Estimation of Geotechnical Parameters for Coal Exploration from Quasi-3D Electrical Resistivity Measurements

Abstract

1. Introduction

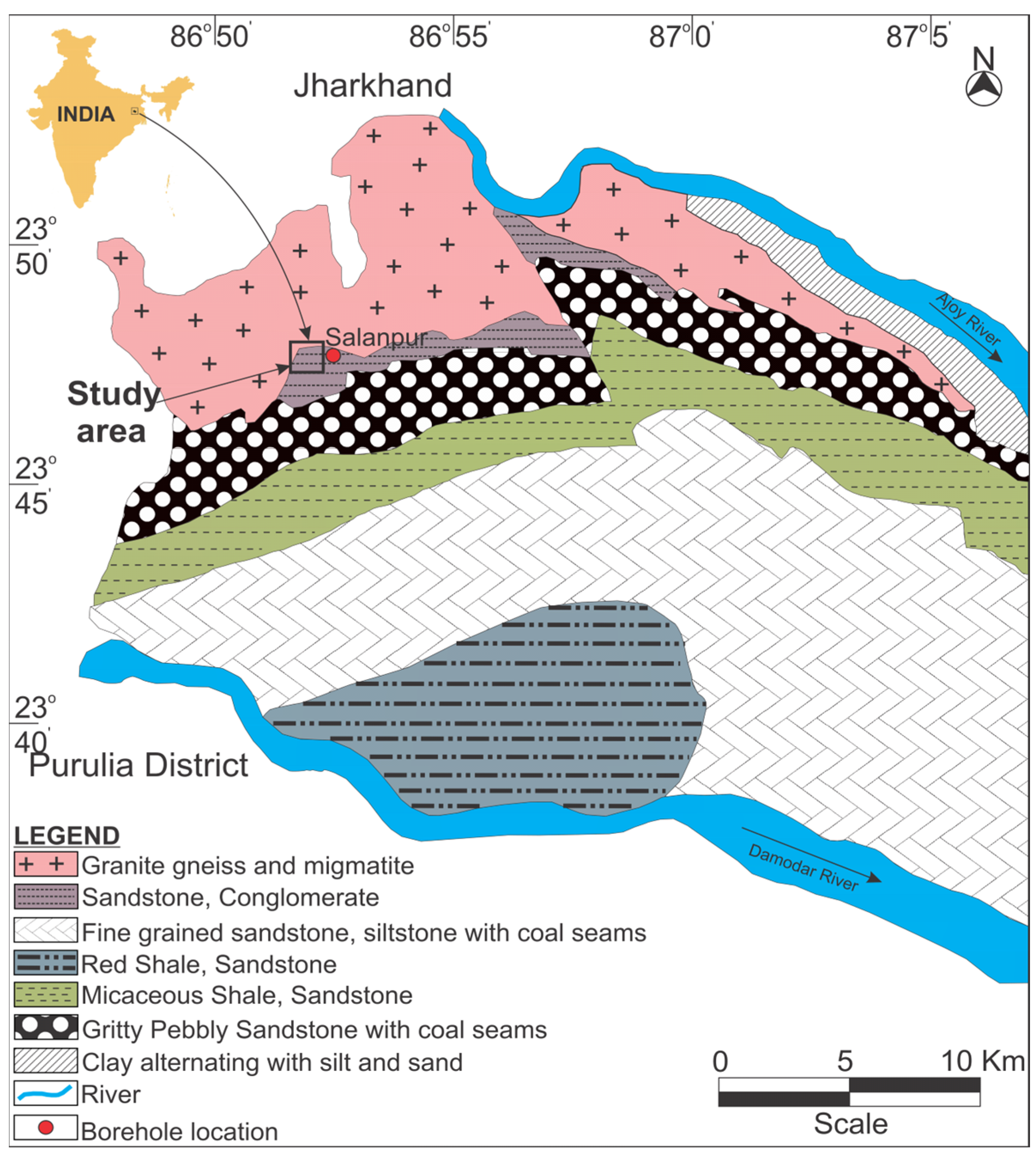

2. Geology of the Study Area

3. Materials and Methods

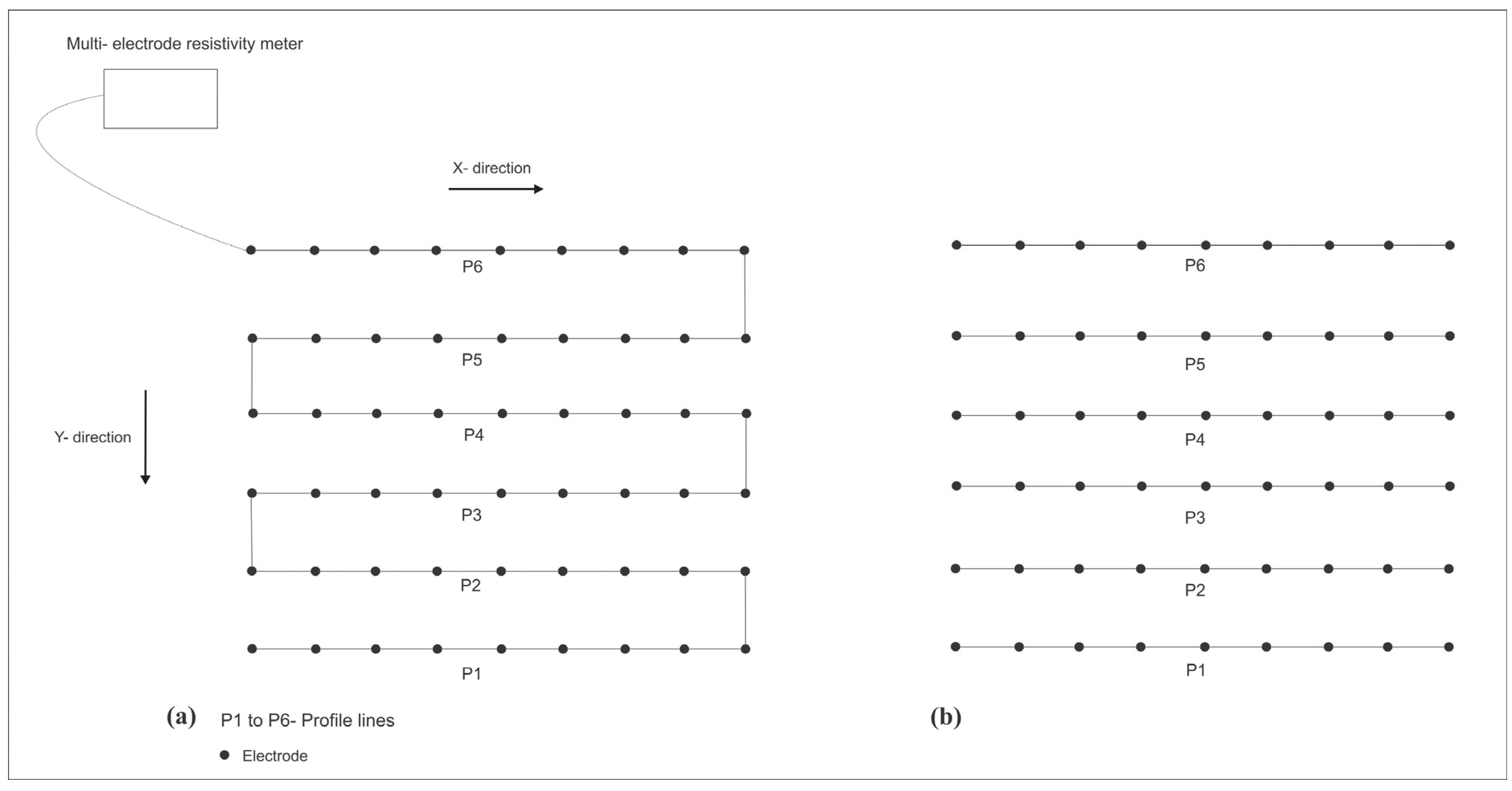

3.1. Data Acquisition

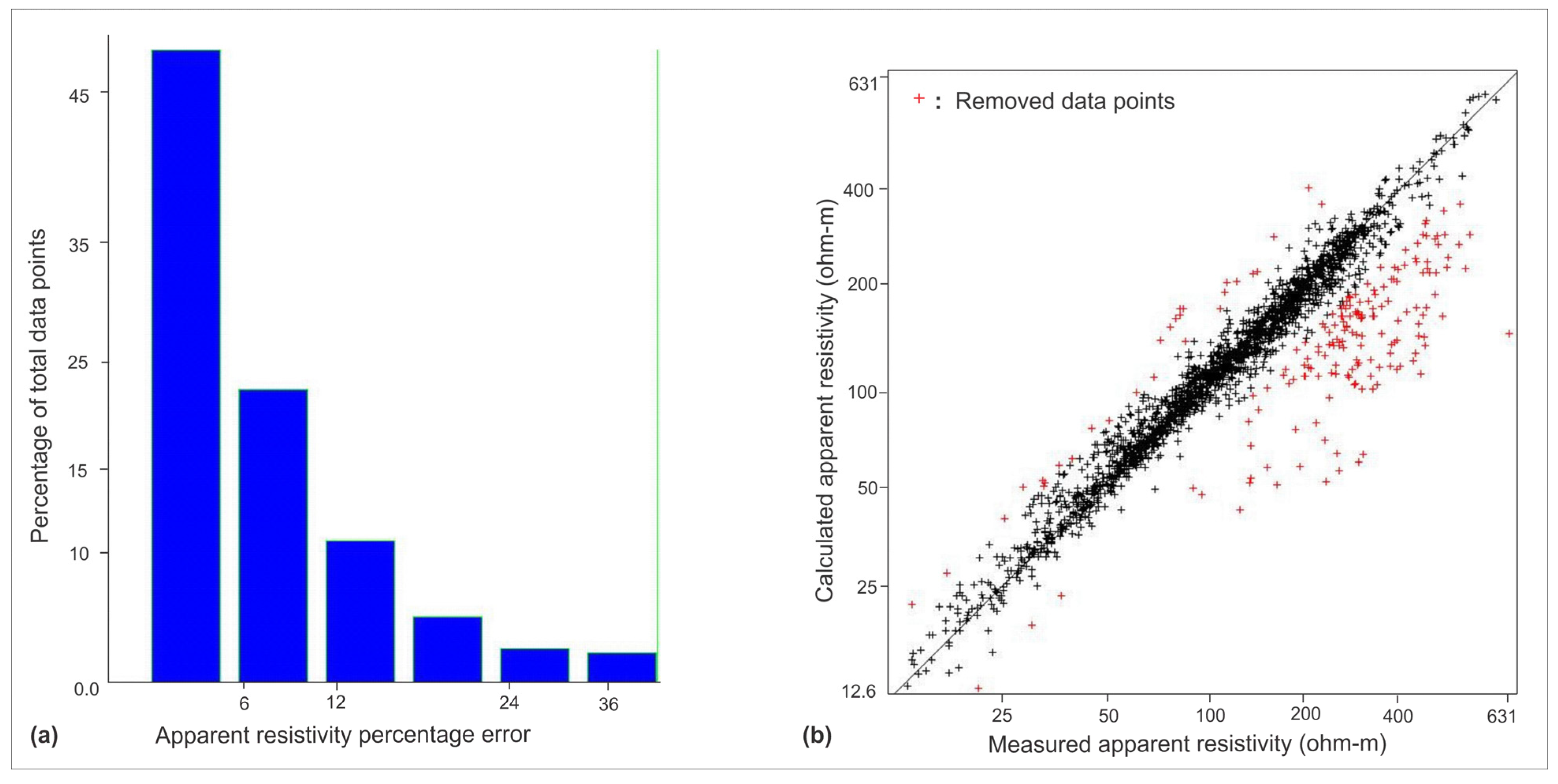

3.2. Data Processing

3.3. Correlation and Regression Equations

4. Results and Discussion

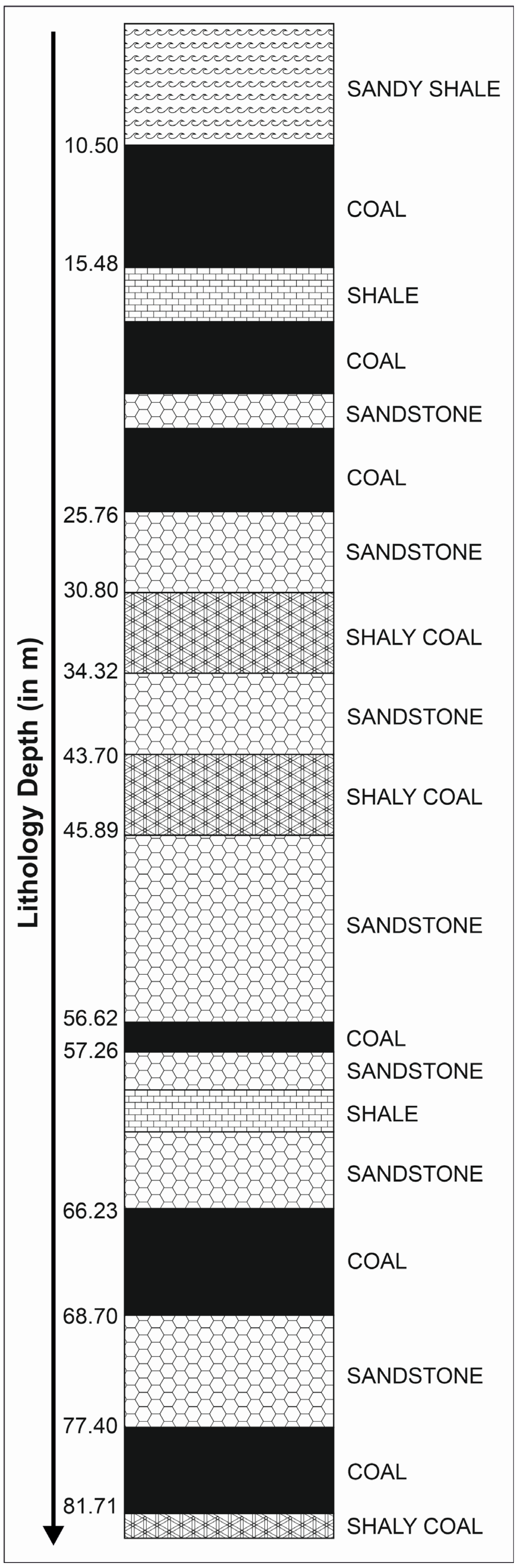

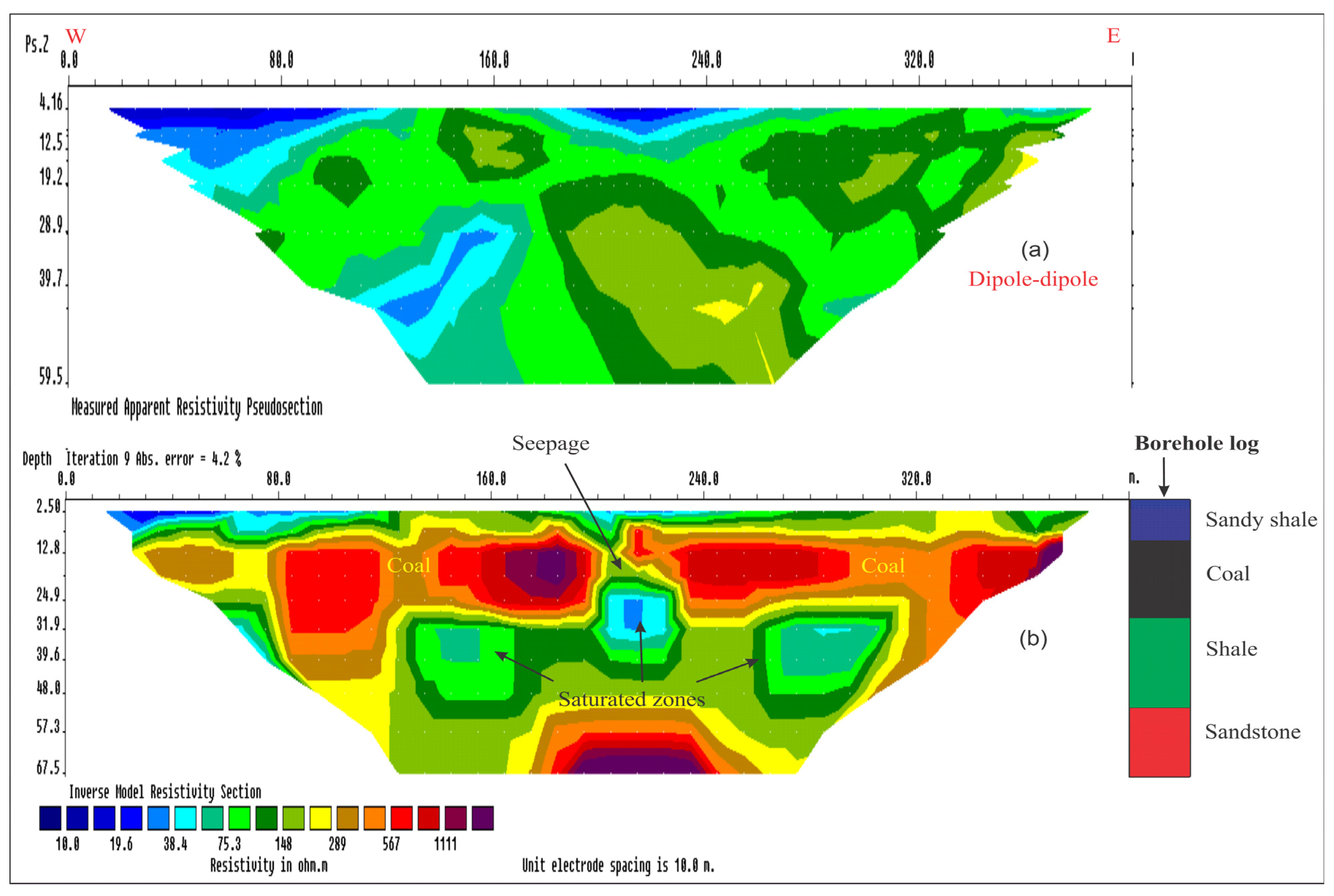

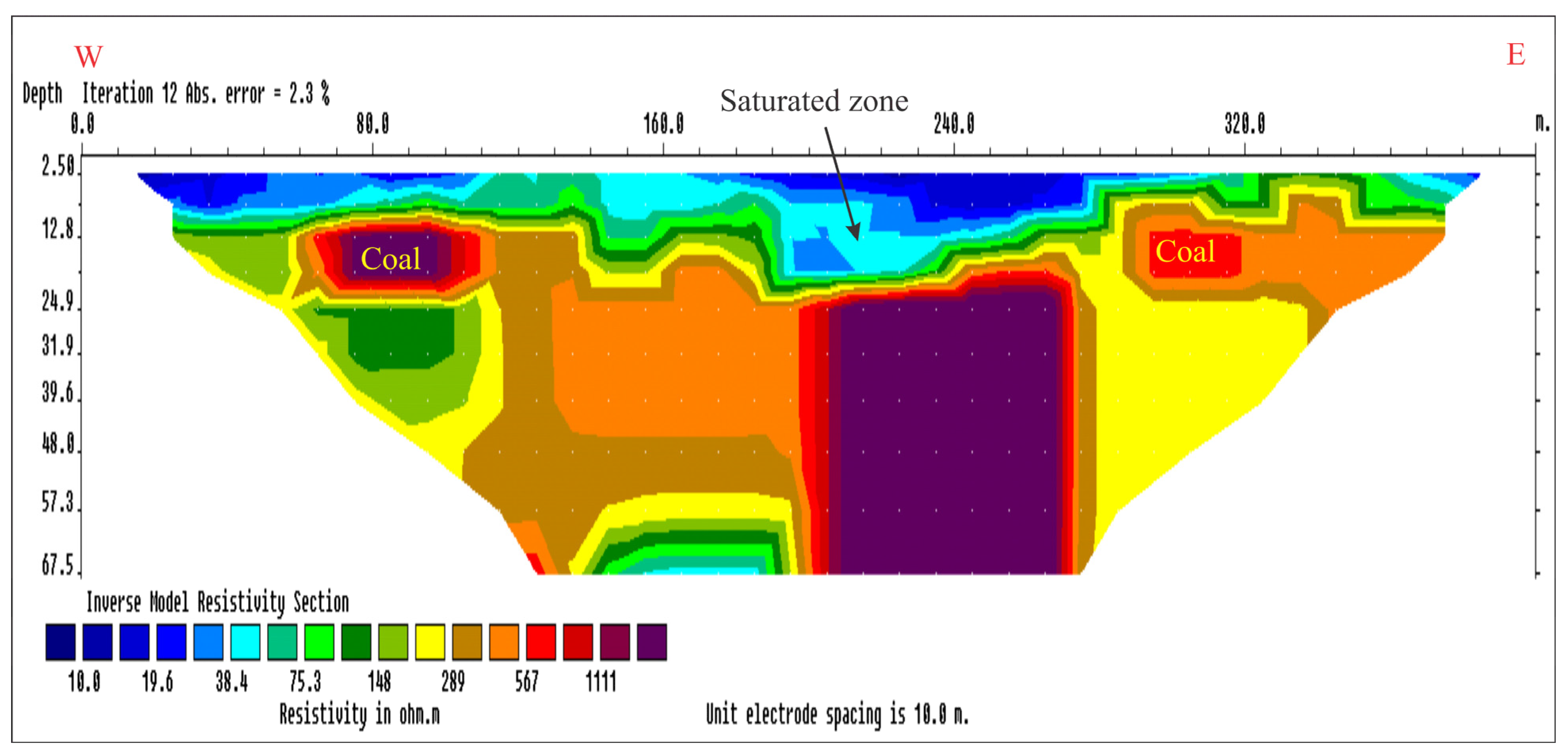

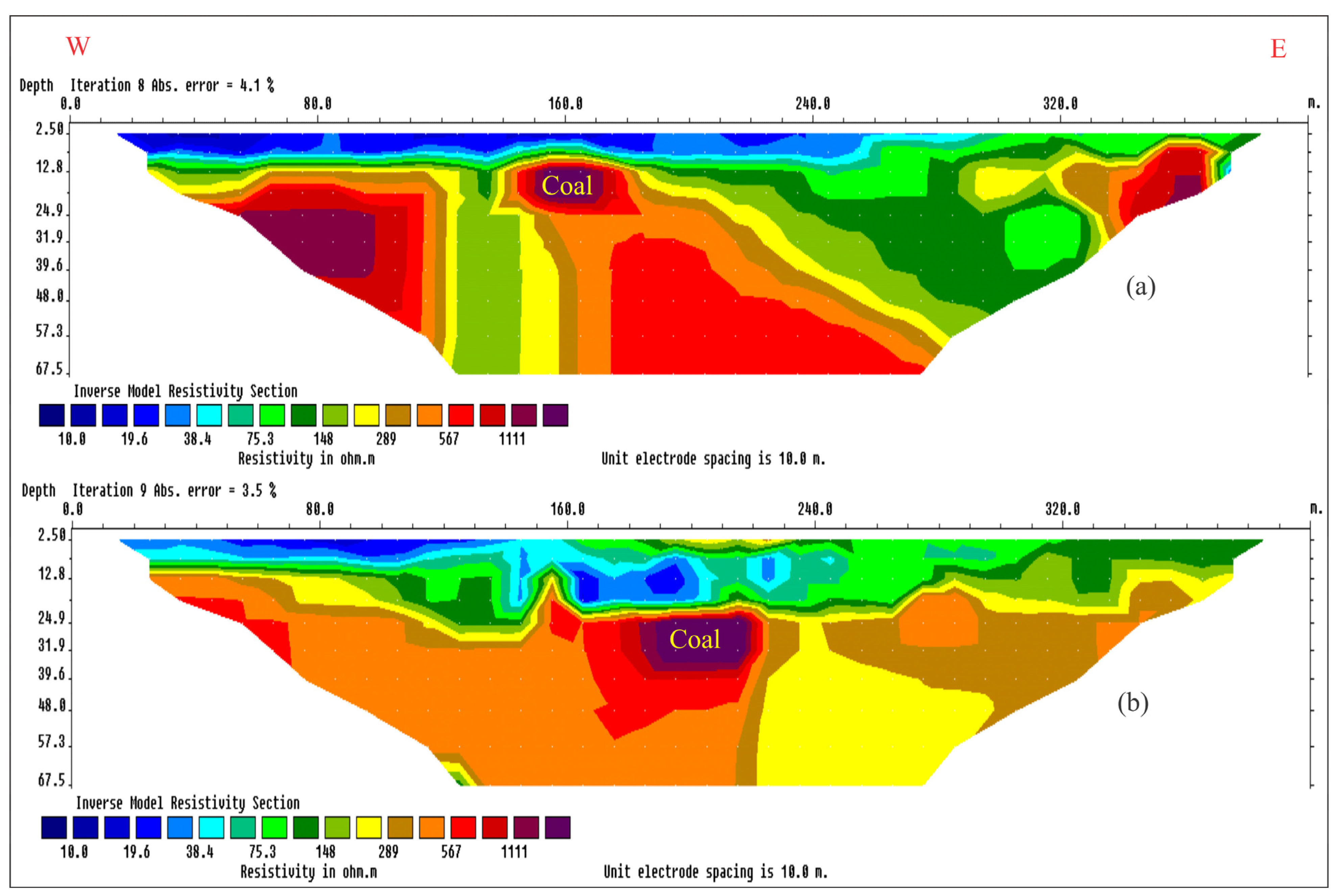

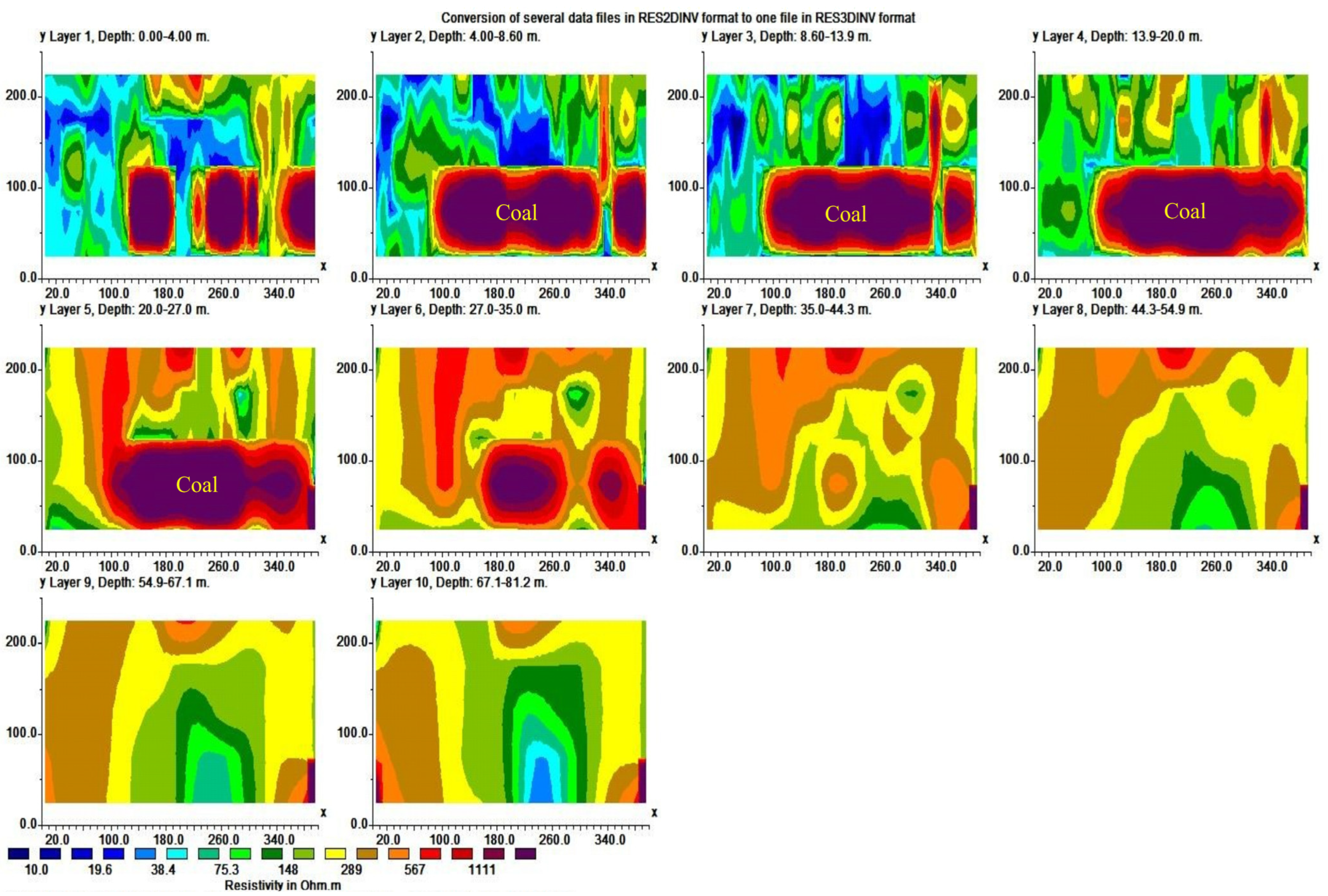

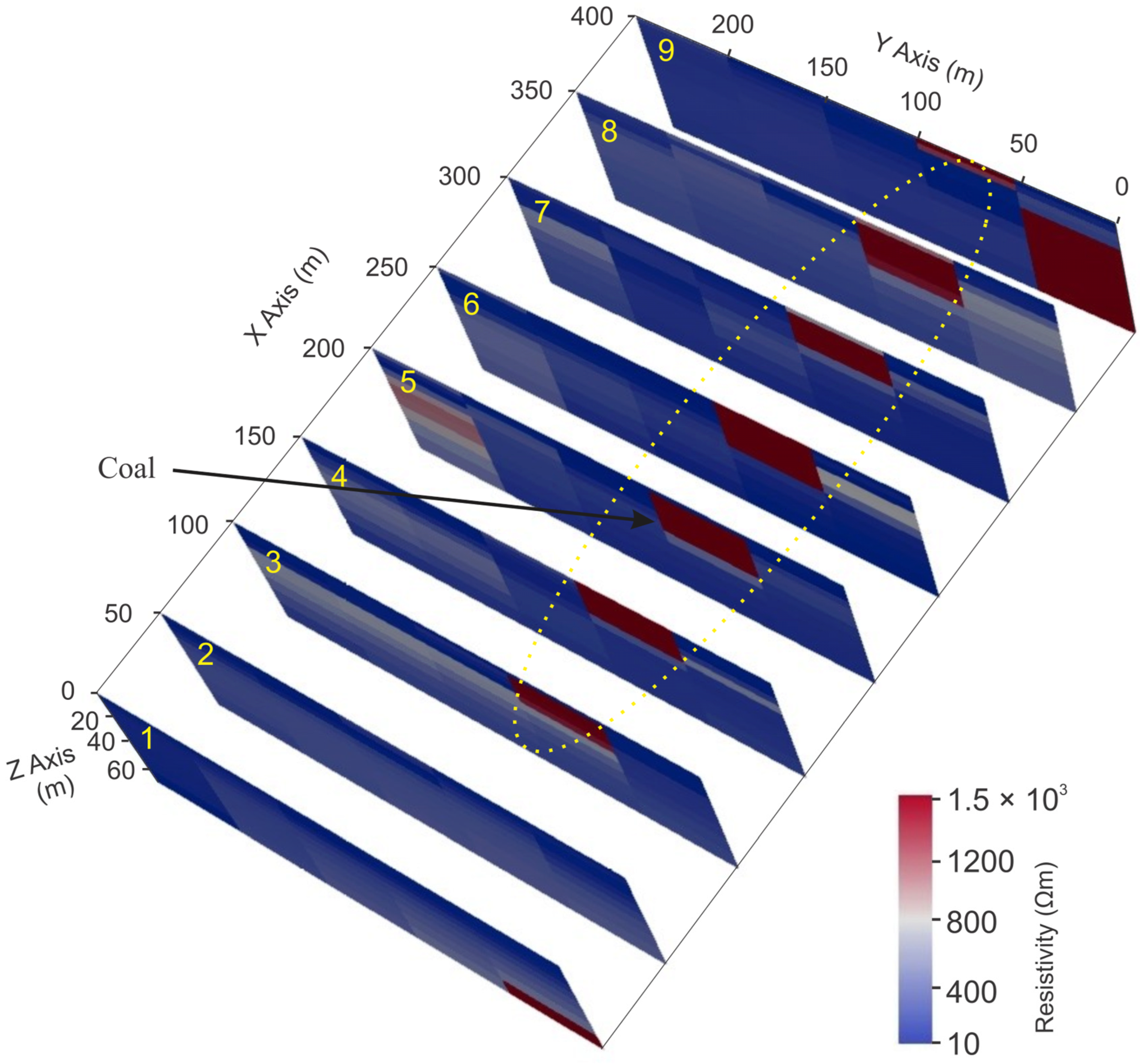

4.1. Geophysical Study

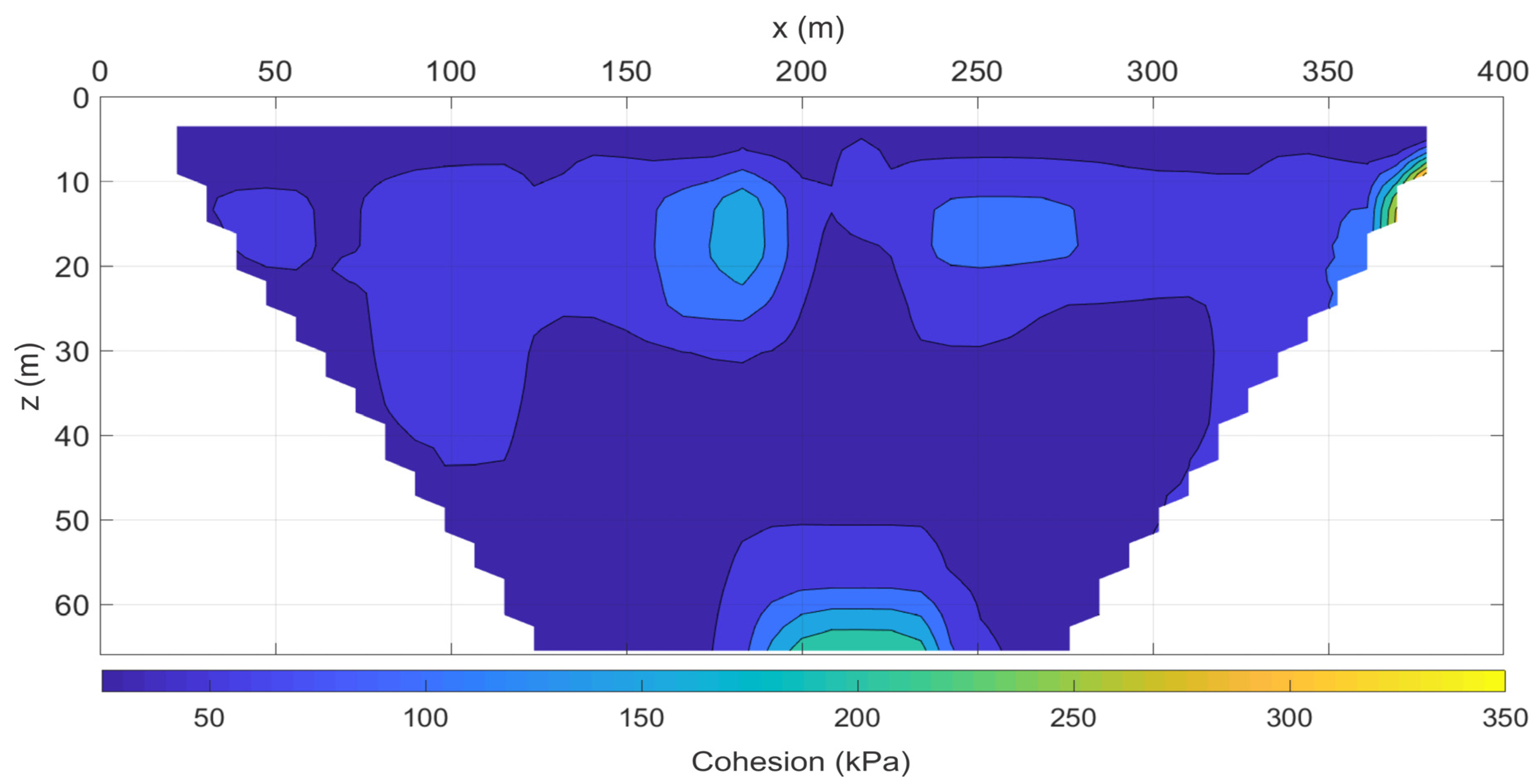

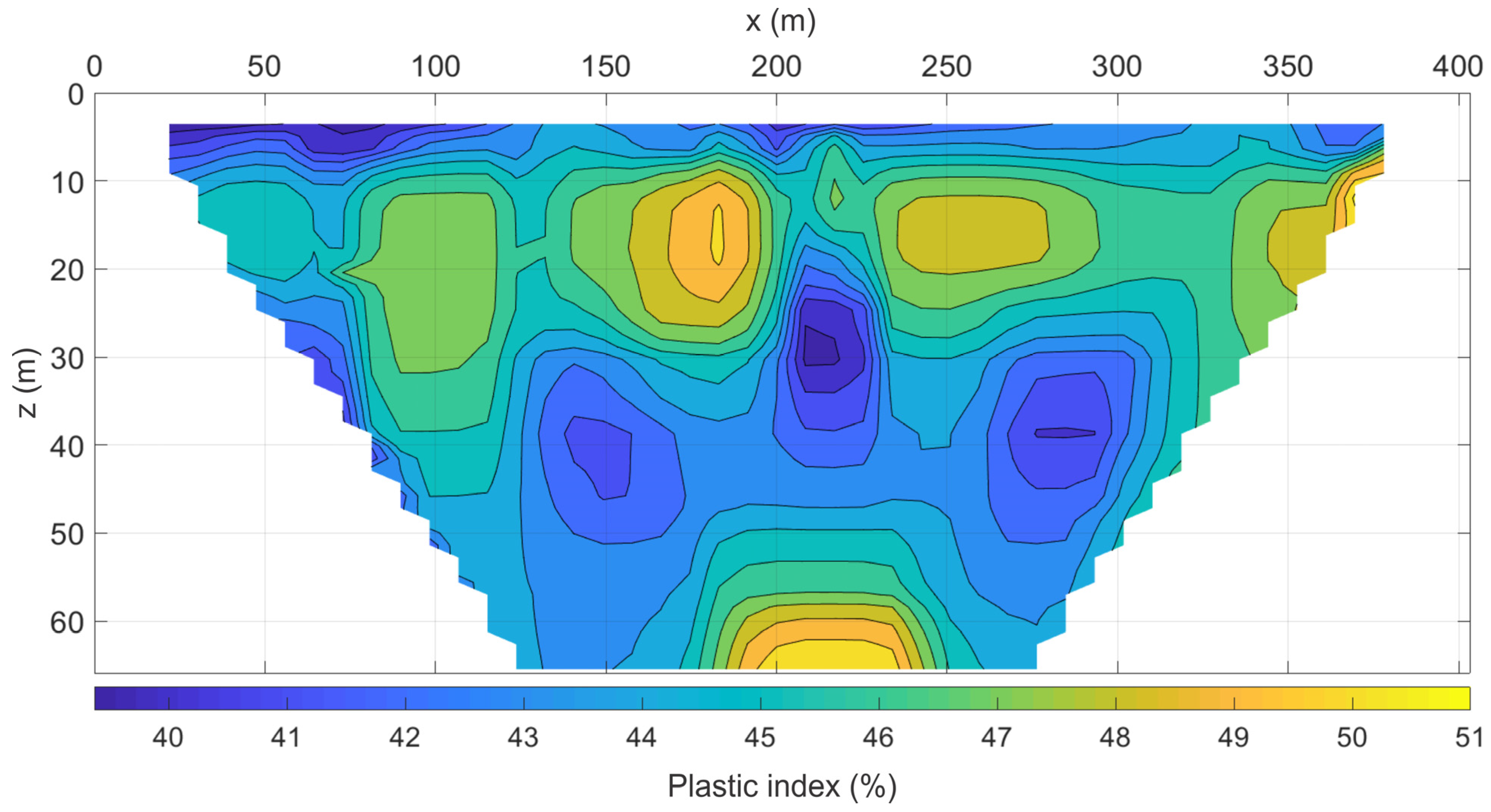

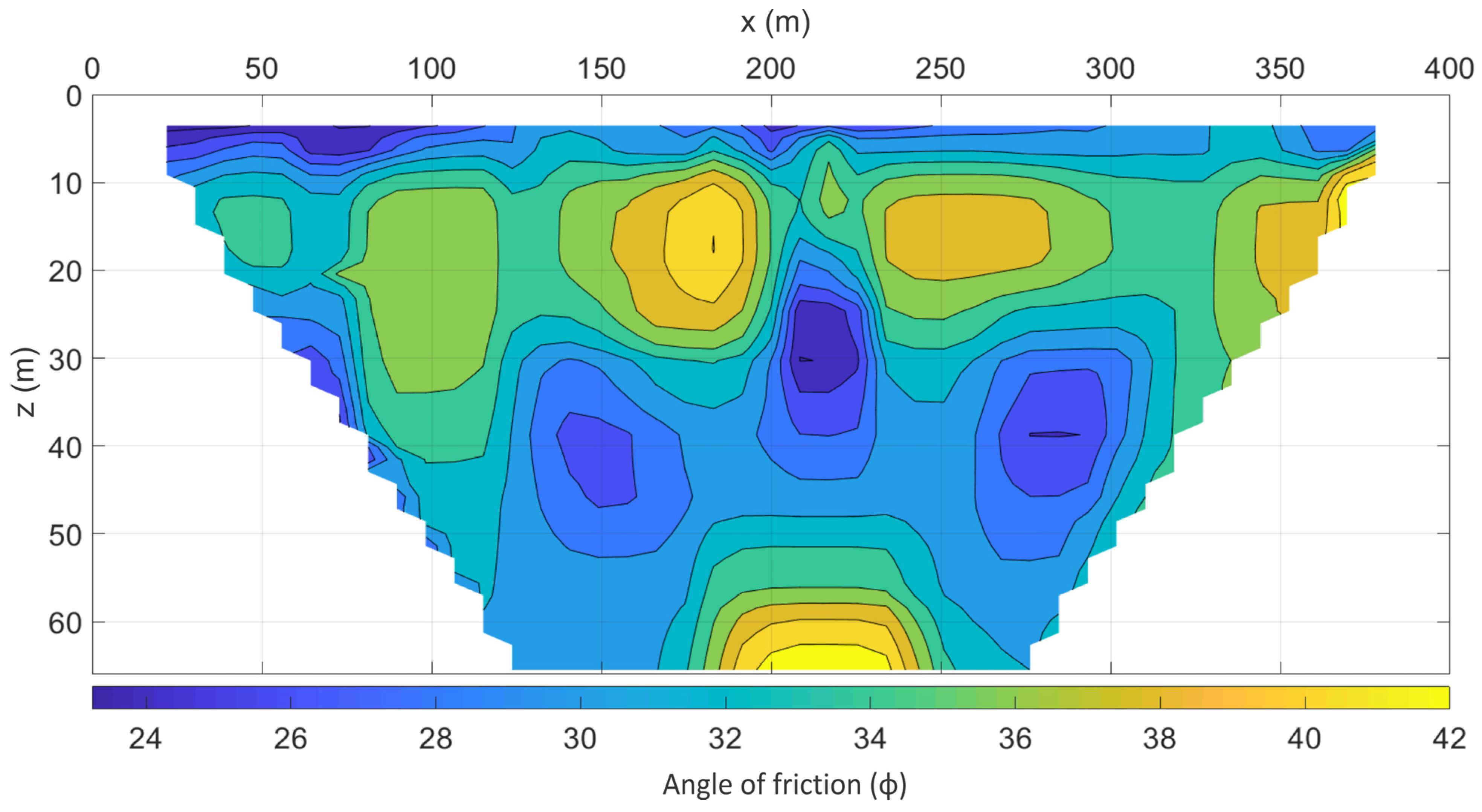

4.2. Geotechnical Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hatcher, P.G.; Clifford, D.J. The organic geochemistry of coal: From plant materials to coal. Org. Geochem. 1997, 27, 251–274. [Google Scholar] [CrossRef]

- Miller, B.G. Coal Energy Systems; Academic Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Aberšek, B.; Flogie, A. Energies and Energetics. In Human Awareness, Energy and Environmental Attitudes; Springer International Publishing: Cham, Switzerland, 2022; pp. 91–110. [Google Scholar]

- Abdelrahman, K.; Hazaea, S.A.; Hazaea, B.Y.; Abioui, M.; Al-Awah, H. Groundwater potentiality in hard-rock terrain of southern Saudi Arabia using electrical resistivity tomography approach. J. King Saud Univ. Sci. 2023, 35, 102928. [Google Scholar] [CrossRef]

- Ariyo, S.O.; Adeyemi, G.O. Role of electrical resistivity method for groundwater exploration in hard rock areas: A case study from Fidiwo/Ajebo areas of Southwestern Nigeria. Pac. J. Sci. Technol. 2009, 10, 483–486. [Google Scholar]

- Goldman, M.; Neubauer, F.M. Groundwater exploration using integrated geophysical techniques. Surv. Geophys. 1994, 15, 331–361. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, D.; Zheng, R. Evolution law of coal seam abutment pressure under the influence of shallow buried complex strata: A case study. Shock Vib. 2021, 6670175. [Google Scholar] [CrossRef]

- Ali, M.A.H.; Mewafy, F.M.; Qian, W.; Alshehri, F.; Ahmed, M.S.; Saleem, H.A. Integration of Electrical Resistivity Tomography and Induced Polarization for Characterization and Mapping of (Pb-Zn-Ag) Sulfide Deposits. Minerals 2023, 13, 986. [Google Scholar] [CrossRef]

- Arjwech, R.; Sriwangpon, P.; Somchat, K.; Pondthai, P.; Everett, M. Electrical resistivity tomography (ERT) data for clay mineral mapping. Data Brief 2020, 30, 105494. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Lü, Q.-T.; Zhang, G.-B.; Lin, P.-R.; Jia, Z.-Y.; Suo, K. Joint interpretation of geological, magnetic, AMT, and ERT data for mineral exploration in the Northeast of Inner Mongolia, China. Pure Appl. Geophys. 2017, 175, 989–1002. [Google Scholar] [CrossRef]

- Dahlin, T.; Bernstone, C.; Loke, M.H. A 3-D resistivity investigation of a contaminated site at Lernacken, Sweden. Geophysics 2002, 67, 1692–1700. [Google Scholar] [CrossRef]

- Ustra, A.T.; Elis, V.R.; Mondelli, G.; Zuquette, L.V.; Giacheti, H.L. Case study: A 3D resistivity and induced polar-ization imaging from downstream a waste disposal site in Brazil. Environ. Earth Sci. 2012, 66, 763–772. [Google Scholar] [CrossRef]

- Yang, P.; Liu, Y.-H.; Zhang, S.-H.; Pan, Y.-F. Experimental investigation on the migration of leachate under flowing conditions through laboratory ERT. Environ. Sci. Pollut. Res. 2019, 26, 17457–17471. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, G.A.F.; Lopes, B.d.C.F.L. ERT Feasibility Study to Assess Unknown Bridge Foundation Depth. J. Bridg. Eng. 2022, 27, 06022002. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Taleshi, A.A.; Abbasinia, M.; Arab-Amiri, A. Two and three-dimensional ERT modelling for a buried tunnel. J. Emerg. Trends Eng. Appl. Sci. 2016, 7, 118–127. [Google Scholar]

- Muceku, Y.; Reçi, H.; Kaba, F.; Kuriqi, A.; Shyti, F.; Kruja, F.; Kumbaro, R. A case study: Integrated geotechnical and geophysical-ERT investigation for bridge foundation of Tirana bypass. In Proceedings of the International Congress on Roads (AACE), Tirana, Albania, 8–9 October 2015. [Google Scholar]

- Ngah, S.A.; Nwankwoala, H.O. Evaluation of sub-soil geotechnical properties for shallow foundation design in onne, Rivers state, Nigeria. Int. J. Eng. Sci. 2013, 2, 8–16. [Google Scholar]

- Afip, I.A.; Taib, S.N.L.; Jusoff, K.; Afip, L.A. Measurement of peat soil shear strength using Wenner four-point probes and vane shear strength methods. Int. J. Geophys. 2019, 2019, 3909032. [Google Scholar]

- Cheng, Q.; Tao, M.; Chen, X.; Binley, A. Evaluation of electrical resistivity tomography (ERT) for mapping the soil–rock interface in karstic environments. Environ. Earth Sci. 2019, 78, 1–14. [Google Scholar] [CrossRef]

- Hatta, K.A.; Osman, S.B.A.S. Correlation of Electrical Resistivity and SPT-N Value from Standard Penetration Test (SPT) of Sandy Soil. Appl. Mech. Mater. 2015, 785, 702–706. [Google Scholar] [CrossRef]

- Lech, M.; Bajda, M.; Markowska-Lech, K. The use of resistivity and seismic cone penetration tests for site characterization. Ann. Wars. Univ. Life Sci. SGGW. Land Reclam. 2008, 40, 87–96. [Google Scholar] [CrossRef]

- Lech, M.; Skutnik, Z.; Bajda, M.; Markowska-Lech, K. Applications of electrical resistivity surveys in solving selected geotechnical and environmental problems. Appl. Sci. 2020, 10, 2263. [Google Scholar] [CrossRef]

- Lee, J.-S.; Kim, S.Y.; Hong, W.-T.; Byun, Y.-H. Assessing subgrade strength using an instrumented dynamic cone penetrometer. Soils Found. 2019, 59, 930–941. [Google Scholar] [CrossRef]

- Perri, M.T.; Boaga, J.; Bersan, S.; Cassiani, G.; Cola, S.; Deiana, R.; Simonini, P.; Patti, S. River embankment characterization: The joint use of geophysical and geotechnical techniques. J. Appl. Geophys. 2014, 110, 5–22. [Google Scholar] [CrossRef]

- Poenaru, A. Correlations between Cone Penetration Test and Seismic Dilatometer Marchetti Test with Common Laboratory Investigations. Energy Procedia 2016, 85, 399–407. [Google Scholar] [CrossRef][Green Version]

- Yoon, H.K.; Jung, S.H.; Lee, J.S. Characterisation of subsurface spatial variability using a cone resistivity pene-trometer. Soil Dyn. Earthq. Eng. 2011, 31, 1064–1071. [Google Scholar] [CrossRef]

- Zhao, Z.; Lu, F.; Yue, C. Study on the Application of Flat Dilatometer Test in Subway Survey Engineering. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 474, p. 072012. [Google Scholar]

- Dahlin, T.; Zhou, B. A numerical comparison of 2D resistivity imaging with 10 electrode arrays. Geophys. Prospect. 2004, 52, 379–398. [Google Scholar] [CrossRef]

- Azarsa, P.; Gupta, R. Electrical Resistivity of Concrete for Durability Evaluation: A Review. Adv. Mater. Sci. Eng. 2017, 2017, 8453095. [Google Scholar] [CrossRef]

- Kowalczyk, S.; Maślakowski, M.; Tucholka, P. Determination of the correlation between the electrical resistivity of non-cohesive soils and the degree of compaction. J. Appl. Geophys. 2014, 110, 43–50. [Google Scholar] [CrossRef]

- Gomaa, M.M. Salinity and water effect on electrical properties of fragile clayey sandstone. Appl. Water Sci. 2020, 10, 1–9. [Google Scholar] [CrossRef]

- Rupesh Tiwari, P.; Sharma, S.P. High-resolution quasi-3D electric resistivity tomography for deciphering ground-water potential zones in lateritic terrain. Nat. Resour. Res. 2021, 30, 3339–3353. [Google Scholar] [CrossRef]

- Jusoh, H.; Osman, S.B.S. The correlation between resistivity and soil properties as an alternative to soil investigation. Indian J. Sci. Technol. 2017, 10, 1–5. [Google Scholar]

- Günaydin, O.; Özbeyaz, A.; Söylemez, M. Regression Analysis of Soil Compaction Parameters Using Support Vector Method. Celal Bayar Univ. J. Sci. 2018, 14, 443–447. [Google Scholar] [CrossRef]

- Karsten, T.K.; Gau, C.; Tiedemann, J. Shear Strength Parameters from Direct Shear Tests—Influencing Factors and Their Significance; IAEG2006 Paper number 484; The Geological Society of London: London, UK, 2006; pp. 1–12. [Google Scholar]

- Geological Survey of India, 2023. Bhukosh. Geological Survey of India. Available online: https://bhukosh.gsi.gov.in/Bhukosh/Public (accessed on 20 November 2023).

- Mahata, S.; Sharma, V.N. Evolution and distribution of coal mines in Salanpur Block, District Paschim Bardhaman, West Bengal. Natl. Geogr. J. India 2022, 65, 122–131. [Google Scholar]

- Roy, J. The Geological Characterstics of the Western Part of Bardhaman District. 2019. Available online: http://www.ijrar.com/upload_issue/ijrar_issue_20543863.pdf (accessed on 9 January 2024).

- Lee, K.S.; Cho, I.K.; Kim, Y.J. Borehole effect in 2.5 D crosshole resistivity tomography. J. Appl. Geophys. 2016, 135, 212–222. [Google Scholar] [CrossRef]

- Lee, K.; Cho, I. Negative apparent resistivities in surface resistivity measurements. J. Appl. Geophys. 2020, 176, 104010. [Google Scholar] [CrossRef]

- Wilkinson, P.B.; Chambers, J.E.; Lelliott, M.; Wealthall, G.P.; Ogilvy, R.D. Extreme sensitivity of crosshole electrical resistivity tomography measurements to geometric errors. Geophys. J. Int. 2008, 173, 49–62. [Google Scholar] [CrossRef]

- Loke, M.; Acworth, I.; Dahlin, T. A comparison of smooth and blocky inversion methods in 2D electrical imaging surveys. Explor. Geophys. 2003, 34, 182–187. [Google Scholar] [CrossRef]

- Claerbout, J.F.; Muir, F. Robust modeling with erratic data. Geophysics 1973, 38, 826–844. [Google Scholar] [CrossRef]

- Cardarelli, E.; De Donno, G. Advances in electric resistivity tomography: Theory and case studies. In Innovation in Near-Surface Geophysics; Elsevier: Amsterdam, The Netherlands, 2019; pp. 23–57. [Google Scholar]

- Loke, M.; Papadopoulos, N.; Wilkinson, P.; Oikonomou, D.; Simyrdanis, K.; Rucker, D.; Feng, J.; Zhu, B.; Li, W.; Chen, H.; et al. The inversion of data from very large three-dimensional electrical resistivity tomography mobile surveys. Geophys. Prospect. 2020, 68, 2579–2597. [Google Scholar] [CrossRef]

- Bharti, A.K.; Pal, S.; Priyam, P.; Pathak, V.K.; Kumar, R.; Ranjan, S.K. Detection of illegal mine voids using electrical resistivity tomography: The case-study of Raniganj coalfield (India). Eng. Geol. 2016, 213, 120–132. [Google Scholar] [CrossRef]

- Bharti, A.K.; Prakash, A.; Verma, A.; Oraon, J.; Chaudhary, D.K.; Kumar, S.; Singh, K.K.K. Mapping of decades-old underground coal mine workings using electrical resistivity tomography. J. Earth Syst. Sci. 2022, 131, 258. [Google Scholar] [CrossRef]

- Singh, K.K.K.; Singh, K.B.; Lokhande, R.D.; Prakash, A. Multielectrode resistivity imaging technique for the study of coal seam. J. Sci. Ind. Res. 2004, 63, 927–930. [Google Scholar]

- Mohammed, M.A.; Adewumi, T.; Ahmed, A.L.; Lawal, K.M. Electrical Resistivity Imaging of a Coal Deposit at Tai Area of Gombe State, North Eastern Nigeria. J. Environ. Earth Sci. 2016, 6, 55. [Google Scholar]

- Olatunji, S.; Jimoh, A. Coal Exploration using Electrical Resistivity Method in Some Parts of Benue Trough, Nigeria. Tanzan. J. Sci. 2020, 46, 859–872. [Google Scholar]

- Pang, C.; Gao, W.; Wu, P.; Wang, L. Grouting Effect Detection within the Floor of a Coal Seam Using 3D Electric Resistivity Tomography (ERT) with Arbitrary Electrode Positions. Appl. Sci. 2022, 12, 5625. [Google Scholar] [CrossRef]

- Ramdani, P.S.; Sehah, M. Modeling of Coal Deposition Using the Resistivity Method with Wenner Configuration in the Bentarsari Basin Area, District of Salem, Brebes Regency, Central Java. J. Fis. dan Apl. 2021, 17, 1–8. [Google Scholar] [CrossRef]

- Sheets, R.A. Use of Electrical Resistivity to Detect Underground Mine Voids in Ohio; US Department of the Interior: Washington, DC, USA; US Geological Survey: Denver, CO, USA, 2002; Volume 2.

- Qarqori, K.; Rouai, M.; Moreau, F.; Saracco, G.; Dauteuil, O.; Hermitte, D.; Boualoul, M.; de Veslud, L.C. Geoelectrical Tomography Investigating and Modeling of Fractures Network around Bittit Spring (Middle Atlas, Morocco). Int. J. Geophys. 2012, 2012, 489634. [Google Scholar] [CrossRef]

- Yue, J.; Wang, Z.; Chen, J.; Wang, B.; An, F. Response characteristics of the resistivity and water content during the imbibition process in remolded coal without gas. Energy Sci. Eng. 2019, 7, 2675–2689. [Google Scholar] [CrossRef]

- Loke, M.H. Electrical imaging surveys for environmental and engineering studies. A Pract. Guide 1999, 2, 70. [Google Scholar]

- Aizebeokhai, A.P.; Olayinka, A.I.; Singh, V.S.; Uhuegbu, C.C. Effectiveness of 3D geoelectrical resistivity imaging using parallel 2D profiles. Curr. Sci. 2011, 101, 1036–1052. [Google Scholar]

- Sasaki, Y.; Hasegawa, N.; Matsuoka, T. Toward practical 3D resistivity surveys: Effects of 3D topography and structures on interpretation. In Proceedings of the 112th SEGJ Conference, Tokyo, Japan, 9–11 May 2005; pp. 207–210. [Google Scholar]

- Ahrens, J.; Geveci, B.; Law, C.; Hansen, C.; Johnson, C. 36-ParaView: An End-User Tool for Large-Data Visualization. The Visualization Handbook; Los Almos National Laboratory: Los Alamos, NM, USA, 2005; Available online: https://www.researchgate.net/publication/247111133_ParaView_An_End-User_Tool_for_Large_Data_Visualization (accessed on 9 January 2024).

- Fuentes, I.; Seguel, O.; Casanova, M. Shear strength of aggregates compared with bulk soil of two haploxerolls from Chile. J. Soil Sci. Plant Nutr. 2013, 13, 819–831. [Google Scholar] [CrossRef][Green Version]

- Moomivand, H. Effect of size on the compressive strength of coal. Min. Sci. Technol. 1999, 99, 399–404. [Google Scholar]

- Bell, F.G.; Donnelly, L.J. Mining and Its Impact on the Environment; CRC Press: London, UK, 2006. [Google Scholar]

- Van Nguyen, D.; Nguyen, H.P.; Do, T.M. Experimental Study on the Efficacy of Water Infusion for Underground Mining of a Coal Seam. Appl. Sci. 2019, 9, 3820. [Google Scholar] [CrossRef]

- Balarabe, B.; Bery, A.A.; Teoh, Y.J.; Khalil, A.E. New empirical approach for the estimation of soil cohesion and friction angle in 2D form for site investigations. Sains Malays. 2022, 51, 405–419. [Google Scholar] [CrossRef]

- Pramanik, A.; Adhikary, A.; Pal, S. Assessment of an Open Cast Coal Mine Slope Stability at Mohanpur Block, Raniganj Coalfield, West Bengal, India. In Proceedings of the Indian Geotechnical Conference 2019, Surat, India, 19–21 December 2021; Springer: Singapore, 2021; Volume I, pp. 765–774. [Google Scholar]

- Linnik, V.Y.; Linnik, Y.N.; Zich, A.; Makar, S.V.; Kerimova, C.V.; I Sadriddinov, M. Assessment of properties of coal seams as destructible environments. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 837, p. 012009. [Google Scholar]

- Haigh, S.; Vardanega, P.; Bolton, M.D. The plastic limit of clays. Géotechnique 2013, 63, 435–440. [Google Scholar] [CrossRef]

- Bery, A.A.; Ismail, N.E.H. Empirical Correlation Between Electrical Resistivity and Engineering Properties of Soils. Soil Mech. Found. Eng. 2018, 54, 425–429. [Google Scholar] [CrossRef]

- Dumont, G.; Pilawski, T.; Dzaomuho-Lenieregue, P.; Hiligsmann, S.; Delvigne, F.; Thonart, P.; Robert, T.; Nguyen, F.; Hermans, T. Gravimetric water distribution assessment from geoelectrical methods (ERT and EMI) in municipal solid waste landfill. Waste Manag. 2016, 55, 129–140. [Google Scholar] [CrossRef]

- Spoor, G.; Godwin, R.J. Soil deformation and shear strength characteristics of some clay soils at different moisture contents. Eur. J. Soil Sci. 1979, 30, 483–498. [Google Scholar] [CrossRef]

- Yang, W.; Lu, C.; Lin, B.; Zhang, J.; Lin, M.; Wang, H. Tunnelling outburst potential affected by mechanical properties of coal seam. Tunn. Undergr. Space Technol. 2019, 83, 99–112. [Google Scholar] [CrossRef]

- Pulat, H.F.; Develioğlu, I.; Rasul, A.Y. Examination of Factors Affecting the Shear Strength of Granulated Blast Furnace Slag. Celal Bayar Univ. J. Sci. 2018, 14, 291–295. [Google Scholar] [CrossRef][Green Version]

- Esterhuizen, G.S.; Bajpayee, T.S.; Ellenberger, J.L.; Murphy, M.M. Practical estimation of rock properties for modeling bedded coal mine strata using the Coal Mine Roof Rating. In Proceedings of the 47th US Rock Mechanics/Geomechanics Symposium, San Francisto, CA, USA, 23–26 June 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rupesh, R.; Tiwari, P.; Sharma, S.P. Estimation of Geotechnical Parameters for Coal Exploration from Quasi-3D Electrical Resistivity Measurements. Minerals 2024, 14, 102. https://doi.org/10.3390/min14010102

Rupesh R, Tiwari P, Sharma SP. Estimation of Geotechnical Parameters for Coal Exploration from Quasi-3D Electrical Resistivity Measurements. Minerals. 2024; 14(1):102. https://doi.org/10.3390/min14010102

Chicago/Turabian StyleRupesh, Rupesh, Prarabdh Tiwari, and Shashi Prakash Sharma. 2024. "Estimation of Geotechnical Parameters for Coal Exploration from Quasi-3D Electrical Resistivity Measurements" Minerals 14, no. 1: 102. https://doi.org/10.3390/min14010102

APA StyleRupesh, R., Tiwari, P., & Sharma, S. P. (2024). Estimation of Geotechnical Parameters for Coal Exploration from Quasi-3D Electrical Resistivity Measurements. Minerals, 14(1), 102. https://doi.org/10.3390/min14010102