Reconstruction of 16th–17th Century Lead Smelting Processes on the Basis of Slag Properties: A Case Study from Sławków, Poland

Abstract

1. Introduction

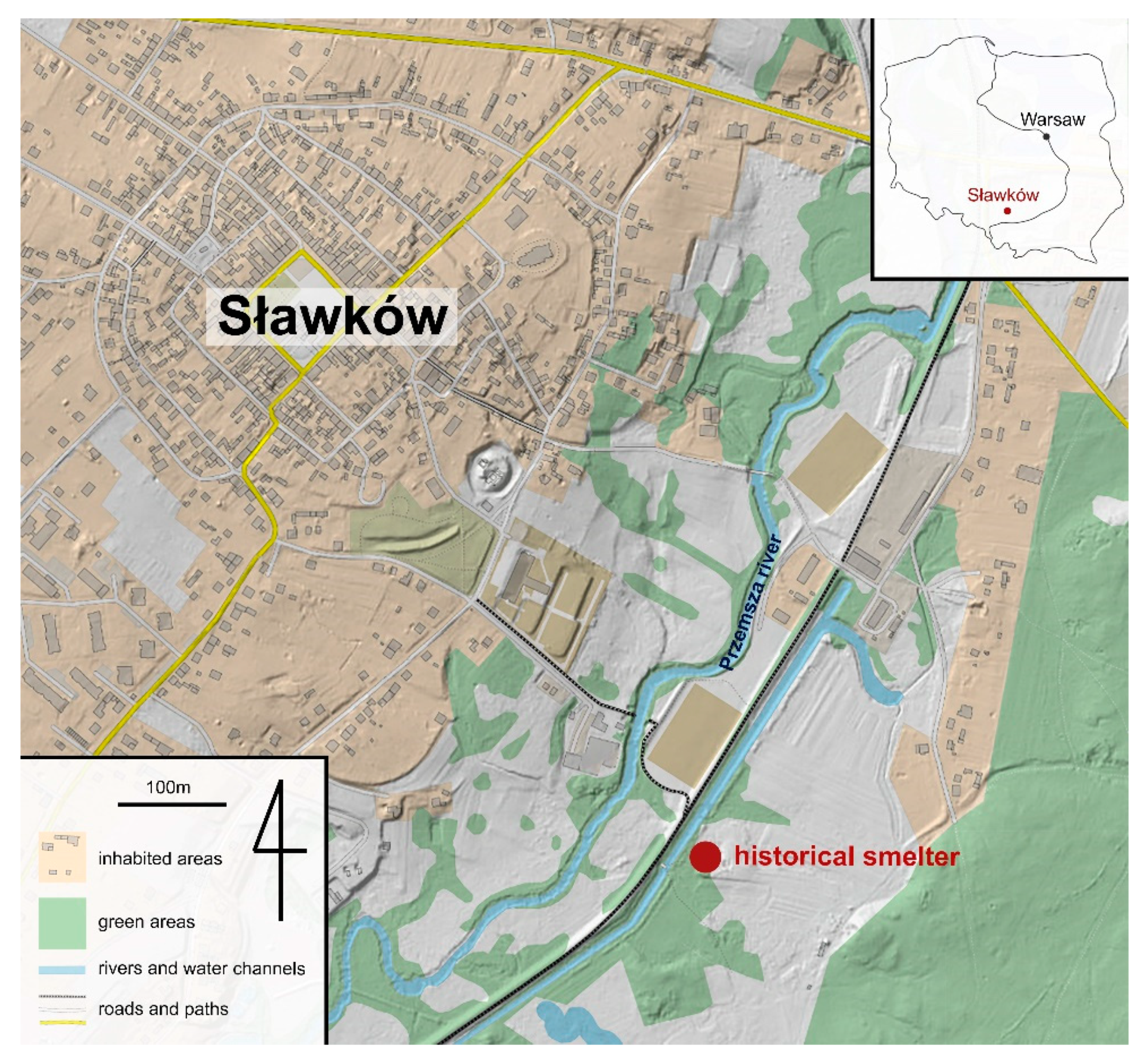

2. Location and Ore Exploitation

3. Materials and Methods

3.1. Sampling

3.2. Furnace Experiments

3.3. Geochemical and Petrological Analyses

3.4. Software

4. Results

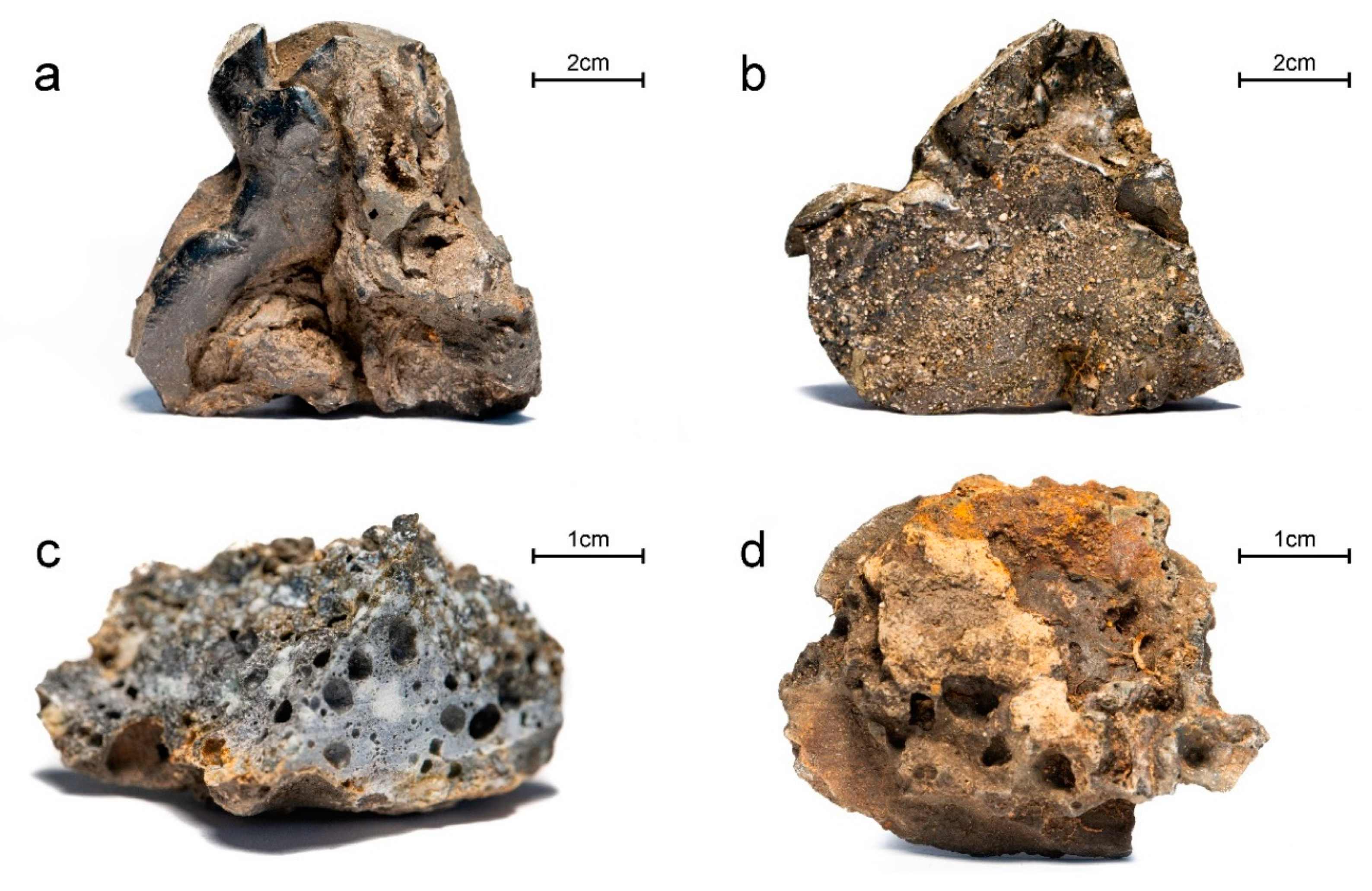

4.1. Slag Types at Sławków Landfill

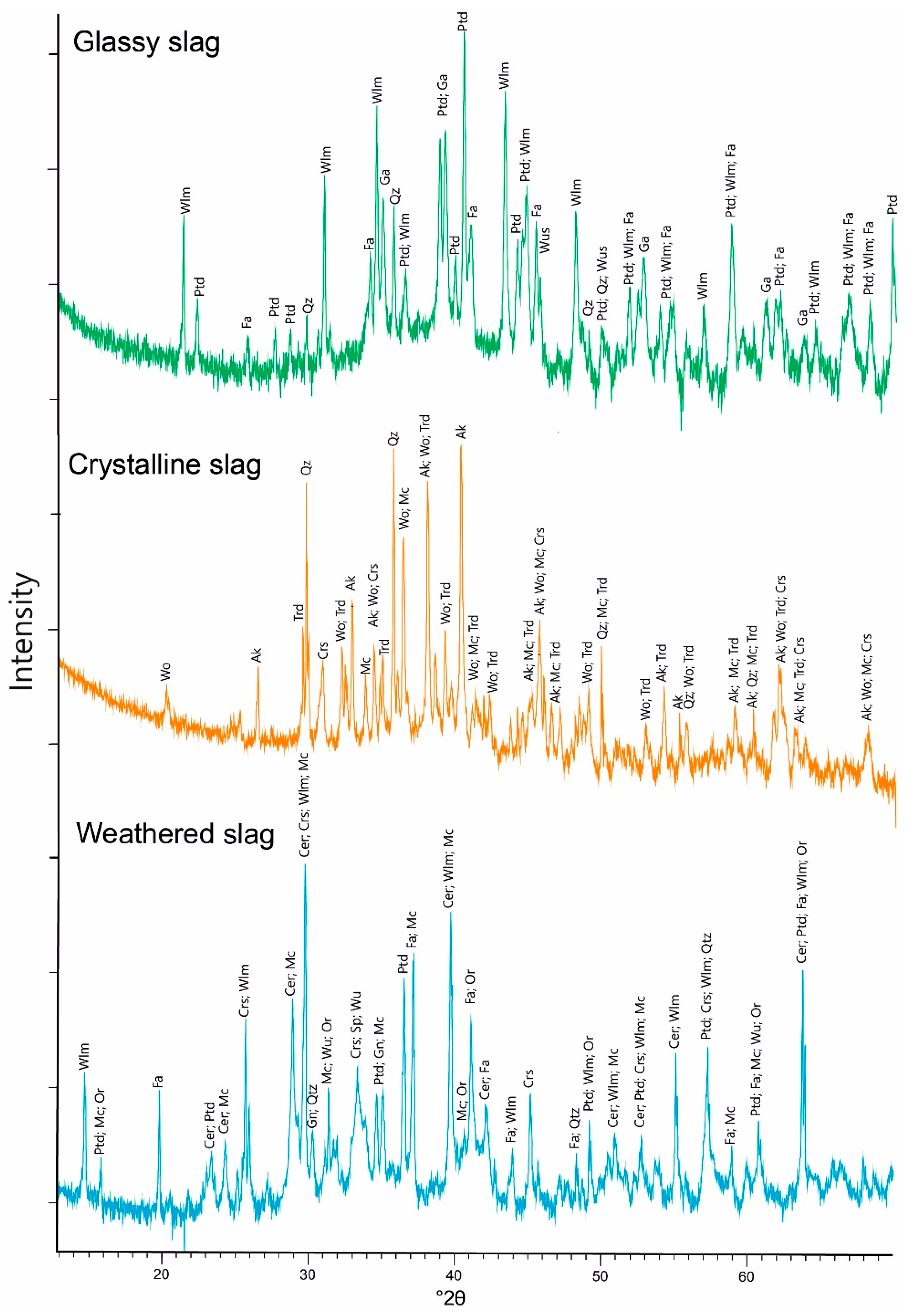

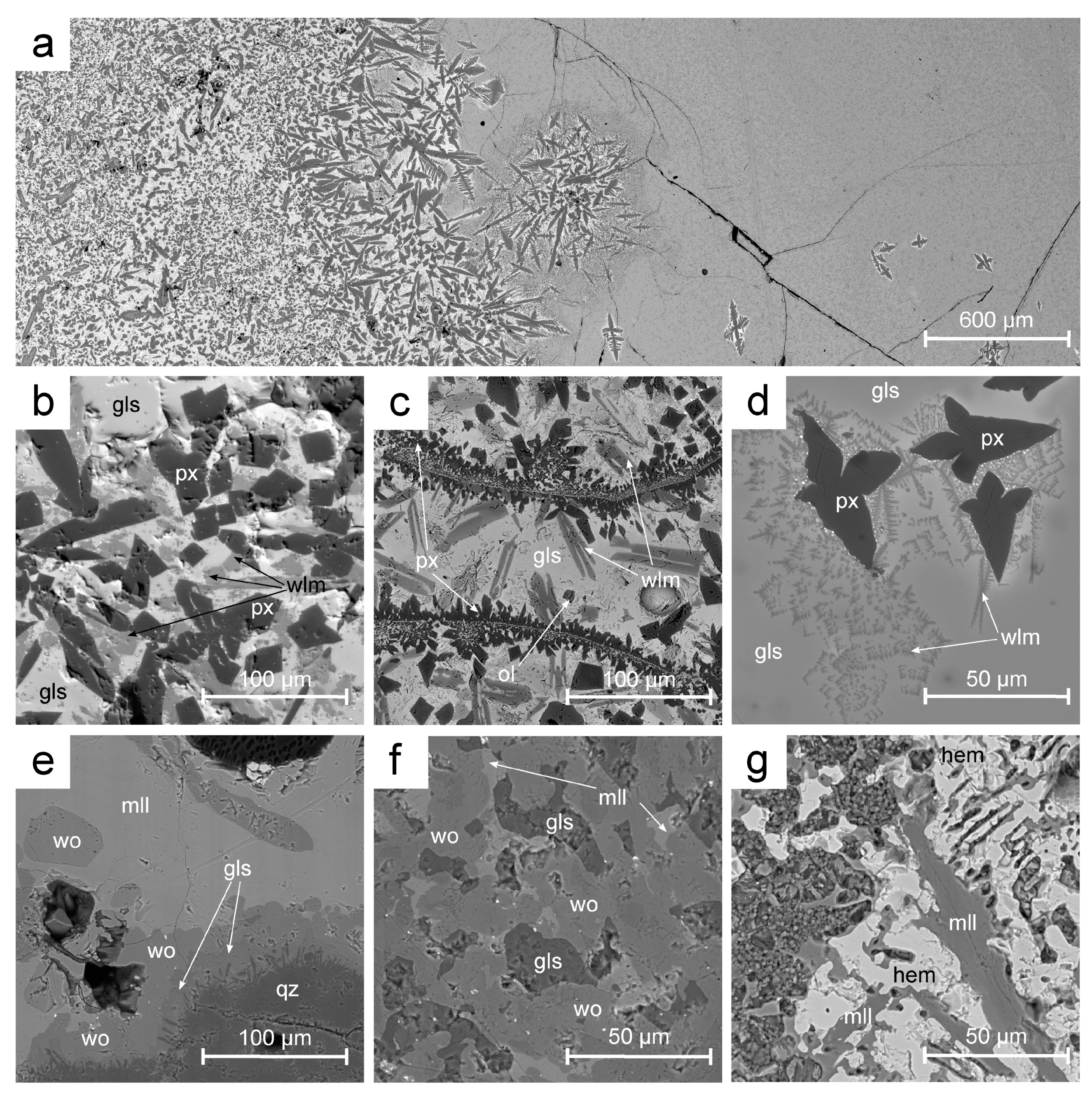

4.2. Phase Composition and Chemistry of Phases

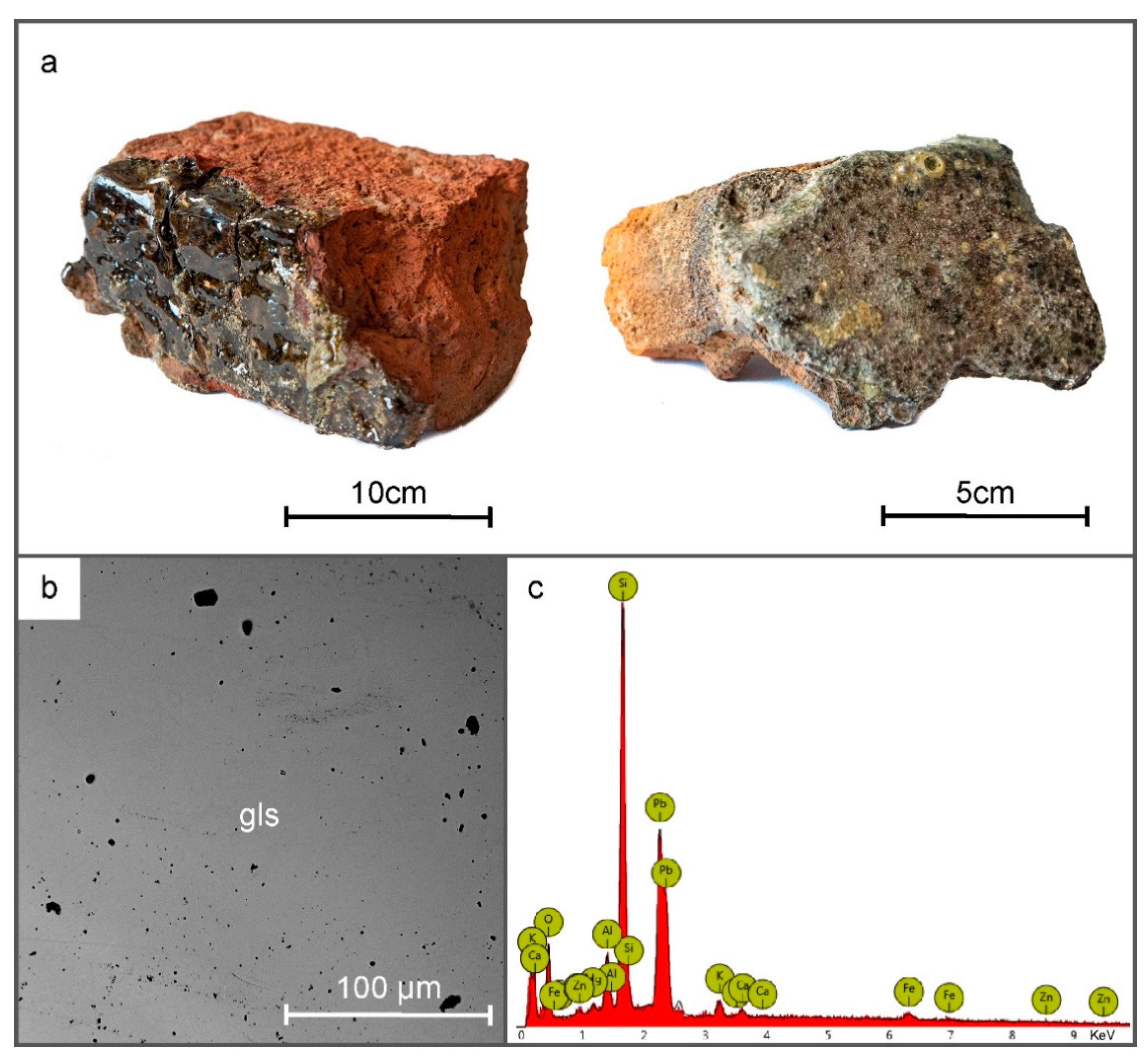

4.2.1. Glassy Slag

4.2.2. Crystalline Slag

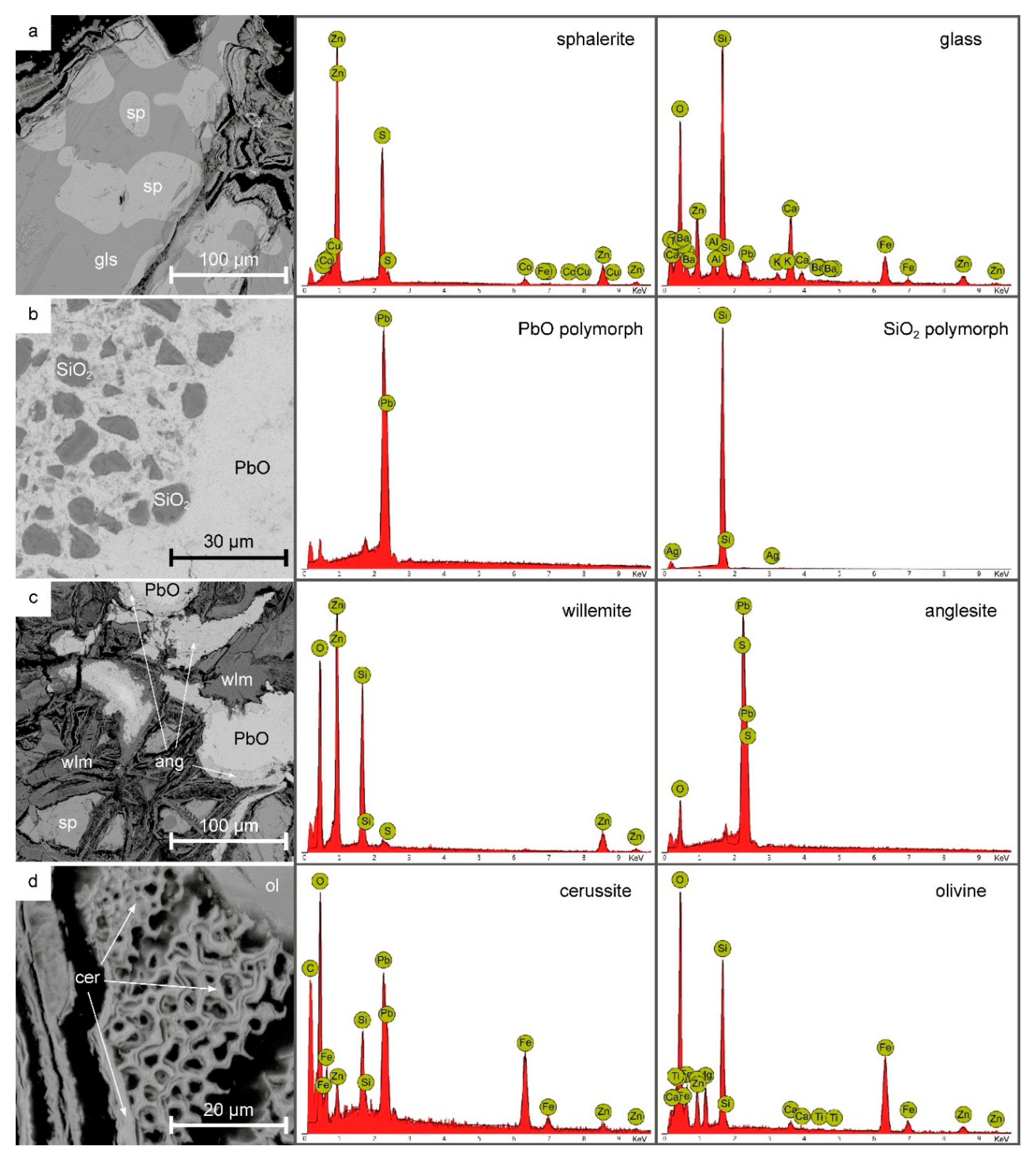

4.2.3. Weathered Slags

4.3. Chemical Composition of Slags

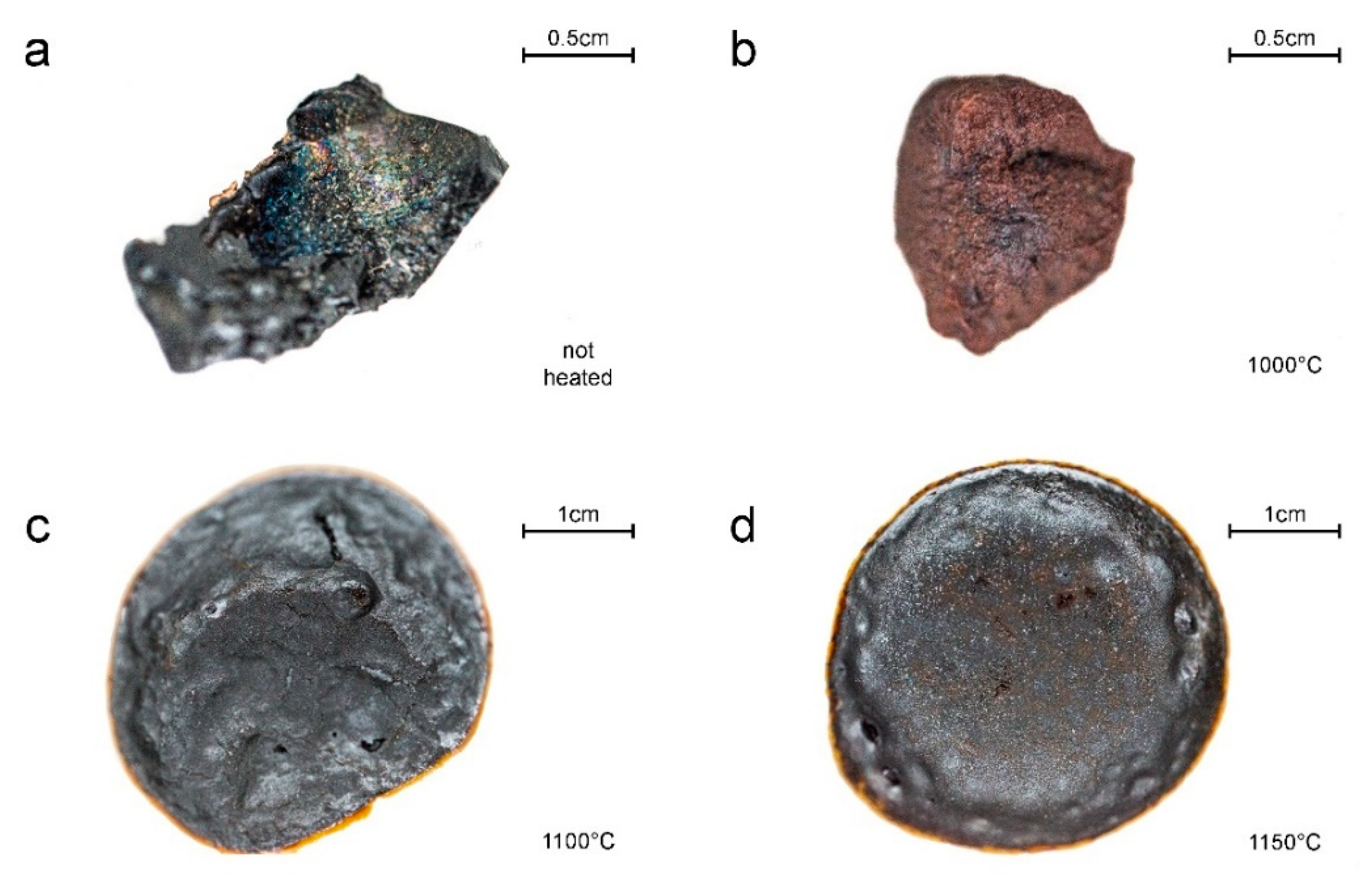

4.4. Melting Point of Slags

5. Discussion

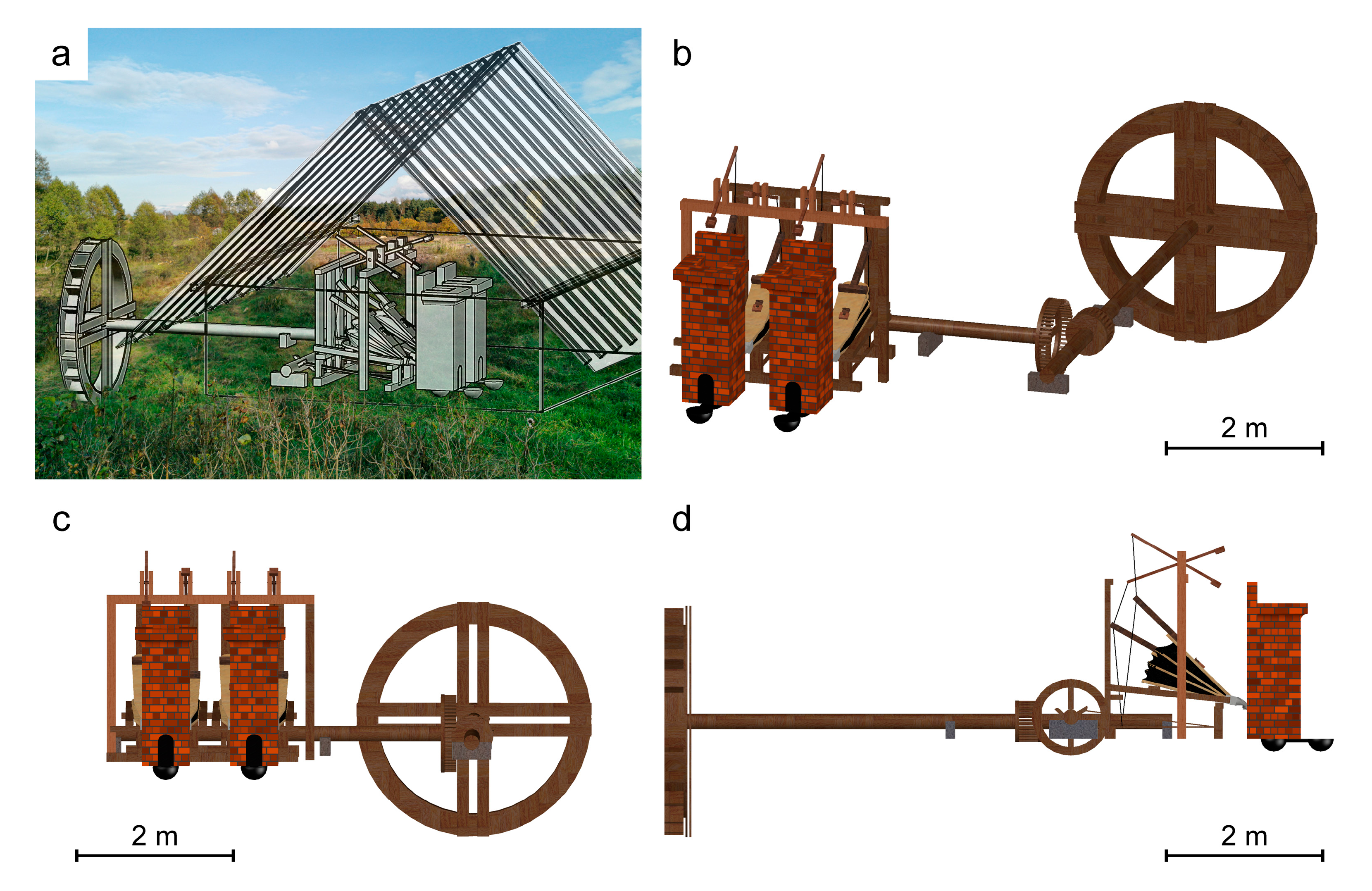

5.1. Furnace Construction

5.2. Temperature Estimates

5.3. Ores and Additions

5.4. Atmosphere

5.5. Viscosity

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Waldron, H.A. Lead poisoning in the ancient world. Med Hist. 1973, 17, 391–399. [Google Scholar] [CrossRef] [PubMed]

- Rozmus, D. Wczesnośredniowieczne Zagłębie Hutnictwa Srebra i Ołowiu na Obszarach Obecnego Pogranicza Śląska i Małopolski (Druga Połowa XI–XII/XIII Wiek); Księgarnia Akademicka: Kraków, Poland, 2014. [Google Scholar]

- Yahalom-Mack, N.; Langgut, D.; Dvir, O.; Tirosh, O.; Eliyahu-Behar, A.; Erel, Y.; Langford, B.; Frumkin, A.; Ullman, M.; Davidovich, U. The earliest lead object in the levant. PLoS ONE 2015, 10, e0142948. [Google Scholar] [CrossRef] [PubMed]

- Hansen, S.; Montero-Ruiz, I.; Rovira, S.; Steiniger, D.; Toderaş, M. The earliest lead ore processing in Europe. 5th millennium BC finds from Pietrele on the Lower Danube. PLoS ONE 2019, 14, e0214218. [Google Scholar] [CrossRef] [PubMed]

- Krzywy, I.; Krzywy, E.; Pastuszak-Gabinowska, M.; Brodkiewicz, A. Ołów-Czy jest się czego obawiać. Rocz. Pomor. Akad. Med. W Szczec. 2010, 56, 118–128. [Google Scholar]

- Retief, F.P.; Cilliers, L. Lead poisoning in ancient Rome. Acta Theol. 2006, 26, 147–164. [Google Scholar] [CrossRef]

- Jerome, O.N. Lead and Lead Poisoning in Antiquity; Wiley: Amsterdam, The Netherlands, 1983. [Google Scholar]

- Cabała, J.; Warchulski, R.; Rozmus, D.; Środek, D.; Szełęg, E. Pb-rich slags, minerals, and pollution resulted from a medieval Ag-Pb smelting and mining operation in the Silesian-Cracovian region (southern Poland). Minerals 2020, 10, 28. [Google Scholar] [CrossRef]

- Mendecki, M.J.; Warchulski, R.; Szczuka, M.; Środek, D.; Pierwoła, J. Geophysical and petrological studies of the former lead smelting waste dump in Sławków, Poland. J. Appl. Geophys. 2020, 179, 104080. [Google Scholar] [CrossRef]

- Ettler, V.; Červinka, R.; Johan, Z. Mineralogy of medieval slags from lead and silver smelting (Bohutín, Příbram district, Czech Republic): Towards estimation of historical smelting conditions. Archaeometry 2009, 51, 987–1007. [Google Scholar] [CrossRef]

- Anguilano, L.; Timberlake, S.; Rehren, T. An early medieval lead-smelting bole from Banc Tynddol, Cwmystwyth, Ceredigion. Hist. Metall. 2010, 19, 85–103. [Google Scholar]

- Ströbele, F.; Wenzel, T.; Kronz, A.; Hildebrandt, L.H.; Markl, G. Mineralogical and geochemical characterization of high-medieval lead-silver smelting slags from Wiesloch near Heidelberg (Germany)—An approach to process reconstruction. Archaeol. Anthropol. Sci. 2010, 2, 191–215. [Google Scholar] [CrossRef][Green Version]

- Kupczak, K.; Warchulski, R.; Dulski, M.; Środek, D. Chemical and Phase Reactions on the Contact between Refractory Materials and Slags, a Case from the 19th Century Zn-Pb Smelter in Ruda Śląska, Poland. Minerals 2020, 10, 1006. [Google Scholar] [CrossRef]

- Ploquin, A.; Allée, P.; Bailly-Maître, M.-C.; Baron, S.; de Beaulieu, J.-L.; Carignan, J.; Laurent, S.; de Veslud, C.L.C.; Lavoie, M.; Pulido, M. Medieval lead smelting on the Mont Lozère, southern France. In Proceedings of the Archaeometallurgy in Europe: International Conference, Milan, Italy, 24–26 September 2003; pp. 635–644. [Google Scholar]

- Warchulski, R.; Mendecki, M.; Gawęda, A.; Sołtysiak, M.; Gadowski, M. Rainwater-induced migration of potentially toxic elements from a Zn-Pb slag dump in Ruda Śląska in light of mineralogical, geochemical and geophysical investigations. Appl. Geochem. 2019, 109, 104396. [Google Scholar] [CrossRef]

- Tyszka, R.; Kierczak, J.; Pietranik, A.; Ettler, V.; Mihaljevič, M. Extensive weathering of zinc smelting slag in a heap in Upper Silesia (Poland): Potential environmental risks posed by mechanical disturbance of slag deposits. Appl. Geochem. 2014, 40, 70–81. [Google Scholar] [CrossRef]

- Ettler, V.; Legendre, O.; Bodénan, F.; Touray, J.-C. Primary phases and natural weathering of old lead–zinc pyrometallurgical slag from Príbram, Czech Republic. Can. Mineral. 2001, 39, 873–888. [Google Scholar] [CrossRef]

- Warchulski, R.; Gawęda, A.; Kupczak, K.; Banasik, K.; Krzykawski, T. Slags from Ruda Śląska, Poland as a large-scale laboratory for the crystallization of rare natural rocks: Melilitolites and paralavas. Lithos 2020, 372–373, 105666. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V. Possible Uses of Steelmaking Slag in Agriculture: An Overview; Intech Open Access Publisher: London, UK, 2012; pp. 335–356. [Google Scholar]

- Geiseler, J. Use of steelworks slag in Europe. Waste Manag. 1996, 16, 59–63. [Google Scholar] [CrossRef]

- Warchulski, R. Zn-Pb slag crystallization: Evaluating temperature conditions on the basis of geothermometry. Eur. J. Mineral. 2016, 28, 375–384. [Google Scholar] [CrossRef]

- Agricola, G. De Re Metallica; Muzeum Karkonoskie w Jeleniej Górze: Jelenia Góra, Poland, 2000. [Google Scholar]

- Chiarantini, L.; Benvenuti, M.; Costagliola, P.; Fedi, M.E.; Guideri, S.; Romualdi, A. Copper production at Baratti (Populonia, southern Tuscany) in the early Etruscan period (9th–8th centuries BC). J. Archaeol. Sci. 2009, 36, 1626–1636. [Google Scholar] [CrossRef]

- Ettler, V.; Johan, Z.; Zavřel, J.; Wallisová, M.S.; Mihaljevič, M.; Šebek, O. Slag remains from the Na Slupi site (Prague, Czech Republic): Evidence for early medieval non-ferrous metal smelting. J. Archaeol. Sci. 2015, 53, 72–83. [Google Scholar] [CrossRef]

- Chirikure, S. Geochemistry of ancient metallurgy: Examples from Africa and elsewhere. In Treatise on Geochemistry, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 169–189. [Google Scholar]

- Warchulski, R.; Juszczuk, P.; Gawȩda, A. Geochemistry, petrology and evolutionary computations in the service of archaeology: Restoration of the historical smelting process at the Katowice-Szopienice site. Archaeol. Anthropol. Sci. 2018, 10, 1023–1035. [Google Scholar] [CrossRef]

- Kierczak, J.; Pietranik, A. Mineralogy and composition of historical Cu slags from the Rudawy Janowickie Mountains, southwestern Poland. Can. Mineral. 2011, 49, 1281–1296. [Google Scholar] [CrossRef]

- Tumiati, S.; Casartelli, P.; Mambretti, A.; Martin, S.; Frizzo, P.; Rottoli, M. The ancient mine of Servette (Saint-Marcel, Val d’Aosta, Western Italian Alps): A mineralogical, metallurgical and charcoal analysis of furnace slags. Archaeometry 2005, 47, 317–340. [Google Scholar] [CrossRef]

- Toffolo, L.; Addis, A.; Martin, S.; Nimis, P.; Rottoli, M.; Godard, G. The Misérègne slag deposit (Valle d’Aosta, Western Alps, Italy): Insights into (pre-) Roman copper metallurgy. J. Archaeol. Sci. Rep. 2018, 19, 248–260. [Google Scholar] [CrossRef]

- Kądziołka, K.; Pietranik, A.; Kierczak, J.; Potysz, A.; Stolarczyk, A. Towards better reconstruction of smelting temperatures: Methodological review and the case of historical K-rich Cu-slags from the Old Copper Basin, Poland. J. Archaeol. Sci. 2020, 118, 105142. [Google Scholar] [CrossRef]

- Manasse, A.; Mellini, M. Chemical and textural characterisation of medieval slags from the Massa Marittima smelting sites (Tuscany, Italy). J. Cult. Herit. 2002, 3, 187–198. [Google Scholar] [CrossRef]

- Manasse, A.; Mellini, M. Archaeometallurgic slags from Kutná Hora. N. Jahrb. Mineral. Mon. 2002, 2002, 369–384. [Google Scholar] [CrossRef]

- Benvenuti, M.; Orlando, A.; Borrini, D.; Chiarantini, L.; Costagliola, P.; Mazzotta, C.; Rimondi, V. Experimental smelting of iron ores from Elba Island (Tuscany, Italy): Results and implications for the reconstruction of ancient metallurgical processes and iron provenance. J. Archaeol. Sci. 2016, 70, 1–14. [Google Scholar] [CrossRef]

- Saez, R.; Nocete, F.; Nieto, J.M.; Capitan, M.A.; Rovira, S. The extractive metallurgy of copper from cabezo Jure, huelva, Spain: Chemical and mineralogical study of slags dated to the third millenium B.C. Can. Mineral. 2003, 41, 627–638. [Google Scholar] [CrossRef]

- Tropper, P.; Krismer, M.; Goldenberg, G. Recent and ancient copper production in the lower inn valley. An overview of prehistoric mining and primary copper metallurgy in the brixlegg mining district. Mitt. Osterr. Mineral. Ges. 2017, 163, 97–115. [Google Scholar]

- Morawiec, J. Szlak handlowy Kijów-Kraków-Praga a ziemie nad Przemszą i Brynicą w IX-XI wieku. In Osadnictwo nad Przemszą i Brynicą w Średniowieczu; Sperka, J., Witkowski, S., Eds.; Polskie Towarzystwo Historyczne, Oddział w Cieszynie: Cieszyn, Poland, 2005; pp. 89–100. [Google Scholar]

- Kownacki, H. O Starozytnosci Kopalni Kruszcow Wyrabiania Metallow Czyli Robot Gorniczych w Kluczu Sławkowskim, Dobrach Niegdyś do Biskupstwa Krakowskiego Należących; i w Całey Tegoż Klucza Okolicy, w Znacznoy Części Powiatu Krakowskiego, Graniczący z Szląskiem; Drukarnia Korpusu Kadetów: Warszawa, Poland, 1791. [Google Scholar]

- Cabała, J.; Żogała, B.; Dubiel, R. Geochemical and geophysical study of historical Zn-Pb ore processing waste dump areas (southern Poland). Pol. J. Environ. Stud. 2008, 17, 693–700. [Google Scholar]

- Cabała, J. Development of Oxidation in Zn-Pb Deposits in Olkusz Area. Mineral Deposits at the Beginning of the 21st Century; Balkema Publ.: Kraków, Poland, 2001; pp. 121–124. [Google Scholar]

- Witkowski, S.; Krajniewski, J. Inwentarz i Lustracje Klucza Sławkowskiego z XVII i XVIII Wieku; Muzeum Miejskie “Sztygarka”: Dąbrowa Górnicza, Poland, 2013. [Google Scholar]

- Geoportal. Available online: https://www.geoportal.gov.pl (accessed on 10 October 2020).

- Openstreetmap. ©OpenStreetMap Contributors under the Open Database License. Available online: https://www.openstreetmap.org (accessed on 10 October 2020).

- Rozmus, D. Wokół Agricoli, czyli znaleziska archeologiczne średniowiecznych i nowożytnych reliktów górnictwa i hutnictwa kruszców. In Z Notatnika Agricoli, Czyli u Źródeł Górnictwa Kruszcowego na Złożach Śląsko-Krakowskich; Rams, A., Ed.; Muzeum Miasta Jaworzna: Jaworzno, Poland, 2016. [Google Scholar]

- Pubchem. Available online: https://www.pubchem.ncbi.nlm.nih.gov/ (accessed on 2 October 2020).

- Zhao, G.; Essene, E.; Zhang, Y. An oxygen barometer for rutile-ilmenite assemblages: Oxidation state of metasomatic agents in the mantle. Earth Planet. Sci. Lett. 1999, 166, 127–137. [Google Scholar] [CrossRef]

- Puziewicz, J.; Zainoun, K.; Bril, H. Primary phases in pyrometallurgical slags from a zinc-smelting waste dump, Świętochłowice, Upper Silesia, Poland. Can. Mineral. 2007, 45, 1189–1200. [Google Scholar] [CrossRef]

- Warchulski, R.; Gawęda, A.; Kądziołka-Gaweł, M.; Szopa, K. Composition and element mobilization in pyrometallurgical slags from the Orzeł Biały smelting plant in the Bytom-Piekary Śląskie area, Poland. Mineral. Mag. 2015, 79, 459–483. [Google Scholar] [CrossRef]

- Bachmann, H.G. The Identification of Slags from Archaeological Sites; Institute of Archaeology Occasional Publication: London, UK, 1982. [Google Scholar]

- Giordano, D.; Mangiacapra, A.; Potuzak, M.; Russell, J.K.; Romano, C.; Dingwell, D.B.; Di Muro, A. An expanded non-Arrhenian model for silicate melt viscosity: A treatment for metaluminous, peraluminous and peralkaline liquids. Chem. Geol. 2006, 229, 42–56. [Google Scholar] [CrossRef]

| Glassy Slag | |||||||

|---|---|---|---|---|---|---|---|

| px | px | wlm | ol | PbO | glsp | glsr | |

| SiO2 | 53.90 | 45.40 | 27.34 | 39.56 | 0.17 | 38.55 | 30.89 |

| TiO2 | bd | 0.12 | na | bd | bd | 0.17 | 0.11 |

| Al2O3 | 1.24 | 2.08 | bd | bd | bd | 2.27 | 2.71 |

| As2O3 | bd | bd | bd | bd | bd | bd | 0.17 |

| Fe2O3 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 21.27 | 11.46 |

| FeO | 7.31 | 19.28 | 18.29 | 15.10 | 0.37 | 0.00 | 0.00 |

| MnO | 0.12 | 0.29 | 0.23 | bd | bd | 0.21 | 0.17 |

| ZnO | bd | 7.34 | 50.10 | bd | 0.40 | 12.61 | 4.92 |

| PbO | na | 0.28 | bd | na | 98.18 | 8.88 | 39.51 |

| BaO | na | na | na | na | na | bd | 0.56 |

| MgO | 21.00 | 5.46 | 2.34 | 44.48 | bd | 3.07 | 0.12 |

| CaO | 16.14 | 17.67 | 0.12 | 0.50 | bd | 11.15 | 3.19 |

| K2O | bd | bd | na | bd | bd | 1.20 | 2.53 |

| Na2O | bd | 0.35 | na | bd | bd | 0.56 | 0.45 |

| P2O5 | na | 0.57 | 0.22 | na | bd | 0.74 | 0.77 |

| SO3 | na | na | na | na | na | 0.43 | 0.27 |

| Total | 99.71 | 98.84 | 98.64 | 99.64 | 99.12 | 101.11 | 97.83 |

| a.p.f.u. (atoms per formula unit) | |||||||

| Si | 1.96 | 1.88 | 0.98 | 1.00 | |||

| Ti4+ | 0.00 | 0.00 | 0.00 | 0.00 | |||

| Al | 0.05 | 0.10 | 0.00 | 0.00 | |||

| As3+ | 0.00 | 0.00 | 0.00 | 0.00 | |||

| Fe3+ | 0.00 | 0.00 | 0.00 | 0.00 | |||

| Fe2+ | 0.22 | 0.67 | 0.55 | 0.32 | |||

| Mn | 0.00 | 0.01 | 0.01 | 0.00 | |||

| Zn | 0.00 | 0.22 | 1.33 | 0.00 | |||

| Pb | 0.00 | 0.00 | 0.00 | 0.00 | |||

| Ba | 0.00 | 0.00 | 0.00 | 0.00 | |||

| Mg | 1.14 | 0.34 | 0.13 | 1.67 | |||

| Ca | 0.63 | 0.78 | 0.00 | 0.01 | |||

| K | 0.00 | 0.00 | 0.00 | 0.00 | |||

| Na | 0.00 | 0.03 | 0.00 | 0.00 | |||

| P5+ | 0.00 | 0.02 | 0.01 | 0.00 | |||

| S6+ | 0.00 | 0.00 | 0.00 | 0.00 | |||

| O2- | 6.00 | 6.00 | 4.00 | 4.00 | |||

| Crystalline Slag | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wo | wo | mll | mll | mll | rnk | pl | kfs | spl | hem | hem | gls | gls | gls | |

| SiO2 | 53.50 | 50.85 | 39.28 | 37.74 | 23.14 | 41.04 | 43.61 | 60.31 | na | na | na | 77.48 | 67.45 | 74.59 |

| TiO2 | bd | 0.10 | bd | bd | bd | bd | bd | bd | 7.74 | 7.93 | 0.52 | 0.17 | bd | 0.11 |

| Al2O3 | 0.83 | 0.11 | 1.36 | 3.16 | 27.43 | bd | 33.03 | 24.09 | 13.24 | 3.28 | 11.57 | 4.38 | 24.69 | 1.22 |

| FeO | 11.17 | 0.43 | - | - | - | 0.67 | 1.04 | 0.62 | 27.68 | - | - | - | - | - |

| Fe2O3calc | - | - | 9.28 | 8.33 | 6.25 | - | - | - | 24.45 | 83.96 | 76.46 | 6.38 | 0.62 | 11.14 |

| Cr2O3 | bd | bd | bd | bd | bd | bd | bd | bd | 10.91 | 0.10 | bd | bd | bd | bd |

| V2O3 | bd | bd | bd | bd | bd | bd | bd | bd | 2.76 | 1.92 | bd | bd | bd | bd |

| MnO | 0.27 | bd | bd | 0.17 | bd | bd | bd | bd | 0.19 | 0.65 | 0.77 | bd | bd | 0.23 |

| ZnO | 2.31 | bd | 11.92 | 8.90 | 1.15 | 0.13 | 0.45 | bd | 10.95 | 0.99 | 6.60 | 3.74 | 0.14 | 4.10 |

| PbO | 0.20 | bd | 0.60 | bd | bd | 0.11 | 0.22 | bd | na | na | na | 1.55 | bd | 0.84 |

| MgO | 1.57 | bd | 0.68 | 2.42 | 0.63 | bd | bd | bd | 0.26 | bd | 2.50 | 0.20 | bd | 0.24 |

| CaO | 27.72 | 47.40 | 35.43 | 36.98 | 39.41 | 56.82 | 18.14 | 0.89 | 1.16 | 1.12 | 0.62 | 1.67 | 0.24 | 2.62 |

| K2O | 1.02 | bd | 0.17 | 0.23 | bd | bd | 0.42 | 13.18 | na | na | na | 2.80 | 6.15 | 3.24 |

| Na2O | 0.10 | bd | 0.73 | 0.33 | bd | bd | 0.43 | bd | na | na | na | 0.30 | 0.14 | 0.31 |

| Total | 98.69 | 98.89 | 99.45 | 98.26 | 98.01 | 98.77 | 97.34 | 99.09 | 99.34 | 99.95 | 99.04 | 98.67 | 99.43 | 98.64 |

| a.p.f.u. (atoms per formula unit) | ||||||||||||||

| Si | 3.15 | 2.99 | 2.01 | 1.92 | 1.11 | 2.00 | 2.09 | 2.79 | na | na | na | |||

| Ti4+ | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.21 | 0.15 | 0.01 | |||

| Al | 0.06 | 0.01 | 0.08 | 0.19 | 1.55 | 0.00 | 1.86 | 1.31 | 0.56 | 0.10 | 0.35 | |||

| Fe2+ | 0.55 | 0.02 | 0.00 | 0.00 | 0.00 | 0.03 | 0.04 | 0.02 | 0.83 | 0.00 | 0.00 | |||

| Fe3+ | 0.00 | 0.00 | 0.36 | 0.32 | 0.22 | 0.00 | 0.00 | 0.00 | 0.66 | 1.61 | 1.47 | |||

| Cr3+ | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.31 | 0.00 | 0.00 | |||

| V3+ | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.08 | 0.04 | 0.00 | |||

| Mn | 0.01 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.01 | 0.02 | |||

| Zn | 0.10 | 0.00 | 0.45 | 0.33 | 0.04 | 0.00 | 0.02 | 0.00 | 0.29 | 0.02 | 0.12 | |||

| Pb | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | na | na | na | |||

| Mg | 0.14 | 0.00 | 0.05 | 0.18 | 0.05 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.10 | |||

| Ca | 1.75 | 2.98 | 1.94 | 2.01 | 2.03 | 2.96 | 0.93 | 0.04 | 0.04 | 0.03 | 0.02 | |||

| K | 0.08 | 0.00 | 0.01 | 0.02 | 0.00 | 0.00 | 0.03 | 0.78 | na | na | na | |||

| Na | 0.01 | 0.00 | 0.07 | 0.03 | 0.00 | 0.00 | 0.04 | 0.00 | na | na | na | |||

| O2- | 9.00 | 9.00 | 7.00 | 7.00 | 7.00 | 7.00 | 8.00 | 8.00 | 4.00 | 3.00 | 3.00 | |||

| Glassy Slag | Crystalline Slag | Weathered Slag | ||

|---|---|---|---|---|

| SiO2 | wt.% | 34.58 | 46.50 | 26.18 |

| TiO2 | wt.% | 0.11 | 0.15 | 0.10 |

| Al2O3 | wt.% | 1.81 | 3.50 | 1.17 |

| Fe2O3 | wt.% | 21.65 | 9.81 | 22.83 |

| MnO | wt.% | 0.20 | 0.18 | 0.25 |

| MgO | wt.% | 3.39 | 0.99 | 4.31 |

| CaO | wt.% | 11.19 | 30.39 | 4.48 |

| K2O | wt.% | 1.19 | 1.69 | 0.28 |

| Na2O | wt.% | 0.11 | 0.11 | 0.04 |

| P2O5 | wt.% | 0.74 | 0.22 | 0.21 |

| TOT/C | wt.% | 0.08 | 0.43 | 0.30 |

| TOT/S | wt.% | 0.62 | 0.15 | 0.90 |

| LOI | wt.% | −1.40 | 2.00 | 0.00 |

| Ag | ppm | 2 | 6 | 10 |

| As | ppm | 330 | 83 | 303 |

| Ba | ppm | 1424 | 273 | 672 |

| Cr | ppm | 48 | 67 | 208 |

| Cu | ppm | 108 | 25 | 87 |

| Pb | ppm | >100,000 | 10,707 | >100,000 |

| Sr | ppm | 384 | 109 | 120 |

| Sb | ppm | 415 | 6 | 101 |

| V | ppm | 52 | 137 | 18 |

| Zn | ppm | 132,504 | 28,276 | 214,973 |

| Zr | ppm | 73 | 73 | 151 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warchulski, R.; Szczuka, M.; Kupczak, K. Reconstruction of 16th–17th Century Lead Smelting Processes on the Basis of Slag Properties: A Case Study from Sławków, Poland. Minerals 2020, 10, 1039. https://doi.org/10.3390/min10111039

Warchulski R, Szczuka M, Kupczak K. Reconstruction of 16th–17th Century Lead Smelting Processes on the Basis of Slag Properties: A Case Study from Sławków, Poland. Minerals. 2020; 10(11):1039. https://doi.org/10.3390/min10111039

Chicago/Turabian StyleWarchulski, Rafał, Monika Szczuka, and Krzysztof Kupczak. 2020. "Reconstruction of 16th–17th Century Lead Smelting Processes on the Basis of Slag Properties: A Case Study from Sławków, Poland" Minerals 10, no. 11: 1039. https://doi.org/10.3390/min10111039

APA StyleWarchulski, R., Szczuka, M., & Kupczak, K. (2020). Reconstruction of 16th–17th Century Lead Smelting Processes on the Basis of Slag Properties: A Case Study from Sławków, Poland. Minerals, 10(11), 1039. https://doi.org/10.3390/min10111039