Abstract

In the view of the recycling and upscaling processes of waste materials, three different precursors, namely metakaolin, fly ash and volcanic ash, were mixed with Na- or K-silicate to produce binders aimed for the synthesis of geopolymer mortars based on construction and demolition wastes (CDWs). These later, used as aggregates in amount of 50 wt.%, were sampled in two geologically different Italian areas. A comparative study was carried out through a multidisciplinary approach using mineralogical–chemical analyses and physical–mechanical tests for the characterization of six binders and twelve mortars. The aim was to verify the effects of CDW interactions on binders as well as the extent of their compositional influences on the final properties. The chemical and mineralogical results evidenced strong compositional differences among the CDWs, differently influencing the physical–mechanical performances (i.e., compressive strength, density, water absorption and porosity) of the mortar samples. Regardless of the types of precursors and CDWs used, a better influence of K-silicate than sodium on the synthetised samples was observed. Furthermore, the higher versatility of metakaolin mortars with any type of CDW used was noted. Contrary, fly ash and volcanic ash mortars showed better properties with CDWs based on their high silica content and volcanic minerals. The study highlighted the critical roles of the CDW composition and precursor selection in mortar production. It confirmed that CDWs can be recycled for geopolymeric synthesis through proper characterisation and binder selection. Optimising these parameters allows for the successful integration of CDWs into geopolymeric materials. This process supports the advancement of a circular economy in the construction industry.

1. Introduction

Construction and demolition wastes (CDWs) represent a serious challenge for waste recycling in the frame of EU directives [1] and in view of the Sustainable Development Goals (SDGs) of Agenda 2030 [2]. The European Commission established a recovery target of 70% under the Waste Framework Directive [3]. The challenge stems from the enormous amount of CDW materials produced every year and their mismanagement, whose amount from the construction sector in Europe is attested to be 37.5 wt.% [4] of the total waste (i.e., most important producer per capita), and an even higher production is recorded in China, the United States and India [5].

Despite Europe having some of the most virtuous examples of CDW management [6], with a recycling rate close to the target of 70 wt.%, the real situation is different, since these values commonly include downcycling applications rather than recycling [7]. In fact, there is not yet a valid large-scale recycling of these materials, which could separate and valorise the different components or use the CDWs in bulk for upcycling applications [8]. This process is counteracted by the extreme CDW variability due to the presence of different types of building materials (bricks, concrete, rocks, wood, glass, etc.) used in ever-changing ratios [9], complicating the estimation of its average composition in a given area over a given period of time [10].

Indeed, by comparing the chemical compositions of CDWs from the literature [11,12,13,14,15,16,17,18,19,20], a huge compositional variability in the CDWs from different areas is observed. However, in some cases, a compositional affinity has been observed between CDW samples from the same area: in fact, two samples investigated by Abudureheman et al., 2021 [11] and Volpintesta et al., 2023 [19] showed similar CaO contents, despite being sampled years apart and at different recycling centres. This similarity suggests a compositional correlation depending on the geological background of the area from which the CDWs originated.

To investigate the effects of CDW variability in this work, two pieces of CDW coming from very different locations under the geological standpoint were sampled: Pollenza (Macerata, Marche, Italy) and Camporotondo Etneo (Catania, Sicily, Italy) [21]. The first sample comes from central Italy, in the Umbria–Marche Apennine Mts. area, with lithologies rich in limestones, travertines and sandstones [22]. The second comes from an area on the south slope of the Mt. Etna volcano, characterised by lava flows, composed mainly of hawaiiti mugeariti [23]. The geological difference between the two areas has important consequences on the availability of the extractive materials to be used as building materials. In detail, limestone, travertine, chalk, sand and gravel are extracted in the Marche area, whereas basalt and other volcanic rocks are from the area of eastern Sicily. This aspect reflects on the local construction sector and traditional construction styles [24], as well as the composition of the CDWs originating in the two areas.

Recently, in Italy, there has been legislative action aimed at revolutionising CDW recycling, which was until now, underestimated. The enactment of the norm “Ecological Transition” (DM No. 152, 27 September 2022) represents a pivotal moment in this endeavour, as it establishes regulations for removing the waste status from CDWs and other mineral-based inert wastes. Therefore, comprehending the application potential of CDWs based on their geographical distribution and geological characteristics assumes a particular significance, with the aim of achieving optimal recycling efficiency. This has the potential to generate a substantial impact in a broader perspective, benefiting the overall framework for recycling CDWs, as well as impact the extraction industry by decreasing the need for quarrying and the need to landfill unused materials, in line with EU directives on waste [25].

Moreover, the demands of the EU policy to find more sustainable solutions in the construction industry as an alternative to the high impact of cement-based materials [26] have boosted the interest in designing geopolymers thanks to their good performance, low CO2 emissions and high versatility [27]. In this scenario, several natural and industrial wastes, such as fly ash and volcanic ash, have been tested in the last years and used in potential applications of particular interest [28,29,30,31,32,33,34].

In this work, the aim is focused on the following research topics: (i) test if a high quantity of CDW used as an aggregate allows for the adequate physical–mechanical performance of the mortars; (ii) investigate how different CDW compositions can affect the mortars; (iii) determine the effectiveness of other waste materials like fly ash (FA) and volcanic ash (VA) as precursors to increase waste recycling and (iv) evaluate the influence of different types of alkaline solutions on the final properties. The motivation behind this investigation stemmed from the existing limitations in CDW recycling to produce high-grade construction materials, which are due to the lack of characterisation and difficulties in using heterogeneous materials such as CDWs [35,36,37]. The novelty of this study is that we chose to investigate two materials sourced from highly different geographical/geological areas to gain a deeper understanding of the behaviours of CDWs when used as aggregates in geopolymer mortars [19,36,37]. The results of this research will be useful in determining the effective recycling potentials of CDWs in geopolymer mortars, as well as investigating the best mix design necessary to obtain the best physical/mechanical performances, with the highest possible incorporation of recycled materials.

2. Materials and Methods

To carry out a comprehensive study, three types of precursors (metakaolin, fly ash and volcanic ash from the Mt. Etna volcano) and two types of alkaline reagents (sodium and potassium silicates) were used to produce six different types of binders. These binders were used to produce the mortars with the two types of CDWs. A multidisciplinary analytical approach was carried out to assess the mineralogical, chemical and physical–mechanical features in order to find the suitable application of these CDWs.

2.1. Materials

2.1.1. Construction and Demolition Wastes

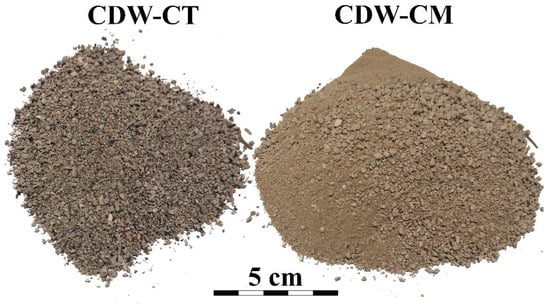

The CDWs were sampled in two geologically different areas in Italy: (i) in a small village located in the south flank of the Mt. Etna volcano (i.e., Camporotondo Etneo, Sicily), labelled as CDW-CT and (ii) in an area rich of sedimentary formations (Pollenza, Marche), indicated by CDW-CM. Both CDWs showed similar components: concrete, brick, natural rocks and traces of organic compounds (wood), whereas metals, plastics, glass, plaster and the eventually occurring cement–asbestos were preliminary removed. CDW-CT shows a greyish colour due to the presence of volcanic components (i.e., basaltic rocks and pyroclastic materials), while CDW-CM shows a brownish colour, caused by sedimentary rocks such as limestones and sandstones (Figure 1).

Figure 1.

CDW samples at the end of the grain-size standardisation procedure in accordance to EN 196-1: CDW-CT on the (left); CDW-CM on the (right).

Once sampled, the CDWs showed different particle sizes: 0–70 and 0–8 mm for CDW-CT and CDW-CM, respectively. They were preliminary quartered and dried in an oven at 105 °C until they reached a constant weight. Afterwards, sieving was carried out following the ASTM C136 procedure [38], to stabilise the samples and to obtain a grain-size distribution of 0.08–2 mm, in accordance with EN 196-1 [39] (7 wt.% for 2–1.6 mm, 26 wt.% for 1.6–1 mm, 34 wt.% for 1–0.5 mm, 20 wt.% for 0.5–0.16 and 13 wt.% for 0.16–0.08 mm).

2.1.2. Binder and Mortar Preparations

Three sets of geopolymeric binders were synthetised using different types of precursors (i.e., metakaolin, d90 = 15 µm; fly ash, d90 = 75 µm; volcanic ash, d90 = 75 µm) and two alkaline solutions (Table 1). In detail, each set was produced using two alkaline solutions: potassium (K2SiO3) and sodium (Na2SiO3) silicates produced by Ingessil s.r.l. (Italy). The molar ratio of the sodium solution (1.70 SiO2/Na2O molar ratio) was decreased and uniformed to that of the potassium solution (1.57 SiO2/K2O molar ratio) by dissolving NaOH pellets (>98 wt.% pure). The VA- and FA-sample sets were synthetised with the same liquid/solid ratio, which were calculated by considering the amount of the solid precursor and the alkaline solution used in the binder mixing. This ratio differs from that of the MK set.

Table 1.

Labels and formulation details of each set of binder and mortar samples.

The first binder, used as benchmark, was synthetised using only commercial metakaolin (MK) MetaverO (provided by GeoMITS s.r.l., Italy), characterised by an almost totally amorphous aluminosilicate composition produced by calcination at 750 °C using concentrated kaolin clay. The reactive Al content of the precursors was balanced by the alkali content of the liquid reagents to achieve a ratio between them of around one, respecting the relationships of a common geopolymer network based on metakaolin [27].

A second set was produced using fly ash (FA) as the main precursor, classified as class F and coming from a coal-fired power plant (Civitavecchia, Italy). A third set was prepared using the volcanic ash of the Mt. Etna volcano (Catania, Italy), which is considered a waste material once fallen on the city roads following Mt. Etna’s eruptions [40]. Once sampled, washed and dried, the pyroclastic materials (VA) underwent milling in a planetary mill to obtain a powder with an average grain size of 50 μm.

Considering previous studies [41,42] and to assure satisfying results, a small amount of MK was added in the last two sets in order to increase the low reactivities of fly ash and volcanic ash due to their low Al amounts compared to that of MK.

For the binder’s preparation, the precursors were mixed with one of the alkaline solutions (Na or K) for 5 min at the maximum speed (no-load speed of 1000 rpm) using a laboratory mixer. To obtain a comparable workability between the sodic and potassic mixtures while maintaining a constant solid/liquid ratio (L/S), a small amount of water was added to the sodium sets to balance the higher viscosity of sodium silicate. With MK being the most reactive precursor, the MK-based binders needed more alkaline reagent to adequately balance the reactive aluminium present in the precursor with the alkalis in the silicate. This behaviour led to an L/S ratio of 1.14, which was higher than that of the FA and VA binders, for which the same L/S ratio (0.42) was maintained by modulating the MK content. For the mortar preparation, the aggregates (CDW-CT or CDW-CM by equal weight to the binder) and extra water (5 wt.% of the aggregates, thus, 2.5 wt.% considering the total mixture amount) were added to the binder mixtures to achieve a satisfying workability for the consequent increase in the solid components. Indeed, the extra water was not accounted for in the percentage calculation of the mortar mixtures, but it was considered as an additive to enhance the workability. The mix designs of the samples are reported in Table 1. With this approach, the recycling of the various waste materials, namely fly ash, volcanic ash and CDWs for mortar production guaranteed the use of ~72 wt.% and ~75 wt.% waste contents in VA and FA mortars, respectively, compared to 50% in MK mortars.

2.2. Methods

Both precursors and CDW samples were characterised using X-ray Fluorescence (XRF) and X-ray Diffraction (XRD) to determine the chemical compositions and the mineralogical species, respectively. Moreover, the CDWs underwent a physical investigation to define their real density with the cone pycnometer test. The synthetised materials were investigated for their physical and mechanical properties after 28 days of curing. The mineralogical compositions of the binders were evaluated with XRD, while Scanning Electron Microscopy (SEM) was used to investigate the morphologies and textures of some mortar samples.

2.2.1. X-ray Fluorescence

An X-ray Fluorescence spectroscopy (XRF) analysis for major elements was carried out on the powders of all precursors and CDW samples using a PANalytical Zetium compact spectrometer with a Rh anode and a 4 kV X-ray generator. The analyses were carried out using 7 g per sample, milled to powder in an agate mortar and then analysed.

2.2.2. X-ray Diffraction

X-ray Diffraction (XRD) measurements were performed on the CDWs and precursors by using a Miniflex Rigaku equipped with a Ni filter and Cu Kα radiation generated at 40 kV and 15 mA. The measurement setting involved a scanning speed of 5.0°/min and step of 0.02° within the 2θ range of 5° to 65°. BGMN/Profex 5.0 software was used for data processing [43]. Moreover, 2 wt.% of a standard corundum powder (NIST code 676a) was added to each sample before the measurements in order to guarantee the centring of the peaks. The structures of the selected phases belong to the BGMN database, which is available at http://www.bgmn.de/index.html (accessed on 19 December 2023).

2.2.3. Uniaxial Compressive Strength

The uniaxial compressive resistance was estimated on cubes with a 40 mm side length after 28 days of curing. For each sample set (i.e., binders and mortars), three specimens were tested. The tests were performed using a cement compression machine with a 300 kN load cell, which was equipped with a compression device to test cubes of 40 mm and had a loading rate of 1 kN/s. The output values of the compressive strength (Rc) were calculated in MPa, considering the average of the replicas of each sample set.

2.2.4. Physical Tests

The real density of the aggregates was determined using the procedure complying to the EN1097-6 reference standard [44]. The test was performed in laboratory-controlled conditions (20 ± 2 °C). Three sets of 10 g of each aggregate were analysed after they were dried and sieved according to the grain size distribution of EN196-1.

The open porosity (OP), water absorption (WA) and density (bulk density ρb and material density ρm) of the binder and mortar samples were measured, after being dried in a laboratory oven, using a precision balance (0.01 g of resolution) equipped with tools for determining the specific weights. Conversely, the OP and WA were calculated for 4 cubic specimens of each mixture with a side length of 20 mm. The samples were immersed in distilled water for 24 h, boiled for 2 h and then left immersed in water until they reached a constant weight. Afterwards, their saturated weights (Ws) and total volumes (Vtot) were calculated using a hydrostatic balance after they completely reached saturation. The dry weight (Wd) in an oven set to 105 °C was recorded. Finally, the measurements allowed us to calculate the density (ρb and ρm), OP and WA as per Equations (1)–(4).

2.2.5. Scanning Electron Microscope

The mortar samples were investigated using a field-emission scanning electron microscope (SEM) Zeiss Sigma-300 in a Back Scattered Electron (BSE) mode with a voltage of 15 kV. Small fragments, once polished, were fixed on aluminium stubs using self-adhesive conductive carbon tabs and coated with a thin layer of graphitic carbon. A 77× magnification was used, allowing us to achieve a resolution down to a few millimetres.

3. Results

3.1. CDW Characterisation

3.1.1. Chemical Composition

Table 2 reports the major element chemical compositions of the aggregates and precursors (i.e., metakaolin, fly ash and volcanic ash). In detail, it shows a strong bulk chemical difference between the two CDWs used as aggregates. As expected, given the different areas of provenance, CDW-CT is higher in SiO2 (~41 wt.%) compared to CDW-CM (~24 wt.%), which, instead, has a higher predominance of CaO (~37 wt.%) compared to CDW-CT (~18 wt.%). Moreover, CDW-CT is much higher in Al2O3 (~13 wt.%) and Fe2O3 ~7 wt%), with a low L.O.I. (~10 wt.%).

Table 2.

Major elements of raw materials studied, obtained using XRF. Abundances are expressed as wt.% of oxides. LLD = Lower Limit Detectable. LOI = Loss of Ignition at 900 °C.

The chemistries of the precursors show an aluminosilicate composition with a SiO2/Al2O3 molar ratio of 1.21, 2.54 and 2.85, respectively, for metakaolin (MK), fly ash (FA) and volcanic ash (VA). Different from MK and FA, VA contains modest amounts of CaO and Fe2O3, equal to ~10 and ~11 wt.%, respectively. Indeed, this difference of a higher SiO2/Al2O3 molar ratio and lower reactivity than MK and FA makes VA a suitable precursor, as demonstrated by previous works [45].

3.1.2. Mineralogical Composition

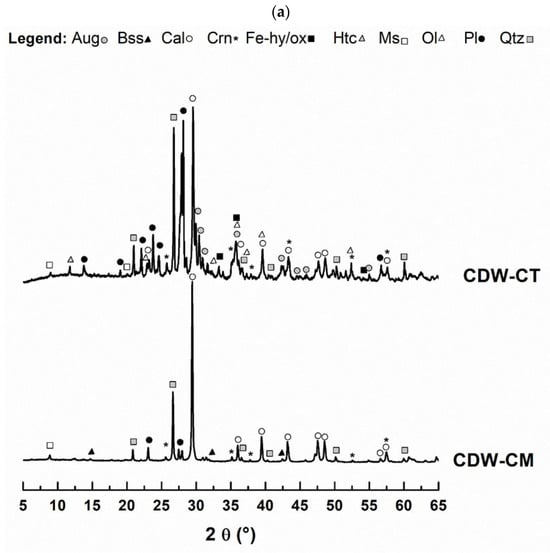

The diffraction patterns of the construction and demolition wastes and precursors are plotted in Figure 2. The two CDW samples evidence strong compositional differences linked to the typology of the waste components and the geology of the sampling areas (Figure 2a). Indeed, CDW-CM shows calcite and contributions of quartz, plagioclase, muscovite and traces of bassanite. Differently, CDW-CT evidences a larger mineral variety, due to the dominant presence of species that are characteristic of basaltic rocks (i.e., plagioclase, augite, forsterite–olivine and iron hydroxide–oxide, mostly hematite and magnetite), quartz and smaller amounts of calcite compared to CDW-CM.

Figure 2.

(a) Powder XRD pattern of construction and demolition wastes (CDWs) from the two areas. Sample labels: CDW-CM = from Camerino; CDW-CT = from Catania; (b) powder XRD pattern of precursors. Sample labels: MK = metakaolin; FA = fly ash; VA = volcanic ash. Mineralogical species associated to the symbolism: Ant = anatase; Aug = augite; Bss = bassanite; Cal = calcite; Chl = chlorite; Crn = corundum; Fe-hy/ox = hematite and/or magnetite; Htc = hydrotalcite; Kln = kaolinite; Ms = muscovite; Mul = mullite; Ol = forsterite; Pl = anorthite; Qtz = quartz.

The mineralogical differences of the precursors were indicated by their diffractometric patterns, which are plotted in Figure 2b. Metakaolin showed little contribution of minerals, namely anatase, muscovite, quartz and kaolinite, due to the dominant amorphous structure. Analogously, fly ash evidenced an amorphous structure with small amounts of magnetite, mullite and quartz. Instead, volcanic ash displayed anorthite–plagioclase, augite, forsterite and ± iron oxide/hydroxide, with little evidence of clay minerals, namely muscovite and chlorite as impurities, demonstrating the heterogeneity of pyroclastic deposits as well as the alteration rate occurring in the sampled deposits [46].

3.1.3. Real Density

The real density was considered using the mean of three replicas for each CDW sample. CDW-CM shows a real density of 2.31 ± 0.08 g/cm3, which is distinctively lower than that of CDW-CT, whose average is 2.45 ± 0.04 g/cm3. This difference reflects the different mineralogical and chemical compositions of the two waste samples.

3.2. Synthesised Materials

3.2.1. Uniaxial Compressive Strength

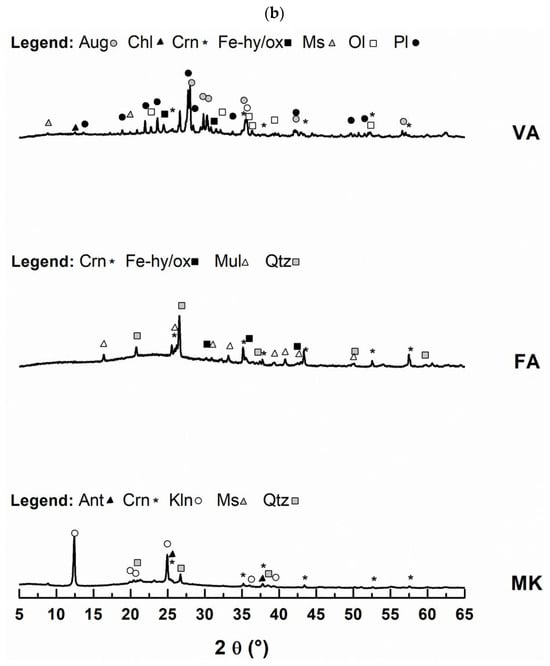

Table 3 reports the results of the uniaxial compressive resistance test of all sample sets (i.e., binders and mortars). The values of binders ranged between 35.1 ± 1.6 (for FA-based) and 61.2 ± 5 MPa (for VA-based), achieving the range of cement strength classes (i.e., 32.5, 42.5 and 52.5 MPa after 28 curing days) in the EN197-1 reference standard [47]. In particular, VA binders evidenced the highest performance of all sample sets, including the benchmarked set based on metakaolin only (MK-based samples, ~54 MPa).

Table 3.

Results obtained from the measurements of physical–mechanical properties: bulk density (ρb), material density (ρm), open porosity (OP), water absorption (WA) and compressive strength (Rc).

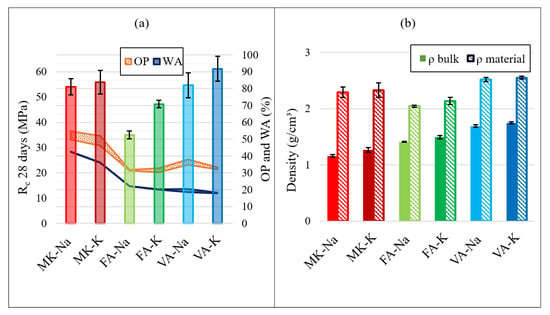

Variations were observed in relation to the type of alkaline solution used, as illustrated in Figure 3. The samples synthesised utilising potassium silicate exhibited higher compressive strength (Rc) values relative to those prepared with the same precursor but employing sodium silicate. This enhancement in the Rc was pronounced for both FA binders and VA binders, where an increase in the compressive strength was recorded: for the FA set, from approximately 35 to 47 MPa; for the VA set, from approximately 54 to 61 MPa. Conversely, the substitution of potassium silicate for sodium silicate did not manifest a significant difference in the compressive strength of the metakaolin-based (MK-based) samples.

Figure 3.

Compressive strengths of binder and mortar samples after 28 days of curing. Legend: MK = metakaolin; FA = fly ash; VA = volcanic ash; Na = sodium silicate; K = potassium silicate; CM = CDW from Macerata; CT = CDW from Catania.

The introduction of CDWs as the aggregate fraction in mortars led to a pronounced decrease in the Rc for all binder types (Figure 3), with variations from a few MPa up to 1/3 of the original values. The addition of CDWs demonstrated variable impacts on the results of the mortar samples: generally, the combination of K sets and CDW-CT showed a superior performance over the combination of Na sets and CDW-CM, regardless of the precursors used. Specifically, MK-based samples exhibited better compressive strengths compared to VA and FA sets, despite a notable reduction in the compressive strength, with values decreasing from approximately 40 MPa in MK-Na-CT samples to 31 MPa in MK-Na-CM samples. This trend was more significant in the VA and FA mortars, with considerably lower values: 20 and 1 MPa, respectively, for Na-CT and Na-CM samples. Therefore, MK mortars evidenced a better versatility regardless of the CDW sample used, as well as a slight difference regarding the silicate used.

Moreover, the influence of the alkaline solution was also evident in the mortar samples, despite the reduction in the compressive resistance due to the aggregate used. The mortars produced with the sodium silicate evidenced worse results compared with those produced with K silicate. However, this decrease was less evident in MK-based compositions (Table 3 and Figure 3).

3.2.2. Physical Tests

The results of the physical tests, namely density (ρb and ρm), open porosity (OP) and water absorption (WA), including the mechanical strengths were listed in Table 3. The ρm values of binders evidenced differences among them: VA-based geopolymers showed the highest values (~2.54 g/cm3), followed by MK-based (~2.31 g/cm3) and FA-based (~2.07 g/cm3) ones. Conversely, a different trend was observed concerning ρb, wherein VA-based binders still exhibited the highest values (~1.72 g/cm3), but they were followed by FA- (~1.43 g/cm3) and MK-based ones (~1.20 g/cm3, respectively). These trends suggested more porous structures for MK-based binders, corroborated by the OP and WA results, which revealed higher values for MK-based binders and lower, comparable values for FA- and VA-based ones, correlating with the variations in ρm (Table 3). This behaviour could be due to high amount of water within the solution, which did not participate in the geopolymerisation reactions except as a carrier for elements and for evaporation generated in the voids [27]. The other binders showed a lower porosity, probably due to the greater amount of non-reactive fractions that act as a filler, partially filling the porosity and counteracting shrinkage [48]. Furthermore, potassic silicate provided denser samples compared to those obtained with sodium silicate.

From the correlation of the physical–mechanical performance of the binders, MK-based binders evidenced good mechanical strengths, which were between those of VA and FA binders, the lowest bulk density (ρb) and the highest OP and WA rates among all other binders. However, their matrix densities (ρm) were higher than those of FA-based binders (Figure 4). The latter showed the lowest mechanical strengths, contrary to the highest of VA ones, but similar behaviours to the volcanic set regarding the OP and WA rates (Figure 4a). The excellent strengths recorded in the VA samples agreed with the highest values of density (Figure 4b); their behaviours can be attributed to the low reactivity of volcanic powder, acting as a fine filler for improving the mechanical resistance [49,50]. Moreover, regardless of the type of precursor and the presence of aggregate or not, the best mechanical performances are obtained using potassium silicate. This finding underlined two different aspects. On one hand, it shows the significant impact produced by the choice of silicate type and precursor on the final physical and mechanical properties of geopolymers [51]. On the other hand, it demonstrates how the compressive strengths are strongly influenced by the physical properties, with higher strengths related to a higher density and lower porosity and water absorption [52,53].

Figure 4.

Physical–mechanical properties of the binders. Legend: (a) compressive strength (Rc), water absorption (WA) and open porosity (OP); (b) bulk density (ρb) and material density (ρm).

After the aggregate addition, the ρm values exhibited changes: an increase was noted in the MK- and FA-based samples, whereas a decrease was observed in the VA-based samples (Table 3). Moreover, the results of ρa and ρb in mortars presented more pronounced variations compared to those for ρm. Such behaviours depend on a modification in the porosity following aggregate addition. This phenomenon was also reflected in the OP and WA, but in an opposite trend. Sudden changes in the physical properties after aggregate addition could be considered an indicator of the importance of secondary reactions that decreased the workability [19]. Therefore, the findings revealed that CDW-CM accelerated the setting of the mixture compared to CDW-CT, particularly in FA- and VA-based samples, with more significant effects in the formulations mixed with sodium silicate (Table 3).

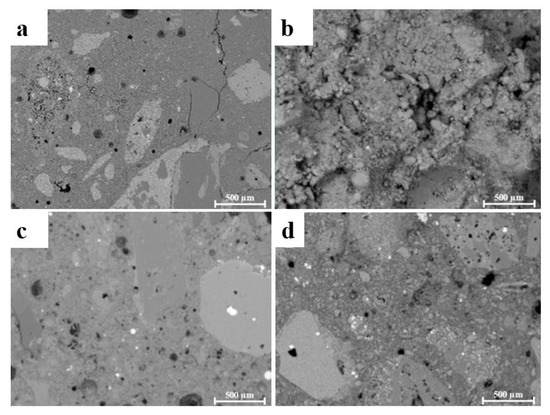

3.2.3. Scanning Electron Microscope

Figure 5 shows the micrographs, obtained using an SEM analysis, of each of the following four representative mortars: MK-Na-CM (a), FA-Na-CM (b), FA-K-CT (c) and VA-K-CT (d). The choice of these samples took into account the compositional variability of the mixtures in terms of the precursors, silicate and CDW aggregate. Figure 5b exhibits a different structure in relation to the others due to the poor cohesion of the binder in the FA-Na-CM sample during the polishing procedure. Generally, all samples displayed a compact structure with spotty voids as well as a pronounced variability in terms of the size (<500 µm) and shape of the aggregates used. In detail, the MK-Na-CM sample displayed a matrix with few voids and cracks, as well as an aggregate with a polymodal size and sub-spherical and elongated shapes (Figure 5a). However, the other mortars did not show any cracks, which was maybe due to the polishing procedure or more generally, the shrinkage phenomena, but showed only sub-spherical voids due to the air trapped during the sample preparations (Figure 5b–d).

Figure 5.

SEM-BSE images of some samples: (a) MK-Na-CM; (b) FA-Na-CM; (c) FA-K-CT; (d) VA-K-CT.

4. Discussion

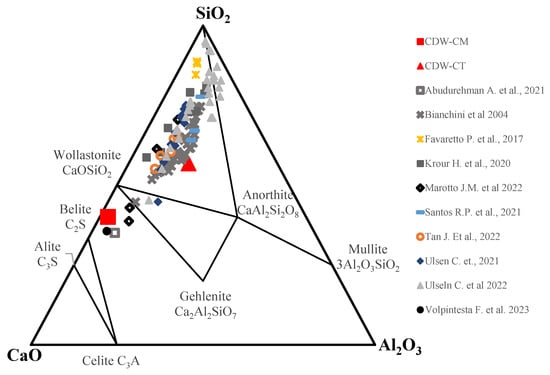

The strong heterogeneity of CDWs, in terms of their composition [54] and size [55], represents a critical issue for their valorisation in geopolymer materials [51]. This is in addition to the complexity of finding optimal mix designs for geopolymer mixtures based on, other waste materials being used as precursor, as in our case. Concerning the type and the nature of both clusters of aggregates, a strong difference in the chemical and mineralogical compositions was recorded due to the different lithologies of the two provenance areas. In particular, CDW-CT showed a chemical predominance of SiO2 compared to that of CaO in CDW-CM. The CaO-Al2O3-SiO2 (CAS) diagram highlighted how our CDW samples fall in very distinct categories due to their strong compositional differences, also against other CDWs in the literature, which are mostly rich in silica, as reported for comparison in Figure 6. This difference in chemical compositions was further confirmed by the mineralogical analysis, showing a prevalence of calcite in CDW-CM and volcanic minerals in CDW-CT.

Figure 6.

CAS diagram (CaO-Al2O3-SiO2) showing the chemical compositions of CDWs from this study and other CDWs in the literature: Volpintesta F. et al., 2023 [19]; Abudurehman. et al., 2021 [11]; Bianchini et al., 2004 [12]; Favaretto P. et al., 2017 [13]; Santos R.P. et al., 2021 [14]; Tan J. et al., 2022 [15]; Ulsen C. et., 2021 [17]; Marotto J.M. et al., 2022 [20]; Krour H. et al., 2020 [18]; Ulseln C. et al., 2022 [16].

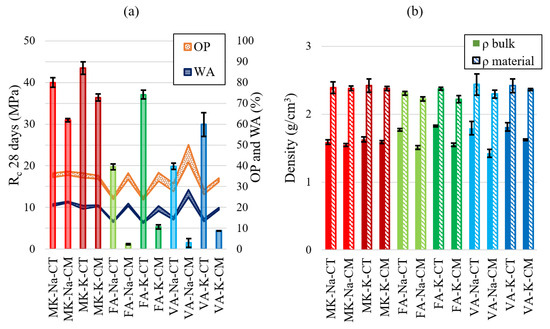

Moreover, the higher LOI value of CDW-CM than the one from Catania resulted in a higher decarbonation rate due to not only to the organic matter but also the cement materials it contained. This finding confirmed the differences in the chemical and mineralogical compositions, and thus, its lower density compared with the CDW-CT sample (2.31 ± 0.08 g/cm3 and 2.45 ± 0.04 g/cm3, respectively). The experimental investigation revealed that the variability in the density observed in the binders persisted also in the mortars, influencing their final physical–mechanical properties.

Specifically, mortars with CDW-CT exhibited a consistently higher ρm and ρb compared to those with the CDW-CM aggregate (Figure 7a). This phenomenon was particularly pronounced in mortars formulated with less reactive precursors, such as fly ash (FA) and volcanic ash (VA), which required a lower L/S ratio. The higher liquid fraction in MK-based binders limited the reduction in the workability of mortars following the inclusion of aggregates. The setting time was faster in relation to the type of aggregate used, with more significant effects for CDW-CM. This behaviour is due to the reaction between its reactive Ca-rich components and the alkaline reagent, inducing the flash set phenomenon, as already observed [56].

Figure 7.

Physical–mechanical properties of the mortars obtained with different precursors (MK, FA and VA), alkaline reagents (K or Na) and CDW (CT or CM). Legend: (a) compression strength (Rc), water absorption (WA) and open porosity (OP); (b) bulk density (ρb) and material density (ρm).

Moreover, mortars with CDW-CM showed less dense structures (Figure 7b), yet concurrently, they were more porous and absorbent, as observed by the high values of OP and WA (Figure 7a). This effect was further accentuated in the mortars formulated with sodium silicate, where the higher viscosity of sodium binders compared to potassium-based ones worsened the adverse effects of rapid setting, reducing the workability. Notoriously, the L/S ratio as well as the mix design of the mixtures (including precursors and type of alkaline solution and aggregate) strongly influence the microstructure in terms of its density and porosity system (e.g., pore size), with a subsequent impact on the final mechanical properties of the consolidated samples [57,58,59,60]. Therefore, the difficulty in creating a suitable mix design necessitates a deep investigation of the raw materials involved in the process as well as the careful choice of alkaline reagent and its ratio.

5. Conclusions

The study showed the substantial differences between CDWs coming from two different Italian geological areas and how their chemical and mineralogical compositions affect the physical–mechanical behaviours of synthetised geopolymer mortars. Although most of the produced mortars, with 50 wt.% CDW in MK mortars and ~75 wt.% in VA and FA ones, demonstrated good to excellent properties, some combinations among precursors, alkaline components and CDW gave the best results:

- Metakaolin (MK) exhibited a favourable response to both types of CDW aggregates, with potassium silicate outperforming sodium silicate in terms of effectiveness.

- Despite the poor compatibility of CDW-CM with FA and VA binders, aggregates from Catania (CDW-CT) showed good compatibility and yielded positive outcomes with both waste materials (FA and VA), suggesting their high potentiality for practical applications.

- The combination of multiple precursors in the geopolymer binder formulation positively influenced the physical–mechanical properties as well as the compactness of the microstructure of the synthesised materials, facilitating an improved mix design and the more efficient recycling of waste materials.

This research underscores the critical significance of performing a comprehensive chemical and mineralogical analysis of CDWs. Such an evaluation is essential not only for identifying novel upcycling opportunities that enhance the values of these waste materials but is particularly useful for their use as geopolymer mortars. This process facilitates the inclusion of substantial quantities of waste materials, extending beyond CDWs to encompass volcanic ash, fly ash and other forms of industrial waste. Thus, the findings advocate for a deep characterisation of CDWs as a foundational step towards the development of geopolymer materials with improved sustainability and environmental benefits.

Author Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis: F.V. and C.F.; first draft of the manuscript: F.V. and C.F.; manuscript review: E.P., G.B. and P.M. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the following grants: P.M. and G.B. for a POR-FESR 2014–2020 project entitled “Sicilia Eco Innovative Technologies—SETI”, CUP G38I18000960007, C.F. for the EU-funded PON REACT project (CUP E65F21002200005) and E.P. for PRIN 2022 and Progetto Coesione Territoriale “Trailed-lab”.

Data Availability Statement

All data used during the study appear in the submitted article.

Acknowledgments

The authors acknowledge the reviewers for the helpful revision works.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Iacoboaea, C.; Aldea, M.; Petrescu, F. Construction and Demolition Waste—A Challenge for the European Union? Theor. Empir. Res. Urban Manag. 2019, 14, 30–52. [Google Scholar]

- Arora, N.K.; Mishra, I. United Nations Sustainable Development Goals 2030 and Environmental Sustainability: Race against Time. Environ. Sustain. 2019, 2, 339–342. [Google Scholar] [CrossRef]

- Moschen-Schimek, J.; Kasper, T.; Huber-Humer, M. Critical Review of the Recovery Rates of Construction and Demolition Waste in the European Union—An Analysis of Influencing Factors in Selected EU Countries. Waste Manag. 2023, 167, 150–164. [Google Scholar] [CrossRef] [PubMed]

- Borghi, G.; Pantini, S.; Rigamonti, L. Life Cycle Assessment of Non-Hazardous Construction and Demolition Waste (CDW) Management in Lombardy Region (Italy). J. Clean. Prod. 2018, 184, 815–825. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Legambiente. Rapporto Cave 2021: La Transizione Dell’economia Circolare Nel Settore Delle Costruzioni; Legambiente: Rome, Italy, 2021. [Google Scholar]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An Overview of the Waste Hierarchy Framework for Analyzing the Circularity in Construction and Demolition Waste Management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Galán, B.; Viguri, J.R.; Cifrian, E.; Dosal, E.; Andres, A. Influence of Input Streams on the Construction and Demolition Waste (CDW) Recycling Performance of Basic and Advanced Treatment Plants. J. Clean. Prod. 2019, 236, 117523. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Campioli, A. Guidelines for Effective and Sustainable Recycling of Construction and Demolition Waste. Des. Sustain. Technol. Prod. Policies 2018, 211–221. [Google Scholar] [CrossRef]

- Simone, M.; Rana, P. Supporting Environmentally Sound Decisions for Construction and Demolition (C&D) Waste Management—A Practical Guide to Life Cycle Thinking (LCT) and Life Cycle Assessment (LCA); Publications Office: Luxembourg, 2011. [Google Scholar] [CrossRef]

- Abudurehman, A.; Stabile, P.; Carroll, M.R.; Santulli, C.; Paris, E. Mineralogical and Chemical Characterization of CDW as Function of Particle Size and Thermal Treatments for Potential Recycling. Detritus 2021, 15, 40. [Google Scholar] [CrossRef]

- Bianchini, G.; Marrocchino, E.; Tassinari, R.; Vaccaro, C. Recycling of Construction and Demolition Waste Materials: A Chemical–Mineralogical Appraisal. Waste Manag. 2005, 25, 149–159. [Google Scholar] [CrossRef]

- Favaretto, P.; Hidalgo, G.E.N.; Sampaio, C.H.; De Almeida Silva, R.; Lermen, R.T. Characterization and Use of Construction and Demolition Waste from South of Brazil in the Production of Foamed Concrete Blocks. Appl. Sci. 2017, 7, 1090. [Google Scholar] [CrossRef]

- Santos, R.P.; Tubino, R. Potential Evaluation of the Use of Construction and Demolition Waste (CDW) in the Recovery of Degraded Soils by Mining in Brazil. Resour. Conserv. Recycl. Adv. 2021, 12, 200060. [Google Scholar] [CrossRef]

- Tan, J.; Cai, J.; Li, J. Recycling of Unseparated Construction and Demolition Waste (UCDW) through Geopolymer Technology. Constr. Build. Mater. 2022, 341, 127771. [Google Scholar] [CrossRef]

- Ulsen, C.; Contessotto, R.; Dos Santos Macedo, R.; Kahn, H. Quantification of the Cement Paste and Phase’s Association in Fine Recycled Aggregates by SEM-Based Image Analysis. Constr. Build. Mater. 2022, 320, 126206. [Google Scholar] [CrossRef]

- Ulsen, C.; Antoniassi, J.L.; Martins, I.M.; Kahn, H. High Quality Recycled Sand from Mixed CDW—Is That Possible? J. Mater. Res. Technol. 2021, 12, 29–42. [Google Scholar] [CrossRef]

- Krour, H.; Trauchessec, R.; Lecomte, A.; Diliberto, C.; Barnes-Davin, L.; Bolze, B.; Delhay, A. Incorporation Rate of Recycled Aggregates in Cement Raw Meals. Constr. Build. Mater. 2020, 248, 118217. [Google Scholar] [CrossRef]

- Volpintesta, F.; Ossoli, E.; Reggiani, A.; Stabile, P.; Santulli, C.; Paris, E. Geopolymers-Based Application for the up-Cycling Utilization of Construction and Demolition Waste from the 2016 Central Italy Earthquakes. Mater. Lett. 2023, 336, 133849. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Delgado-Plana, P.; Cabezas-Rodríguez, R.; Mejía de Gutiérrez, R.; Eliche-Quesada, D.; Pérez-Villarejo, L.; Galán-Arboledas, R.J.; Bueno, S. Alkaline Activation of High-Crystalline Low-Al2O3 Construction and Demolition Wastes to Obtain Geopolymers. J. Clean. Prod. 2022, 330, 129770. [Google Scholar] [CrossRef]

- Compagnoni, B.; Galluzzo, B.; Bonomo, R.; Capotorti, F.; D’Ambrogi, C.; Di Stefano, R.; Graziano, R.; Martarelli, L.; Pampaloni, M.L.; Pantaloni, M.; et al. Carta Geologica alla Scala 1 a 1,000,000. 2011. Available online: https://www.isprambiente.gov.it/it/attivita/suolo-e-territorio/cartografia/carte-geologiche-a-piccola-scala/carta-geologica-alla-scala-1-a-1000000 (accessed on 19 December 2023).

- Cello, C. Note Illustrative Della Carta Geologica d’Italia alla Scala 1:50,000—Foglio 303 Macerata; Istituto Superiore per la Protezione e la Ricerca Ambientale: Rome, Italy, 2009. [Google Scholar]

- Branca, S.; Coltelli, M.; Groppelli, G.; Lentini, F. Geological Map of Etna Volcano, 1:50,000 Scale. Ital. J. Geosci. 2011, 130, 265–291. [Google Scholar] [CrossRef]

- Belfiore, C.M.; Montalto, G.; Finocchiaro, C.; Cultrone, G.; Mazzoleni, P. Durability Tests on Lime-Based Mortars from the Historic Built Heritage of Catania (Eastern Sicily, Italy): An Experimental Study. J. Build. Eng. 2023, 80, 108137. [Google Scholar] [CrossRef]

- Chioatto, E.; Sospiro, P. Transition from Waste Management to Circular Economy: The European Union Roadmap. Environ. Dev. Sustain. 2023, 25, 249–276. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and Carbon Emissions for Geopolymer Pastes in Comparison to Ordinary Portland Cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Institut Géopolymère: Saint-Quentin, France, 2020; ISBN 9782954453118. [Google Scholar]

- Fugazzotto, M.; Occhipinti, R.; Cristina Caggiani, M.; Coccato, A.; Finocchiaro, C.; Lanzafame, G.; Mazzoleni, P.; Nucatolo, G.; Piacenti, G.; Starinieri, S.; et al. Restoration Feasibility Study by Using Alkali Activated Mortars Based on Mt. Etna Volcanic Ash: The Case Study of Monreale Cathedral (Palermo, Italy). Mater. Lett. 2023, 333, 133626. [Google Scholar] [CrossRef]

- Traven, K.; Češnovar, M.; Škapin, S.D.; Ducman, V. High Temperature Resistant Fly-Ash and Metakaolin-Based Alkali-Activated Foams. Ceram. Int. 2021, 47, 25105–25120. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R. Fly Ash-Based Geopolymers Containing Added Silicate Waste. A Review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Abbas, S.; Saleem, M.A.; Kazmi, S.M.S.; Munir, M.J. Production of Sustainable Clay Bricks Using Waste Fly Ash: Mechanical and Durability Properties. J. Build. Eng. 2017, 14, 7–14. [Google Scholar] [CrossRef]

- Tigue, A.A.S.; Dungca, J.R.; Hinode, H.; Kurniawan, W.; Promentilla, M.A.B. Synthesis of a One-Part Geopolymer System for Soil Stabilizer Using Fly Ash and Volcanic Ash. MATEC Web Conf. 2018, 156, 05017. [Google Scholar] [CrossRef]

- Çelikten, S.; Erdoğan, G. Effects of Perlite/Fly Ash Ratio and the Curing Conditions on the Mechanical and Microstructural Properties of Geopolymers Subjected to Elevated Temperatures. Ceram. Int. 2022, 48, 27870–27877. [Google Scholar] [CrossRef]

- Sarıdemir, M.; Çelikten, S. Effects of Ms Modulus, Na Concentration and Fly Ash Content on Properties of Vapour-Cured Geopolymer Mortars Exposed to High Temperatures. Constr. Build. Mater. 2023, 363, 129868. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Yamada, M.; Kawamoto, K. A Review of Construction and Demolition Waste Management in Southeast Asia. J. Mater. Cycles Waste Manag. 2020, 22, 315–325. [Google Scholar] [CrossRef]

- Panizza, M.; Natali, M.; Garbin, E.; Ducman, V.; Tamburini, S. Optimization and Mechanical-Physical Characterization of Geopolymers with Construction and Demolition Waste (CDW) Aggregates for Construction Products. Constr. Build. Mater. 2020, 264, 120158. [Google Scholar] [CrossRef]

- Panizza, M.; Natali, M.; Garbin, E.; Tamburini, S.; Secco, M. Assessment of Geopolymers with Construction and Demolition Waste (CDW) Aggregates as a Building Material. Constr. Build. Mater. 2018, 181, 119–133. [Google Scholar] [CrossRef]

- ASTM, C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM: West Conshohocken, PA, USA, 2015.

- EN 196-1; CEN Standard Sand. CEN: Brussels, Belgium, 2016.

- Cavalieri, M.; Ferrara, P.L.; Finocchiaro, C.; Martorana, M.F. An Economic Analysis of the Use of Local Natural Waste: Volcanic Ash of Mt. Etna Volcano (Italy) for Geopolymer Production. Sustainability 2024, 16, 740. [Google Scholar] [CrossRef]

- Finocchiaro, C.; Belfiore, C.M.; Barone, G.; Mazzoleni, P. IR-Thermography as a Non-Destructive Tool to Derive Indirect Information on the Physical-Mechanical Behaviour of Alkali Activated Materials. Ceram. Int. 2022, 48, 36178–36185. [Google Scholar] [CrossRef]

- Scanferla, P.; Finocchiaro, C.; Gharzouni, A.; Barone, G.; Mazzoleni, P.; Rossignol, S. High Temperature Behavior of Sodium and Potassium Volcanic Ashes-Based Alkali-Activated Materials (Mt. Etna, Italy). Constr. Build. Mater. 2023, 408, 133702. [Google Scholar] [CrossRef]

- Doebelin, N.; Kleeberg, R. Profex: A Graphical User Interface for the Rietveld Refinement Program BGMN. J. Appl. Crystallogr. 2015, 48, 1573–1580. [Google Scholar] [CrossRef] [PubMed]

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates. Determination of Particle Density and Water Absorption. CEN: Brussels, Belgium, 2022.

- Finocchiaro, C.; Barone, G.; Mazzoleni, P.; Sgarlata, C.; Lancellotti, I.; Leonelli, C.; Romagnoli, M. Artificial Neural Networks Test for the Prediction of Chemical Stability of Pyroclastic Deposits-Based AAMs and Comparison with Conventional Mathematical Approach (MLR). J. Mater. Sci. 2021, 56, 513–527. [Google Scholar] [CrossRef]

- Lanzafame, G.; Caggiani, M.C.; Finocchiaro, C.; Barone, G.; Ferlito, C.; Gigli, L.; Mazzoleni, P. Multidisciplinary Characterization of the “Ghiara” Volcanic Paleosoil (Mt. Etna Volcano, Italy): Petrologic Characters and Genetic Model. Lithos 2022, 418–419, 106679. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. CEN: Brussels, Belgium, 2011.

- Khan, M.N.N.; Jamil, M.; Karim, M.R.; Zain, M.F.M.; Kaish, A.B.M.A. Filler Effect of Pozzolanic Materials on the Strength and Microstructure Development of Mortar. KSCE J. Civ. Eng. 2017, 21, 274–284. [Google Scholar] [CrossRef]

- Djon Li Ndjock, B.I.; Elimbi, A.; Cyr, M. Rational Utilization of Volcanic Ashes Based on Factors Affecting Their Alkaline Activation. J. Non-Cryst. Solids 2017, 463, 31–39. [Google Scholar] [CrossRef]

- Baenla, J.; Bike Mbah, J.B.; Djon Li Ndjock, I.B.; Elimbi, A. Partial Replacement of Low Reactive Volcanic Ash by Cassava Peel Ash in the Synthesis of Volcanic Ash Based Geopolymer. Constr. Build. Mater. 2019, 227, 116689. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Vlachou, A.; Bartzas, G.; Galetakis, M. Effect of Synthesis Parameters on the Quality of Construction and Demolition Wastes (CDW) Geopolymers. Adv. Powder Technol. 2015, 26, 368–376. [Google Scholar] [CrossRef]

- Raza, M.H.; Khan, M.; Zhong, R.Y. Strength, Porosity and Life Cycle Analysis of Geopolymer and Hybrid Cement Mortars for Sustainable Construction. Sci. Total Environ. 2024, 907, 167839. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Ruan, S.; Zeng, Q.; Liu, Y.; Zhang, M.; Tian, Y.; Yan, D. Pore Structure of Geopolymer Materials and Its Correlations to Engineering Properties: A Review. Constr. Build. Mater. 2022, 328, 127064. [Google Scholar] [CrossRef]

- Vásquez, A.; Cárdenas, V.; Robayo, R.A.; De Gutiérrez, R.M. Geopolymer Based on Concrete Demolition Waste. Adv. Powder Technol. 2016, 27, 1173–1179. [Google Scholar] [CrossRef]

- De Rossi, A.; Ribeiro, M.J.; Labrincha, J.A.; Novais, R.M.; Hotza, D.; Moreira, R.F.P.M. Effect of the Particle Size Range of Construction and Demolition Waste on the Fresh and Hardened-State Properties of Fly Ash-Based Geopolymer Mortars with Total Replacement of Sand. Process Saf. Environ. Prot. 2019, 129, 130–137. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Use of OPC to Improve Setting and Early Strength Properties of Low Calcium Fly Ash Geopolymer Concrete Cured at Room Temperature. Cem. Concr. Compos. 2015, 55, 205–214. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Influence of Microstructure of Geopolymer Concrete on Its Mechanical Properties—A Review. In Advances in Sustainable Construction Materials and Geotechnical Engineering, Proceedings of Trends and Recent Advances in Civil Engineering TRACE-2018; Shukla, S.K., Barai, S.V., Mehta, A., Eds.; Springer: Singapore, 2020; pp. 119–129. [Google Scholar]

- Zhong, Q.; Su, M.; Tian, X.; Peng, H. Workability and Mechanical Properties for GGBFS–MK Geopolymer Synthesis: Influencing Factor Analysis and a Mix Design Method. Mater. Struct. Mater. Et Constr. 2023, 56, 144. [Google Scholar] [CrossRef]

- Zailani, W.W.A.; Apandi, N.M.; Adesina, A.; Alengaram, U.J.; Faris, M.A.; Tahir, M.F.M. Physico-Mechanical Properties of Geopolymer Mortars for Repair Applications: Impact of Binder to Sand Ratio. Constr. Build. Mater. 2024, 412, 134721. [Google Scholar] [CrossRef]

- Yilmazoglu, A.; Yildirim, S.T.; Yıldız, S.; Behçet, Ö.F. Effect of GGBS Content and Water/Geopolymer Solid Ratio on the Mechanical, Elevated Temperature Resistance, and Sorptivity Properties of FA/GGBS-Based Geopolymer Concrete. J. Mater. Civ. Eng. 2024, 36, 04024032. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).