Angle-of-Attack, Induced Attitude Evolution in a Coupled Crater, and Plugging Penetration of Thin Concrete Targets

Abstract

1. Introduction

2. Theoretical Model

2.1. Theoretical Foundations and Model Inheritance

- (1)

- Chen et al. [27] developed the classical three-stage model describing rigid projectile penetration into concrete—comprising crater formation, tunnel extension, and shear plugging. Grounded in momentum and energy conservation, this model captures trajectory deflection and angular response caused by asymmetric loading and remains widely used.

- (2)

- Duan et al. [28,29] introduced a theoretical model for attitude deviation in oblique penetration, focusing on torque caused by eccentricity between the projectile’s center of mass and the pressure center on the nose. Their formulation established differential equations for angular velocity evolution, revealing how asymmetric pressure fields destabilize projectile orientation. However, it did not account for feedback from the shear plugging region.

- (3)

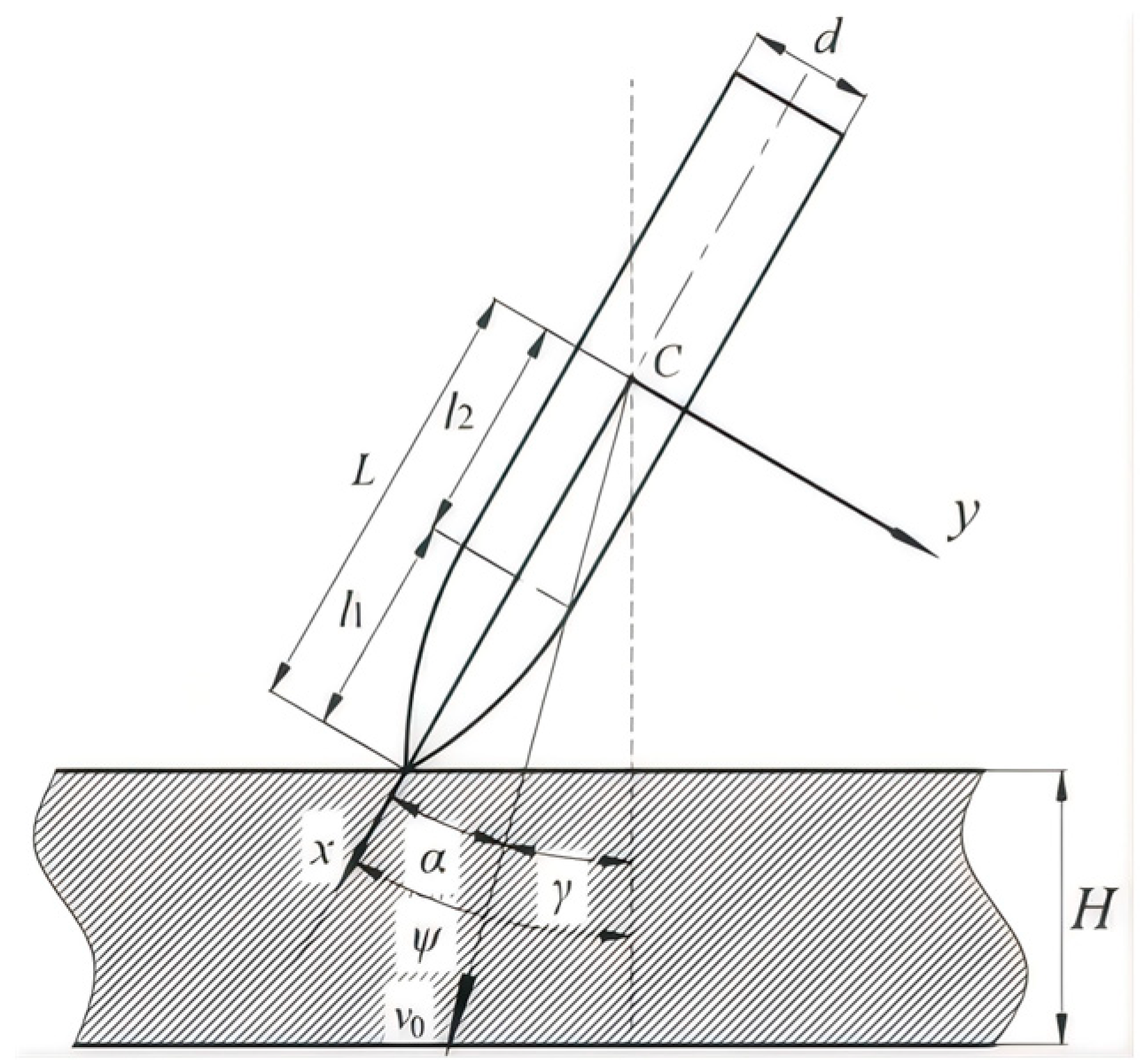

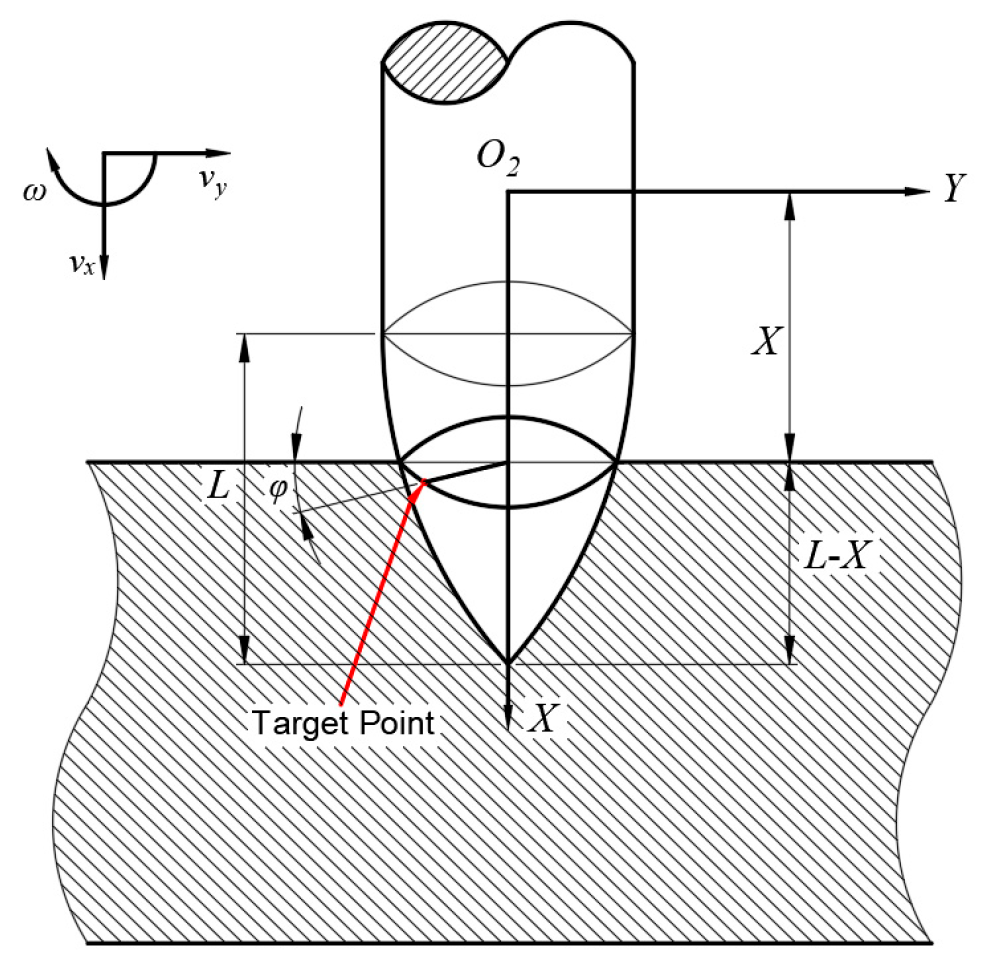

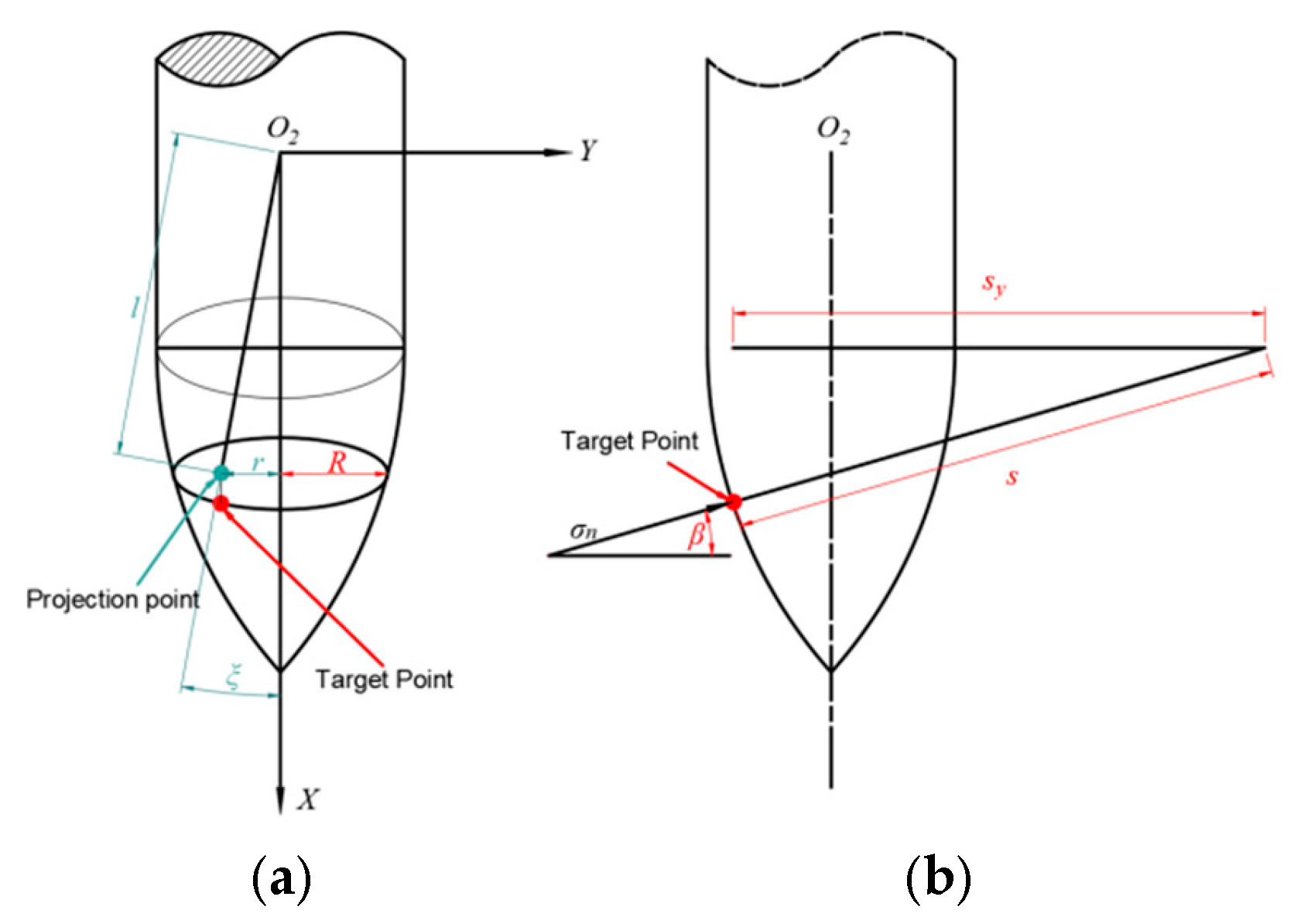

- Liu et al. [30] extended the model to include angle-of-attack effects, showing how asymmetric nose-surface velocities induce contact force imbalances. By considering free-surface effects and using the differential surface force method, they improved the accuracy in modeling projectile behavior during the crater phase.

- (1)

- Projectile is rigid, with no deformation or damage;

- (2)

- Resistance acts only on the nose of the projectile;

- (3)

- No rotation occurs about the projectile’s longitudinal axis during motion; only planar motion is considered;

- (4)

- Coarse aggregates are neglected, and the concrete is assumed to be a homogeneous and isotropic material.

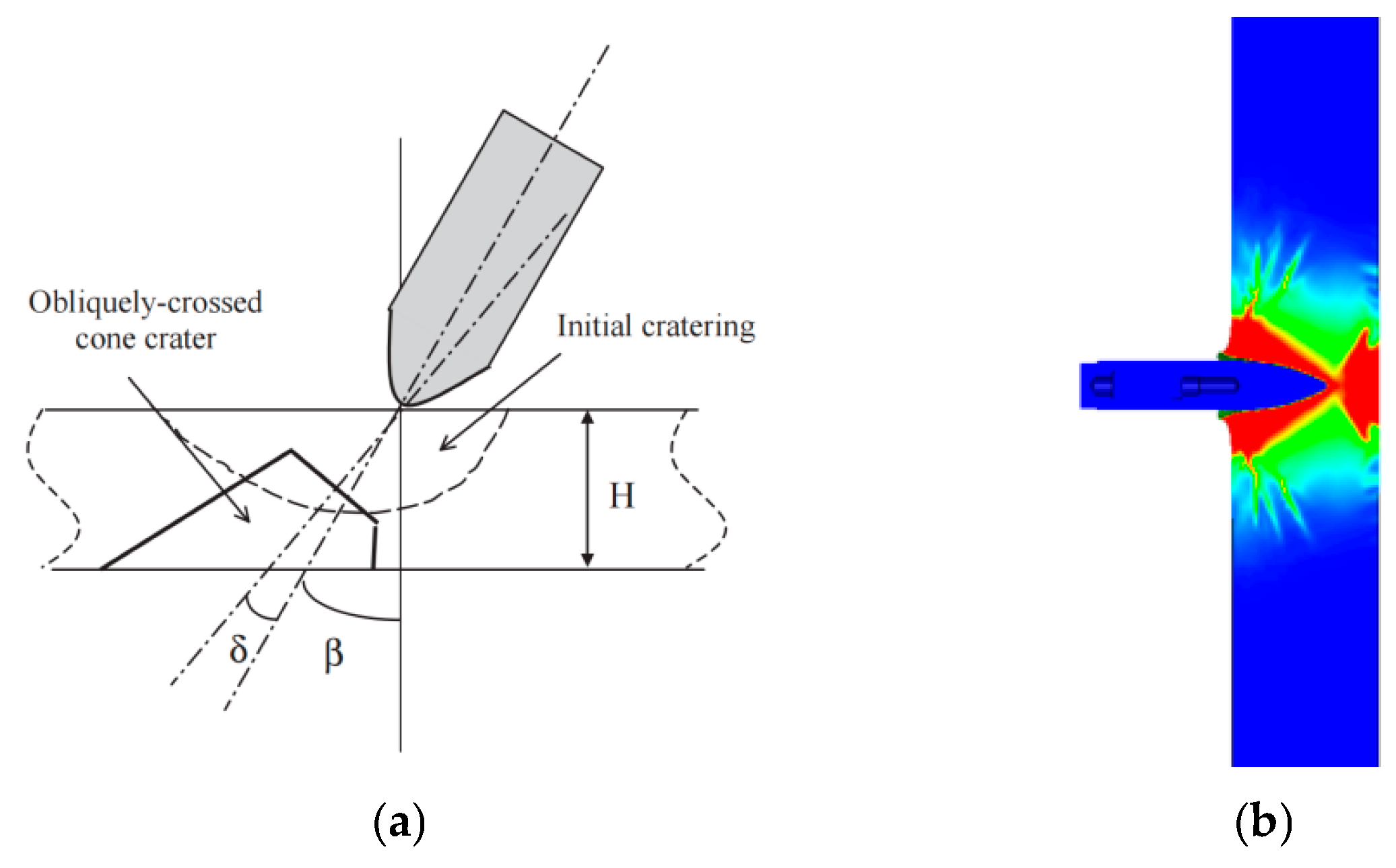

2.2. Dynamic Shear_Plugging Model

- (1)

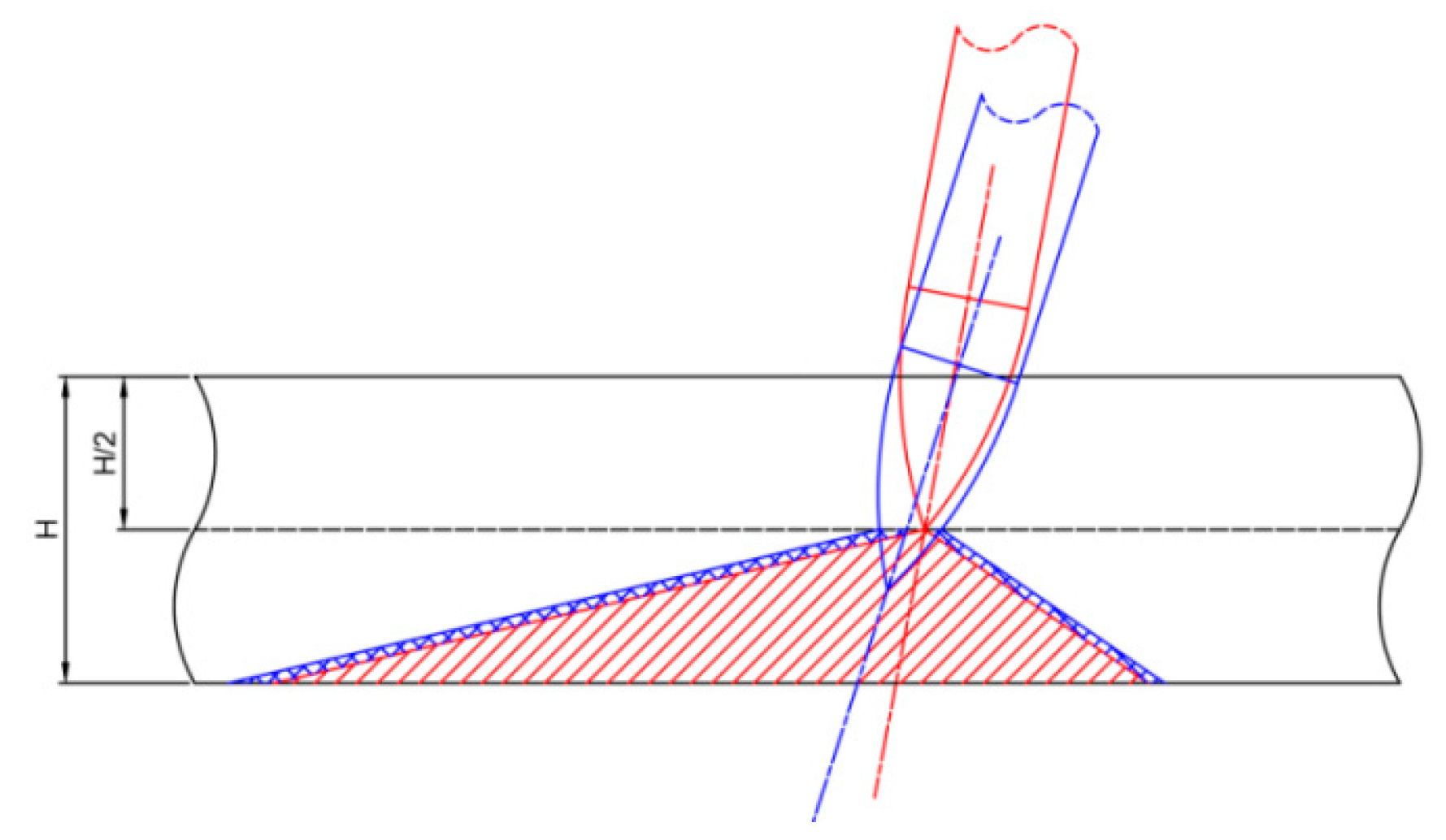

- Based on the findings of Peng et al. [44], the thickness of the shear plug formed during the penetration of thin concrete targets is approximately half the target thickness. When the projectile nose reaches mid-thickness, an initial conical shear plug is generated behind the projectile (see red region in Figure 7).

- (2)

- The axis of the shear plug is colinear with the projectile axis. The half-cone angle of the subsequent shear plug remains consistent with that of the initial plug, and their central axes are parallel.

- (3)

- During penetration, the initial shear plug remains relatively intact and continues to exert resistance on the projectile. However, newly generated shear zones (see blue region in Figure 7), which peel off in layers, no longer resist the projectile. Once the projectile nose reaches the rear surface of the target, the plug is fully fractured and ceases to offer resistance.

- (4)

- The failure surface during the shear-plugging process originates at the intersection between the projectile nose surface and the mid-plane of the target. It propagates toward the rear surface while maintaining a constant half-cone angle.

2.3. Model Implementation and Numerical Solution

3. Experimental Study and Model Validation

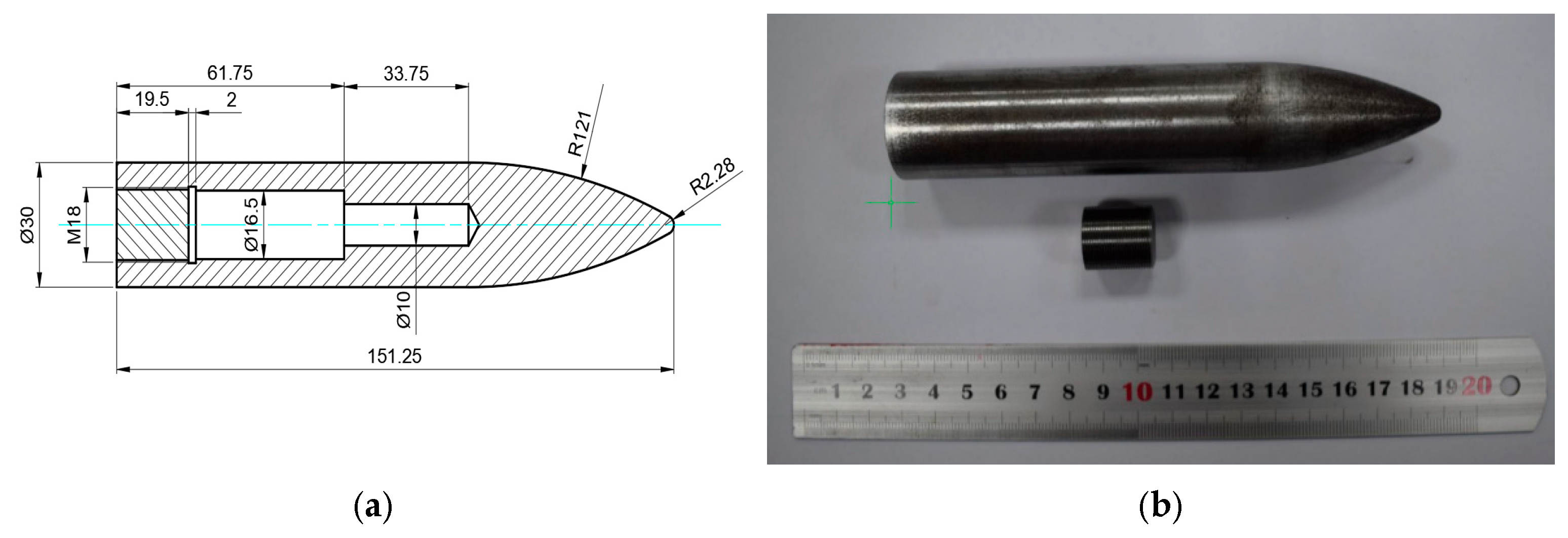

3.1. Experimental Design

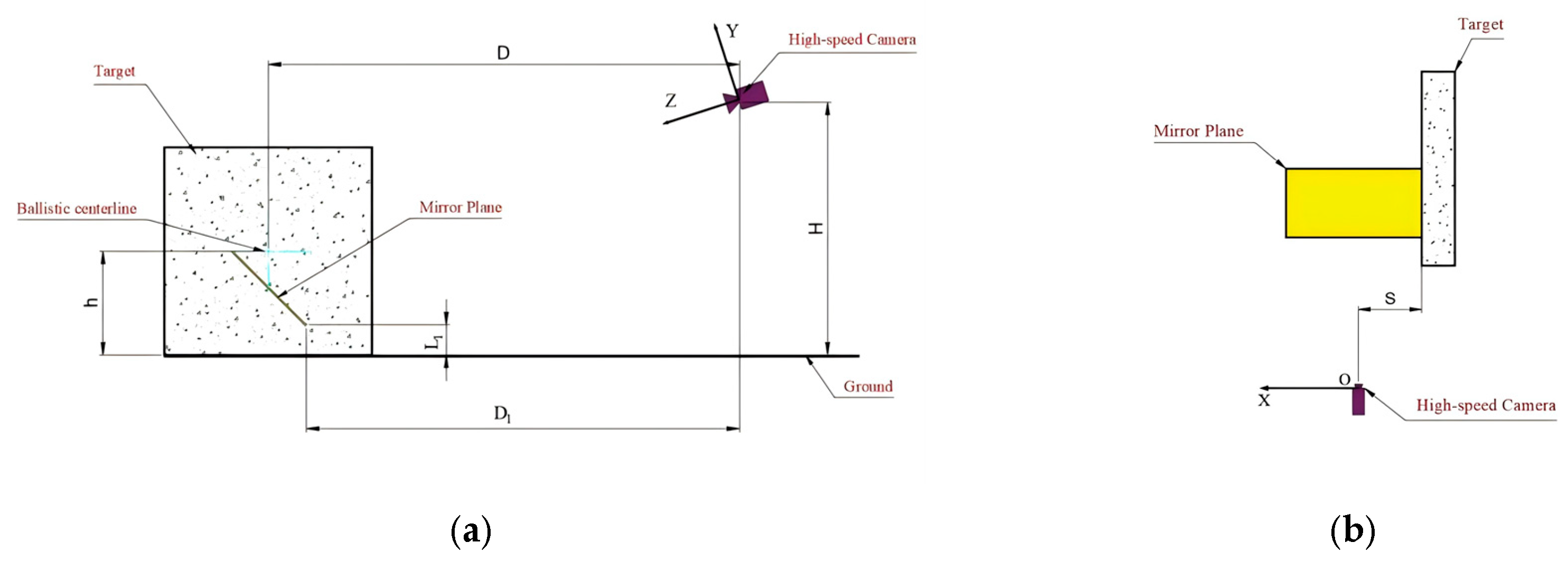

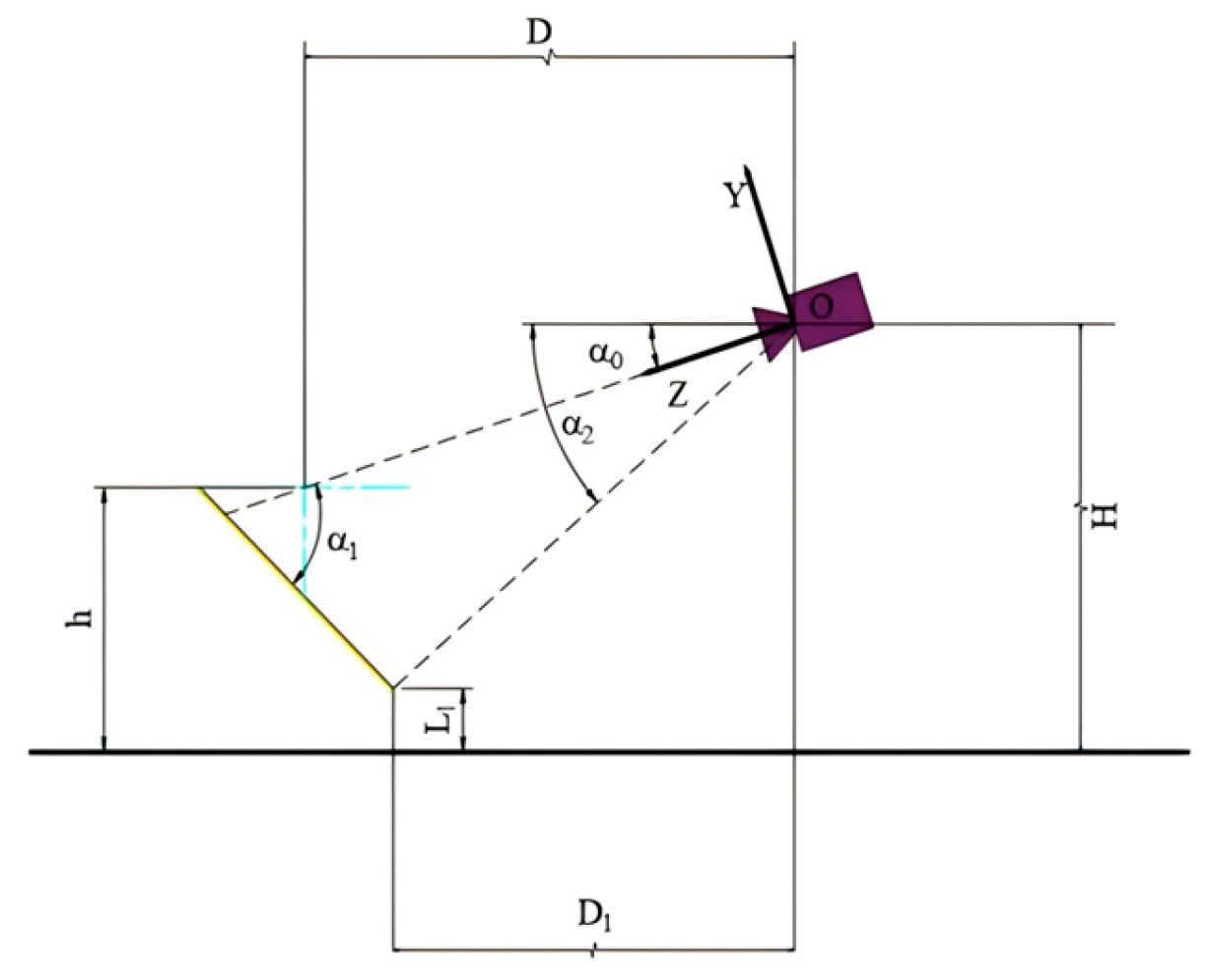

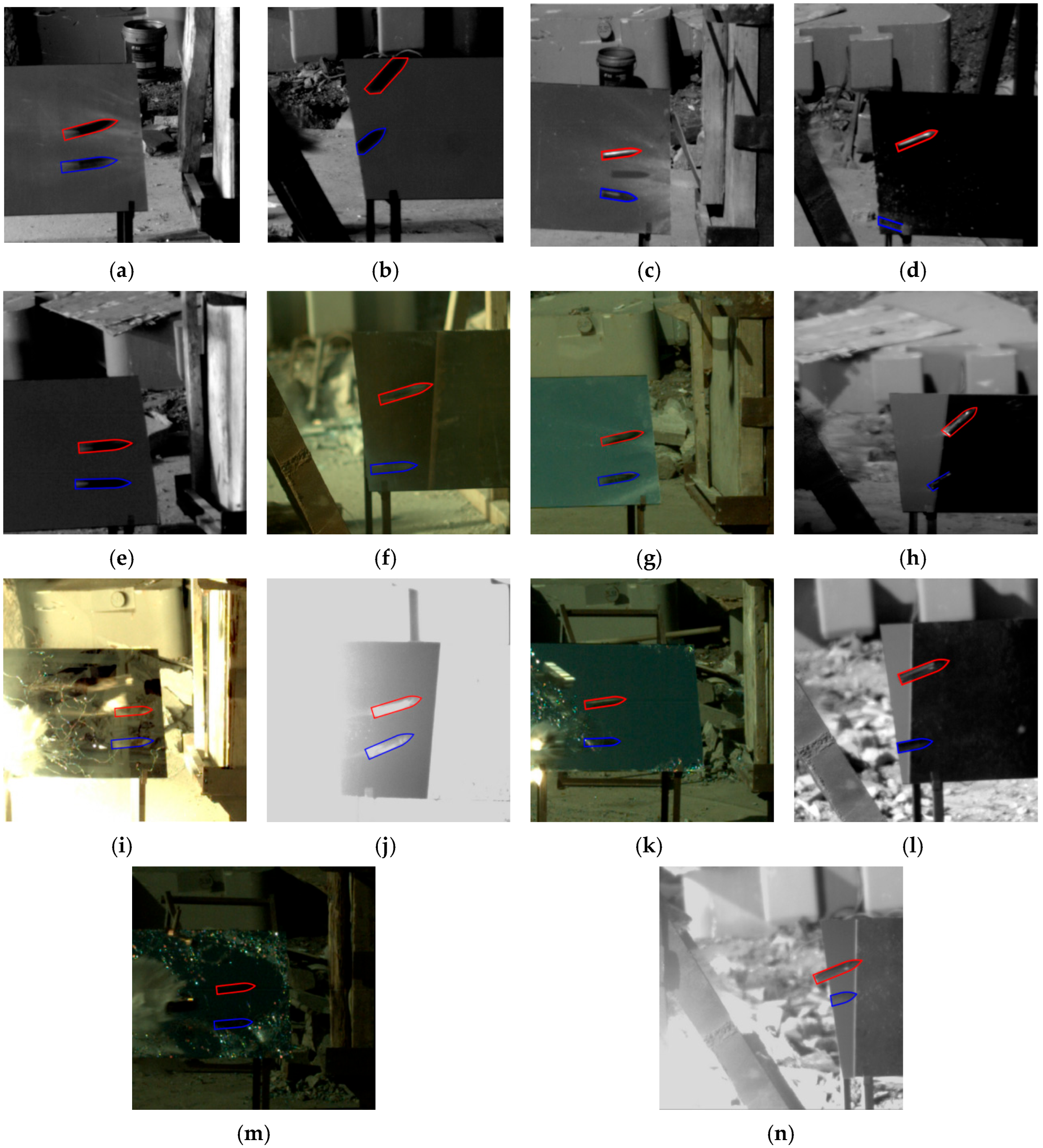

3.2. Measurement System

3.3. Results and Model Validation

4. Parametric Analysis of the Evolution of Projectile Attitude Angle and Angle of Attack During Penetration

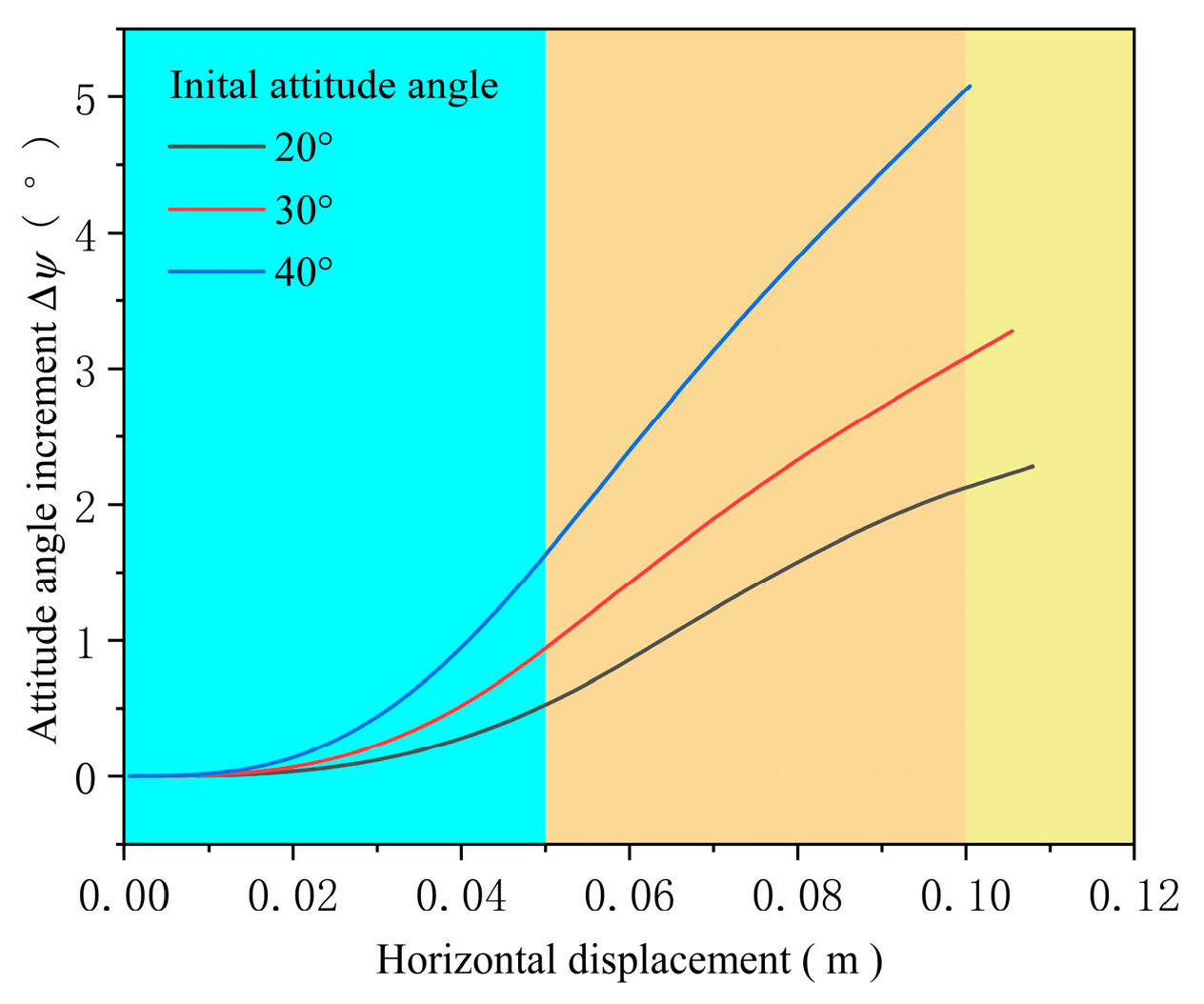

4.1. Influence of the Initial Attitude Angle

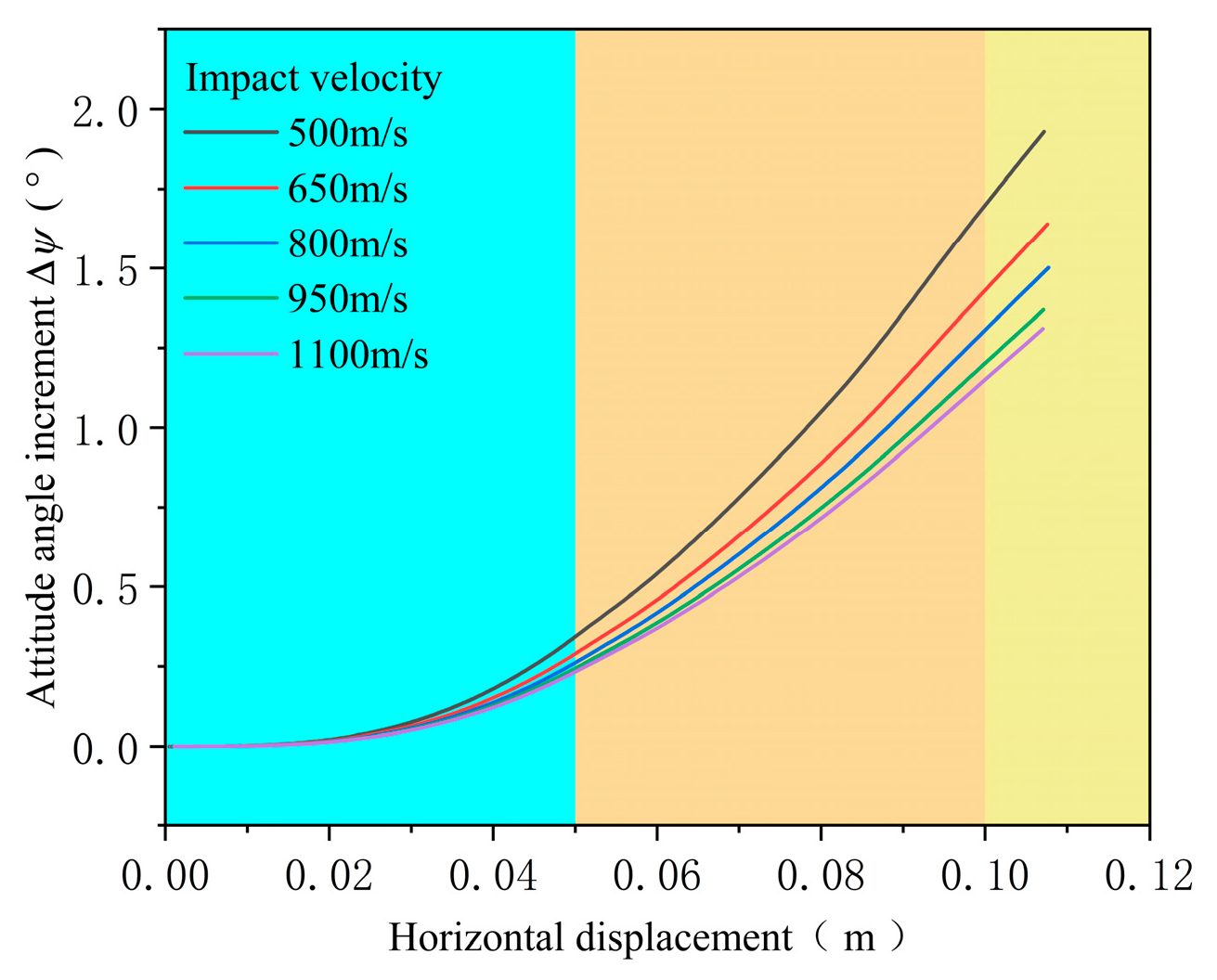

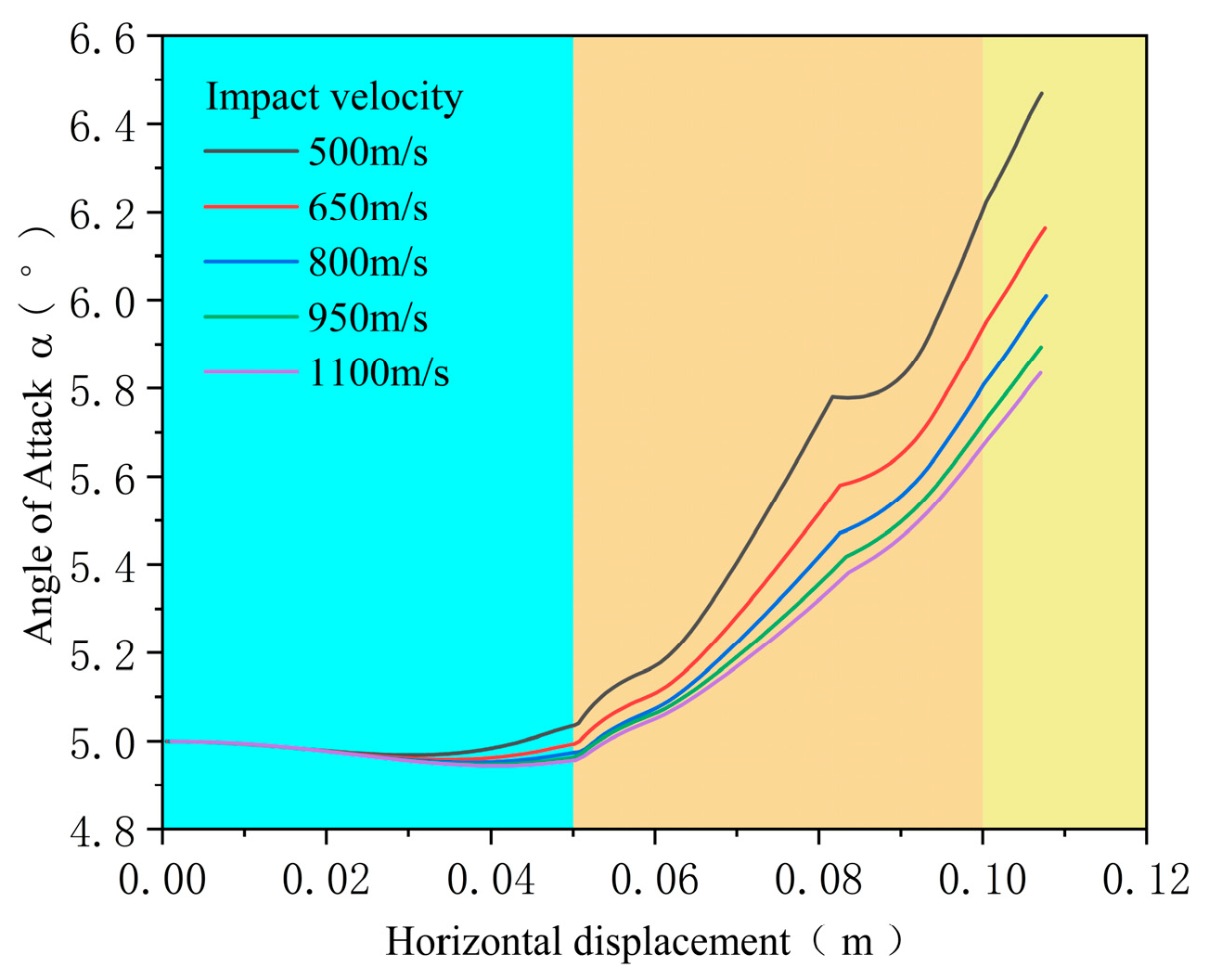

4.2. Influence of Impact Velocity

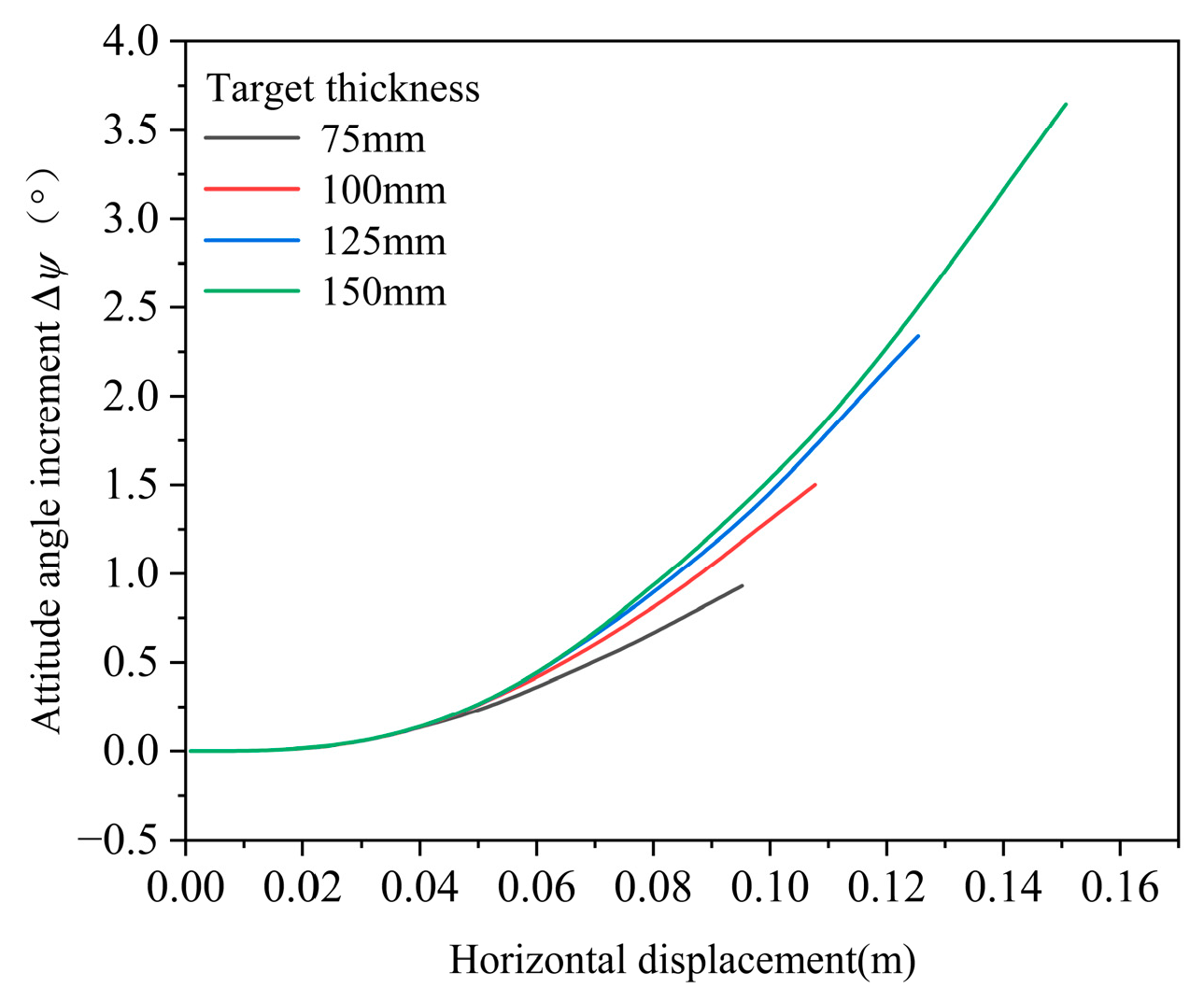

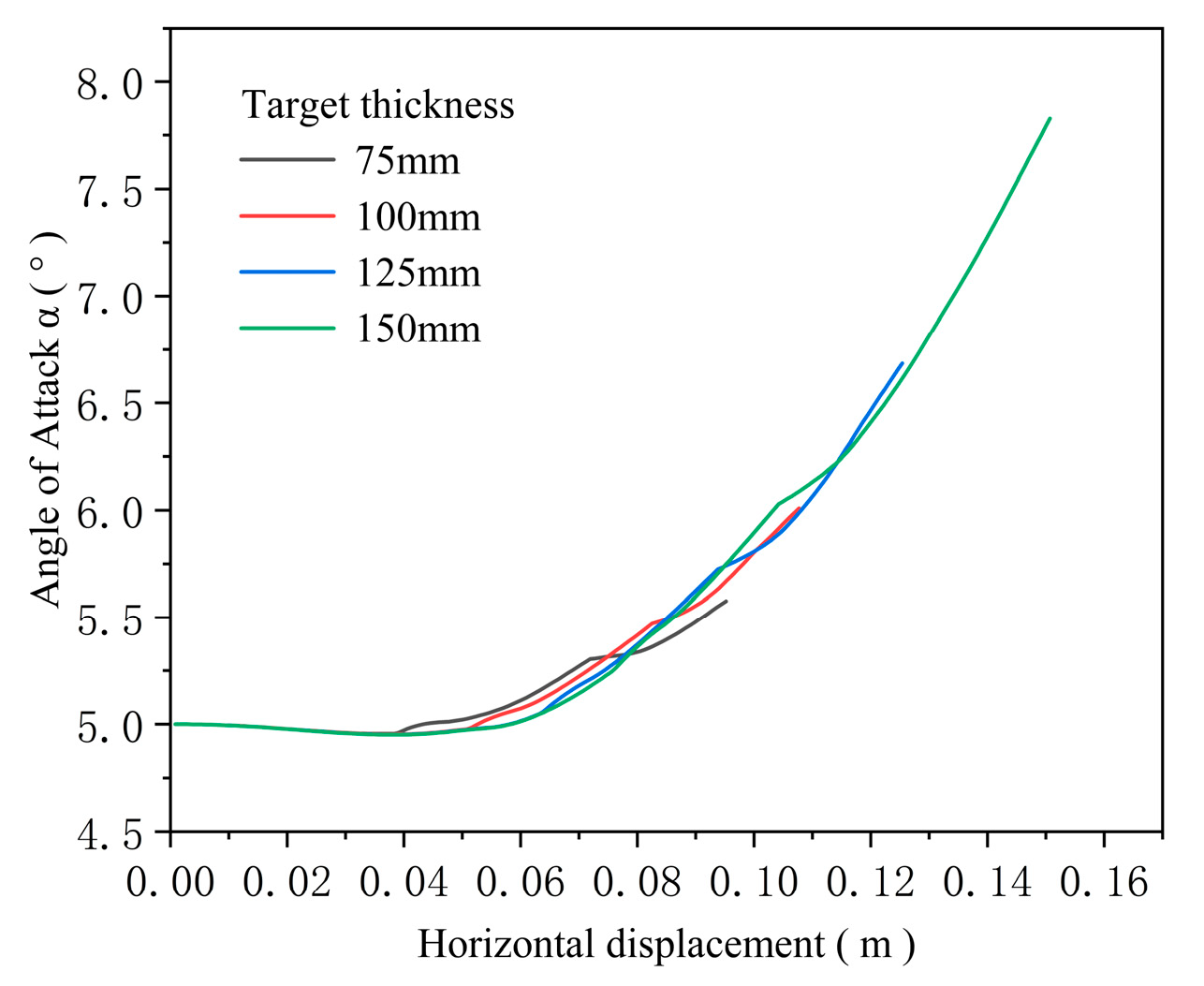

4.3. Influence of Target Thickness

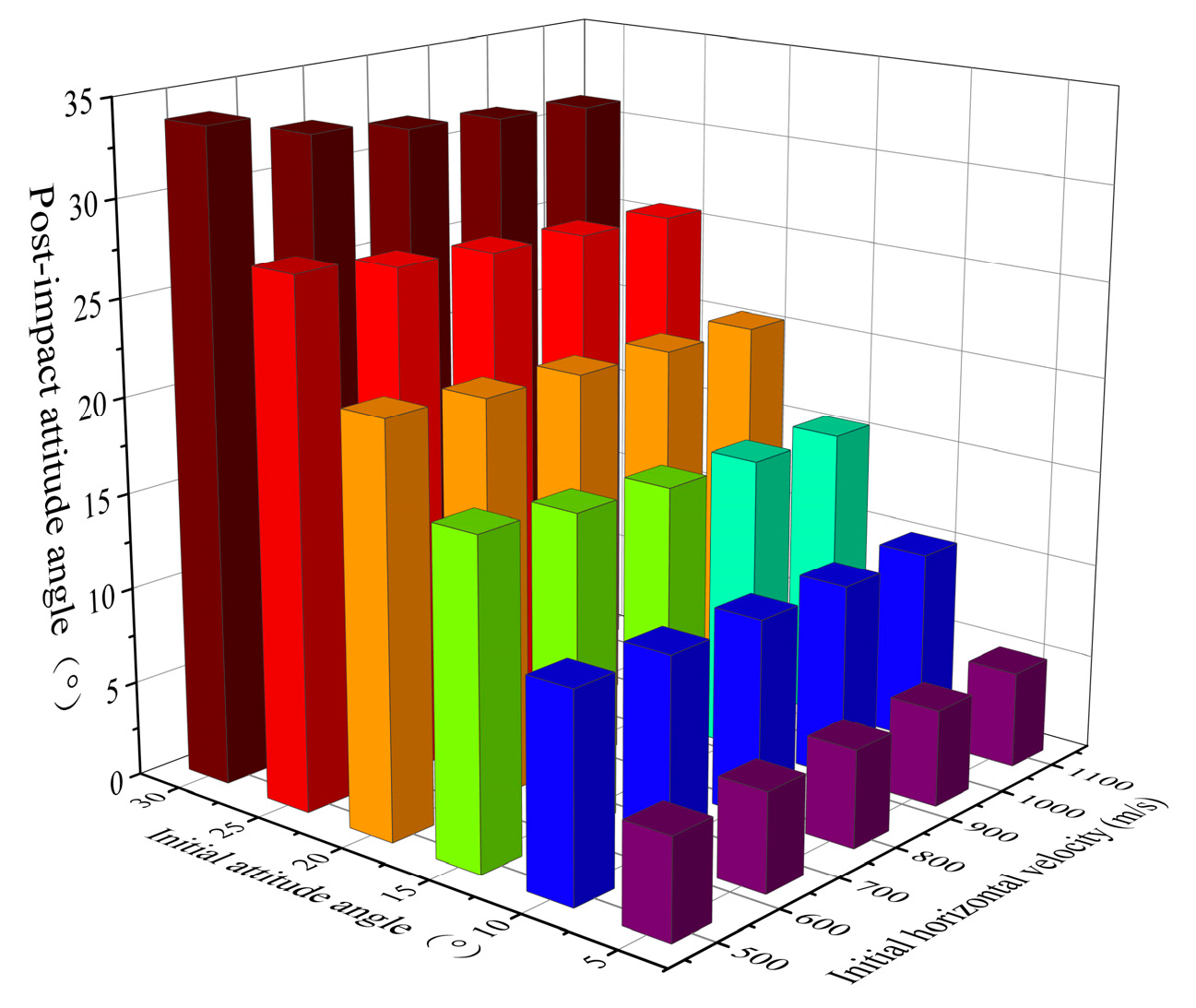

4.4. Combined Influence of Multiple Parameters

5. Conclusions

- (1)

- For rigid projectiles penetrating thin concrete targets—especially when the target thickness is less than twice the projectile nose length—the shear plugging stage initiates before the cavity formation phase is fully completed. Treating cavity formation and shear plugging as isolated processes can lead to significant errors in predicting projectile deflection trends. By introducing a dynamic shear plugging stage, the proposed model accurately captures the evolution of projectile attitude angle during penetration.

- (2)

- Application of the proposed theoretical model to the penetration of a 30 mm projectile with an angle of attack into concrete with a uniaxial compressive strength of 27 MPa yielded a maximum error of 15% in post-impact velocity and 19.7% in post-impact attitude angle relative to the experimental results. These accuracies demonstrate a higher consistency with experimental observations than those obtained from existing theoretical models.

- (3)

- When the projectile’s velocity vector lies between the projectile axis and the normal vector of the target’s front face, the angle of attack tends to decrease during the early phase of penetration. This decreasing trend becomes more pronounced as the initial attitude angle increases. However, both the final attitude angle and angle of attack upon target exit increase with higher initial attitude angles.

- (4)

- The impact velocity of the projectile influences the evolution of its attitude and angle of attack during concrete target penetration. Although a lower impact velocity reduces the normal velocity component and thus the local stress on the projectile nose surface, it also increases the time required to reach a given penetration depth. As a result, both the final attitude angle and angle of attack at exit decrease as impact velocity increases.

- (5)

- During the early stage of penetration into concrete targets of varying thicknesses, the effect of the rear free surface is negligible, and the initial resistance remains consistent across cases. Consequently, the evolution of the projectile attitude and angle of attack is initially similar. Once shear plugging begins, the angle of attack increases more rapidly, followed by a decrease in the rate of growth. Eventually, the projectile is no longer subjected to resistance from the target and rotates at a constant angular velocity, resulting in a constant rate of increase in the angle of attack per unit time. Both the final attitude angle and angle of attack increase with target thickness.

- (1)

- Conduct meso-scale numerical simulations of oblique projectile penetration into concrete to investigate the influence of aggregate on projectile attitude evolution.

- (2)

- Develop a theoretical study on the shear-plugging mechanism of concrete, aiming to explore the dynamic process of plug formation and improve the description of dynamic plugging behavior.

- (3)

- Carry out additional experimental studies on projectile penetration with an angle of attack into thin concrete targets of different strengths, in order to verify the universality of the proposed theoretical model.

- (4)

- Perform projectile penetration experiments equipped with onboard sensors to record acceleration histories during the penetration process, thereby enabling continuous refinement of the theoretical model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, R.; He, M.; Ren, H.; Shi, P. Effect of Attack Angle on a Projectile’s Penetration. Trans. Beijing Inst. Technol. 2003, 23, 26–29. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Yan, J.; Zhang, K. High-speed penetration of ogive-nose projectiles into thick concrete targets: Tests and a projectile nose evolution model. Def. Technol. 2023, 19, 1521–1532. [Google Scholar] [CrossRef]

- Hála, P.; Hurtig, K.; Řídký, R.; Šejnoha, M. Resistance of high-performance concrete panels with dispersed fiber reinforcement to oblique-angle projectile impact. J. Mater. Civ. Eng. 2025, 37, 04024001. [Google Scholar] [CrossRef]

- Yang, Z.; Lv, Z.; Wu, B. Comparative research on depth empirical formula of projectile with attack angle oblique penetration into concrete. J. Sichuan Ordnance 2014, 1, 37–40. [Google Scholar] [CrossRef]

- Li, P.; Zhang, X.; Liu, C.; Wei, H.; Liu, J.; Deng, Y. Study on the Influence of Attack Angle and Incident Angle on Ballistic Characteristics of Projectiles Penetration into Thin Concrete Targets. Explos. Shock. Waves 2022, 42, 113302. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, Y.; Guo, Z.; Zou, H. Penetration of Rigid Projectile into Concrete Target with Effect of Attack Angle: Theory and Experiment. Int. J. Struct. Stab. Dyn. 2017, 17, 1750080. [Google Scholar] [CrossRef]

- Jiang, X.; Li, Q.; Yin, X.; Xu, S. Effects of Steel Fiber and Target Thickness on the Penetration Resistance of UHPC under High Velocity Small Projectile Impact Loading. Cem. Concr. Compos. 2023, 140, 105064. [Google Scholar] [CrossRef]

- Wu, Y.; Tao, X.; Liu, Y.; Zhang, Q.; Xue, Y. Analysis on Deflection of Projectile Penetrating into Composite Concrete Targets. Materials 2022, 15, 7871. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Q.; Yin, J.; Wang, Z.; Li, X.; Yi, J. Research on the Factors Influencing the Process of Prefabricated Fragments Penetrating Finite Thickness Concrete. Sci. Rep. 2024, 14, 5380. [Google Scholar] [CrossRef]

- Xu, X.; Tao, X.; Wu, Y.; Lu, Y.; Liu, Y.; Zhang, J.; Zhang, Y. Deflection Characteristics and Influencing Factors of Projectile Oblique Impact on Concrete Targets. AIP Adv. 2024, 14, 095109. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, J.; Cheng, F.; Yu, H.; Chen, J. Mechanical Behavior and Failure Mechanism of Rock—Concrete Composites under the Coupling Effect of Inclined Interface Angle and Ground Temperature. Symmetry 2025, 17, 52. [Google Scholar] [CrossRef]

- Yan, L.; Wang, D.; Xu, Y.; Liu, M. Analysis of numerical calculation methods for oblique penetration of projectiles into concrete targets. J. Phys. Conf. Ser. 2024, 2891, 052024. [Google Scholar] [CrossRef]

- Ma, A.; Huang, F.; Chu, Z.; Li, J. Numerical Simulation on Yawed Penetration into Concrete. Explos. Shock. Waves 2008, 28, 33–36. [Google Scholar] [CrossRef]

- Zhu, Z.; Shi, Q.; Wang, G.; Hu, Q.; Zhao, S. Numerical Simulation of Attack Angle to Trajectory in Oblique Penetration. J. Proj. Rocket. Missiles Guid. 2012, 32, 609–611. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Z.; Shi, X.; Liu, F. Study on the Oblique Penetration of Kinetic Energy Projectiles Considering Incident Angle and Attack Angle. In Proceedings of the Chinese Congress of Theoretical and Applied Mechanics, Milan, Italy, 22–27 August 2021; Sichuan Aerospace System Engineering Institute: Chengdu, China, 2021. [Google Scholar]

- Liu, Y.; Ma, A.; Huang, F. Numerical Simulation of Oblique-Angle Penetration by Deformable Projectile into Concrete Target. Int. J. Impact Eng. 2009, 36, 438–446. [Google Scholar] [CrossRef]

- Jurecs, S.P.; Tabei, A. Simulation of the Effects of Angle of Attack and Projectile Contour in Damage Development in Reinforced Concrete. Designs 2021, 5, 49. [Google Scholar] [CrossRef]

- Shi, H.; Ma, S.; Li, F.; Wei, J.; Tang, T. The Influence of Attack Angle on Projectile Trajectory and Fuze in Oblique Penetration. J. Phys. Conf. Ser. 2021, 2029, 012023. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Wang, Z.; Shu, X.; Li, Q. Penetration Trajectory of Rigid Projectile in the Heterogeneous Meso-Scale Concrete Target. Adv. Struct. Eng. 2022, 25, 1469–1482. [Google Scholar] [CrossRef]

- Radchenko, P.A. Influence of Reinforcement and Attack Angle on the Destruction of a Concrete Barrier under a High-Speed Impact. Russ. Phys. J. 2023, 65, 2224–2230. [Google Scholar] [CrossRef]

- Zhang, Q.; Yuan, R.; Wang, D.; Feng, C.; Yue, J.; Sun, L. The Impact Fracture Characteristics of Concrete Slabs under Different Hammerhead Shapes, Impact Velocities and Concrete Strengths. Constr. Build. Mater. 2023, 392, 131919. [Google Scholar] [CrossRef]

- Dar, R.U.N.; Alagappan, P. Ballistic Evaluation of Reinforced Concrete Panel under Oblique Impact Scenarios: A Numerical Study. Struct. Concr. 2025; in press. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Rong, Y.; Wang, Z. Mesoscopic Analysis on Projectile Motion Characteristics in Oblique Penetration into Concrete. Def. Technol. 2025; in press. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, C.; Sheng, Q.; Deng, Y.; Wang, X. Dynamic Response of Projectile and Charge during Penetration into Concrete Target with High Velocity. Lat. Am. J. Solids Struct. 2025, 22, e8546. [Google Scholar] [CrossRef]

- Omidian, P.; Choubdar, S.; Khaledi, R.; Najafi, H. Simplified Numerical Simulation Modeling of a Reinforced Concrete Cold Joint: Case Study of Industrial Tower Foundation. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025; in press. [Google Scholar] [CrossRef]

- Rosenberg, Z.; Dekel, E.; Vayig, Y.; Kositski, R.; Malka-Markovitz, A. Penetration Mechanics of Rigid Projectiles Impacting Metallic and Concrete Targets—A Summary of Our Work. Int. J. Prot. Struct. 2025, 16, 566–590. [Google Scholar] [CrossRef]

- Chen, X.W.; Fan, S.C.; Li, Q.M. Oblique and normal perforation of concrete targets by a rigid projectile. Int. J. Impact Eng. 2004, 30, 617–637. [Google Scholar] [CrossRef]

- Duan, Z.; Li, S.; Ma, Z.; Zhang, X. Analytical model for attitude deflection of rigid projectile during oblique perforation of concrete targets. Explos. Shock. Waves 2019, 39, 060801. [Google Scholar] [CrossRef]

- Duan, Z.P.; Li, S.R.; Ma, Z.F.; Zhang, X.L. Attitude deflection of oblique perforation of concrete targets by a rigid projectile. Def. Technol. 2020, 16, 540–549. [Google Scholar] [CrossRef]

- Liu, H.; Huang, F.; Bai, Z.; Duan, Z. Analytical model research on penetration of rigid projectile into concrete target with oblique and attacking angle. Acta Armen. 2023, 44, 2381–2390. [Google Scholar] [CrossRef]

- Gao, X.; Li, Q. Trajectory Analysis of Projectile Obliquely Penetrating into Concrete Target at Attack Angle. Acta Armamentarii 2014, 35, 33–39. [Google Scholar]

- Xue, J.; Shen, P.; Wang, X. Engineering Calculation Model for a Projectile’s Penetrating into a Concrete Target with Attack Angle. J. Vib. Shock 2017, 36, 40–48. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, R.; Cui, J.; Zan, S.; Fu, J.; Wang, W.; Chen, Z. Study on Ballistic Characteristics of Projectile Penetrating Concrete Target under the Combined Action of Angle of Attack and Angle of Impact. J. Proj. Rockets Missiles Guid. 2024, 44, 43–50. [Google Scholar] [CrossRef]

- Cho, H.; Choi, M.K.; Park, S.; Kim, M.; Han, J.; Sohn, D. Determination of Critical Ricochet Conditions for Oblique Impact of Ogive-Nosed Projectiles on Concrete Targets Using Semi-Empirical Model. Int. J. Impact Eng. 2022, 165, 104214. [Google Scholar] [CrossRef]

- Li, P.; Zhang, X.; Liu, C.; Deng, Y.; Deng, Y. The Three-Dimensional Trajectory Characteristics of the Elliptical Cross-Section Projectile into Concrete Target. Int. J. Impact Eng. 2025, 206, 105414. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, M.; Zhou, S.; Ge, C.; Chen, P.; Yu, Q. Enhanced Damage Mechanism of Reinforced Concrete Targets Impacted by Reactive PELE: An Analytical Model and Experimental Validation. Def. Technol. 2024, 42, 12–30. [Google Scholar] [CrossRef]

- Gao, L.; Jiang, L.; Wang, X.; Gao, S.; Cui, H.; Liu, J.; Zhou, H. Expressions for Stress Concentration Factors for T-Joints of Hollow and Concrete-Filled Square Cross-Sections for In-Plane Axial and Bending Loads. Symmetry 2024, 16, 1082. [Google Scholar] [CrossRef]

- Li, G.; Yang, Y.; Wen, Y.; Li, J. CGSW-YOLO Enhanced YOLO Architecture for Automated Crack Detection in Concrete Structures. Symmetry 2025, 17, 890. [Google Scholar] [CrossRef]

- Mo, C.; Huang, J.; Huang, J.; Li, T.; Yang, Y. Prediction of Flexural Bearing Capacity of Aluminum-Alloy-Reinforced RC Beams Based on Machine Learning. Symmetry 2025, 17, 944. [Google Scholar] [CrossRef]

- Warren, T.L.; Poormon, K.L. Penetration of 6061-T6511 aluminum targets by ogive-nosed VAR 4340 steel projectiles at oblique angles: Experiments and simulations. Int. J. Impact Eng. 2001, 25, 993–1022. [Google Scholar] [CrossRef]

- Warren, T.L.; Forsten, R.; Cline, J.; Reaugh, J.E. Penetration of limestone targets by ogive-nosed VAR 4340 steel projectiles at oblique angles: Experiments and simulations. Int. J. Impact Eng. 2004, 30, 1307–1331. [Google Scholar] [CrossRef]

- Shan, Y. Investigation on the Mass Abrasion and Motion of the Projectile Non-Normal Penetrating into Concrete. Ph.D. Thesis, Beijing Institute of Technology, Beijing, China, 2015. (In Chinese). [Google Scholar]

- Dancygier, A.N. Rear face damage of normal and high-strength concrete elements caused by hard projectile impact. ACI Struct. J. 1998, 95, 291–304. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, H.; Fang, Q.; Zhang, J. A note on the deep penetration and perforation of hard projectiles into thick targets. Int. J. Impact Eng. 2015, 78, 37–44. [Google Scholar] [CrossRef]

- Feng, X. A Numerical Study of the Cavity Expansion Process and its Application to Penetration Mechanics. Master’s Thesis, National University of Defense Technology, Changsha, China, 2011. (In Chinese). [Google Scholar]

| NO. | Impact Velocity (m/s) | Initial Angle of Attack (°) | Target Thickness (mm) |

|---|---|---|---|

| 1# | 600 | 12 | 90 |

| 2# | 600 | 6 | 75 |

| 3# | 900 | 6 | 90 |

| 4# | 900 | 12 | 105 |

| 5# | 1200 | 6 | 90 |

| 6# | 900 | 6 | 105 |

| 7# | 900 | 6 | 75 |

| Mass (kg) | Centroid (mm) | Moment of Inertia (kg·m2) | ||||

|---|---|---|---|---|---|---|

| X | Y | Z | X-axis | Y-axis | Z-axis | |

| 0.59 | 67.99 | 0.01 | −0.02 | 9.76 × 10−5 | 9.03 × 10−4 | 9.14 × 10−4 |

| NO. | Pre-Impact Horizontal Velocity, vx0 (m/s) | Pre-Impact Attitude Angle, Ψ0 (°) | Post-Impact Horizontal Velocity, vx1 (m/s) | Post-Impact Attitude Angle, Ψ1 (°) | Target Plate Thickness, (mm) | Nose–Rear Surface Distance, (mm) |

|---|---|---|---|---|---|---|

| #1* | 610.4 | 14.9 | 496.2 | 47.9 | 90 | 505.4 |

| #2 | 617.1 | 8.7 | 559.9 | 24.4 | 79 | 683.7 |

| #3 | 871.5 | 7.1 | 803.2 | 15.5 | 94 | 738.6 |

| #4 | 933.1 | 14.2 | 780.4 | 51.3 | 98 | 729.8 |

| #5 | 1147.4 | 6.9 | 1080.5 | 25.3 | 94 | 474.5 |

| #6* | 903.9 | 6.6 | 803.3 | 23.8 | 105 | 503.6 |

| #7 | 899.4 | 8.5 | 820.9 | 27.5 | 79 | 701.6 |

| NO. | Experimental Result | Theoretical Result | Error | |||

|---|---|---|---|---|---|---|

| Post-Impact Attitude Angle, Ψ1e (°) | Post-Impact Horizontal Velocity, vx1e (m/s) | Post-Impact Attitude Angle Ψ1t (°) | Post-Impact Horizontal Velocity, vx1t (m/s) | ΔΨ/Ψ1e | Δvx/vx1e | |

| #1* | 47.9 | 496.2 | 56.6 | 570.5 | 18.0% | 15.0% |

| #2 | 24.4 | 559.9 | 26.6 | 588.5 | 8.9% | 5.1% |

| #3 | 15.5 | 803.2 | 18.5 | 839.7 | 19.7% | 4.5% |

| #4 | 51.3 | 780.4 | 60.5 | 832.2 | 17.8% | 6.6% |

| #5 | 25.3 | 1080.5 | 21.6 | 1115.4 | −14.5% | 3.2% |

| #6* | 23.8 | 803.3 | 25.4 | 865.8 | 6.7% | 7.8% |

| #7 | 27.5 | 820.9 | 27.8 | 873.8 | 1.1% | 6.4% |

| NO. | Duan’s Theoretical Result | Liu’s Theoretical Result | ||

|---|---|---|---|---|

| Post-Impact Attitude Angle, Ψ1D (°) | Post-Impact Horizontal Velocity, Vx1D (m/s) | Post-Impact Attitude Angle, Ψ1L (°) | Post-Impact Horizontal Velocity, Vx1L (m/s) | |

| #1* | 2.4 | 559.5 | 0.2 | 539.4 |

| #2 | 3.6 | 594.6 | 2.1 | 581.0 |

| #3 | 3.4 | 848.5 | 2.7 | 833.4 |

| #4 | 6.2 | 867.2 | 4.3 | 848.6 |

| #5 | 5.3 | 1121.9 | 4.5 | 1109.0 |

| #6* | 3.0 | 880.1 | 2.4 | 862.4 |

| #7 | 5.6 | 872.9 | 4.5 | 862.5 |

| Theoretical Model | Mean Absolute Error (MAE) | Root Mean Square Error (RMSE) | Mean Absolute Percentage Error (MAPE) |

|---|---|---|---|

| the present model | 4.1 | 5.2 | 12.4% |

| Duan’s model | 26.6 | 29.3 | 84.6% |

| Liu’s model | 27.9 | 30.6 | 88.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, Z.; Li, W.; Zhu, W.; Xu, J.; Yan, J. Angle-of-Attack, Induced Attitude Evolution in a Coupled Crater, and Plugging Penetration of Thin Concrete Targets. Symmetry 2025, 17, 1572. https://doi.org/10.3390/sym17091572

Tao Z, Li W, Zhu W, Xu J, Yan J. Angle-of-Attack, Induced Attitude Evolution in a Coupled Crater, and Plugging Penetration of Thin Concrete Targets. Symmetry. 2025; 17(9):1572. https://doi.org/10.3390/sym17091572

Chicago/Turabian StyleTao, Zheng, Wenbin Li, Wei Zhu, Junjie Xu, and Jihua Yan. 2025. "Angle-of-Attack, Induced Attitude Evolution in a Coupled Crater, and Plugging Penetration of Thin Concrete Targets" Symmetry 17, no. 9: 1572. https://doi.org/10.3390/sym17091572

APA StyleTao, Z., Li, W., Zhu, W., Xu, J., & Yan, J. (2025). Angle-of-Attack, Induced Attitude Evolution in a Coupled Crater, and Plugging Penetration of Thin Concrete Targets. Symmetry, 17(9), 1572. https://doi.org/10.3390/sym17091572