Viscosity and Strength Properties of Cemented Tailings Backfill with Fly Ash and Its Strength Predicted

Abstract

1. Introduction

2. Materials and Methods

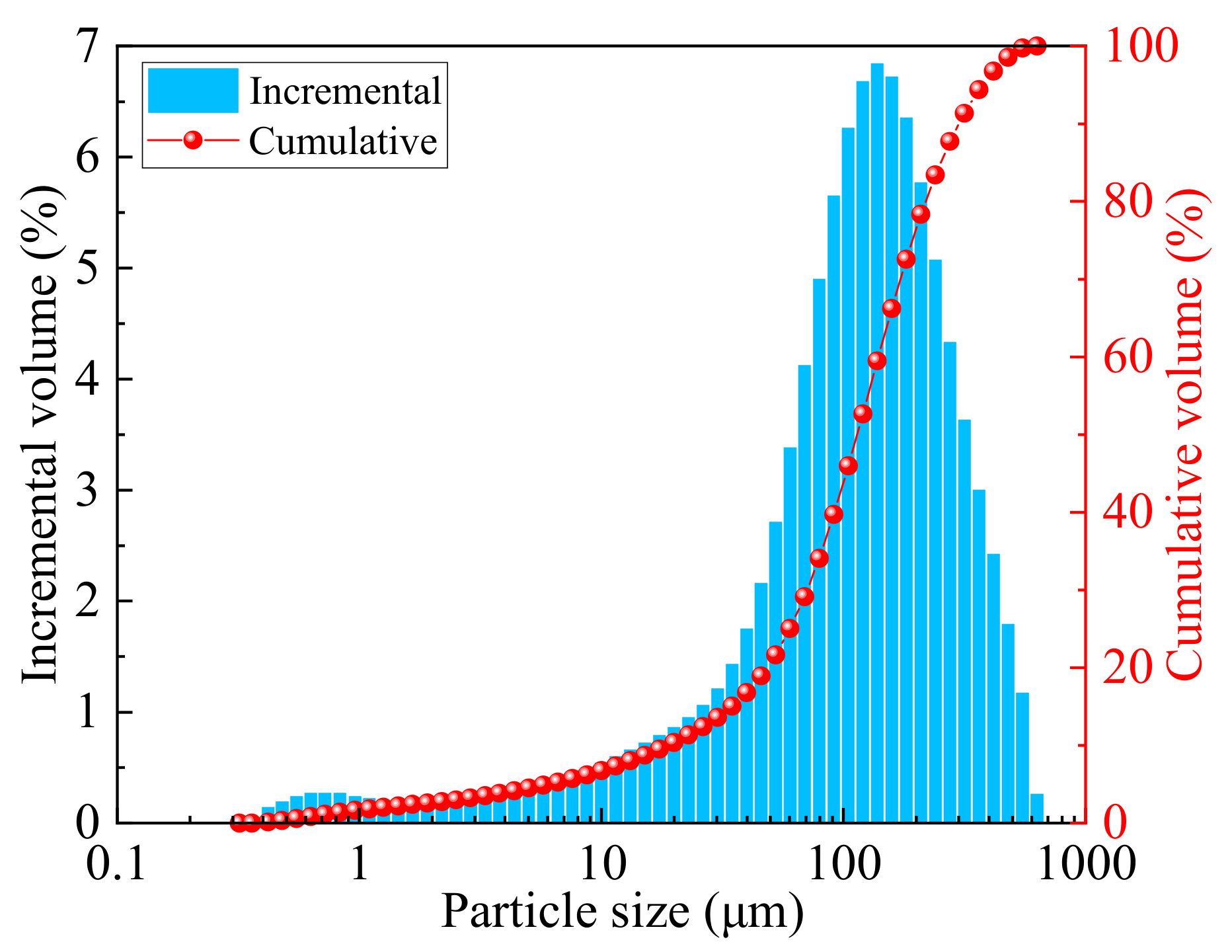

2.1. Experimental Materials and Characteristics

2.2. Experiment Scheme Design

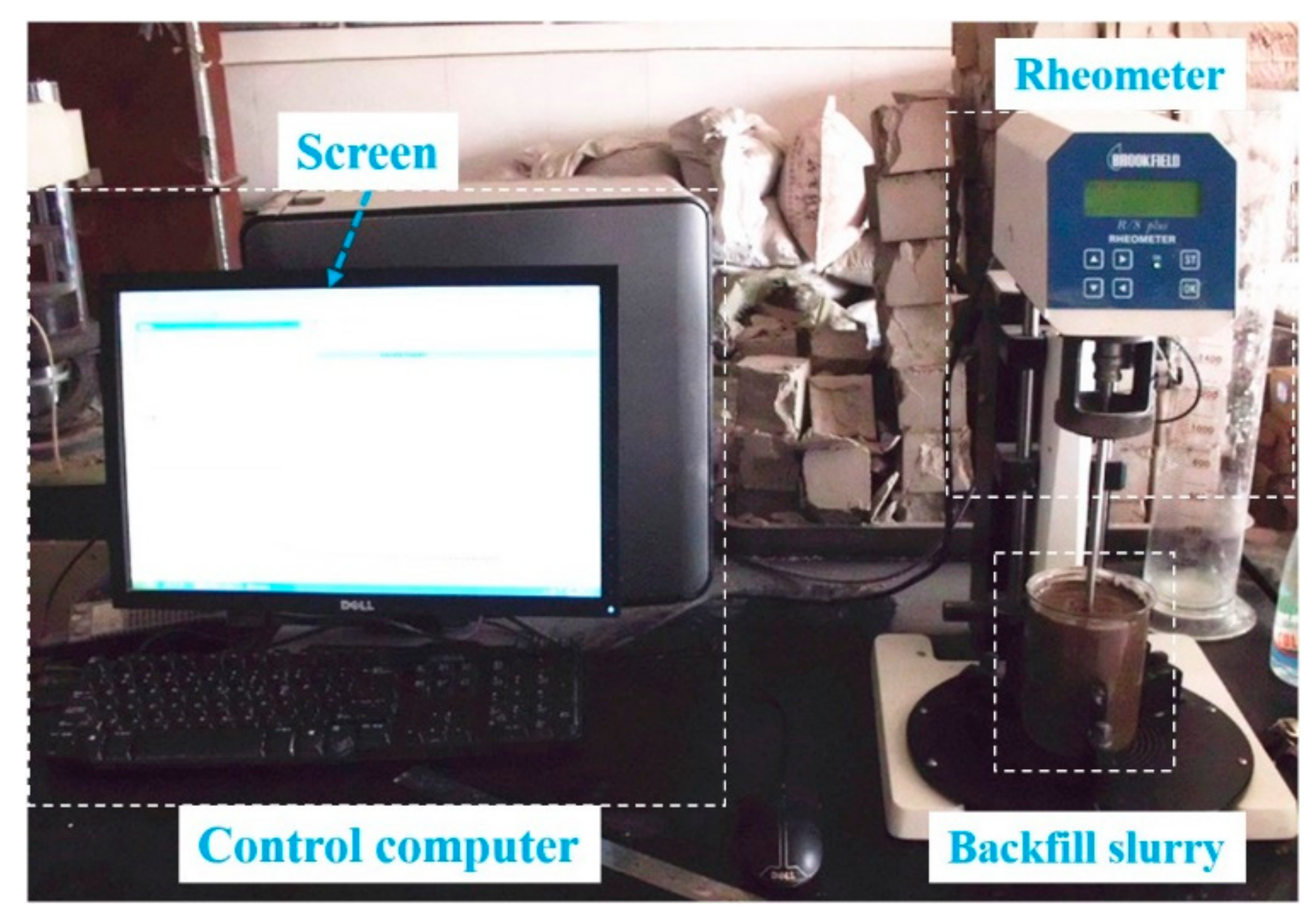

2.3. Viscosity Testing

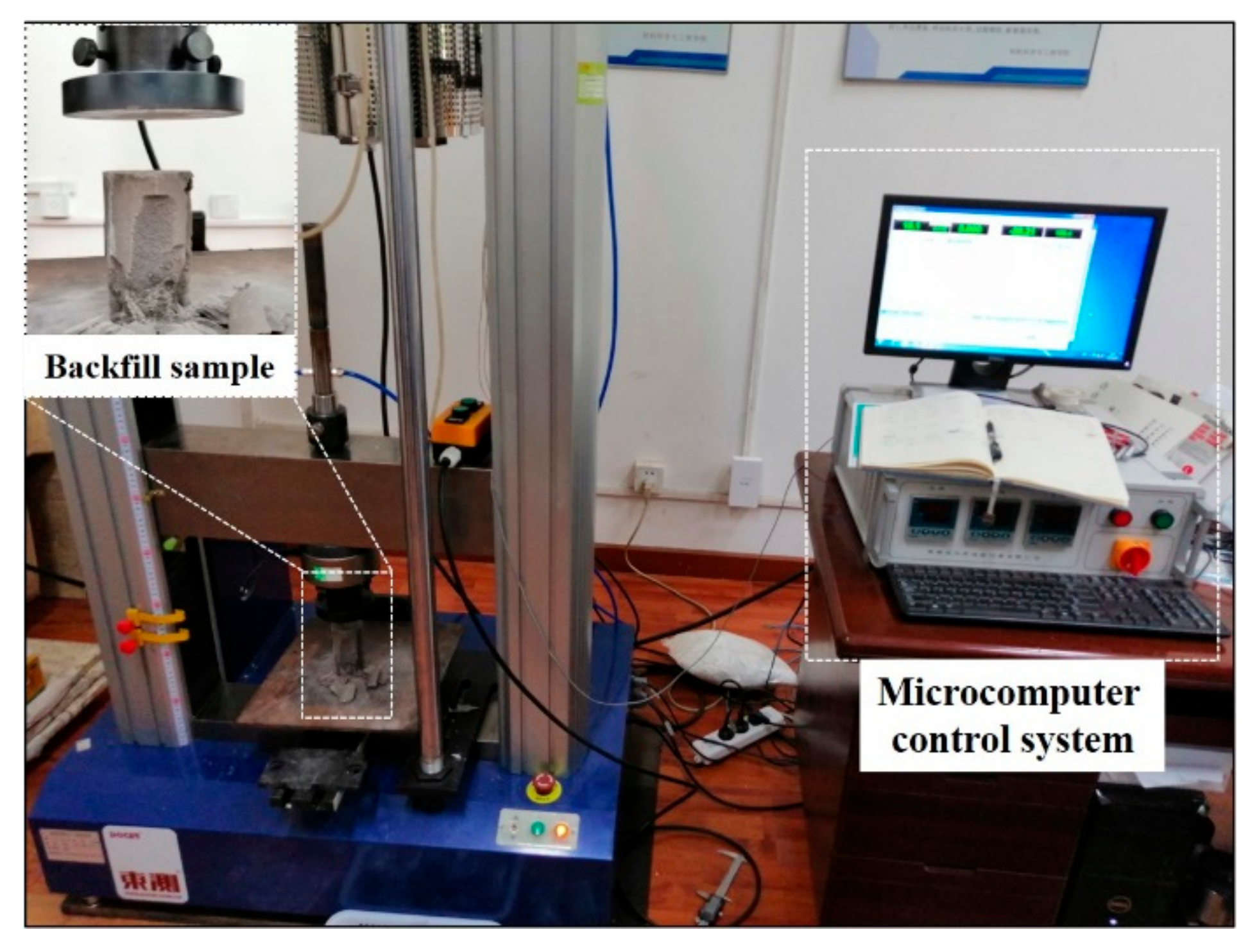

2.4. Uniaxial Compressive Testing

3. Results and Discussion

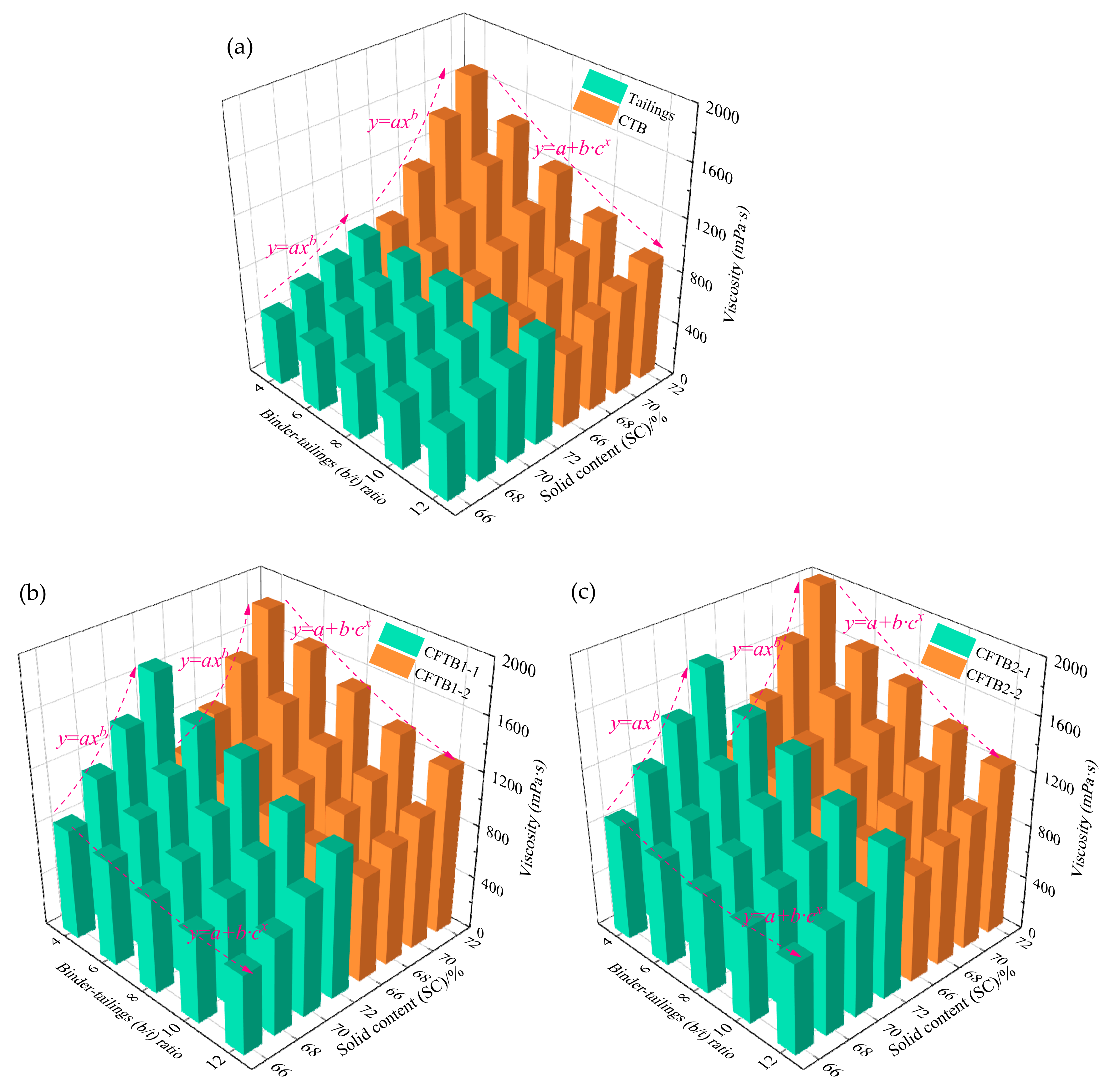

3.1. Viscosity Results of Different Types of Backfill Samples

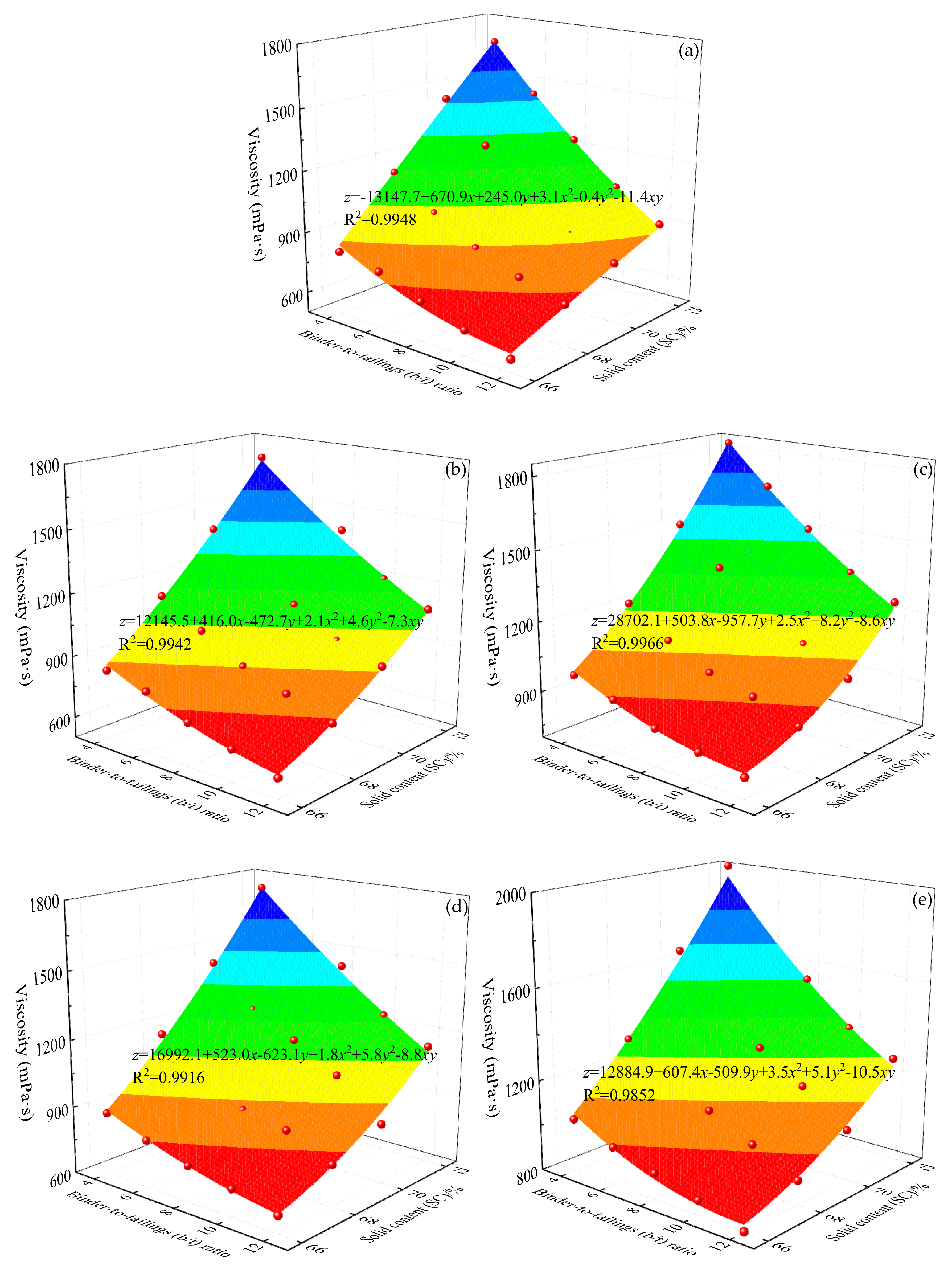

3.1.1. Viscosity Analysis of Different Type Backfill Samples

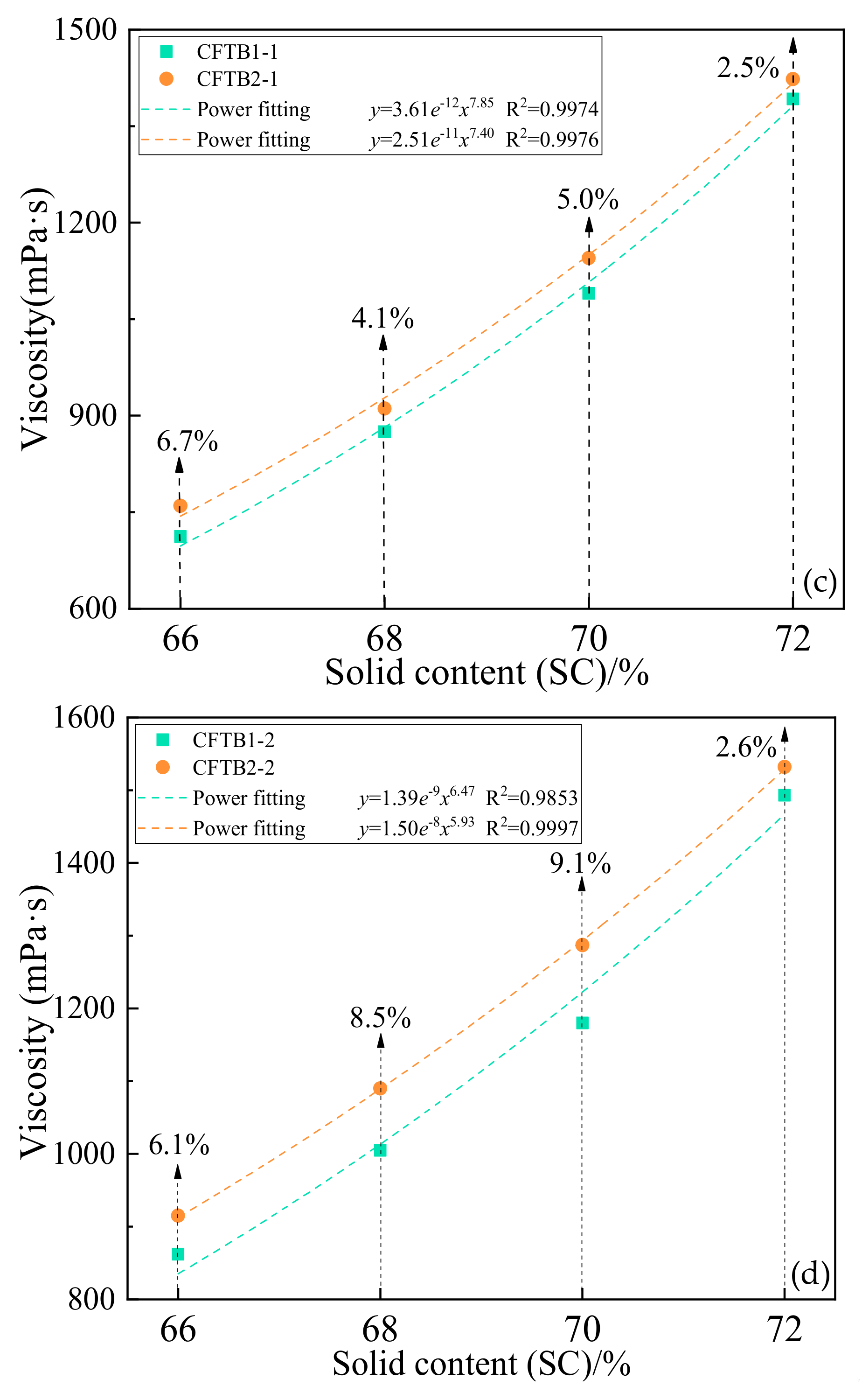

3.1.2. Comparative Analysis of Viscosity of Different Types of Backfill Samples

3.2. UCS Results of Different Types of Backfills Samples

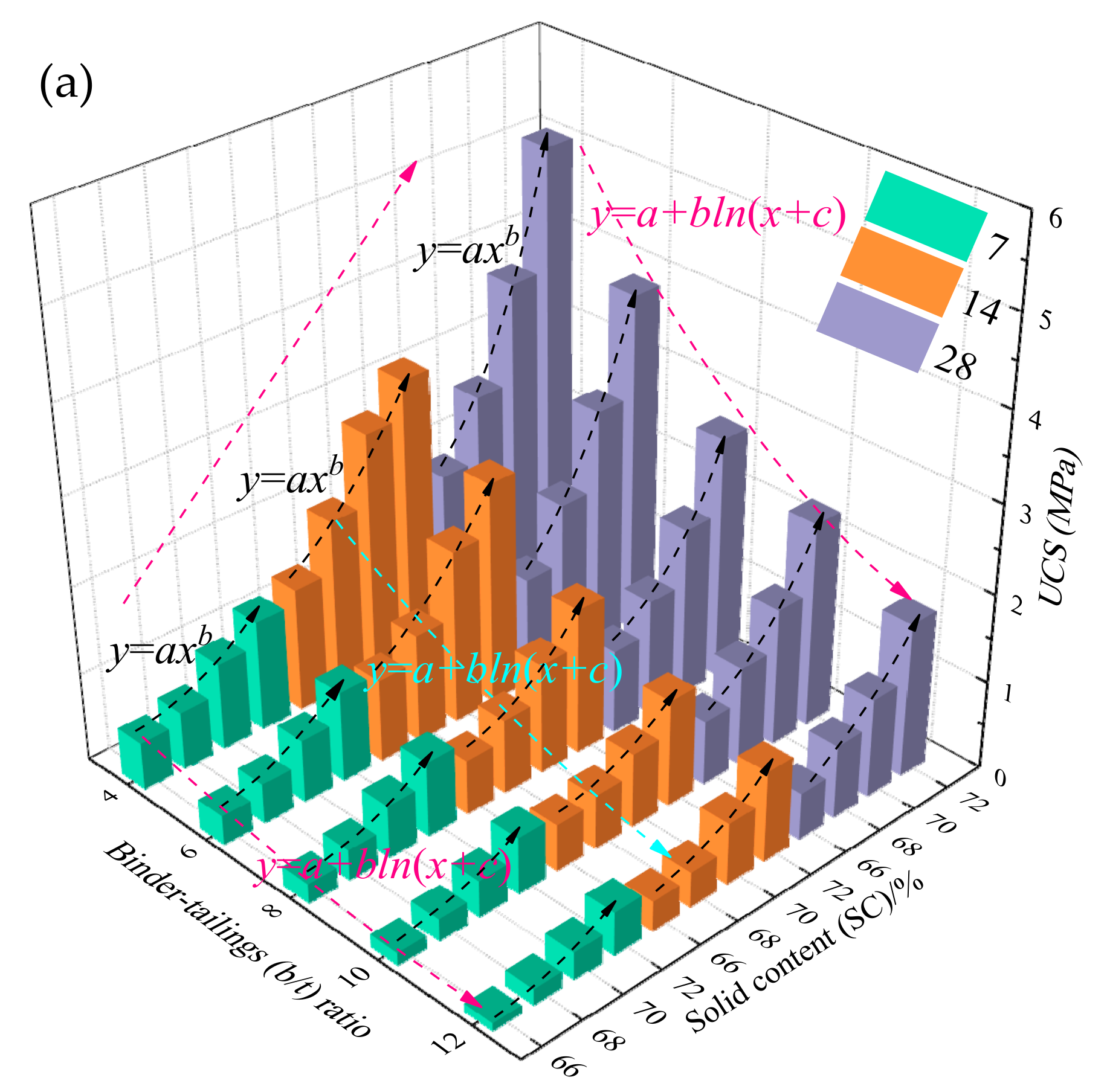

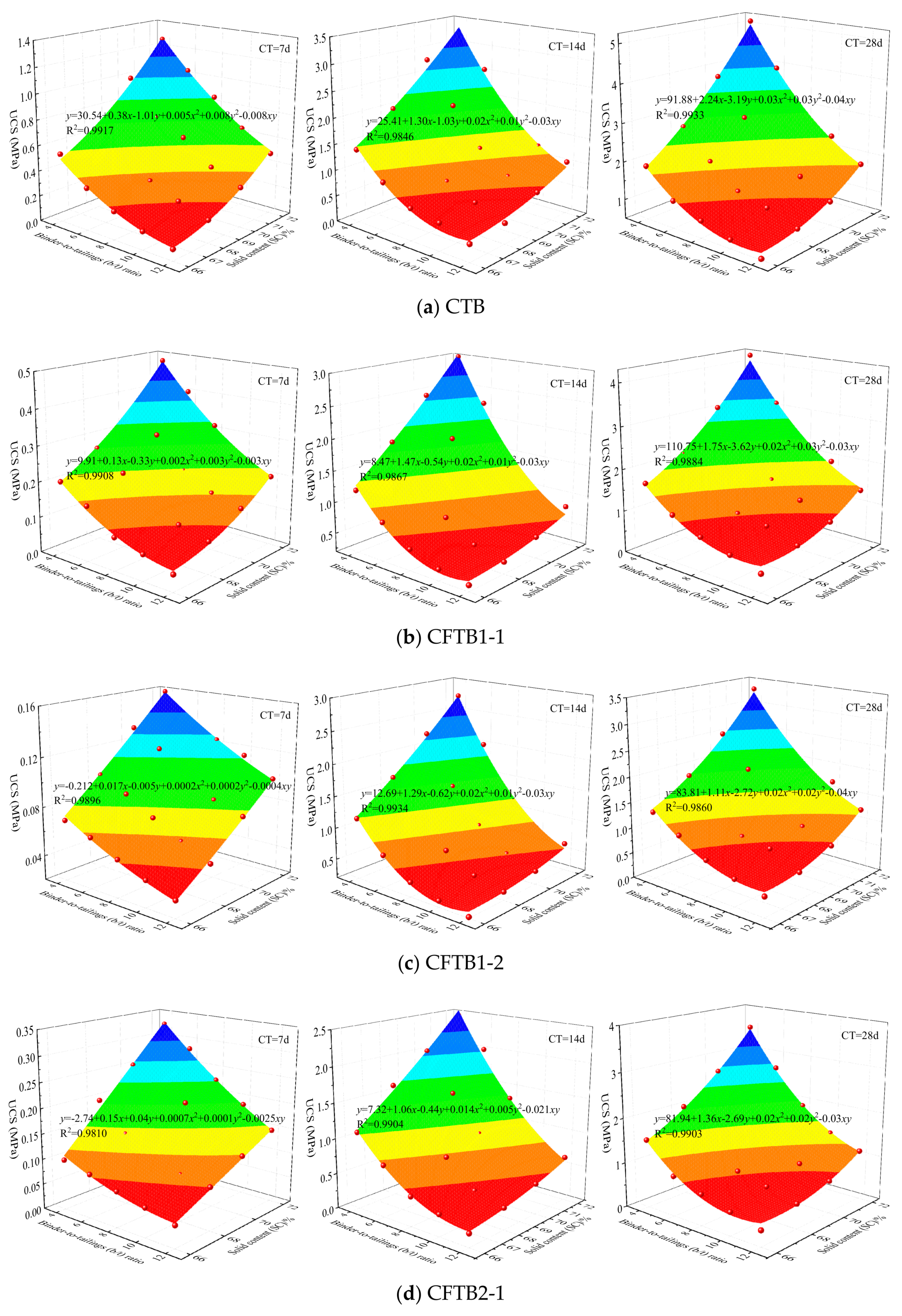

3.2.1. UCS Analysis of Different Type Backfill Samples

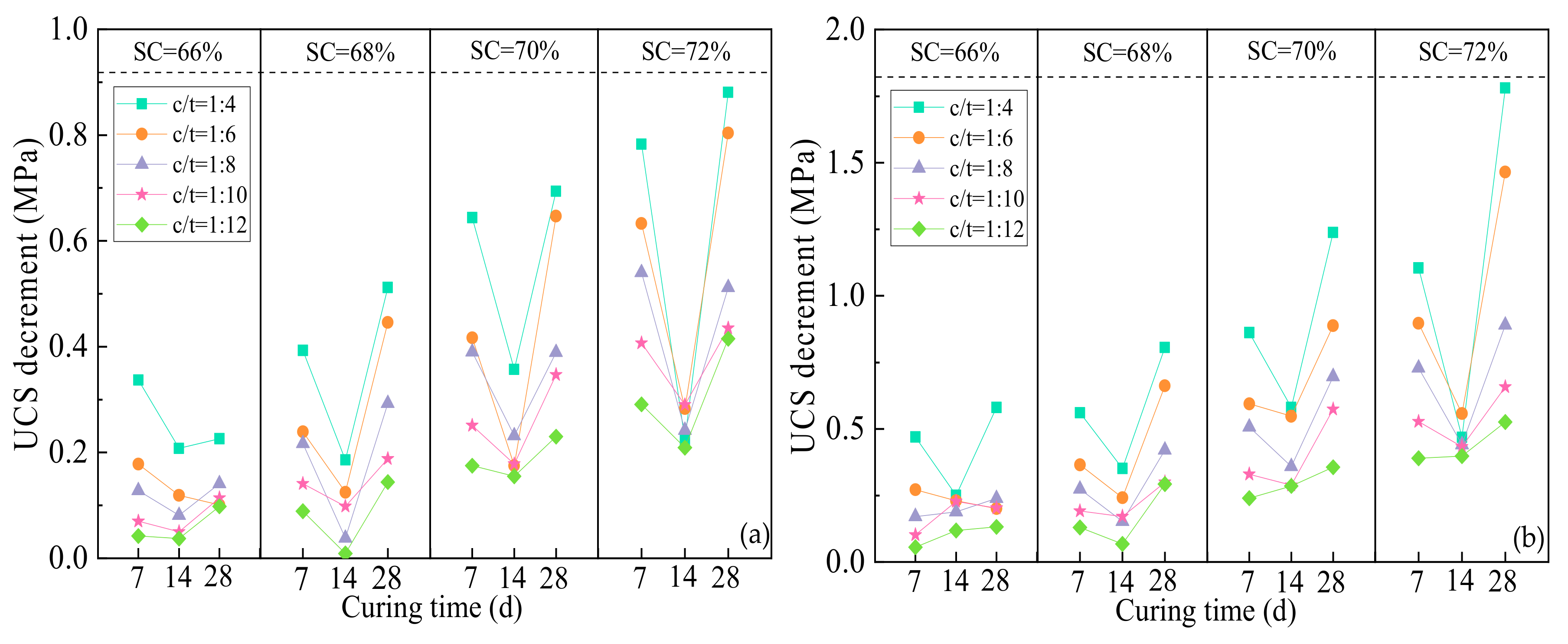

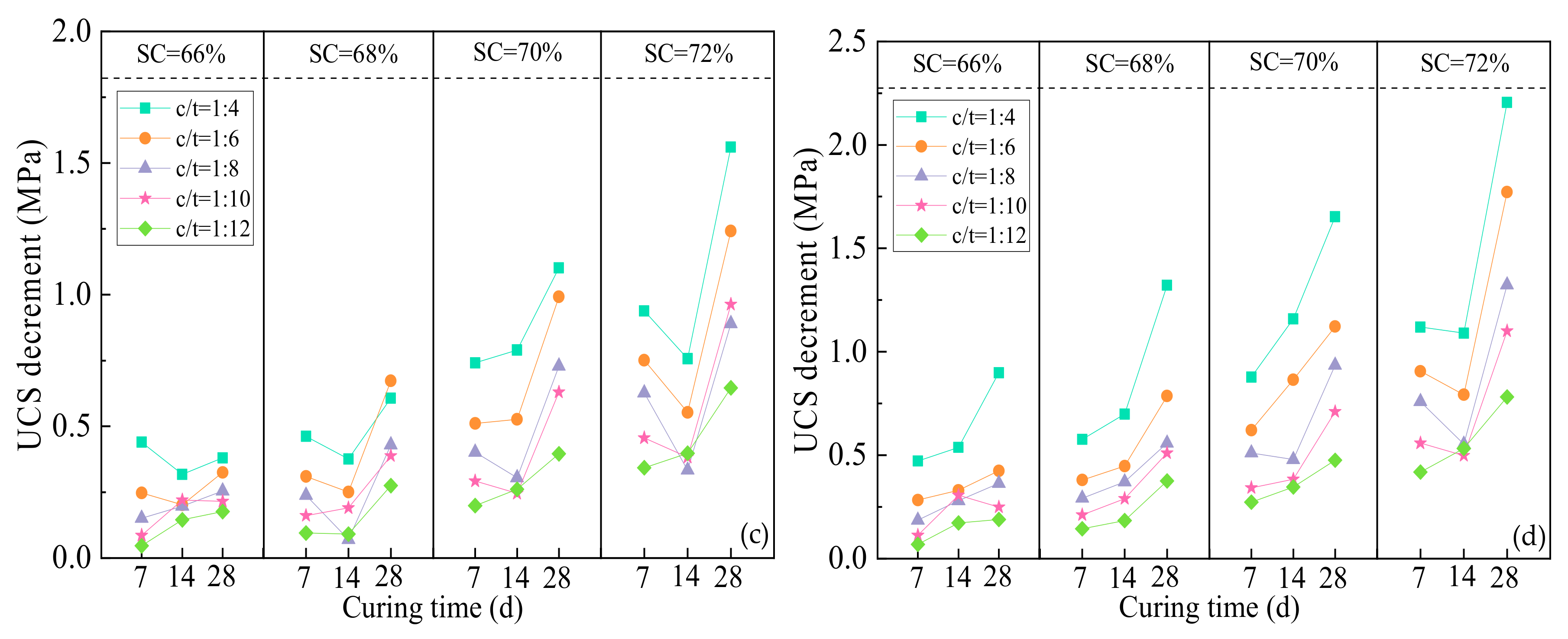

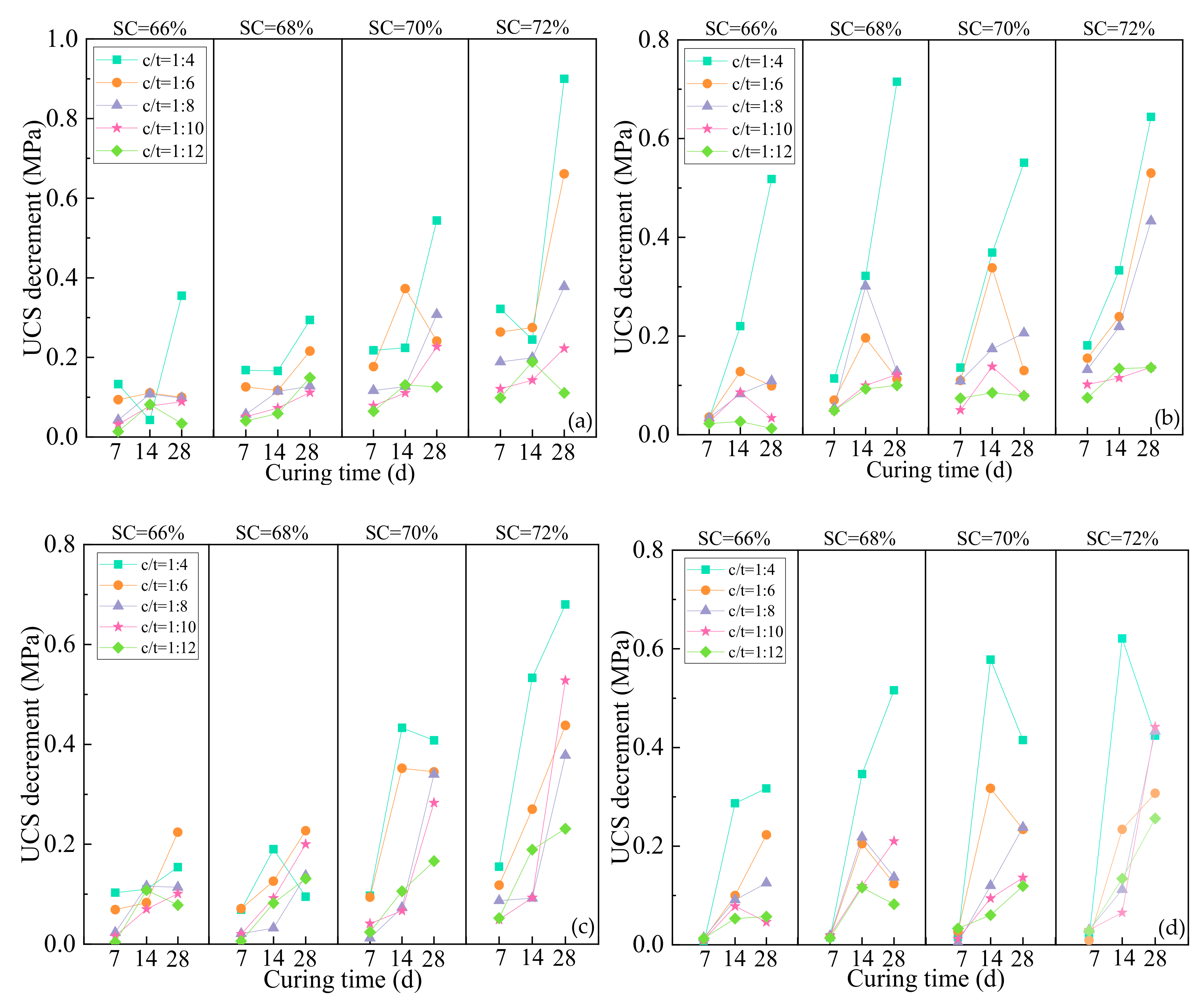

3.2.2. Comparative Analysis of UCS of Different Types of Backfill Samples

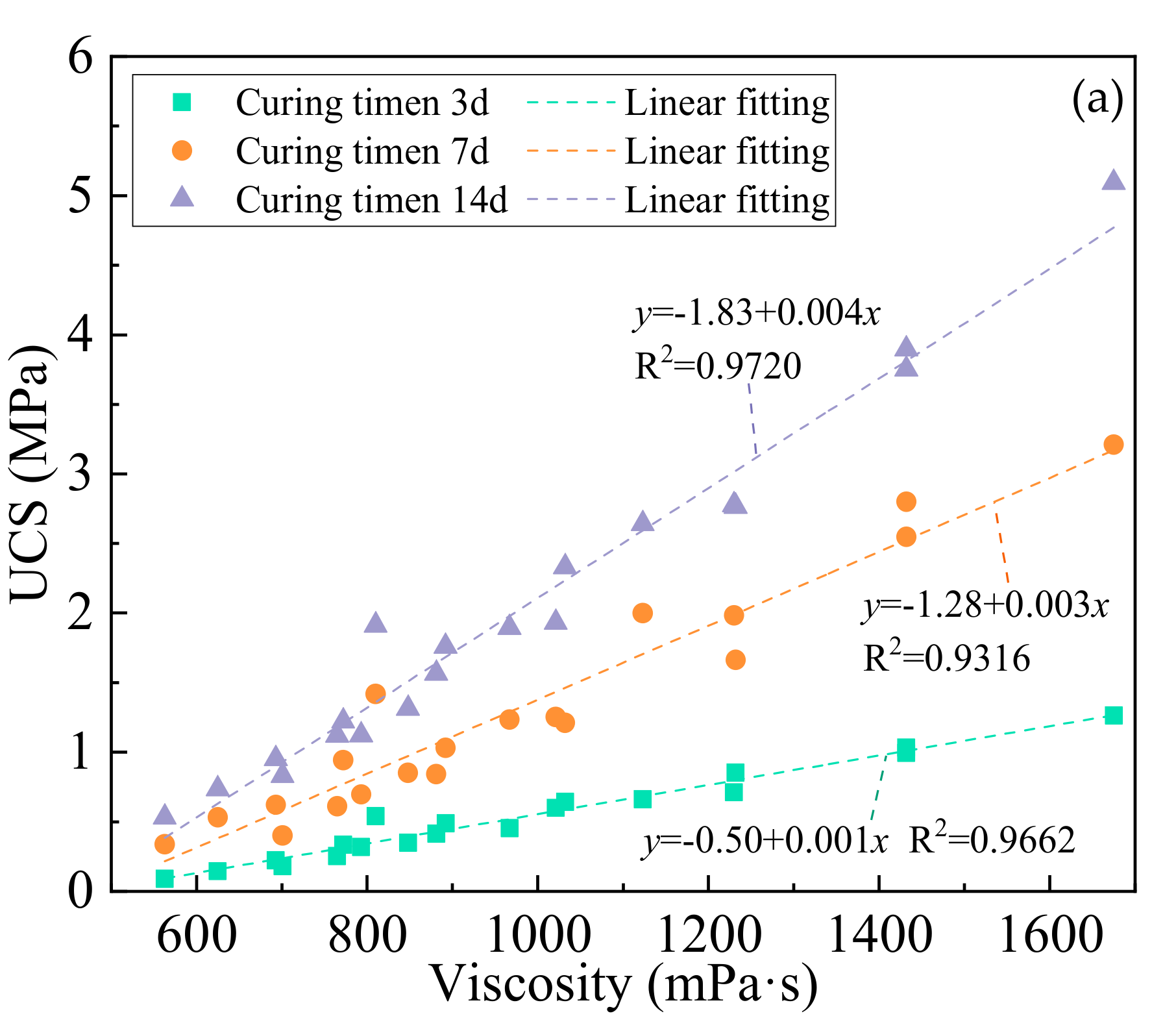

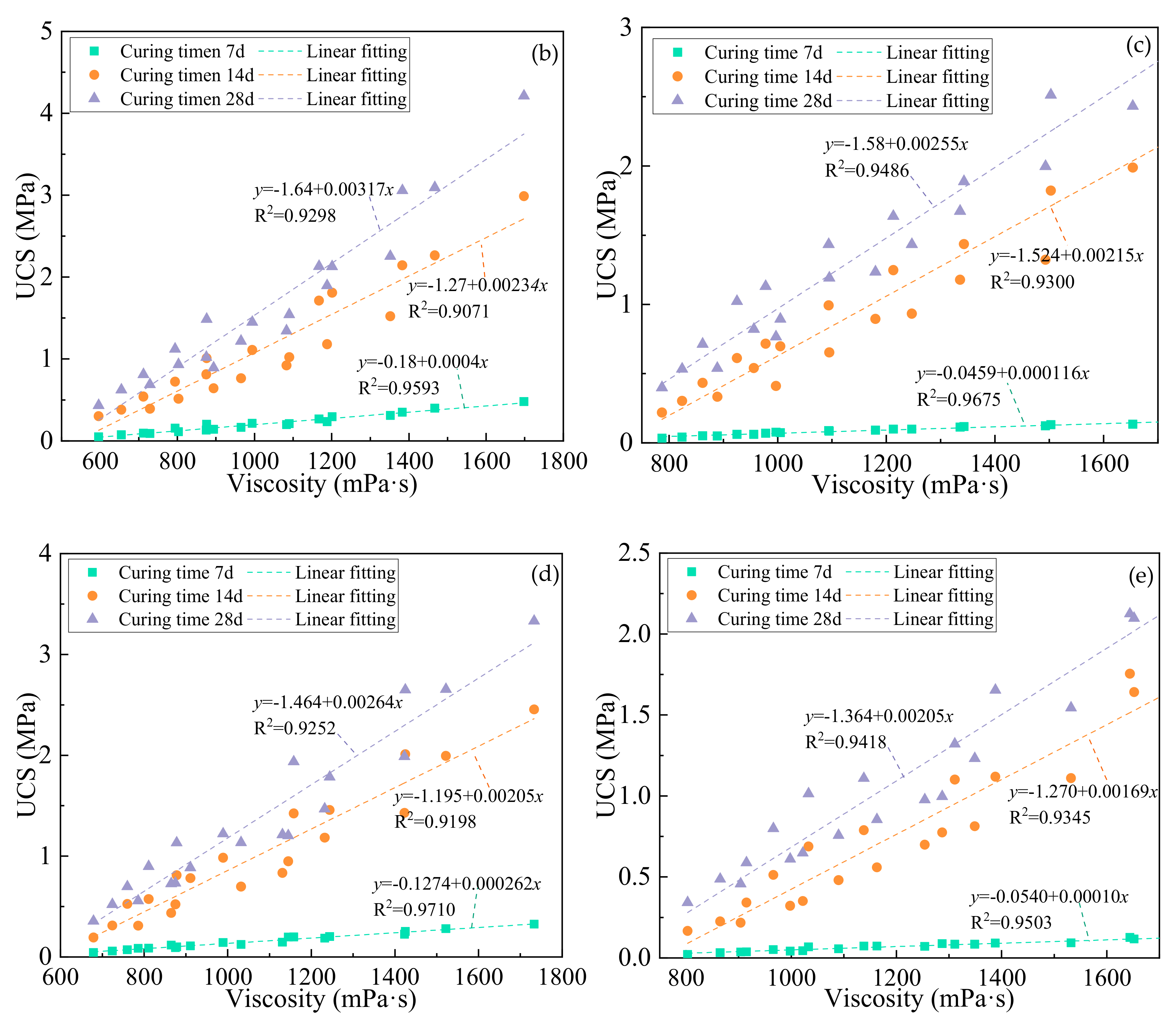

3.3. Relation Between UCS of Backfill and Its Viscosity

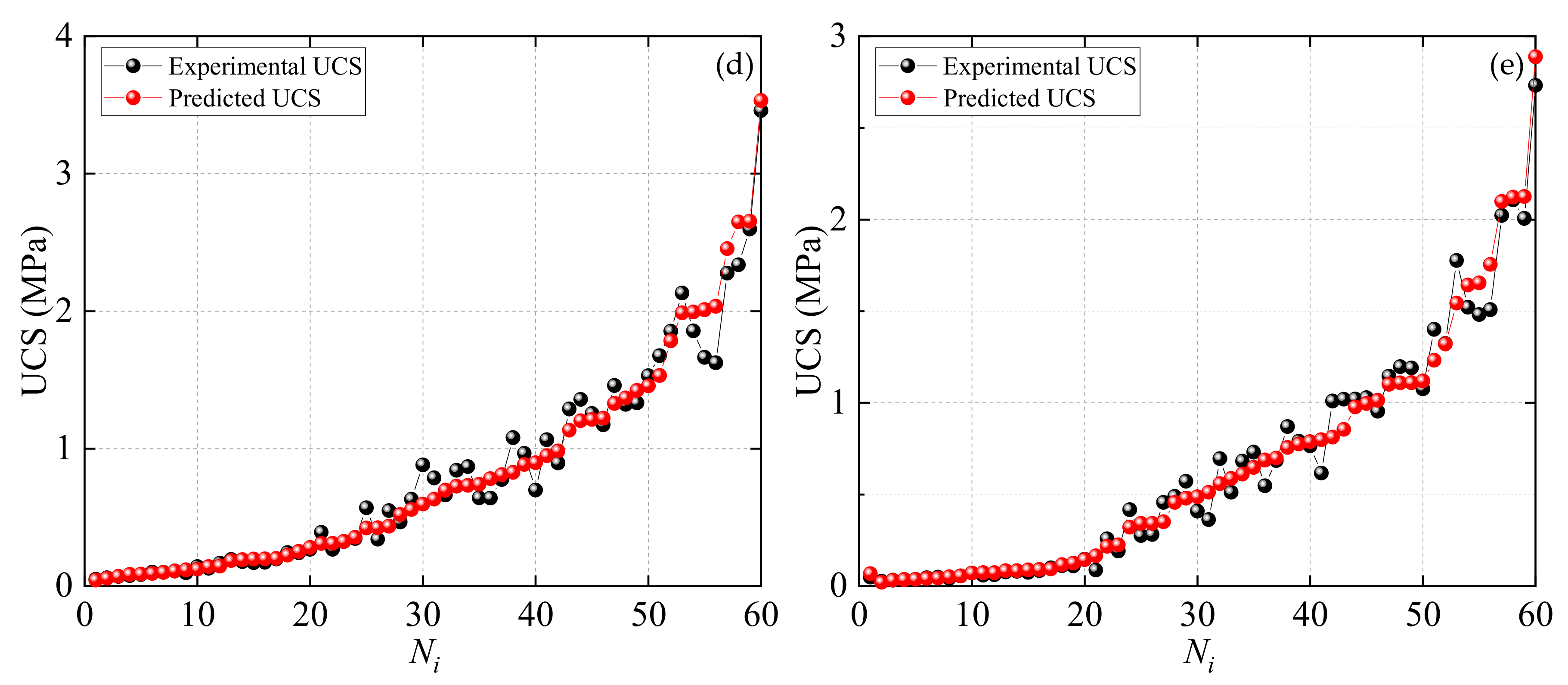

3.4. Prediction of Backfill Strength

4. Conclusions

- (1)

- As SC increases, the viscosity of the backfill slurry increases as a power function. As the b/t ratio decreases, the viscosity of the backfill slurry decreases as an exponential function. The coupling effect of SC and b/t ratio has a great influence on the viscosity of the backfill slurry. The relationship between SC, b/t ratio and viscosity are a quadratic polynomial function of z = a + bx + cy + dx2 + ey2 + fxy.

- (2)

- The viscosity of the backfill slurry mixed with binder is higher than that of a pure tailings slurry. The viscosity of the backfill slurry mixed with FA is higher than that of the backfill slurry without FA. The viscosity of the backfill slurry mixed with FA2 is higher than that of the backfill slurry mixed with FA1. The more FA is added, the higher the viscosity.

- (3)

- With the increase of SC, the UCS of backfill increases as a power function. With the decrease of the b/t ratio, the UCS of all backfill samples decreases as an exponential function. The UCS of all backfill samples increased with an increase of curing time. The coupling effect of the SC and b/t ratio has a great influence on the UCS of backfill samples. The relationship between SC, b/t ratio and viscosity are a quadratic polynomial function of z = a + bx + cy + dx2 + ey2 + fxy.

- (4)

- The UCS of the backfill samples mixed with FA is smaller than that without FA. The higher the FA dosage is, the smaller the UCS of the backfill sample is. At the same FA dosage, the UCS of the backfill sample mixed with FA2 is smaller than that of mixed with FA1.

- (5)

- The UCS of backfill increases with the increase of viscosity, and both of them show a good linear function relationship. The fitting multiple correlation coefficient R2 is higher than 0.9. According to the functional relationship between viscosity and UCS, the viscosity is used to predict the strength of the backfill. The error range of the prediction result is within 15%, and the majority of the error range is within 10%, indicating that it is feasible to use the viscosity parameter to predict the strength parameter of the backfill.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sofrá, F.; Boger, D. Environmental rheology for waste minimisation in the minerals industry. Chem. Eng. J. 2002, 86, 319–330. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and Application of Underground Mine Paste Backfill Technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Fu, J.X.; Song, W.D.; Tan, Y.Y. Study of stability and evolution indexes of gobs under unloading effect in the deep mines. Geomech. Geoeng. 2018, 14, 439–451. [Google Scholar]

- Fu, J.X.; Song, W.D.; Tan, Y.Y. Study on microstructural evolution and strength growth and fracture mechanism of cemented tailings backfill. Adv. Mater. Sci. Eng. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Fourie, A. Preventing catastrophic failures and mitigating environmental impacts of tailings storage facilities. Procedia Earth Planet. Sci. 2009, 1, 1067–1071. [Google Scholar] [CrossRef]

- He, X.; Zheng, C.; Sui, X.; Jing, Q.; Wu, X.; Wang, J.; Si, W.; Zhang, X.-F. Biological damage to Sprague-Dawley rats by excessive anions contaminated groundwater from rare earth metals tailings pond seepage. J. Clean. Prod. 2018, 185, 523–532. [Google Scholar] [CrossRef]

- Fu, J.; Song, W.; Tan, Y. Criterion of local energy release rate of gob instability in deep mines considering unloading stress path. Int. J. Min. Sci. Technol. 2017, 27, 1011–1017. [Google Scholar] [CrossRef]

- Xie, S.-R.; Pan, H.; Chen, D.; Zeng, J.-C.; Song, H.-Z.; Cheng, Q.; Xiao, H.-B.; Yan, Z.-Q.; Li, Y.-H. Stability analysis of integral load-bearing structure of surrounding rock of gob-side entry retention with flexible concrete formwork. Tunn. Undergr. Space Technol. 2020, 103, 103492. [Google Scholar] [CrossRef]

- Tariq, A.; Yanful, E.K. A review of binders used in cemented paste tailings for underground and surface disposal practices. J. Environ. Manag. 2013, 131, 138–149. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q. Neural network and particle swarm optimization for predicting the unconfined compressive strength of cemented paste backfill. Constr. Build. Mater. 2018, 159, 473–478. [Google Scholar] [CrossRef]

- Yilmaz, E. Advances in reducing large volumes of environmentally harmful mine waste rocks and tailings. Miner. Resour. Manag. 2011, 27, 89–112. [Google Scholar]

- Zhang, N.; Yuan, L.; Han, C.; Xue, J.; Kan, J. Stability and deformation of surrounding rock in pillarless gob-side entry retaining. Saf. Sci. 2012, 50, 593–599. [Google Scholar] [CrossRef]

- Ouellet, S.; Bussière, B.; Mbonimpa, M.; Benzaazoua, M.; Aubertin, M. Reactivity and mineralogical evolution of an underground mine sulphidic cemented paste backfill. Miner. Eng. 2006, 19, 407–419. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Bussière, B.; Demers, I.; Aubertin, M.; Fried, É.; Blier, A. Integrated mine tailings management by combining environmental desulphurization and cemented paste backfill: Application to mine Doyon, Quebec, Canada. Miner. Eng. 2008, 21, 330–340. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Sivakugan, N.; Veenstra, R.; Naguleswaran, N. Underground Mine Backfilling in Australia Using Paste Fills and Hydraulic Fills. Int. J. Geosynth. Ground Eng. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented paste backfill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Xue, Z.; Gan, D.; Zhang, Y.; Liu, Z. Rheological behavior of ultrafine-tailings cemented paste backfill in high-temperature mining conditions. Constr. Build. Mater. 2020, 253, 119212. [Google Scholar] [CrossRef]

- He, Y.; Chen, Q.; Qi, C.; Zhang, Q.; Xiao, C. Lithium slag and fly ash-based binder for cemented fine tailings backfill. J. Environ. Manag. 2019, 248, 109282. [Google Scholar] [CrossRef]

- Huang, L.; Yan, P.; Liu, Y. Effect of alkali content in cement on the fluidity and structural build-up of plasticized cement pastes. Constr. Build. Mater. 2020, 253, 119180. [Google Scholar] [CrossRef]

- Rößler, C.; Eberhardt, B.A.; Kučerova, H.; Moser, B. Influence of hydration on the fluidity of normal Portland cement pastes. Cem. Concr. Res. 2008, 38, 897–906. [Google Scholar] [CrossRef]

- Uchikawa, H.; Hanehara, S.; Shirasaka, T.; Sawaki, D. Effect of admixture on hydration of cement, adsorptive behavior of admixture and fluidity and setting of fresh cement paste. Cem. Concr. Res. 1992, 22, 1115–1129. [Google Scholar] [CrossRef]

- Liu, L.; Xin, J.; Qi, C.; Jia, H.; Song, K.-I. Experimental investigation of mechanical, hydration, microstructure and electrical properties of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120137. [Google Scholar] [CrossRef]

- Panchal, S.; Deb, D.; Sreenivas, T. Variability in rheology of cemented paste backfill with hydration age, binder and superplasticizer dosages. Adv. Powder Technol. 2018, 29, 2211–2220. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Effects of curing temperature on shear behavior of cemented paste backfill-rock interface. Int. J. Rock Mech. Min. Sci. 2018, 112, 184–192. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W. Evaluation of Viscosity, Strength and Microstructural Properties of Cemented Tailings Backfill. Minerals 2018, 8, 352. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Qi, C.; Zhang, B.; Guo, L.; Song, K.-I. Numerical study on the pipe flow characteristics of the cemented paste backfill slurry considering hydration effects. Powder Technol. 2019, 343, 454–464. [Google Scholar] [CrossRef]

- Zhou, X.; Hu, S.; Zhang, G.; Li, J.; Xuan, D.; Gao, W. Experimental investigation and mathematical strength model study on the mechanical properties of cemented paste backfill. Constr. Build. Mater. 2019, 226, 524–533. [Google Scholar] [CrossRef]

- Ercikdi, B.; Yılmaz, T.; Külekci, G. Strength and ultrasonic properties of cemented paste backfill. Ultrasonics 2014, 54, 195–204. [Google Scholar] [CrossRef]

- Zhao, K.; Yu, X.; Zhu, S.; Yan, Y.; Zhou, Y.; He, Z.; Song, Y.; Huang, M. Acoustic emission fractal characteristics and mechanical damage mechanism of cemented paste backfill prepared with tantalum niobium mine tailings. Constr. Build. Mater. 2020, 258, 119720. [Google Scholar] [CrossRef]

- Lu, H.; Qi, C.; Chen, Q.; Gan, D.; Xue, Z.; Hu, Y. A new procedure for recycling waste tailings as cemented paste backfill to underground stopes and open pits. J. Clean. Prod. 2018, 188, 601–612. [Google Scholar] [CrossRef]

- Dong, Q.; Liang, B.; Jia, L.; Jiang, L. Effect of sulfide on the long-term strength of lead-zinc tailings cemented paste backfill. Constr. Build. Mater. 2019, 200, 436–446. [Google Scholar] [CrossRef]

- Zheng, J.R.; Sun, X.X.; Guo, L.J.; Zhang, S.M.; Chen, J.Y. Strength and hydration products of cemented paste backfill from sulphide-rich tailings using reactive MgO-activated slag as a binder. Constr. Build. Mater. 2019, 203, 111–119. [Google Scholar] [CrossRef]

- Bull, A.J.; Fall, M. Curing temperature dependency of the release of arsenic from cemented paste backfill made with Portland cement. J. Environ. Manag. 2020, 269, 110772. [Google Scholar] [CrossRef]

- Libos, I.L.S.; Cui, L. Effects of curing time, cement content, and saturation state on mode-I fracture toughness of cemented paste backfill. Eng. Fract. Mech. 2020, 235, 107174. [Google Scholar] [CrossRef]

- Cui, L.; Fall, M. Mechanical and thermal properties of cemented tailings materials at early ages: Influence of initial temperature, curing stress and drainage conditions. Constr. Build. Mater. 2016, 125, 553–563. [Google Scholar] [CrossRef]

- Yilmaz, E.; Benzaazoua, M.; Belem, T.; Bussière, B. Effect of curing under pressure on compressive strength development of cemented paste backfill. Miner. Eng. 2009, 22, 772–785. [Google Scholar] [CrossRef]

- Yingliang, Z.; Jingping, Q.; Xing, J.; Sun, X. Recycling of quarry dust for supplementary cementitious materials in low carbon cement. Constr. Build. Mater. 2020, 237, 117608. [Google Scholar] [CrossRef]

- Saedi, A.; Jamshidi-Zanjani, A.; Darban, A.K. A review on different methods of activating tailings to improve their cementitious property as cemented paste and reusability. J. Environ. Manag. 2020, 270, 110881. [Google Scholar] [CrossRef]

- Peyronnard, O.; Benzaazoua, M. Estimation of the cementitious properties of various industrial by-products for applications requiring low mechanical strength. Resour. Conserv. Recycl. 2011, 56, 22–33. [Google Scholar] [CrossRef]

- Yan, B.; Ren, F.; Cai, M.; Qiao, C. Influence of new hydrophobic agent on the mechanical properties of modified cemented paste backfill. J. Mater. Res. Technol. 2019, 8, 5716–5727. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Li, E.; Du, X. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced cemented paste backfill. Constr. Build. Mater. 2018, 190, 211–221. [Google Scholar] [CrossRef]

- Yi, X.; Ma, G.; Fourie, A. Centrifuge model studies on the stability of fibre-reinforced cemented paste backfill stopes. Geotext. Geomembr. 2018, 46, 396–401. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.; Wang, K.; Wu, H.; Cui, B. Effects of accelerator–water reducer admixture on performance of cemented paste backfill. Constr. Build. Mater. 2020, 242, 118187. [Google Scholar] [CrossRef]

- Marquez, M.; Robben, A.; Grady, B.P.; Robb, I. Viscosity and yield stress reduction in non-colloidal concentrated suspensions by surface modification with polymers and surfactants and/or nanoparticle addition. J. Colloid Interface Sci. 2006, 295, 374–387. [Google Scholar] [CrossRef]

- Li, W.; Fall, M. Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr. Build. Mater. 2016, 106, 296–304. [Google Scholar] [CrossRef]

- Yin, S.; Shao, Y.; Wu, A.; Wang, Z.; Yang, L. Assessment of expansion and strength properties of sulfidic cemented paste backfill cored from deep underground stopes. Constr. Build. Mater. 2020, 230, 116983. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B.; Alp, I.; Deveci, H. Effect of properties of tailings and binder on the short-and long-term strength and stability of cemented paste backfill. Mater. Lett. 2005, 59, 3703–3709. [Google Scholar] [CrossRef]

- Yılmaz, T.; Ercikdi, B.; Karaman, K.; Külekçi, G. Assessment of strength properties of cemented paste backfill by ultrasonic pulse velocity test. Ultrasonics 2014, 54, 1386–1394. [Google Scholar] [CrossRef]

- Hassani, F.P.; Razavi, S.M.; Isagon, I. A study of physical and mechanical behaviour of gel fill. Cim. Bull. 2007, 100, 1–7. [Google Scholar]

- Zhao, Y.; Taheri, A.; Karakus, M.; Chen, Z.; Deng, A. Effects of water content, water type and temperature on the rheological behaviour of slag-cement and fly ash-cement paste backfill. Int. J. Min. Sci. Technol. 2020, 30, 271–278. [Google Scholar] [CrossRef]

- Du, X.; Feng, G.; Zhang, Y.; Wang, Z.; Guo, Y.; Qi, T. Bearing mechanism and stability monitoring of cemented gangue-fly ash backfill column with stirrups in partial backfill engineering. Eng. Struct. 2019, 188, 603–612. [Google Scholar] [CrossRef]

- Behera, S.K.; Ghosh, C.; Mishra, D.; Singh, P.; Mishra, K.; Buragohain, J.; Mandal, P.K. Strength development and microstructural investigation of lead-zinc mill tailings based paste backfill with fly ash as alternative binder. Cem. Concr. Compos. 2020, 109, 103553. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Belem, T.; Bussière, B. Chemical factors that influence the performance of mine sulphidic paste backfill. Cem. Concr. Res. 2002, 32, 1133–1144. [Google Scholar] [CrossRef]

- Zhao, Y.; Soltani, A.; Taheri, A.; Karakus, M.; Deng, A. Application of Slag–Cement and Fly Ash for Strength Development in Cemented Paste Backfills. Minerals 2018, 9, 22. [Google Scholar] [CrossRef]

- Zhao, Y.; Taheri, A.; Soltani, A.; Karakus, M.; Deng, A. Strength development and strain localization behaviour of cemented paste backfills using portland cement and fly ash. Materials 2019, 3282, 2019. [Google Scholar]

| Materials | Density (g/cm3) | Bulk Density (g/cm3) | Porosity (%) |

|---|---|---|---|

| Tailings | 2.67 | 1.65 | 38.20 |

| FA1 | 2.59 | 0.88 | 66.02 |

| FA2 | 3.09 | 1.47 | 52.43 |

| Composition | Tailings | FA1 | FA2 |

|---|---|---|---|

| K | 0.02% | 0.10% | 0.97% |

| Na | 0.09% | 0.11% | 0.33% |

| Si | 1.55% | 16.19% | 16.35% |

| Al | / | 13.20% | 2.40% |

| Ca | 24.99% | 1.40% | 35.20% |

| Fe | 0.19% | 15.70% | 0.20% |

| Mg | 10.30% | 0.50% | 1.10% |

| Pb | 0.05% | <0.05% | 0.06% |

| Mn | 0.04% | <0.05% | 0.05% |

| S | <0.05% | / | / |

| Sample Type | Binder | OPC: FA | Aggregate |

|---|---|---|---|

| CTB | OPC | / | Tailings |

| CFTB1-1 | OPC + FA1 | 0.8:0.2 | |

| CFTB1-2 | 0.5:0.5 | ||

| CFTB2-1 | OPC + FA2 | 0.8:0.2 | |

| CFTB2-2 | 0.5:0.5 |

| Binder-Tailings Ratio (b/t) | Solid Content (SC)/% | Sample Type | |||||

|---|---|---|---|---|---|---|---|

| CTB | CFTB1-1 | CFTB1-2 | CFTB2-1 | CFTB2-2 | Tailings | ||

| 1:4 | 66 | 810 | 836 | 978 | 878 | 1033 | 512 |

| 1:6 | 772 | 794 | 925 | 811 | 966 | ||

| 1:8 | 693 | 712 | 862 | 760 | 915 | ||

| 1:10 | 625 | 655 | 824 | 724 | 865 | ||

| 1:12 | 563 | 596 | 787 | 679 | 803 | ||

| 1:4 | 68 | 1123 | 1117 | 1213 | 1158 | 1311 | 629 |

| 1:6 | 967 | 994 | 1094 | 989 | 1138 | ||

| 1:8 | 848 | 875 | 1005 | 911 | 1090 | ||

| 1:10 | 765 | 803 | 956 | 875 | 998 | ||

| 1:12 | 701 | 729 | 889 | 786 | 904 | ||

| 1:4 | 70 | 1432 | 1383 | 1503 | 1425 | 1652 | 715 |

| 1:6 | 1230 | 1201 | 1343 | 1244 | 1388 | ||

| 1:8 | 1021 | 1090 | 1180 | 1145 | 1287 | ||

| 1:10 | 881 | 965 | 1095 | 1032 | 1163 | ||

| 1:12 | 793 | 894 | 997 | 865 | 1022 | ||

| 1:4 | 72 | 1675 | 1698 | 1825 | 1733 | 1998 | 805 |

| 1:6 | 1432 | 1467 | 1654 | 1522 | 1644 | ||

| 1:8 | 1232 | 1392 | 1493 | 1423 | 1532 | ||

| 1:10 | 1032 | 1188 | 1336 | 1232 | 1349 | ||

| 1:12 | 892 | 1083 | 1247 | 1131 | 1254 | ||

| Sample Type | Fitting Relationship | R2 |

|---|---|---|

| CTB | V = 13147.7 + 670.9x + 245.0y + 3.1x2− 0.4y2 − 11.4xy | 0.9948 |

| CFTB1-1 | V = 12145.5 + 416.0x − 472.7y + 2.1x2 + 4.6y2 − 7.3xy | 0.9942 |

| CFTB1-2 | V = 28702.1 + 503.8x − 957.7y + 2.5x2 + 8.2y2 − 8.6xy | 0.9966 |

| CFTB2-1 | V = 16992.1 + 523.0x − 623.1y + 1.8x2 + 5.8y2 − 8.8xy | 0.9916 |

| CFTB2-2 | V = 12884.9 + 607.4x − 509.9y + 3.5x2 + 5.1y2 − 10.5xy | 0.9852 |

| Sample Type | CT (d) | Fitting Relationship | R2 |

|---|---|---|---|

| CTB | 7 | UCS = 30.54 + 0.38x − 1.01y + 0.005x2 + 0.008y2 − 0.008xy | 0.9917 |

| 14 | UCS = 25.41 + 1.30x − 1.03y + 0.02x2 + 0.01y2 − 0.03xy | 0.9846 | |

| 28 | UCS = 91.88 + 2.24x − 3.19y + 0.03x2 + 0.03y2 − 0.04xy | 0.9933 | |

| CFTB1-1 | 7 | UCS = 9.91 + 0.13x − 0.33y + 0.002x2 + 0.003y2−0.003xy | 0.9908 |

| 14 | UCS = 8.47 + 1.47x − 0.54y + 0.02x2 + 0.01y2 − 0.03xy | 0.9867 | |

| 28 | UCS = 110.75 + 1.75x − 3.62y + 0.02x2 + 0.03y2 − 0.03xy | 0.9884 | |

| CFTB1-2 | 7 | UCS =−0.212 + 0.017x − 0.005y + 0.0002x2 + 0.0002y2 − 0.0004xy | 0.9896 |

| 14 | UCS = 12.69 + 1.29x − 0.62y + 0.02x2 + 0.01y2 − 0.03xy | 0.9934 | |

| 28 | UCS = 83.81 + 1.11x − 2.72y + 0.02x2 + 0.02y2 − 0.04xy | 0.9860 | |

| CFTB2-1 | 7 | UCS = −2.74 + 0.15x + 0.04y + 0.0007x2 + 0.0001y2 − 0.0025xy | 0.9810 |

| 14 | UCS = 7.32 + 1.06x − 0.44y + 0.014x2 + 0.005y2 − 0.021xy | 0.9904 | |

| 28 | UCS = 81.94 + 1.36x − 2.69y + 0.02x2 + 0.02y2 − 0.03xy | 0.9903 | |

| CFTB2-2 | 7 | UCS =0.425 + 0.034x − 0.024y + 0.0002x2 + 0.0003y2 − 0.0007xy | 0.9730 |

| 14 | UCS =40.24 + 1.02x − 1.38y + 0.01x2 + 0.01y2 − 0.02xy | 0.9897 | |

| 28 | UCS =58.36 + 1.47x − 2.00y + 0.01x2 + 0.02y2 − 0.03xy | 0.9769 |

| Scheme. | CT (d) | MSE | RMSE | MAE | MAPE/% |

|---|---|---|---|---|---|

| CTB | 7 | 0.002 | 0.044 | 0.033 | 7.8 |

| 14 | 0.032 | 0.178 | 0.150 | 11.9 | |

| 28 | 0.030 | 0.172 | 0.136 | 8.1 | |

| CFTB1-1 | 7 | 0.001 | 0.020 | 0.016 | 8.7 |

| 14 | 0.017 | 0.131 | 0.107 | 11.7 | |

| 28 | 0.028 | 0.166 | 0.130 | 9.3 | |

| CFTB1-2 | 7 | 0.001 | 0.005 | 0.005 | 5.5 |

| 14 | 0.009 | 0.097 | 0.082 | 10.9 | |

| 28 | 0.028 | 0.168 | 0.146 | 11.7 | |

| CFTB2-1 | 7 | 0.001 | 0.013 | 0.010 | 7.4 |

| 14 | 0.012 | 0.111 | 0.099 | 11.7 | |

| 28 | 0.031 | 0.177 | 0.148 | 11.5 | |

| CFTB2-2 | 7 | 0.001 | 0.008 | 0.006 | 10.3 |

| 14 | 0.008 | 0.089 | 0.071 | 10.8 | |

| 28 | 0.011 | 0.107 | 0.092 | 9.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Fu, J.; Song, W.; Zhang, Y. Viscosity and Strength Properties of Cemented Tailings Backfill with Fly Ash and Its Strength Predicted. Minerals 2021, 11, 78. https://doi.org/10.3390/min11010078

Wang J, Fu J, Song W, Zhang Y. Viscosity and Strength Properties of Cemented Tailings Backfill with Fly Ash and Its Strength Predicted. Minerals. 2021; 11(1):78. https://doi.org/10.3390/min11010078

Chicago/Turabian StyleWang, Jie, Jianxin Fu, Weidong Song, and Yongfang Zhang. 2021. "Viscosity and Strength Properties of Cemented Tailings Backfill with Fly Ash and Its Strength Predicted" Minerals 11, no. 1: 78. https://doi.org/10.3390/min11010078

APA StyleWang, J., Fu, J., Song, W., & Zhang, Y. (2021). Viscosity and Strength Properties of Cemented Tailings Backfill with Fly Ash and Its Strength Predicted. Minerals, 11(1), 78. https://doi.org/10.3390/min11010078