google Scholar] [CrossRef]

- Ansari, A.; Saadatbakhsh, M.; Sohrabi, M.; Asl, S.J.; Nouri, N.M. Antifouling activity of superhydrophobic PDMS/hydrophobic silica coating. Surf. Eng. 2023, 39, 35–48. [Google Scholar] [CrossRef]

- Renda, V.; De Buergo, M.A.; Saladino, M.L.; Caponetti, E. Assessment of protection treatments for carbonatic stone using nanocomposite coatings. Prog. Org. Coat. 2020, 141, 105515. [Google Scholar] [CrossRef]

- Antonini, J.M.; McKinney, W.G.; Lee, E.G.; Afshari, A.A. Review of the physicochemical properties and associated health effects of aerosols generated during thermal spray coating processes. Toxicol. Ind. Health 2021, 37, 47–58. [Google Scholar] [CrossRef]

- UNI EN16581; Conservation of Cultural Heritage–Surface Protection for Porous Inorganic Materials–Laboratory Test Methods for the Evaluation of the Performance of Water Repellent Products. Ente Italiano di Normazione: Milano, Italy, 2016.

- UNI EN15802; Conservation of Cultural Property-Test Methods-Determination of Static Contact Angle. Ente Italiano di Normazione: Milano, Italy, 2010.

- UNI EN15801; Conservation of Cultural Property-Test Methods-Determination of Water Absorption by Capillarity. Ente Italiano di Normazione: Milano, Italy, 2010.

- UNI EN15803; Conservation of Cultural Property-Test Methods-Determination of Water Vapor Permeability. Ente Italiano di Normazione: Milano, Italy, 2010.

- UNI EN15886; Conservation of Cultural Property-Test Methods—Colour Measurement of Surfaces. Ente Italiano di Normazione: Milano, Italy, 2010.

- Huhtamäki, T.; Tian, X.; Korhonen, J.T.; Ras, R.H.A. Surface-wetting characterization using contact-angle measurements. Nat. Protoc. 2018, 13, 1521–1538. [Google Scholar] [CrossRef] [PubMed]

- Occhipinti, R.; Stroscio, A.; Maria Belfiore, C.; Barone, G.; Mazzoleni, P. Chemical and colorimetric analysis for the characterization of degradation forms and surface colour modification of building stone materials. Constr. Build. Mater. 2021, 302, 124356. [Google Scholar] [CrossRef]

- Vasanelli, E.; Calia, A.; Masieri, M.; Baldi, G. Stone consolidation with SiO2 nanoparticles: Effects on a high porosity limestone. Constr Build Mater. 2019, 219, 154–163. [Google Scholar] [CrossRef]

- Sayan, P. Effect of sodium oleate on the agglomeration of calcium carbonate. Cryst. Res. Technol. 2005, 40, 226–232. [Google Scholar] [CrossRef]

- Hu, A.; Li, R.; Chen, G.; Chen, S. Impact of Respiratory Dust on Health: A Comparison Based on the Toxicity of PM2.5, Silica, and Nanosilica. Int. J. Mol. Sci. 2024, 25, 7654. [Google Scholar] [CrossRef]

- Laohaviraphap, N.; Waroonkun, T. Integrating Artificial Intelligence and the Internet of Things in Cultural Heritage Preservation: A Systematic Review of Risk Management and Environmental Monitoring Strategies. Buildings 2024, 14, 3979. [Google Scholar] [CrossRef]

- Sirisathitkul, Y.; Dinmeung, N.; Noonsuk, W.; Sirisathitkul, C. Accuracy and precision of smartphone colorimetry: A comparative analysis in RGB, HSV, and CIELAB color spaces for archaeological research. STAR Sci. Technol. Archaeol. Res. 2025, 11, e2444168. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).