Migration and Removal of Microplastics in a Dual-Cone Mini-Hydrocyclone

Abstract

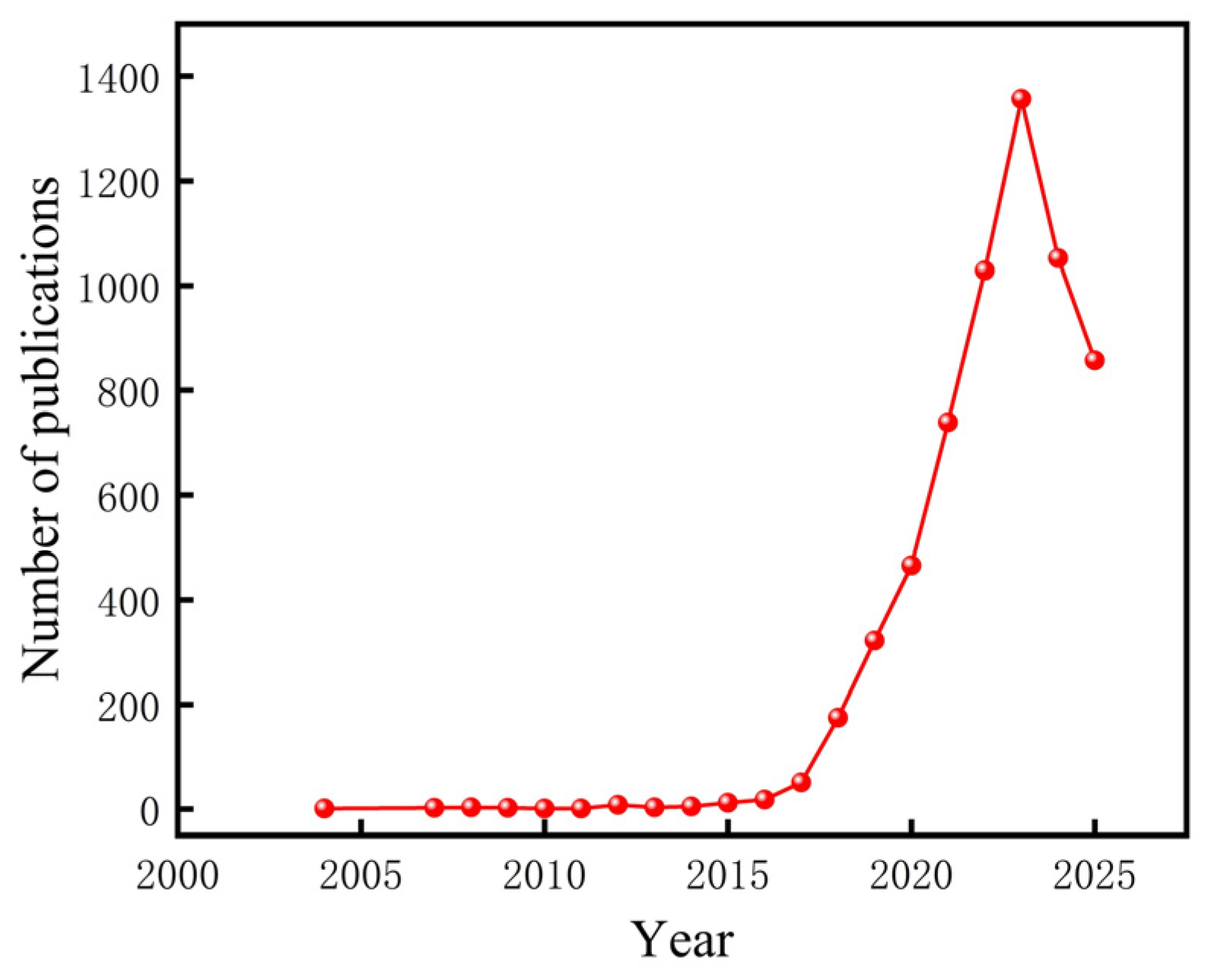

1. Introduction

2. Mathematical Model

2.1. Governing Equations

2.2. Interphase Interactions

3. Numerical Method

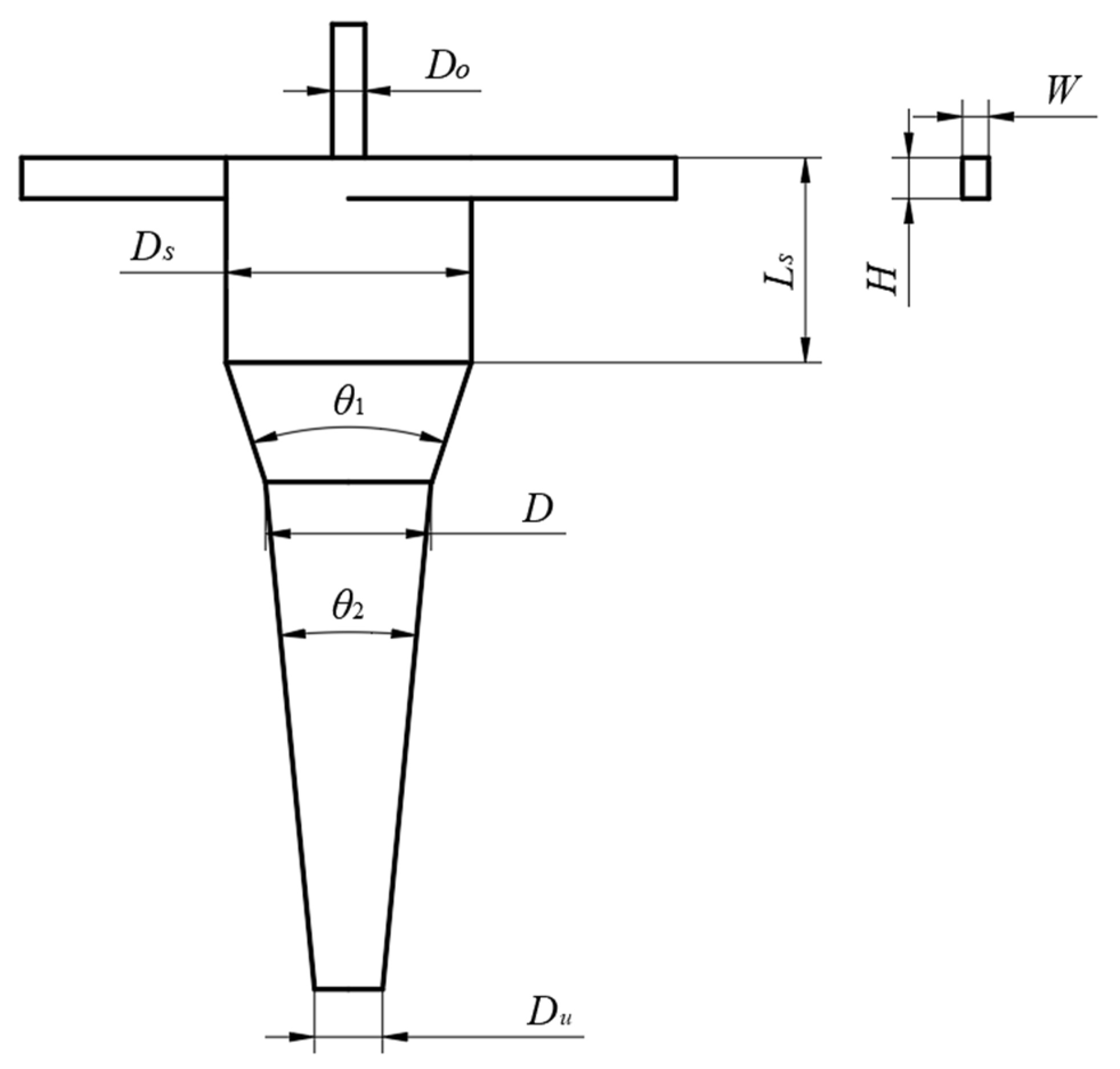

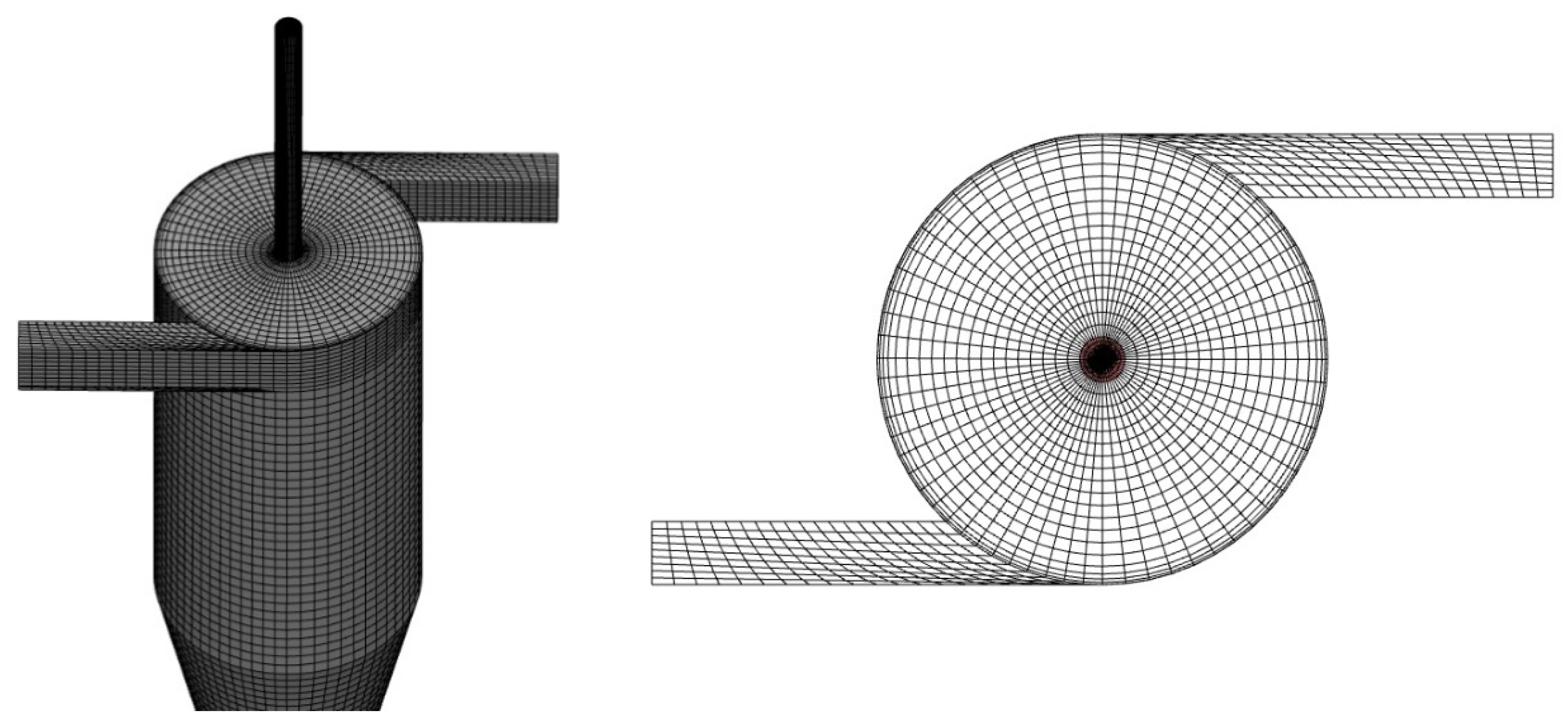

3.1. Computational Domain and Mesh Generation

3.2. Parameters and Boundary Conditions

3.3. Numerical Schemes

4. Results and Discussion

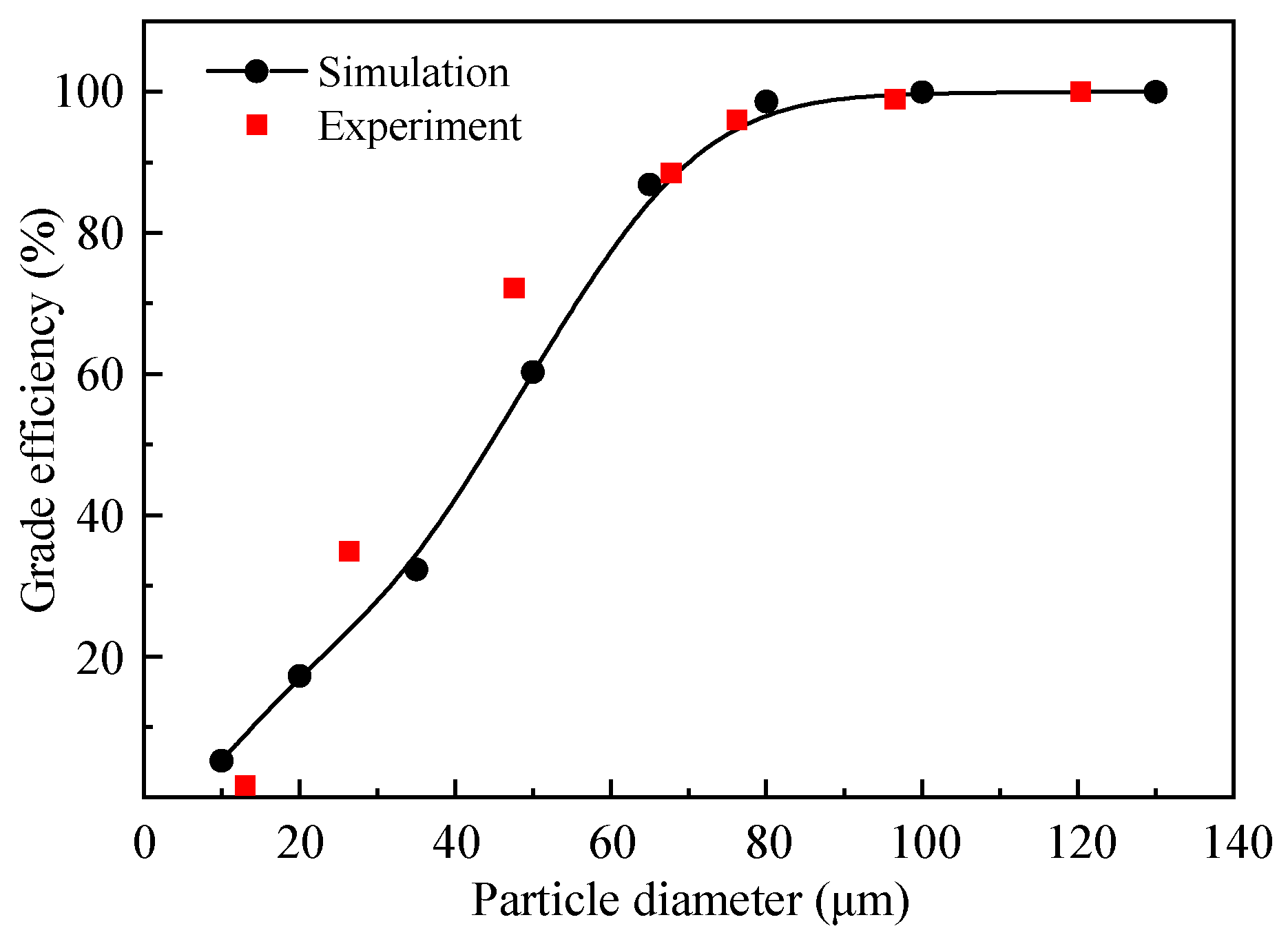

4.1. Calculation Verification

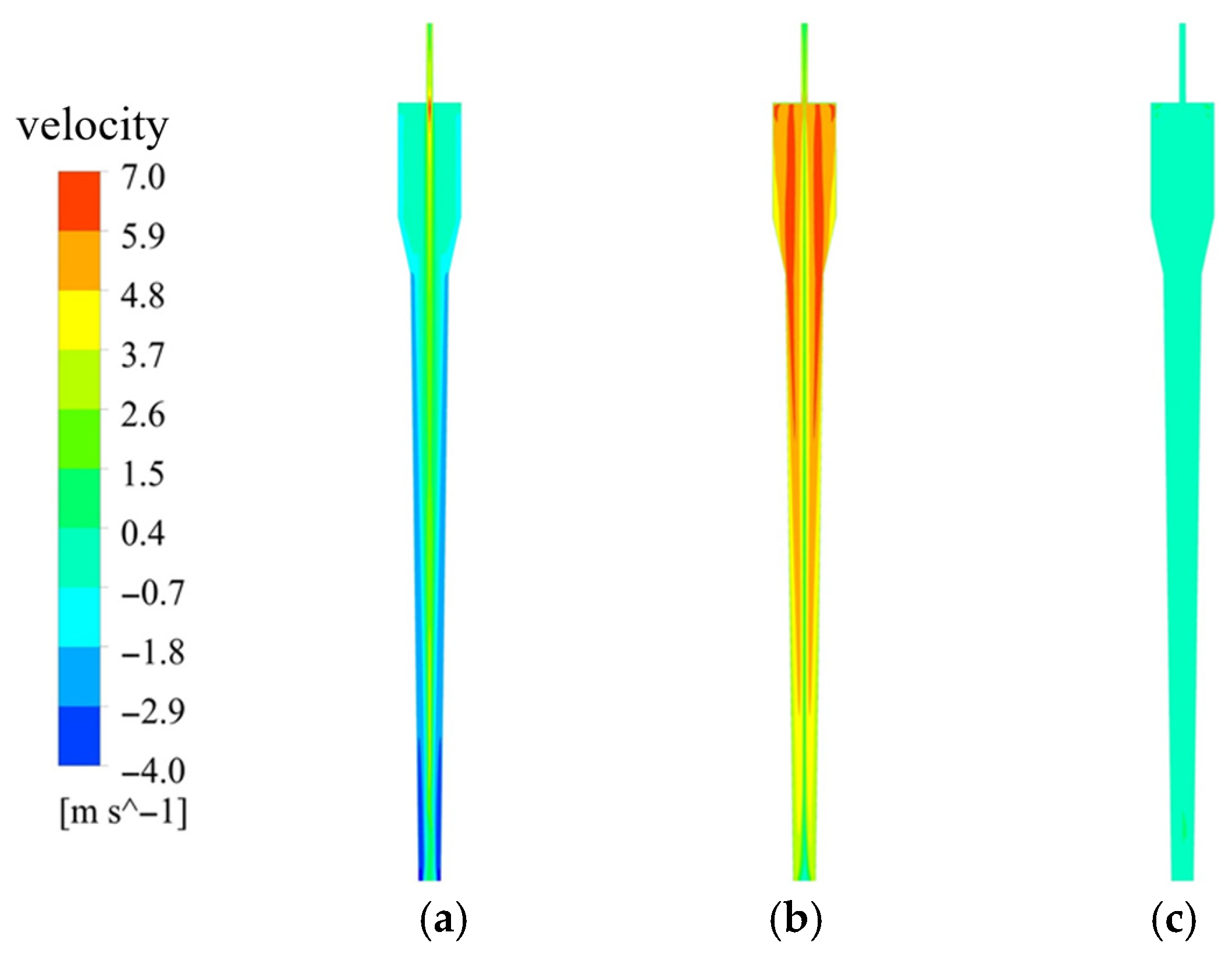

4.2. Velocity Distribution of Flow Field

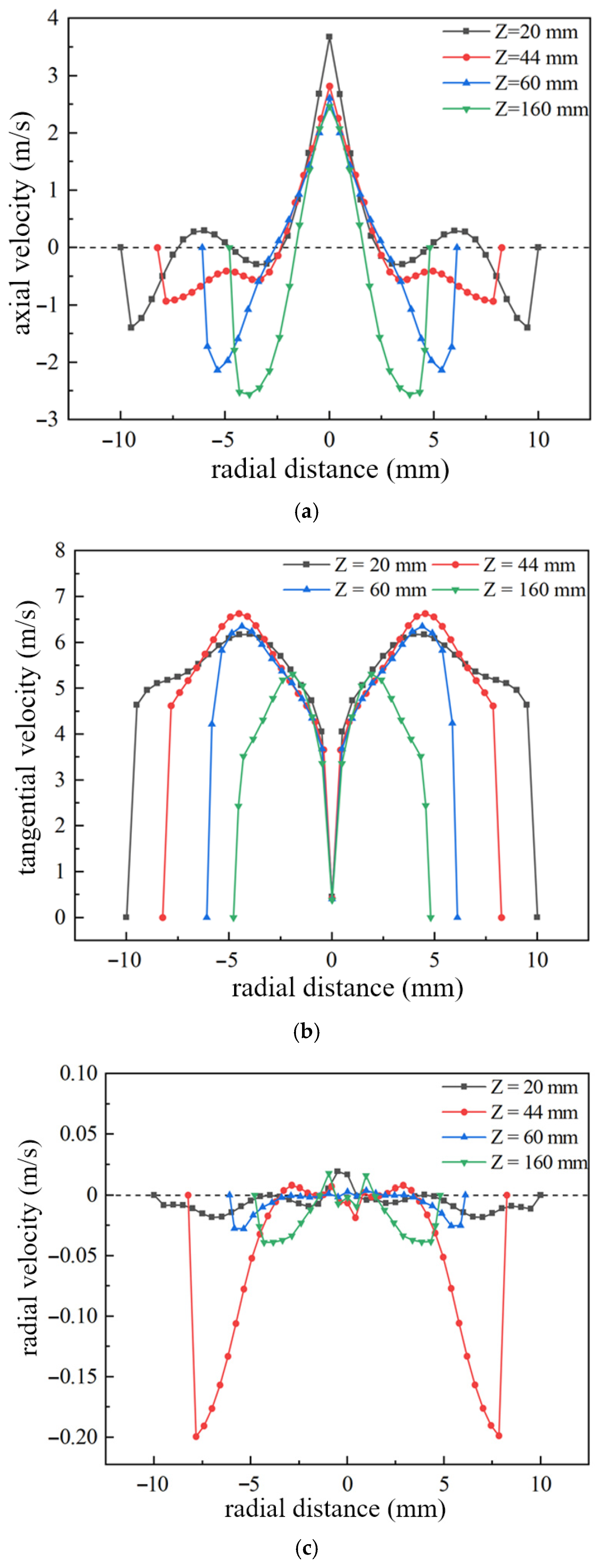

4.2.1. Axial Velocity

4.2.2. Tangential Velocity

4.2.3. Radial Velocity

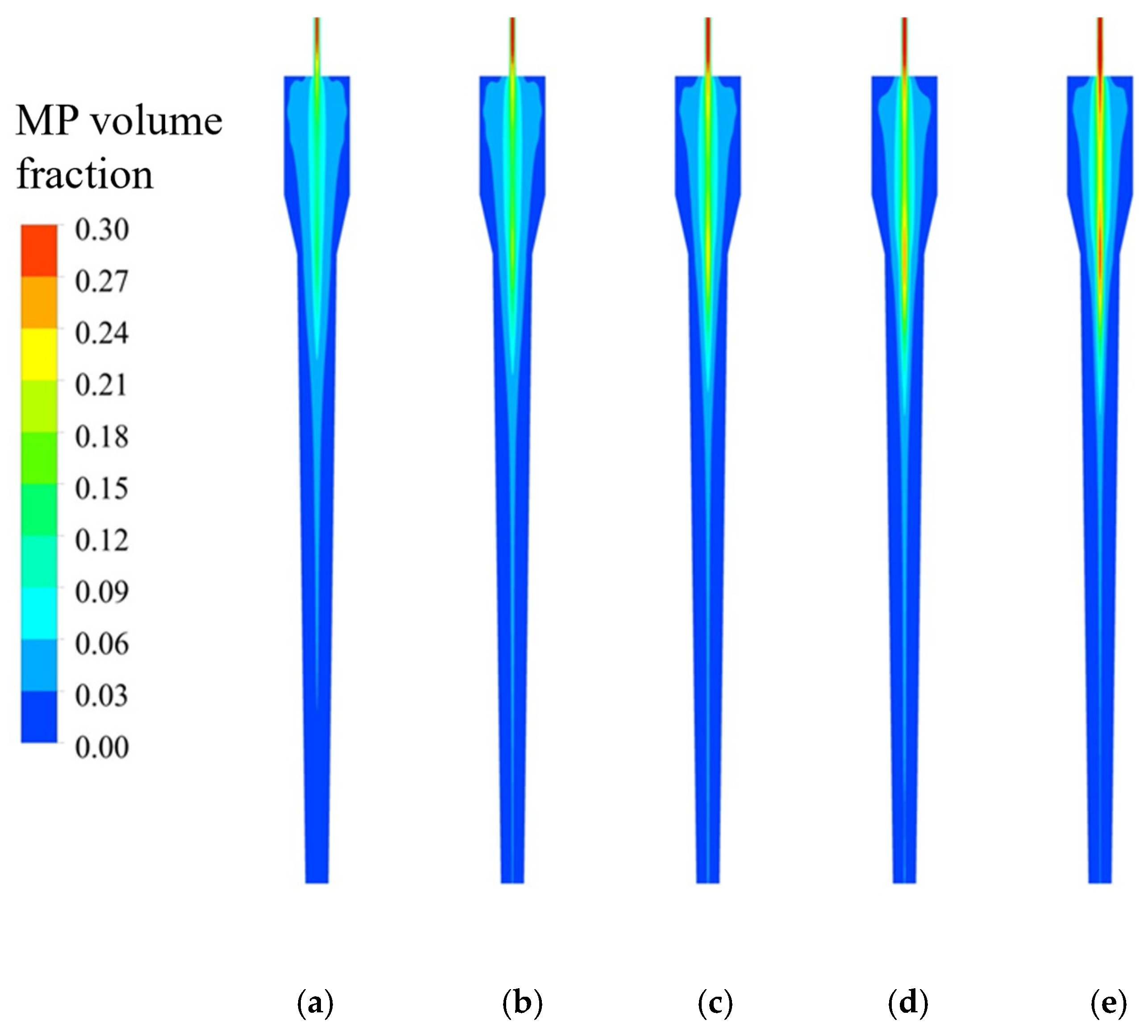

4.3. MP Distribution and Migration

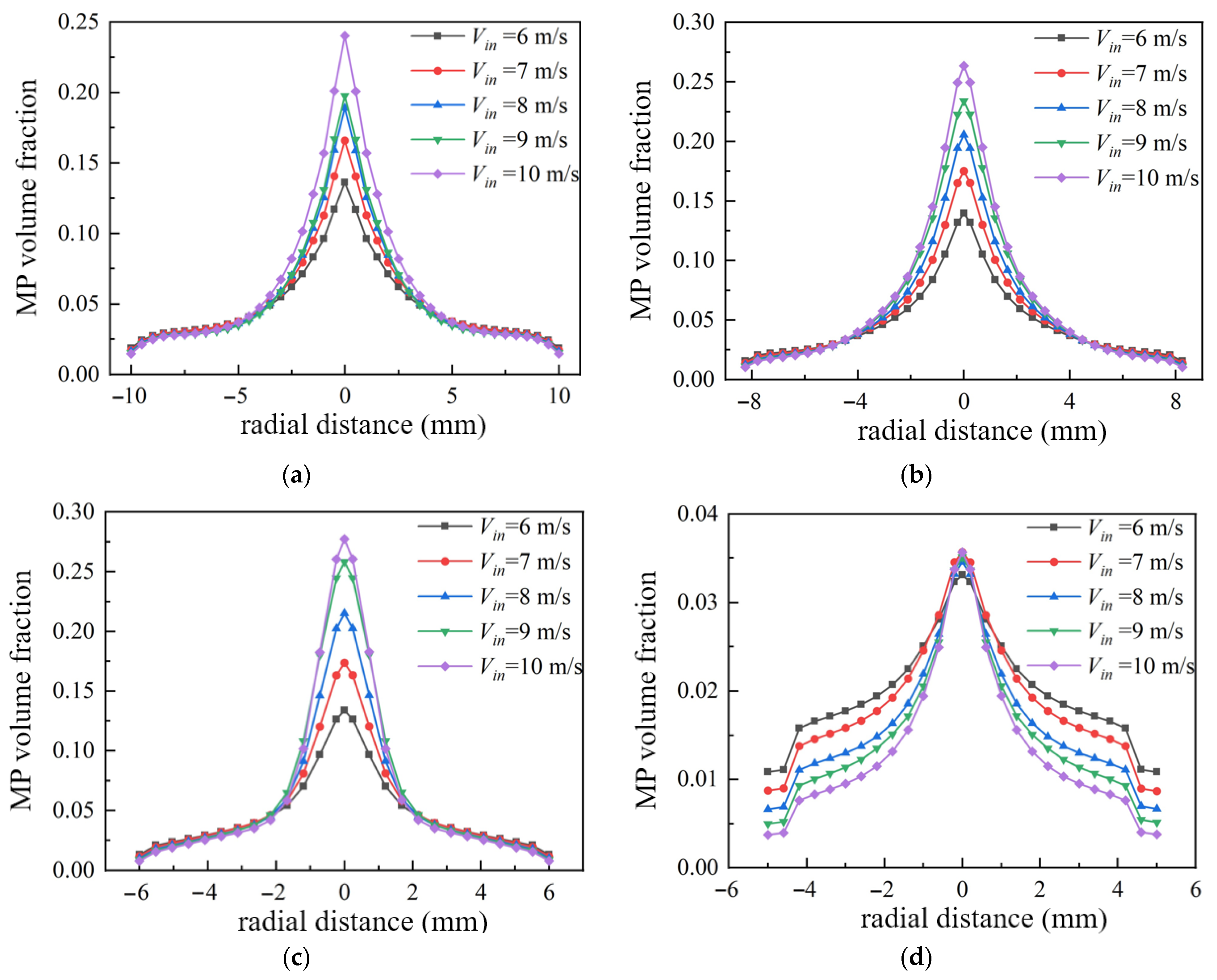

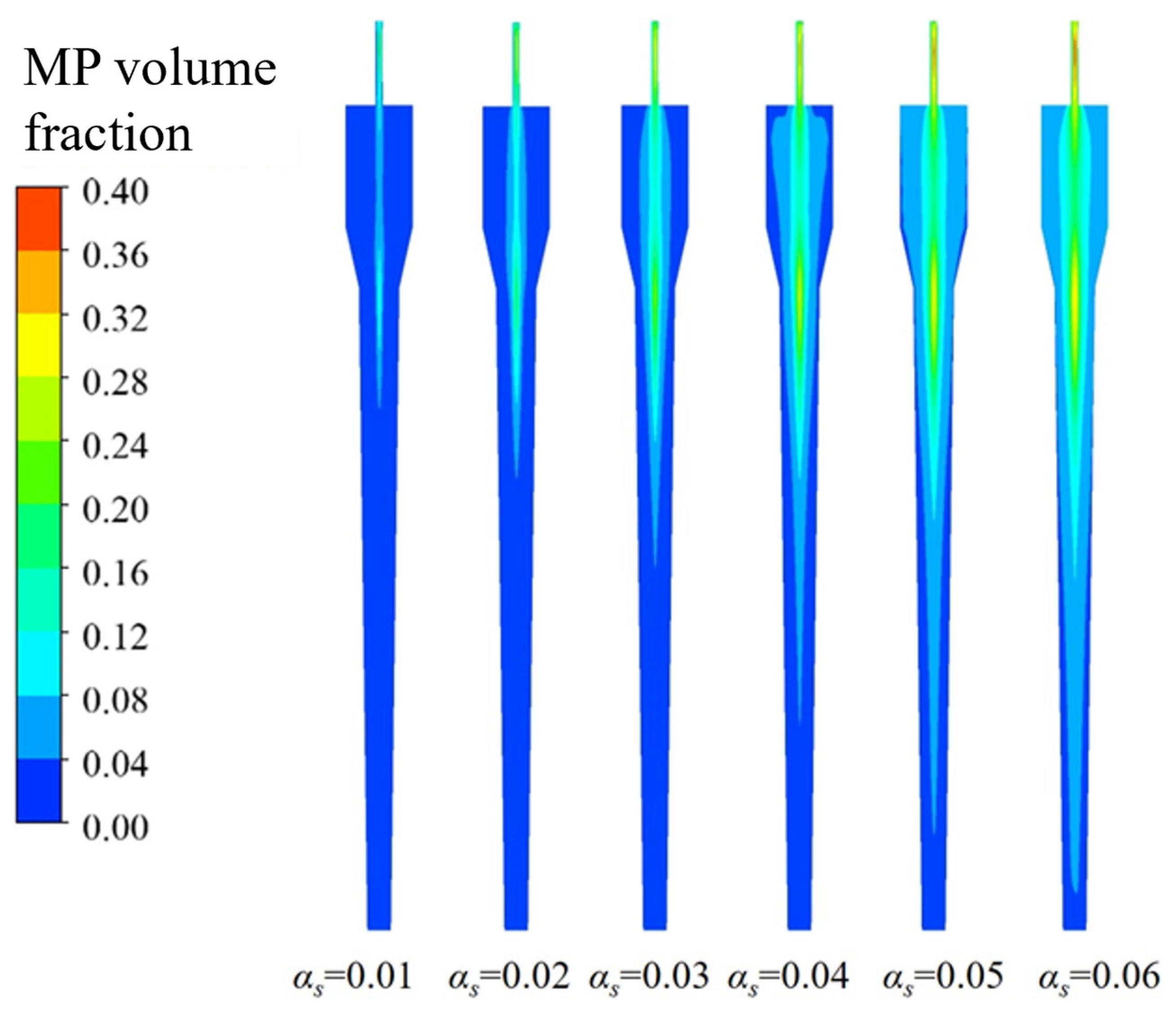

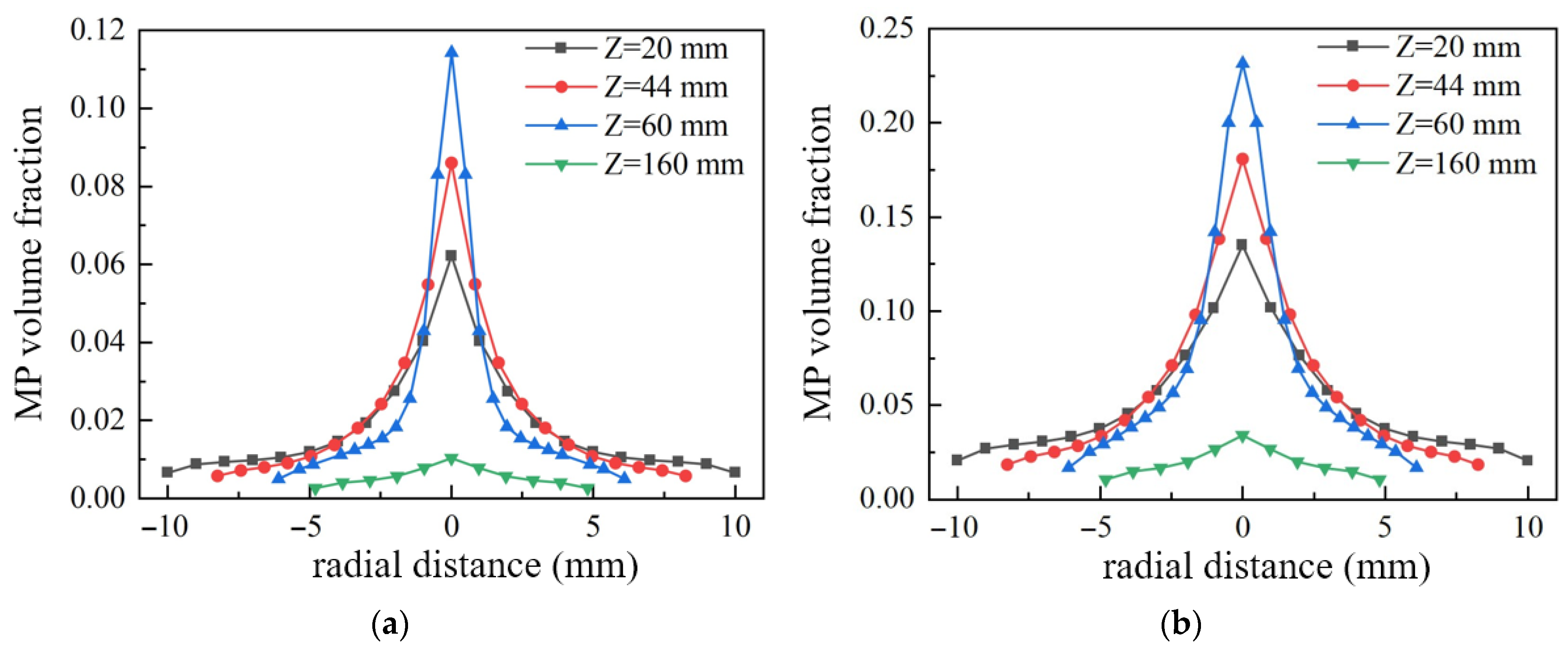

4.3.1. Effect of the Feed Flow Rate

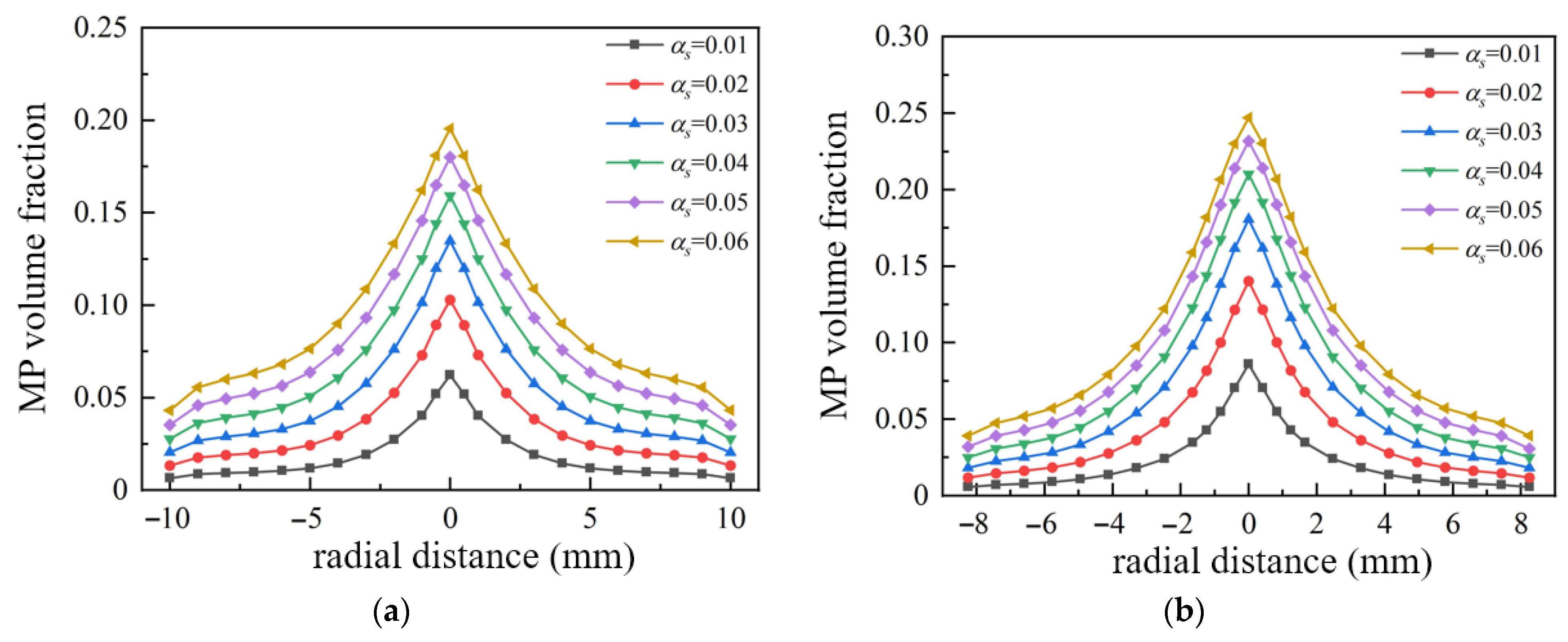

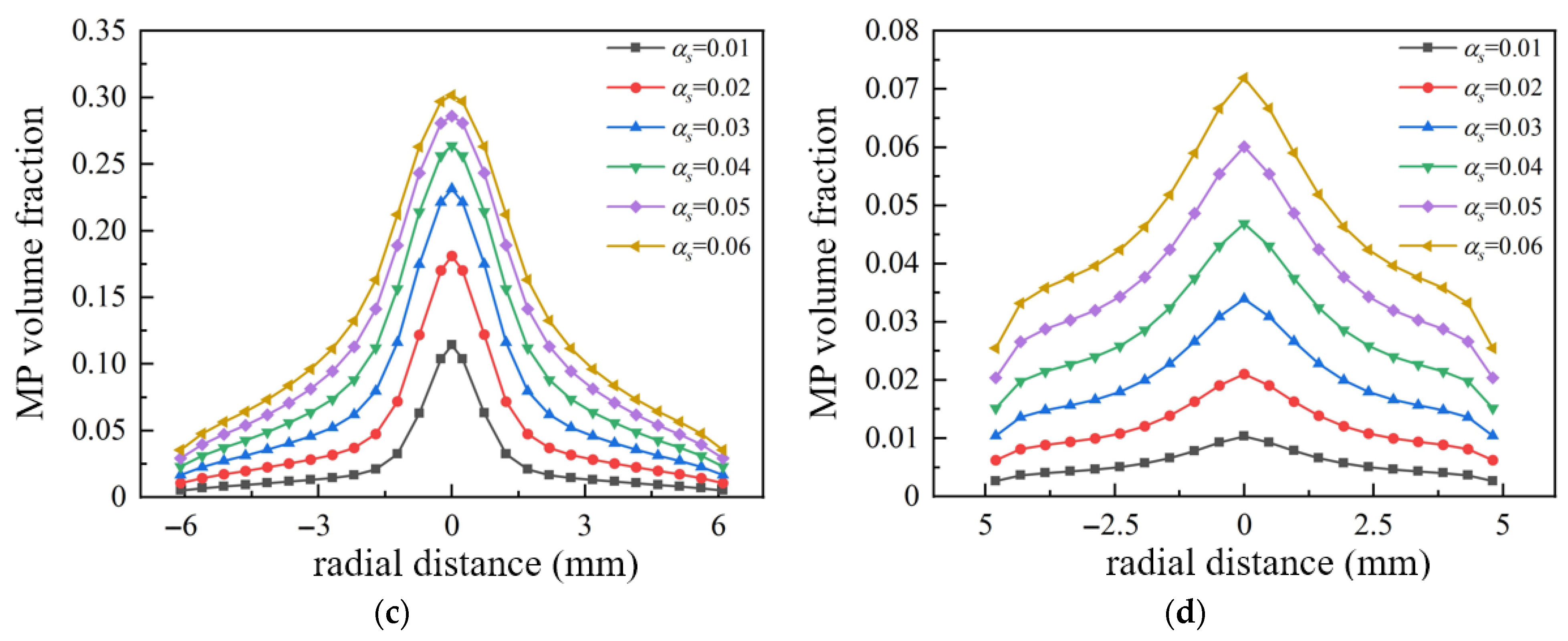

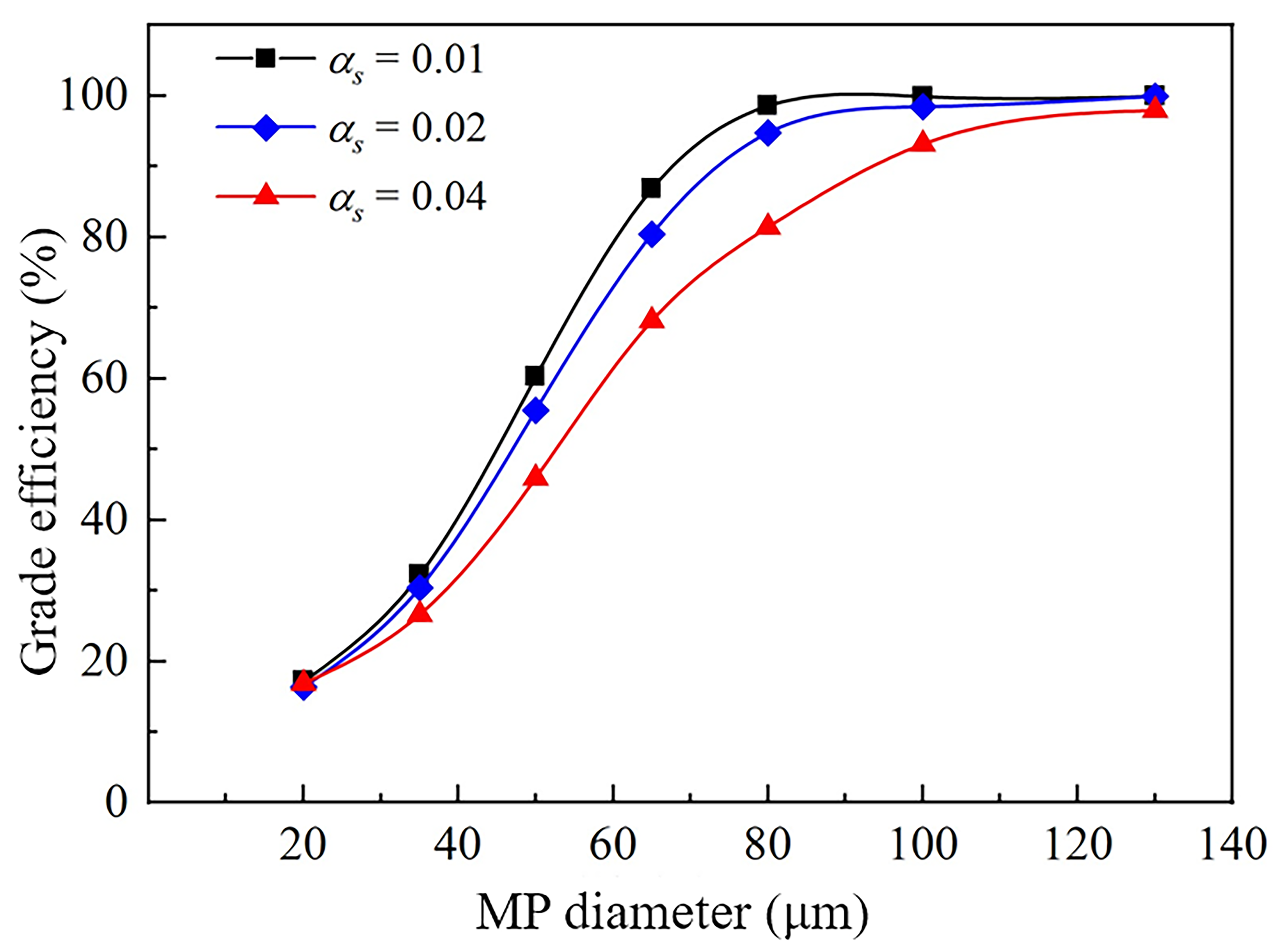

4.3.2. Effect of Feed MP Volume Fraction

4.3.3. Effect of MP Density

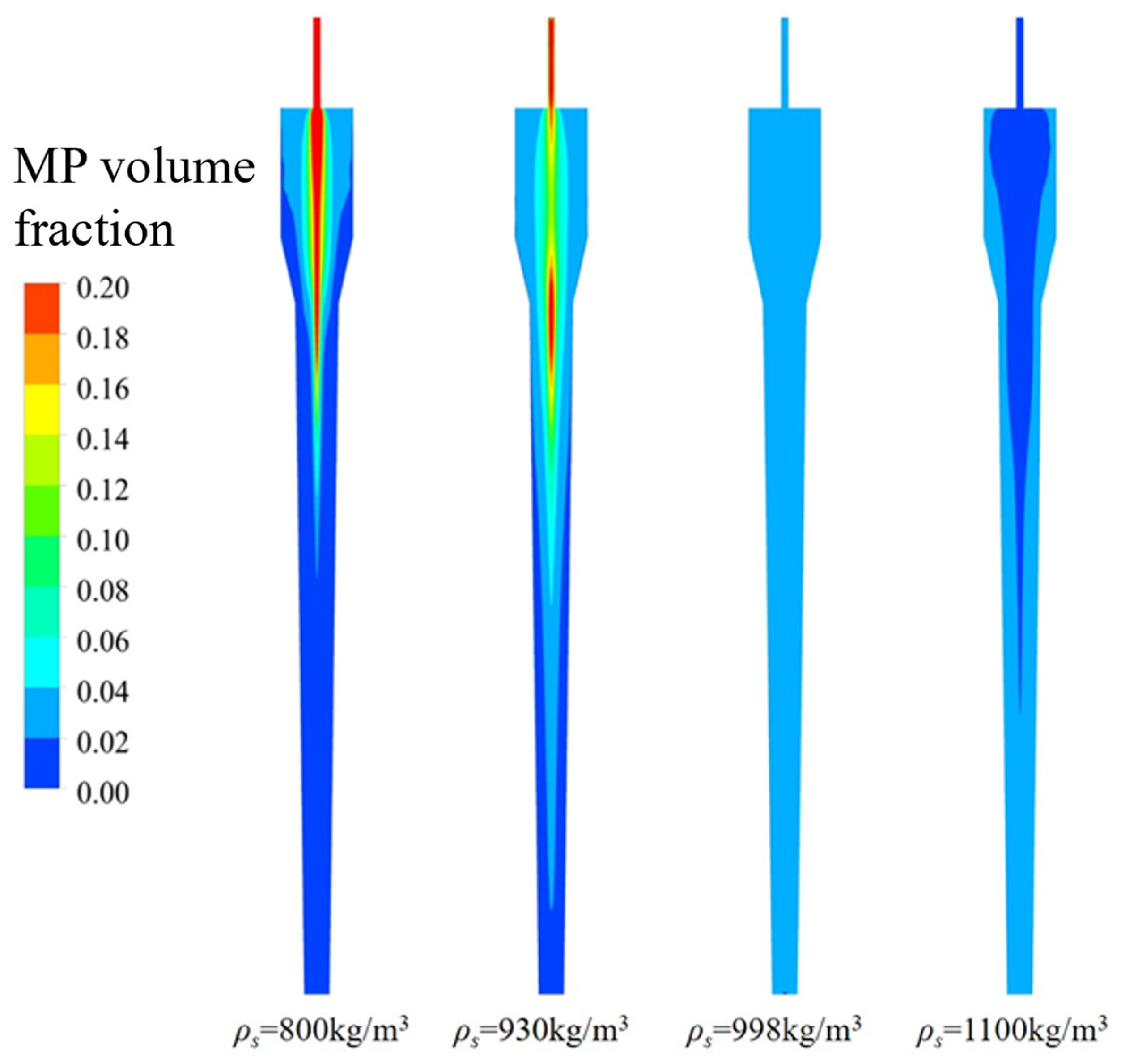

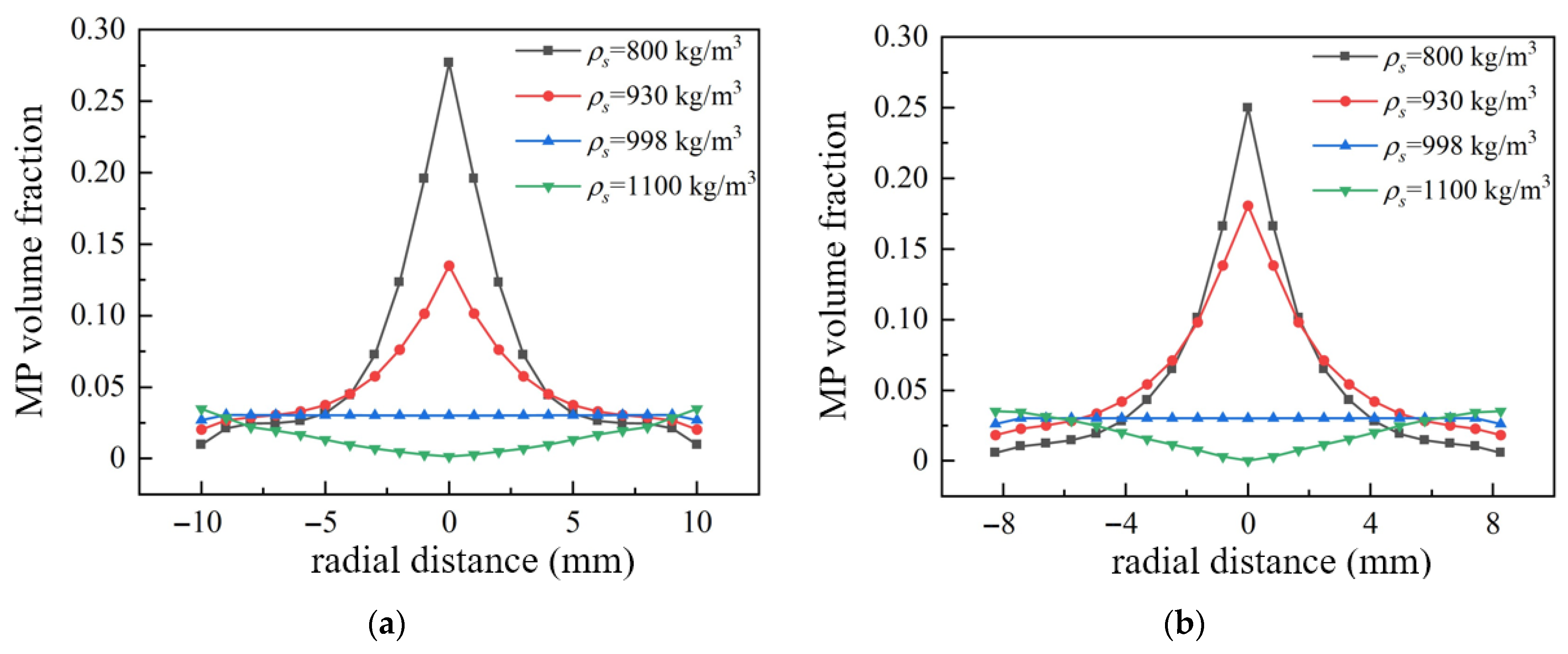

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thompson, R.C.; Olsen, Y.; Mitchell, R.P.; Davis, A.; Rowland, S.J.; John, A.W.G.; McGonigle, D.; Russell, A.E. Lost at sea: Where is all the plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef]

- Han, M.; Niu, X.; Tang, M.; Zhang, B.T.; Wang, G.; Yue, W.; Kong, X.; Zhu, J. Distribution of microplastics in surface water of the lower Yellow River near estuary. Sci. Total Environ. 2020, 707, 135601. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Zhang, Y.; Bian, K.; Wang, C.; Xie, X.; Wang, H.; Zhao, H. Is it possible to efficiently and sustainably remove microplastics from sediments using froth flotation? Chem. Eng. J. 2022, 448, 137692. [Google Scholar] [CrossRef]

- Nohara, N.M.L.; Ariza-Tarazona, M.C.; Triboni, E.R.; Nohara, E.L.; Villarreal-Chiu, J.F.; Cedillo-González, E.I. Are you drowned in microplastic pollution? A brief insight on the current knowledge for early career researchers developing novel remediation strategies. Sci. Total Environ. 2024, 918, 170382. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Li, L.; Guo, Z.; Yang, X.; Dong, D. Emerging isolation and degradation technology of microplastics and nanoplastics in the environment. Environ. Res. 2024, 243, 117864. [Google Scholar] [CrossRef]

- Inoue, T.; Asai, K.; Morisawa, T.; Tamaue, K. New method for extracting microplastics from sediments using a hydrocyclone and sieve. Results Eng. 2024, 24, 103232. [Google Scholar] [CrossRef]

- Fu, S.; Qian, Y.; Yuan, H.; Fang, Y. Effect of cone angles of a hydrocyclone for the separation of waste plastics with low value of density difference. Waste Manag. 2022, 140, 183–192. [Google Scholar] [CrossRef]

- Borgia, F. Performance analysis and modeling of microplastic separation through hydro cyclones. In Waste Material Recycling in the Circular Economy-Challenges and Developments; IntechOpen: London, UK, 2021. [Google Scholar]

- Lorentzon, A.C.C. Separation of Microfibers from Laundry Waste Water by Hydrocyclone: In Cooperation with Electrolux Professional. Master’s Thesis, The Swedish School of Textiles, University of Borås, Borås, Sweden, 2021. [Google Scholar]

- He, L.Q.; Ji, L.; Sun, X.; Chen, S.Y.; Kuang, S.B. Investigation of mini-hydrocyclone performance in removing small-size microplastics. Particuology 2022, 71, 1–10. [Google Scholar] [CrossRef]

- Liu, L.; Sun, Y.; Kleinmeyer, Z.; Habil, G.; Yang, Q.; Zhao, L.; Rosso, D. Microplastics separation using stainless steel mini-hydrocyclones fabricated with additive manufacturing. Sci. Total Environ. 2022, 840, 156697. [Google Scholar] [CrossRef]

- Habil, G. Exploring the Effectiveness of Mini-Hydrocyclone Technology for the Removal of Microplastics in Water Matrices; University of California: Irvine, CA, USA, 2023. [Google Scholar]

- Kulkarni, J. Hydro Cyclonic Separation of Polyester Microfibers from Washing Machine Wastewater. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2023. [Google Scholar]

- Yang, Z.; Jespersen, S.; Hansen, D.S.; Pajuro, K.F.; Liu, F.; Vollertsen, J. Capturing microplastics from aquatic systems using vortex based cyclone technique. In Proceedings of the 18th International Conference on Environmental Science and Technology, Athens, Greece, 29 August–1 September 2023. [Google Scholar]

- Liu, Y.; Zhang, Y.; Yan, L.; Yuan, P.; Ji, L.; Chu, K.; Li, Z.; Kuang, S. Mini-hydrocyclone performance enhancement in removing small-size microplastics using flocculants. J. Water Process Eng. 2023, 53, 103755. [Google Scholar] [CrossRef]

- Thiemsakul, D.; Piemjaiswang, R.; Sema, T.; Feng, Y.; Piumsomboon, P.; Chalermsinsuwan, B. Effect of hydrocyclone design in microplastics-water separation by using computational fluid dynamics simulations. Results Eng. 2024, 22, 102034. [Google Scholar] [CrossRef]

- Bu, T.; Mesa, D.; Pukkella, A.K.; Brito-Parada, P.R. Optimising miniaturised hydrocyclones for enhanced separation of microplastics. Chem. Eng. J. 2024, 496, 153718. [Google Scholar] [CrossRef]

- Zhang, T.; Li, J.; Yang, D.; Wang, Z.; Zhao, W.; Fu, P.; Wang, H. High-efficiency microplastic removal in water treatment based on short flow control of hydrocyclone: Mechanism and performance. Water Res. 2024, 267, 122492. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, R.; Billah, M.M.; Roy, S.; Banik, S.C.; Barua, A. Analyzing the effect of the density of medium on efficiency of hydrocyclone separator in sorting of PVC and PET using CFD. Results Mater. 2024, 21, 100497. [Google Scholar] [CrossRef]

- Senfter, T.; Walter, A.; Dür, L.; Alber, F.; Berger, M.; Kraxner, M.; Pillei, M. The standard and reverse mode operation of a hydrocyclone for microplastic separation. Microplastics 2024, 3, 22–30. [Google Scholar] [CrossRef]

- Liu, L.; Sun, Y.; Zhao, L.; Wang, Y.; Kleinmeyer, Z.; Yang, Q.; Rosso, D. Mini-hydrocyclones in water: State-of-the-art. Green Chem. Eng. 2024; in press. [Google Scholar] [CrossRef]

- Pandey, S.; Brar, L.S. The impact of Increasing the length of the conical segment on cyclone performance using large-eddy simulation. Symmetry 2023, 15, 682. [Google Scholar] [CrossRef]

- Yuan, F.; Li, X.; Yu, W.; Du, J.; Wang, D.; Yang, X.; Zhou, C.; Wang, J.; Yuan, H. A high-efficiency mini-hydrocyclone for microplastic separation from water via air flotation. J. Water Process Eng. 2022, 49, 103084. [Google Scholar] [CrossRef]

- Garcia-Villalba, M.; Colonius, T.; Desjardins, O.; Lucas, D.; Mani, A.; Marchisio, D.; Matar, O.K.; Picano, F.; Zaleski, S. Numerical methods for multiphase flows. Int. J. Multiph. Flow 2025, 191, 105285. [Google Scholar] [CrossRef]

- Wen, C.Y.; Yu, Y.H. Mechanics of fluidization. In Proceedings of the Fluid Particle Technology. Chem. Eng. Prog. Symp. Ser. 1966, 62, 100–111. [Google Scholar]

- Gidaspow, D.; Bezburuah, R.; Ding, J. Hydrodynamics of Circulating Fluidized Beds: Kinetic Theory Approach; Department of Chemical, Illinois Institute of Technology: Chicago, IL USA, 1990. [Google Scholar]

- Syamlal, M.; O’Brien, T.J. Computer simulation of bubbles in a fluidized bed. In Proceedings of the AIChE Symposium Series; AIChE: New York, NY, USA, 1989; pp. 22–31. [Google Scholar]

- Huilin, L.; Gidaspow, D. Hydrodynamics of binary fluidization in a riser: CFD simulation using two granular temperatures. Chem. Eng. Sci. 2003, 58, 3777–3792. [Google Scholar] [CrossRef]

- Brucato, A.; Grisafi, F.; Montante, G. Particle drag coefficients in turbulent fluids. Chem. Eng. Sci. 1998, 53, 3295–3314. [Google Scholar] [CrossRef]

- Burns, A.D.; Frank, T.; Hamill, I.; Shi, J.-M. The favre averaged drag model for turbulent dispersion in eulerian multi-phase flows. In Proceedings of the 5th International Conference on Multiphase Flow, ICMF, Yokohama, Japan, 30 May–4 June 2004; pp. 1–17. [Google Scholar]

| Authors | MP Material (Density, g/cm3) | MP Size (μm) | Hydrocyclone Diameter (mm) | Experimental Efficiencies (%) | Numerical Efficiencies (%) |

|---|---|---|---|---|---|

| Fu et al. [7] | PVC (1.22) & PET (1.31) | 80 | 68 | 80 | 90.2 |

| Borgia [8] | ABS, PET, PVC/(1.5) | 5 | 29.65 | / | 50–98.8 |

| Lorentzon [9] | PES /PET (1.35) | Microfibers with D = 9 | 15 | 11 | / |

| He et al. [10] | PMMA (1.19) | 5–15(D50≈10) | 10 | 52–88 | 51–95 |

| Liu et al. [11] | Nylon (1.15), LDPE (0.924) | 5–50 | 10 | 45–98.1 | / |

| Gina [12] | Nylon (1.15) | 5–50 | 10 | 70–85 | / |

| Gina [12] | LDPE (0.924) | 5–50 | 20 | 77–88 | / |

| Kulkarni [13] | PET (1.39) | Microfiber with D = 9 | 38.1 | ~50 | / |

| Yang et al. [14] | PE (0.98) | 53–63, 70–90 | 15 | 10–88 | / |

| Liu et al. [15] | PMMA (1.19) | 10 | 10 | 51–65 | / |

| Thiemsakul et al. [16] | PET (1.25) | 10 | 10 | / | 55–89.5 |

| Bu et al. [17] | PVC (1.4) | 10 | 10 | 76.85–88.53 | 79.97–89.82 |

| Zhang et al. [18] | PMMA (1.19) | 8 | 18 | / | 65–98.1 |

| Chowdhury et al. [19] | PVC (1.4), PET (1.33) | 300, 1 | 284 | / | 75–83 |

| Senfter et al. [20] | HDPE (0.95) | 118 | 100 | 0–99.12 | / |

| Senfter et al. [20] | PP (0.82) | 670 | 100 | 0–99.23 | / |

| Senfter et al. [20] | PS (1.07) | 85 | 100 | 3.01–93.85 | / |

| Senfter et al. [20] | PMMA (1.2) | 520 | 100 | 98.42–98.54 | / |

| Drag Models | Phase Exchange Coefficients |

|---|---|

| Wen–Yu [25] | |

| Gidaspow [26] | |

| Syamlal–O’Brien [27] | |

| Huilin–Gidaspow [28] | where |

| Geometrical Parameters | Values |

|---|---|

| Diameter of the cylindrical body Ds | 20 mm |

| Length of the cylindrical body Ls | 36 mm |

| Nominal diameter D | 12 mm |

| Upper cone angle θ1 | 25° |

| Lower cone angle θ2 | 1.5° |

| Diameter of the vortex finder Do | 2 mm |

| Diameter of the spigot Du | 7 mm |

| Width and height of the entrance W × H | 3.8 mm × 4.2 mm |

| Spatial Discretization | Discrete Schemes |

|---|---|

| Gradient | Least Squares Cell-Based |

| Pressure | PRESTO! |

| Momentum | QUICK |

| Volume fraction | Modified HRIC |

| Turbulent kinetic energy | Second Order Upwind |

| Turbulent dissipation rate | Second Order Upwind |

| Reynolds stress | Second Order Upwind |

| Feeding Velocities | Separation Efficiencies |

|---|---|

| 6 m/s | 56.41% |

| 7 m/s | 61.14% |

| 8 m/s | 66.24% |

| 9 m/s | 71.89% |

| 10 m/s | 78.56% |

| Feeding Densities | Separation Efficiencies |

|---|---|

| 800 kg/m3 | 98.51% |

| 930 kg/m3 | 50.32% |

| 998 kg/m3 | 10.78% |

| 1100 kg/m3 | 2.97% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Yang, X.; Du, J.; Yu, W.; Wang, D.; Yuan, F. Migration and Removal of Microplastics in a Dual-Cone Mini-Hydrocyclone. Symmetry 2025, 17, 1559. https://doi.org/10.3390/sym17091559

Dai Y, Yang X, Du J, Yu W, Wang D, Yuan F. Migration and Removal of Microplastics in a Dual-Cone Mini-Hydrocyclone. Symmetry. 2025; 17(9):1559. https://doi.org/10.3390/sym17091559

Chicago/Turabian StyleDai, Yiwei, Xinjun Yang, Jiyun Du, Wei Yu, Dongxiang Wang, and Fangyang Yuan. 2025. "Migration and Removal of Microplastics in a Dual-Cone Mini-Hydrocyclone" Symmetry 17, no. 9: 1559. https://doi.org/10.3390/sym17091559

APA StyleDai, Y., Yang, X., Du, J., Yu, W., Wang, D., & Yuan, F. (2025). Migration and Removal of Microplastics in a Dual-Cone Mini-Hydrocyclone. Symmetry, 17(9), 1559. https://doi.org/10.3390/sym17091559