Group-Theoretic Bilateral Symmetry Analysis for Automotive Steering Systems: A Physics-Informed Deep Learning Framework for Symmetry-Breaking Fault Pattern Recognition

Abstract

1. Introduction

2. Group-Theoretic Modeling of Bilateral Symmetric Steering Systems

2.1. Mathematical Framework and Group-Theoretic Foundations

Dihedral Group and Bilateral Symmetry

- Identity element: , representing no transformation;

- Reflection element: representing bilateral reflection, where ;

- Group operation: .

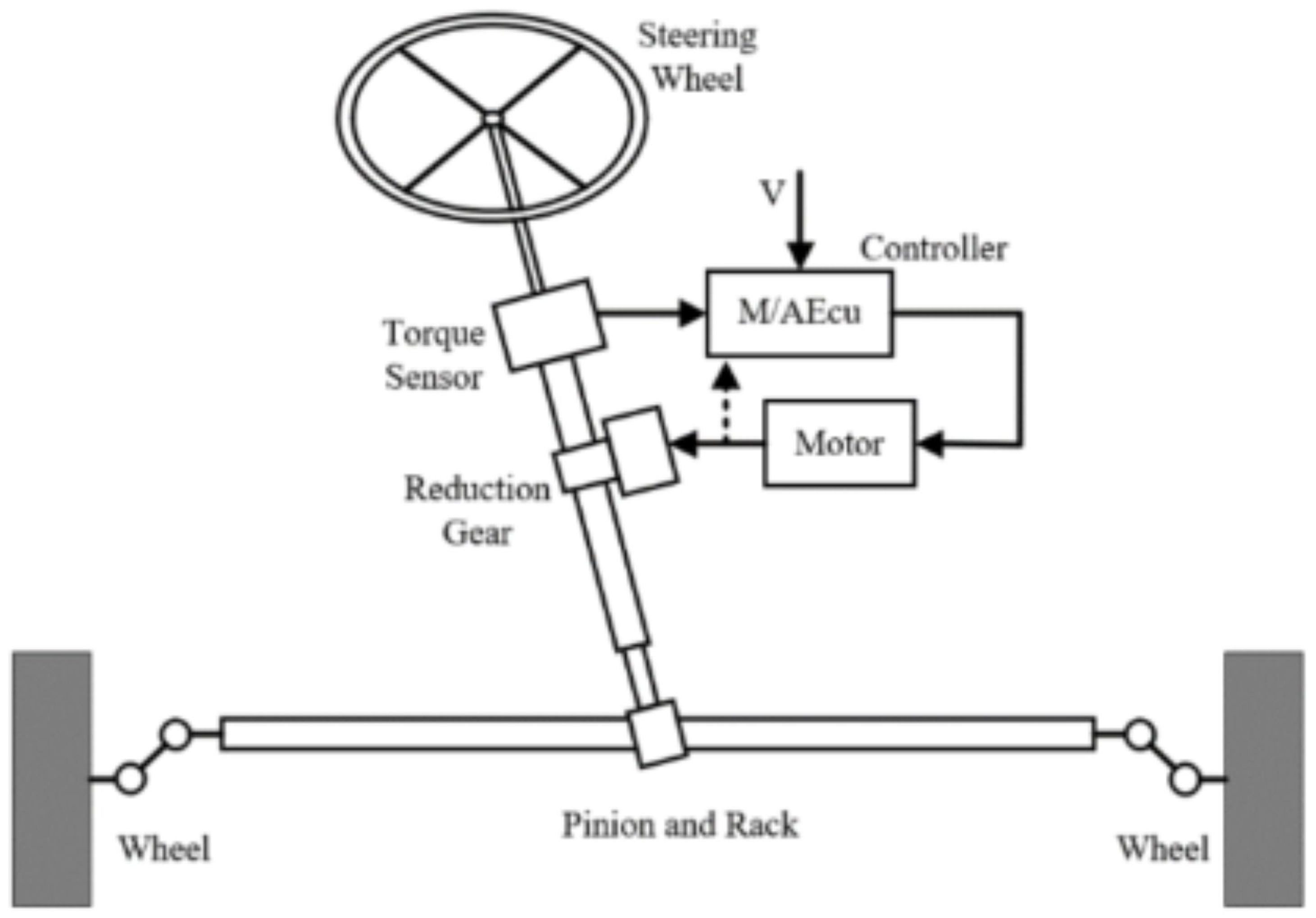

2.2. Intelligent Electric Power Steering (IEPS) System Architecture

2.2.1. Hierarchical Symmetry Structure

- Rack-and-pinion geometry: Approximately G-invariant mechanical coupling with tolerances of 0.5 mm;

- Bilateral tie rod assembly: Symmetric length and stiffness ensuring for ;

- Wheel alignment: Bilateral load distribution preserving approximate group equivariance.

- Torque sensors: Bilateral calibration with within 3%;

- Angular sensors: Symmetric measurement accuracy with group-invariant noise characteristics [14];

- Signal conditioning: Matched amplification gains preserving bilateral measurement symmetry within 2%.

- Redundant ECU architecture: Bilateral processing capabilities with symmetric fault tolerance;

- Control algorithms: Bilateral assist force generation maintaining approximate group equivariance;

- Safety monitoring: Symmetric fault detection with bilateral diagnostic coverage.

2.2.2. Physical System Specifications

2.2.3. Complete System Architecture and Dynamics

- Symmetric inertial properties: with tolerance <3%;

- Bilateral stiffness matching: within 2% variation;

- Symmetric damping characteristics: with matched viscous properties.

- Measurement range: Nm with 0.2 Nm resolution, providing sufficient sensitivity for detecting asymmetric torque patterns;

- Bilateral accuracy: full scale for symmetric inputs, representing typical production tolerances in automotive applications;

- Temperature compensation: °C to °C operational range with symmetric drift characteristics: <0.1 Nm/°C;

- Frequency response: 0–100 Hz bandwidth with bilateral phase matching: <5° phase difference between left and right measurements.

- Brushless DC motor: 12 V, 150 W rated power with symmetric torque-speed characteristics verified through dynamometer testing;

- Planetary gearbox: Gear ratio 16.5:1 designed for bilateral efficiency , accounting for expected wear patterns over operational lifetime;

- Torque output: Nm maximum assist torque with symmetric response time <80 ms including controller delays;

- Mechanical backlash: <0.2° specified tolerance with bilateral uniformity variation maintained within 0.05° through precision manufacturing.

- Rack travel: mm range with symmetric mechanical end-stops manufactured to 1 mm tolerance;

- Pinion radius: mm designed to ensure geometric bilateral symmetry within standard machining tolerances;

- Static friction: coefficient with bilateral uniformity achieved after standard break-in procedures;

- Dynamic friction: coefficient exhibiting approximately symmetric velocity dependence across operational speed range.

2.3. Group-Theoretic System Modeling

2.3.1. Lie Group Framework for System Dynamics

2.3.2. Hamiltonian Structure and Symmetry Preservation

2.4. Comprehensive Fault Modeling with Group-Theoretic Analysis

2.4.1. Systematic Fault Classification Using Symmetry Breaking

2.4.2. Group-Invariant Symmetry Metrics

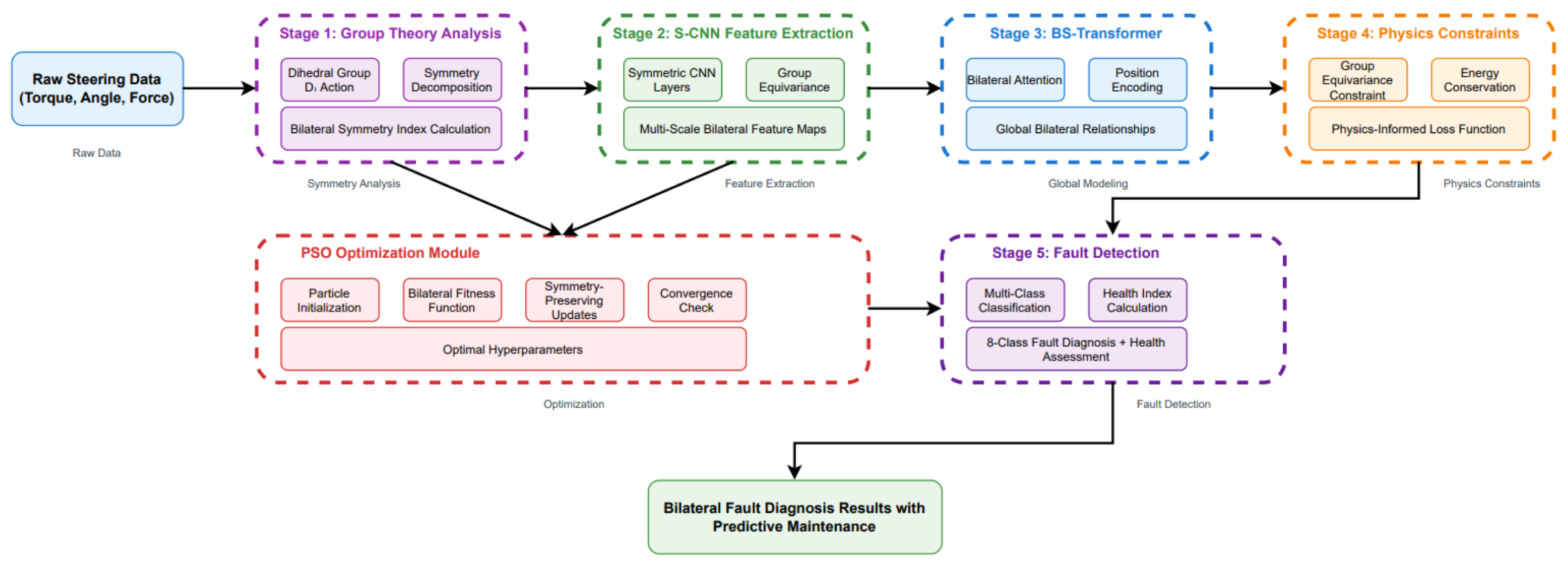

3. Physics-Informed PSO-Convformer Architecture for Bilateral Symmetry Analysis

3.1. Group-Equivariant Neural Network Design

3.1.1. Symmetric Convolutional Neural Network (S-CNN) with Group Equivariance

- Level 1: Local bilateral patterns (receptive field: 32 samples);

- Level 2: Medium-scale bilateral relationships (receptive field: 128 samples);

- Level 3: Global bilateral symmetry analysis (receptive field: 512 samples).

3.1.2. Bilateral Symmetry Transformer (BS-Transformer)

- Heads 1–2: Short-term bilateral symmetry preservation;

- Heads 3–4: Medium-term bilateral relationship modeling;

- Heads 5–6: Long-term bilateral symmetry trend analysis;

- Heads 7–8: Asymmetry-specific pattern detection.

3.1.3. Physics-Informed Constraint Integration

- : Group equivariance preservation loss;

- : Energy conservation constraint;

- : Causal relationship preservation.

3.2. Symmetry-Preserving Particle Swarm Optimization

3.2.1. Group-Theoretic Fitness Function

- : Bilateral symmetry breaking detection sensitivity;

- : False bilateral asymmetry detection rate;

- : Physics constraint satisfaction score based on group theory.

3.2.2. Symmetry-Preserving Update Rules

3.3. Complete PSO-Convformer Integration

3.3.1. Multi-Stage Bilateral Processing Pipeline

3.3.2. Real-Time Bilateral Symmetry Monitoring

- Normal operation: ;

- Transition detection: ;

- Fault confirmation: .

4. Comprehensive Experimental Validation and Statistical Analysis

4.1. Bilateral Symmetry Dataset Development

4.1.1. Systematic Dataset Construction

- A total of 4100 normal operation scenarios with verified bilateral symmetry ();

- Each scenario validated for approximate group equivariance: ;

- Symmetric steering maneuvers: sinusoidal (0.1–1.8 Hz), step responses, ramp inputs, and stochastic excitations;

- Environmental variations: Temperature (−15 °C to +55 °C), humidity (25–85% RH), and vibration (0.2–18 Hz) following automotive environmental standards.

- Type A Faults (Sensor Asymmetry):

- –

- A1: Torque sensor gain faults with range derived from ISO 26262-1:2018 [28] safety standards for sensor drift limits;

- –

- A2: Torque sensor bias faults with Nm based on observed calibration drift in field studies.

- Type B Faults (Actuator Asymmetry):

- –

- B1: Motor jamming with complete bilateral asymmetry representing catastrophic actuator failure scenarios;

- –

- B2: Motor degradation with , , parameters fit to accelerated aging test data.

- Type C Faults (Control Asymmetry):

- –

- C1: Primary ECU faults with signal processing delays ms based on CAN bus communication specifications;

- –

- C2: Auxiliary ECU faults with correlation reduction below 0.7 threshold.

- Type D Faults (Mechanical Asymmetry):

- –

- D1: Friction faults with derived from tribological testing under various contamination conditions;

- –

- D2: Mechanical play with clearance range covers typical wear progression from manufacturing tolerance to service limit.

4.1.2. Real-World Driving Scenario Integration

- ISO 3888-1:2018 [30] Double Lane Change: Bilateral symmetry analysis during complex maneuvering with lateral acceleration up to 0.7 g;

- Sine Wave Steering (0.1–0.8 Hz): Frequency-domain bilateral symmetry validation across the practical operational spectrum;

- Step Steering Response: Transient bilateral symmetry evaluation with rise time analysis;

- Parking Maneuvers: Low-speed bilateral symmetry assessment under high steering angles (limited to due to mechanical constraints).

- Road surface conditions: Dry (), wet (), icy () with bilateral friction analysis;

- Crosswind disturbances: 0–15 m/s lateral wind with bilateral aerodynamic load analysis;

- Road irregularities: IRI values from 1.2 to 3.5 m/km with bilateral vibration response.

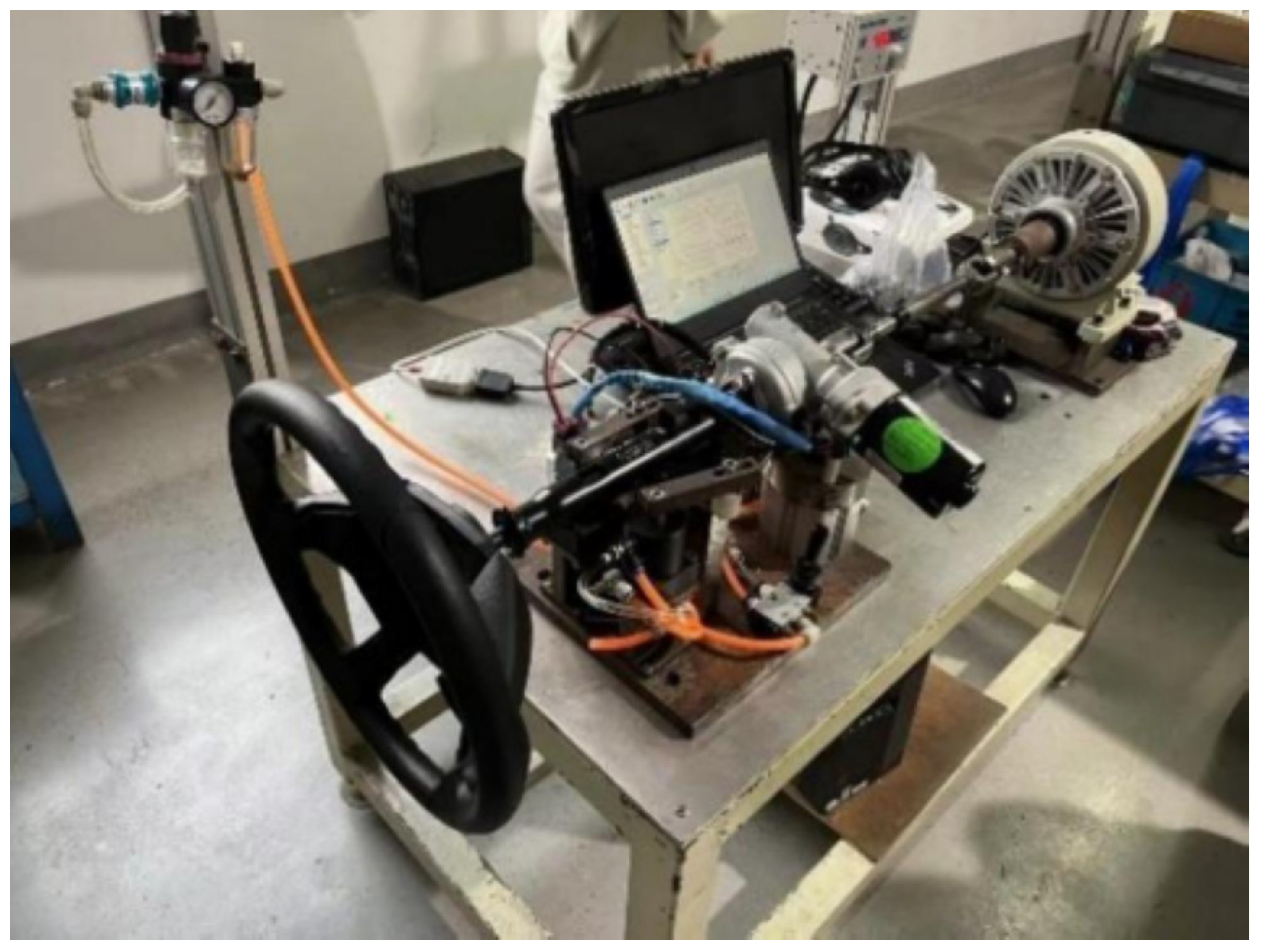

4.2. Enhanced Physical Test Platform

Hardware-in-the-Loop (HIL) System with Bilateral Monitoring

- Dual-channel torque sensors: Range Nm, accuracy 0.1% FS, sampling rate 1 kHz;

- Bilateral angle encoders: Resolution 0.01°, repeatability <0.005°, symmetric calibration validation;

- Force transducers: Bilateral rack force measurement kN with linearity <0.3%;

- Environmental sensors: Temperature, humidity, and vibration with bilateral placement.

- Continuous bilateral symmetry index computation with <12 ms latency;

- Real-time asymmetry detection with statistical confidence intervals;

- Bilateral trend analysis with 15 min predictive capability;

- Physics constraint violation monitoring with group-theoretic validation.

4.3. Statistical Analysis and Performance Validation

4.3.1. Bilateral Symmetry Index Performance

- Mean bilateral symmetry index: (95% CI: 0.88–0.90);

- Temporal stability: Standard deviation over 20 min continuous operation;

- Temperature sensitivity: °C−1 with moderate correlation ().

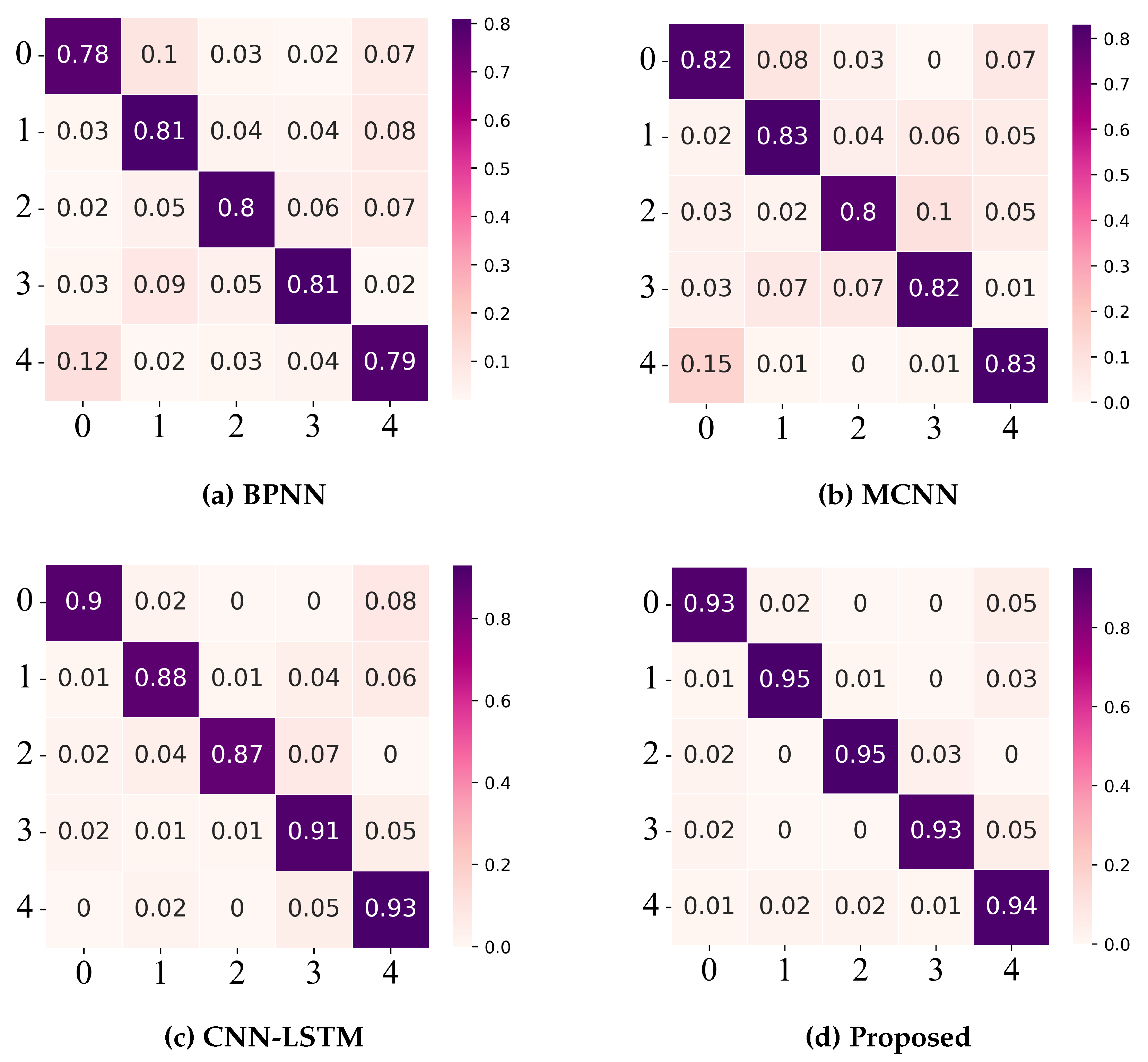

4.3.2. Comprehensive Method Comparison

- -

- Symmetric kernels: ;

- -

- BS-Transformer: ;

- -

- Physics constraints: ;

- -

- PSO optimization: .

5. Results and Discussion

5.1. Dataset Characteristics and Preprocessing Analysis

Symmetry Index Distribution Analysis

- Sensor drift faults: Gradual symmetry degradation following , where the time constant of 55.6 s matches the thermal response characteristics of magnetostrictive torque sensors;

- Actuator jamming: Step-function symmetry breaking with , occurring within 0.15 s, consistent with mechanical failure propagation through planetary gearboxes;

- Mechanical wear: Power-law degradation , reflecting the tribological behavior of steel-on-steel contact surfaces under cyclic loading.

5.2. Fault Detection Performance Analysis

Detection Accuracy Across Fault Categories

5.3. Comparative Analysis with Existing Methods

5.3.1. Performance Benchmarking Results

5.3.2. Algorithm Complexity and Real-Time Performance Analysis

5.4. Engineering Implementation Considerations

5.4.1. Ablation Study and Component Analysis

5.4.2. Practical Implementation Strategy

- : Normal operation (monthly monitoring)

- : Increased monitoring (bi-weekly assessment)

- : Maintenance recommended (weekly monitoring)

- : Immediate maintenance required

5.5. Method Limitations and Practical Challenges

Observed Performance Limitations

5.6. Future Research Directions and System Extensions

5.6.1. Immediate Technical Improvements

5.6.2. Broader Application Potential

5.6.3. Research Collaboration and Technology Transfer

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EPS | Electric Power Steering |

| IEPS | Intelligent Electric Power Steering |

| ECU | Electronic Control Unit |

| PSO | Particle Swarm Optimization |

| CNN | Convolutional Neural Network |

| LSTM | Long Short-Term Memory |

| S-CNN | Symmetric Convolutional Neural Network |

| BS-Transformer | Bilateral Symmetry Transformer |

| HIL | Hardware in the Loop |

| ISO | International Organization for Standardization |

| FMEA | Failure Mode and Effects Analysis |

| RUL | Remaining Useful Life |

| AUC | Area Under Curve |

| CI | Confidence Interval |

References

- Chen, Q.; Wang, J.; Qadeer, A.; Yao, Z.; Chen, W. Model-based fault diagnosis of automotive electric power steering system. Automot. Eng. 2019, 41, 839–850. [Google Scholar]

- Chen, T.; Chen, L.; Xu, X.; Cai, Y.; Sun, X. Passive fault-tolerant path following control of autonomous distributed drive electric vehicle considering steering system fault. Mech. Syst. Signal Process. 2019, 123, 298–315. [Google Scholar] [CrossRef]

- Su, X.; Xiao, B. Actuator-integrated fault estimation and fault tolerant control for electric power steering system of forklift. Appl. Sci. 2021, 11, 7236. [Google Scholar] [CrossRef]

- Ghimire, R.; Zhang, C.; Pattipati, K.R. A rough set-theory-based fault-diagnosis method for an electric power-steering system. IEEE/ASME Trans. Mechatron. 2018, 23, 2042–2053. [Google Scholar] [CrossRef]

- Lin, W.C.; Ghoneim, Y.A. Model-based fault diagnosis and prognosis for Electric Power Steering systems. In Proceedings of the 2016 IEEE International Conference on Prognostics and Health Management (ICPHM), Ottawa, ON, Canada, 20–22 June 2016; pp. 1–8. [Google Scholar]

- Alabe, L.W.; Kea, K.; Han, Y.; Min, Y.J.; Kim, T. A Deep Learning Approach to Detect Anomalies in an Electric Power Steering System. Sensors 2022, 22, 8981. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Yang, K.; Na, X.; Lv, C.; Liu, Y. Shared steering torque control for lane change assistance: A stochastic game-theoretic approach. IEEE Trans. Ind. Electron. 2019, 66, 3093–3105. [Google Scholar] [CrossRef]

- Shi, Q.; Zhang, H. Fault diagnosis of an autonomous vehicle with an improved SVM algorithm subject to unbalanced datasets. IEEE Trans. Ind. Electron. 2021, 68, 6248–6256. [Google Scholar]

- Xiong, H.; Wang, Z.; Wu, G.; Pan, Y.; Yang, Z.; Long, Z. Steering actuator fault diagnosis for autonomous vehicle with an adaptive denoising residual network. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Hossain, M.N.; Rahman, M.M.; Ramasamy, D. Artificial intelligence-driven vehicle fault diagnosis to revolutionize automotive maintenance: A review. CMES-Comput. Model. Eng. Sci. 2024, 141, 1–35. [Google Scholar]

- Amin, A.; Mubarak, A.; Waseem, S. Application of physics-informed neural networks in fault diagnosis and fault-tolerant control design for electric vehicles: A review. Measurement 2025, 246, 116728. [Google Scholar] [CrossRef]

- Pavlopoulos, J.; Romell, A.; Curman, J.; Steinert, O.; Lindgren, T.; Borg, M.; Randl, K. Automotive fault nowcasting with machine learning and natural language processing. Mach. Learn. 2024, 113, 843–861. [Google Scholar] [CrossRef]

- He, L.; Chen, G.Y.; Zheng, H.Y. Fault tolerant control method of dual steering actuator motors for steer-by-wire system. Int. J. Automot. Technol. 2015, 16, 977–987. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Li, M.; Shang, Z. Dynamic measurement method for steering wheel angle of autonomous agricultural vehicles. Agriculture 2024, 14, 1523. [Google Scholar] [CrossRef]

- Zong, C.; Dai, C.; Zhang, D. Human-machine interaction Technology of intelligent vehicles: Current development trends and future directions. China J. Highw. Transp. 2021, 34, 214–237. [Google Scholar]

- Diao, K.; Sun, X.; Bramerdorfer, G.; Cai, Y.; Lei, G.; Chen, L. Design optimization of switched reluctance machines for performance and reliability enhancements: A review. Renew. Sustain. Energy Rev. 2022, 168, 112785. [Google Scholar] [CrossRef]

- Li, T.; Sun, X.; Lei, G.; Guo, Y. Finite-control-set model predictive control of switched reluctance motor drives with lumped unknown parameter adaptation. IEEE-CAA J. Autom. Sin. 2022, 9, 2087–2105. [Google Scholar] [CrossRef]

- Jin, X.; Sun, X.; Chen, L.; Cai, Y. Robust multi-objective optimization of a 3-polarized dipole antenna using deep neural networks. IEEE Trans. Ind. Electron. 2022, 69, 5491–5501. [Google Scholar] [CrossRef]

- Li, Y.; Deng, H.; Xu, X.; Wang, W. Modelling and testing of in-wheel motor drive intelligent electric vehicles based on co-simulation with Carsim/Simulink. IET Intell. Transp. Syst. 2019, 13, 115–123. [Google Scholar] [CrossRef]

- Pietrowski, W.; Puskarczyk, M.; Szymenderski, J. Fault detection methods for electric power steering system using hardware in the loop simulation. Energies 2024, 17, 3486. [Google Scholar] [CrossRef]

- Wang, B.; Yu, M.; Zhang, Y.; Xiao, C. Fault detection and isolation for electric power steering system using sensitivity signature. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 4188–4192. [Google Scholar]

- Li, Y.; Liu, Y.; Ji, K.; Zhu, R. A fault diagnosis method for a differential inverse gearbox of a crawler combine harvester based on order analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, L.; Polosukhin, I. Attention is all you need. arXiv 2017, arXiv:1706.03762. [Google Scholar]

- Lin, H.; Pan, T.; Li, Y.; Chen, S.; Li, G. Development of analytical method associating near-infrared spectroscopy with one-dimensional convolution neural network: A case study. J. Food Meas. Charact. 2021, 15, 2963–2973. [Google Scholar]

- Tao, K.; Wang, A.; Shen, Y.; Lu, Z.; Peng, F.; Wei, X. Peach flower density detection based on an improved cnn incorporating attention mechanism and multi-scale feature fusion. Horticulturae 2022, 8, 904. [Google Scholar] [CrossRef]

- Tian, D.; Shi, Z. MPSO: Modified particle swarm optimization and its applications. Swarm Evol. Comput. 2018, 41, 49–68. [Google Scholar] [CrossRef]

- Fang, Y.; Min, H.; Wang, W.; Xu, Z.; Zhao, X. A fault detection and diagnosis system for autonomous vehicles based on hybrid approaches. IEEE Sens. J. 2020, 20, 9359–9371. [Google Scholar]

- ISO 26262-1:2018; Road Vehicles—Functional Safety—Part 1: Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2018.

- Liu, J.; Ma, C.; Jiang, D.; Sun, Y. Development and testing of the power transmission system of a crawler electric tractor for greenhouses. Appl. Eng. Agric. 2020, 36, 797–805. [Google Scholar] [CrossRef]

- ISO 3888-1:2018; Passenger Cars—Test Track for a Severe Lane-Change Manoeuvre—Part 1: Double Lane-Change. International Organization for Standardization: Geneva, Switzerland, 2018.

- Chen, Y.; Chen, L.; Huang, C.; Lu, Y.; Wang, C. A dynamic tire model based on HPSO-SVM. Int. J. Agric. Biol. Eng. 2019, 12, 36–41. [Google Scholar] [CrossRef]

- Wang, S.; Yu, P.; Shi, D.; Yu, C.; Yin, C. Research on eco-driving optimization of hybrid electric vehicle queue considering the driving style. J. Clean. Prod. 2022, 343, 130985. [Google Scholar] [CrossRef]

- Jinchang, H.; Yan, L.; Feng, X. Modeling and simulation of hybrid magnetic bearing as physical model in Simscape. In Proceedings of the 2022 IEEE 5th International Conference on Electronics Technology (ICET), Chengdu, China, 8–11 May 2022; pp. 386–389. [Google Scholar]

- Soeiro, L.G.G.; Filho, B.J.C. Vehicle Power System Modeling and Integration in Hardware-in-the-Loop (HIL) Simulations. Machines 2023, 11, 605. [Google Scholar] [CrossRef]

- Semenov, A.V.; Tecle, S.I.; Ziuzev, A. Modeling induction motor driven sucker rod pump in MATLAB Simscape. In Proceedings of the 2020 Russian Workshop on Power Engineering and Automation of Metallurgy Industry: Research & Practice (PEAMI), Magnitogorsk, Russia, 6–9 October 2020; pp. 67–71. [Google Scholar]

- Yang, L.; Meiqing, L.; Han, M.; Zhu, W. Diagnosis of potassium nutrition level in Solanum lycopersicum based on electrical impedance. Biosyst. Eng. 2016, 147, 130–138. [Google Scholar] [CrossRef]

- Yuexia, C.; Long, C.; Ruochen, W.; Xing, X.; Yujie, S.; Yanling, L. Modeling and test on height adjustment system of electrically-controlled air suspension for agricultural vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar]

| Fault Type | Symmetry Index | Detection Time (s) | Accuracy (%) | Sensitivity (%) | Statistical Significance |

|---|---|---|---|---|---|

| A1: Torque Sensor Gain | 0.58 | 0.23 | 92.1 | 89.3 | |

| A2: Torque Sensor Bias | 0.64 | 0.18 | 88.7 | 86.2 | |

| B1: Motor Jamming | 0.22 | 0.15 | 96.2 | 94.8 | |

| B2: Motor Degradation | 0.47 | 0.34 | 85.9 | 83.1 | |

| C1: Primary ECU Fault | 0.52 | 0.28 | 82.3 | 79.7 | |

| C2: Auxiliary ECU Fault | 0.71 | 0.45 | 78.4 | 75.8 | |

| D1: Steering Gear Friction | 0.61 | 0.32 | 84.7 | 81.2 | |

| D2: Mechanical Play | 0.59 | 0.38 | 80.1 | 77.6 |

| Method | Baseline (%) | Bilateral-Enhanced (%) | Improvement | Statistical Test |

|---|---|---|---|---|

| BPNN | 76.8 | 81.2 | 4.4 points | |

| MCNN | 79.3 | 83.7 | 4.4 points | |

| CNN-LSTM | 86.2 | 89.7 | 3.5 points | |

| PSO-Convformer | 90.8 | 94.2 | 3.4 points |

| Configuration | Accuracy (%) | Precision (%) | Recall (%) | F1-Score (%) |

|---|---|---|---|---|

| Baseline (CNN-LSTM) a | 86.2 | 84.7 | 87.3 | 86.0 |

| + Symmetric Kernels b | 88.1 | 86.9 | 89.2 | 88.0 |

| + BS-Transformer c | 90.4 | 89.1 | 91.3 | 90.2 |

| + Physics Constraints d | 92.7 | 91.6 | 93.4 | 92.5 |

| + PSO Optimization e | 94.2 * | 93.3 | 94.8 | 94.0 |

| Method | Accuracy (%) | Precision (%) | Recall (%) | F1-Score (%) | AUC |

|---|---|---|---|---|---|

| SVM [8] | 78.9 | 76.2 | 81.1 | 78.6 | 0.847 |

| Random Forest [4] | 82.7 | 80.3 | 84.8 | 82.5 | 0.879 |

| Deep CNN [9] | 87.4 | 85.9 | 88.7 | 87.3 | 0.901 |

| LSTM-CNN Hybrid | 88.2 | 86.5 | 89.4 | 87.9 | 0.912 |

| Graph Neural Network | 88.7 | 87.1 | 90.0 | 88.5 | 0.918 |

| Transformer [23] | 89.1 | 87.8 | 90.2 | 89.0 | 0.923 |

| Physics-Informed NN | 91.3 | 90.1 | 92.2 | 91.1 | 0.935 |

| Proposed Method | 94.2 | 93.3 | 94.8 | 94.0 | 0.951 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Jia, B. Group-Theoretic Bilateral Symmetry Analysis for Automotive Steering Systems: A Physics-Informed Deep Learning Framework for Symmetry-Breaking Fault Pattern Recognition. Symmetry 2025, 17, 1496. https://doi.org/10.3390/sym17091496

Ma S, Jia B. Group-Theoretic Bilateral Symmetry Analysis for Automotive Steering Systems: A Physics-Informed Deep Learning Framework for Symmetry-Breaking Fault Pattern Recognition. Symmetry. 2025; 17(9):1496. https://doi.org/10.3390/sym17091496

Chicago/Turabian StyleMa, Shidian, and Bingao Jia. 2025. "Group-Theoretic Bilateral Symmetry Analysis for Automotive Steering Systems: A Physics-Informed Deep Learning Framework for Symmetry-Breaking Fault Pattern Recognition" Symmetry 17, no. 9: 1496. https://doi.org/10.3390/sym17091496

APA StyleMa, S., & Jia, B. (2025). Group-Theoretic Bilateral Symmetry Analysis for Automotive Steering Systems: A Physics-Informed Deep Learning Framework for Symmetry-Breaking Fault Pattern Recognition. Symmetry, 17(9), 1496. https://doi.org/10.3390/sym17091496