Self-Sensing Alkali-Activated Materials: A Review

Abstract

1. Introduction

2. Alkali Activated Material Sensors

2.1. Fabrication

2.1.1. Material Binder

- i.

- a solid aluminosilicate precursor, typically metakaolin (calcined clay), fly ash or ground granulated blast furnace slag (GGBFS) [30] and;

- ii.

- an alkaline solution, which is usually a mixture of an alkali hydroxide (MOH) and a silicate solution (M2O∙rSiO2) typically sodium (Na+) or potassium based (K+) [31].

2.1.2. Fillers and Additives

- (a)

- Pastes/binders: precursor + alkaline solution

- (b)

- Mortars: precursor + alkaline solution + fine aggregate (typically sand)

- (c)

- Concretes: precursor + alkaline solution + fine aggregate + coarse aggregate

- A.

- B.

2.1.3. Sensor Fabrication

2.2. Electrical (Ionic) Conductivity: Mechanisms

2.2.1. Overview of Mechanisms

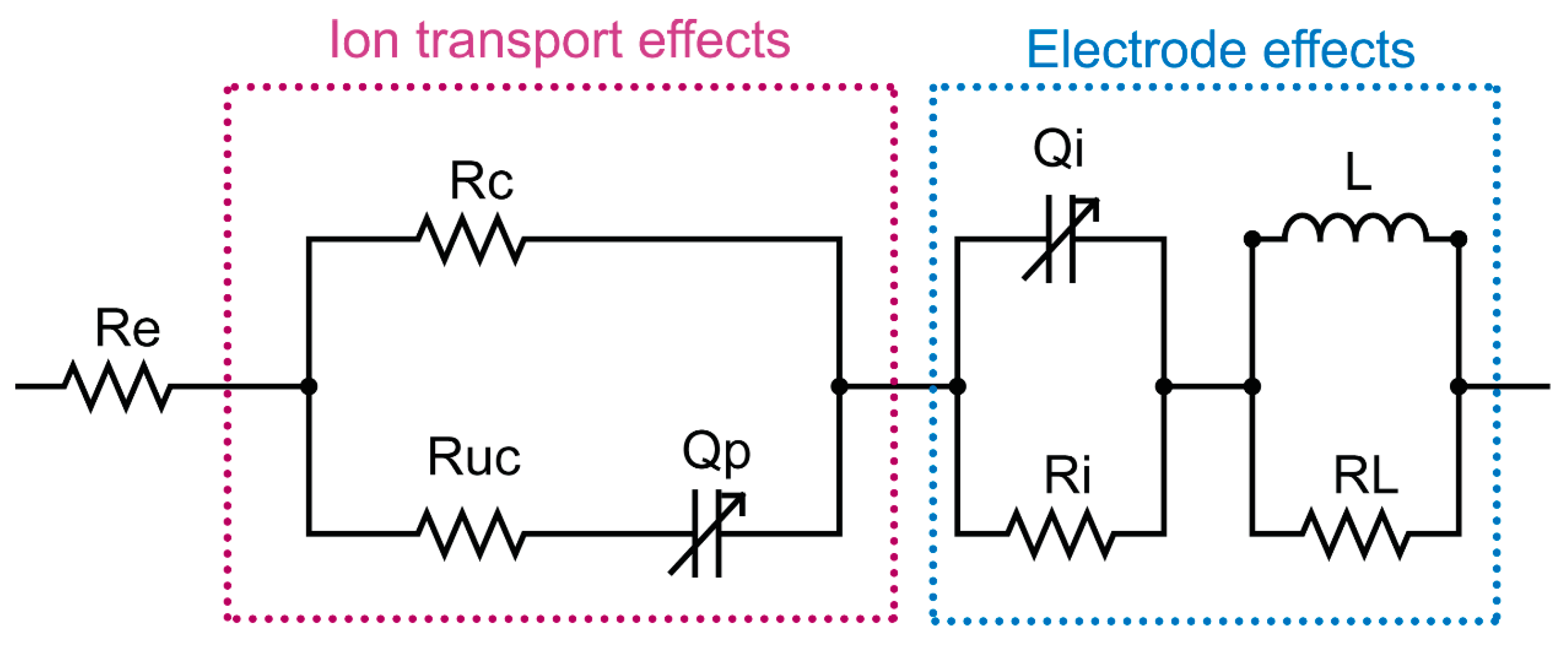

2.2.2. Equivalent Circuits

- i.

- The resistance of the electrolyte, Re: refers to the liquid electrolyte in the AAM pores and is dependent on the number of ions (which is based on the concentration of the volume of the AAM) and ion mobility (which is a function of ion concentration, alkali metal and temperature).

- ii.

- The connected pore resistance, Rc, and unconnected pore resistance, Ruc: are the resistance of the ion conducting pathways between the connected (percolating) and unconnected pores in the AAM matrix.

- iii.

- An interface resistance, Ri: refers to the specimen- electrode interface in which a single layer of Na+ ions in the AAM will adhere to the negatively charged surface of the metal electrode. This layer acts as a dielectric, separating the electrons in the metal electrode from the Na+ in the AAM [69,70].

- iv.

- Qi and Qp are double-layer capacitances: this is an imperfect capacitor, or “constant phase element” used to describe the net result of ion dynamics in electrochemical systems.

- v.

- L refers to inductance effects: that are observed at high frequencies due to factors such as electrode cross-talk, particularly when measured currents are small and due to relaxation of adsorbates on the electrodes.

2.2.3. The Impact of Conductive Fillers

2.3. Electrical Impedance

2.4. Electrical (Ionic) Conductivity: Reported Magnitudes

2.4.1. Without Conductive Fillers

2.4.2. With Conductive Fillers

- On the contrary, Behera et al. [59] added over 10% by volume carbon microfibre to metakaolin AAM, and found conductivity only increased from 10−3 S/m to 10−2 S/m.

2.5. Electrode Layout

2.5.1. Serial Arrangement

2.5.2. Van der Pauw Arrangement

2.5.3. Embed or Surface Mount

2.6. Sensor Interrogation

3. Strain Sensing

3.1. Loading Schemes

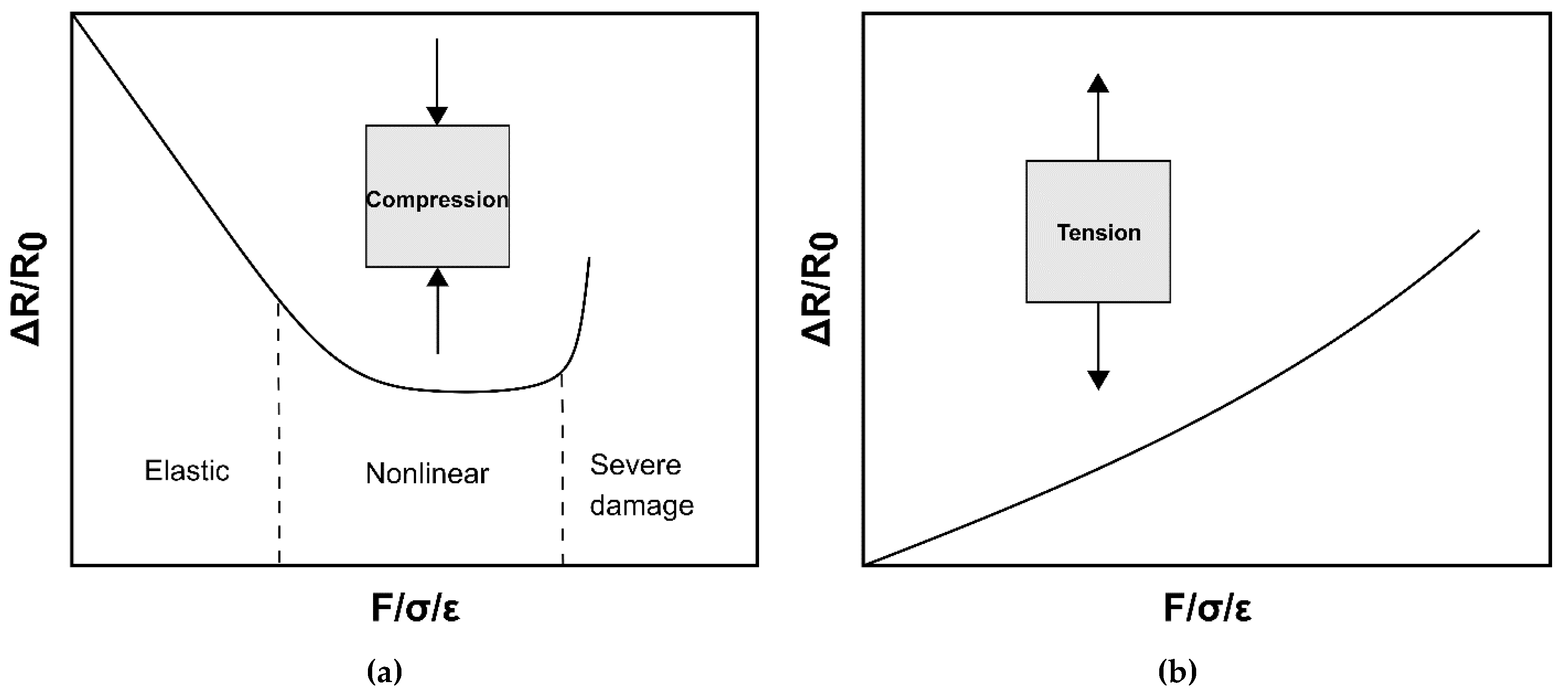

3.1.1. Monotonic Loading

- (1)

- Elastic: The first region of monotonic loading coincides with the elastic region of the substrate. In this zone, the relationship between change in resistance and applied strain is considered to be linear [73,121] or of a linear-like function [122,123]. The sensor’s performance is usually at its peak within this region. In various cases, a nonlinear segment with low sensitivity at the very early stages of loading has been detected [55,86] which has also been regarded as a separate region in monotonic compression altogether [124]. This has led to applications commencing above zero [24,55,86]. While this has been attributed to contact resistance between the substrate and electrodes in two-probe sensing [86], this behaviour has also been observed in four-probe sensing applications as well [55].

- (2)

- Non-linear: In the second region of monotonic loading, the resistance of the materials continues to change, however the sensing performance is generally lower and the response at this stage is nonlinear which eventually plateaus (small-no change for load applied) [117,125]. At this stage damage to the matrix has begun in the form of cracks and defects. This leads to the destruction and reconstruction of the conductive network and ultimately reaching a state of balance [2,126].

- (3)

- Severe damage: Lastly, the third region of monotonic compression is associated with severe damage to the matrix as the cracks continue to expand and the performance is being compromised. At this juncture an abrupt increase in resistance is typically expected with increasing load [126]. The substrate in this instance essentially loses its sensing capabilities, and resistance may not even begin to return to its original baseline value once load is removed [126,127].

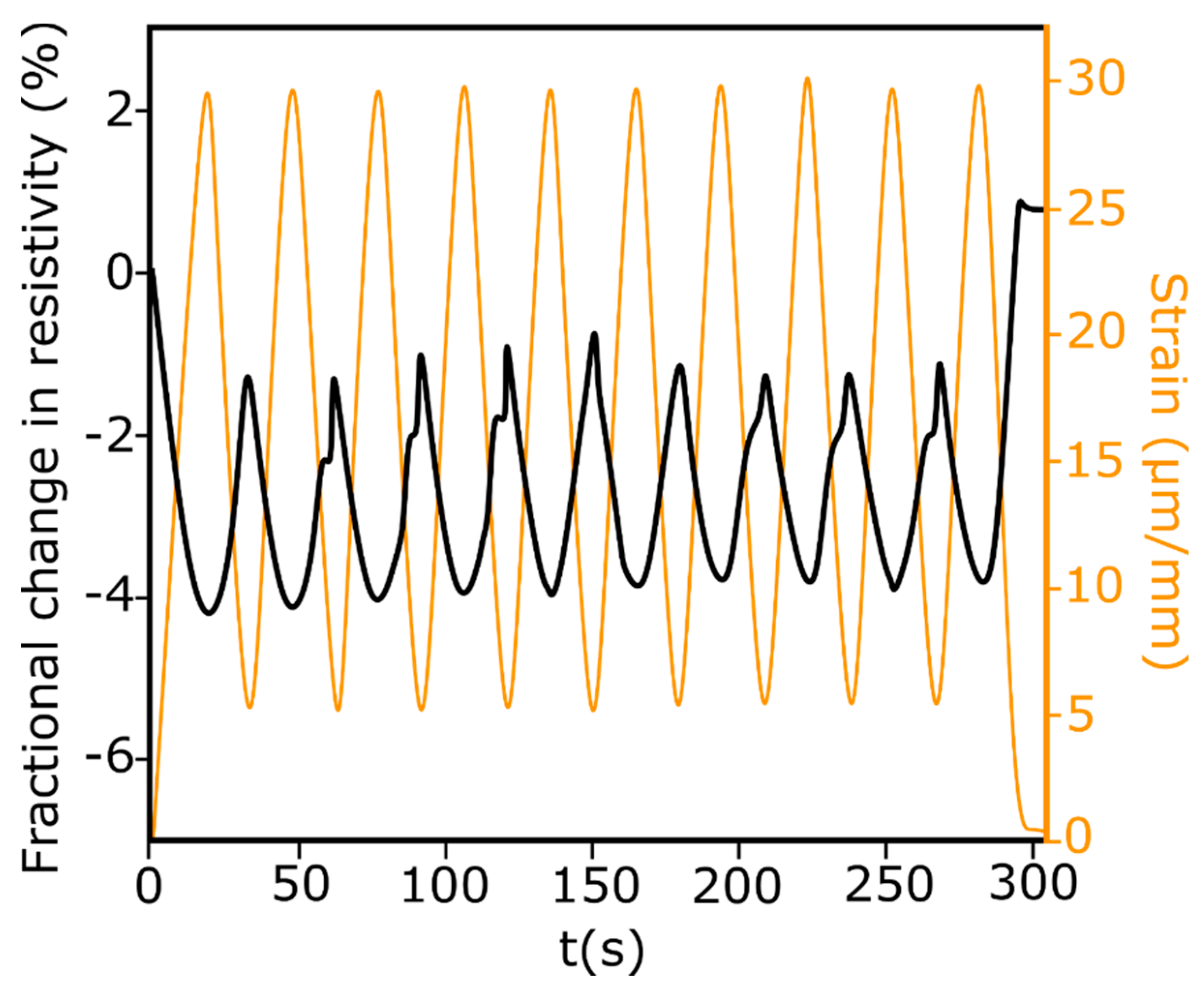

3.1.2. Cyclic Loading

3.1.3. Other Strain Responses in AAM Samples

3.2. Gauge Factors

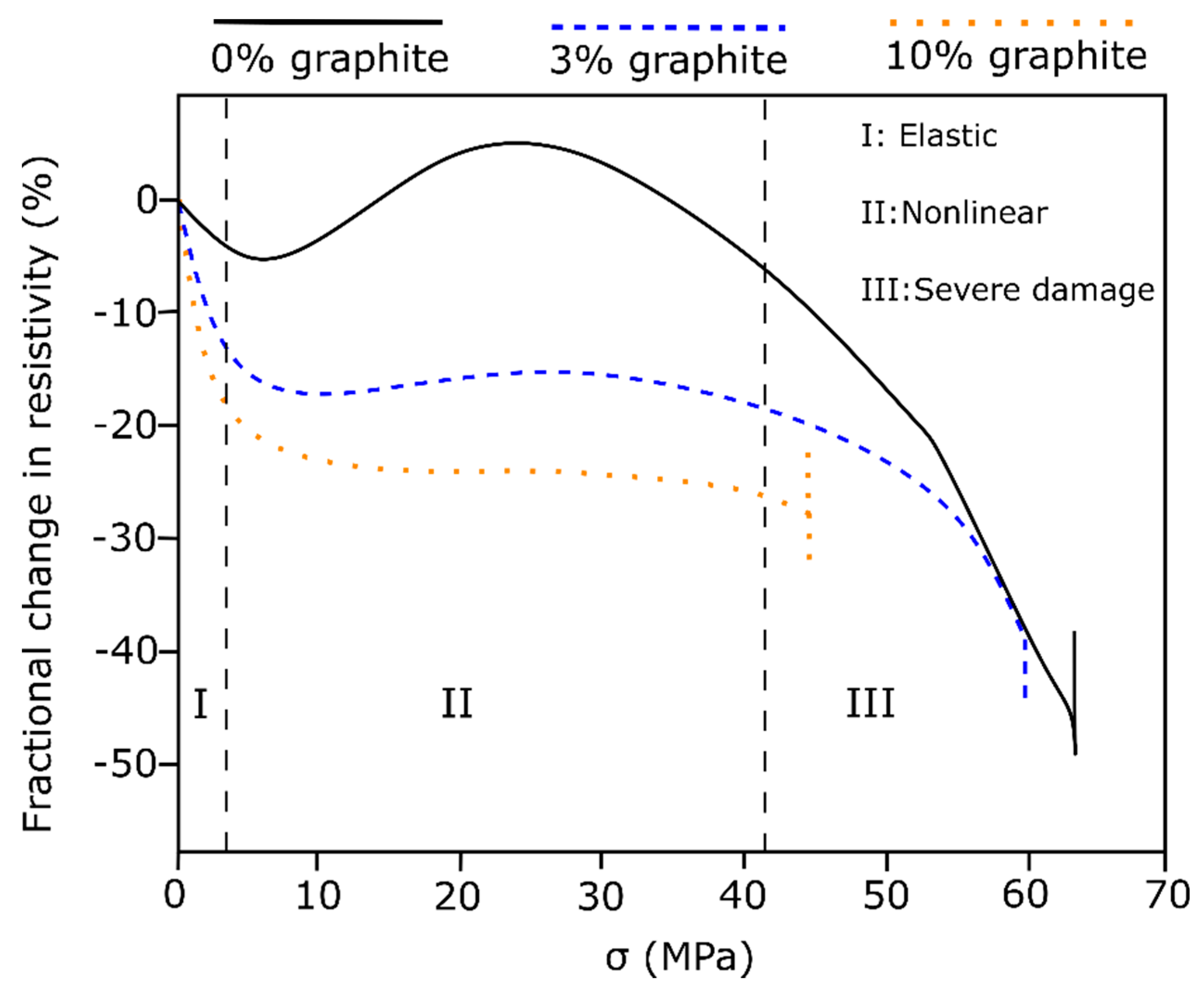

3.3. Conductive Filler Applications

- For a graphene-based application, Saafi et al. [57] reported that the electrical response of graphene composites is attributed to the contact resistance of the overlapped graphene filler. When the contact area between the graphene sheets increased under compression, the resistance of the material would decrease. Similar behaviour was also reported by Lamuta et al. [55] in a graphene metakaolin-based application under compression.

- Similar to carbon fibres, in carbon nanotube applications the resistance of the matrix is influenced by the distances between the filler under mechanical load [23,58]. Coating carbon nanotubes with SiO2 was reported to result into a better conductive network, due to greater dispersion, allowing for the greater detection of cracks [23].

- For graphite powder and carbon black the changes in resistance have been attributed to changes in the conductive path the current follows in the matrix [51,52]. Chen et al. [141] coated metakaolin AAM with a conductive polymer PEDOT:PSS solution. The sample was subjected to natural and artificial cracking and tested under uniaxial compression. The conducting mechanism proposed by Chen et al. was coupled-mechanical-conductive contact mechanism based on the Hertizan contact model between cracks.

3.4. Filler Free Applications

- I.

- Lamuta et al. [22] proposed a chemical-physical model to explain the piezoelectric effect of AAM based on ionic mobility due to the presence of water. This effect is promoted by the migration of mobile hydrated cations under loading in the pores of the AAM matrix, thus creating a charge imbalance and local dipoles. The Na+ ions balance the single negative charge associated with aluminium (III) in tetrahedral coordination. In completely dry samples, the AAM did not exhibit any piezoelectric effect due to the absence of water. Hydration reduces the cation–lattice electrostatic interaction through cation–water interaction, thus resulting in a weaker bond that promotes the Na+ migration away from the framework wall during mechanical loading and therefore creates the charge imbalance.

- II.

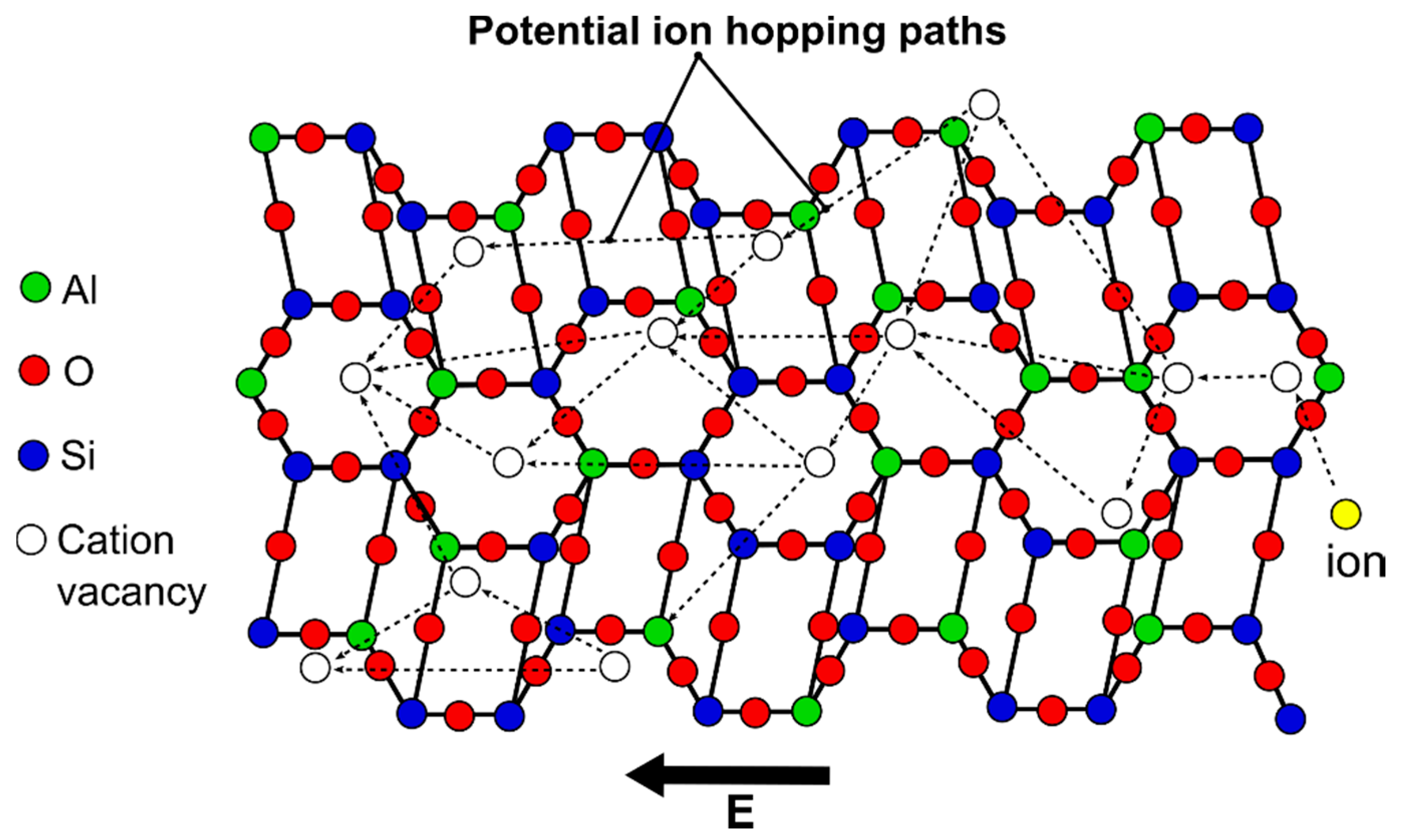

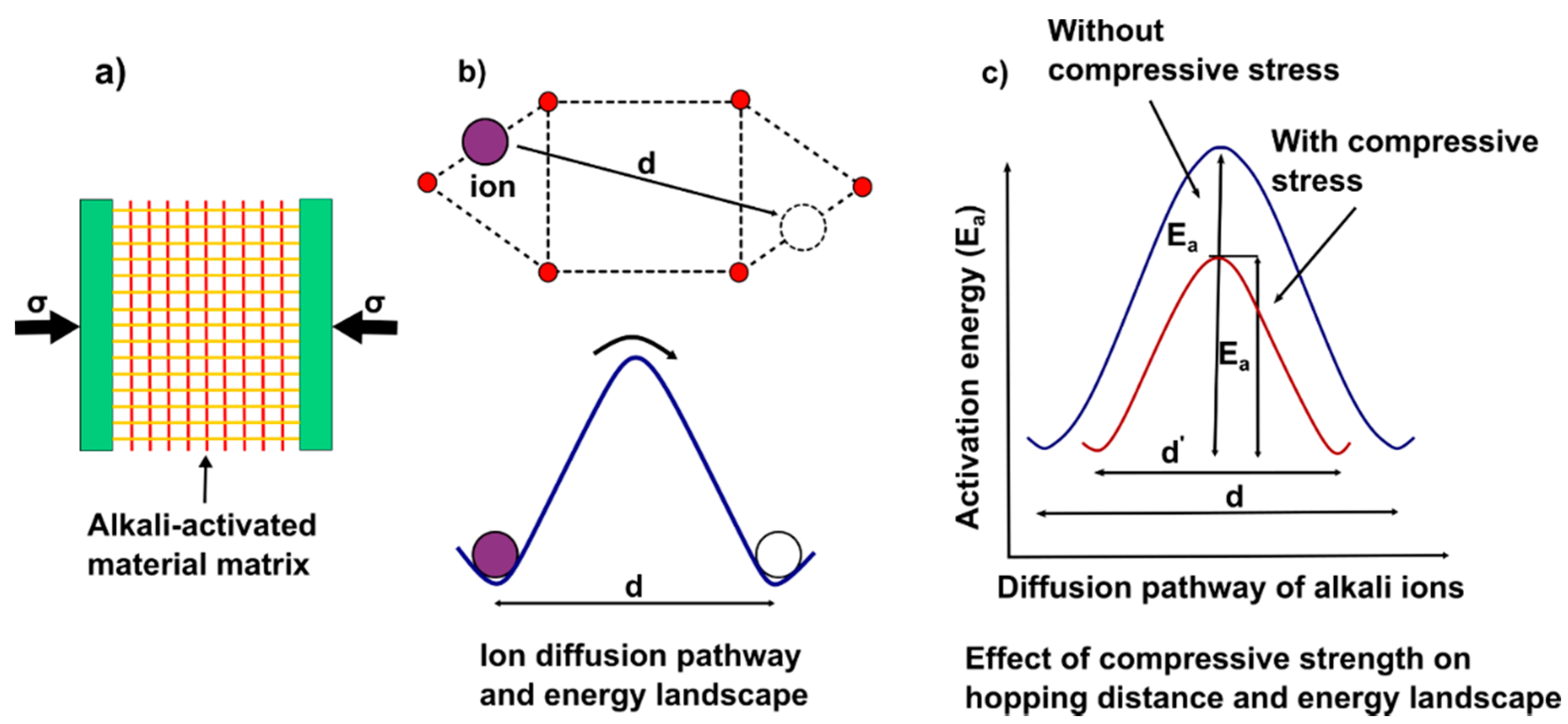

- Saafi et al. [24,92] stated that the alkali ions diffuse in the structure by hopping through vacancy sites to balance the negative charge on the AlO4− tetrahedral. It was hypothesized that the induced load to the substrate changes the lattice structure and alters the ion diffusion paths (essentially the distances between electron holes) in the matrix. As a result, it has been speculated that this changes the activation energy barrier the ion is required to overcome to accommodate a vacant site. As the hopping distance changes this subsequently affects the ion movement inside the AAM and as a result the resistance of the substrate changes accordingly. Figure 7 presents a schematic drawing of the ion hopping mechanism that can be found in AAM and Figure 8 explains the ion diffusion paths in AAM under applied stress.

- III.

- Bi et al. [23] mentioned that the water in the matrix facilitates the migration of Na+ ions within the framework during mechanical loading which leads into ionic conduction. As ionic conduction is associated with the movement of hydrated Na+ ions, the formation of the cracks in the substrate during loading potentially hindered the migration process.

- IV.

- Moreover, in the case of slag-based AAM it was reported by Rovanik et al. [86] that apart from the alkali metals ions in the matrix, the Fe ions found in the precursor also have a positive effect on the sensing capability of the substrate. This ultimately led to a combination of ionic, contact and tunneling conduction. This was explained due to the fact that the Fe content in the slag precursor does not always contribute to the overall chemistry of the binder and is passivated in the pore solution [144]. However, that is not to say that all Fe does not contribute to alkaline activation. Slag with high Fe content has seen successful applications in the formulation of AAM [145,146,147]. As a result, this conduction mechanism remains unproven.

4. Temperature Sensing

4.1. Overview

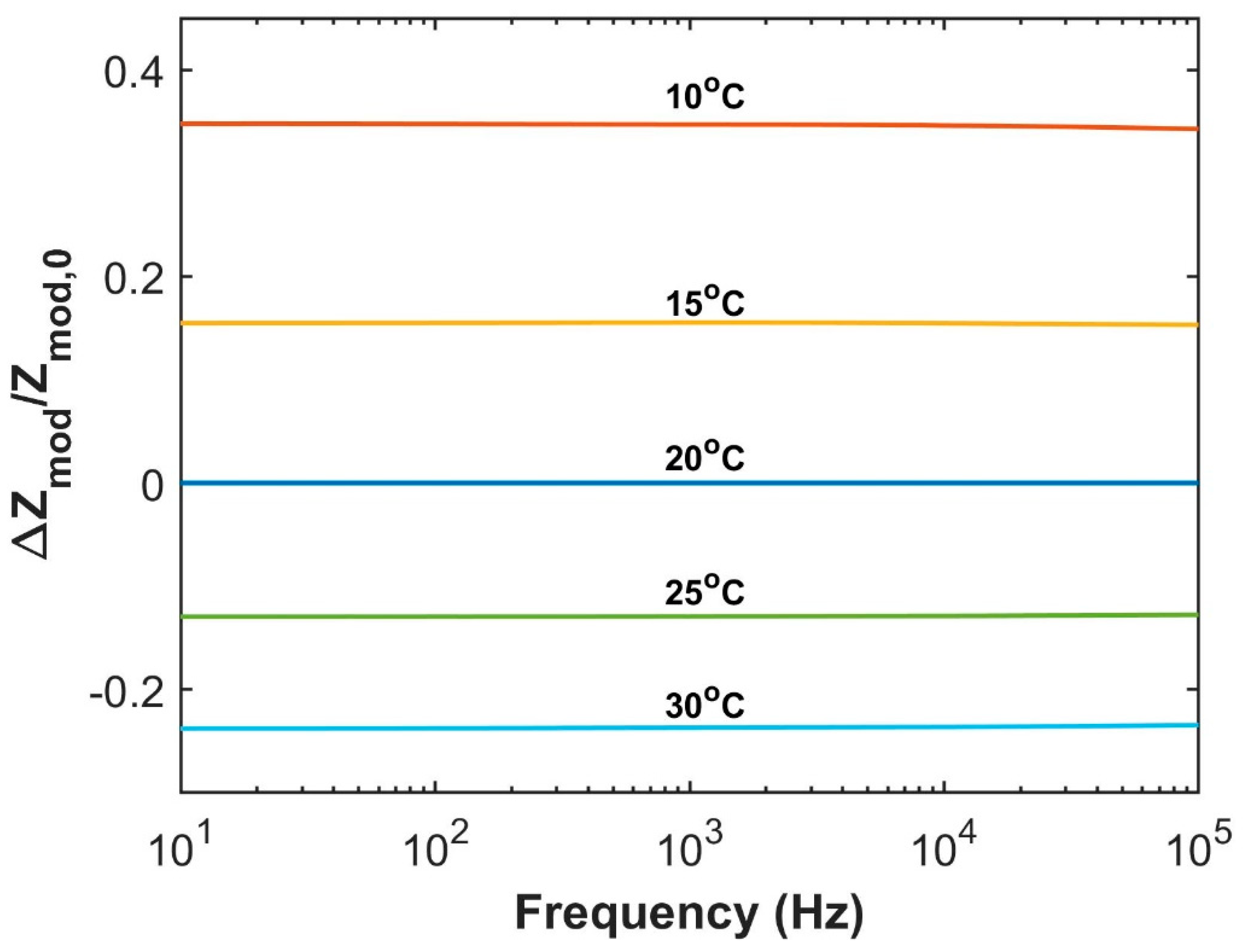

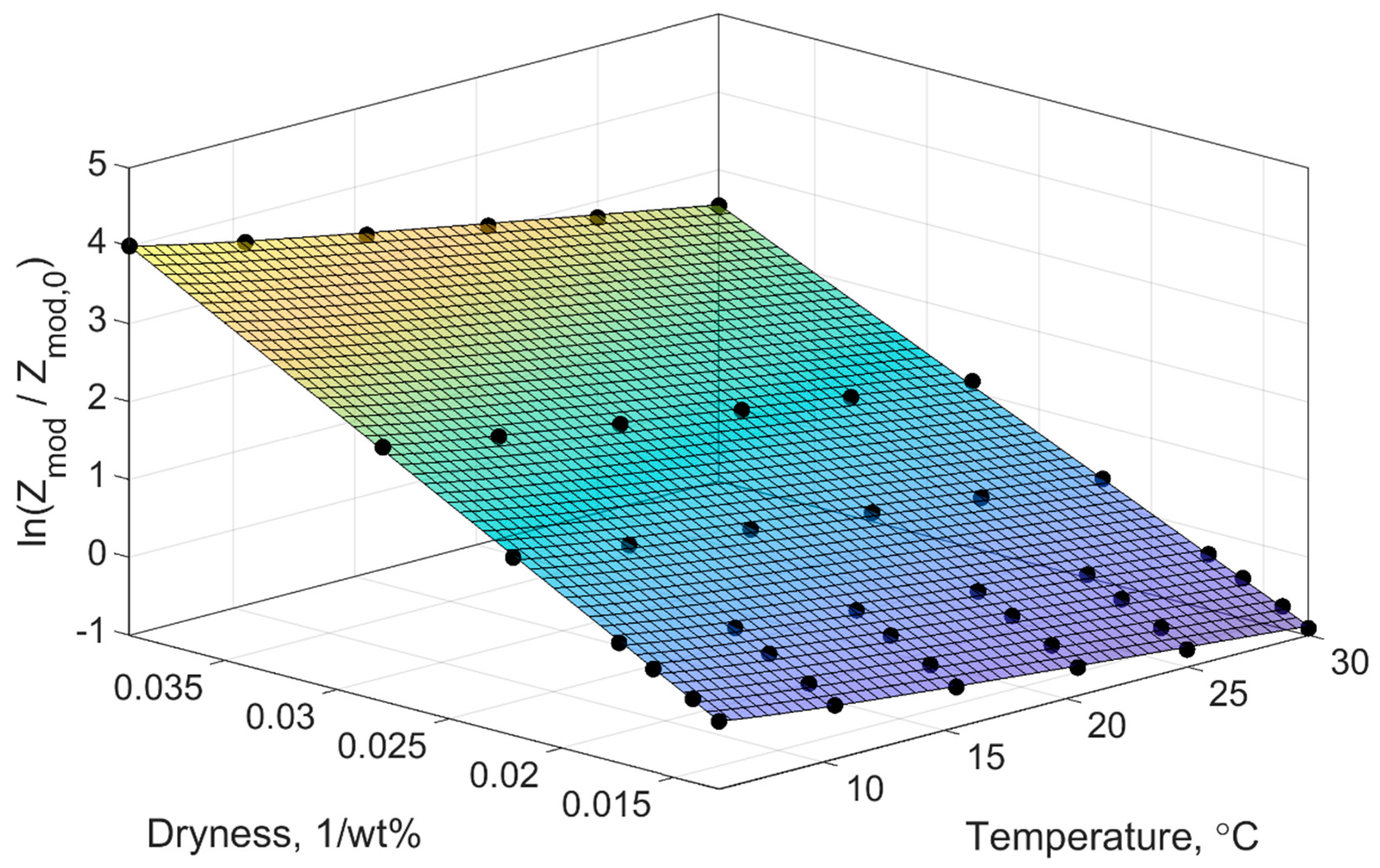

Sensing Behaviour at Different Temperatures

4.2. Temperature Sensing: Characterization Equation

4.3. Temperature Sensitivity Values

5. Moisture Sensing

6. Future Work and Recommendations

- AAM sensor response to humidity has not been investigated

- while strain applications exist, they have primarily focused on uniaxial loading: multiaxial applications are quite limited.

- the combined effects of multiple phenomena on the sensing performance of AAM have not been looked into apart from combined moisture and temperature. The impact of both moisture and temperature on strain sensitivity have not yet been explored.

- The chemical composition of all constituents should be reported where possible. A thorough mix design with both solid-liquid ratios and molar ratios of AAM should be included. The curing regime should also be clearly stated e.g., heated cured, sealed conditions etc.

- Gauge factors or common equivalent sensing performance units should be reported in all applications. For strain applications the applied strain and/or modulus of elasticity should also be provided where possible to allow for further analysis and comparisons in future applications.

- An average gauge factor/sensing performance with standard deviation and coefficient of determination should be provided instead of reporting the highest sensing performance values achieved.

- The surrounding conditions e.g., temperature and humidity should be monitored with an external sensing device to ensure a relatively constant testing environment. Strain sensing in particular can be impacted by fluctuations in temperature and humidity.

- The number of samples tested and number of measurements per sample should be reported.

- Proper insulation between the binder and the surrounding environment must be ensured throughout the entire duration of the experiment.

- The type of current, direct or alternating, should be explicitly mentioned. The frequency and sampling rate should also be reported if alternating current is used.

- The orientation of the electrodes should be consistent throughout subsequent tests. For strain sensing, the direction of the electrodes should reflect the anticipated behaviour of the sample e.g., current and voltage are parallel to the applied load for compression and perpendicular for tension.

- A period of stabilization should be allowed for samples prior to testing.

- The state of the binder e.g., dried, saturated, unsaturated etc. and the testing conditions, sealed or unsealed, should be stated.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ding, S.; Dong, S.; Ashour, A.; Han, B. Development of sensing concrete: Principles, properties and its applications. J. Appl. Phys. 2019, 126, 241101. [Google Scholar] [CrossRef]

- Tian, Z.; Li, Y.; Zheng, J.; Wang, S. A state-of-the-art on self-sensing concrete: Materials, fabrication and properties. Compos. Part B 2019, 177, 107437. [Google Scholar] [CrossRef]

- Downey, A.; D’Alessandro, A.; Laflamme, S.; Ubertini, F. Smart bricks for strain sensing and crack detection in masonry structures. Smart Mater. Struct. 2018, 27, 015009. [Google Scholar] [CrossRef]

- Meoni, A.; D’Alessandro, A.; Ubertini, F. Characterization of the strain-sensing behavior of smart bricks: A new theoretical model and its application for monitoring of masonry structural elements. Constr. Build. Mater. 2020, 250, 118907. [Google Scholar] [CrossRef]

- Kong, Q.; Fan, S.; Bai, X.; Mo, Y.L.; Song, G. A novel embeddable spherical smart aggregate for structural health monitoring: Part I. Fabrication and electrical characterization. Smart Mater. Struct. 2017, 26, 095050. [Google Scholar] [CrossRef]

- Zhao, S.; Fan, S.; Yang, J.; Kitipornchai, S. A spherical smart aggregate sensor based electro-mechanical impedance method for quantitative damage evaluation of concrete. Struct. Heal. Monit. 2019, 19, 1560–1576. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Burnham, T.; Kwon, E.; Yu, X. Integration and road tests of a self-sensing CNT concrete pavement system for traffic detection. Smart Mater. Struct. 2013, 22, 015020. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Sassani, A.; Gopalakrishnan, K.; Mina, M. Electrically-conductive asphalt mastic: Temperature dependence and heating efficiency. Mater. Des. 2018, 157, 303–313. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, H.; Ju, C.; Yang, Y. Novel selection of environment-friendly cementitious materials for winter construction: Alkali-activated slag/Portland cement. J. Clean. Prod. 2020, 258, 120592. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.; Elbatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef]

- Provis, J.L.; Arbi, K.; Bernal, S.A.; Bondar, D.; Buchwald, A.; Castel, A.; Chithiraputhiran, S.; Cyr, M.; Dehghan, A.; Dombrowski-Daube, K.; et al. RILEM TC 247-DTA round robin test: Mix design and reproducibility of compressive strength of alkali-activated concretes. Mater. Struct. Constr. 2019, 52, 1–13. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Sarker, P.K. Effect of waste glass fine aggregate on the strength, durability and high temperature resistance of alkali-activated fly ash and GGBFS blended mortar. Constr. Build. Mater. 2020, 263, 120177. [Google Scholar] [CrossRef]

- Aguirre-Guerrero, A.M.; Robayo-Salazar, R.A.; Mejía de Gutiérrez, R. Corrosion resistance of alkali-activated binary reinforced concrete based on natural volcanic pozzolan exposed to chlorides. J. Build. Eng. 2021, 33, 101593. [Google Scholar] [CrossRef]

- Komljenović, M.; Tanasijević, G.; Džunuzović, N.; Provis, J.L. Immobilization of cesium with alkali-activated blast furnace slag. J. Hazard. Mater. 2020, 388, 121765. [Google Scholar] [CrossRef]

- Nunes, V.A.; Borges, P.H.R.; Zanotti, C. Mechanical compatibility and adhesion between alkali-activated repair mortars and Portland cement concrete substrate. Constr. Build. Mater. 2019, 215, 569–581. [Google Scholar] [CrossRef]

- Biondi, L.; Perry, M.; Vlachakis, C.; Wu, Z.; Hamilton, A.; McAlorum, J. Ambient Cured Fly Ash Geopolymer Coatings for Concrete. Materials 2019, 12, 923. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Kan, L.L.; Lv, J.W.; Duan, B.B.; Wu, M. Self-healing of Engineered Geopolymer Composites prepared by fly ash and metakaolin. Cem. Concr. Res. 2019, 125, 105895. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W. Durability and life cycle evaluation of self-compacting concrete containing fly ash as GBFS replacement with alkali activation. Constr. Build. Mater. 2020, 235, 117458. [Google Scholar] [CrossRef]

- He, J.; Zhang, G.; Hou, S.; Cai, C.S. Geopolymer-Based Smart Adhesives for Infrastructure Health Monitoring: Concept and Feasibility. J. Mater. Civ. Eng. 2011, 23, 100–109. [Google Scholar] [CrossRef]

- Suweni Muntini, M.; Ahmadi, H. Performance of metakaolin geopolymer ceramic for fiber optic temperature sensor. Mater. Today Proc. 2018, 5, 15137–15142. [Google Scholar] [CrossRef]

- Lamuta, C.; Candamano, S.; Crea, F.; Pagnotta, L. Direct piezoelectric effect in geopolymeric mortars. Mater. Des. 2016, 107, 57–64. [Google Scholar] [CrossRef]

- Bi, S.; Liu, M.; Shen, J.; Hu, X.M.; Zhang, L. Ultrahigh Self-Sensing Performance of Geopolymer Nanocomposites via Unique Interface Engineering. ACS Appl. Mater. Interfaces 2017, 9, 12851–12858. [Google Scholar] [CrossRef] [PubMed]

- Saafi, M.; Piukovics, G.; Ye, J. Hybrid graphene/geopolymeric cement as a superionic conductor for structural health monitoring applications. Smart Mater. Struct. 2016, 25. [Google Scholar] [CrossRef]

- Vilaplana, J.L.; Baeza, F.J.; Galao, O.; Zornoza, E.; Garcés, P. Self-sensing properties of alkali activated blast furnace slag (BFS) composites reinforced with carbon fibers. Materials 2013, 6, 4776–4786. [Google Scholar] [CrossRef]

- Perry, M.; Saafi, M.; Fusiek, G.; Niewczas, P. Hybrid optical-fibre/geopolymer sensors for structural health monitoring of concrete structures. Smart Mater. Struct. 2015, 24, 45011. [Google Scholar] [CrossRef]

- Vlachakis, C.; Perry, M.; Biondi, L.; Mcalorum, J. 3D printed temperature-sensing repairs for concrete structures. Addit. Manuf. 2020, 34, 101238. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Tao, Z.; Wang, K. Piezoresistive properties of cement-based sensors: Review and perspective. Constr. Build. Mater. 2019, 203, 146–163. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Hu, Y.; Zhou, J.L.; Tam, V.W.Y. Review on designs and properties of multifunctional alkali-activated materials (AAMs). Constr. Build. Mater. 2019, 200, 474–489. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L. Designing precursors for geopolymer cements. J. Am. Ceram. Soc. 2008, 91, 3864–3869. [Google Scholar] [CrossRef]

- Provis, J.L. Geopolymers and other alkali activated materials: Why, how, and what? Mater. Struct. Constr. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; Van Deventer, J.S.J. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surfaces A Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Pouhet, R.; Cyr, M. Formulation and performance of flash metakaolin geopolymer concretes. Constr. Build. Mater. 2016, 120, 150–160. [Google Scholar] [CrossRef]

- Provis, J.L.; Bernal, S.A. Geopolymers and Related Alkali-Activated Materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Qureshi, M.N.; Ghosh, S. Effect of Si/Al ratio on engineering properties of alkali-activated GGBS pastes. Green Mater. 2014, 2, 123–131. [Google Scholar] [CrossRef]

- Sisol, M.; Kudelas, D.; Marcin, M.; Holub, T.; Varga, P. Statistical evaluation of mechanical properties of slag based alkali-activated material. Sustain. 2019, 11, 5935. [Google Scholar] [CrossRef]

- Jiao, Z.; Wang, Y.; Zheng, W.; Huang, W. Effect of Dosage of Alkaline Activator on the Properties of Alkali-Activated Slag Pastes. Adv. Mater. Sci. Eng. 2018, 2018, 10–12. [Google Scholar] [CrossRef]

- Aydin, S.; Baradan, B. Mechanical and microstructural properties of heat cured alkali-activated slag mortars. Mater. Des. 2012, 35, 374–383. [Google Scholar] [CrossRef]

- Tänzer, R.; Buchwald, A.; Stephan, D. Effect of slag chemistry on the hydration of alkali-activated blast-furnace slag. Mater. Struct. Constr. 2014, 48, 629–641. [Google Scholar] [CrossRef]

- Haha, M.B.; Lothenbach, B.; Le Saout, G.; Winnefeld, F. Influence of slag chemistry on the hydration of alkali-activated blast-furnace slag—Part I: Effect of MgO. Cem. Concr. Res. 2011, 41, 955–963. [Google Scholar] [CrossRef]

- Bernal, S.A.; San Nicolas, R.; Myers, R.J.; Mejía De Gutiérrez, R.; Puertas, F.; Van Deventer, J.S.J.; Provis, J.L. MgO content of slag controls phase evolution and structural changes induced by accelerated carbonation in alkali-activated binders. Cem. Concr. Res. 2014, 57, 33–43. [Google Scholar] [CrossRef]

- Park, S.; Park, H.M.; Yoon, H.N.; Seo, J.; Yang, C.-M.; Provis, J.L.; Yang, B. Hydration kinetics and products of MgO-activated blast furnace slag. Constr. Build. Mater. 2020, 249, 118700. [Google Scholar] [CrossRef]

- Haha, M.B.; Lothenbach, B.; Le Saout, G.; Winnefeld, F. Influence of slag chemistry on the hydration of alkali-activated blast-furnace slag—Part II: Effect of Al2O3. Cem. Concr. Res. 2012, 42, 74–83. [Google Scholar] [CrossRef]

- Bernal, S.A.; San Nicolas, R.; Van Deventer, J.S.J.; Provis, J.L. Alkali-activated slag cements produced with a blended sodium carbonate/sodium silicate activator. Adv. Cem. Res. 2016, 28, 262–273. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L.; Fernández-Jiménez, A.; Krivenko, P.V.; Kavalerova, E.; Palacios, M.; Shi, C. Binder Chemistry—High-Calcium Alkali-Activated Materials. In Alkali Activated Materials State-of-the-Art Report, RILEM TC 224-AAM.; Provis, J.L., van Deventer, J.S.J., Eds.; RILEM: Dordrecht, The Netherlands; Heidelberg, Germany; New York, NY, USA; London, UK, 2014; pp. 59–91. ISBN 978-94-007-7672-2. [Google Scholar]

- Kim, G.M.; Yang, B.J.; Cho, K.J.; Kim, E.M.; Lee, H.K. Influences of CNT dispersion and pore characteristics on the electrical performance of cementitious composites. Compos. Struct. 2017, 164, 32–42. [Google Scholar] [CrossRef]

- Candamano, S.; Sgambitterra, E.; Lamuta, C.; Pagnotta, L.; Chakraborty, S.; Crea, F. Graphene nanoplatelets in geopolymeric systems: A new dimension of nanocomposites. Mater. Lett. 2019, 236, 550–553. [Google Scholar] [CrossRef]

- Rovnaník, P.; Mizerová, C.; Kusák, I.; Schmid, P. Self-sensing properties of alkali-activated slag composite with carbon black during bending test. Solid State Phenom. 2019, 296 SSP, 167–172. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Electrical and self-sensing properties of alkali-activated slag composite with graphite filler. Materials 2019, 12, 1616. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.; Ma, Y.; Hu, J.; Yin, S.; Ouyang, X.; Fu, J.; Liu, A.; Zhang, Z. Preparation and piezoresistive properties of carbon fiber-reinforced alkali-activated fly ash/slag mortar. Constr. Build. Mater. 2019, 222, 738–749. [Google Scholar] [CrossRef]

- Saafi, M.; Tang, L.; Fung, J.; Rahman, M.; Liggat, J. Enhanced properties of graphene/fly ash geopolymeric composite cement. Cem. Concr. Res. 2015, 67, 292–299. [Google Scholar] [CrossRef]

- Lamuta, C.; Bruno, L.; Candamano, S.; Pagnotta, L. Piezoresistive characterization of graphene/metakaolin based geopolymeric mortar composites. MRS Adv. 2017, 2, 3773–3779. [Google Scholar] [CrossRef]

- Payakaniti, P.; Pinitsoontorn, S.; Thongbai, P.; Amornkitbamrung, V. Electrical conductivity and compressive strength of carbon fiber reinforced fly ash geopolymeric composites. Constr. Build. Mater. 2017, 135, 164–176. [Google Scholar] [CrossRef]

- Saafi, M.; Tang, L.; Fung, J.; Rahman, M.; Sillars, F.; Liggat, J.; Zhou, X. Graphene/fly ash geopolymeric composites as self-sensing structural materials. Smart Mater. Struct. 2014, 23, 65006. [Google Scholar] [CrossRef]

- Saafi, M.; Andrew, K.; Tang, P.L.; McGhon, D.; Taylor, S.; Rahman, M.; Yang, S.; Zhou, X. Multifunctional properties of carbon nanotube/fly ash geopolymeric nanocomposites. Constr. Build. Mater. 2013, 49, 46–55. [Google Scholar] [CrossRef]

- Behera, P.; Baheti, V.; Militky, J.; Naeem, S. Microstructure and mechanical properties of carbon microfiber reinforced geopolymers at elevated temperatures. Constr. Build. Mater. 2018, 160, 733–743. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Shah, S.F.A.; Chen, B.; Oderji, S.Y.; Aminul Haque, M.; Ahmad, M.R. Comparative study on the effect of fiber type and content on the performance of one-part alkali-activated mortar. Constr. Build. Mater. 2020, 243, 118221. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Falah, M.; Shaad, K.M.; Luukkonen, T.; Illikainen, M. Durability of the Reinforced One-Part Alkali-Activated Slag Mortars with Different Fibers. Waste Biomass Valorization 2020. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. Fiber-reinforced one-part alkali-activated slag/ceramic binders. Ceram. Int. 2018, 44, 8963–8976. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.H. High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: A micromechanics-based investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Biondi, L.; Perry, M.; McAlorum, J.; Vlachakis, C.; Hamilton, A. Geopolymer-based moisture sensors for reinforced concrete health monitoring. Sens. Actuators B Chem. 2020, 309, 127775. [Google Scholar] [CrossRef]

- Hansson, I.L.H.; Hansson, C.M. Ion-conduction in cement-based materials. Cem. Concr. Res. 1985, 15, 201–212. [Google Scholar] [CrossRef]

- Xu, J.; Zhong, W.; Yao, W. Modeling of conductivity in carbon fiber-reinforced cement-based composite. J. Mater. Sci. 2010, 45, 3538–3546. [Google Scholar] [CrossRef]

- Cui, X.M.; Zheng, G.J.; Han, Y.C.; Su, F.; Zhou, J. A study on electrical conductivity of chemosynthetic Al2O3-2SiO2geoploymer materials. J. Power Sources 2008, 184, 652–656. [Google Scholar] [CrossRef]

- McCarter, W.J.; Brousseau, R. The A.C. response of hardened cement paste. Cem. Concr. Res. 1990, 20, 891–900. [Google Scholar] [CrossRef]

- Gu, P.; Xie, P.; Beaudoin, J.J.; Brousseau, R.A.C. impedance spectroscopy (I): A new equivalent circuit model for hydrated portland cement paste. Cem. Concr. Res. 1992, 22, 833–840. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. The role of electronic and ionic conduction in the electrical conductivity of carbon fiber reinforced cement. Carbon 2006, 44, 2130–2138. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Effect of carbon fiber grade on the electrical behavior of carbon fiber reinforced cement. Carbon 2001, 39, 369–373. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.; Ou, J. Effect of compressive strain on electrical resistivity of carbon black-filled cement-based composites. Cem. Concr. Compos. 2006, 28, 824–828. [Google Scholar] [CrossRef]

- Chen, B.; Wu, K.; Yao, W. Conductivity of carbon fiber reinforced cement-based composites. Cem. Concr. Compos. 2004, 26, 291–297. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Effect of water content on the piezoresistivity of MWNT/cement composites. J. Mater. Sci. 2010, 45, 3714–3719. [Google Scholar] [CrossRef]

- Sun, S.; Han, B.; Jiang, S.; Yu, X.; Wang, Y.; Li, H.; Ou, J. Nano graphite platelets-enabled piezoresistive cementitious composites for structural health monitoring. Constr. Build. Mater. 2017, 136, 314–328. [Google Scholar] [CrossRef]

- Fiala, L.; Jerman, M.; Rovnaník, P.; Černý, R. Basic physical, mechanical and electrical properties of electrically enhanced alkali-activated aluminosilicates. Mater. Tehnol. 2017, 51, 1005–1009. [Google Scholar] [CrossRef]

- Rovnaník, P.; Míková, M.; Kusák, I. Electrical properties of alkali-activated slag mortar with carbon fibres. Mater. Sci. Forum 2017, 908, 100–105. [Google Scholar] [CrossRef]

- Chung, D.D.L. Piezoresistive cement-based materials for strain sensing. J. Intell. Mater. Syst. Struct. 2002, 13, 599–609. [Google Scholar] [CrossRef]

- Al-Dahawi, A.; Sarwary, M.H.; Öztürk, O.; Yildirim, G.; Akin, A.; Şahmaran, M.; Lachemi, M. Electrical percolation threshold of cementitious composites possessing self-sensing functionality incorporating different carbon-based materials. Smart Mater. Struct. 2016, 25, 105005. [Google Scholar] [CrossRef]

- Pour-Ghaz, M.; Isgor, O.B.; Ghods, P. The effect of temperature on the corrosion of steel in concrete. Part 1: Simulated polarization resistance tests and model development. Corros. Sci. 2009, 51, 415–425. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Electric polarization in carbon fiber-reinforced cement. Cem. Concr. Res. 2001, 31, 141–147. [Google Scholar] [CrossRef]

- Song, G. Theoretical analysis of the measurement of polarization resistance in reinforced concrete. Cem. Concr. Compos. 2000, 22, 407–415. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Ou, J. Electrical characteristics and pressure-sensitive response measurements of carboxyl MWNT/cement composites. Cem. Concr. Compos. 2012, 34, 794–800. [Google Scholar] [CrossRef]

- Lasia, A. Electrochemical Impedance Spectroscopy and Its Applications; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 9781461489320. [Google Scholar]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Comparison of electrical and self-sensing properties of Portland cement and alkali-activated slag mortars. Cem. Concr. Res. 2019, 118, 84–91. [Google Scholar] [CrossRef]

- MacKenzie, K.J.D.; Bolton, M.J. Electrical and mechanical properties of aluminosilicate inorganic polymer composites with carbon nanotubes. J. Mater. Sci. 2009, 44, 2851–2857. [Google Scholar] [CrossRef]

- Zhang, Y.J.; He, P.Y.; Zhang, Y.X.; Chen, H. A novel electroconductive graphene/fly ash-based geopolymer composite and its photocatalytic performance. Chem. Eng. J. 2018, 334, 2459–2466. [Google Scholar] [CrossRef]

- Zhong, J.; Zhou, G.X.; He, P.G.; Yang, Z.H.; Jia, D.C. 3D printing strong and conductive geo-polymer nanocomposite structures modified by graphene oxide. Carbon 2017, 117, 421–426. [Google Scholar] [CrossRef]

- Fiala, L.; Petříková, M.; Lin, W.T.; Podolka, L.; Černý, R. Self-heating ability of geopolymers enhanced by carbon black admixtures at different voltage loads. Energies 2019, 12, 4121. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Chindaprasirt, P.; Pimraksa, K. Electrical conductivity and dielectric property of fly ash geopolymer pastes. Int. J. Miner. Metall. Mater. 2011, 18, 94–99. [Google Scholar] [CrossRef]

- Saafi, M.; Gullane, A.; Huang, B.; Sadeghi, H.; Ye, J.; Sadeghi, F. Inherently multifunctional geopolymeric cementitious composite as electrical energy storage and self-sensing structural material. Compos. Struct. 2018, 201, 766–778. [Google Scholar] [CrossRef]

- Kusak, I.; Lunak, M. On the effect of addition of carbon nanotubes on the electric conductivity of alkali-activated slag mortars. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2017; Volume 246, p. 012044. [Google Scholar] [CrossRef]

- Sellami, M.; Barre, M.; Toumi, M. Synthesis, thermal properties and electrical conductivity of phosphoric acid-based geopolymer with metakaolin. Appl. Clay Sci. 2019, 180, 105192. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 117868. [Google Scholar] [CrossRef]

- Salem, T.M.; Ragai, S.M. Electrical conductivity of granulated slag cement kiln dust-silica fume pastes at different porosities. Cem. Concr. Res. 2001, 31, 781–787. [Google Scholar] [CrossRef]

- Liu, K.; Cheng, X.; Li, J.; Gao, X.; Cao, Y.; Guo, X.; Zhuang, J.; Zhang, C. Effects of microstructure and pore water on electrical conductivity of cement slurry during early hydration. Compos. Part B Eng. 2019, 177, 107435. [Google Scholar] [CrossRef]

- Liang, K.; Zeng, X.; Zhou, X.; Qu, F.; Wang, P. A new model for the electrical conductivity of cement-based material by considering pore size distribution. Mag. Concr. Res. 2017, 69, 1067–1078. [Google Scholar] [CrossRef]

- Kultayeva, S.; Ha, J.H.; Malik, R.; Kim, Y.W.; Kim, K.J. Effects of porosity on electrical and thermal conductivities of porous SiC ceramics. J. Eur. Ceram. Soc. 2020, 40, 996–1004. [Google Scholar] [CrossRef]

- Gu, P.; Xie, P.; Beaudoin, J.J.; Brousseau, R. AC impedance spectroscopy (II): Microstructural characterization of hydrating cement-silica fume systems. Cem. Concr. Res. 1993, 23, 157–168. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, J.; Lake, M. Characterization of mechanical and electric properties of geopolymers synthesized using four locally available fly ashes. Constr. Build. Mater. 2016, 121, 386–399. [Google Scholar] [CrossRef]

- Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. Do geopolymers actually contain nanocrystalline zeolites? A reexamination of existing results. Chem. Mater. 2005, 17, 3075–3085. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Jin, Z. Electrical conductivity characterization and variation of carbon fiber reinforced cement composite. J. Mater. Sci. 2002, 37, 223–227. [Google Scholar] [CrossRef]

- Chuang, W.; Geng-sheng, J.; Bing-liang, L.; Lei, P.; Ying, F.; Ni, G.; Ke-zhi, L. Dispersion of carbon fibers and conductivity of carbon fiber-reinforced cement-based composites. Ceram. Int. 2017, 43, 15122–15132. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Ou, J. Influence of water content on conductivity and piezoresistivity of cement-based material with both carbon fiber and carbon black. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 147–151. [Google Scholar] [CrossRef]

- Han, B.G.; Han, B.Z.; Ou, J.P. Experimental study on use of nickel powder-filled Portland cement-based composite for fabrication of piezoresistive sensors with high sensitivity. Sens. Actuators A Phys. 2009, 149, 51–55. [Google Scholar] [CrossRef]

- Khater, H.M.; Abd El Gawaad, H.A. Characterization of alkali activated geopolymer mortar doped with MWCNT. Constr. Build. Mater. 2016, 102, 329–337. [Google Scholar] [CrossRef]

- Abbasi, S.M.; Ahmadi, H.; Khalaj, G.; Ghasemi, B. Microstructure and mechanical properties of a metakaolinite-based geopolymer nanocomposite reinforced with carbon nanotubes. Ceram. Int. 2016, 42, 15171–15176. [Google Scholar] [CrossRef]

- Vilaplana, J.L.; Baeza, F.J.; Galao, O.; Alcocel, E.G.; Zornoza, E.; Garcés, P. Mechanical properties of alkali activated blast furnace slag pastes reinforced with carbon fibers. Constr. Build. Mater. 2016, 116, 63–71. [Google Scholar] [CrossRef]

- Vaidya, S.; Allouche, E.N. Strain sensing of carbon fiber reinforced geopolymer concrete. Mater. Struct. 2011, 44, 1467–1475. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, R.; Tam, V.W.Y.; Li, W.; Xiao, J. Strain monitoring for a bending concrete beam by using piezoresistive cement-based sensors. Constr. Build. Mater. 2018, 167, 338–347. [Google Scholar] [CrossRef]

- Van der Pauw, L.J. A method of measuring specific resistivity and and Hall effect of discs of arbitrary shape. Philips Res. Rep. 1958, 13, 1–9. [Google Scholar]

- Yao, Y.; Duan, X.; Luo, J.; Liu, T. Two-probe versus van der Pauw method in studying the piezoresistivity of single-wall carbon nanotube thin films. Nanotechnology 2017, 28, 445501. [Google Scholar] [CrossRef]

- Chiarello, M.; Zinno, R. Electrical conductivity of self-monitoring CFRC. Cem. Concr. Compos. 2005, 27, 463–469. [Google Scholar] [CrossRef]

- Han, B.; Guan, X.; Ou, J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors. Sens. Actuators A Phys. 2007, 135, 360–369. [Google Scholar] [CrossRef]

- Tang, S.W.; Cai, X.H.; He, Z.; Zhou, W.; Shao, H.Y.; Li, Z.J.; Wu, T.; Chen, E. The review of pore structure evaluation in cementitious materials by electrical methods. Constr. Build. Mater. 2016, 117, 273–284. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Xiao, H.; Li, H.; Ou, J. Strain sensing properties of cement-based sensors embedded at various stress zones in a bending concrete beam. Sens. Actuators A Phys. 2011, 167, 581–587. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, S.; Lee, S.H. Self-sensing capability of ultra-high-performance concrete containing steel fibers and carbon nanotubes under tension. Sens. Actuators A Phys. 2018, 276, 125–136. [Google Scholar] [CrossRef]

- Han, B.; Wang, Y.; Ding, S.; Yu, X.; Zhang, L.; Li, Z.; Ou, J. Self-sensing cementitious composites incorporated with botryoid hybrid nano-carbon materials for smart infrastructures. J. Intell. Mater. Syst. Struct. 2017, 28, 699–727. [Google Scholar] [CrossRef]

- Sun, M.Q.; Liew, R.J.Y.; Zhang, M.H.; Li, W. Development of cement-based strain sensor for health monitoring of ultra high strength concrete. Constr. Build. Mater. 2014, 65, 630–637. [Google Scholar] [CrossRef]

- Ding, S.; Ruan, Y.; Yu, X.; Han, B.; Ni, Y.Q. Self-monitoring of smart concrete column incorporating CNT/NCB composite fillers modified cementitious sensors. Constr. Build. Mater. 2019, 201, 127–137. [Google Scholar] [CrossRef]

- Han, B.; Ou, J. Embedded piezoresistive cement-based stress/strain sensor. Sens. Actuators A Phys. 2007, 138, 294–298. [Google Scholar] [CrossRef]

- Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Strain and damage sensing properties on multifunctional cement composites with CNF admixture. Cem. Concr. Compos. 2014, 46, 90–98. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Youn, H.; Lee, S.J. Electrical and piezoresistive properties of cement composites with carbon nanomaterials. J. Compos. Mater. 2018, 52, 3325–3340. [Google Scholar] [CrossRef]

- Wang, W.; Dai, H.; Wu, S. Mechanical behavior and electrical property of CFRC-strengthened RC beams under fatigue and monotonic loading. Mater. Sci. Eng. A 2008, 479, 191–196. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Meas. J. Int. Meas. Confed. 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self sensing carbon nanotube (CNT) and nanofiber (CNF) cementitious composites for real time damage assessment in smart structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Lee, S.J. Electrical and piezoresistive sensing capacities of cement paste with multi-walled carbon nanotubes. Arch. Civ. Mech. Eng. 2018, 18, 371–384. [Google Scholar] [CrossRef]

- Beer, F.P.; Johnston, E.R.J.; DeWolf, J.T.; Mazurek, D.F. Mechanics of Materials, 5th ed.; McGraw-Hill: New York, NY, USA, 2009; ISBN 978–0–07–352938–7. [Google Scholar]

- Sun, S.; Ding, S.; Han, B.; Dong, S.; Yu, X.; Zhou, D.; Ou, J. Multi-layer graphene-engineered cementitious composites with multifunctionality/intelligence. Compos. Part B Eng. 2017, 129, 221–232. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D.D.L. Self-monitoring of fatigue damage in carbon fiber reinforced cement. Cem. Concr. Res. 1996, 26, 15–20. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Uniaxial compression in carbon fiber reinforced cement, sensed by electrical resistivity measurement in longitudinal and transverse directions. Cem. Concr. Res. 2000, 30, 1289–1294. [Google Scholar] [CrossRef]

- Yoo, D.; You, I.; Zi, G.; Lee, S. Effects of carbon nanomaterial type and amount on self-sensing capacity of cement paste. Measurement 2019, 134, 750–761. [Google Scholar] [CrossRef]

- Materazzi, A.L.; Ubertini, F.; D’Alessandro, A. Carbon nanotube cement-based transducers for dynamic sensing of strain. Cem. Concr. Compos. 2013, 37, 2–11. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix composites for SHM applications. Cem. Concr. Compos. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- Baeza, F.J.; Galao, O.; Zornoza, E.; Garcés, P. Multifunctional Cement Composites Strain and Damage Sensors Applied on Reinforced Concrete (RC) Structural Elements. Materials 2013, 6, 841–855. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Ding, S.; Han, B.; Yu, X.; Ni, Y.Q. Effect of water content on the piezoresistive property of smart cement-based materials with carbon nanotube/nanocarbon black composite filler. Compos. Part A Appl. Sci. Manuf. 2019, 119, 8–20. [Google Scholar] [CrossRef]

- Demircilioğlu, E.; Teomete, E.; Schlangen, E.; Baeza, F.J. Temperature and moisture effects on electrical resistance and strain sensitivity of smart concrete. Constr. Build. Mater. 2019, 224, 420–427. [Google Scholar] [CrossRef]

- Hong, Y.; Li, Z.; Qiao, G.; Ou, J.; Cheng, W. Pressure sensitivity of multiscale carbon-admixtures–enhanced cement-based composites. Nanomater. Nanotechnol. 2018, 8, 1–8. [Google Scholar] [CrossRef]

- Chen, S.; Li, Y.; Yan, D.; Wu, C.; Leventis, N. Piezoresistive geopolymer enabled by crack-surface coating. Mater. Lett. 2019, 255, 1–4. [Google Scholar] [CrossRef]

- Rovnaník, P.; Šimonová, H.; Topolář, L.; Keršner, Z. Mechanical Fracture Properties of Alkali-Activated Slag with Graphite Filler. Procedia Eng. 2017, 190, 43–48. [Google Scholar] [CrossRef]

- Padma Kumar, P.; Yashonath, S. Ionic Conduction in the Solid State. ChemInform 2006, 37, 135–154. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rose, V.; Provis, J.L. The fate of iron in blast furnace slag particles during alkali-activation. Mater. Chem. Phys. 2014, 146, 1–5. [Google Scholar] [CrossRef]

- Peys, A.; Douvalis, A.P.; Hallet, V.; Rahier, H.; Blanpain, B.; Pontikes, Y. Inorganic Polymers from CaO-FeOx-SiO2 Slag: The Start of Oxidation of Fe and the Formation of a Mixed Valence Binder. Front. Mater. 2019, 6, 1–10. [Google Scholar] [CrossRef]

- Machiels, L.; Arnout, L.; Jones, P.T.; Blanpain, B.; Pontikes, Y. Inorganic polymer cement from fe-silicate glasses: Varying the activating solution to glass ratio. Waste Biomass Valorization 2014, 5, 411–428. [Google Scholar] [CrossRef]

- Peys, A.; White, C.E.; Olds, D.; Rahier, H.; Blanpain, B.; Pontikes, Y. Molecular structure of CaO–FeOx–SiO2 glassy slags and resultant inorganic polymer binders. J. Am. Ceram. Soc. 2018, 101, 5846–5857. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Yilmaz, K. Investigation of specimen size, geometry and temperature effects on resistivity of electrically conductive concretes. Constr. Build. Mater. 2020, 250, 118864. [Google Scholar] [CrossRef]

- Chang, C.; Song, G.; Gao, D.; Mo, Y.L. Temperature and mixing effects on electrical resistivity of carbon fiber enhanced concrete. Smart Mater. Struct. 2013, 22, 35021. [Google Scholar] [CrossRef]

- Lee, S.Y.; Le, H.V.; Kim, D.J. Self-stress sensing smart concrete containing fine steel slag aggregates and steel fibers under high compressive stress. Constr. Build. Mater. 2019, 220, 149–160. [Google Scholar] [CrossRef]

- Teomete, E. The effect of temperature and moisture on electrical resistance, strain sensitivity and crack sensitivity of steel fiber reinforced smart cement composite. Smart Mater. Struct. 2016, 25, 75024. [Google Scholar] [CrossRef]

- Gulicovski, J.; Nenadovic, S.; Kljajevic, L.; Mirkovic, M.; Nišavic, M.; Kragovic, M.; Stojmenovic, M. Geopolymer/CeO2 as Solid Electrolyte for IT-SOFC. Polymers 2020, 12, 248. [Google Scholar] [CrossRef]

- Lo Monte, F.; Felicetti, R.; Miah, M.J. The influence of pore pressure on fracture behaviour of Normal-Strength and High-Performance Concretes at high temperature. Cem. Concr. Compos. 2019, 104, 103388. [Google Scholar] [CrossRef]

- Perry, M.; Saafi, M.; Fusiek, G.; Niewczas, P. Geopolymeric thermal conductivity sensors for surface-mounting onto concrete structures. In Environment, Efficiency and Economic Challenges for Concrete; University of Dundee: Dundee, UK, 2016. [Google Scholar]

- Van Meurs, N. Temperature Dependence of the Conductivity of Electrolyte Solutions. Nature 1958, 182, 1532–1533. [Google Scholar] [CrossRef]

- Funke, K.; Banhatti, R.D. Ionic motion in materials with disordered structures. Solid State Ionics 2006, 177, 1551–1557. [Google Scholar] [CrossRef]

- Cai, J.; Tan, J.; Li, X. Thermoelectric behaviors of fly ash and metakaolin based geopolymer. Constr. Build. Mater. 2020, 237, 117757. [Google Scholar] [CrossRef]

- Brantervik, K.; Berg, A.; Niklasson, G.A.; Hedberg, B.; Nilsson, L.O. Percolation effects in the electrical conductivity of porous cement mortar. EPL Europhys. Lett. 1990, 13, 549–554. [Google Scholar] [CrossRef]

- Saleem, M.; Shameem, M.; Hussain, S.E.; Maslehuddin, M. Effect of moisture, chloride and sulphate contamination on the electrical resistivity of Portland cement concrete. Constr. Build. Mater. 1996, 10, 209–214. [Google Scholar] [CrossRef]

- Nguyen, A.Q.; Klysz, G.; Deby, F.; Balayssac, J.P. Evaluation of water content gradient using a new configuration of linear array four-point probe for electrical resistivity measurement. Cem. Concr. Compos. 2017, 83, 308–322. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

| Matrix | Precursor | Activator | Liquid-Binder Ratio | Molar Ratios | Filler Content | Filler Concentration | Order of Magnitude for Conductivity (S/m) | AC or DC? | Reference |

|---|---|---|---|---|---|---|---|---|---|

| Paste | GGBFS | K2SiO3 + KOH | Unreported | Si/Al = 1.64 * K/Al = 1.56 * | Single wall carbon nanotubes | 0.2 wt% | 10−3 | DC | [87] |

| Mortar | Fly ash Class C + GGBFS | Na2SiO3+ NaOH | 0.4 | Cannot calculate | Carbon fibre | 0.5 %volume | 1 | DC | [53] |

| Paste | Fly ash Class F | Na2SiO3 + KOH | 0.51 | Si/Al = 3.10 * Na + K/Al = 2.23 * | Graphene | 1 wt% | 10−1 | DC | [88] |

| Paste | Metakaolin | Na2SiO3 + NaOH | 1.2 | Si/Al = 2 | Carbon microfibre | 15 wt% | 10−2 | DC | [59] |

| Paste | Unreported | Unreported | 0.53 | Cannot calculate | Graphene oxide | 20 wt% | 102 | Unreported | [89] |

| Mortar | GGBFS | Na2SiO3 | 0.84 | Cannot calculate | Carbon black | 2.25 wt% | 10−1 | DC | [90] |

| Paste | GGBFS | Na2SiO3 + NaOH | 0.43 | Si/Al = 3.20 * Na/Al = 1.19 * | Carbon fibre | 0.76 wt% | 101 | Unreported | [25] |

| Paste | Fly ash Class F | Na2SiO3 + NaOH | 0.39 | Cannot calculate | Graphene oxide | 0.35 wt% | 1 | AC | [57] |

| Mortar | Fly ash Class F | Na2SiO3 + NaOH | 0.36 | Si/Al = 1.57 * Na/Al = 0.27 * | Multiwall carbon nanotubes | 1 wt% | 1 | AC | [58] |

| Paste | Fly ash Class C | Na2SiO3 + NaOH | 0.5 | Si/Al = 2.05 * Na/Al = 0.85 * | Carbon fibre | 0.5 wt% | 101 | AC | [56] |

| Paste | Fly ash Class C | Na2SiO3 + NaOH | 0.4 | Si/Al = 1.93 * Na/Al = 0.51 * | No filler | - | 10−1 | AC | [91] |

| Paste | Fly ash Class F | Na2SiO3 + NaOH | 0.37 | Si/Al = near 2 | No filler | - | 10−2 | AC | [24] |

| Paste | Fly ash Class F | K2SiO3 | 0.6 | Si/Al = 1.17 | No filler | - | 10−1 | AC | [92] |

| Paste | Fly ash Class F | Na2SiO3 + NaOH | 0.4 | Si/Al = 2.15 * Na/Al = 1.18 * | No filler | - | 1 | AC | [60] |

| Mortar | GGBFS | Na2SiO3 + NaOH | 0.61 | Cannot calculate | Carbon nanotubes | 2.5 wt% | 10−6 | AC | [93] |

| Mortar | GGBFS | Na2SiO3 | 0.36 | Si/Al = 6.71 * Na/Al = 1.11 * | Graphite powder | 30 wt% | 10−4 | AC | [52,86] |

| Mortar | GGBFS | Na2SiO3 | 0.61 | Si/Al = 6.71 * Na/Al = 1.11 * | No filler | - | 10−6 | AC | [52,86] |

| Paste | Metakaolin | Na2SiO3 | Unreported | Si/Al = 1.04 * Na/Al = 0.17 * | No filler | - | 10−4 | AC | [68] |

| Paste | Metakaolin | Phosphoric acid | Unreported | Si/P = 1 | No filler | - | 10−7 | AC | [94] |

| Matrix | Precursor | Number of Probes | Material of Probe | Attachment Method | Reference |

|---|---|---|---|---|---|

| Paste | Fly ash | 2-probe | Graphene | Embedded | [24] |

| Paste | Fly ash | 4-probe | Copper | Embedded | [57,58] |

| Paste | Fly ash | 2-probe | Steel mesh | Embedded | [92] |

| Paste | Fly ash | 4-probe | Copper fibres | Embedded | [26] |

| Paste | Fly ash | 4-probe | Stainless steel wires | Embedded | [65] |

| Paste | Fly ash | 4-probe | Brass plates | Embedded | [56] |

| Paste | Metakaolin | 2-probe | Copper wires | Embedded | [23] |

| Paste | Metakaolin | 4-probe | Stainless steel wires | Embedded | [27] |

| Paste | GGBFS | 4-probe | Copper wires | Wound around substrate with conductive silver paint | [25] |

| Mortar | Metakaolin | 2-probe | Copper foils | Attached | [22,50] |

| Mortar | Metakaolin | 4-probe | Copper wires | Wound around substrate with conductive paste | [55] |

| Mortar | GGBFS | 2-probe | Copper mesh | Embedded | [52,86] |

| Mortar | GGBFS | 4-probe | Self-adhesive copper tape | Attached with graphite conductive paste | [51] |

| Mortar | GGBFS+ fly ash | 4-probe | Titanium mesh | Embedded | [53] |

| Concrete | Fly ash | 2-probe | Copper wires | Wound around substrate with conductive silver paste | [110] |

| Matrix | Precursor | Activator | Conductive Filler | Filler Concentration | Application | Loading Amplitude | Gauge Factor or Reported Response | Reference |

|---|---|---|---|---|---|---|---|---|

| Paste | Fly ash | Na2SiO3 + NaOH | No filler | - | Tension | 10–40 N | 358 | [24] |

| Paste | Fly ash | Na2SiO3 + NaOH | Graphene oxide sheet | 0.35 wt% | Compression Tension | 0.6–12 MPa 200–1000 µε | 43.87 20.7 | [57] |

| Paste | Fly ash | Na2SiO3 + NaOH | No filler | - | Compression | 0–100 kN | 47 * | [26] |

| Paste | Metakaolin | Na2SiO3 + NaOH | Carbon nanotubes | 0.25 %volume | Compression Bending | 7–9% 0.05–0.08% | 663 724.6 | [23] |

| Paste | Metakaolin | Na2SiO3 + NaOH | PEDOT: PSS solution | - | Compression | Up to 200 N | loading: 376.9 unloading: 513.3 | [141] |

| Paste | GGBFS | Na2SiO3 + NaOH | Carbon fibre | 0.58 %volume | Compression | 0–8 kN | 662 | [25] |

| Mortar | Metakaolin | Na2SiO3 + NaOH | Graphene | 1 wt% | Compression | 1–5 kN | 1986 | [55] |

| Mortar | GGBFS | Na2SiO3 | No filler | - | Compression | 5–50 kN | 97.13 Ω /MPa; 35 * | [86] |

| Mortar | GGBFS | Na2SiO3 | Graphite powder | 30 wt% | Compression | 5–50 kN | 292 * | [52,142] |

| Mortar | GGBFS | Na2SiO3 | Carbon black | 4 wt% | Flexure | 0.07–0.50 kN | ≈1300 * | [51] |

| Paste | Fly ash | K2SiO3 | No filler | - | Compression | 0–15 kN | 11 Ω/MPa | [92] |

| Mortar | Metakaolin | Na2SiO3 + NaOH | No filler | - | Compression | 0–2500 N | 4.02 ± 0.49 pC/N | [22] |

| Mortar | Metakaolin | Na2SiO3 + NaOH | Graphene | 1 wt% | Compression | 0–2500 N | 11.99 pC/N | [50] |

| Mortar | GGBFS+ fly ash | Na2SiO3 + NaOH | Carbon fibre | 0.1 %volume | Compression | 6.25–18.75 MPa | ΔR/R0 = 0.11 | [53] |

| Concrete | Fly ash | Na2SiO3 + NaOH | Carbon fibre | 0.4 wt% | Compression Bending | 0–9.34 kN | 6–7.5 Ω/MPa | [110] |

| Matrix | Precursor | Activator | Application | Loading Amplitude | Gauge Factor or Reported Response | Reference |

|---|---|---|---|---|---|---|

| Paste | Fly ash | Na2SiO3 + NaOH | Tension | 10–40 N | 358 | [24] |

| Paste | Fly ash | Na2SiO3 + NaOH | Compression Tension | 0.6–12 MPa 200–1000 µε | 21.6 9.76 | [57] |

| Paste | Fly ash | Na2SiO3 + NaOH | Compression | 0–100 kN | 47 * | [26] |

| Paste | Metakaolin | Na2SiO3 + NaOH | Compression Bending | 7–9% 0.05–0.08% | 62.7 189.8 | [23] |

| Mortar | Metakaolin | Na2SiO3 + NaOH | Compression | 1–5 kN | 1662 | [55] |

| Mortar | GGBFS | Na2SiO3 | Compression | 5–50 kN | 97.13 Ω/MPa 35 * | [86] |

| Mortar | GGBFS | Na2SiO3 | Flexure | 0.07–0.50 kN | ≈1150 * | [51] |

| Mortar | GGBFS+ fly ash | Na2SiO3 + NaOH | Compression | 6.25–18.75 MPa | Close to 0 | [53] |

| Paste | Fly ash | K2SiO3 | Compression | 0–15 kN | 11 Ω/MPa | [92] |

| Mortar | Metakaolin | Na2SiO3 + NaOH | Compression | 0–2500 N | 4.02 ± 0.49 pC/N | [22] |

| Matrix | Precursor | Conductive Filler | Temperature Range | Reported Response | Reference |

|---|---|---|---|---|---|

| Paste | Fly ash | No filler | −10–35 °C | 21.5 kΩ °C−1 | [24] |

| Paste | Fly ash | No filler | 10–30 °C | 0.5 °C−1 | [26] |

| Paste | Fly ash | No filler | 5–30 °C | 0.1 °C−1 | [65] |

| Paste | Fly ash | Magnetite | ΔT = 3 °C | 0.0781 °C−1 * | [154] |

| Paste | Metakaolin | Graphite, single wall carbon nanotube | Up to 340 °C | Conductivity function of temperature | [87] |

| Paste | Metakaolin | No filler | 10–30 °C | 0.1 °C−1 | [27] |

| Paste | Metakaolin Fly ash | No filler | ΔT = 45 °C | −15.12 μV/°C −6.31 μV/°C | [157] |

| Application | a | b | Reference |

|---|---|---|---|

| OPC | 0.054 | 1.01 | [149] |

| OPC | 0.050 | 1.00 | [150] |

| OPC | 0.040 | 0.86 | [131] |

| OPC | 0.030 | 0.68 | [139] |

| AAM | 0.028 | 0.58 | [27] |

| Material | Strain | Temperature | Moisture | Humidity | Strain-Temperature | Strain-Moisture | Temperature-Moisture |

|---|---|---|---|---|---|---|---|

| AAM | Uniaxial, multiaxial limited | Yes | Yes | No | No | No | Yes |

| OPC | Yes | Yes | Yes | Yes | Yes | Yes | No |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vlachakis, C.; Perry, M.; Biondi, L. Self-Sensing Alkali-Activated Materials: A Review. Minerals 2020, 10, 885. https://doi.org/10.3390/min10100885

Vlachakis C, Perry M, Biondi L. Self-Sensing Alkali-Activated Materials: A Review. Minerals. 2020; 10(10):885. https://doi.org/10.3390/min10100885

Chicago/Turabian StyleVlachakis, Christos, Marcus Perry, and Lorena Biondi. 2020. "Self-Sensing Alkali-Activated Materials: A Review" Minerals 10, no. 10: 885. https://doi.org/10.3390/min10100885

APA StyleVlachakis, C., Perry, M., & Biondi, L. (2020). Self-Sensing Alkali-Activated Materials: A Review. Minerals, 10(10), 885. https://doi.org/10.3390/min10100885