3.1. Statistical Analysis

In order to study the effects of the experimental conditions on the extraction of zinc from direct leaching of sphalerite, the results obtained in the present work were compared with the results of other researchers. Obviously, mineralogy plays a very important role in hydrometallurgical processes. In this case, direct leaching studies were identified where the concentration of sphalerite was similar, and with no or low presence of marmatite. This meant that the focus was the effect on the leaching parameters and their impact on the formation and characteristics of the sulfur layer. In turn, it was possible to compare the kinetics of the reaction.

Table 5 and

Table 6 show the chemical analysis and mineralogical composition of the sphalerite concentrates used in previous studies that were compared with the present work.

Analysis of variance (ANOVA) was conducted to evaluate the individual effect of selected leaching factors on the extraction of zinc.

Table 7 shows the factors used for statistical analysis. Factors and levels used for ANOVA were: Leaching time (2 and 5 h), reactor type (1 = opened, 2 = closed), [H

2SO

4] (0.5, 1.0, 1.5 and 2 M), [Fe

2+] (0, 0.05, 0.2 and 0.25 M), [Fe

3+] (0, 0.25, 0.5 and 1.2 M), O

2/O

3 (1 = without oxygen or ozone as oxidants, 2 = oxygen and 3 = ozone), temperature (301, 353, 363 and 365 K) and pulp density (50, 100, 166 and 200 g/L).

Table 8 presents the main effects as a function of zinc extraction, as determined by ANOVA. According to the F-value and the levels of significance (

p-values), it can be stated that under the conditions studied, leaching time was the most influential factor followed by the use of O

2 or O

3, pulp density, and Fe

3+ concentration, which had a similar significant effect.

Figure 1 shows the individual effects of the most significant factors on the extraction of Zn: Leaching time, non-use or use of O

2 or O

3, pulp density, and concentration of Fe

3+. As can be seen, the efficiency of Zn extraction increased from 52% to 65% when the leaching time was increased from 2 to 5 h (

Figure 1a). Increasing the pulp density from 50 to 166 g/L resulted in an increase of the leaching process efficiency from 60% to 85%, but it decreased up to 30% for a pulp density of 200 g/L. This result was consistent with the results of other researchers [

16], who reported incomplete dissolution of metals present in the concentrate during autoclave batch-type experiments carried out at atmospheric pressure with high pulp densities. It was suggested that the increase in the percentage of extraction at a pulp density of 166 g/L was primarily determined by the change in temperature and type of reactor used. However, at sufficiently high pulp density, diffusion of reactants appears to be limited given the increasing concentration of products of the reaction.

With respect to the oxidation of sphalerite, several authors reported the overall chemical reaction of the leaching process [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19] as follows (Gibbs energy values were obtained from HSC Chemistry 6 [

29]:

Some authors [

20] reported that leaching of sphalerite occurred mainly according to Equation (2). Other researchers [

18] reported that the sphalerite dissolution rate in acid media was controlled by oxygen diffusion through a porous surface layer of polysulfide or S

0. In addition, this equation has been represented, as indicated by Equation (3). We can also consider the chemical equilibrium of the species (

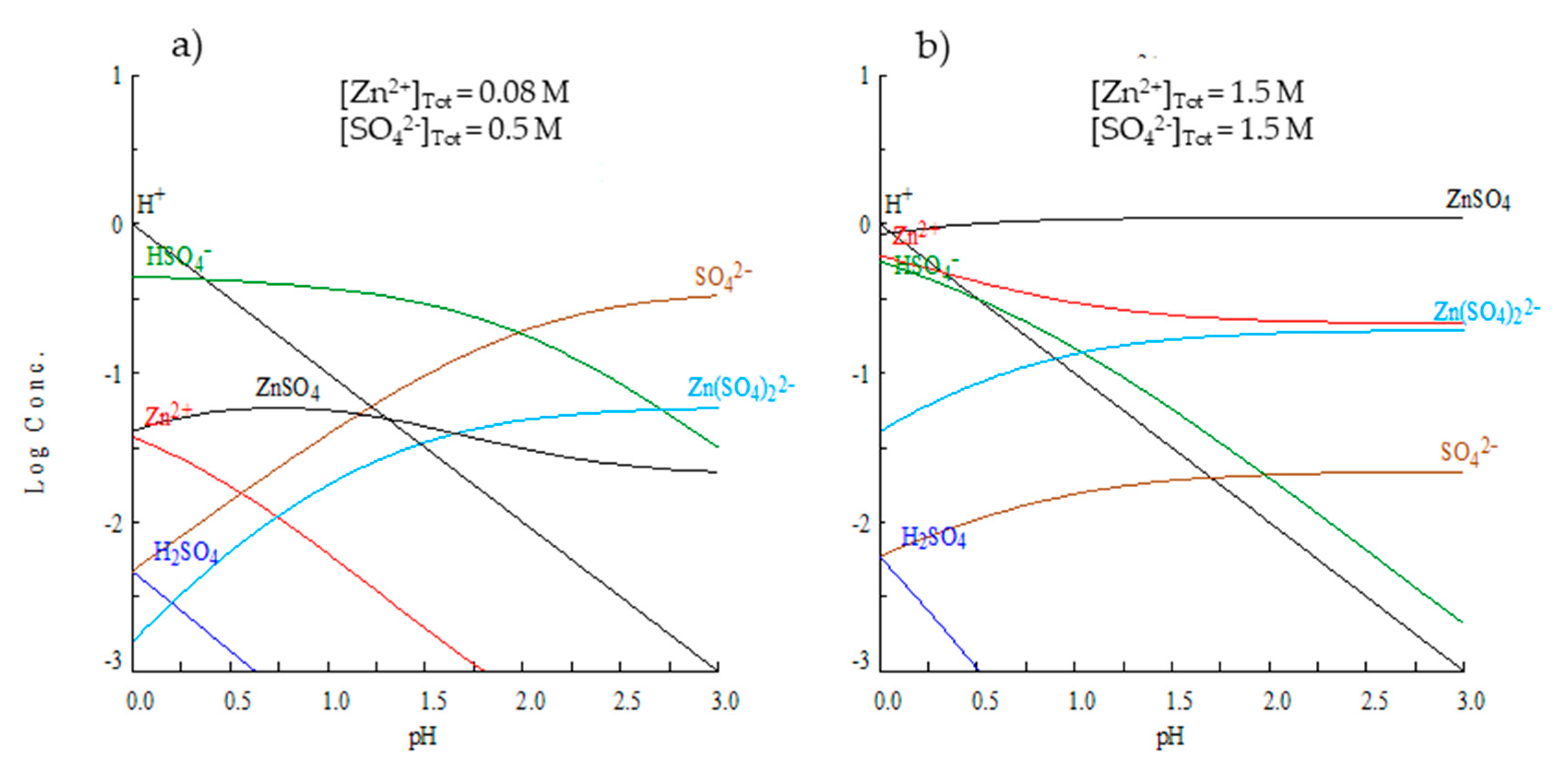

Figure 2, from Medusa Software) [

31].

According to these figures, the most stable products of sulfuric acid dissociation were H

+ and HSO

4−. In addition, under batch-test conditions (

Figure 2a) or equimolar (pilot test) conditions (

Figure 2b), the primary product formed from ZnS leaching was ZnSO4 aqueous. Considering these predictions, the following equation is proposed:

Therefore, based upon the Gibbs energy, values of Equation (2) and the information given in

Figure 2, the leaching of sphalerite was indicated to occur by zinc sulfation and sulfur oxidation. This indicated the involvement of the sulfate ion (or HSO

4− anion), which, along with the ZnSO

4 ion (both larger molecules), must diffuse through the sulfur layer. Therefore, diffusion of these species can be a limiting step of the reaction.

On the other hand, the chemical theory generally accepted for leaching of ZnS can be described by a process in which ferric sulfate is reduced to ferrous sulfate and elemental sulfur and sphalerite dissolves forming zinc sulfate (aqueous) according to Equation (5) [

32,

33]. Equation (6) shows only the metallic ion indicating a Gibbs free energy value lower than Equation (5). This indicates that the sulfur is oxidized by the ferric sulfate species, and that the sulfate ion allows the formation of zinc sulfate as aqueous species.

Ferrous iron oxidizes to ferric iron in the presence of oxygen, according to Equation (7). However, comparing the energies values between Equations (7) and (8), its shows that the oxidation reaction is more thermodynamically possible in the presence of sulphuric acid rather than just H

+.

According to previous equations, ferric iron reacts with ZnS and is reduced to ferrous ion, which the oxidizes to ferric ion when it reacts with oxygen present in the leaching system; these reaction favor oxidant conditions during leaching [

11]. The thermodynamics seems to indicate that the formation of zinc sulfate (aqueous) is more favored than the zinc ion.

As observed in

Figure 1c, low zinc extractions (50%) were obtained in the direct leaching of sphalerite without added Fe

3+. However, the efficiency increased up to 75% with additions of Fe

3+; this percentage was independent of the amount of Fe

3+ concentration (0.25 M to 1.2 M).

Figure 1d shows the variations in the zinc extractions as a function of the oxidant (1 = without O

2 or O

3 as oxidants, 2 = O

2, and 3 = O

3) present in the leaching media. The reactions between the sphalerite and O

2 is indicated in Equation (2), while the reaction of sphalerite with O

3 occurs according to the following:

Again, formation of zinc sulfate aqueous (Equation (9)) resulted in a higher Gibbs energy value than the formation of zinc as an ion (Equation (10)). As can be seen, experiments without any gas or with O

2 lead to an average zinc extraction of 65%. On the other hand, the use of O

3 (the strongest oxidant) caused a decrease in zinc extraction to 45%.

Figure 1d shows the average of the extraction results of experiments 3 and 4 (

Table 7) and Mubarok et al. [

22] tests. It is notable that the latter [

22] used ozone without Fe

3+ at room temperature, while experiments 3 and 4 were run at 80 °C. The low average zinc extraction may be due to the averaging of data obtained from the use of ozone under high temperature leaching conditions (where the stability and solubility of ozone is lower). The conclusion of Mubarok et al. [

22] was that ozone promoted fast oxidation of Fe

2+ to Fe

3+ and that constant availability of Fe

3+ may promote the formation of a non-porous sulfur layer and, therefore, inhibit the extraction of zinc as the reaction proceeds. This and the lower stability of ozone at a higher temperature may explain the low zinc extractions obtained in this study.

3.2. Kinetic analysis

The kinetics of the leaching process was determined from zinc extraction data as a function of time obtained from lab-scale experiments (experiment 1) and pilot-scale experiments (experiments 5, 6, and 7), and it was described by the shrinking core model.

Table 9 shows a compilation of experimental data obtained in the present work and data reported in the literature made to determine the rate-determining step of the dissolution of zinc under different conditions of leaching.

The rate-limiting step of the zinc dissolution was obtained from a comparison between experimental data and some kinetic models reported in the literature [

34], as shown in

Table 10.

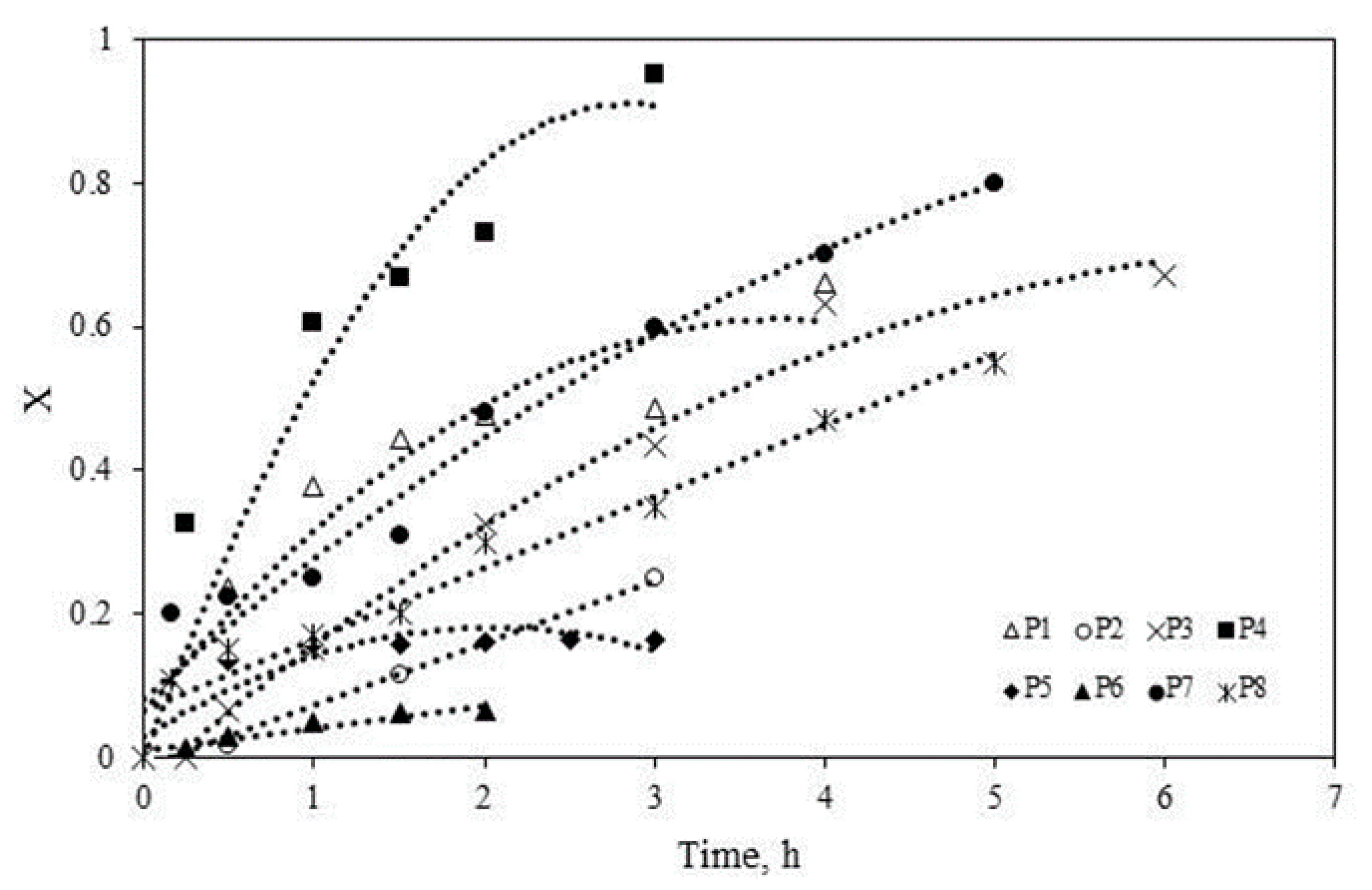

Figure 3 shows the leaching fraction (X) as a function of time for experiments shown in

Table 9.

The kinetics analysis was conducted to compare the models reported in the literature using the zinc extraction data (reacted fraction) from

Figure 3.

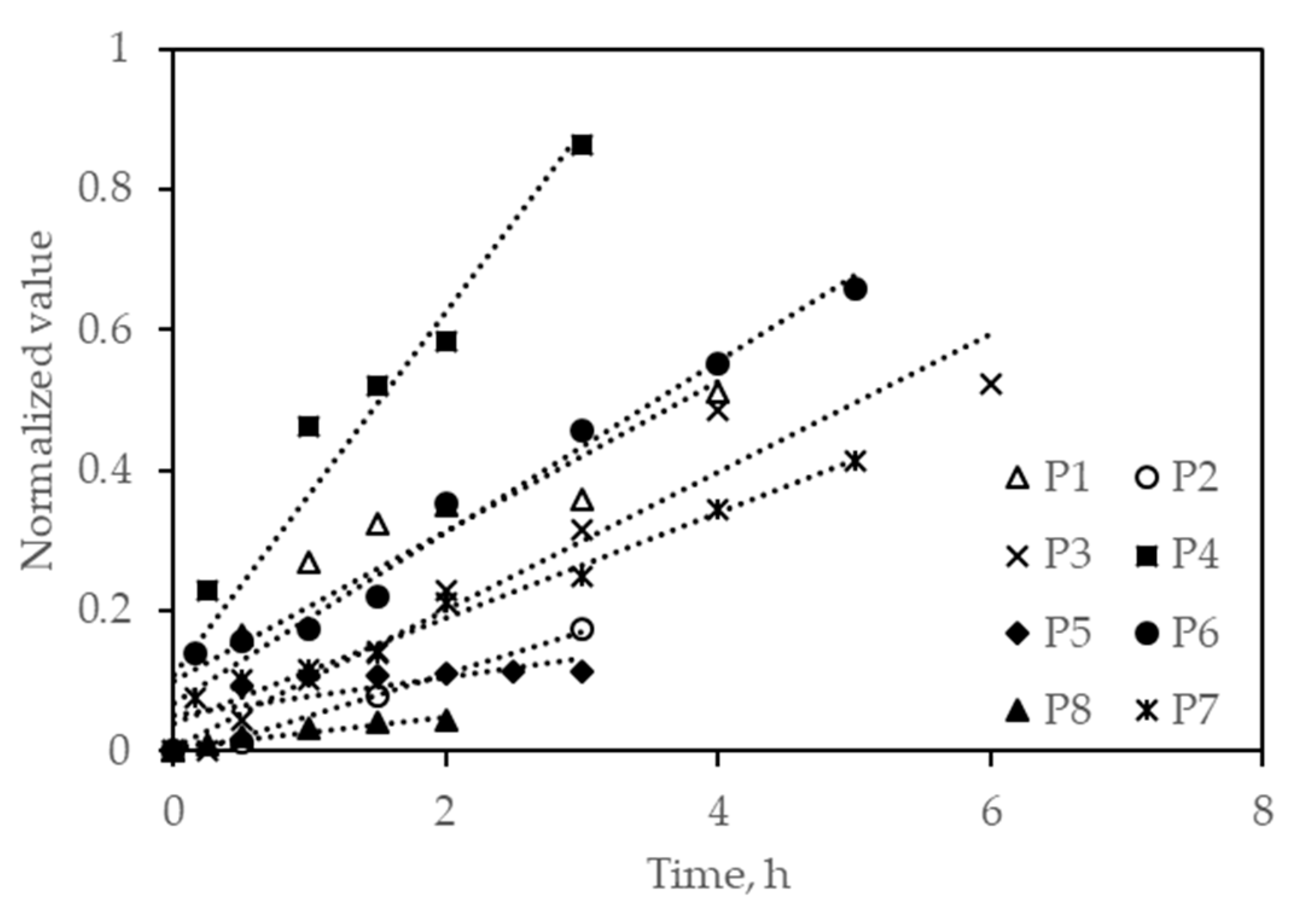

Figure 4 shows a comparison of the reaction rate of experiments shown in

Table 7, which is represented by the slope corresponding to each curve. It is worth mentioning that this figure was obtained after plotting the corresponding model for each test. The data obtained from each model were normalized in the range of 0 to 1 to be able to visualize and compare the slope of each line. Normalization consisted simply of adjusting the values obtained from each model; for example, if the model gave values on the order of 10

−2, it was multiplied by 10, thus that the values were in the order of 10

−1. In the case of 10

−3, by 100 for the same effect, and so on. Being multiples, the slope of each model was conserved, which allowed a comparison of values of the same order (from 10

−1) on the Y-axis. Each slope line was proportional to the apparent constant of the reaction rate of the experiments studied. The higher the slope, the higher the reaction rate. As can be observed, the reaction rate of experiments P1, P2, P5 and P6 was slower than P3, P4, P7, and P8.

All the experiments presented in

Table 9 were adjusted to the shrinking model, however, differences were found in the controlling stages. Experiment P1 fits well to the mechanism that involves the product layer model, according to the following equation.

The kinetics of the leaching process in experiments P5 and P6 (conducted at laboratory scale and at pilot-scale, respectively), is described by the following model:

Some authors have reported that the sphalerite reacts mainly with Fe

3+ ions forming a surface product layer, which is probably dense [

12,

22].

In the case of these experiments, Equations (11) and (12) that represent the oxidation cycle of iron, can be rapid at the beginning, which causes the rapid formation of the elemental sulfur layer due to the type of solid-liquid reaction. As can be seen in

Table 7, both tests were conducted in a batch reactor without supplying additional oxygen to the leaching system, therefore, this inhibits the speed of Equations (3) and (4), and consequently, the rate of dissolution of zinc.

Results of experiments P3 and P4 carried out at pilot-scale showed that the chemical reaction was the rate-determining step of the direct leaching of sphalerite concentrates. It suggested that the product layer formed at the surface of mineral particles was porous, thin or, that it can be easily detached from the particle and not limiting for the diffusion of reactants and reaction products. The fraction leached as a function of time in these experiments, which exhibited chemically controlled kinetic behavior is expressed as follows:

The kinetics of the leaching process in experiments P5 and P6 (conducted at laboratory scale and at pilot-scale, respectively), is described by the following model:

This model relates the diffusion process where the concentration of the reactants decreases as the reaction progresses. This can occur when there is a relatively high percentage of solids within the solution.

The use of a high pulp density (200 g/L) in experiment P5 leads to a slow dissolution rate, which may be associated with the low availability of reactants with respect to solids in the leaching media. Furthermore, in experiment P5, Fe2+ ions were used, without supplying oxygen to the leaching medium, an initial amount of H2O2 was added, which could have caused the rapid formation of a dense sulfur layer on the surface of the sphalerite particles, in a similar way to experiments P1 and P2.

Experiment P6 conducted in a low-pressure reactor in the presence of sulfuric acid, and oxygen exhibited the presence of H2S. Initially, oxygen consumption was observed; then it stopped, and negative pressure was observed (a characteristic that a gas is leaving the same oxygen inlet line). When purging the line, the H

2S gas came out (detected by its smell). Some researchers reported that the dissolution of sphalerite follows the indirect oxidation reactions involving acid dissolution (Equation (15)), the release of H2S, and its further oxidation to elemental sulfur by oxygen or ferric ions (Equation (16)) present in the leaching medium. Therefore, in this case, the chemical reaction in the interface is supposed to be the rate-determining step of the sphalerite leaching process [

19].

It is possible that the formation of H2S in experiment P6 was faster than its oxidation, which may have caused its accumulation in the reactor, making the passage of oxygen difficult and inhibiting the rate of zinc dissolution.

The leaching medium used during experiments P3 and P4 may be the cause of the formation of a porous sulfur layer, since Fe

2+ and O

2 ions were used. Based on the results of the previous experiments, it was inferred that during the P3 and P4 experiments, the reaction of the Fe

3+ ions with the sphalerite occurred in a controlled manner, since it involved first the oxidation reaction of Fe

2+ to Fe

3+ and in secondly the reaction of Fe

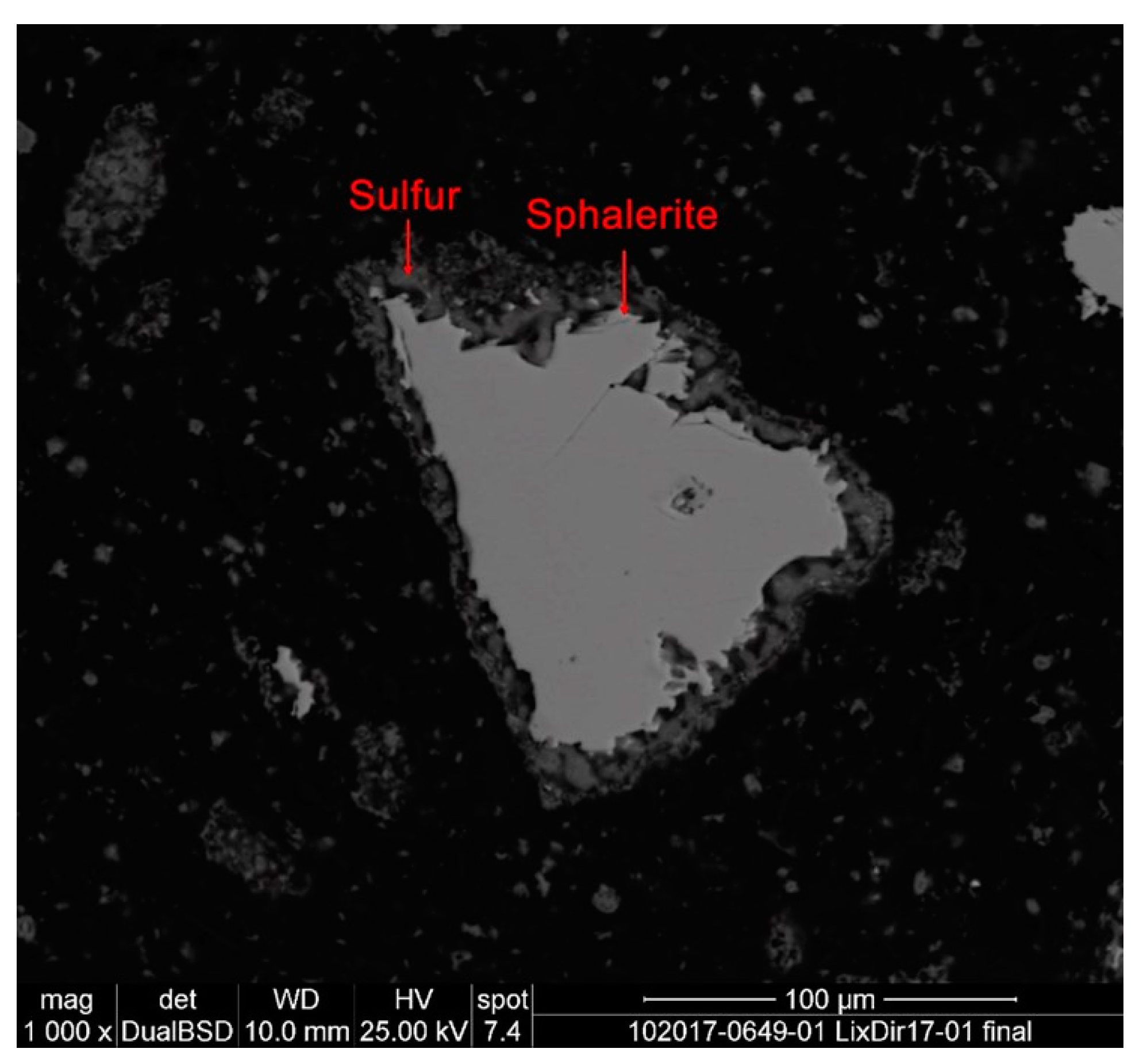

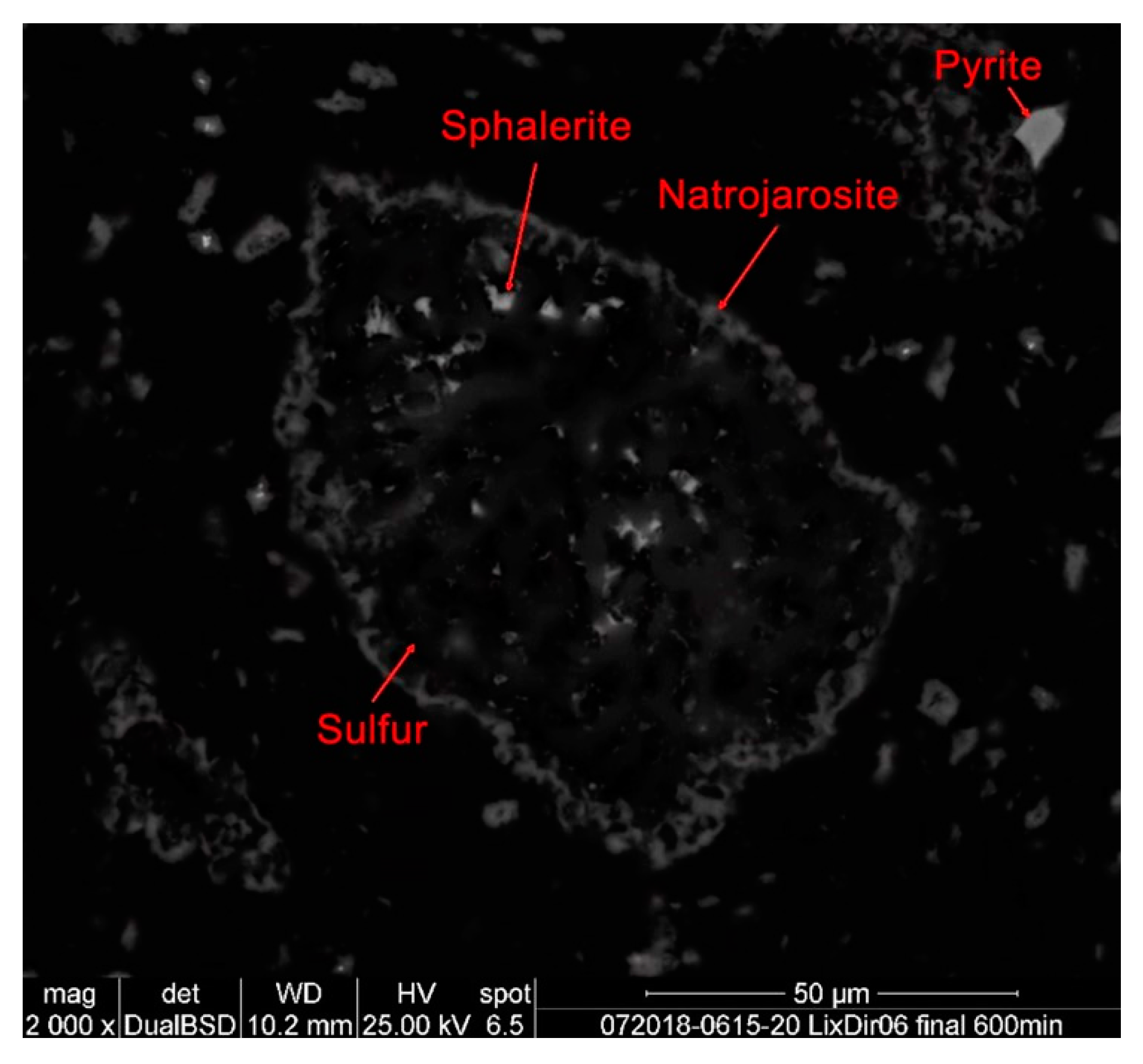

3+ with the sphalerite. Oxygen (supplied into the pulp) reacts with sphalerite and in the oxidation-reduction cycle of iron, which can be the cause of the pores observed in the sulfur layer, which allows a greater dissolution of zinc. SEM characterization of the leaching residues (P3 and P4 experiments) showed a porous layer of sulfur on the surface of the unreacted sphalerite particles, as shown in

Figure 5 and

Figure 6.

Cháidez et al. [

35] carried out a direct acid leaching of chalcopyrite in the same type of reactor used in experiments P3 and P4 and observed a type of porous sulfur layer on unreacted chalcopyrite particles.

Table 11 shows the mineralogical species present in the residue of experiment P4. As can be observed, the percentage of sulfur increases from 3% at t = 0 h up to 56% at t = 4 h. In addition, despite the formation of a layer of elemental sulfur (apparently porous), 4 h later, most of the zinc has already been dissolved.

The chemical reaction is also the rate-determining step of experiments P7 and P8 [

22]. In these cases, elemental sulfur present in the leaching residue floated easily, forming independent particles, which were released on the mineral surface instead of promoting the formation of layers on the reacted particle. Unlike the atmospheric leaching of sphalerite concentrates with ferric sulfates, there was no apparent obstacle for the dissolution of zinc during the entire leaching process [

5,

12]. Mubarok et al. [

22] also reported that the chemical reaction was the rate-determining step of the sphalerite leaching reaction, which was consistent with the kinetic analysis conducted in the present work.