Study on the Effect of Grinding Media Material and Proportion on the Cyanide Gold Extraction Process

Abstract

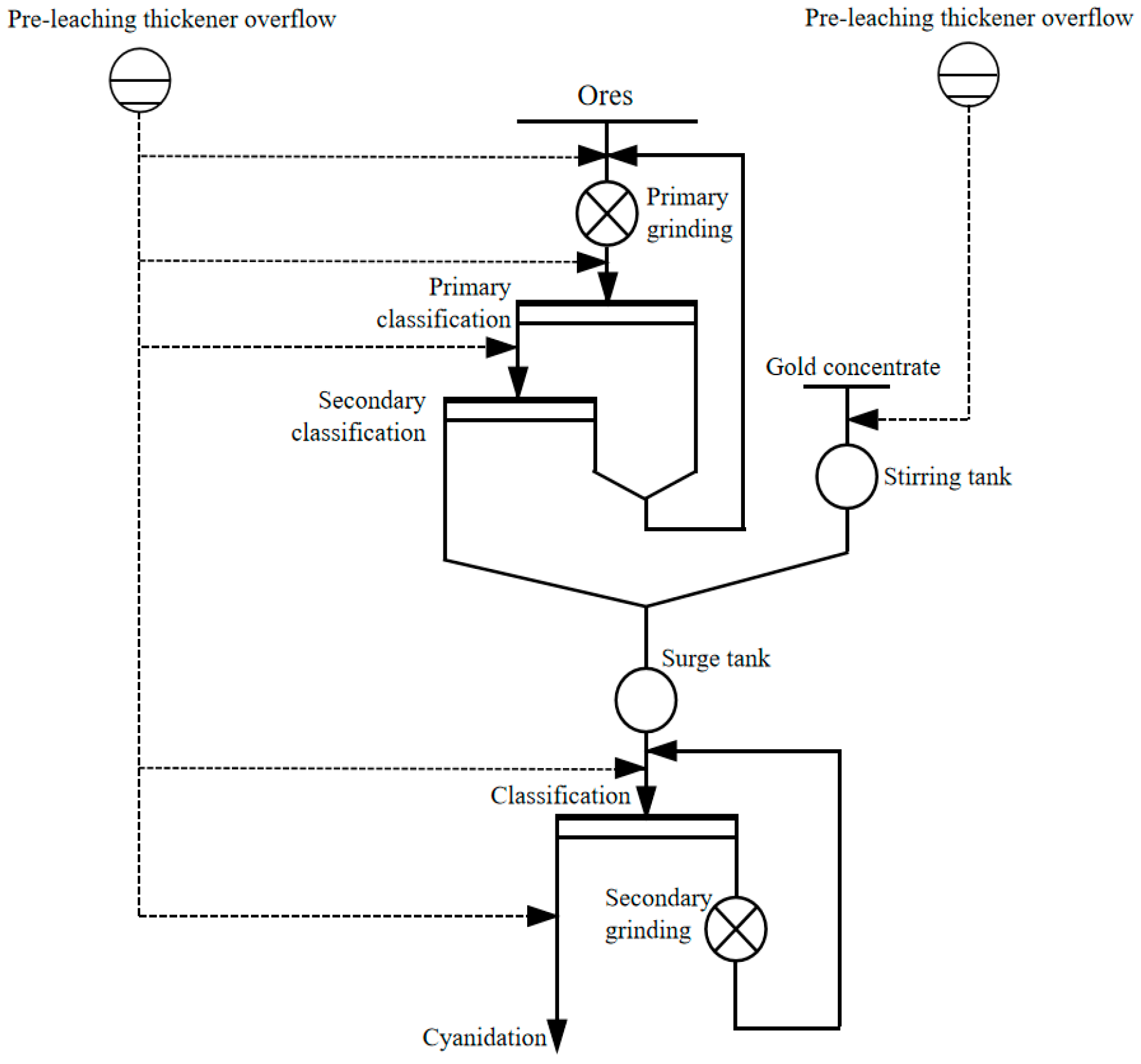

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Grinding Media

2.3. Grinding Tests

2.4. Comparison Test of Sodium Cyanide Consumption, Iron Leaching Rate, and Gold Leaching Rate

2.5. Grinding Media Wear Test

2.6. Industrial Tests

3. Results and Discussion

3.1. Analysis of Grinding Test Results

3.1.1. Analysis of Test Results of Ceramic Balls and Steel Balls in Grinding

3.1.2. Analysis of % Solids Test Results

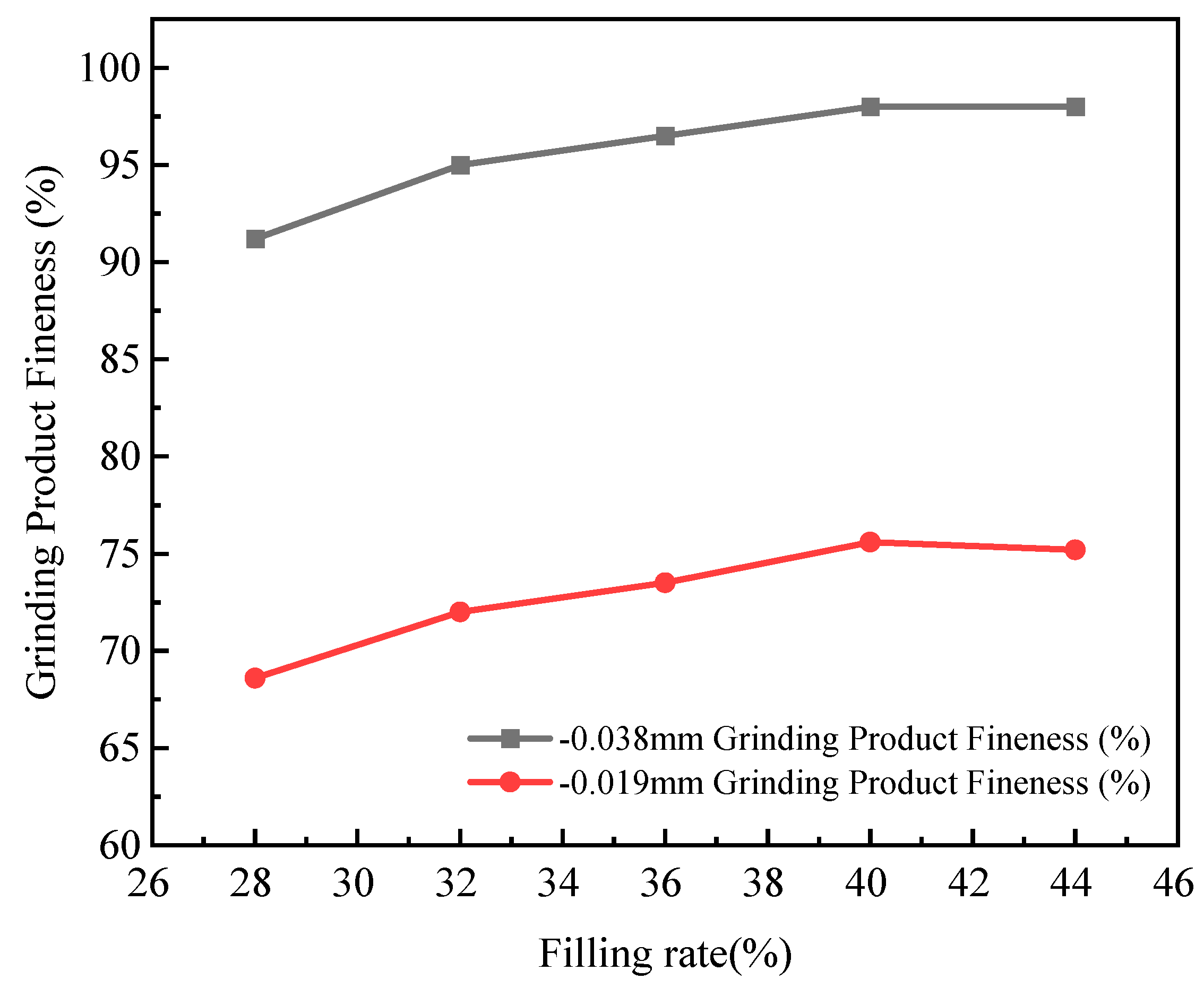

3.1.3. Analysis of Filling Rate Test Results

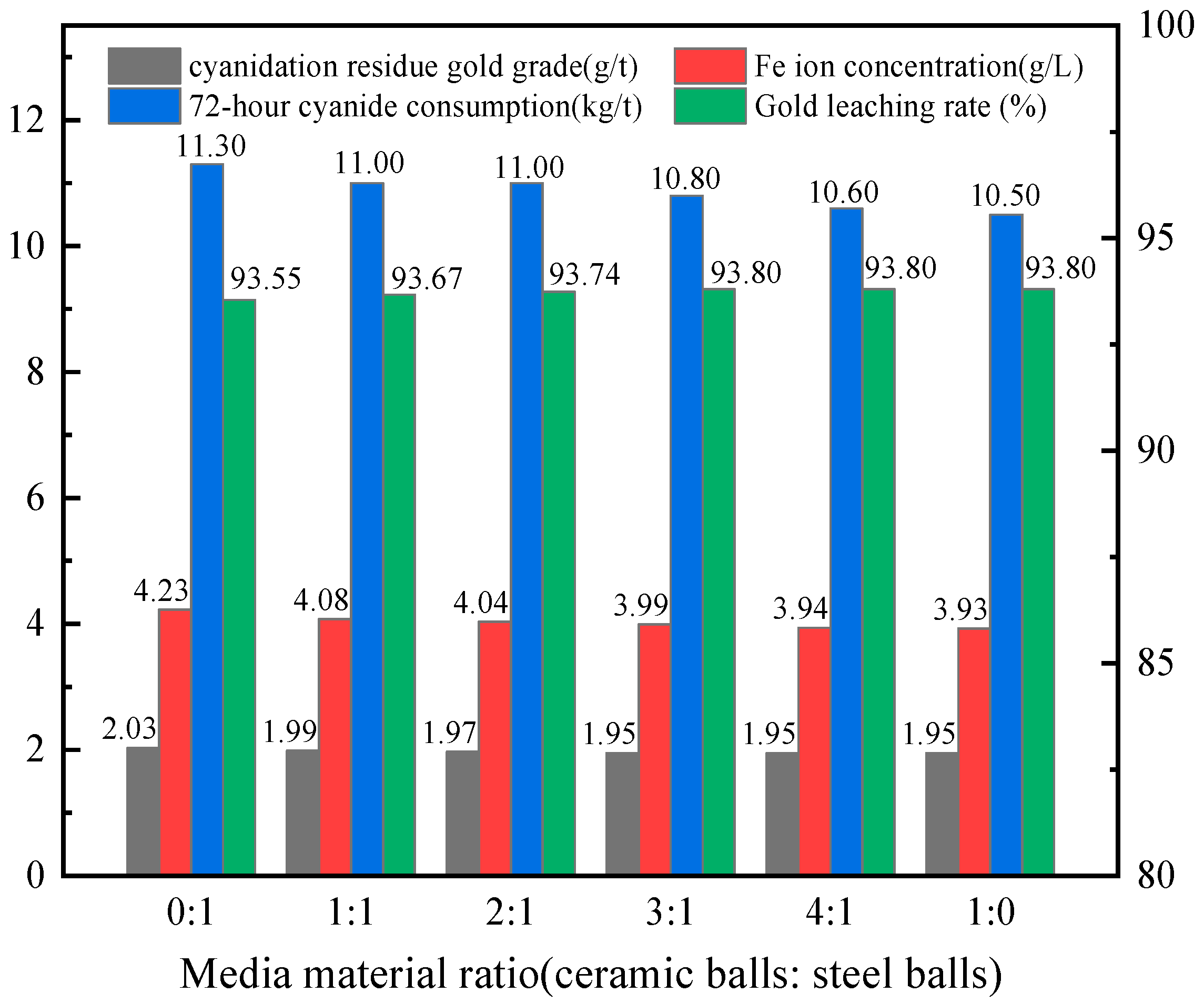

3.2. Analysis of Test Results Comparing Ceramic Balls and Steel Balls with Various Mixture Ratios

3.3. Analysis of Test Results for Sodium Cyanide Consumption, Iron Leaching Rate, and Gold Leaching Rate

3.4. Analysis of Grinding Media Consumption Test Results

3.5. Analysis of Industrial Application Results

3.5.1. Analysis of Industrial Production Indicators

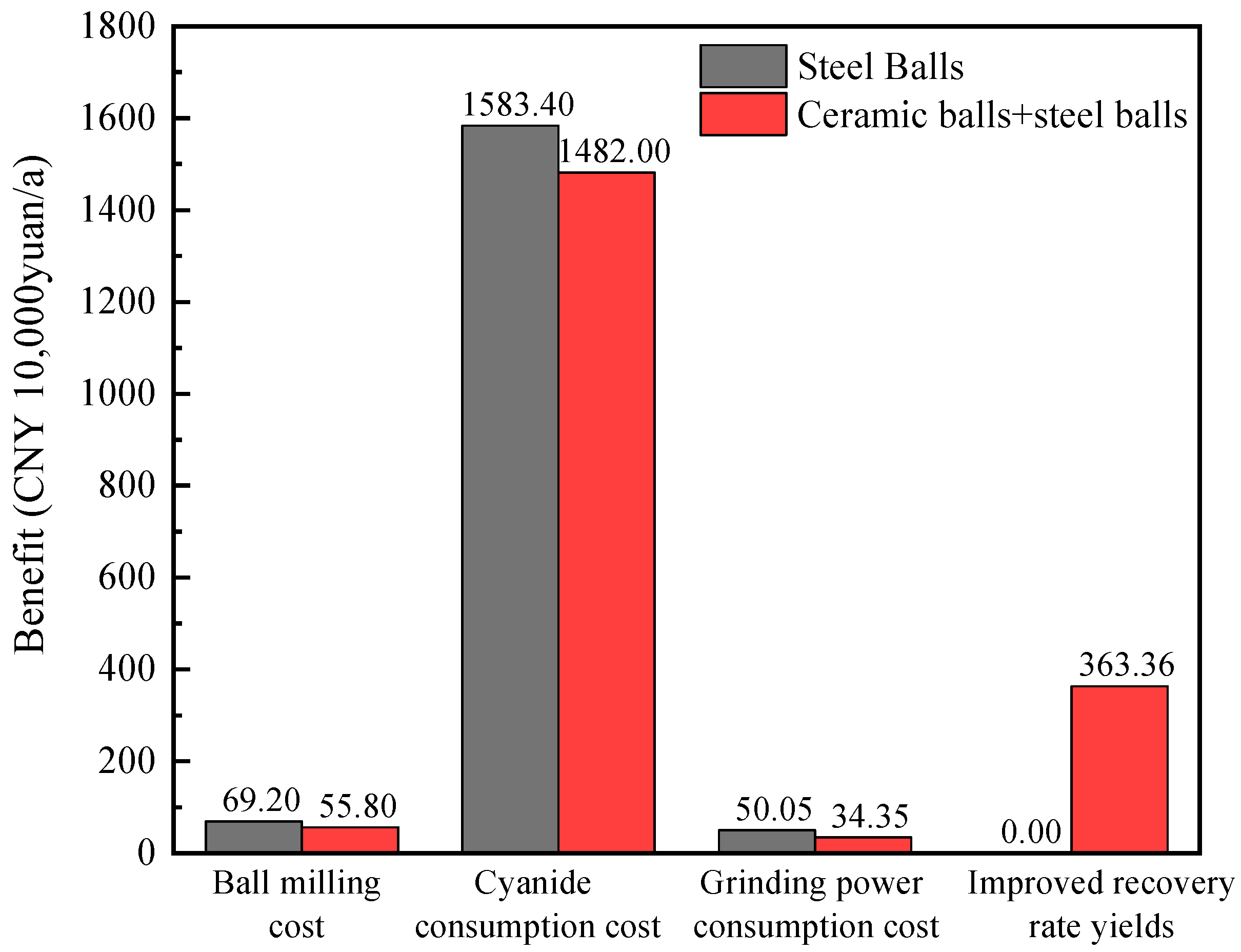

3.5.2. Analysis of the Economic Benefits of Industrial Production

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mudd, G. Global trends in gold mining: Towards quantifying environmental and resource sustainability. Resour. Policy 2007, 32, 42–56. [Google Scholar] [CrossRef]

- Cai, L.; Yan, X.; Yang, H.; Wang, Y.; Tong, L.; Wang, H.; Shi, M.; Han, W. Development Potential of Green Gold Metallurgy in China. Strateg. Study CAE 2025, 27, 205–215. [Google Scholar] [CrossRef]

- Matsanga, N.; Nheta, W.; Chimwani, N. Grinding Media in Ball Mills-A Review. Preprints 2023, 2023040811. [Google Scholar] [CrossRef]

- Órdenes, J.; Wilson, R.; Peña-Graf, F.; Navarra, A. Incorporation of Geometallurgical Input into Gold Mining System Simulation to Control Cyanide Consumption. Minerals 2021, 11, 1023. [Google Scholar] [CrossRef]

- Barani, K.; Kogani, Y.; Nazarian, F. Leaching of complex gold ore using a cyanide-glycine solution. Miner. Eng. 2022, 180, 107475. [Google Scholar] [CrossRef]

- Feng, D.; Van Deventer, J. The effect of iron contaminants on thiosulfate leaching of gold. Miner. Eng. 2010, 23, 399–406. [Google Scholar] [CrossRef]

- Cui, R.; Yang, H.; Chen, S.; Ma, P. Effect of associated minerals on cyanide leaching gold in refractory gold ore. J. Northeast. Univ. 2011, 32, 1291–1294. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, H.; Tong, L.; Ma, P.; Jin, R.; Zhang, Q. An Investigation into the Effects of Grinding Medium on Interface Characteristics and Flotation Performance of Sphalerite in Cyanide System. Minerals 2022, 12, 1231. [Google Scholar] [CrossRef]

- Yao, W.; Li, M.; Zhang, M.; Cui, R.; Ning, J.; Shi, J. Effects and mechanisms of grinding media on the flotation behavior of scheelite. ACS Omega 2020, 5, 32076–32083. [Google Scholar] [CrossRef]

- Liao, N.; Wu, C.; Xu, J.; Feng, B.; Wu, J.; Gong, Y. Effect of grinding media on grinding-flotation behavior of chalcopyrite and pyrite. Front. Mater. 2020, 7, 176. [Google Scholar] [CrossRef]

- Liao, N.; Wu, C.; Li, J.; Fang, X.; Li, Y.; Zhang, Z.; Yin, W. A Comparison of the Fine-Grinding Performance between Cylpebs and Ceramic Balls in the Wet Tumbling Mill. Minerals 2022, 12, 1007. [Google Scholar] [CrossRef]

- Jing, Y.; Xu, G. Research and Application of Mixed Replacement of Ceramic Ball and Steel Ball in Ball Mill. Copp. Eng. 2021, 3, 32–35. [Google Scholar] [CrossRef]

- Matsanga, N.; Nheta, W.; Chimwani, N. A Review of the Grinding Media in Ball Mills for Mineral Processing. Minerals 2023, 13, 1373. [Google Scholar] [CrossRef]

- Yin, Z.; Zhang, Y.; Zhu, H.; Ding, H.; Wu, Q.; Zhu, Z.; Song, J. Optimization and Experimental Study of Iron Ore Grinding Medium Parameters Using EDEM Discrete Element Software. Materials 2024, 17, 4726. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Xiao, Q.; Zhou, Q.; Liu, X.; Jin, S.; Pei, Y.; Shen, C. An innovatory approach for determining grinding media system to optimize fraction compositions of grinding products based on grinding dynamics principle. Powder Technol. 2024, 434, 119302. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, Q.; Fu, Y.; Jin, S.; Wang, G.; Wang, M.; Sun, B.; Tian, H.; Liu, X.; Tian, J. An innovative theoretical model for optimizing ball diameter in tumbling mills. Miner. Eng. 2025, 233, 109635. [Google Scholar] [CrossRef]

- Yuan, C.; Wu, C.; Ling, L.; Yao, X.; Li, Z.; Xie, F.; Tian, J. Ceramic Grinding Kinetics of Fine Magnetite Ores in the Batch Ball Mill. Minerals 2023, 13, 1188. [Google Scholar] [CrossRef]

- Lai, J.; Xiang, Z.; Li, Y.; Wu, C. Grinding Kinetics Study of Nano-ceramic Spheres as Fine Grinding Medium. Nonferrous Met. Sci. Eng. 2021, 12, 100–105. [Google Scholar] [CrossRef]

- Abdelhaffez, G.S.; Ahmed, A.A.; Ahmed, H.M. Effect of Grinding Media on the Milling Efficiency of a Ball Mill. Rud. -Geološko-Naft. Zb. 2022, 37, 171–177. [Google Scholar] [CrossRef]

- Zhang, X.; Qin, Y.; Jin, J.; Li, Y.; Gao, P. High-efficiency and energy-conservation grinding technology using a special ceramic-medium stirred mill: A pilot-scale study. Powder Technol. 2022, 396, 354–365. [Google Scholar] [CrossRef]

- Shao, Y.; Zhou, Q.; Xiao, Q.; Jin, S.; Huang, S.; Liu, X.; Wang, Y. The Comparative Experimental Study of Ceramic Ball and Steel Ball Media in Tower Mill. Nonferrous Met. (Miner. Process. Sect.) 2024, 12, 97–102. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Z.; Han, C.; Hou, Y. Analysis of Influencing Factors of Grinding Efficiency of Tower Mill. J. Guizhou Univ. (Nat. Sci.) 2023, 40, 40–44. [Google Scholar] [CrossRef]

- Rabieh, A.; Eksteen, J.; Albijanic, B. The effect of grinding chemistry on cyanide leaching of gold in the presence of pyrrhotite. Hydrometallurgy 2017, 173, 115–124. [Google Scholar] [CrossRef]

| element | Au * | Ag * | Cu | Pb | Zn |

| Content (%) | 31.46 | 7.72 | 0.03 | 0.05 | 0.006 |

| element | As | Fe | S | C | SiO2 |

| Content (%) | 6.54 | 39.65 | 39.74 | 1.08 | 4.33 |

| Mineral Name | Content (%) | Mineral Name | Content (%) |

|---|---|---|---|

| Pyrite | 67.73 | Calcite | 4.80 |

| Arsenopyrite | 14.13 | Siderite | 3.40 |

| Pyrrhotite | 1.84 | Iron dolomite | 1.23 |

| Arsenopyrite–galena–pyrite | 0.15 | Quartz | 4.33 |

| Chalcopyrite, Covellite (CuS) | 0.07 | Kaolinite | 0.51 |

| Sphalerite | 0.01 | Feldspar | 0.93 |

| Magnetite | 0.33 | Others | 0.54 |

| Total (%) | 100 | ||

| Grinding Media | Filling Rate (%) | Number of Balls | % Solids (%) | Medium Material Ratio (Ceramic Balls: Steel Balls) | Medium Size Ratio (⌀30 mm: ⌀25 mm: ⌀20 mm) |

|---|---|---|---|---|---|

| Steel balls | — | 180 | 65 | 0:1 | 0:1:0 |

| Ceramic balls | — | 180 | 65 | 1:0 | 0:1:0 |

| Steel balls | — | 180 | 65 | 0:1 | 1:1:1 |

| Steel balls | — | 180 | 65 | 0:1 | 1:1:2 |

| Steel balls | — | 180 | 65 | 0:1 | 1:2:2 |

| Ceramic balls | — | 180 | 65 | 1:0 | 1:1:1 |

| Ceramic balls | — | 180 | 65 | 1:0 | 1:1:2 |

| Ceramic balls | — | 180 | 65 | 1:0 | 1:2:2 |

| Ceramic balls | — | 180 | 55 | 1:0 | 1:1:2 |

| Ceramic balls | — | 180 | 60 | 1:0 | 1:1:2 |

| Ceramic balls | — | 180 | 70 | 1:0 | 1:1:2 |

| Ceramic balls | — | 180 | 75 | 1:0 | 1:1:2 |

| Ceramic balls | 28 | — | 70 | 1:0 | 1:1:2 |

| Ceramic balls | 32 | — | 70 | 1:0 | 1:1:2 |

| Ceramic balls | 36 | — | 70 | 1:0 | 1:1:2 |

| Ceramic balls | 40 | — | 70 | 1:0 | 1:1:2 |

| Ceramic balls | 44 | — | 70 | 1:0 | 1:1:2 |

| Ceramic + steel balls | 40 | — | 70 | 1:1 | 1:1:2 |

| Ceramic + steel balls | 40 | — | 70 | 2:1 | 1:1:2 |

| Ceramic + steel balls | 40 | — | 70 | 3:1 | 1:1:2 |

| Ceramic + steel balls | 40 | — | 70 | 4:1 | 1:1:2 |

| Grinding Media | Media Material Ratio (Ceramic Balls: Steel Balls) | Added Ball Mass (g) | Number of Added Balls |

|---|---|---|---|

| Ceramic balls | 1:0 | 5509.6 | 180 |

| Steel balls | 0:1 | 14,560.0 | 180 |

| Ceramic balls + steel balls | 1:1 | 10,034.8 | 180 |

| Ceramic balls + steel balls | 2:1 | 8526.4 | 180 |

| Ceramic balls + steel balls | 3:1 | 7772.2 | 180 |

| Ceramic balls + steel balls | 4:1 | 7319.7 | 180 |

| Media Material Ratio (Ceramic Balls: Steel Balls) | Added Ball Mass (g) | Remaining Medium Mass After 10 h of Grinding (g) | Loss After 10 h of Grinding (g) | Loss Rate After 10 h of Grinding (kg/t) | Remaining Medium Mass After 100 h of Grinding (g) | Loss After 100 h of Grinding (g) | Loss Rate After 100 h of Grinding (kg/t) |

|---|---|---|---|---|---|---|---|

| 0:1 | 14,560.0 | 14,509.0 | 51.0 | 3.50 | 14,184.4 | 375.6 | 25.8 |

| 1:1 | 10,034.8 | 10,004.0 | 30.8 | 3.07 | 9806.8 | 228.0 | 22.7 |

| 2:1 | 8526.4 | 8502.8 | 23.6 | 2.77 | 8364.1 | 162.3 | 19.0 |

| 3:1 | 7772.2 | 7755.4 | 16.8 | 2.16 | 7634.7 | 137.5 | 17.7 |

| 4:1 | 7319.7 | 7305.4 | 14.3 | 1.95 | 7219.4 | 100.3 | 13.7 |

| 1:0 | 5509.6 | 5499.0 | 10.6 | 1.92 | 5438.5 | 71.1 | 12.9 |

| Grinding Media | Feed −0.038 mm Content (%) | Discharge −0.038 mm Content (%) | Change in Iron Ions (g/m3) | Cyanide Consumption in Grinding (kg/t) | Total Cyanide Consumption (kg/t) | Gold Recovery Rate (%) | Ball Consumption (kg/t) | Mill Current (A) |

|---|---|---|---|---|---|---|---|---|

| Steel balls | 55.0 | 67.2 | 302.0 | 4.5 | 20.3 | 93.6 | 1.73 | 220 |

| Ceramic + steel balls | 55.0 | 64.1 | 77.0 | 3.7 | 19.0 | 93.9 | 0.93 | 151 |

| Ceramic balls | 55.0 | 66.9 | 52.0 | 3.6 | 18.5 | 93.9 | 0.75 | 135 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, G.; Shao, Y.; Xiao, Q.; Wang, M.; Jin, S.; Wang, G.; Cao, Y. Study on the Effect of Grinding Media Material and Proportion on the Cyanide Gold Extraction Process. Minerals 2025, 15, 1031. https://doi.org/10.3390/min15101031

Niu G, Shao Y, Xiao Q, Wang M, Jin S, Wang G, Cao Y. Study on the Effect of Grinding Media Material and Proportion on the Cyanide Gold Extraction Process. Minerals. 2025; 15(10):1031. https://doi.org/10.3390/min15101031

Chicago/Turabian StyleNiu, Guiqiang, Yunfeng Shao, Qingfei Xiao, Mengtao Wang, Saizhen Jin, Guobin Wang, and Yijun Cao. 2025. "Study on the Effect of Grinding Media Material and Proportion on the Cyanide Gold Extraction Process" Minerals 15, no. 10: 1031. https://doi.org/10.3390/min15101031

APA StyleNiu, G., Shao, Y., Xiao, Q., Wang, M., Jin, S., Wang, G., & Cao, Y. (2025). Study on the Effect of Grinding Media Material and Proportion on the Cyanide Gold Extraction Process. Minerals, 15(10), 1031. https://doi.org/10.3390/min15101031