Replacing Fossil Carbon in the Production of Ferroalloys with a Focus on Bio-Based Carbon: A Review

Abstract

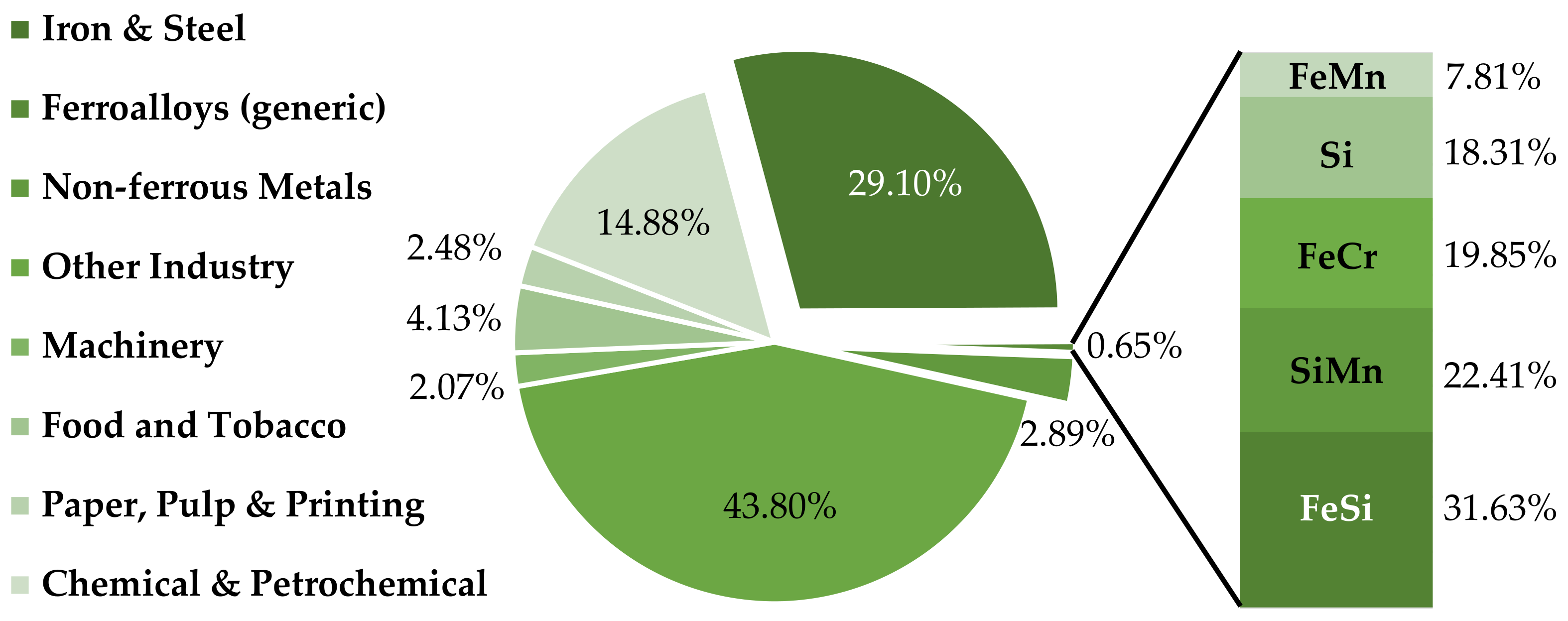

:1. Introduction

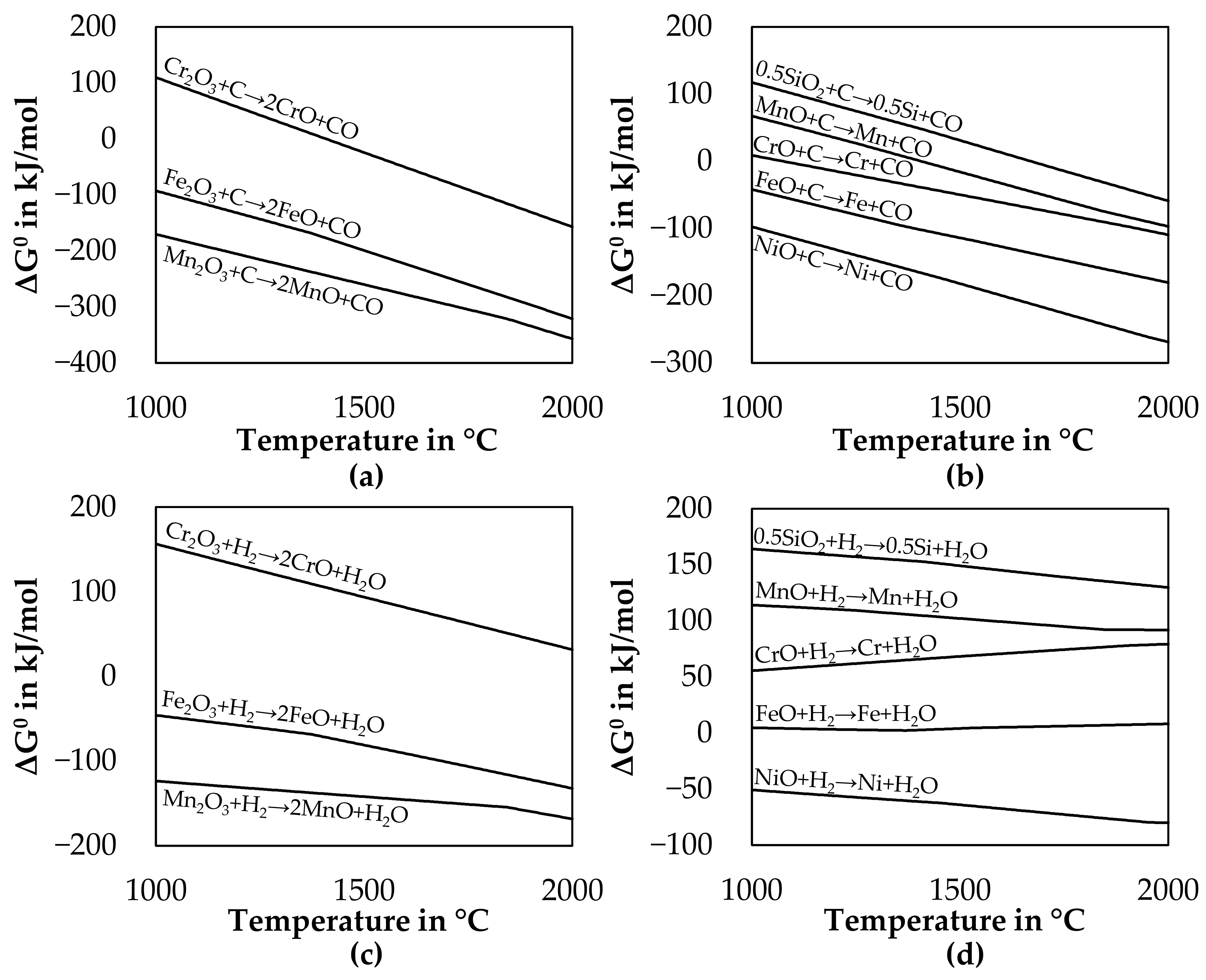

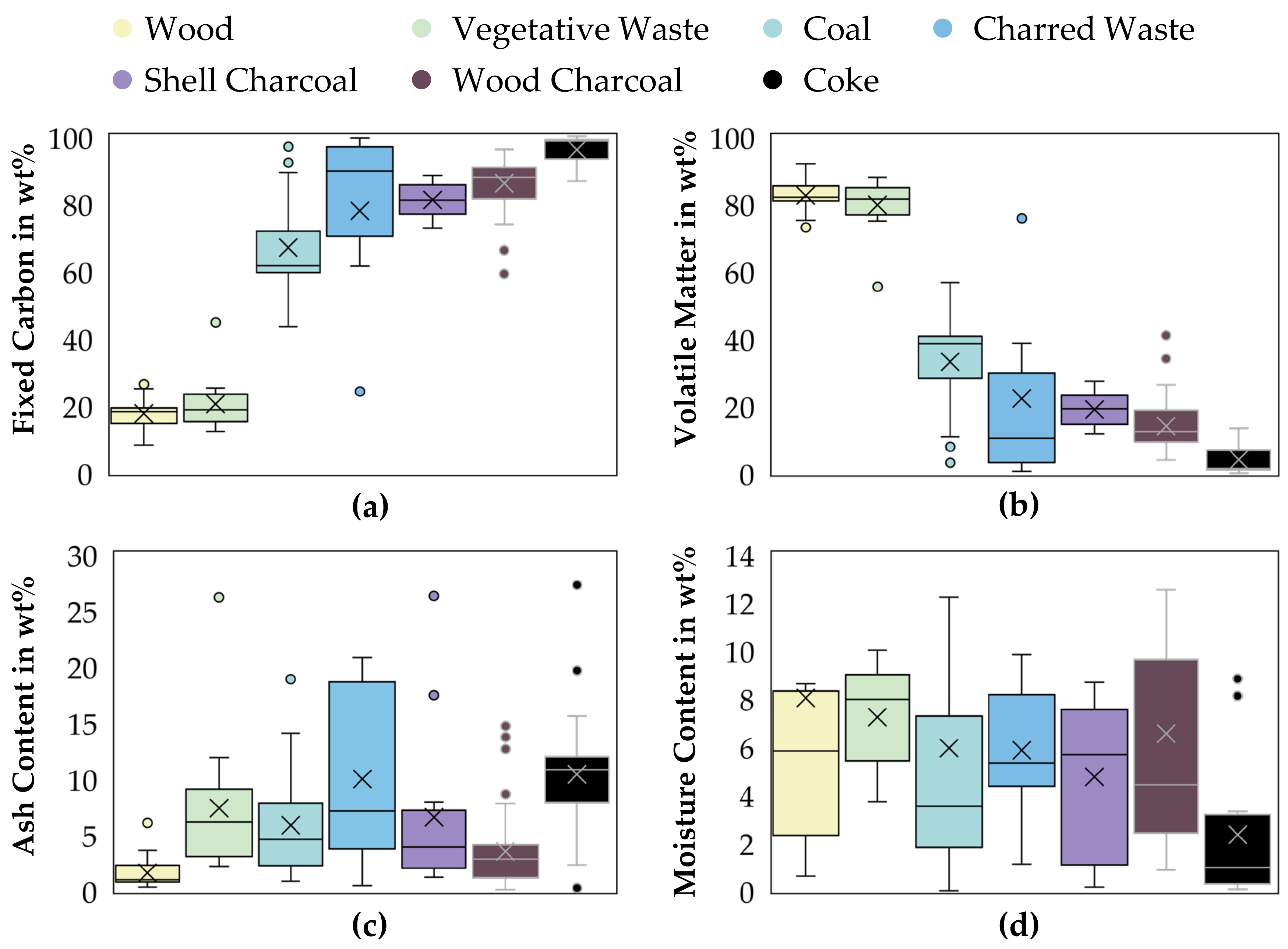

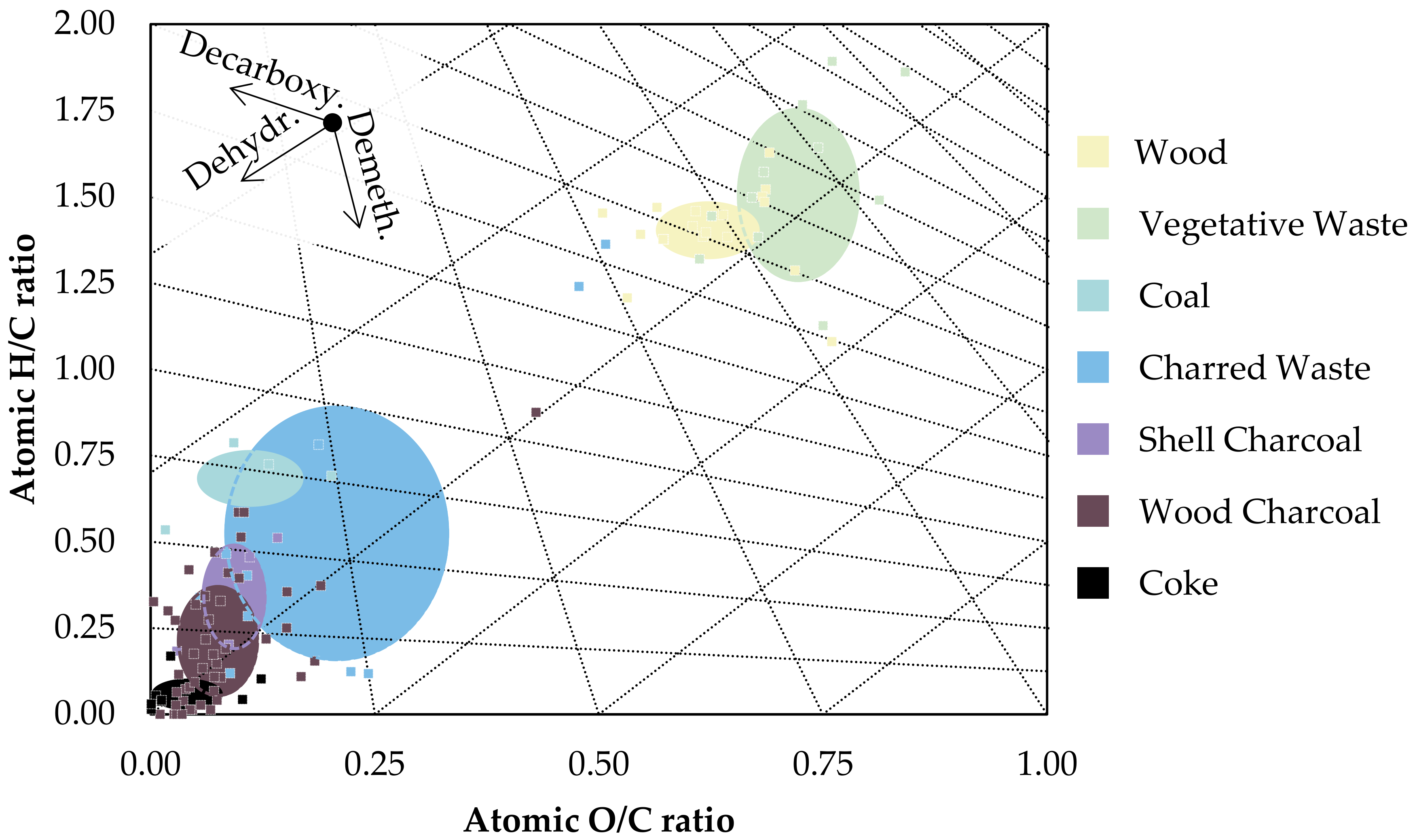

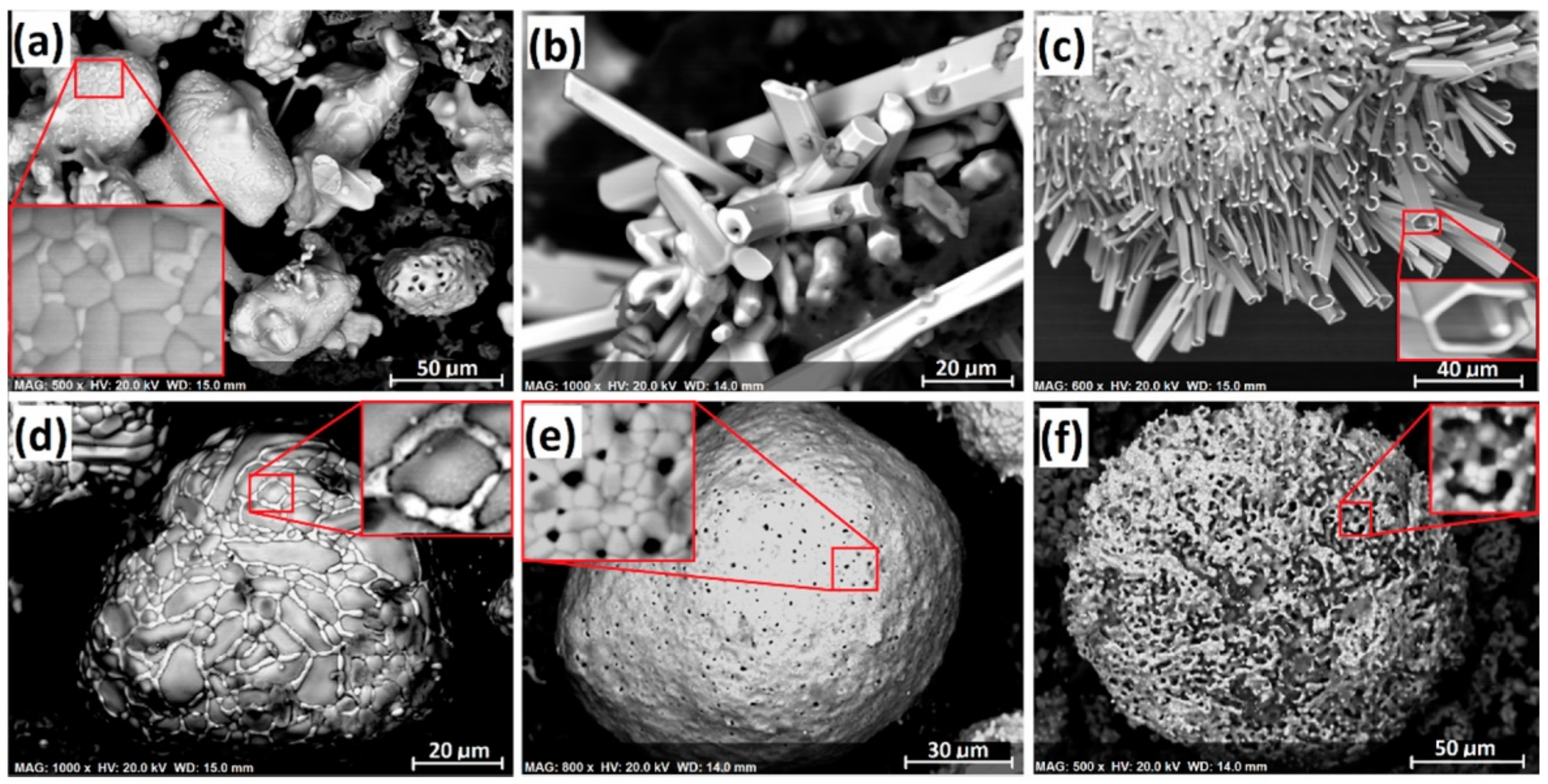

2. Characterization of Reducing Agents

2.1. Proximate Analysis

2.2. Ultimate Analysis

3. Unit Operations Presented in this Review

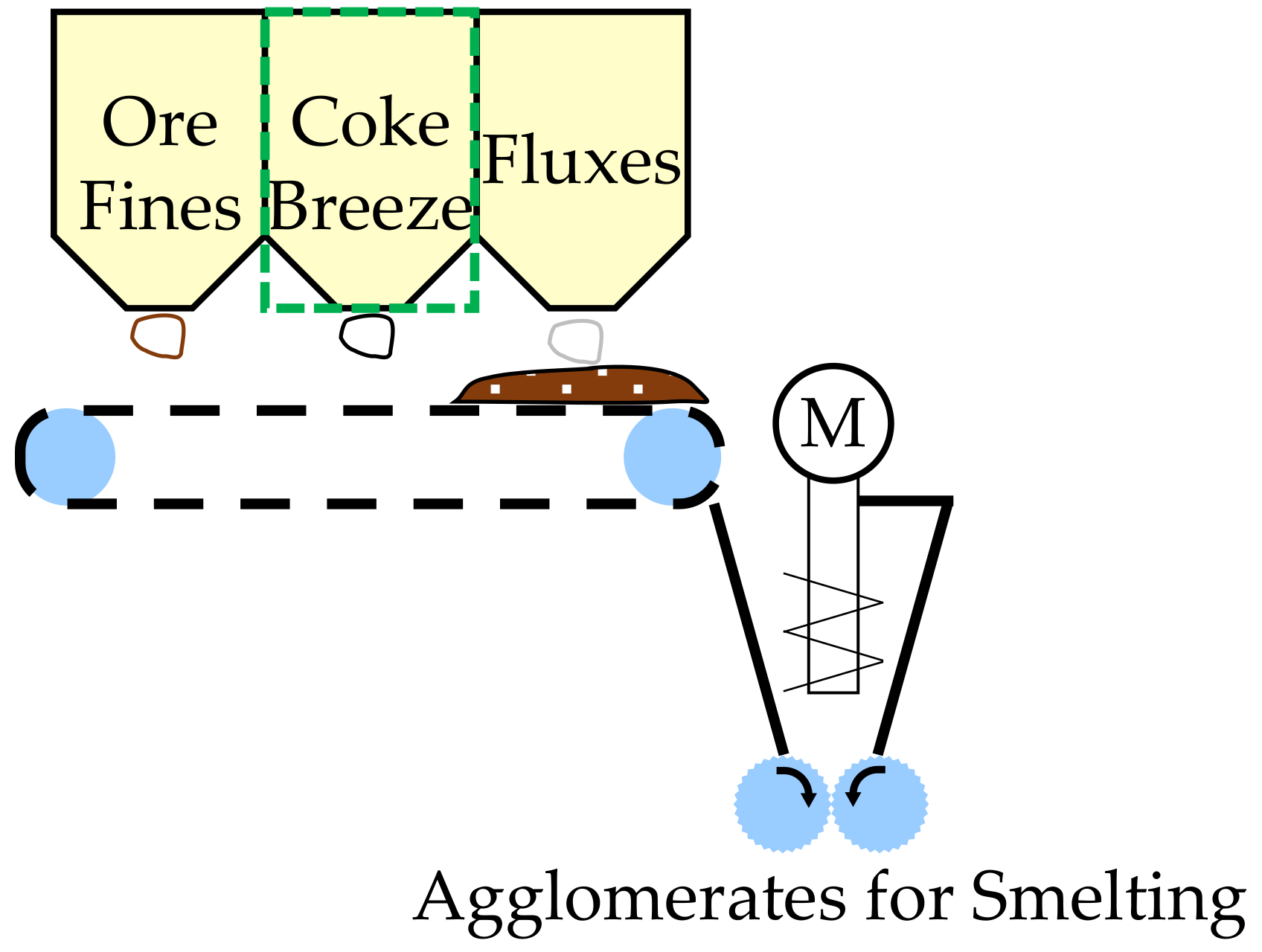

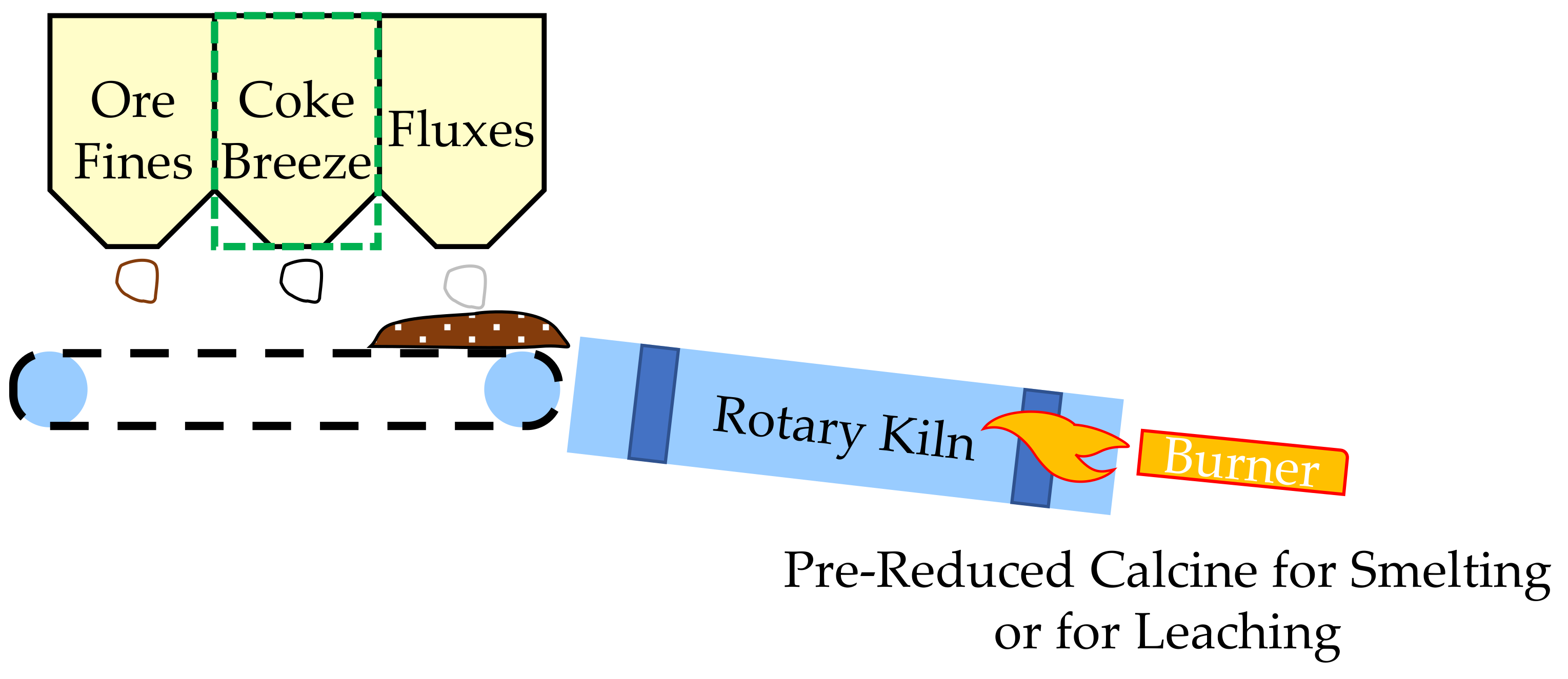

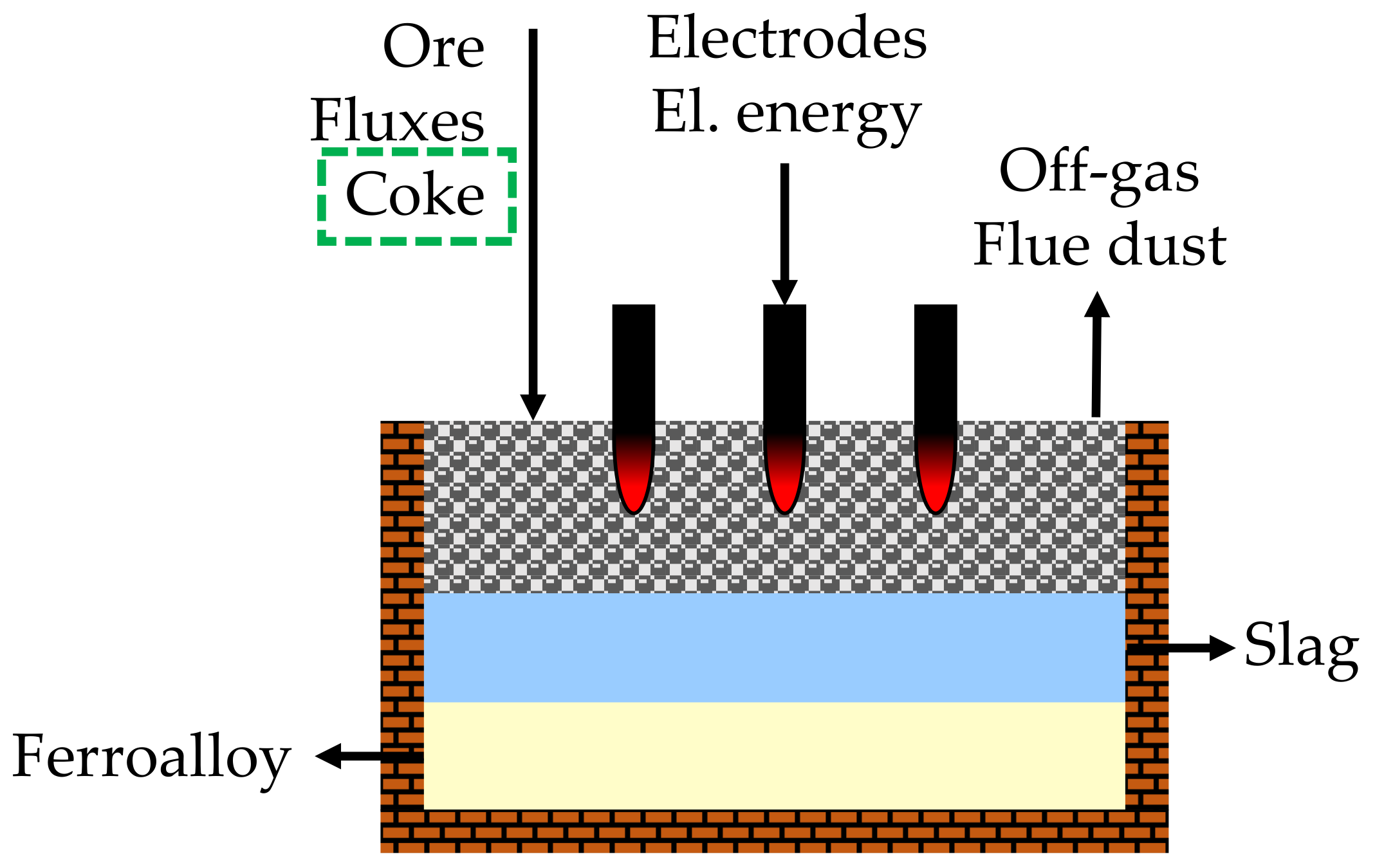

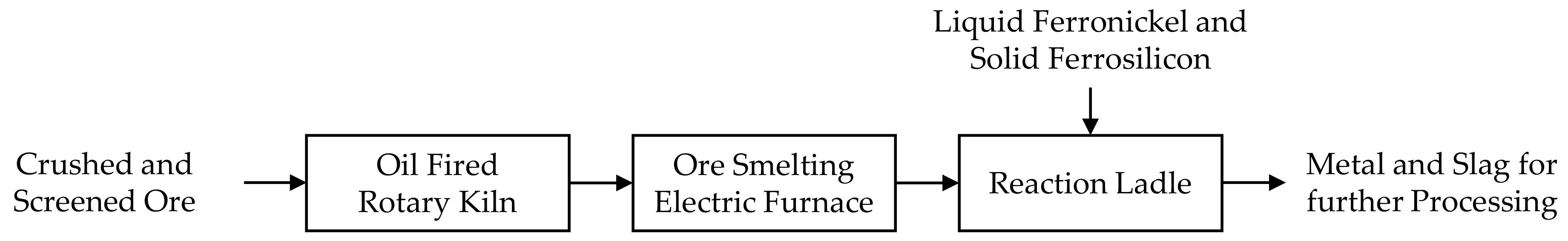

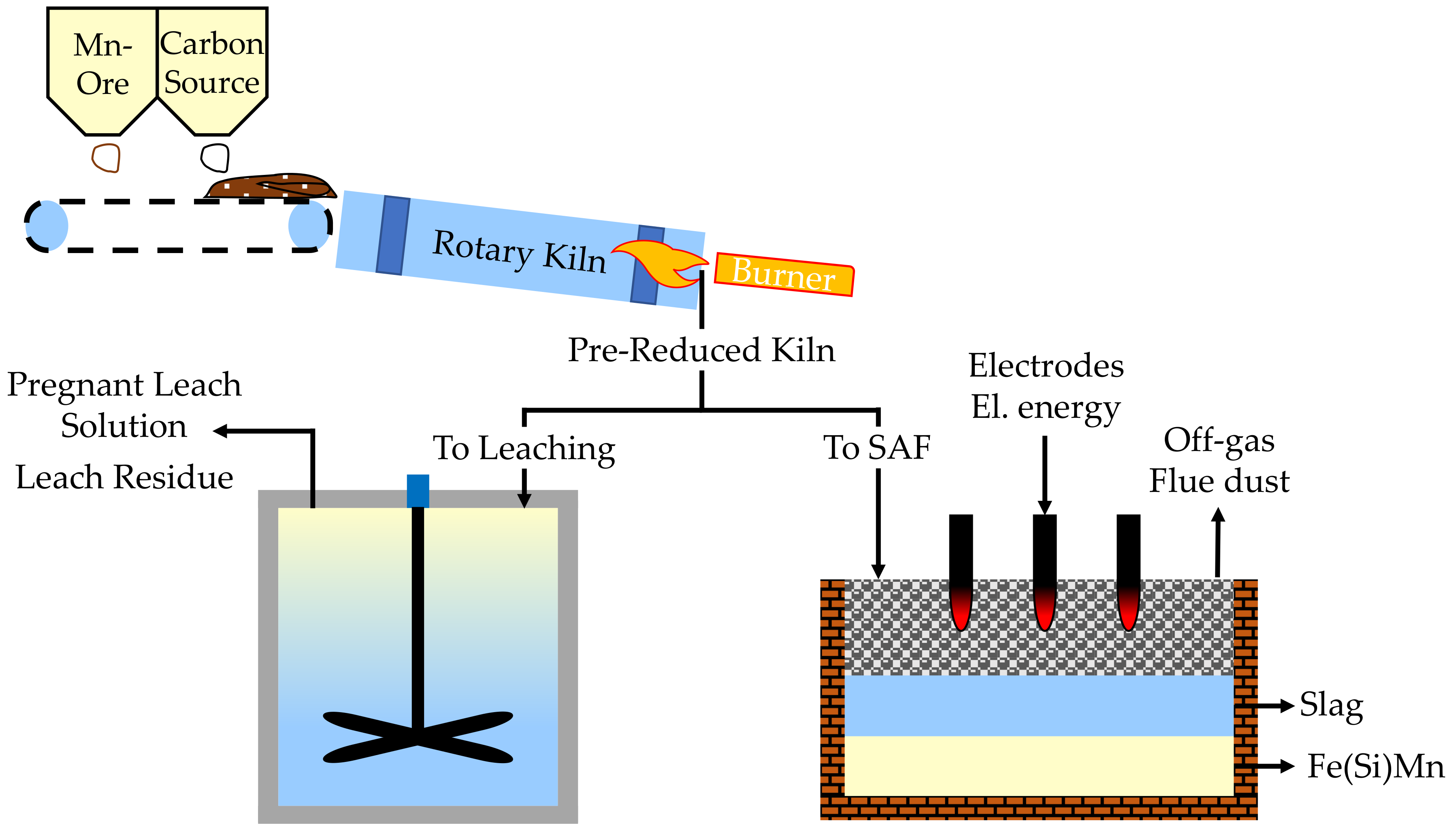

3.1. Established Unit Operations Carried out in the Industry

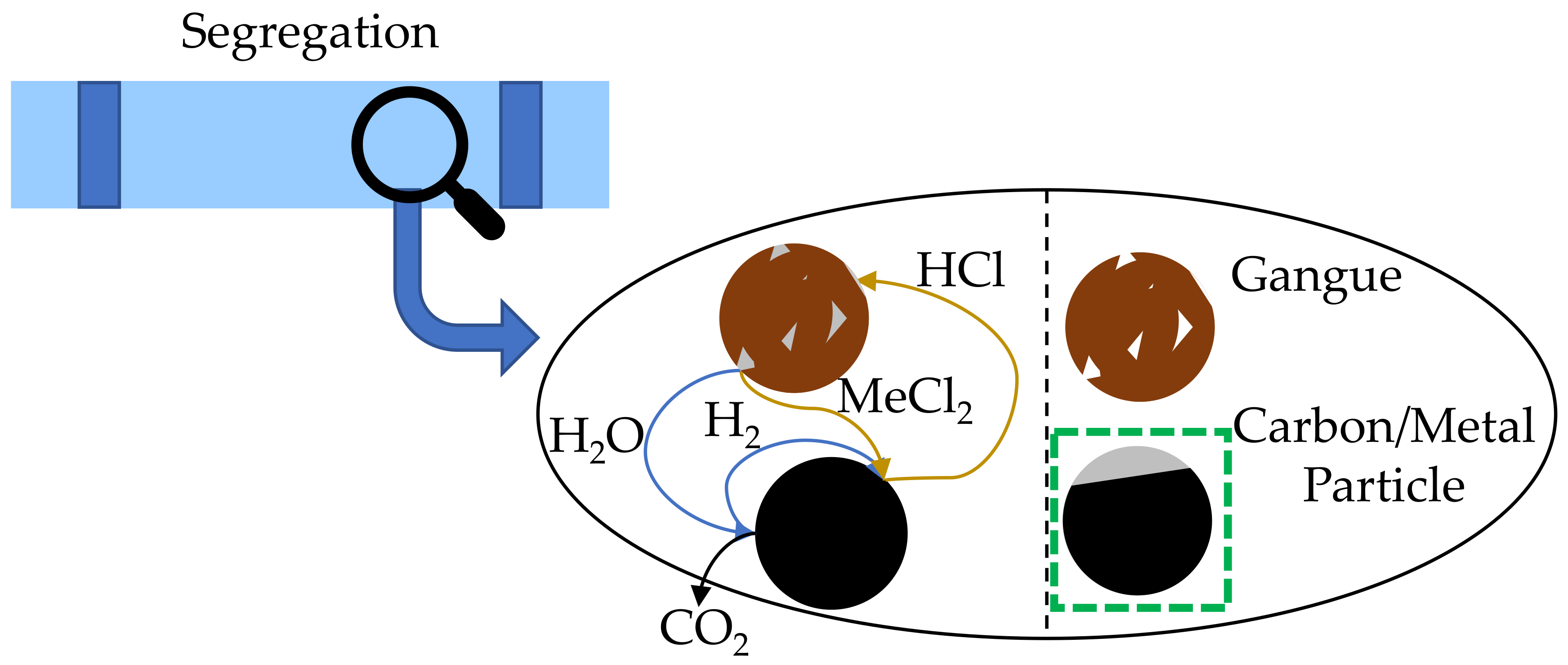

3.2. Innovative Unit Operations of Current Research Interest

4. Production of Nickel Alloys Using Bio-Based Carbon

4.1. Solid-State Processes Using Bio-Based Carbon for the Production of Nickel Alloys

4.1.1. Pre-Reduction of Nickel Resources Using Bio-Based Carbon

4.1.2. Segregation Processes Using Nickel Resources and Bio-Based Carbon

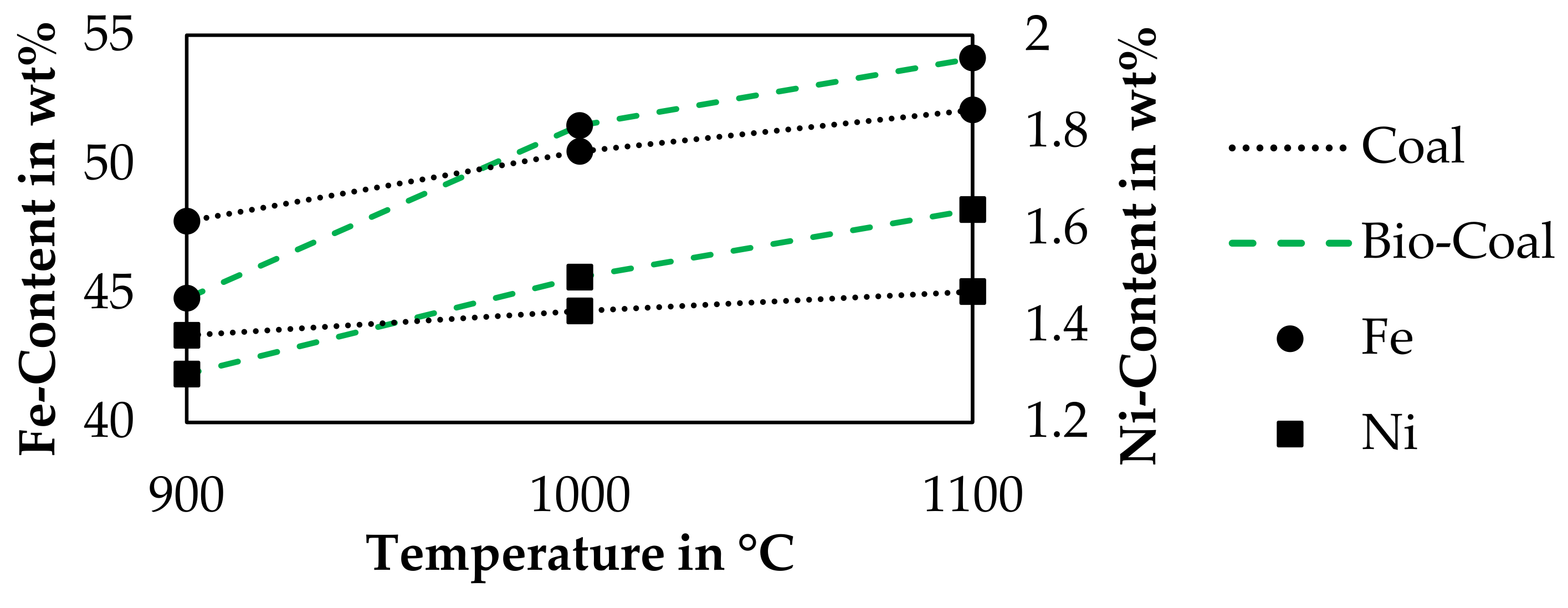

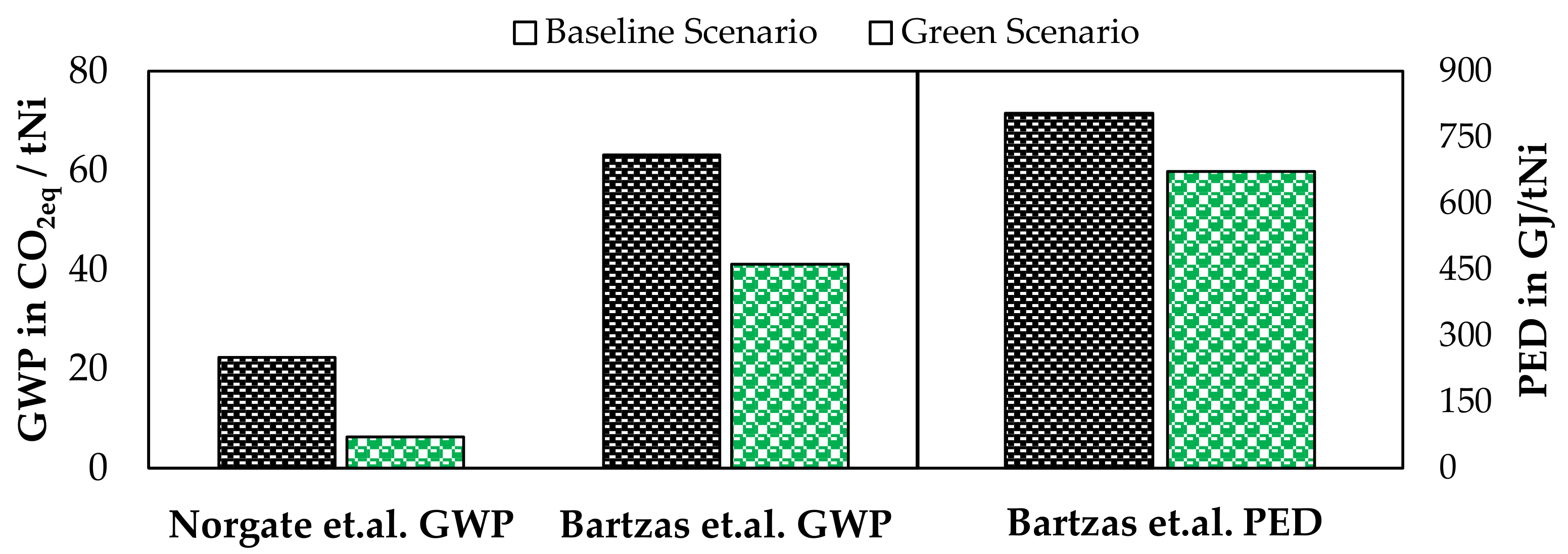

4.2. Smelting Processes Using Bio-Based Carbon to Produce Nickel Alloys

5. Production of Chromium Alloys Using Bio-Based Carbon

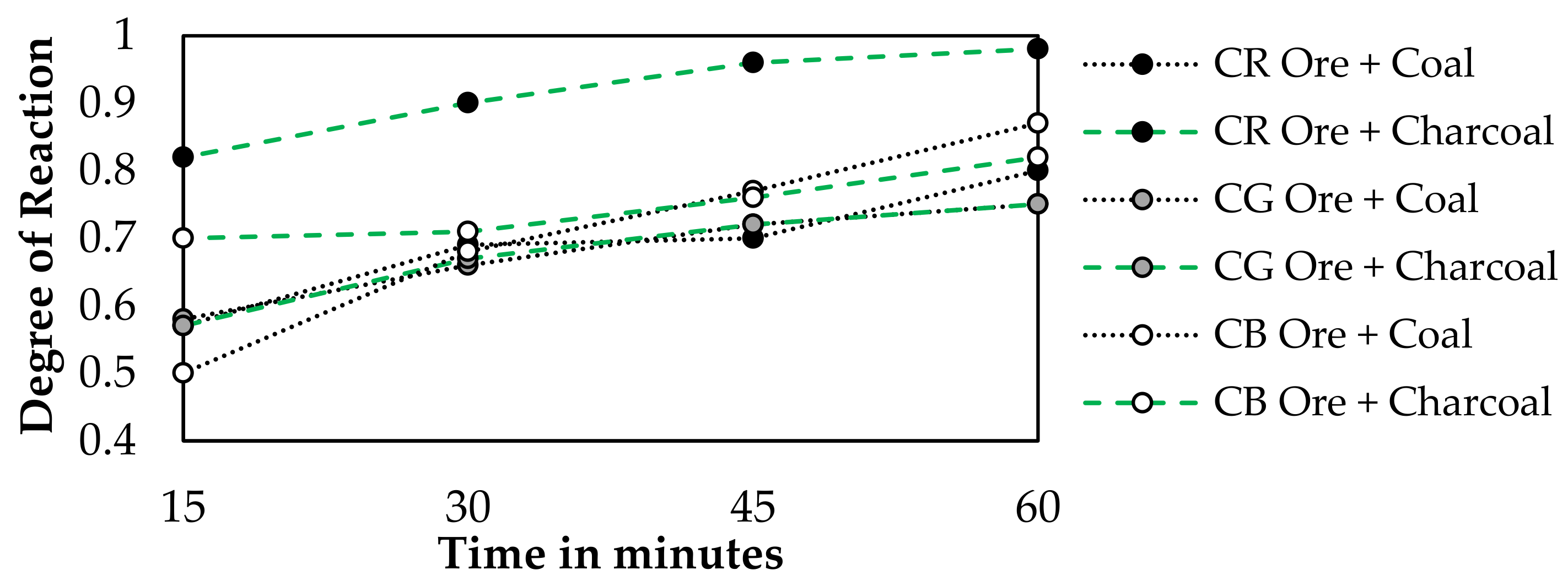

5.1. Solid-State Processes Using Bio-Based Carbon for the Production of Chromium Alloys

5.1.1. Pre-Reduction and Agglomeration of Chromium Resources Using Bio-Based Carbon

5.1.2. Segregation Processes Using Chromium Resources and Bio-Based Carbon

5.2. Smelting Processes Using Bio-Based Carbon to Produce Chromium Alloys

6. Production of Ferrosilicon and Silicon Alloys Using Bio-Based Carbon

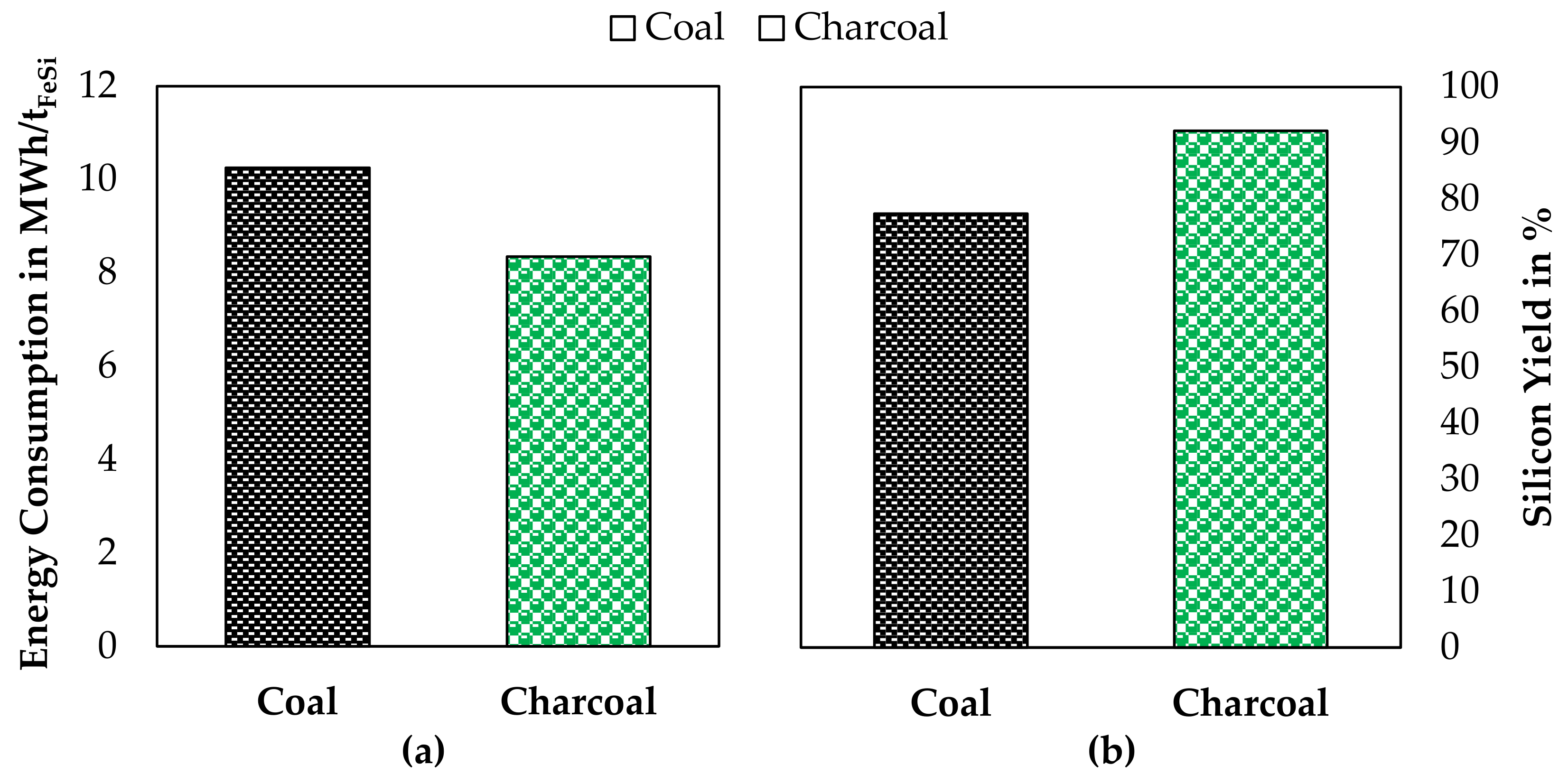

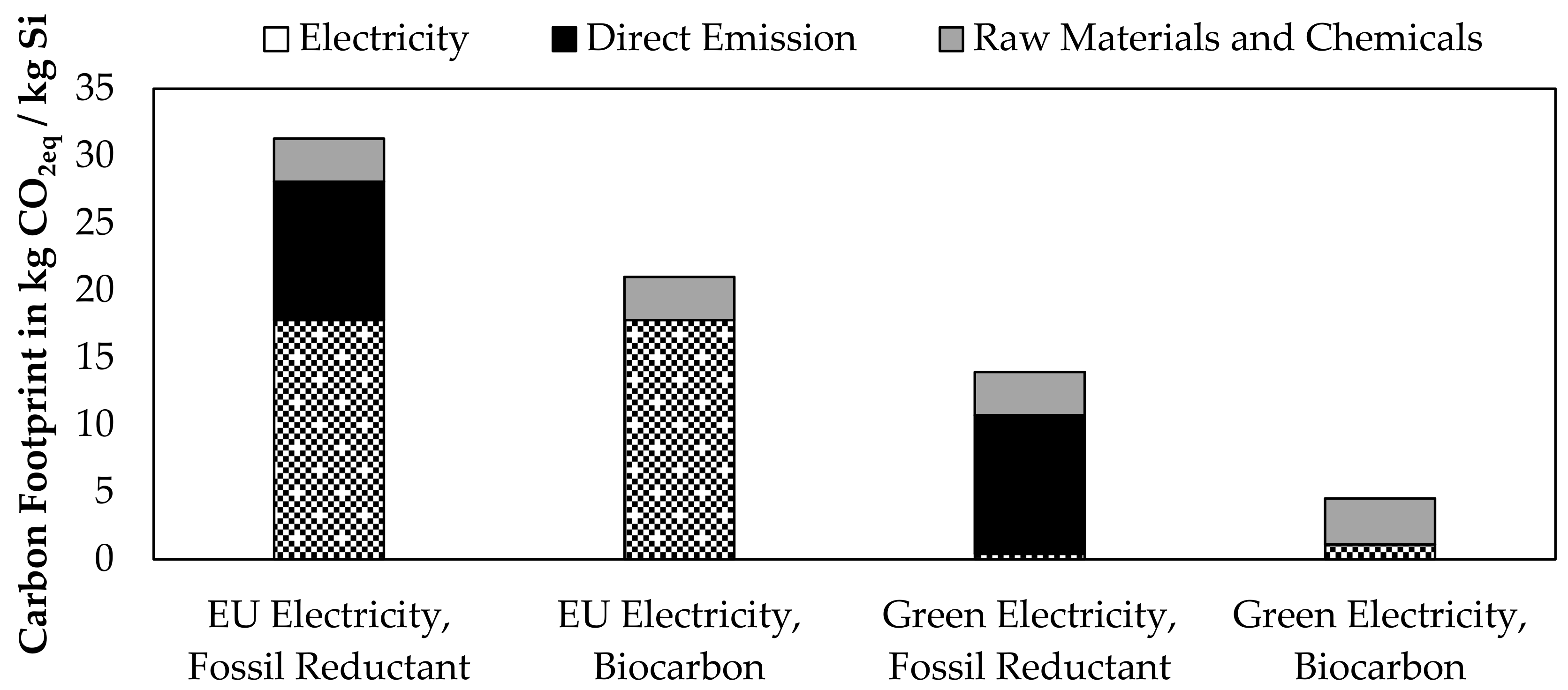

6.1. Smelting Processes Using Bio-Based Carbon to Produce Silicon Alloys

6.2. Production of Agglomerates Containing Biomass for the Application in Silicon Furnaces

6.3. Solar Thermal Production of Silicon Using Bio-Based Carbon

7. Production of Manganese Alloys Using Bio-Based Carbon

7.1. Solid-State Processes Using Bio-Based Carbon for the Production of Manganese Alloys

7.1.1. Pre-Reduction and Agglomeration of Manganese Resources Using Bio-Based Carbon

7.1.2. Reduction-Roasting Processes of Low-Grade Manganese Ore Using Bio-Based Carbon

7.2. Smelting Processes Using Bio-Based Carbon to Produce Manganese Alloys

8. Upgrading of Ilmenite Ore Using Bio-Based Carbon

9. Conclusion and Outlook

- Determination of metal qualities obtainable using biomass, since biomass can contain more phosphorous, but less sulfur compared to fossil reducing agents

- Gas emissions, especially monitoring NOx-, SO2- and chlorine emissions

- Improvement of bio-based carbon in regards to density, mechanical strength and CO2 reactivity

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pachauri, R.K.; Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W.; Christ, R.; Church, J.A.; Clarke, L.; Dahe, Q.; Dasgupta, P.; et al. Climate change 2014: Synthesis report; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2015; ISBN 978-92-9169-143-2. [Google Scholar]

- Fick, G.; Mirgaux, O.; Neau, P.; Patisson, F. Using Biomass for Pig Iron Production: A Technical, Environmental and Economical Assessment. Waste Biomass Valorization 2014, 5, 43–55. [Google Scholar] [CrossRef] [Green Version]

- Monsen, B.; Lindstad, T.; Tuset, J.K. CO2 Emissions from the Production of Ferrosilicon and Silicon metal in Norway. In Proceedings of the 56th Electric Furnace Conference Proceedings, Electric Furnace Conference, New Orleans, LA, USA, 15–18 November 1998; Iron and Steel Society: Warrendale, PA, USA, 1998; pp. 371–378. [Google Scholar]

- Bale, C.W.; Bélisle, E.; Chartrand, P.; Decterov, S.A.; Eriksson, G.; Gheribi, A.E.; Hack, K.; Jung, I.-H.; Kang, Y.-B.; Melançon, J.; et al. FactSage Thermochemical Software and Databases, 2010–2016. Calphad 2016, 54, 35–53. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Gupta, R.C. Industrial Uses of Wood Char. Energy Sources 1998, 20, 575–589. [Google Scholar] [CrossRef]

- da Silviera, R.C.; do Carmo, W.F.; Neto, M.V.B. Utilization of Charcoal by the Ferro Alloy Industry in Brazil. Technical Analysis. In Proceedings of the Fourth International Ferroalloys Congress, INFACON IV, Rio de Janeiro, Brazil, 1986, 31 August–3 September; pp. 482–500.

- Dobrynin, D.; Jarlebring, N.Y.; Mustalahti, I.; Sotirov, M.; Kulikova, E.; Lopatin, E. The forest environmental frontier in Russia: Between sustainable forest management discourses and ‘wood mining’ practice. Ambio 2021, 50, 2138–2152. [Google Scholar] [CrossRef] [PubMed]

- Kiruki, H.; van der Zanden, E.H.; Zagaria, C.; Verburg, P.H. Sustainable woodland management and livelihood options in a charcoal producing region: An agent-based modelling approach. J. Environ. Manage. 2019, 248, 109245. [Google Scholar] [CrossRef] [PubMed]

- Watson, J.E.M.; Evans, T.; Venter, O.; Williams, B.; Tulloch, A.; Stewart, C.; Thompson, I.; Ray, J.C.; Murray, K.; Salazar, A.; et al. The exceptional value of intact forest ecosystems. Nat. Ecol. Evol. 2018, 2, 599–610. [Google Scholar] [CrossRef] [PubMed]

- Suopajärvi, H.; Umeki, K.; Mousa, E.; Hedayati, A.; Romar, H.; Kemppainen, A.; Wang, C.; Phounglamcheik, A.; Tuomikoski, S.; Norberg, N.; et al. Use of biomass in integrated steelmaking—Status quo, future needs and comparison to other low-CO2 steel production technologies. Appl. Energy 2018, 213, 384–407. [Google Scholar] [CrossRef] [Green Version]

- Mousa, E.; Wang, C.; Riesbeck, J.; Larsson, M. Biomass applications in iron and steel industry: An overview of challenges and opportunities. Renew. Sustain. Energy Rev. 2016, 65, 1247–1266. [Google Scholar] [CrossRef]

- Quader, M.A.; Ahmed, S.; Ghazilla, R.A.R.; Ahmed, S.; Dahari, M. A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing. Renew. Sustain. Energy Rev. 2015, 50, 594–614. [Google Scholar] [CrossRef]

- Suopajärvi, H.; Kemppainen, A.; Haapakangas, J.; Fabritius, T. Extensive review of the opportunities to use biomass-based fuels in iron and steelmaking processes. J. Clean. Prod. 2017, 148, 709–734. [Google Scholar] [CrossRef]

- Rosenfeld, D.C.; Böhm, H.; Lindorfer, J.; Lehner, M. Scenario analysis of implementing a power-to-gas and biomass gasification system in an integrated steel plant: A techno-economic and environmental study. Renew. Energy 2020, 147, 1511–1524. [Google Scholar] [CrossRef]

- Mandova, H.; Leduc, S.; Wang, C.; Wetterlund, E.; Patrizio, P.; Gale, W.; Kraxner, F. Possibilities for CO2 emission reduction using biomass in European integrated steel plants. Biomass Bioenerg. 2018, 115, 231–243. [Google Scholar] [CrossRef]

- Suopajärvi, H.; Pongráczb, E.; Fabritiusa, T. The potential of using biomass-based reducing agents in the blast furnace: A review of thermochemical conversion technologies and assessments related to sustainability. Renew. Sustain. Energy Rev. 2013, 25, 511–528. [Google Scholar] [CrossRef]

- Gupta, R.C. Woodchar as a Sustainable Reductant for Ironmaking in the 21st Century. Min. Proc. Ext. Met. Rev. 2003, 24, 203–231. [Google Scholar] [CrossRef]

- Wei, R.; Zhang, L.; Cang, D.; Li, J.; Li, X.; Xu, C.C. Current status and potential of biomass utilization in ferrous metallurgical industry. Renew. Sustain. Energy Rev. 2017, 68, 511–524. [Google Scholar] [CrossRef]

- Schulte, R.F.; Tuck, C.A. U.S. Geological Survey 2016 Minerals Yearbook: Ferroalloys [Advanced Release]; United States Geological Survey: Reston, VA, USA, 2020.

- Schnebele, E.K. U.S. Geological Survey 2017 Minerals Yearbook: Silicon [Advanced Release]; United States Geological Survey: Reston, VA, USA, 2020.

- Fenton, M.D.; Tuck, C.A. U.S. Geological Survey 2016 Minerals Yearbook: Iron and Steel [Advanced Release]; United States Geological Survey: Reston, VA, USA, 2019.

- Lindstad, T.; Olsen, S.E.; Tranell, G.; Færden, T.; Lubetsky, J. Greenhouse Gas Emissions from Ferroalloy Production. In Proceedings of the Eleventh International Ferroalloys Congress, INFACON XI, New Delhi, India, 18–21 February 2007; pp. 457–466. [Google Scholar]

- Climate Watch, Washington DC. 2020. Available online: https://www.climatewatchdata.org (accessed on 27 February 2021).

- Ritchie, H.; Roser, M. Global Greenhouse Gas Emissions by Sector. Available online: https://ourworldindata.org/emissions-by-sector (accessed on 27 February 2021).

- United Nations, Department of Economic and Social Affairs. International Standard Industrial Classification of All Economic Activities (ISIC), Rev.4; United Nations: New York, NY, USA, 2008; ISBN 9789211615180. [Google Scholar]

- Monsen, B.; Grønlin, M.; Nygaard, L.; Tveit, H. The Use of Biocarbon in Norwegian Ferroalloy Production. In Proceedings of the Ninth International Ferroalloys Congress, INFACON IX, Quebec City, Qc, Canada, 3–6 June 2001; pp. 268–276. [Google Scholar]

- Monsen, B.; Olsen, S.E.; Lindstad, T. CO2-emissions from the production of manganese and chromium alloys in Norway. In Proceedings of the 56th Electric Furnace Conference Proceedings, New Orleans, LA, USA, 15–18 November 1998; Iron and Steel Society: Warrendale, PA, USA, 1998; pp. 363–369. [Google Scholar]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of binders on the properties of bio-char pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Monsen, B.; Tangstad, M.; Solheim, I.; Syverstsen, M.; Ishak, R.; Mitgaard, H. Charcoal for Manganese Alloy Production. In Proceedings of the Eleventh International Ferroalloys Congress, INFACON XI, New Delhi, India, 2007., 18–21 February.

- Noumi, E.S.; Rousset, P.; de Cassia Oliveira Carneiro, A.; Blin, J. Upgrading of carbon-based reductants from biomass pyrolysis under pressure. J. Anal. Appl. Pyrolysis 2016, 118, 278–285. [Google Scholar] [CrossRef]

- Surup, G.R.; Foppe, M.; Schubert, D.; Deike, R.; Heidelmann, M.; Timko, M.T.; Trubetskaya, A. The effect of feedstock origin and temperature on the structure and reactivity of char from pyrolysis at 1300–2800 °C. Fuel 2019, 235, 306–316. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, G.; Yan, H.; Li, T.; Feng, X. Thermogravimetric Analysis and Kinetics on Reducing Low-Grade Manganese Dioxide Ore by Biomass. Metall. Mater. Trans. B 2013, 44, 878–888. [Google Scholar] [CrossRef]

- Guo, D.; Hu, M.; Pu, C.; Xiao, B.; Hu, Z.; Liu, S.; Wang, X.; Zhu, X. Kinetics and mechanisms of direct reduction of iron ore-biomass composite pellets with hydrogen gas. Int. J. Hydrogen Energ. 2015, 40, 4733–4740. [Google Scholar] [CrossRef]

- Konishi, H.; Ichikawa, K.; Usui, T. Effect of Residual Volatile Matter on Reduction of Iron Oxide in Semi-charcoal Composite Pellets. ISIJ Int. 2010, 50, 386–389. [Google Scholar] [CrossRef] [Green Version]

- Machulec, B.; Gil, S.; Bialik, W.; Kozłowski, S. Production of ultrapure ferrosilicon chrome with controlled contents of carbon and other chemical elements for manufacturing of innovative metallic materials. In Proceedings of the Conference Proceedings—METAL 2019, 28th International Conference on Metallurgy and Materials, Brno, Czech Republic, 22–24 May 2019; pp. 117–122. [Google Scholar]

- Liu, J.; Chen, Z.; Ma, W.; Wei, K.; Ding, W. Application of a Waste Carbon Material as the Carbonaceous Reductant During Silicon Production. Silicon 2018, 10, 2409–2417. [Google Scholar] [CrossRef]

- Riva, L.; Surup, G.R.; Buø, T.V.; Nielsen, H.K. A study of densified biochar as carbon source in the silicon and ferrosilicon production. Energy 2019, 181, 985–996. [Google Scholar] [CrossRef]

- Riva, L.; Nielsen, H.K.; Skreiberg, Ø.; Wang, L.; Bartocci, P.; Barbanera, M.; Bidini, G.; Fantozzi, F. Analysis of optimal temperature, pressure and binder quantity for the production of biocarbon pellet to be used as a substitute for coke. Appl. Energy 2019, 256, 113933. [Google Scholar] [CrossRef]

- Riva, L.; Cardarelli, A.; Andersen, G.J.; Buø, T.V.; Barbanera, M.; Bartocci, P.; Fantozzi, F.; Nielsen, H.K. On the self-heating behavior of upgraded biochar pellets blended with pyrolysis oil: Effects of process parameters. Fuel 2020, 278, 118395. [Google Scholar] [CrossRef]

- Surup, G.R.; Nielsen, H.K.; Heidelmann, M.; Trubetskaya, A. Characterization and reactivity of charcoal from high temperature pyrolysis (800–1600 °C). Fuel 2019, 235, 1544–1554. [Google Scholar] [CrossRef]

- Surup, G.R.; Hunt, A.J.; Attard, T.; Budarin, V.L.; Forsberg, F.; Arshadi, M.; Abdelsayed, V.; Shekhawat, D.; Trubetskaya, A. The effect of wood composition and supercritical CO2 extraction on charcoal production in ferroalloy industries. Energy 2020, 193, 116696. [Google Scholar] [CrossRef]

- Kieush, L.; Boyko, M.; Koveria, A.; Yaholnyk, M.; Poliakova, N. Manganese Sinter Production with Wood Biomass Application. Key Eng. Mater. 2020, 844, 124–134. [Google Scholar] [CrossRef]

- Langberg, D.E.; Somerville, M.A.; Freeman, D.E.; Washington, B.M. The use of Mallee charcoal in metallurgical reactors. In Proceedings of the Green Processing 2006. 3rd International Conference on the Sustainable Processing of Minerals, Newcastle, Australia, 5–6 June 2006; pp. 69–75. [Google Scholar]

- Surup, G.R.; Leahy, J.J.; Timko, M.T.; Trubetskaya, A. Hydrothermal carbonization of olive wastes to produce renewable, binder-free pellets for use as metallurgical reducing agents. Renew. Energy 2020, 155, 347–357. [Google Scholar] [CrossRef]

- Maksum, A.; Husein, M.K.E.; Permana, S.; Rustandi, A.; Soedarsono, J.W. A preliminary study on the reduction of limonite ore by using rice husk as a reducing agent. IOP Conf. Ser. Mater. Sci. Eng. 2018, 316, 12050. [Google Scholar] [CrossRef]

- Rahayu, D.; Maksum, A.; Soedarsono, J.W. Effects of reduction time on carbothermic reduction of lateritic nickel ore using palm kernel shell as green reducing agent. IOP Conf. Ser. Earth Environ. Sci. 2018, 105, 12037. [Google Scholar] [CrossRef] [Green Version]

- Rashid, R.Z.A.; Salleh, H.M.; Ani, M.H.; Yunus, N.A.; Akiyama, T.; Purwanto, H. Reduction of low grade iron ore pellet using palm kernel shell. Renew. Energy 2014, 63, 617–623. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, G.; Cheng, Z. Thermal analysis and kinetic modeling of manganese oxide ore reduction using biomass straw as reductant. Hydrometallurgy 2010, 105, 96–102. [Google Scholar] [CrossRef]

- Li, K.; Chen, G.; Chen, J.; Peng, J.; Ruan, R.; Srinivasakannan, C. Microwave pyrolysis of walnut shell for reduction process of low-grade pyrolusite. Bioresour. Technol. 2019, 291, 121838. [Google Scholar] [CrossRef]

- Supriyatna, Y.I.; Zulhan, Z.; Triapriani, Y. The ferromanganese production using Indonesian low-grade manganese ore using charcoal and palm kernel shell as reductant in mini electric arc furnace. IOP Conf. Ser. Mater. Sci. Eng. 2018, 285, 12022. [Google Scholar] [CrossRef]

- George, A.; Kelukutty, V.S.; Radhika, L.G.; Mohandas, P.N.; Rohatgi, P.K. Rutile from ilmenite using coconut pith as a reductant. J. Mater. Sci. 1984, 19, 1522–1529. [Google Scholar] [CrossRef]

- Agirre, I.; Griessacher, T.; Rösler, G.; Antrekowitsch, J. Production of charcoal as an alternative reducing agent from agricultural residues using a semi-continuous semi-pilot scale pyrolysis screw reactor. Fuel Process. Technol. 2013, 106, 114–121. [Google Scholar] [CrossRef]

- El-Tawil, A.A.; Ahmed, H.M.; Ökvist, L.S.; Björkman, B. Self-Reduction Behavior of Bio-Coal Containing Iron Ore Composites. Metals 2020, 10, 133. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.-Q.; Sun, T.-C.; Zhao, H.-Y.; Chen, C.; Wang, X.-P. Effect of reductant type on the embedding direct reduction of beach titanomagnetite concentrate. Int. J. Miner. Metall. Mater. 2019, 26, 152–159. [Google Scholar] [CrossRef]

- Petrus, H.T.B.M.; Putera, A.D.P.; Sugiarto, E.; Perdana, I.; Warmada, I.W.; Nurjaman, F.; Astuti, W.; Mursito, A.T. Kinetics on roasting reduction of limonitic laterite ore using coconut-charcoal and anthracite reductants. Miner. Eng. 2019, 132, 126–133. [Google Scholar] [CrossRef]

- Rasyid, M.H.A.; Rhamdani, A.R.; Putera, A.D.P.; Petrus, H.T.B.M. Study on biomass performance in reduction of nickel laterite from Pomalaa, Sulawesi Tenggara. AIP Conf. Proc. 2016, 1755, 50007. [Google Scholar] [CrossRef] [Green Version]

- Nurjaman, F.; Sa’adah, A.; Shofi, A.; Apriyana, W.; Suharno, B. The Effect of Additives and Reductors in Selective Reduction Process of Laterite Nickel Ore. Jsmi 2018, 20, 8. [Google Scholar] [CrossRef]

- Pamungkas, B.C.; Hadi, H. Potential of Biomass Utilization in Rotary Kiln of Nickel Processing Plant. IOP Conf. Ser. Mater. Sci. Eng. 2019, 588, 12006. [Google Scholar] [CrossRef]

- Andika, R.; Astuti, W.; Syafriadi; Nurjaman, F. Effect of flux addition and reductant type in smelting process of Indonesian limonite ore in electric arc furnace. IOP Conf. Ser. Mater. Sci. Eng. 2019, 478, 12007. [Google Scholar] [CrossRef]

- Shofi, A.; Rahmahwati, A.; Nurjaman, F.; Suharno, B. Effect of reduction temperature and sodium-based additives on nickel upgrading process of laterites ores. IOP Conf. Ser. Mater. Sci. Eng. 2019, 541, 12002. [Google Scholar] [CrossRef]

- Sugiarto, E.; Putera, A.D.P.; Petrus, H.T.B.M. Kinetic study of nickel laterite reduction roasting by palm kernel shell charcoal. IOP Conf. Ser. Earth Environ. Sci. 2017, 65, 12027. [Google Scholar] [CrossRef] [Green Version]

- Abidin, F.; Harjanto, S.; Kawigraha, A.; Permatasari, N.V. Characterization on particle size distribution of reduced lateritic nickel ore using biomass carbon reduction. IOP Conf. Ser. Mater. Sci. Eng. 2019, 602, 12080. [Google Scholar] [CrossRef]

- Nurjaman, F.; Subandrio, S.; Ferdian, D.; Suharno, B. Effect of basicity on beneficiated chromite sand smelting process using submerged arc furnace. AIP Conf. Proc. 2018, 1964, 020009. [Google Scholar] [CrossRef]

- Balangao, J.K.B.; Podiotan, F.J.; Ambolode, A.E.C.; Anacleto, N.M.; Namoco, C.S. Production of Iron-Chromium-Nickel Metal Alloys Via Reduction of Mixed Chromite Ore from Zambales and Laterite Ore from Taganito, Surigao del Norte under Argon Atmosphere. Indian J. Sci. Technol. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Suharto; Nurjaman, F.; Shofi, A.; Sudibyo; Milandia, A.; Rismananda, M.H. Analysis of the effect of temperature on the reduction roasting process of Lampung manganese ore using palm kernel shell charcoal. IOP Conf. Ser. Earth Environ. Sci. 2020, 483, 12012. [Google Scholar] [CrossRef]

- Setiawan, A.; Shaw, M.; Torpy, A.; Pownceby, M.I.; Harjanto, S.; Rhamdhani, M.A. Solar Carbothermic Reduction of Ilmenite Using Palm Kernel Shell Biomass. JOM 2020. [Google Scholar] [CrossRef]

- Surup, G.R.; Pedersen, T.A.; Chaldien, A.; Beukes, J.P.; Tangstad, M. Electrical Resistivity of Carbonaceous Bed Material at High Temperature. Processes 2020, 8, 933. [Google Scholar] [CrossRef]

- Li, F.; Tangstad, M.; Ringdalen, E. Carbothermal Reduction of Quartz and Carbon Pellets at Elevated Temperatures. Metall. Mater. Trans. B 2018, 49, 1078–1088. [Google Scholar] [CrossRef]

- Gaal, S.; Berg, K.; Tranell, G.; Olsen, S.E.; Tangstad, M. An investigation into aspects of liquid phase reduction of manganese and silica containing slag. In Proceedings of the VII International Conference Molten Slags, Fluxes & Salts, Cape Town, South Africa, 25–28 January 2004; pp. 651–658. [Google Scholar]

- Petrus, H.T.B.M.; Diga, A.; Rhamdani, A.R.; Warmada, I.W.; Yuliansyah, A.T.; Perdana, I. Lamtoro charcoal (l. leucocephala) as bioreductor in nickel laterite reduction: Performance and kinetics study. J. Phys. Conf. Ser. 2017, 817, 12065. [Google Scholar] [CrossRef] [Green Version]

- Rocha, M.G.; Silva, A.S.d.; Mourao, M.B.; Kurauchi, M.H.N.; Takano, C. Fundamental aspects of sintering of chromites concentrates. Min. Proc. Ext. Met. 2014, 123, 251–256. [Google Scholar] [CrossRef]

- Safarian, J.; Tranell, G.; Kolbeinsen, L.; Tangstad, M.; Gaal, S.; Kaczorowski, J. Reduction Kinetics of MnO from High-Carbon Ferromanganese Slags by Carbonaceous Materials in Ar and CO Atmospheres. Metall. Mater. Trans. B 2008, 39, 702–712. [Google Scholar] [CrossRef]

- International Organization for Standardization. Hard Coal—Determination of Total Moisture; (ISO 589:2008(E)); ISO: Geneva, Switzerland, 2008. [Google Scholar]

- International Organization for Standardization. Hard Coal and Coke—Determination of Volatile Matter; (ISO 562:2010(E)); ISO: Geneva, Switzerland, 2010. [Google Scholar]

- International Organization for Standardization. Solid Mineral Fuels—Determination of Ash; (ISO 1171:2010(E)); ISO: Geneva, Switzerland, 2010. [Google Scholar]

- International Organization for Standardization. Coal—Proximate Analysis; (ISO 17246:2010(E)); ISO: Geneva, Switzerland, 2010. [Google Scholar]

- International Organization for Standardization. Solid Mineral Fuels—Determination of Total Carbon, Hydrogen and Nitrogen Content–Instrumental Method; (ISO 29541:2010(E)); ISO: Geneva, Switzerland, 2010. [Google Scholar]

- International Organization for Standardization. Solid Mineral Fuels—Determination of Sulfur by IR Spectrometry; (ISO 19579:2006(E)); ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. Coal and Coke—Calculation of Analyses to Different Bases; (ISO 1170:2020(E)); ISO: Geneva, Switzerland, 2020. [Google Scholar]

- Adrados, A.; de Marco, I.; López-Urionabarrenechea, A.; Solar, J.; Caballero, B.M.; Gastelu, N. Biomass Pyrolysis Solids as Reducing Agents: Comparison with Commercial Reducing Agents. Materials 2016, 9, 3. [Google Scholar] [CrossRef]

- Dı́ez, M.A.; Alvarez, R.; Barriocanal, C. Coal for metallurgical coke production: Predictions of coke quality and future requirements for cokemaking. Int. J. Coal Geol. 2002, 50, 389–412. [Google Scholar] [CrossRef]

- van Krevelen, D.W. Graphical-statistical method for the study of structure and reaction processes of coal. Fuel 1950, 29, 260–284. [Google Scholar]

- Schrama, F.N.H.; Beunder, E.M.; van den Berg, B.; Yang, Y.; Boom, R. Sulphur removal in ironmaking and oxygen steelmaking. Ironmak. Steelmak. 2017, 44, 333–343. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Ferrosilicon; (A100-07(2018)); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. Standard Specification for Ferromanganese; (A99-03(2019)); ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM International. Standard Specification for Silicomanganese; (A483/A483M-10(2020)); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM International. Standard Specification for Nickel; (B39-79(2018)); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. Standard Specification for Ferrochromium; (A101-04(2019)); ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Dai, W.; Shu, L. On Sulfur Control in HC FeCr Production. In Proceedings of the Seventh International Ferroalloys Congress, INFACON VII, Trondheim, Norway, 11–14 June 1995; pp. 287–296. [Google Scholar]

- Yu, D.; Paktunc, D. Calcium Chloride-Assisted Segregation Reduction of Chromite: Influence of Reductant Type and the Mechanism. Minerals 2018, 8, 45. [Google Scholar] [CrossRef] [Green Version]

- Grimsey, D.E.; Grimsey, E.J.; Ibana, D.C. Fundamental aspects of the recovery of nickel, cobalt and iron from nontronite laterite using the segregation process. Can. Metall. Q. 2020, 59, 169–179. [Google Scholar] [CrossRef]

- Ogura, T.; Kuwayama, K.; Ono, A.; Yamada, Y. Production of Fe-Ni by the rotary kiln-electric furnace process at Hyuga Smelter. Int. J. Miner. Process. 1987, 19, 189–198. [Google Scholar] [CrossRef]

- Li, G.; Jia, H.; Luo, J.; Peng, Z.; Zhang, Y.; Jiang, T. Ferronickel Preparation from Nickeliferous Laterite by Rotary Kiln-Electric Furnace Process. In Proceedings of the Characterization of Minerals, Metals, and Materials 2016, Nashville, TN, USA, 14–18 November 2016; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 143–149. [Google Scholar]

- Keskinkilic, E. Nickel Laterite Smelting Processes and Some Examples of Recent Possible Modifications to the Conventional Route. Metals 2019, 9, 974. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Li, B.; Cheung, S.C.P.; Wu, W. Material and energy flows in rotary kiln-electric furnace smelting of ferronickel alloy with energy saving. Appl. Therm. Eng. 2016, 109, 542–559. [Google Scholar] [CrossRef]

- Chen, Y.-Q.; Zhao, H.-L.; Wang, C.-Y. Two-stage reduction for the preparation of ferronickel alloy from nickel laterite ore with low Co and high MgO contents. Int. J. Miner. Metall. Mater. 2017, 24, 512–522. [Google Scholar] [CrossRef] [Green Version]

- Mehmetaj, B.; Boom, R. Ferronickel production in Kosova—Past performance and new opportunities. Steel Res. Int. 2001, 72, 428–433. [Google Scholar] [CrossRef]

- Swinbourne, D.R. Understanding ferronickel smelting from laterites through computational thermodynamics modelling. Min. Proc. Ext. Met. 2014, 123, 127–140. [Google Scholar] [CrossRef]

- Coleman, E.E.; Vedensky, D.N. Ferro-Nickel Production in Oregon. JOM 1960, 12, 197–201. [Google Scholar] [CrossRef]

- United States Congress. Senate. Committee on Armed Services. Inquiry Into the Strategic and Critical Material Stockpiles of the United States: Hearings Before the National Stockpile and Naval Petroleum Reserves Subcommittee of the Committee on Armed Services, United States Senate, Eighty-Seventh Congress, Second Session; U.S. Government Printing Office: Washington, DC, USA, 1962.

- Chen, G.-J.; Hwang, W.-S.; Liu, S.-H.; Shiau, J.-S. The Effect of Bio-Coal on the Carbothermic Reduction of Laterite Ores. Mater. Trans. 2015, 56, 550–555. [Google Scholar] [CrossRef] [Green Version]

- Swamy, Y.V.; Murthy, B.V.R.; Reddy, B.R. Extraction of nickel from chromitiferous overburden by roasting with a CO-CO2-N2 gas mixture. Mining Metall. Explor. 2000, 17, 223–227. [Google Scholar] [CrossRef]

- Rhamdani, A.R.; Petrus, H.T.B.M.; Fahrurrozi, M. Characterization of nickel laterite reduction from Pomalaa, Sulawesi Tenggara. AIP Conf. Proc. 2015, 1699, 50012. [Google Scholar] [CrossRef]

- Adzhani, S.; Hidayanti, R.; Maksum, A.; Permana, S.; Soedarsono, J.W. The influence of palm kernel shell mass ratio as a reducing agent in the lateritic nickel ore carbothermic reduction process. IOP Conf. Ser. Earth Environ. Sci. 2018, 105, 12016. [Google Scholar] [CrossRef]

- Hidayanti, R.; Permana, S.; Maksum, A.; Soedarsono, J.W. Study on the effects of temperature in the carbothermic reduction laterite ore using palm kernel shell as reducing agent. IOP Conf. Ser. Earth Environ. Sci. 2018, 105, 12015. [Google Scholar] [CrossRef]

- Shofi, A.; Supriyatna, Y.I.; Prasetyo, A.B. Selective Reduction of Southeast Sulawesi Nickel Laterite using Palm Kernel Shell Charcoal: Kinetic Studies with Addition of Na2SO4 and NaCl as Additives. Bull. Chem. React. Eng. Catal. 2020, 15, 501–513. [Google Scholar] [CrossRef]

- Suharno, B.; Ilman, N.P.; Shofi, A.; Ferdian, D.; Nurjaman, F. Study of Low-Grade Nickel Laterite Processing Using Palm Shell Charcoal as Reductant. Mater. Sci. Forum 2020, 1000, 436–446. [Google Scholar] [CrossRef]

- Putera, A.D.P.; Sugiarto, E.; Sutijan; Warmada, I.W.; Petrus, H.T.B.M. Coconut Shell Charcoal as a Bioreductor in Roasting Process of Nickel Laterite from Pomalaa, Southeast Sulawesi: Performance and Kinetics Study. Mater. Sci. Forum 2017, 901, 182–189. [Google Scholar] [CrossRef]

- Ericson, A.S.; Svensson, J.; Ishii, K. Development of the MINPRO-PAMCO Nickel Segregation Process. JOM 1984, 36, 42–46. [Google Scholar] [CrossRef]

- Grimsey, D.E.; Grimsey, E.J.; Ibana, D.C. Key factors affecting nickel recovery during the segregation of laterite ores. Can. Metall. Q. 2017, 56, 401–409. [Google Scholar] [CrossRef]

- Rao, M.; Li, G.; Jiang, T.; Luo, J.; Zhang, Y.; Fan, X. Carbothermic Reduction of Nickeliferous Laterite Ores for Nickel Pig Iron Production in China: A Review. JOM 2013, 65, 1573–1583. [Google Scholar] [CrossRef]

- Sihotang, I.H.; Supriyatna, Y.I.; Ismail, I.; Sulistijono. The effect of smelting time and composition of palm kernel shell charcoal reductant toward extractive Pomalaa nickel laterite ore in mini electric arc furnace. AIP Conf. Proc. 2018, 1945, 20023. [Google Scholar] [CrossRef]

- Supriyatna, Y.I.; Sihotang, I.H.; Sudibyo. Preliminary Study of Smelting of Indonesian Nickel Laterite Ore using an Electric Arc Furnace. Mater. Today. Proc. 2019, 13, 127–131. [Google Scholar] [CrossRef]

- Norgate, T.; Jahanshahi, S. Assessing the energy and greenhouse gas footprints of nickel laterite processing. Miner. Eng. 2011, 24, 698–707. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Life cycle assessment of ferronickel production in Greece. Resour. Conserv. Recy. 2015, 105, 113–122. [Google Scholar] [CrossRef]

- Norgate, T.; Langberg, D. Environmental and Economic Aspects of Charcoal Use in Steelmaking. ISIJ Int. 2009, 49, 587–595. [Google Scholar] [CrossRef] [Green Version]

- Jochens, P.R.; Howat, D.D. The application of the fluo-solids reactor to the pyrometallurgical beneficiation of South African chromite. J. S. Afr. Inst. Min. Metall. 1964, 65, 236–253. [Google Scholar]

- Guo, D.; Li, Y.; Cui, B.; Chen, Z.; Luo, S.; Xiao, B.; Zhu, H.; Hu, M. Direct reduction of iron ore/biomass composite pellets using simulated biomass-derived syngas: Experimental analysis and kinetic modelling. Chem. Eng. J. 2017, 327, 822–830. [Google Scholar] [CrossRef]

- Khan, D.M.A. Pre-Reduction of Chromite by Thermogravimetric (TG) Analysis. Mater. Sci. Forum 2013, 760, 23–32. [Google Scholar] [CrossRef]

- Khan, D.M.A. Reduction Kinetics of Chromite Pellets. Mater. Sci. Forum 2013, 760, 85–94. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Friedrich, B. Towards Green Ferroalloys: Replacement of Fossil Reductants in the Pre-Reduction Process of Chromite by Bio-Based Alternatives. In Proceedings of the REWAS 2022, Anaheim, CA, USA, 27 February–3 March 2022. [Google Scholar]

- Zandia, M.; Martinez-Pachecob, M.; Fray, T.A.T. Biomass for iron ore sintering. Miner. Eng. 2010, 23, 1139–1145. [Google Scholar] [CrossRef]

- Gan, M.; Fan, X.-H.; Jiang, T.; Chen, X.-L.; Yu, Z.-Y.; Ji, Z.-Y. Fundamental study on iron ore sintering new process of flue gas recirculation together with using biochar as fuel. J. Cent. South Univ. 2014, 21, 4109–4114. [Google Scholar] [CrossRef]

- Kawaguchi, T.; Hara, M. Utilization of Biomass for Iron Ore Sintering. ISIJ Int. 2013, 53, 1599–1606. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Zhang, Y.; Zhao, K.; Xing, H.; Kang, Y. Effect of biomass on reaction performance of sintering fuel. J. Mater. Sci. 2019, 54, 3262–3272. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, J.; Zhou, L.; Liu, Y.; Wang, Q. Characteristics of charcoal combustion and its effects on iron-ore sintering performance. Appl. Energy. 2016, 161, 364–374. [Google Scholar] [CrossRef]

- Fan, X.; Ji, Z.; Gan, M.; Chen, X.; Li, Q.; Jiang, T. Influence of charcoal replacing coke on microstructure and reduction properties of iron ore sinter. Ironmak. Steelmak. 2016, 43, 5–10. [Google Scholar] [CrossRef]

- Gan, M.; Fan, X.; Ji, Z.; Chen, X.; Jiang, T.; Yu, Z. Effect of distribution of biomass fuel in granules on iron ore sintering and NOx emission. Ironmak. Steelmak. 2014, 41, 430–434. [Google Scholar] [CrossRef]

- Murakami, K.; Sugawara, K.; Kawaguchi, T. Analysis of Combustion Rate of Various Carbon Materials for Iron Ore Sintering Process. ISIJ Int. 2013, 53, 1580–1587. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Adam, M.; Kilburn, M.; Hapugoda, S.; Somerville, M.; Jahanshahi, S.; Mathieson, J.G. Substitution of Charcoal for Coke Breeze in Iron Ore Sintering. ISIJ Int. 2013, 53, 1607–1616. [Google Scholar] [CrossRef] [Green Version]

- Gan, M.; Fan, X.; Chen, X.; Ji, Z.; Lv, W.; Wang, Y.; Yu, Z.; Jiang, T. Reduction of Pollutant Emission in Iron Ore Sintering Process by Applying Biomass Fuels. ISIJ Int. 2012, 52, 1574–1578. [Google Scholar] [CrossRef] [Green Version]

- Jha, G.; Soren, S.; Mehta, K.D. Life cycle assessment of sintering process for carbon footprint and cost reduction: A comparative study for coke and biomass-derived sintering process. J. Clean. Prod. 2020, 259, 120889. [Google Scholar] [CrossRef]

- Findorák, R.; Legemza, J.; Fröhlichová, M.; Fabriciová, G.; Džupková, M. New Utilization of Specific Biomass: Lignin in the Iron Ore Sintering Process. Metals 2020, 10, 1170. [Google Scholar] [CrossRef]

- Liu, Z.; Bi, X.; Gao, Z.; Liu, W. Carbothermal Reduction of Iron Ore in Its Concentrate-Agricultural Waste Pellets. Adv. Mater. Sci. Eng. 2018, 2018, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Lopes, G.D.O. Chrome Ore Fines Sintering in Ferbasa. In Proceedings of the Fourth International Ferroalloys Congress, INFACON IV, Rio de Janeiro, Brazil, 31 August–3 September 1986; pp. 147–156. [Google Scholar]

- Sakaranaho, M.; Heikkilä, A.; Suopajärvi, H.; Päätalo, M.; Fabritius, T. Charcoal Use in Chromite Pellets − Effect on Sintering Process, Pellet Properties, and Electrical Conductivity. Steel Res. Int. 2018, 89, 1700260. [Google Scholar] [CrossRef]

- Yape, E.O.; Anacleto, N.M. Direct Smelting of Chromite and Laterite Ores with Carbon under Argon Atmosphere. Adv. Mat. Res. 2013, 849, 170–176. [Google Scholar] [CrossRef]

- Handbook of Extractive Metallurgy; Habashi, F. (Ed.) Wiley-VCH: Weinheim, Germany, 1997; ISBN 3527287922. [Google Scholar]

- Annual Report 2018; Elkem ASA: Oslo, Norway, 2018. Available online: https://www.elkem.com/globalassets/corporate/documents/elkem-annual-report-2018-print-and-tablet2.pdf (accessed on 25 March 2020).

- Annual Report 2019; Elkem ASA: Oslo, Norway, 2019; Available online: https://www.elkem.com/globalassets/corporate/documents/annual-report-2019-web2.pdf (accessed on 25 March 2020).

- Kamfjord, N.E.; Myrhaug, E.H.; Wittgens, B. Energy Balance of a 45 MW (Ferro-) Silicon Submerged Arc Furnace. In Proceedings of the Twelfth International Ferroalloys Congress, INFACON XII, Helsinki, Finland, 6–9 June 2010; pp. 729–738. [Google Scholar]

- Hasannezhad, H.; Meysami, A. Comparison of Biomass and Coal in the Recovery Process of silicon in an Electric Arc Furnace. JOM 2021, 73, 1030–1036. [Google Scholar] [CrossRef]

- Raveendran, K.; Ganesh, A. Heating value of biomass and biomass pyrolysis products. Fuel 1996, 75, 1715–1720. [Google Scholar] [CrossRef]

- CPichler, C.; Antrekowitsch, J. Pyrolysis Gas as a Renewable Reducing Agent for the Recycling of Zinc- and Lead-Bearing Residues: A Status Report. JOM 2017, 69, 999–1006. [Google Scholar] [CrossRef] [Green Version]

- Riva, L.; Nielsen, H.K.; Buø, T.V.; Zhuo, H.; Yang, Q.; Yang, H.; Skreiberg, Ø.; Wang, L.; Bartocci, P.; Barbanera, M.; et al. LCA Analysis of Biocarbon Pellet Production to Substitute Coke. Dteees 2019. [Google Scholar] [CrossRef]

- De Wild-Scholten, M.J.; Gløckner, R.; Odden, J.O.; Halvorsen, G.; Tronstad, R. LCA Comparison of the Elkem Solar Metallurgical Route and Conventional Gas Routes to Solar Silicon. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference, Valencia, Spain, 1–5 September 2008; pp. 1225–1229. [Google Scholar]

- Surup, G.R.; Vehus, T.; Eidem, P.-A.; Trubetskaya, A.; Nielsen, H.K. Characterization of renewable reductants and charcoal-based pellets for the use in ferroalloy industries. Energy 2019, 167, 337–345. [Google Scholar] [CrossRef]

- Surup, G.R.; Nielsen, H.K.; Großarth, M.; Deike, R.; van den Bulcke, J.; Kibleur, P.; Müller, M.; Ziegner, M.; Yazhenskikh, E.; Beloshapkin, S.; et al. Effect of operating conditions and feedstock composition on the properties of manganese oxide or quartz charcoal pellets for the use in ferroalloy industries. Energy 2020, 193, 116736. [Google Scholar] [CrossRef]

- Monsen, B.; Tangstad, M.; Mitgaard, H. Use of Charcoal in Silicomanganese Production. In Proceedings of the Tenth International Ferroalloys Congress, INFACON X, Cape Town, South Africa, 1–4 February 2004; pp. 392–404. [Google Scholar]

- Loutzenhiser, P.G.; Guglielmini, E.; Frei, A.; Steinfeld, A. Vacuum Distillation of Aluminum and Silicon Via Carbothermal Reduction of Their Oxides with Concentrated Solar Energy. In Proceedings of the Energy Technology 2011, Carbon Dioxide and Other Greenhouse Gas Reduction Metallurgy and Waste Heat Recovery, TMS 2011 Annual Meeting & Exhibition, San Diego, CA, USA, 27 Feburary–3 March 2011; pp. 175–181. [Google Scholar]

- Olsen, S.E.; Tangstad, M.; Lindstad, T. Production of Manganese Ferroalloys; Tapir Akademisk Forlag: Trondheim, Norway, 2007; ISBN 9788251921916. [Google Scholar]

- Tangstad, M.; Ichihara, K.; Ringdalen, E. Pretreatment Unit in Ferromanganese Production. In Proceedings of the Fourteenth International Ferroalloys Congress, INFACON XIV, Kiev, Ukraine, 31 May–4 June 2015. [Google Scholar]

- Abdel Halim, K.S.; Bahgat, M.; Morsi, M.B.; El-Barawy, K. Pre-reduction of manganese ores for ferromanganese industry. Ironmak. Steelmak. 2011, 38, 279–284. [Google Scholar] [CrossRef]

- Teguri, D.; Saito, K.; Miyauchi, Y. Manganese ore pre-reduction using a rotary kiln to manufacture super-low-phosphorus ferromanganese. In Proceedings of the Infacon XV: International Ferro-Alloys Congress, R.T. Jones, P. den Hoed, & M.W. Erwee. Infacon XV: International Ferro-Alloys Congress; Cape Town, South Africa, 25–28 February 2018, pp. 183–196.

- Zhang, Y.; Luo, W.; You, Z.; Su, Z.; Li, G.; Jiang, T. Optimizing the Sintering Process of Low-Grade Ferromanganese Ores. In Proceedings of the 4th International Symposium on High-Temperature Metallurgical Processing, San Antonio, TX, USA, 3–7 March 2013; Jiang, T., Ed.; Wiley: Hoboken, NJ, USA, 2013; pp. 527–534. [Google Scholar]

- Zhang, Y.; Zhao, Y.; You, Z.; Duan, D.; Li, G.; Jiang, T. Manganese extraction from high-iron-content manganese oxide ores by selective reduction roasting-acid leaching process using black charcoal as reductant. J. Cent. South Univ. 2015, 22, 2515–2520. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, G.; Yan, H.; Zhao, Y.; Chen, F.; Wang, W. An investigation on stability of biomass reduced manganese dioxide ore. Acta Metall. Sin. Engl. 2012, 25, 435–442. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, G.; Yan, H.; Li, T.; Zhao, Y. The Mechanism on Biomass Reduction of Low-Grade Manganese Dioxide Ore. Metall. Mater. Trans. B 2013, 44, 889–896. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, G.; Yan, H.; Zhao, Y.; Li, T.; Feng, X. Reduction of low-grade manganese dioxide ore pellets by biomass wheat stalk. Acta Metall. Sin. Engl. 2013, 26, 167–172. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, D.; You, Z.; Li, G.; Fan, X.; Jiang, T. Researches on Reduction Roasting of Low-Grade Manganese Oxide Ores Using Biomass Charcoal as Reductant. In Proceedings of the 4th International Symposium on High-Temperature Metallurgical Processing, San Antonio, USA, 3–7 March 2013; Jiang, T., Ed.; Wiley: Hoboken, NJ, USA, 2013; pp. 317–323. [Google Scholar]

- Song, J.; Zhu, G.; Zhao, Y.; Zhang, P. Reduction treatment of low-grade manganese ore by biomass roasting. Acta Metall. Sin. Engl. 2010, 23, 223–229. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhu, G.; Zhao, Y. Study in reduction-roast leaching manganese from low-grade manganese dioxide ores using cornstalk as reductant. Hydrometallurgy 2009, 96, 176–179. [Google Scholar] [CrossRef]

- Li, K.; Chen, G.; Li, X.; Peng, J.; Ruan, R.; Omran, M.; Chen, J. High-temperature dielectric properties and pyrolysis reduction characteristics of different biomass-pyrolusite mixtures in microwave field. Bioresour. Technol. 2019, 294, 122217. [Google Scholar] [CrossRef]

- Li, K.; Chen, J.; Chen, G.; Peng, J.; Ruan, R.; Srinivasakannan, C. Microwave dielectric properties and thermochemical characteristics of the mixtures of walnut shell and manganese ore. Bioresour. Technol. 2019, 286, 121381. [Google Scholar] [CrossRef]

- Long, Y.; Le Ruan; Lv, X.; Lv, Y.; Su, J.; Wen, Y. TG–FTIR analysis of pyrolusite reduction by major biomass components. Chin. J. Chem. Eng. 2015, 23, 1691–1697. [Google Scholar] [CrossRef]

- Long, Y.-F. Overall Reduction Kinetics of Low-grade Pyrolusite Using a Mixture of Hemicellulose and Lignin as Reductant. Kem. Ind. 2015, 64, 593–602. [Google Scholar] [CrossRef] [Green Version]

- Sustainability Report 2016; ERAMET Norway: Porsgrunn, Norway, 2016; Available online: https://issuu.com/erametnorway/docs/eramet_b__rekraftrapp2016_eng-issuu (accessed on 29 July 2020).

- Sustainability Report 2017; ERAMET Norway: Porsgrunn, Norway, 2017. Available online: https://issuu.com/erametnorway/docs/eramet_norway_sustainability_report (accessed on 29 July 2020).

- Sustainability Report 2018; ERAMET Norway: Porsgrunn, Norway, 2018. Available online: https://2kaamo43d6qnc0etemarvpj6t-wpengine.netdna-ssl.com/wp-content/uploads/Eramet-Sustainability-Report-2018-ENG-low.pdf (accessed on 29 July 2020).

- Sustainability Report 2019; ERAMET Norway: Porsgrunn, Norway, 2019. Available online: https://2kaamo43d6qnc0etemarvpj6t-wpengine.netdna-ssl.com/wp-content/uploads/Eramet_b%C3%A6rekraft_2019_EN_oppslag_web.pdf (accessed on 29 July 2020).

- Safarian, J.; Kolbeinsen, L.; Tangstad, M.; Tranell, G. Kinetics and Mechanism of the Simultaneous Carbothermic Reduction of FeO and MnO from High-Carbon Ferromanganese Slag. Metall. Mater. Trans. B 2009, 40, 929–939. [Google Scholar] [CrossRef] [Green Version]

- Safarian, J.; Tangstad, M. Slag-Carbon Reactivity. In Proceedings of the Twelfth International Ferroalloys Congress, INFACON XII, Helsinki, Finland, 6–9 June 2010; pp. 327–338. [Google Scholar]

- Tranell, G.; Gaal, S.; Lu, D.; Tangstad, M.; Safarian, J. Reduction Kinetics of Manganese Oxide from HC FeMn Slags. In Proceedings of the Eleventh International Ferroalloys Congress, INFACON XI, New Delhi, India, 18–21 February 2007; pp. 231–240. [Google Scholar]

- Braga, R.S.; Takano, C.; Mourão, M.B. Prereduction of self-reducing pellets of manganese ore. Ironmak. Steelmak. 2007, 34, 279–284. [Google Scholar] [CrossRef]

- Yeşiltepe, S.; Şeşen, M.K. Production of Composite Pellets from Waste Coffee Grounds, Mill Scale and Waste Primary Battery to Produce Ferromanganese; A Zero Waste Approach. Acta Metall. Slovaca. 2020, 26, 45–48. [Google Scholar] [CrossRef]

- Pistorius, P.C. Ilmenite smelting: The basics. J. S. Afr. Inst. Min. Metall. 2008, 108, 35–43. [Google Scholar]

- Jones, R.T. DC Arc Furnaces—Past, Present, and Future. In Celebrating the Megascale, Proceedings of the Extraction and Processing Division Symposium on Pyrometallurgy in Honor of David, G.C. Robertson; Mackey, P.J., Grimsey, E.J., Jones, R.T., Brooks, G.A., Eds.; Springer: Cham, Switzerland, 2016; pp. 129–139. ISBN 978-3-319-48234-7. [Google Scholar]

- Reva, V.P.; Yagofarov, V.Y.; Filatenkov, A.É.; Gulevskii, D.A.; Kuryavyi, V.G.; Mansurov, Y.N. Carbide Synthesis Resulting from Mechanical Activation of Titanium and Various Carbon Components. Refract. Ind. Ceram. 2017, 58, 169–173. [Google Scholar] [CrossRef]

- Setiawan, A.; Harjanto, S. Effect of sulfur and sodium sulfate on phase transformation and microstructure on carbothermic reduction of Indonesian ilmenite. IOP Conf. Ser. Mater. Sci. Eng. 2020, 833, 12092. [Google Scholar] [CrossRef]

- Guo, S.; Li, W.; Peng, J.; Niu, H.; Huang, M.; Zhang, L.; Zhang, S.; Huang, M. Microwave-absorbing characteristics of mixtures of different carbonaceous reducing agents and oxidized ilmenite. Int. J. Miner. Process. 2009, 93, 289–293. [Google Scholar] [CrossRef]

| Alloy | FeCr [19] | FeMn [19] | SiMn [19] | FeNi [19] | FeSi [19] | Si [20] | Raw Steel [21] |

|---|---|---|---|---|---|---|---|

| Production in million tons | 11.900 | 4.655 | 12.500 | 3.740 | 6.870 | 2.850 | 1551.5 |

| Alloy | FeCr | HC FeMn | SiMn | FeSi65 | Si |

|---|---|---|---|---|---|

| Ton CO2/ton liquid metal [22] | 1.3 | 1.3 | 1.4 | 3.6 | 5.0 |

| Million tons CO2/per year | 15.5 | 6.1 | 17.5 | 24.7 | 14.3 |

| Category | Examples | Reference |

|---|---|---|

| Wood | Sawdust, Chips, Twigs, Needles, Branches, Bark | [32,33,34,35,36,37,38,39,40,41,42,43,44] |

| Vegetative Waste | Olive Pulp, Straw, Shells, Husks, Pith | [32,33,45,46,47,48,49,50,51,52] |

| Charred Waste | Charred-Olive Pulp, Corn Cobs, Vegetative Waste, Fruit Cuttings, Straw | [37,44,52,53,54,55] & own data |

| Shell Charcoal | Charred-Coconut Shells, Palm Kernel Shells | [56,57,58,59,60,61,62,63,64,65,66,67] & own data |

| Wood Charcoal | Charred- Bamboo, Cypress, Lamtoro, Pine, Spruce, Eucalyptus, Mallee | [26,30,35,38,39,40,41,43,44,51,54,57,68,69,70,71,72] & own data |

| Coal | Coal, Anthracite, Newcastle Blend Coal, Bitumite | [3,35,36,37,44,55,56,57,58,59,60,61,68,69,70] |

| Coke | Lignite Coke, Coke, Semi-Coke, Petroleum Coke, Coke Breeze | [3,22,30,35,37,41,43,44,54,55,60,64,68,69,70,73] & own data |

| Reducing Agent | Wood | Vegetative Waste | Coal | Charred Waste | Shell Charcoal | Wood Charcoal | Coke |

|---|---|---|---|---|---|---|---|

| Mean mass of ash in kg per ton fixed carbon | 91.6 | 393.7 | 91.3 | 117.3 | 83.4 | 41.1 | 110.4 |

| Upper quartile in kg | 128.9 | 587.7 | 117.1 | 192.1 | 85.3 | 46.0 | 121.9 |

| Lower quartile in kg | 41.6 | 147.7 | 28.3 | 46.6 | 23.4 | 12.7 | 79.3 |

| Reducing Agent | Wood | Vegetative Waste | Coal | Charred Waste | Shell Charcoal | Wood Charcoal | Coke |

|---|---|---|---|---|---|---|---|

| Mean mass of sulfur in kg per ton fixed carbon | 2.1 | 4.7 | 7.9 | 0.6 | 1.0 | 0.3 | 5.4 |

| Upper quartile in kg | 2.8 | 7.6 | 9.0 | 0.9 | 1.2 | 0.4 | 6.7 |

| Lower quartile in kg | 0.9 | 2.1 | 6.4 | 0.3 | 0.8 | 0.1 | 3.8 |

| Study | Reducing Agent | Furnace and Reduction Temperature | Special Emphasis |

|---|---|---|---|

| [158] | Dry moso bamboo | Tubular Furnace, 500 °C | Investigation of reoxidation during cooling |

| [33] | Rice straw, sawdust, wheat stalk, maize straw, bamboo, lignite | Tubular furnace, 200–900 °C and nonisothermal TGA | Kinetics and XRD-analysis * |

| [159] | Dry bamboo scrap, hemicellulose, cellulose, lignin | Tubular furnace, 200–500 °C | Reaction mechanism, kinetics, XRD-, SEM-, EDS-analysis * |

| [160] | Wheat stalk | Tubular furnace, 300–550 °C | Kinetics, XRD-, SEM-, EDS-analysis * |

| [157] | Black charcoal, anthracite | Muffle furnace, 600–850 °C | Comparison of charcoal and anthracite, XRD-analysis * |

| [161] | Pine charcoal | Muffle furnace, 500–850 °C | XRD-analysis * |

| [162] | Sawdust | Muffle furnace, 350–600 °C | XRD-analysis, leaching parameters * |

| [49] | Straw | Muffle furnace, 200–600 °C | Reaction mechanism, kinetics, XRD-analysis * |

| [163] | Cornstalk | Muffle furnace | Leaching parameters |

| [50] | Walnut shell | Microwave heating reactor, STA * | TG-DTG-DSC of biomass and ore mixtures, XRD- and SEM-analysis, reaction mechanism * |

| [164] | Raw biomass: poplar, pine, ageratina adenophora, rapeseed shell, walnut shell | Dielectric test system, STA, 25–800 °C * | Dielectric properties, reaction mechanism |

| [165] | Walnut shell | Dielectric test system, STA, 25–800 °C * | Dielectric properties, thermochemical characteristics |

| [166] | Hemicellulose, cellulose, lignin | STA, 25–800 °C * | FT-IR analysis, kinetics, XRD-analysis * |

| [167] | Hemicellulose, lignin | STA, 25–800 °C * | Kinetics, XRD-analysis * |

| Unit Operation | Category | Metal Product or Process | ||||

|---|---|---|---|---|---|---|

| FeNi | FeCr | Si&FeSi | FeMn&SiMn | Ilmenite Upgrading | ||

| Pelletizing & Briquetting | Amount | - | + | - | - * | - |

| Scale | o | Laboratory | o | o | o | |

| Sintering | Amount | - | + | - | + | - |

| Scale | o | Industrial | o | Laboratory | o | |

| Pre-Reduction & Solid-State Reduction | Amount | ++ | + | - | ++ | + |

| Scale | Industrial | Laboratory | o | Laboratory | Laboratory | |

| Smelting | Amount | + | + | ++ | + | - |

| Scale | Enhanced Laboratory | Enhanced Laboratory | Industrial | Industrial | o | |

| LCA | Amount | ++ | - | + | - | - |

| Metal Product or Process | ||||

|---|---|---|---|---|

| FeNi | FeCr | Si&FeSi | FeMn&SiMn | Ilmenite Upgrading |

| Segregation | Segregation | Production of suitable bio-based carbon, usage of solar energy | Reduction-roasting | Usage of solar energy, usage of microwaves |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sommerfeld, M.; Friedrich, B. Replacing Fossil Carbon in the Production of Ferroalloys with a Focus on Bio-Based Carbon: A Review. Minerals 2021, 11, 1286. https://doi.org/10.3390/min11111286

Sommerfeld M, Friedrich B. Replacing Fossil Carbon in the Production of Ferroalloys with a Focus on Bio-Based Carbon: A Review. Minerals. 2021; 11(11):1286. https://doi.org/10.3390/min11111286

Chicago/Turabian StyleSommerfeld, Marcus, and Bernd Friedrich. 2021. "Replacing Fossil Carbon in the Production of Ferroalloys with a Focus on Bio-Based Carbon: A Review" Minerals 11, no. 11: 1286. https://doi.org/10.3390/min11111286

APA StyleSommerfeld, M., & Friedrich, B. (2021). Replacing Fossil Carbon in the Production of Ferroalloys with a Focus on Bio-Based Carbon: A Review. Minerals, 11(11), 1286. https://doi.org/10.3390/min11111286