NURBS Morphing Optimization of Drag and Lift in a Coupe-Class Vehicle Using Symmetry-Plane Comparison of Aerodynamic Performance

Abstract

1. Introduction

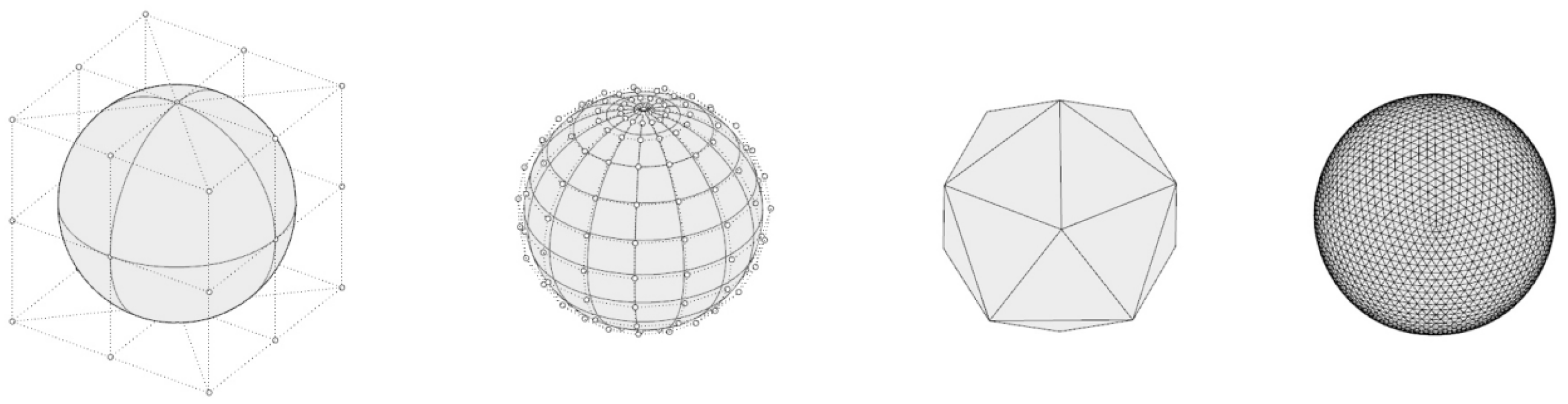

2. Basis of NURBS

2.1. NURBS Definition

2.1.1. Components of NURBS Definitions

2.1.2. Knot Vector

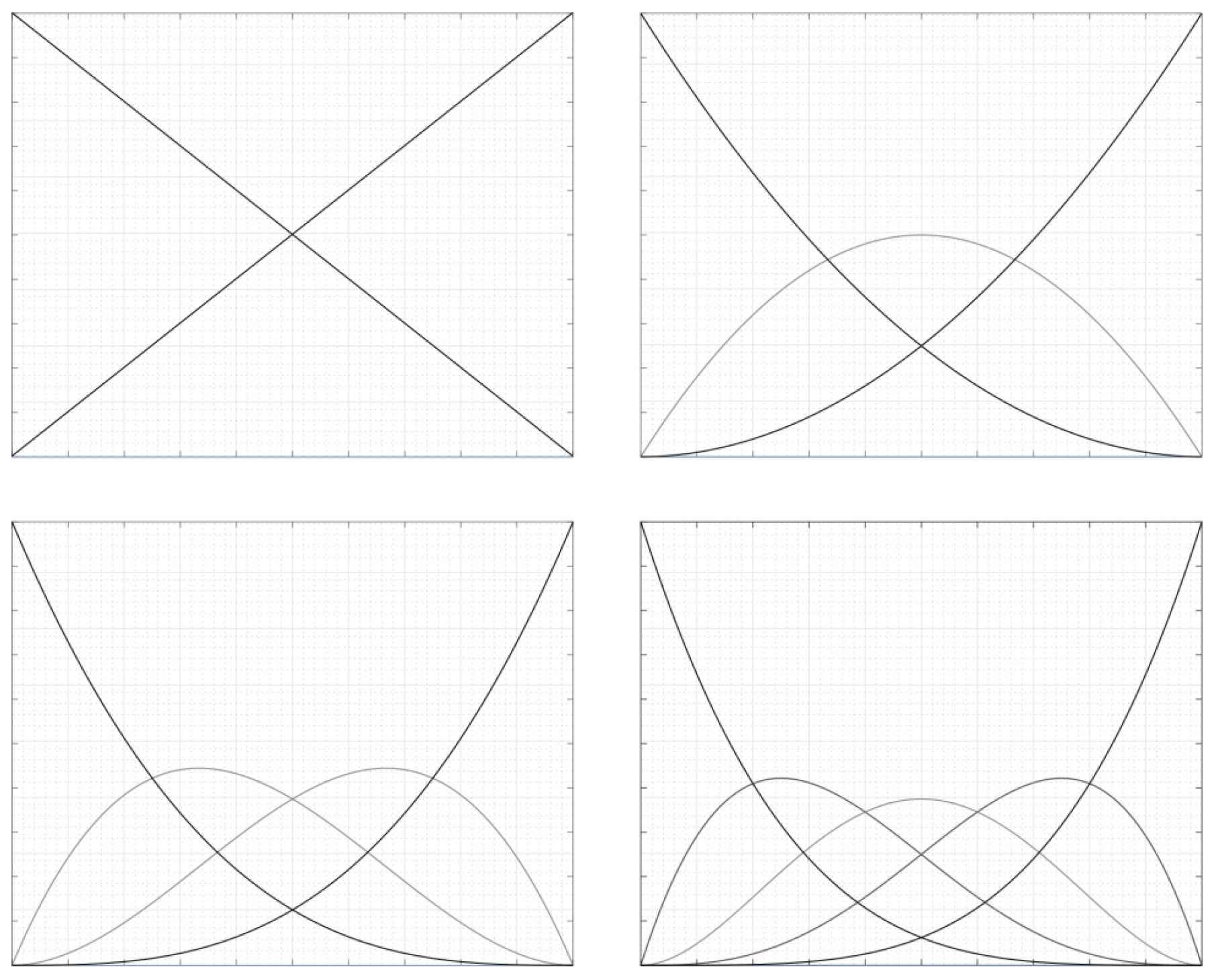

2.1.3. B-Spline

2.1.4. Basis Functions

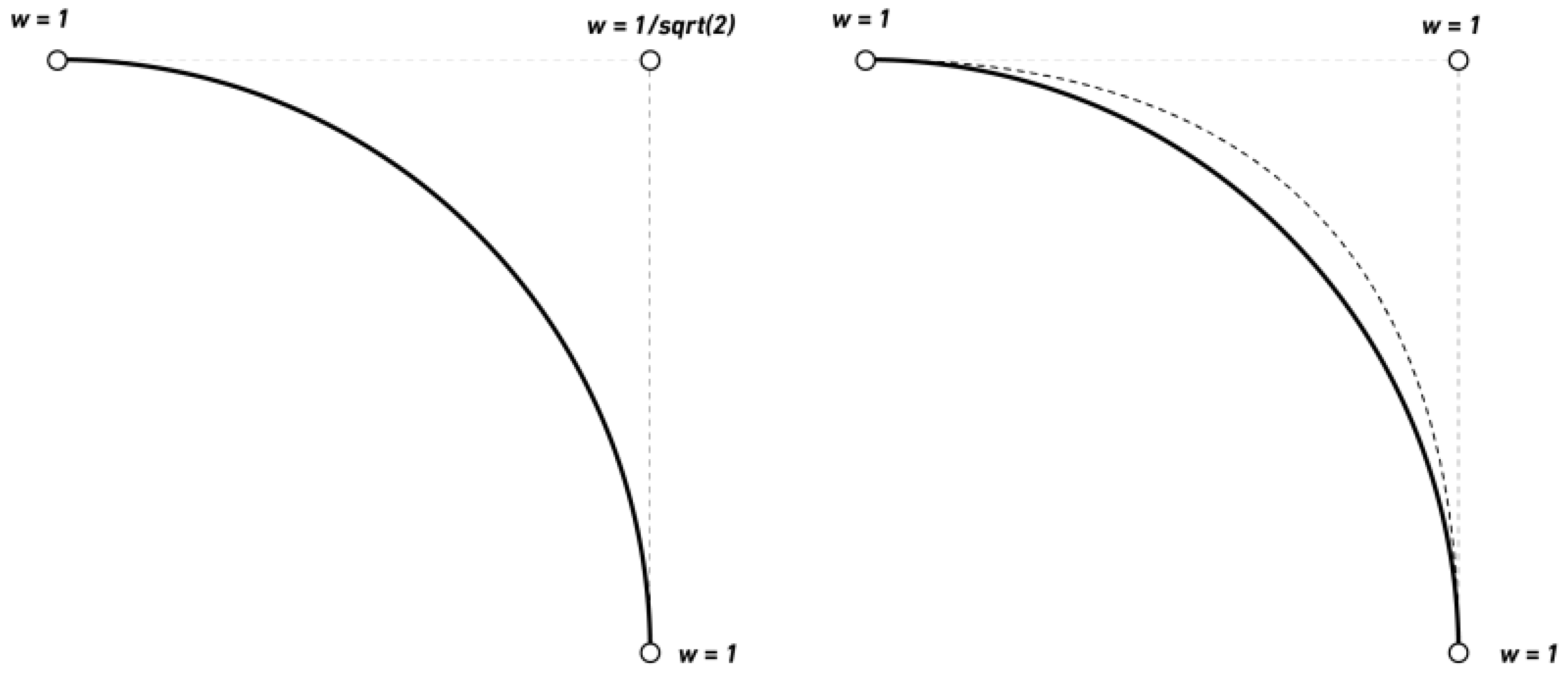

2.1.5. NURBS Basis

2.2. NURBS Surfaces

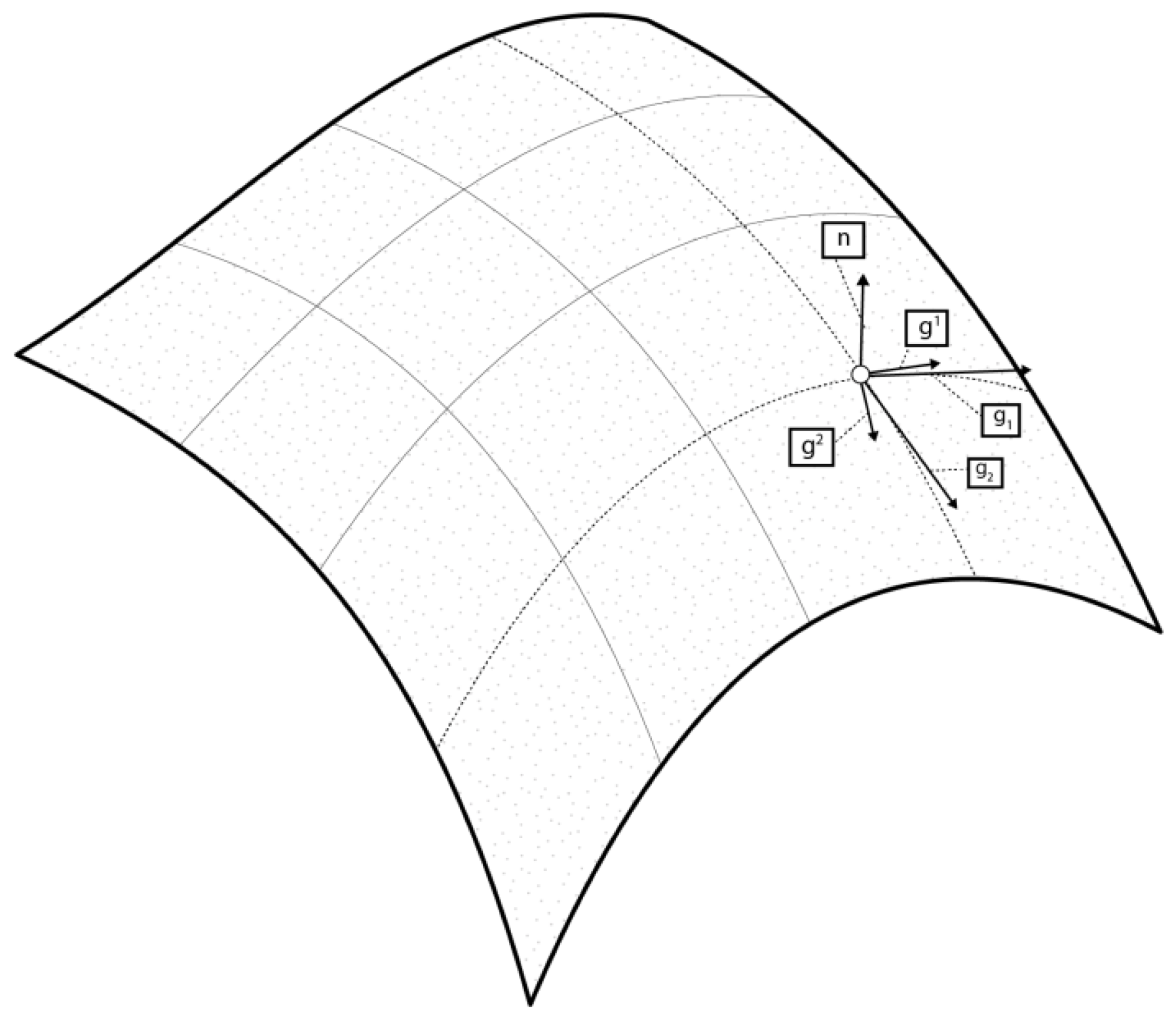

2.3. Differential Geometry

3. Problem Setup

3.1. Turbulence Modeling

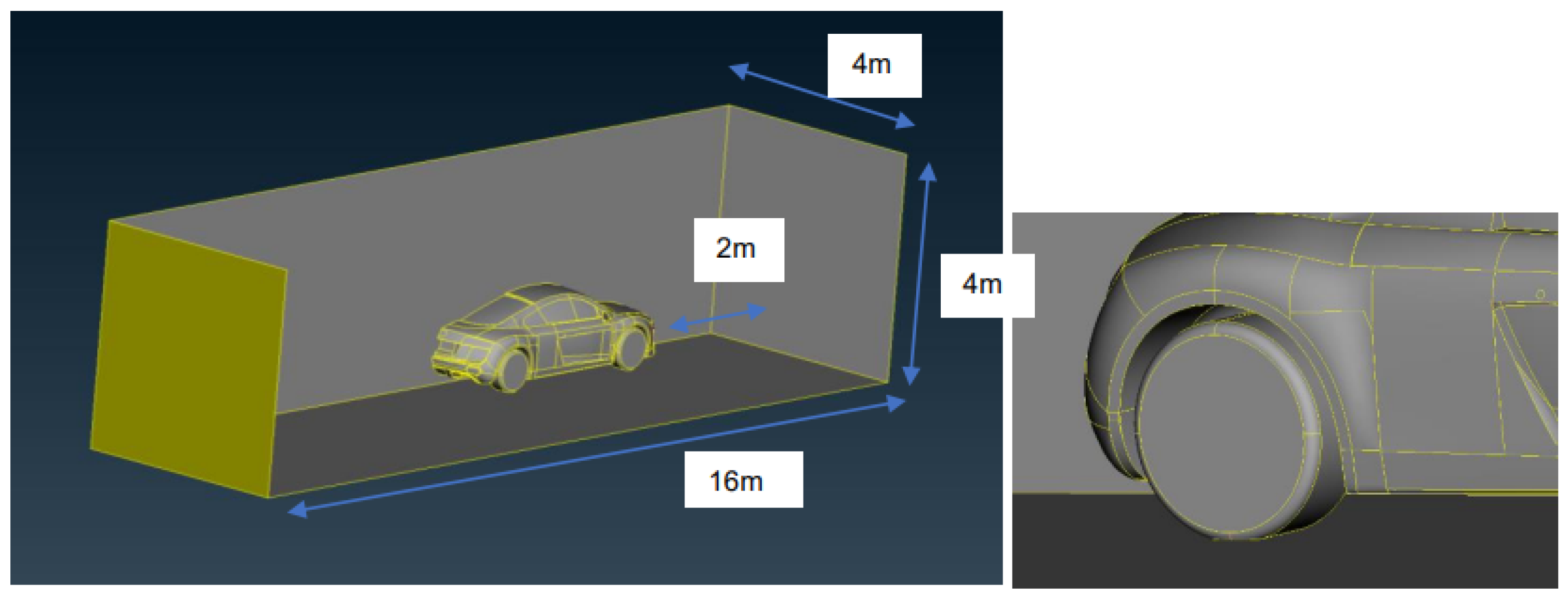

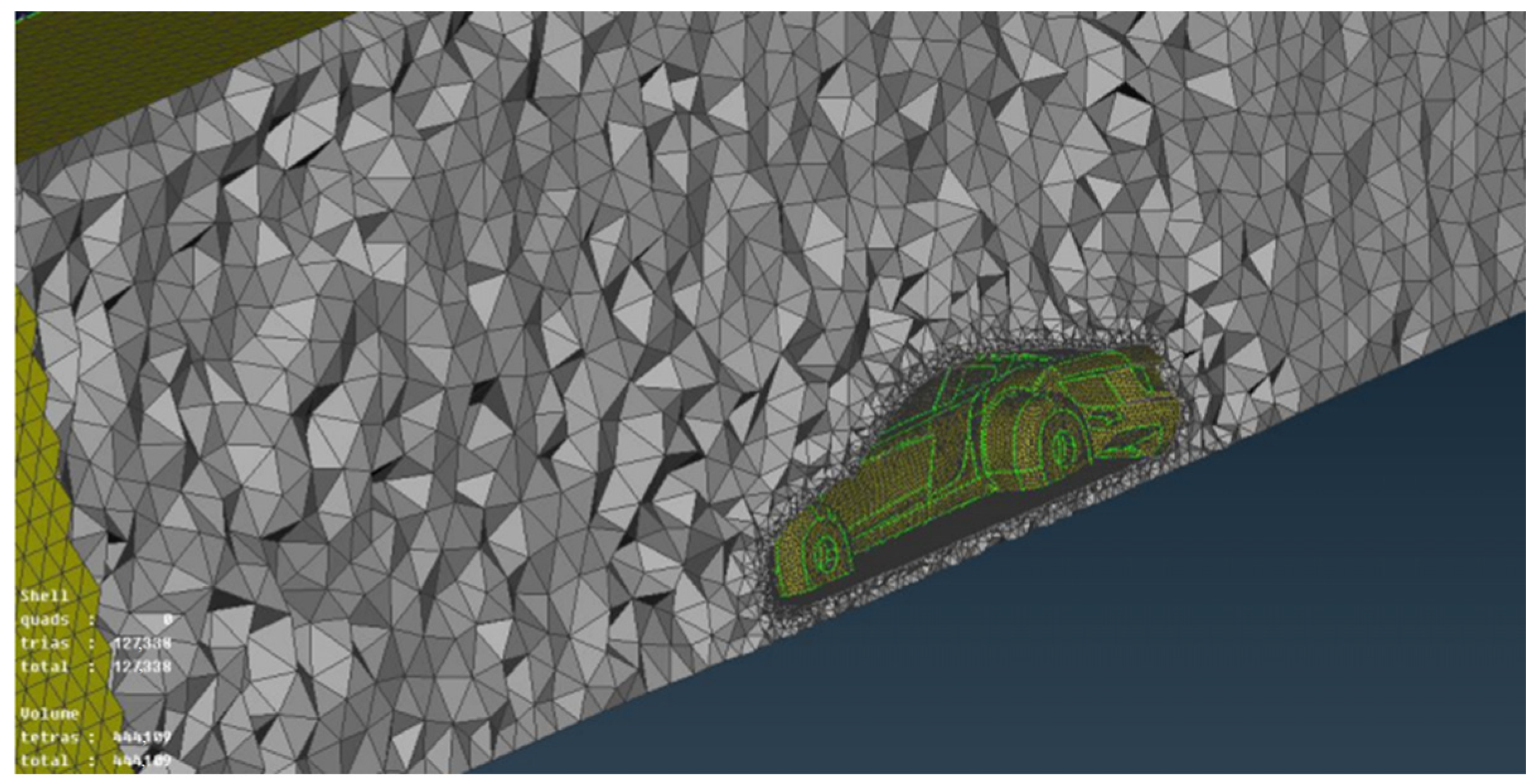

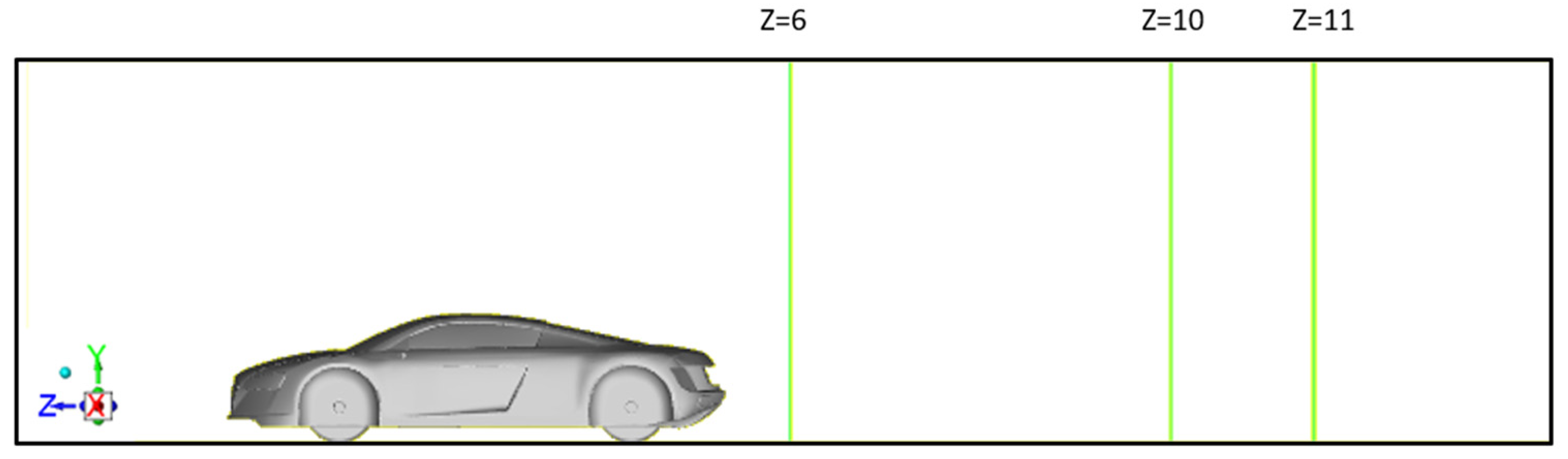

3.2. Domain and Boundary Conditions

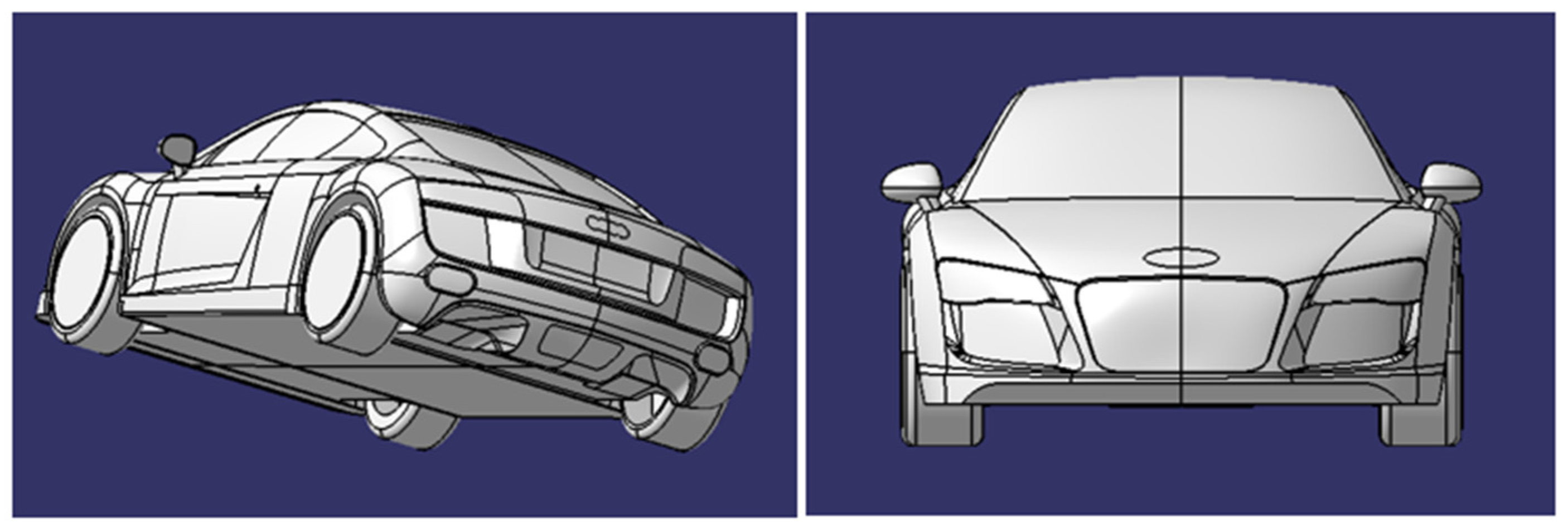

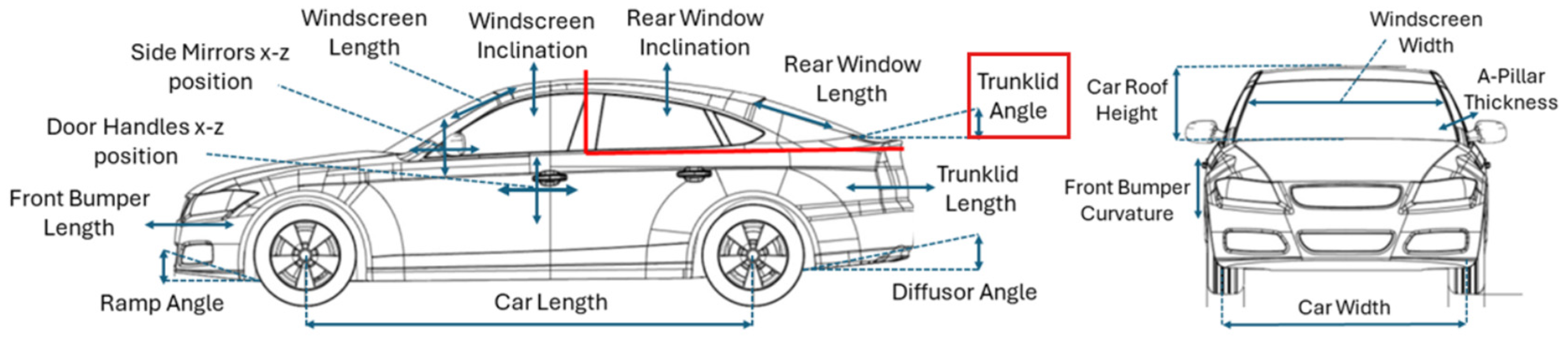

3.2.1. 3D Model

3.2.2. Boundary Conditions

4. Results and Discussion

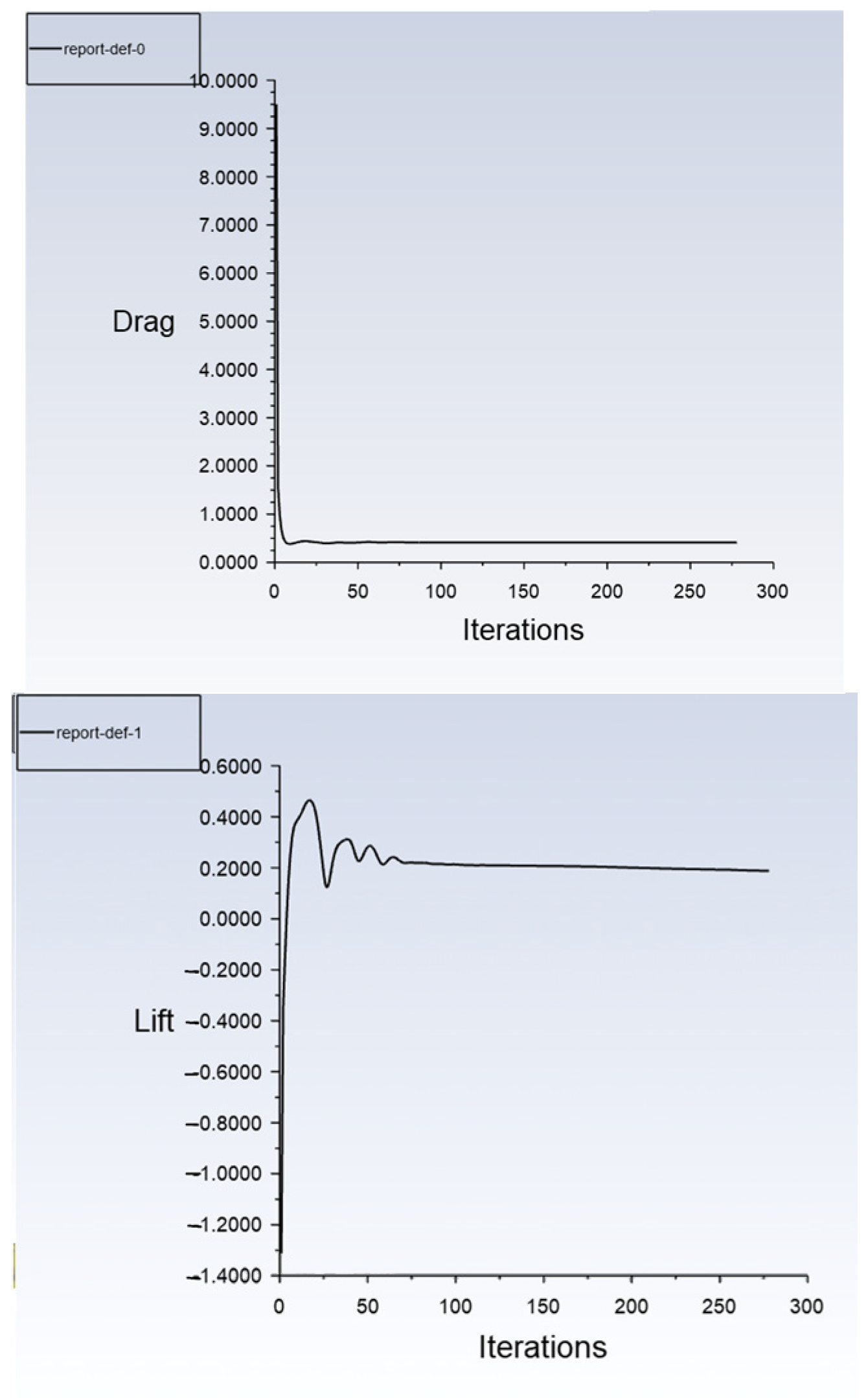

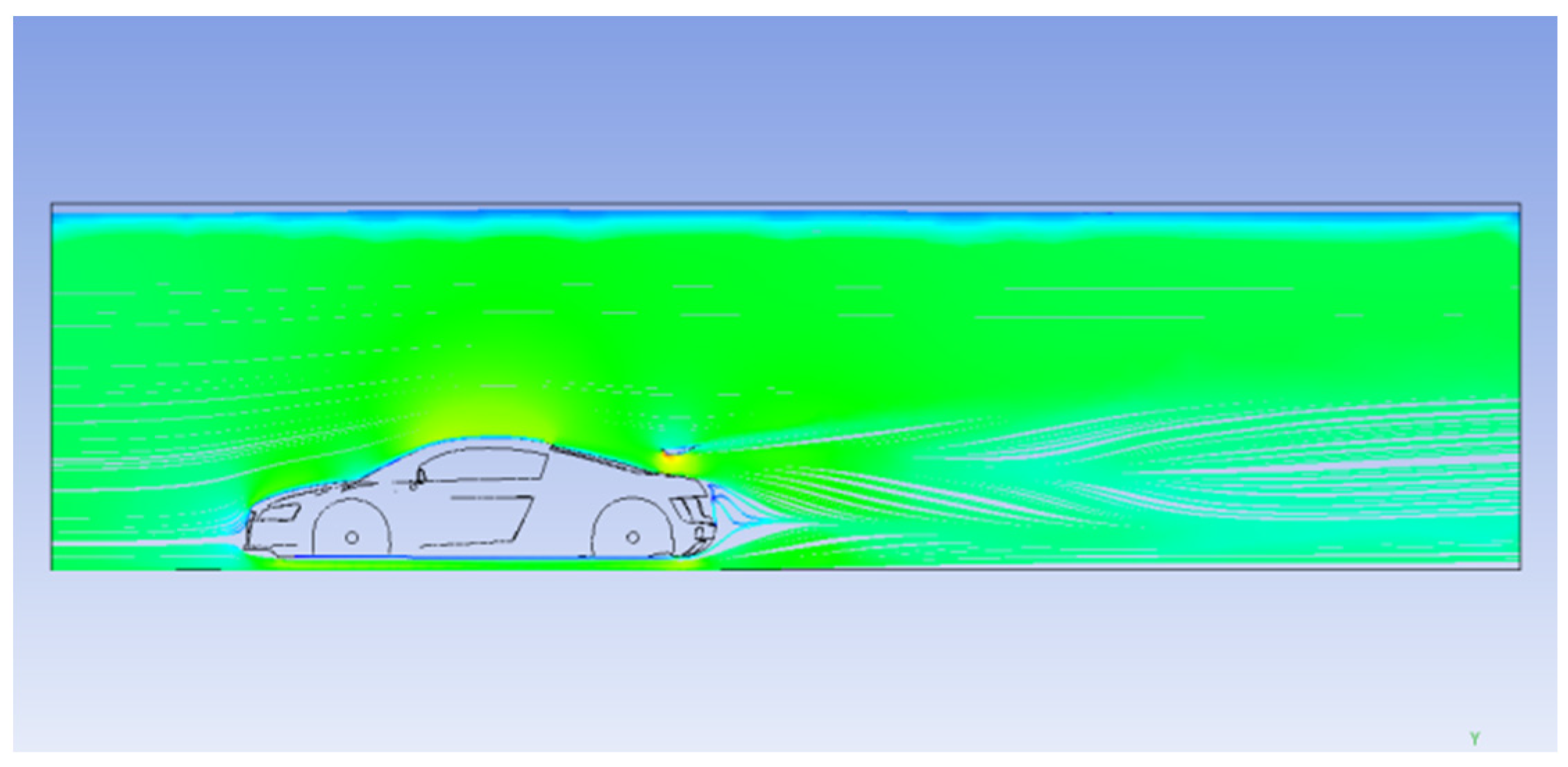

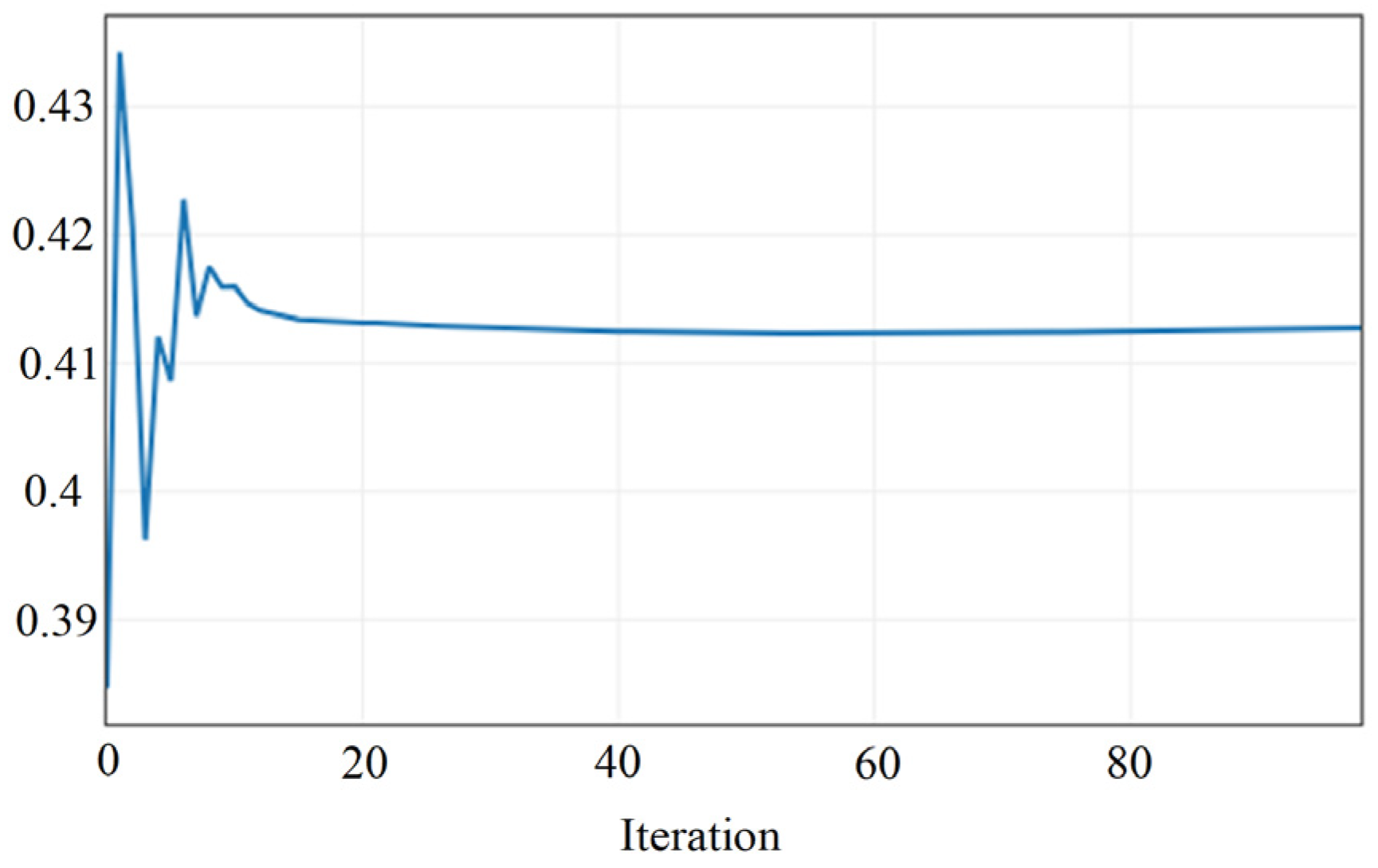

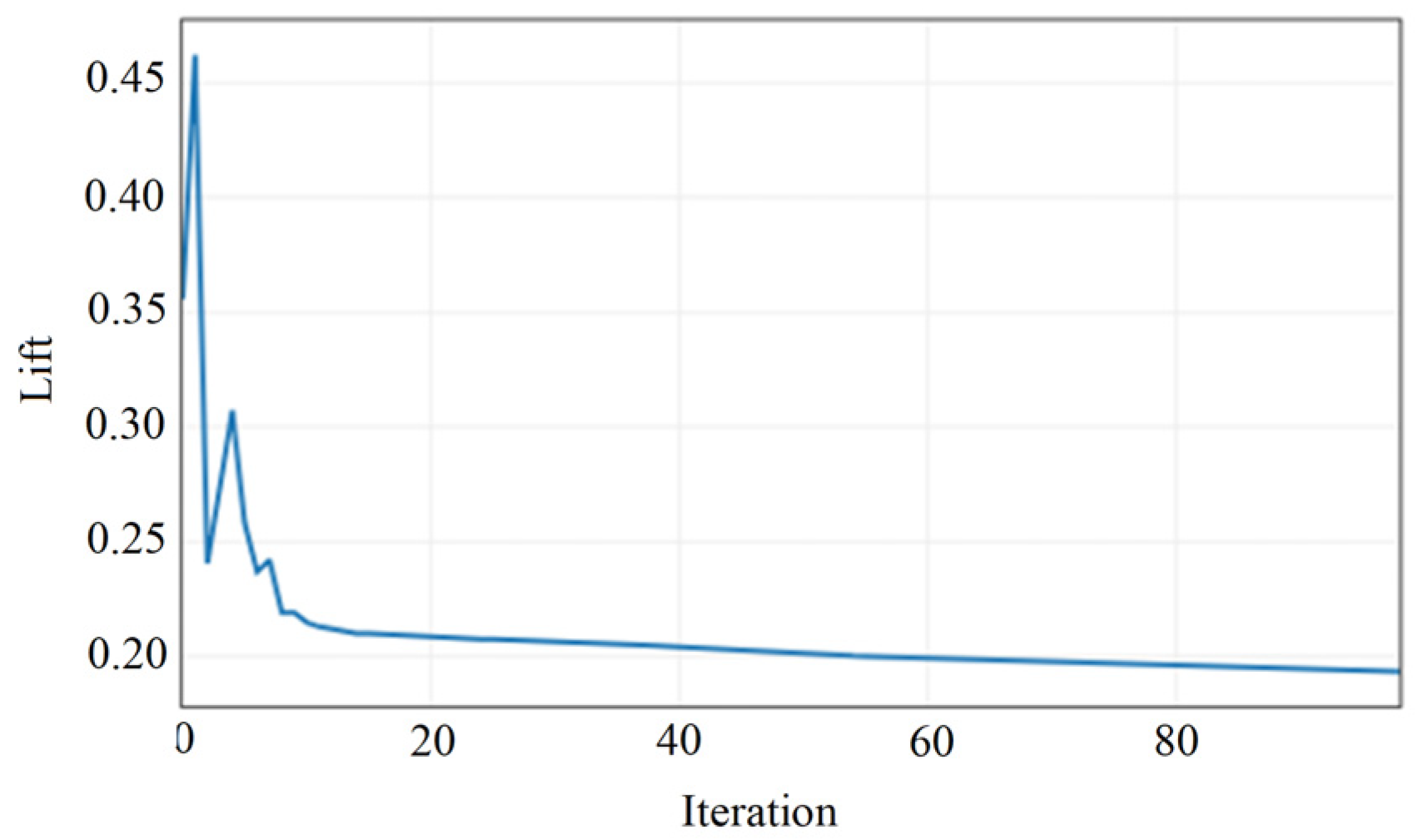

4.1. Post-Processing of the Original Geometry

4.2. Geometry Optimization by Adding Spoiler to the CAD Geometry

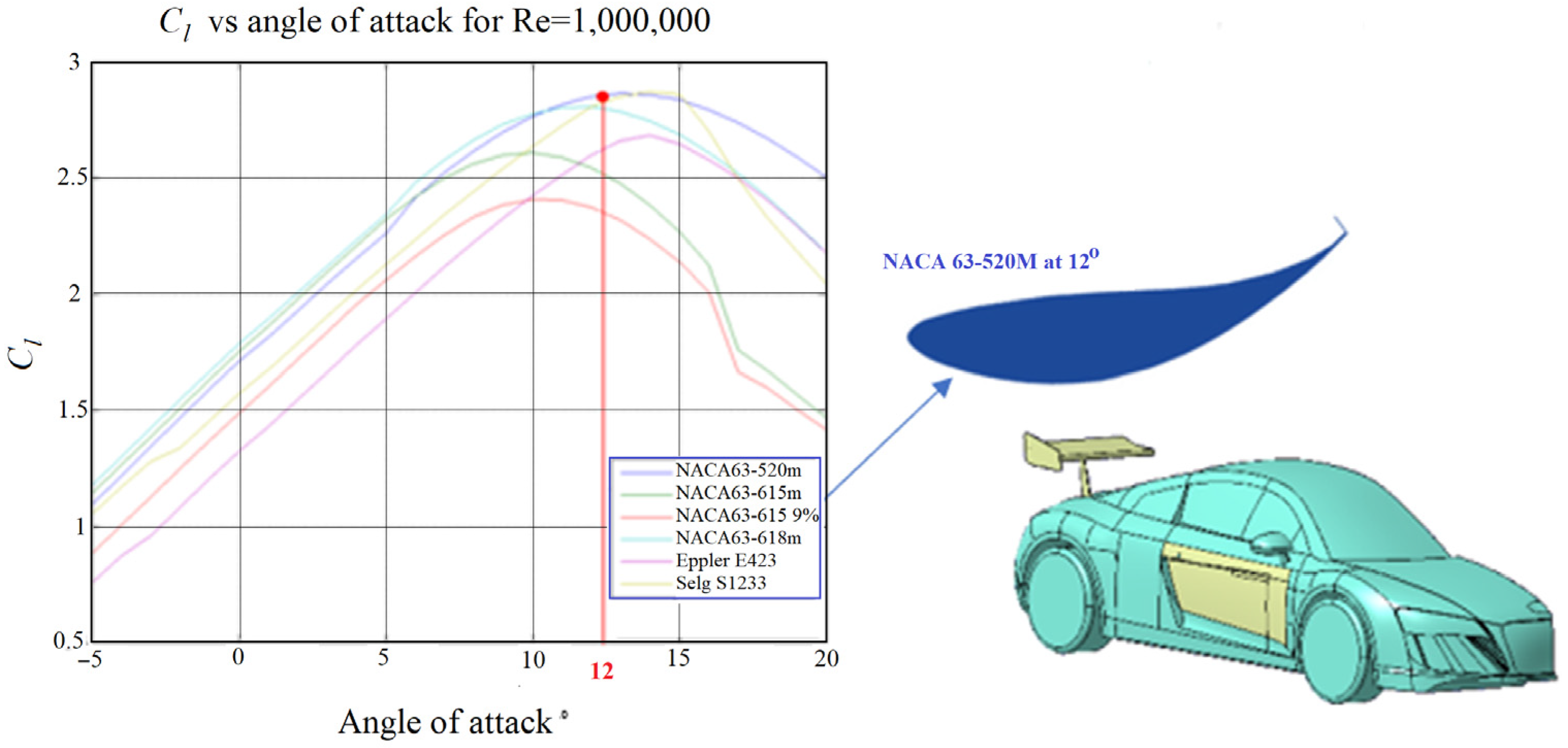

4.2.1. Spoiler Design

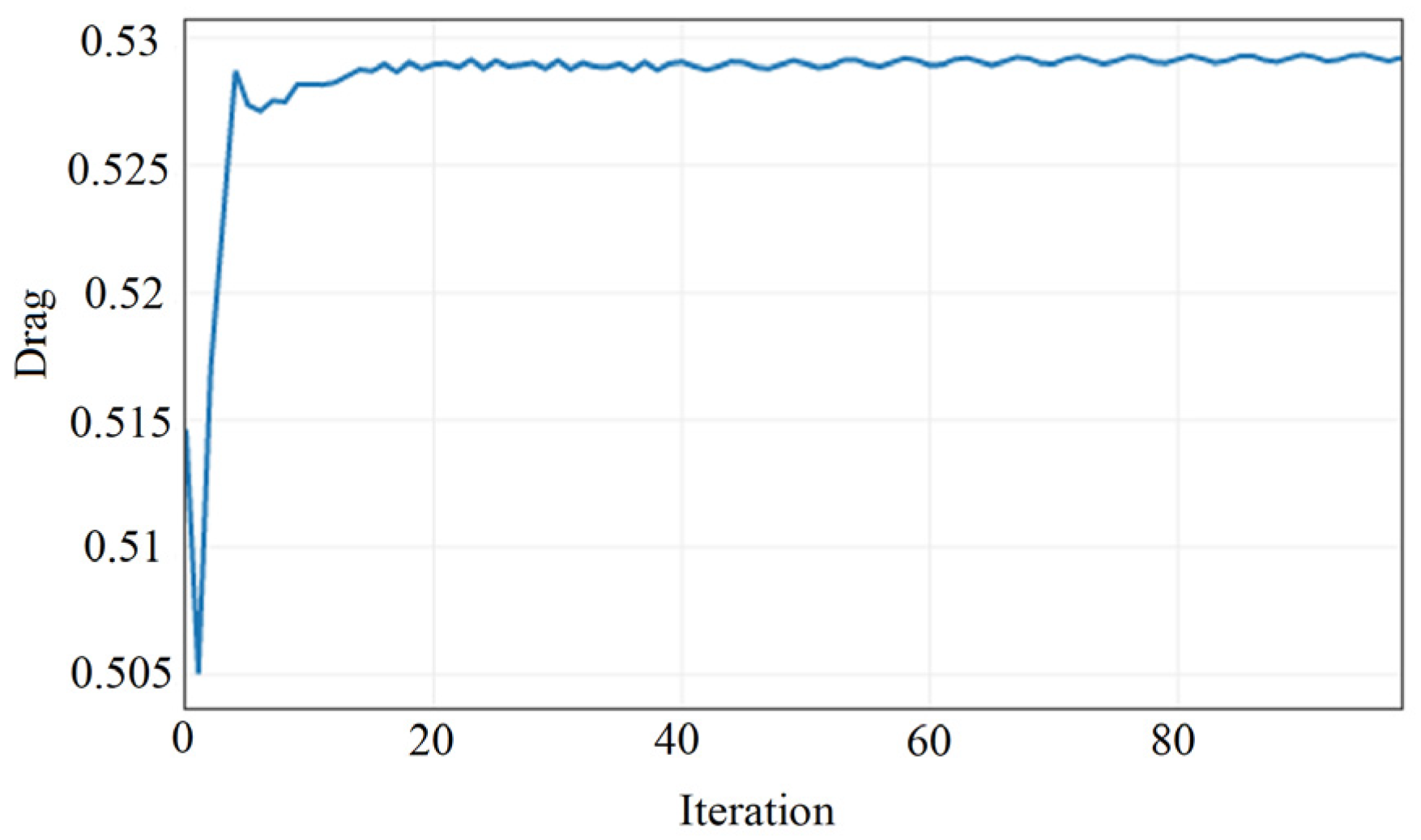

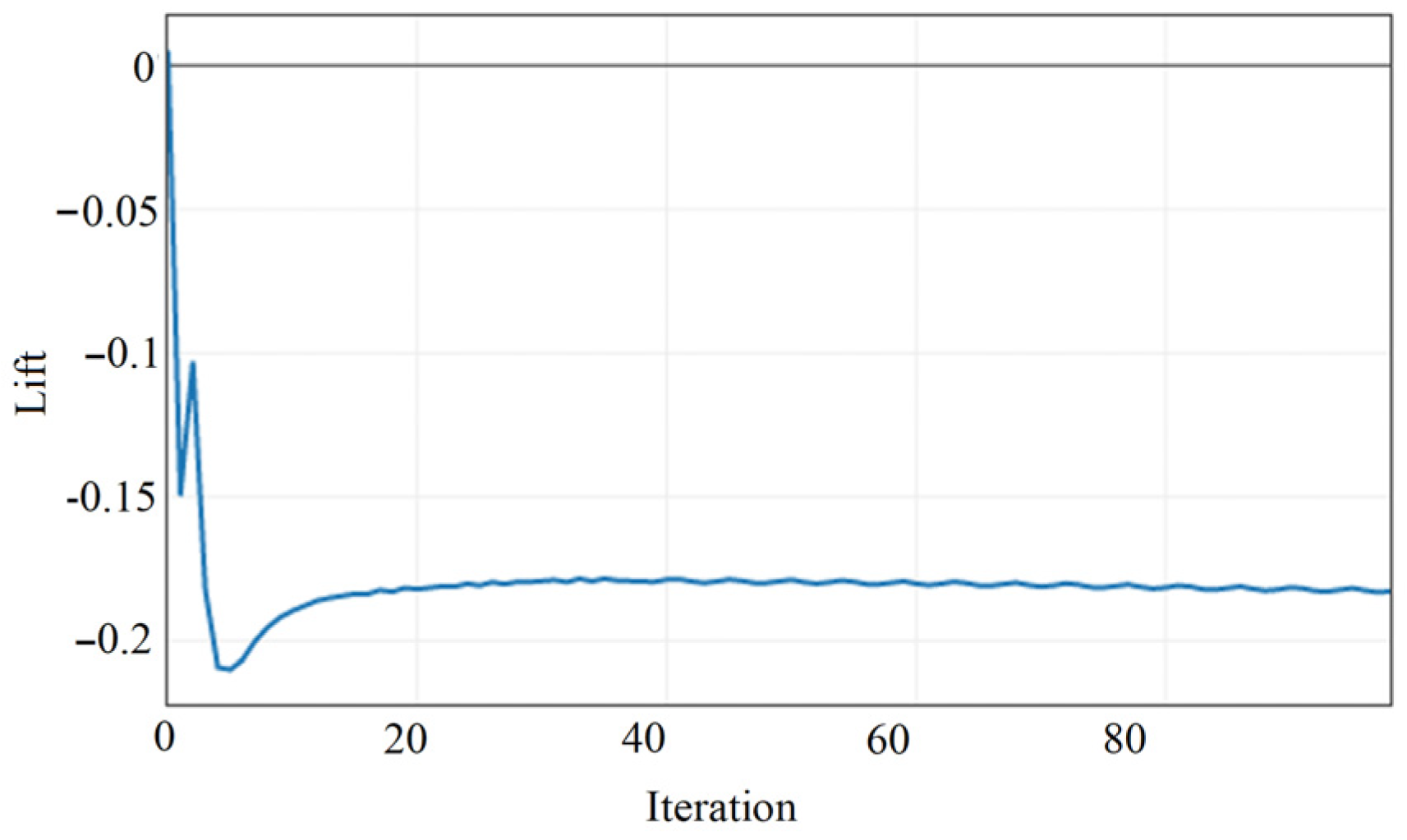

4.2.2. Post-Processing of the Geometry with Spoiler

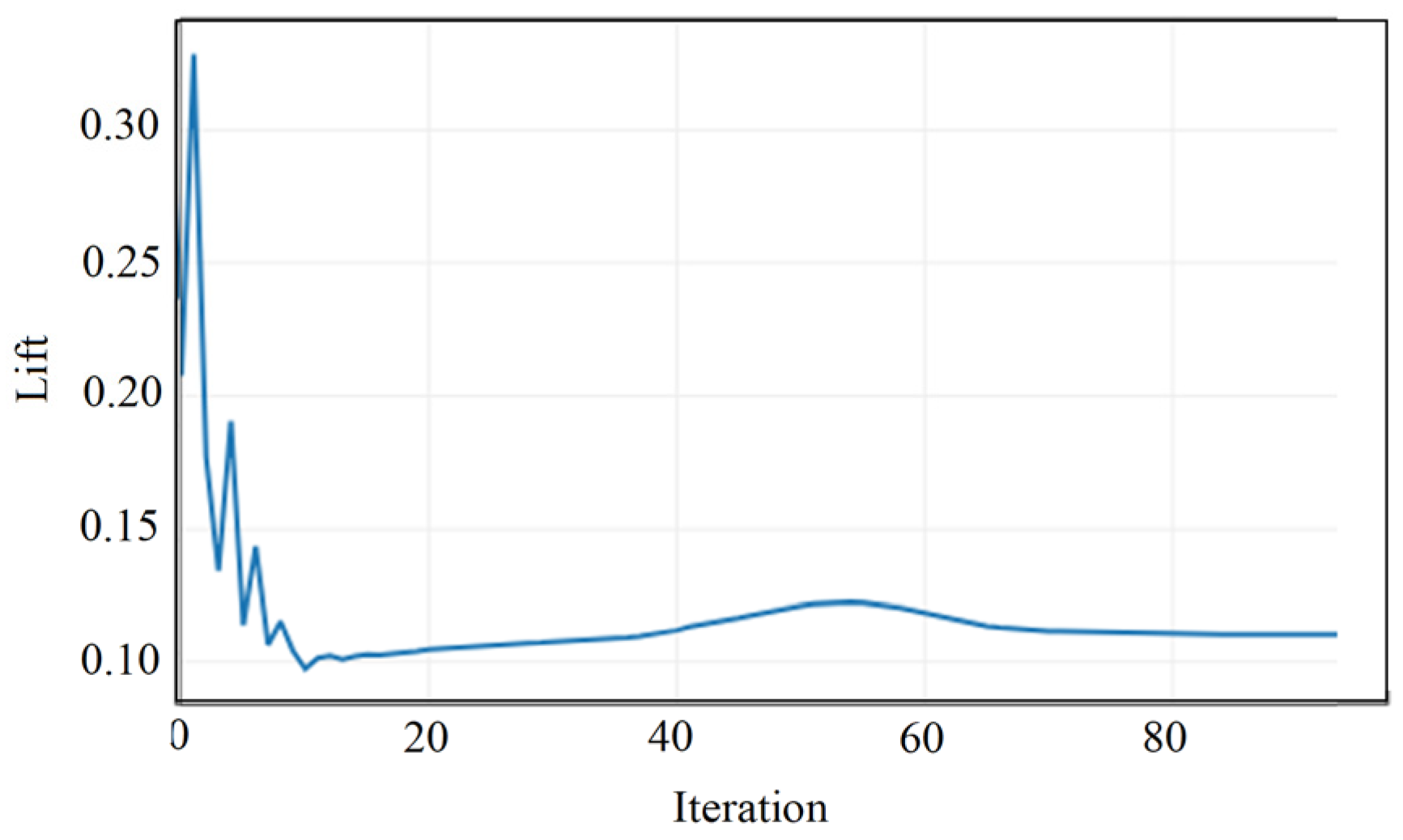

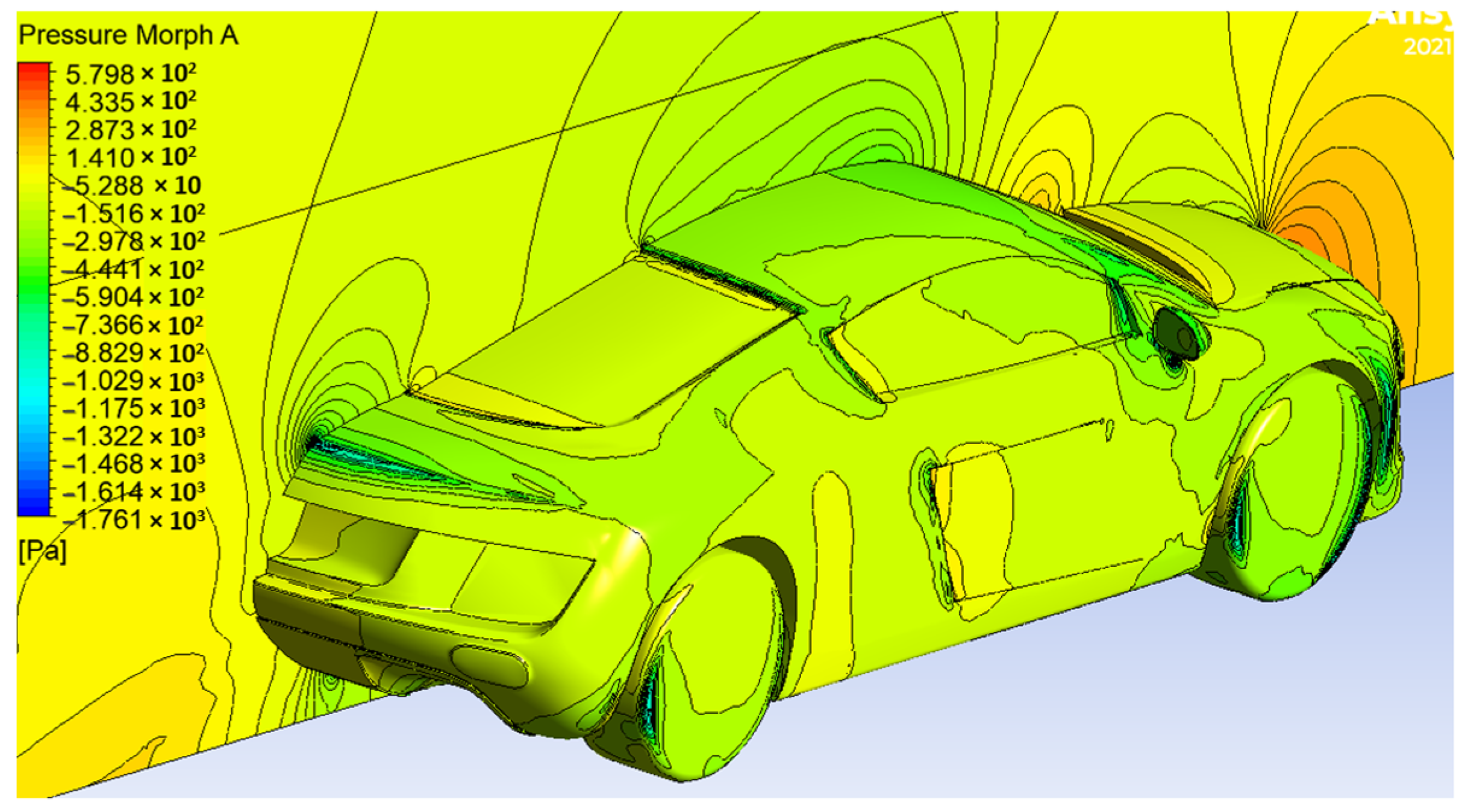

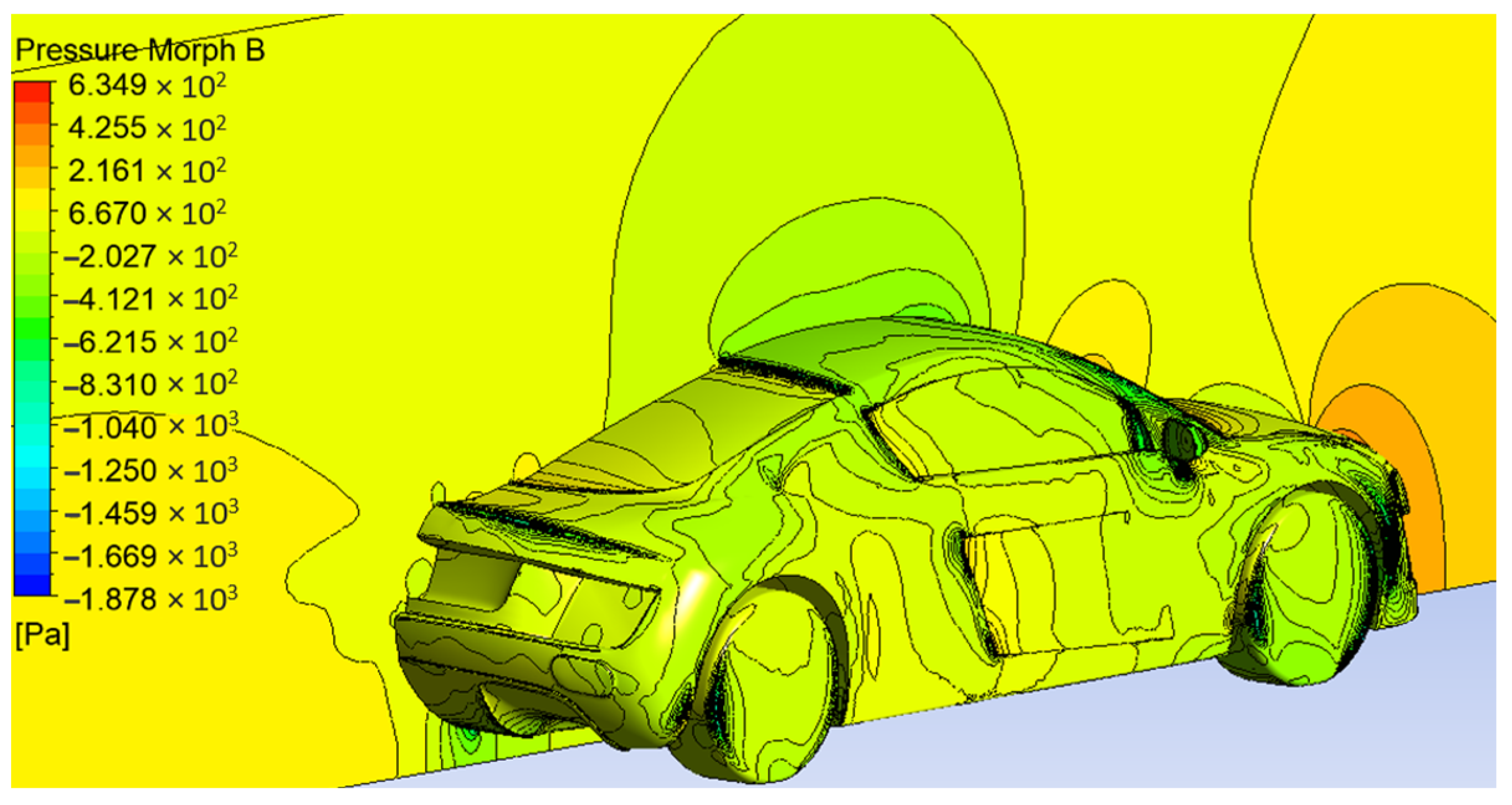

4.3. Design Parameter Optimization Using NURBS

NURBS Morphing Optimization

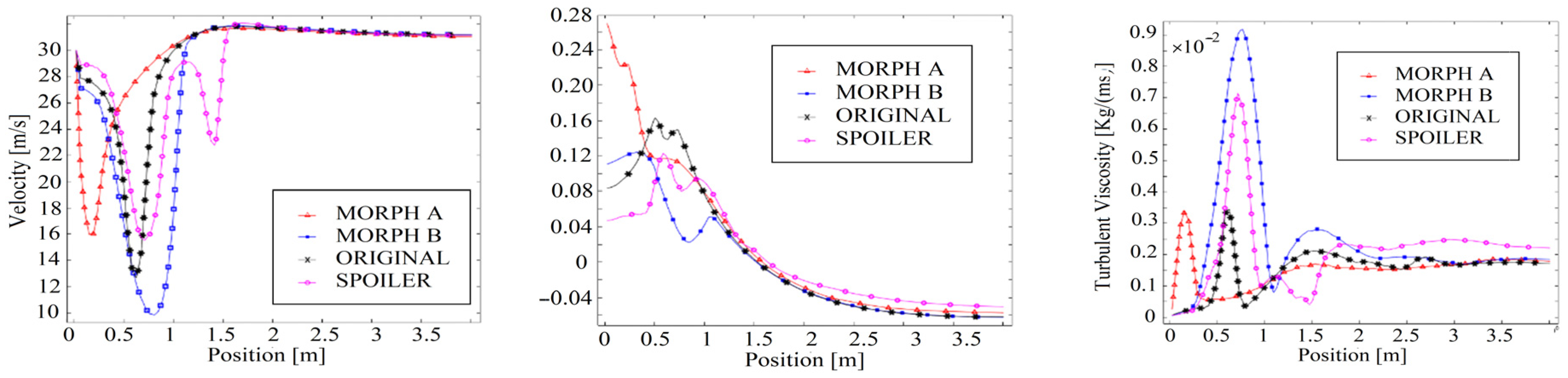

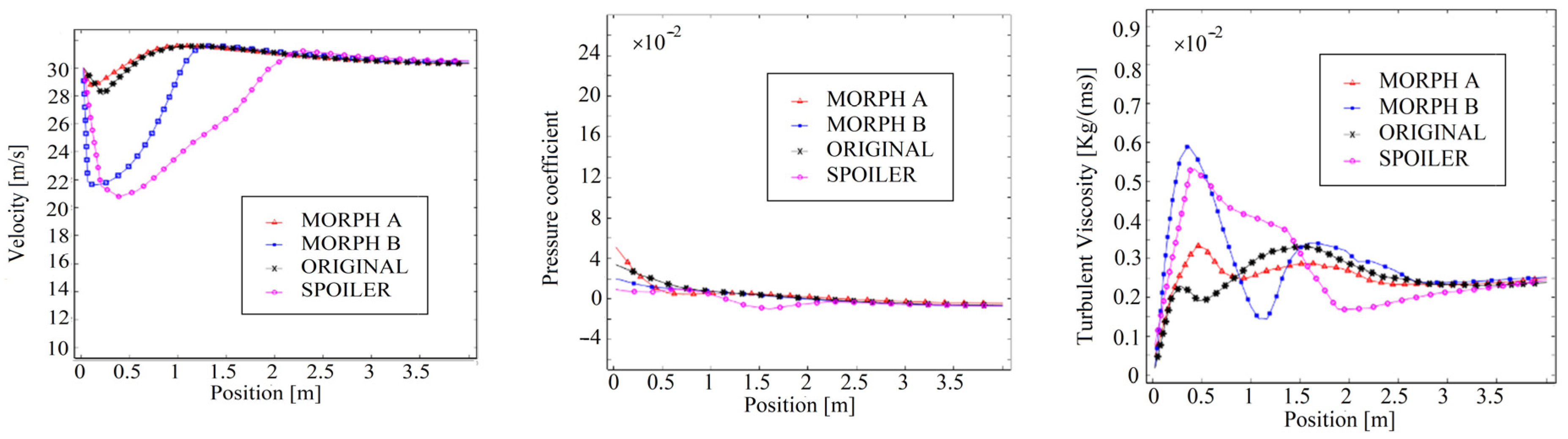

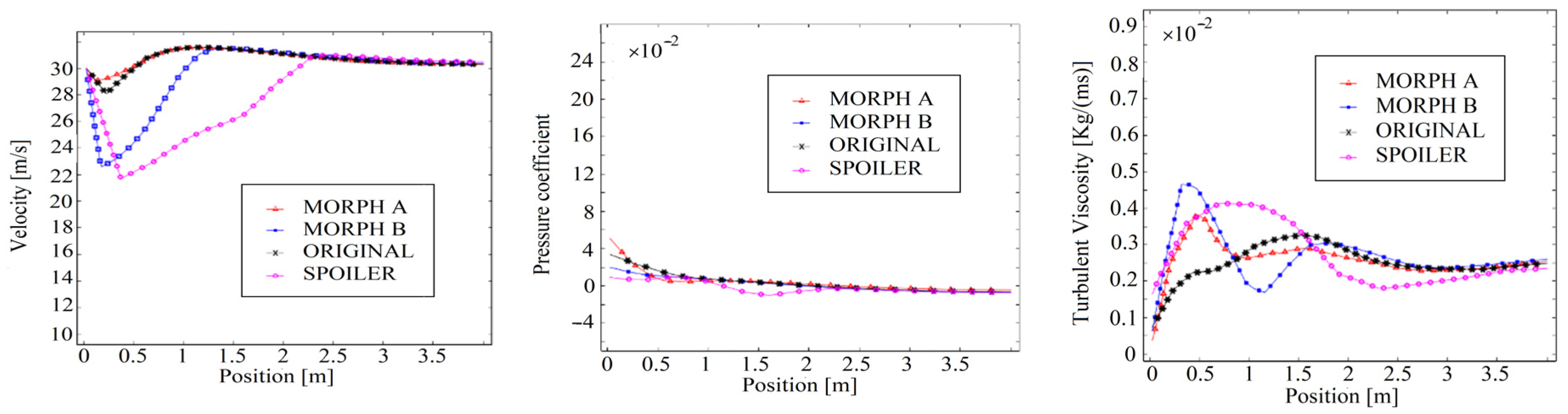

4.4. Comparative Analysis Framework

4.4.1. Pressure Coefficient

4.4.2. Velocity Magnitude

4.4.3. Turbulent Viscosity

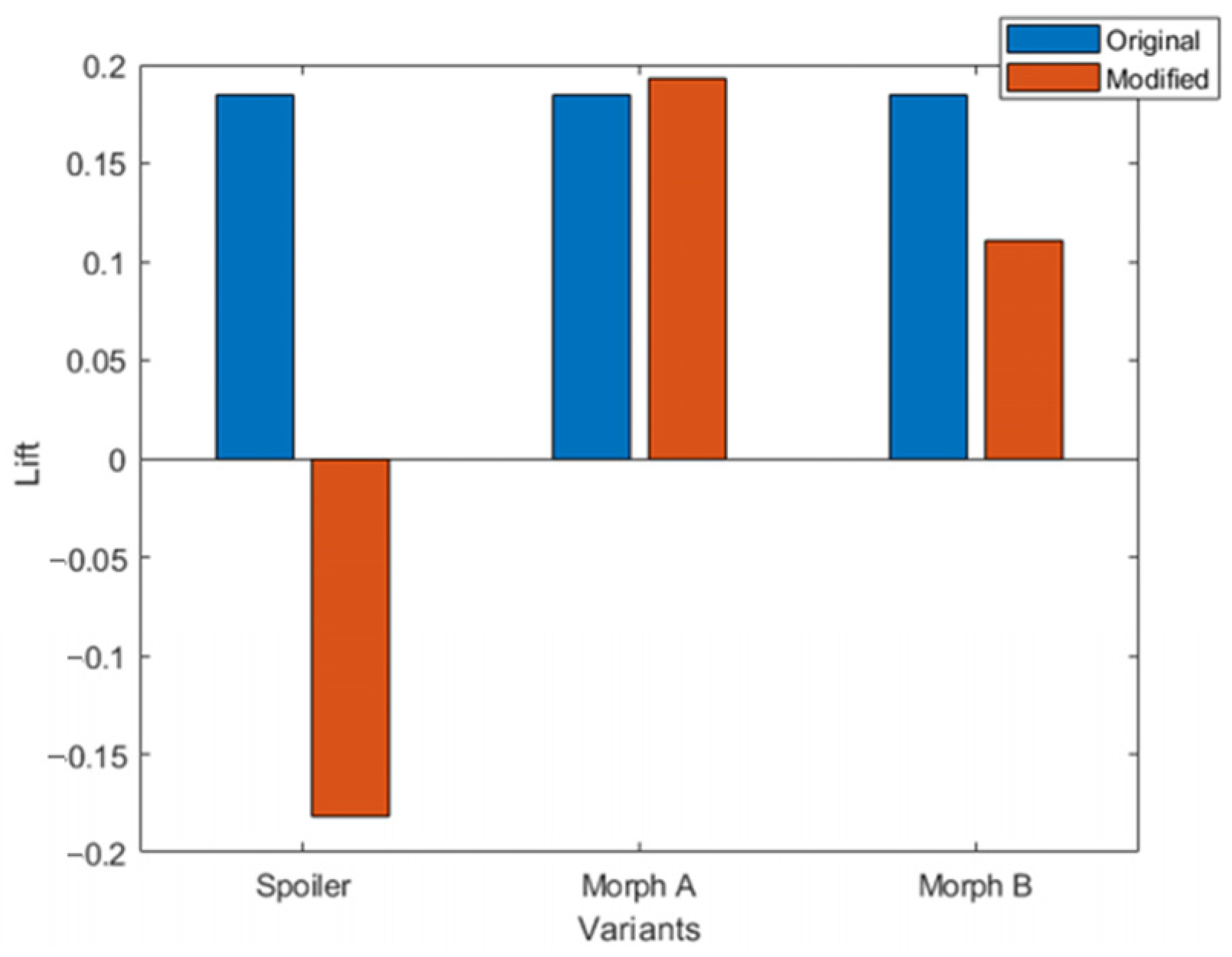

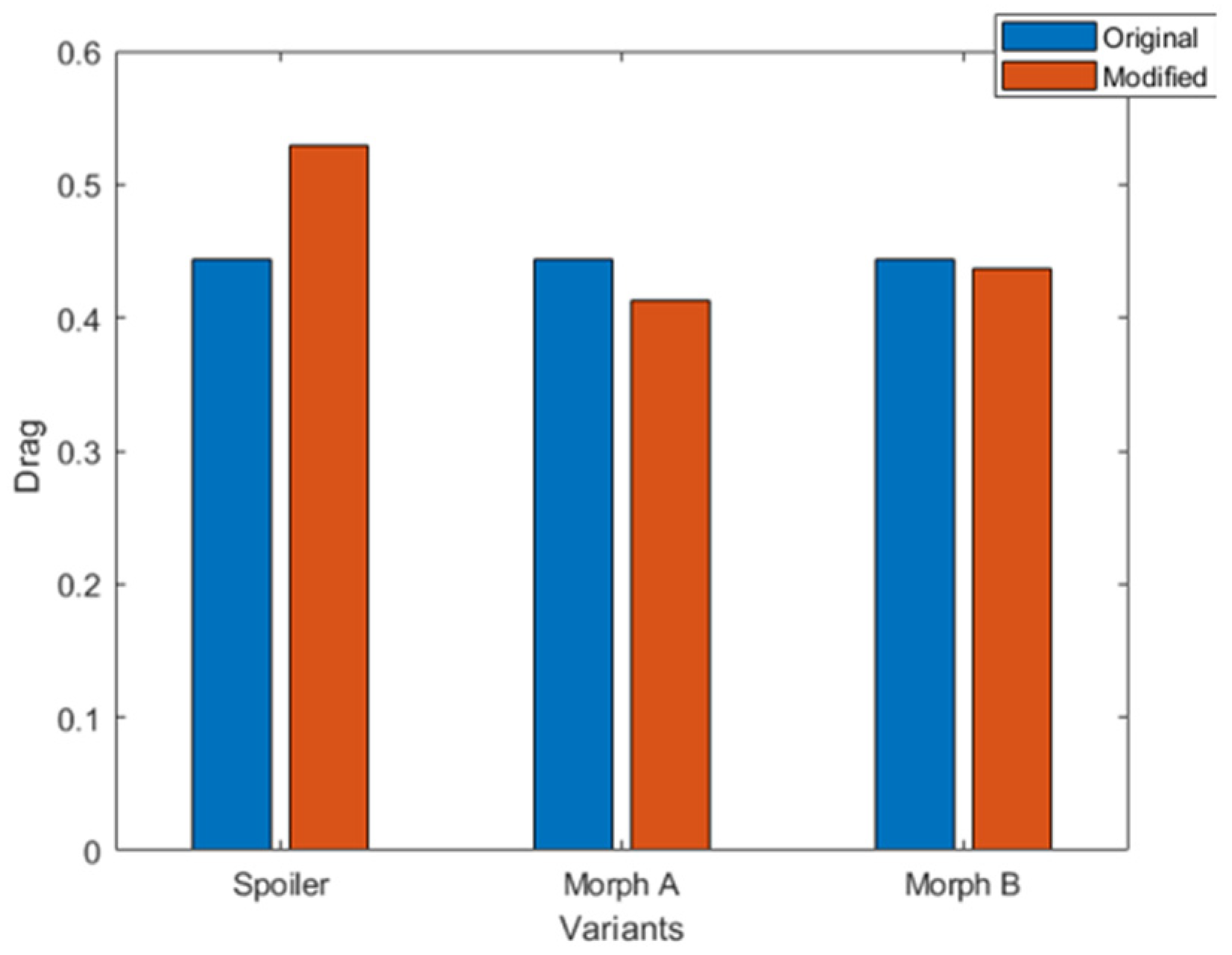

4.5. Justification of NURBS Morphing Effectiveness

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aerodynamics. Nature 1958, 181, 671–672. [CrossRef]

- Lyu, Z.; Martins, J.R.R.A. Aerodynamic Design Optimization Studies of a Blended-Wing-Body Aircraft. J. Aircr. 2014, 51, 1604–1617. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Hejazi, F. Advancing Wind Energy Efficiency: A Systematic Review of Aerodynamic Optimization in Wind Turbine Blade Design. Energies 2024, 17, 2919. [Google Scholar] [CrossRef]

- Thangadurai, M.; Kumar, R.; Rana, S.C.; Chatterjee, D. Aerodynamic Influence of Added Surfaces on the Performance Characteristics of a Sports Car. J. Inst. Eng. India Ser. C 2019, 100, 411–421. [Google Scholar] [CrossRef]

- Hiemstra, R.R.; Shepherd, K.M.; Johnson, M.J.; Quan, L.; Hughes, T.J.R. Towards untrimmed NURBS: CAD embedded reparameterization of trimmed B-rep geometry using frame-field guided global parameterization. Comput. Methods Appl. Mech. Eng. 2020, 369, 113227. [Google Scholar] [CrossRef]

- Gao, J.; Xiao, M.; Zhou, M.; Gao, L. Isogeometric topology and shape optimization for composite structures using level-sets and adaptive Gauss quadrature. Compos. Struct. 2022, 285, 115263. [Google Scholar] [CrossRef]

- Thunich, P.; Tong, Y.; Müller, M. Efficient modelling of thermo-hydrodynamic properties in lubricated technical systems using NURBS-based isogeometric analysis. Tribol. Int. 2024, 199, 109934. [Google Scholar] [CrossRef]

- Sarkar, S.; Thummar, K.; Shah, N.; Vagrecha, V. A Review paper on Aerodynamic Drag Reduction and CFD Analysis of Vehicles. Int. J. Progress. Res. Eng. Manag. Sci. 2019, 6. [Google Scholar]

- Josefsson, E.; Hobeika, T.; Sebben, S. Evaluation of wind tunnel interference on numerical prediction of wheel aerodynamics. J. Wind Eng. Ind. Aerodyn. 2022, 224, 104945. [Google Scholar] [CrossRef]

- Guendaoui, S.; Ouadefli, L.E.; El Akkad, A.; Elkhalfi, A.; Vlase, S.; Scutaru, M.L. Comparative Analysis of NURBS and Finite Element Method in Computational Fluid Dynamics Applications: Case Study on NACA 2412 Airfoil Aerodynamics. Mathematics 2024, 12, 3211. [Google Scholar] [CrossRef]

- Goel, M.; Sharma, R.; Bhattacharyya, S.K.; Kim, T. NON-UNIFORM RATIONAL B-SPLINE BASED ISO-GEOMETRIC ANALYSIS FOR A CLASS OF HYDRODYNAMIC PROBLEMS. Int. J. Marit. Eng. 2020, 162. [Google Scholar] [CrossRef]

- Zheng, R.; Kim, C. An Enhanced Topology Optimization Approach Based on the Combined MMC and NURBS-Curve Boundaries. Int. J. Precis. Eng. Manuf. 2020, 21, 1529–1538. [Google Scholar] [CrossRef]

- Malik, F.E.; Mohammed, A.E.; Elhadi, I.D.; Al Hussein, M.S. CFD analysis and aerodynamic effects of add-on devices on an audi TT vehicle model. JME 2024, 14, 1. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Adriaenssens, S.; Block, P.; Veenendaal, D.; Williams, C. (Eds.) Shell Structures for Architecture; Routledge: Oxford, UK, 2014. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Cottrell, J.A.; Bazilevs, Y. Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 2005, 194, 4135–4195. [Google Scholar] [CrossRef]

- Cottrell, J.A.; Hughes, T.J.R.; Bazilevs, Y. Isogeometric Analysis: Toward Integration of CAD and FEA; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Nouri, B.; Juhász, I.; Saeidian, J. A polynomial basis with a shape parameter for curve and surface modeling. Math. Comput. Simul. 2025, 229, 690–705. [Google Scholar] [CrossRef]

- Chudy, F.; Woźny, P. Efficient evaluation of Bernstein-Bézier coefficients of B-spline basis functions over one knot span 2024. arXiv 2024, arXiv:2404.10396. [Google Scholar]

- Laín, S.; Taborda, M.A.; López, O.D. Numerical Study of the Effect of Winglets on the Performance of a Straight Blade Darrieus Water Turbine. Energies 2018, 11, 297. [Google Scholar] [CrossRef]

- Dornisch, W.; Stöckler, J.; Müller, R. Dual and approximate dual basis functions for B-splines and NURBS—Comparison and application for an efficient coupling of patches with the isogeometric mortar method. Comput. Methods Appl. Mech. Eng. 2017, 316, 449–496. [Google Scholar] [CrossRef]

- Bidnichenko, H. Featured of Geometric Surfaces and Methods of their Computer Modeling. AGEG 2022, 102, 13–26. [Google Scholar] [CrossRef]

- Eivazi, H.; Tahani, M.; Schlatter, P.; Vinuesa, R. Physics-informed neural networks for solving Reynolds-averaged Navier–Stokes equations. Phys. Fluids 2022, 34, 075117. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. Mathematical Models of Turbulence; Academic Press: London, UK; New York, NY, USA, 1972. [Google Scholar]

- Renold Elsen, S.; Jegadeesan, K.; Ronald Aseer, J. A Comparative Study of Flow Characteristics of BMW M6 and AUDI R8 Commercial Sports Car Using Flow Design Software. In Advances in Manufacturing Technology; Hiremath, S.S., Shanmugam, N.S., Bapu, B.R.R., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019; pp. 243–253. [Google Scholar] [CrossRef]

- Elrefaie, M.; Dai, A.; Ahmed, F. DrivAerNet: A Parametric Car Dataset for Data-Driven Aerodynamic Design and Prediction. In Proceedings of the Volume 3A: 50th Design Automation Conference (DAC), Washington, DC, USA, 25–28 August 2024; p. V03AT03A019. [Google Scholar] [CrossRef]

- Yu, P.X.; Tian, Z.F. An upwind compact difference scheme for solving the streamfunction–velocity formulation of the unsteady incompressible Navier–Stokes equation. Comput. Math. Appl. 2018, 75, 3224–3243. [Google Scholar] [CrossRef]

- Patel, A.; Boersma, B.J.; Pecnik, R. The influence of near-wall density and viscosity gradients on turbulence in channel flows. J. Fluid Mech. 2016, 809, 793–820. [Google Scholar] [CrossRef]

- Cavar, D.; Réthoré, P.-E.; Bechmann, A.; Sørensen, N.N.; Martinez, B.; Zahle, F.; Berg, J.; Kelly, M.C. Comparison of OpenFOAM and EllipSys3D for neutral atmospheric flow over complex terrain. Wind Energy Sci. 2016, 1, 55–70. [Google Scholar] [CrossRef]

- Sarjito, S.; Junaidin, B.; Wijayanto, B. Modification of Drag and Lift Balance at Analog Wind Tunnel for Identification of Aerodynamic Performance. In Proceedings of the 6th International Conference on Advanced Materials Science, Surakarta, Indonesia, 23–24 August 2024; pp. 113–118. [Google Scholar] [CrossRef]

- Eftekhari, H.; Al-Obaidi, A.S.M.; Eftekhari, S. The Effect of Spoiler Shape and Setting Angle on Racing Cars Aerodynamic Performance. Indones. J. Sci. Technol. 2020, 5, 11–20. [Google Scholar] [CrossRef]

- Magalhães Júnior, J.M.; Halila, G.L.O.; Kim, Y.; Khamvilai, T.; Vamvoudakis, K.G. Intelligent data-driven aerodynamic analysis and optimization of morphing configurations. Aerosp. Sci. Technol. 2022, 121, 107388. [Google Scholar] [CrossRef]

- Qin, P.; Ricci, A.; Blocken, B. CFD simulation of aerodynamic forces on the DrivAer car model: Impact of computational parameters. J. Wind Eng. Ind. Aerodyn. 2024, 248, 105711. [Google Scholar] [CrossRef]

- Bauer, A.; Breitenberger, M.; Philipp, B.; Wüchner, R.; Bletzinger, K.-U. Embedded structural entities in NURBS-based isogeometric analysis. Comput. Methods Appl. Mech. Eng. 2017, 325, 198–218. [Google Scholar] [CrossRef]

- Hui, X.; Bai, J.; Wang, H.; Zhang, Y. Fast pressure distribution prediction of airfoils using deep learning. Aerosp. Sci. Technol. 2020, 105, 105949. [Google Scholar] [CrossRef]

- Das, R.; Girimaji, S. Characterization of velocity-gradient dynamics in incompressible turbulence using local streamline geometry. J. Fluid Mech. 2020, 895. [Google Scholar] [CrossRef]

- Menter, F.; Kuntz, M. Adaptation of Eddy-Viscosity Turbulence Models to Unsteady Separated Flow Behind Vehicles. In The Aerodynamics of Heavy Vehicles: Trucks, Buses, and Trains; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef]

- Nath, D.; Pujari, P.; Jain, A.; Rastogi, V. Drag reduction by application of aerodynamic devices in a race car. Adv. Aerodyn. 2021, 3, 4. [Google Scholar] [CrossRef]

- Chen, G.; Fidkowski, K. Variable-fidelity multipoint aerodynamic shape optimization with output-based adapted meshes. Aerosp. Sci. Technol. 2020, 105, 106004. [Google Scholar] [CrossRef]

- He, P.; Mader, C.; Martins, J.; Maki, K. An aerodynamic design optimization framework using a discrete adjoint approach with OpenFOAM. Comput. Fluids 2018, 168, 285–303. [Google Scholar] [CrossRef]

- El-Mekkaoui, J.; Elkhalfi, A.; Elakkad, A. Resolution of stokes equations with the Ca,b boundary condition using mixed finite element method. WSEAS Trans. Math. 2013, 12, 586–597. [Google Scholar]

- El Fakkoussi, S.; Moustabchir, H.; Elkhalfi, A.; Pruncu, C.I. Application of the extended isogeometric analysis (X-IGA) to evaluate a pipeline structure containing an external crack. J. Eng. 2018, 2018, 4125765. [Google Scholar] [CrossRef]

- El Barkany, A.; Abdelouahhab, J.; El Khalfi, A. Optimizing the integrated production and maintenance planning using genetic algorithm. Int. J. Eng. Bus. Manag. 2018, 102018, 1–9. [Google Scholar] [CrossRef]

| P | Knot Vector |

|---|---|

| 1 | [0 0 0.25 0.5 0.75 1 1] |

| 2 | [0 0 0 0.33 0.66 1 1 1] |

| 3 | [0 0 0 0 0.5 1 1 1 1] |

| 4 | [0 0 0 0 0 1 1 1 1 1] |

| Specification | Details (mm) |

|---|---|

| Length | 4426 |

| Width | 2037 |

| Height | 1240 |

| Ground clearance | 110 |

| Wheel base | 2650 |

| Front tread | 1599 |

| Rear shoulder room | 1454 |

| V.No | Model | Cd | Cl | Cd Reducing (%) | Cl Reducing (%) |

|---|---|---|---|---|---|

| 1 | Baseline | 0.443415 | 0.184196 | - | - |

| 2 | Spoiler | 0.529347 | −0.182030 | +19.38 | −198.84 |

| 3 | Morph A | 0.412729 | 0.193074 | −6.92 | +4.82 |

| 4 | Morph B | 0.445455 | 0.110303 | +0.46 | −40.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guendaoui, S.; El Akkad, A.; El Khalfi, A.; Vlase, S.; Marin, M. NURBS Morphing Optimization of Drag and Lift in a Coupe-Class Vehicle Using Symmetry-Plane Comparison of Aerodynamic Performance. Symmetry 2025, 17, 1571. https://doi.org/10.3390/sym17091571

Guendaoui S, El Akkad A, El Khalfi A, Vlase S, Marin M. NURBS Morphing Optimization of Drag and Lift in a Coupe-Class Vehicle Using Symmetry-Plane Comparison of Aerodynamic Performance. Symmetry. 2025; 17(9):1571. https://doi.org/10.3390/sym17091571

Chicago/Turabian StyleGuendaoui, Sohaib, Abdeslam El Akkad, Ahmed El Khalfi, Sorin Vlase, and Marin Marin. 2025. "NURBS Morphing Optimization of Drag and Lift in a Coupe-Class Vehicle Using Symmetry-Plane Comparison of Aerodynamic Performance" Symmetry 17, no. 9: 1571. https://doi.org/10.3390/sym17091571

APA StyleGuendaoui, S., El Akkad, A., El Khalfi, A., Vlase, S., & Marin, M. (2025). NURBS Morphing Optimization of Drag and Lift in a Coupe-Class Vehicle Using Symmetry-Plane Comparison of Aerodynamic Performance. Symmetry, 17(9), 1571. https://doi.org/10.3390/sym17091571