Computational Modeling and Prediction on Viscosity of Slags by Big Data Mining

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection and Preprocessing

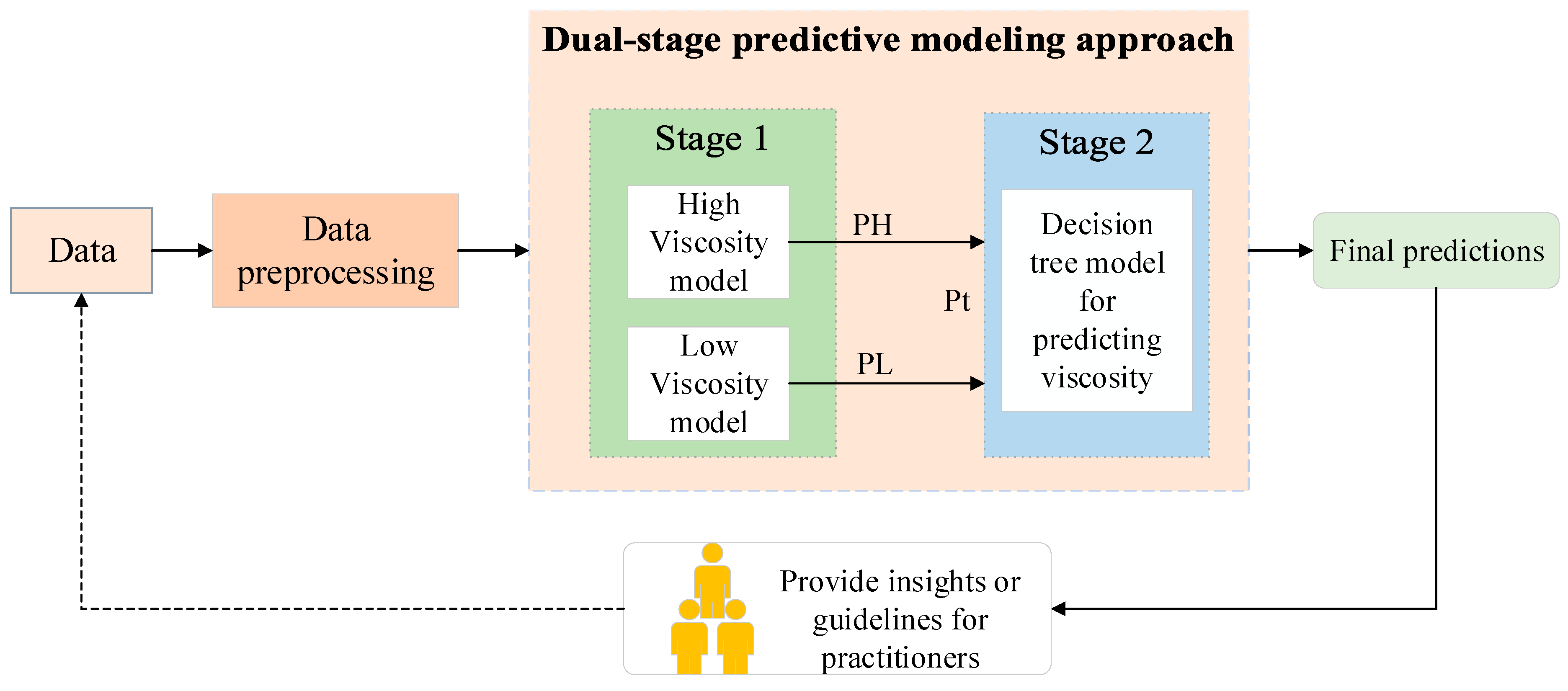

2.2. The Proposed Dual-Stage Predictive Modeling Approach

2.3. Metrics for Performance Evaluation

2.4. The Identification of Significant Factors

3. Results

3.1. Prediction Performance of the Baseline Methods

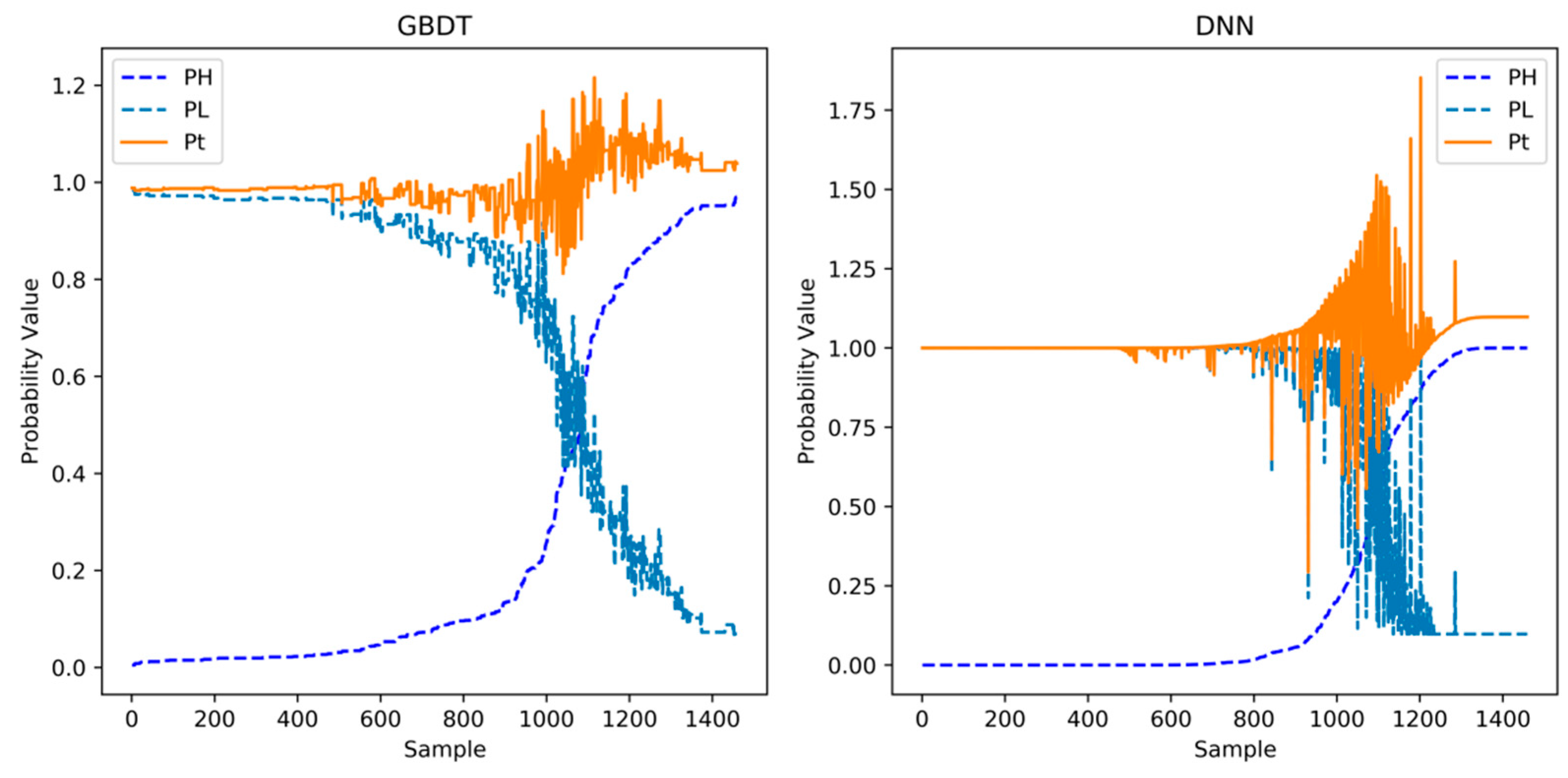

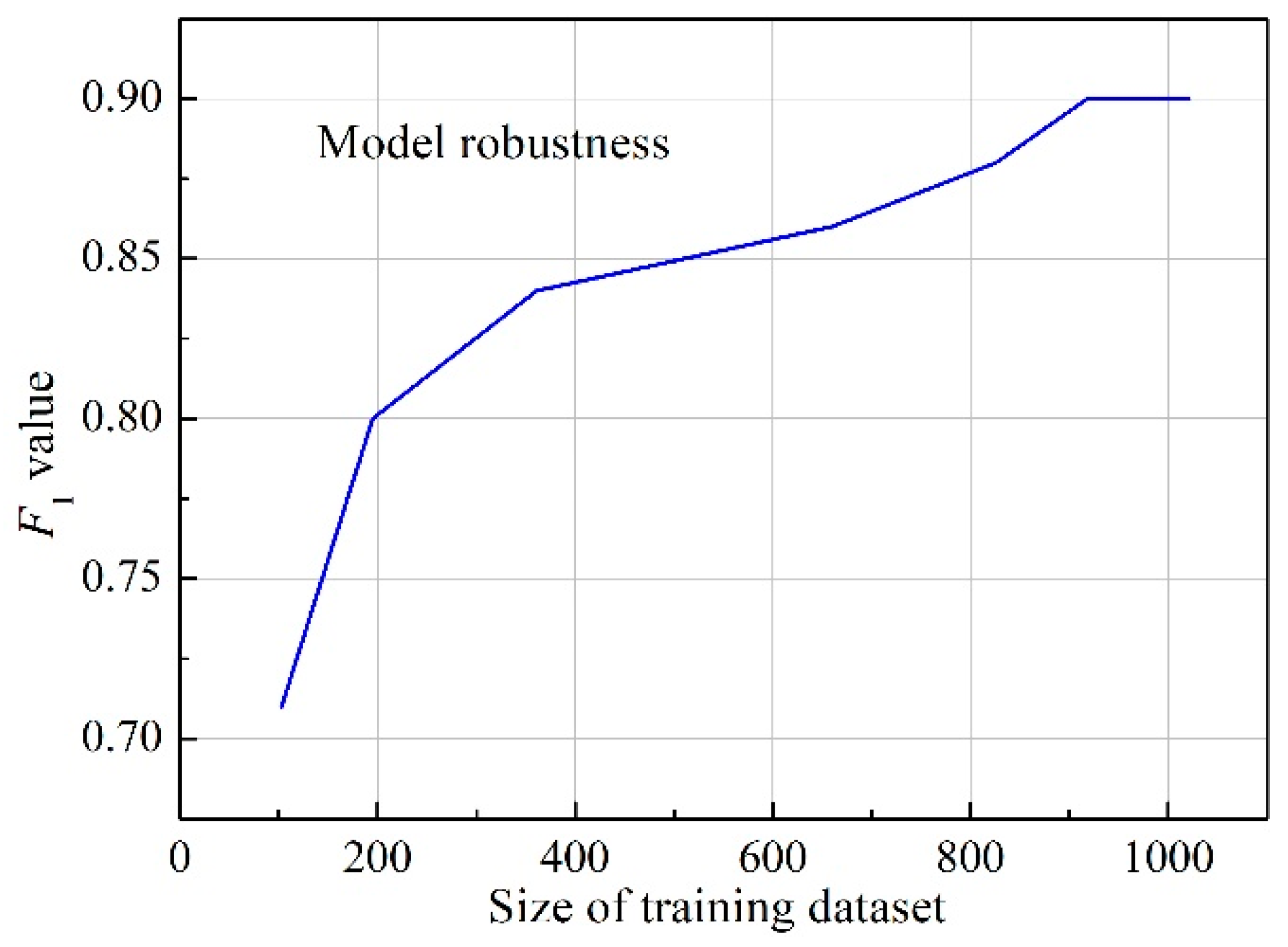

3.2. Prediction Performance of the Proposed Dual-Stage Predictive Modeling Approach

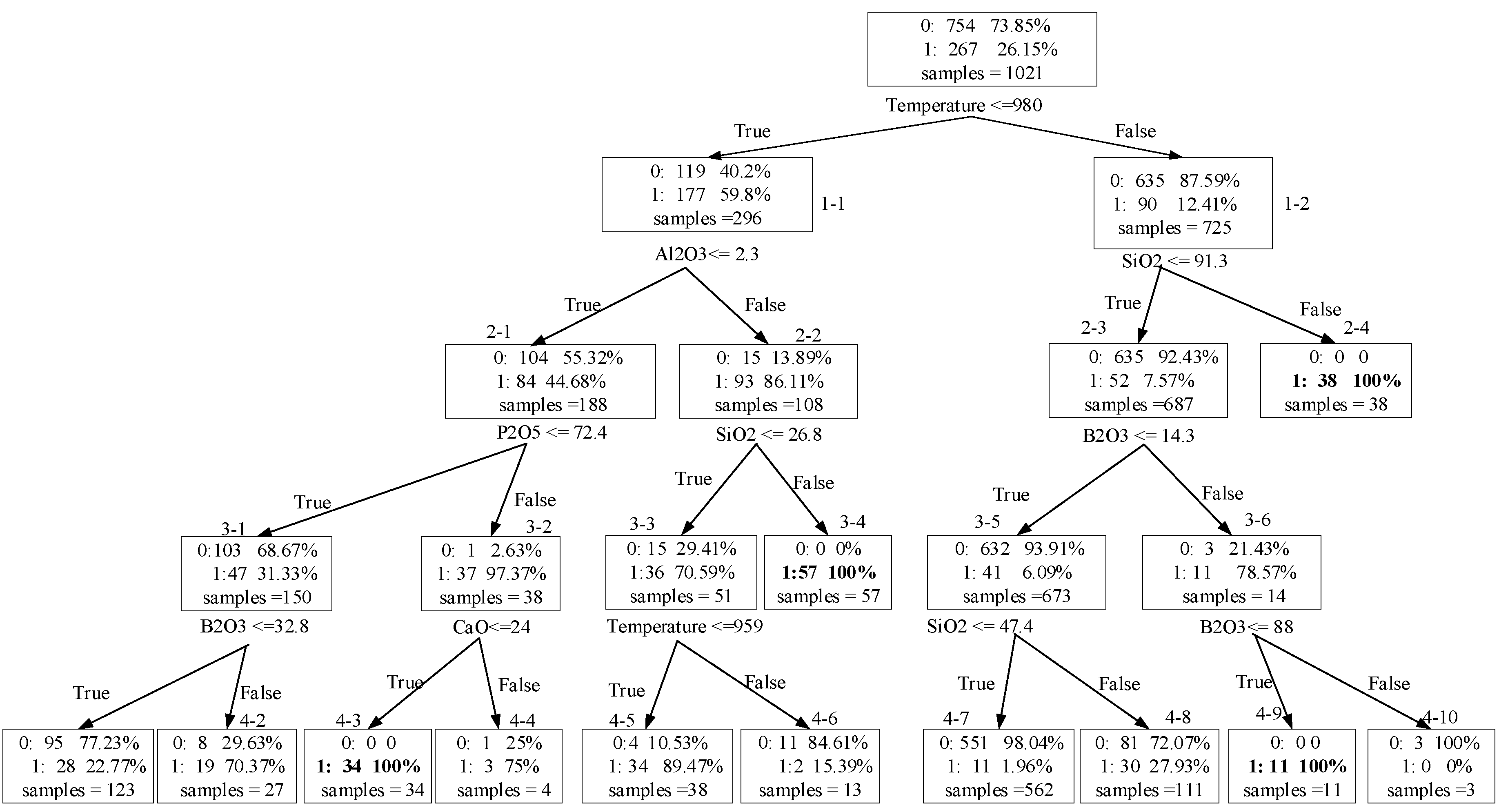

3.3. Significant Factors of the Slag’s Viscosity

- Rule 1-1: Temperature ≤ 980 °C (0/1: 0.402/0.598)

- Rule 1-2: Temperature > 980 °C (0/1: 0.876/0.124)

- Rule 2-1: 1-1 + Al2O3 ≤ 2.3% (0/1: 0.553/0.447)

- Rule 2-2: 1-1 + Al2O3 > 2.3% (0/1: 0.139/0.861)

- Rule 2-3: 1-2 + SiO2 ≤ 91.3% (0/1: 0.924/0.076)

- *Rule 2-4: 1-2 + SiO2 > 91.3% (0/1: 0/1)

- Rule 3-1: 1-1 + 2-1 + P2O5 ≤ 72.4% (0/1: 0.688/0.312)

- Rule 3-2: 1-1 + 2-1 + P2O5 > 72.4% (0/1: 0.026/0.974)

- Rule 3-3: 1-2 + 2-2 + SiO2 ≤ 26.8% (0/1: 0.294/0.706)

- *Rule 3-4: 1-2 + 2-2 + SiO2 > 26.8% (0/1: 0/1)

- Rule 3-5: 1-2 + 2-3 + B2O3 ≤ 14.3% (0/1: 0.939/0.061)

- Rule 3-6: 1-2 + 2-3 + B2O3 > 14.3% (0/1: 0.214/0.786)

- Rule 4-1: 1-1 + 2-1 + 3-1 + B2O3 ≤ 32.8% (0/1: 0.772/0.228)

- Rule 4-2: 1-1 + 2-1 + 3-1 + B2O3 > 32.8% (0/1: 0.296/0.704)

- *Rule 4-3: 1-1 + 2-1 + 3-2 + CaO ≤ 24% (0/1: 0 /1)

- Rule 4-4: 1-1 + 2-1 + 3-2 + CaO > 24% (0/1: 0.25/0.75)

- Rule 4-5: 1-1 + 2-2 + 3-3 + Temperature ≤ 959 °C (0/1: 0.105/0.895)

- Rule 4-6: 1-2 + 2-2 + 3-3 + Temperature > 959 °C (0/1: 0.846/0.154)

- Rule 4-7: 1-2 + 2-3 + 3-5 + SiO2 ≤ 47.4% (0/1: 0.98/0.02)

- Rule 4-8: 1-2 + 2-3 + 3-6 + SiO2 > 47.4% (0/1: 0.721/0.279)

- *Rule 4-9: 1-2 + 2-3 + 3-6 + B2O3 ≤ 88% (0/1: 0/1)

- Rule 4-8: 1-2 + 2-3 + 3-5 + B2O3 > 88% (0/1: 1/0)

4. Discussion

4.1. High Recall Rate and Low Misclassification Rate of the Proposed Approach

4.2. The Significant Factors and Prediction for Slag’s Viscosity

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, M.B.; Li, J.G.; Ma, H.Q. Effect of ingredient on viscosity of CaO-MgO-SiO2-Al2O3 quaternary refining slag series. Spec. Steel 2013, 34, 28–31. [Google Scholar]

- Huang, A.; Harald, H.; Marianne, D.; Sandra, V. Towards CFD modelling of slag entrainment in gas stirred ladles. Steel Res. Int. 2015, 86, 1447–1454. [Google Scholar] [CrossRef]

- Zhao, G.Z.; Zhang, L.L.; Cang, D.Q. Fundamental and industrial investigation on preparation of high acidity coefficient steel slag derived slag wool. J. Ceram. Soc. Jpn. 2019, 127, 180–185. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, J.J.; Wang, X.Y.; Zhou, H.S.; Xu, J.F.; Wan, K. Measure and model calculation of metallurgical slag viscosity. Hot Work. Technol. 2014, 43, 70–72. [Google Scholar]

- Jiang, L. Fundamental Research on the Structure and Viscosity of Molten CaO-SiO2-P2O5-FeO Slag; Chongqing Univ.: Chongqing, China, 2015. [Google Scholar]

- Heller, H.P.; Schürmann, M.; Scholl, K.; Haustein, N.; Lychatz, B.; Falkus, J. Calibration problems with the viscosity measurement of liquid metallurgical slags. J. Phys. Conf. Ser. 2017, 790, 1–5. [Google Scholar] [CrossRef]

- Urbain, G. Viscosity estimation of slags. Steel Res. 1987, 58, 111–116. [Google Scholar] [CrossRef]

- De Wijn, A.S.; Vesovic, V.; Jackson, G.; Martin Trusler, J.P. A kinetic theory description of the viscosity of dense fluids consisting of chain molecules. J. Chem. Phys. 2008, 128, 204901. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.M. Scaling law of shear viscosity in atomic liquid and liquid mixtures. J. Chem. Phys. 2006, 124, 2181. [Google Scholar]

- Chou, K.C.; Chang, Y.A. A study of ternary geometrical models. Ber. Bunsenges. Phys. Chem. 1989, 93, 735–741. [Google Scholar] [CrossRef]

- Chou, K.C.; Zhong, X.; Xu, K. Calculation of physicochemical properties in a ternary system with miscibility gap. Metall. Mater. Trans. B 2004, 35, 715–720. [Google Scholar] [CrossRef]

- Folkedahl, B.C.; Schobert, H.H. Effects of atmosphere on viscosity of selected bituminous and low-rank coal ash slags. Energy Fuels 2005, 19, 208–215. [Google Scholar] [CrossRef]

- Duchesne, M.A.; Macchi, A.; Lu, D.Y.; Hughes, R.W. Artificial neural network model to predict slag viscosity over a broad range of temperatures and slag compositions. Fuels Process. Technol. 2010, 91, 831–836. [Google Scholar] [CrossRef]

- Pummill, R. Physical and Computational Studies of Slag Behavior in an Entrained Flow Gasifier; The University of Utah: Salt Lake City, UT, USA, 2012. [Google Scholar]

- Han, J.; Pei, J.; Kamber, M. Data mining: Concepts and techniques. Data Min. Concepts Models Methods Algorithms Second Ed. 2006, 5, 1–18. [Google Scholar]

- Leban, G.; Zupan, B.; Vidmar, G.; Bratko, I. VizRank: Data visualization guided by machine learning. Data Min. Knowl. Discov. 2006, 13, 119–136. [Google Scholar] [CrossRef]

- Kaufman, K.A.; Michalski, R.S. From data mining to knowledge mining. Data Min. Data Vis. 2005, 24, 47–75. [Google Scholar]

- Provost, F.; Fawcett, T. Data science and its relationship to big data and data-driven decision making. Big Data 2013, 1, 51–59. [Google Scholar] [CrossRef]

- Joseph, R.C.; Johnson, N.A. Big data and transformational government. IT Prof. 2013, 15, 43–48. [Google Scholar] [CrossRef]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.T.; Papadopoulos, T. Big data analytics in logistics and supply chain management: Certain Investigations for research and applications. Int. J. Prod. Econ. 2016, 176, 98–110. [Google Scholar] [CrossRef]

- Raghupathi, W.; Raghupathi, V. Big data analytics in healthcare: Promise and potential. Health Inf. Sci. Syst. 2014, 2, 3. [Google Scholar] [CrossRef]

- Schildkamp, K.; Lai, M.K.; Earl, L.M. Data-based decision making in education. Stud. Educ. Lead. 2013, 17, 205–224. [Google Scholar]

- O’Donovan, P.; Leahy, K.; Bruton, K.; O’Sullivan, D.T.J. An industrial big data pipeline for data-driven analytics maintenance applications in large-scale smart manufacturing facilities. J. Big Data 2015, 2, 1–26. [Google Scholar] [CrossRef]

- Huang, A.; Huo, Y.Z.; Yang, J.; Li, G.Q. Computational simulation and prediction on electrical conductivity of oxide-based melts by big data mining. Materials 2019, 12, 1059. [Google Scholar] [CrossRef] [PubMed]

- Mills, K.C. Slag Atlas. VDEh, 2nd ed.; Verlag Stahleisen GmbH: Düsseldorf, Germany, 1995; pp. 349–401. [Google Scholar]

- Li, S.P.; Song, B.; Lv, X.W.; Xu, J. Dependence of the Viscosity of High Titania Slag on Composition; Academic Exchange Meeting on New Technology of Comprehensive Utilization of Titanium Resources: Chongqing, China, 2014; pp. 94–98. [Google Scholar]

- Park, H.; Park, J.Y.; Kim, G.H.; Sohn, I. Effect of TiO2 on the viscosity and slag structure in blast furnace type slags. Steel Res. Int. 2012, 83, 150–156. [Google Scholar] [CrossRef]

- Jiao, K.X.; Zhang, J.L.; Wang, Z.Y.; Liu, Y.X.; Xu, R.Z. Melting features and viscosity of TiO2-containing primary slag in a blast furnace. High Temp. Mat. Process. 2018, 37, 149–156. [Google Scholar] [CrossRef]

- Fu, G.Q.; Ju, H.X.; Xue, X.; Sun, J.; Wang, C.Y.; Zhu, M.Y. Study on viscosity and melting temperature of acidic vanadium-titanium-containing Slag. Chin. J. Process. Eng. 2008, S1, 276–279. [Google Scholar]

- Schaffer, C. Selecting a classification method by cross-validation. Mach. Learn. 1993, 13, 135–143. [Google Scholar] [CrossRef]

- Singh, R.; Mangat, N.S. Stratified sampling. Elem. Surv. Sampl. 1996, 15, 102–144. [Google Scholar]

- He, H.; Garcia, E.A. Learning from imbalanced data. IEEE Trans. Knowl. Data Eng. 2009, 21, 1263–1284. [Google Scholar]

- Wolpert, D.H. Stacked generalization. Neural Netw. 1992, 5, 241–260. [Google Scholar] [CrossRef]

- Surrogate Model. Available online: https://en.wikipedia.org/wiki/Surrogate_model (accessed on 8 November 2018).

- Marbouti, F.; Diefes-Dux, H.A.; Madhavan, K. Models for early prediction of at-risk students in a course using standards-based grading. Comput. Educ. 2016, 103, 1–15. [Google Scholar] [CrossRef]

- Aler, R.; Handl, J.; Knowles, J.D. Comparing multi-objective and threshold-moving ROC curve generation for a prototype-based classifier. In Proceedings of the Genetic and Evolutionary Computation Conference, Amsterdam, The Netherlands, 8–12 July 2013; pp. 1029–1036. [Google Scholar]

- Collell, G.; Prelec, D.; Patil, K.R. A simple plug-in bagging ensemble based on threshold-moving for classifying binary and multiclass imbalanced data. Neurocomputing 2018, 275, 330–340. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.J.; Zhang, P.R. A score fusion algorithm based on the multivariate polynomial model. J. Univ. Sci. Technol. Chin. 2009, 39, 1177–1182. [Google Scholar]

- Wang, B.X. Polynomial Modeling on Relationship between Incidence of Scarlet Fever and Meteorological Factors; Anhui Medical University: Anhui, China, 2014. [Google Scholar]

- Mills, K.C. The influence of structure on the physico-chemical properties of slags. ISIJ Int. 1993, 33, 148–155. [Google Scholar] [CrossRef]

- Choi, S.Y.; Lee, D.H.; Shin, D.W.; Choi, S.Y.; Cho, J.W.; Park, J.M. Properties of F-free glass system as a mold flux: Viscosity, thermal conductivity and crystallization behavior. J. Non Cryst. Solids 2004, 345, 156–160. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, J.L.; Wu, L.S.; Liu, W.J.; Bai, Y.N.; Xing, X.D.; SU, B.X.; Kong, D.W. Influence of B2O3 on viscosity of high Ti-bearing blast furnace slag. ISIJ Int. 2012, 52, 984–991. [Google Scholar] [CrossRef]

| Variables | Attribute | Description |

|---|---|---|

| Al2O3 | Numeric | Al2O3 mass fraction in slag |

| FeO | Numeric | FeO mass fraction in slag |

| SiO2 | Numeric | SiO2 mass fraction in slag |

| P2O5 | Numeric | P2O5 mass fraction in slag |

| CaF2 | Numeric | CaF2 mass fraction in slag |

| Li2O | Numeric | Li2O mass fraction in slag |

| B2O3 | Numeric | B2O3 mass fraction in slag |

| CaO | Numeric | CaO mass fraction in slag |

| Gd2O3 | Numeric | Gd2O3 mass fraction in slag |

| La2O3 | Numeric | La2O3 mass fraction in slag |

| Nd2O3 | Numeric | Nd2O3 mass fraction in slag |

| TiO2 | Numeric | TiO2 mass fraction in slag |

| Fe2O3 | Numeric | Fe2O3 mass fraction in slag |

| K2O | Numeric | K2O mass fraction in slag |

| MgO | Numeric | MgO mass fraction in slag |

| MnO | Numeric | MnO mass fraction in slag |

| Na2O | Numeric | Na2O mass fraction in slag |

| ZrO2 | Numeric | ZrO2 mass fraction in slag |

| CaS | Numeric | CaS mass fraction in slag |

| SrO | Numeric | SrO mass fraction in slag |

| ZnO | Numeric | ZnO mass fraction in slag |

| V2O5 | Numeric | V2O5 mass fraction in slag |

| Cr2O3 | Numeric | Cr2O3 mass fraction in slag |

| S | Numeric | S mass fraction in slag |

| Temperature | Numeric | Temperature of slag |

| Viscosity | Categorical | Slag’s viscosity value |

| Methods | LR | NB | SVM | KNN | GBDT | DNN |

|---|---|---|---|---|---|---|

| Accuracy | 0.87 | 0.55 | 0.86 | 0.91 | 0.92 | 0.94 |

| Misclassification | 0.13 | 0.45 | 0.14 | 0.09 | 0.08 | 0.06 |

| Recall | 0.60 | 0.95 | 0.63 | 0.80 | 0.81 | 0.82 |

| F1 | 0.87 | 0.54 | 0.72 | 0.85 | 0.85 | 0.88 |

| Metrics | MH | ML | ||

|---|---|---|---|---|

| GBDT | DNN | GBDT | DNN | |

| Accuracy | 0.92 | 0.94 | 0.92 | 0.94 |

| Misclassification | 0.08 | 0.06 | 0.08 | 0.08 |

| Recall | 0.81 | 0.82 | 0.95 | 0.99 |

| F1 | 0.85 | 0.88 | 0.94 | 0.96 |

| Metrics | Coordination Based on GBDT | Coordination Based on DNN |

|---|---|---|

| Accuracy | 0.95 (0.92) | 0.95 (0.94) |

| Misclassification | 0.05 (0.08) | 0.05 (0.06) |

| Recall | 0.89 (0.81) | 0.85 (0.82) |

| F1 | 0.90 (0.85) | 0.90 (0.88) |

| The Slag System | Content of Each Component (wt%) | A | Eη (kJ/mol) |

|---|---|---|---|

| SiO2 | SiO2: 100 | 6.00 × 10−9 | −567.97 |

| Al2O3-Gd2O3 | Al2O3: 52.987; Gd2O3: 47.013 | 8.00 × 10−5 | −124.65 |

| Al2O3-La2O3 | Al2O3: 55.586; La2O3: 44.414 | 2.00 × 10−5 | −145.24 |

| Al2O3-Nd2O3 | Al2O3: 54.839; Nd2O3: 45.161 | 7.00 × 10−5 | −122.48 |

| SiO2-B2O3 | SiO2: 71.463; B2O3: 28.537 | 2.00 × 10−5 | −304.53 |

| SiO2: 43.185; B2O3: 56.815 | 0.0005 | −176.65 | |

| SiO2: 34.441; B2O3: 65.559 | 0.0005 | −162.29 | |

| SiO2: 25; B2O3: 75 | 0.0146 | −100.94 | |

| SiO2: 15.385; B2O3: 84.615 | 0.0497 | −72.55 | |

| SiO2: 8.696; B2O3: 91.304 | 0.129 | −52.56 | |

| SiO2: 5.187; B2O3: 94.813 | 0.1247 | −48.10 | |

| P2O5-CaO | P2O5: 43.4; CaO: 56.6 | 4.00 × 10−5 | −132.82 |

| P2O5: 51.2; CaO: 48.8 | 0.0034 | −73.05 | |

| P2O5: 57.4; CaO: 42.6 | 0.0354 | −43.61 | |

| P2O5: 68.9; CaO: 31.1 | 0.0003 | −110.05 | |

| P2O5: 75.2; CaO: 24.8 | 0.0001 | −128.58 | |

| P2O5: 76.8; CaO: 23.2 | 2.00 × 10−5 | −150.07 | |

| P2O5: 77.2; CaO: 22.8 | 1.00 × 10−5 | −158.58 | |

| P2O5: 78.6; CaO: 21.4 | 1.00 × 10−5 | −157.87 | |

| P2O5: 83.1; CaO: 16.9 | 5.00 × 10−5 | −144.27 | |

| CaO-Fe2O3 | CaO: 13.885; Fe2O3: 86.115 | 0.0007 | −79.97 |

| CaO: 16.520; Fe2O3: 83.480 | 0.0005 | −85.68 | |

| CaO: 19.476; Fe2O3: 80.524 | 0.0006 | −82.74 | |

| Al2O3-CaO-ZrO2 | Al2O3: 60; CaO: 30; ZrO2: 10 | 5.00×10−7 | −257.55 |

| Al2O3: 50; CaO: 25; ZrO2: 25 | 0.0002 | −179.42 | |

| SiO2-CaO-TiO2 | SiO2: 27.454; CaO: 29.894; TiO2:42.652 | 0.0004 | −107.59 |

| SiO2-LiO2-TiO2 | SiO2: 31.902; LiO2: 18.535; TiO2: 49.563 | 0.0069 | −52.98 |

| Al2O3-SiO2-CaO-MgO | Al2O3: 4; SiO2: 48.95; CaO: 44.05; MgO: 3 | 0.0012 | −124.89 |

| Al2O3: 9; SiO2: 48; CaO: 28; MgO: 15 | 0.0037 | −108.91 | |

| Al2O3: 5.5; SiO2: 47.2; CaO: 37.8; MgO: 9.5 | 0.0034 | −112.48 | |

| Al2O3: 8; SiO2: 46.5; CaO: 32.5; MgO: 13 | 0.0009 | −128.83 | |

| Al2O3: 6.5; SiO2: 45.85; CaO: 36.65; MgO: 11 | 0.0017 | −120.86 | |

| Al2O3: 12; SiO2: 45.4; CaO: 22.6; MgO: 20 | 9.00 × 10−6 | −194.94 | |

| Al2O3: 5.5; SiO2: 44.75; CaO: 40.25; MgO: 9.5 | 0.0023 | −117.54 | |

| Al2O3: 11; SiO2: 44.5; CaO: 26.5; MgO: 18 | 6.00 × 10−6 | −200.92 | |

| Al2O3: 4; SiO2: 44.3; CaO: 48.7; MgO: 3 | 0.0022 | −119.21 | |

| Al2O3: 8; SiO2: 43.9; CaO: 35.1; MgO: 13 | 0.0004 | −139.45 | |

| Al2O3: 6.5; SiO2: 43.4; CaO: 39.1; MgO: 11 | 0.0014 | −120.49 | |

| Al2O3: 4; SiO2: 42.3; CaO: 50.7; MgO: 3 | 7.00 × 10−6 | −200.17 | |

| Al2O3: 11; SiO2: 41.75; CaO: 29.25; MgO: 18 | 0.0036 | −110.26 | |

| Al2O3: 8; SiO2: 41.6; CaO: 37.4; MgO: 13 | 4.00 × 10−5 | −173.26 | |

| Al2O3: 6.5; SiO2: 41.25; CaO: 41.25; MgO: 11 | 0.0058 | −101.22 | |

| Al2O3: 12; SiO2: 40; CaO: 28; MgO: 20 | 0.0024 | −110.77 | |

| Al2O3: 8; SiO2: 39.5; CaO: 39.5; MgO: 13 | 0.0019 | −117.08 | |

| Al2O3: 9; SiO2: 36.2; CaO: 39.8; MgO: 15 | 2.00 × 10−5 | −182.75 | |

| Al2O3: 8; SiO2: 35.9; CaO: 43.1; MgO: 13 | 3.00 × 10−12 | −403.35 | |

| Al2O3: 12; SiO2: 35.8; CaO: 32.2; MgO: 20 | 6.00 × 10−6 | −202.51 | |

| Al2O3: 12; SiO2: 30.9; CaO: 37.1; MgO: 20 | 2.00 × 10−8 | −282.90 | |

| Al2O3-FeO-SiO2-CaO-TiO2-MgO | Al2O3: 11.26; FeO: 5; SiO2: 27.85; CaO: 36.76; TiO2: 10; MgO: 9.13 | 6.00 × 10−21 | −667.25 |

| Al2O3: 11.26; FeO: 15; SiO2: 23.54; CaO: 31.07; TiO2: 10; MgO: 9.13 | 9.00 × 10−21 | −644.31 | |

| Al2O3: 11.26; FeO: 10; SiO2: 25.69; CaO: 33.92; TiO2: 10; MgO: 9.13 | 0.2643 | −21.17 | |

| Al2O3:11.26; FeO: 15; SiO2: 23.54; CaO: 31.07; TiO2: 10; MgO: 9.13 | 4.00 × 10−18 | −564.46 | |

| Al2O3:11.26; FeO: 15; SiO2: 21.38; CaO: 28.23; TiO2: 15; MgO: 9.13 | 3.00 × 10−20 | −647.89 | |

| Al2O3-FeO-SiO2-CaO-TiO2-MgO-V2O5 | Al2O3:15.76; FeO: 4; SiO2: 30.12; CaO: 6.02; TiO2: 30; MgO: 12.7; V2O5: 1.4 | 2.00 × 10−23 | −750.58 |

| Al2O3:15.76; FeO: 14; SiO2: 20.11; CaO: 5.03; TiO2: 30; MgO: 12.7; V2O5: 2.4 | 2.00 × 10−9 | −1566.86 | |

| Al2O3-CaF2-CaO | Al2O3: 10; CaF2: 50; CaO: 40 | 0.0003 | −108.12 |

| Al2O3: 20; CaF2: 60; CaO: 20 | 0.0001 | −116.07 | |

| Al2O3: 30; CaF2: 40; CaO: 30 | 7.00 × 10−5 | −146.63 | |

| Al2O3: 40; CaF2: 40; CaO: 20 | 1.00 × 10−6 | −205.41 | |

| FeO-SiO2-TiO2 | FeO: 13.92; SiO2: 2; TiO2: 84.08 | 3.00 × 10−74 | −2713.68 |

| FeO: 13.63; SiO2: 4; TiO2: 82.37 | 1.00 × 10−101 | −3732.29 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, A.; Huo, Y.; Yang, J.; Gu, H.; Li, G. Computational Modeling and Prediction on Viscosity of Slags by Big Data Mining. Minerals 2020, 10, 257. https://doi.org/10.3390/min10030257

Huang A, Huo Y, Yang J, Gu H, Li G. Computational Modeling and Prediction on Viscosity of Slags by Big Data Mining. Minerals. 2020; 10(3):257. https://doi.org/10.3390/min10030257

Chicago/Turabian StyleHuang, Ao, Yanzhu Huo, Juan Yang, Huazhi Gu, and Guangqiang Li. 2020. "Computational Modeling and Prediction on Viscosity of Slags by Big Data Mining" Minerals 10, no. 3: 257. https://doi.org/10.3390/min10030257

APA StyleHuang, A., Huo, Y., Yang, J., Gu, H., & Li, G. (2020). Computational Modeling and Prediction on Viscosity of Slags by Big Data Mining. Minerals, 10(3), 257. https://doi.org/10.3390/min10030257