1. Introduction

Against the background of coordinated development in greening and digitalization, as important hubs of international trade, ports are facing the dual challenges of improving operational efficiency and achieving environmentally sustainable development. In a port collection and dispatching system, external container trucks play a significant role in transportation between ports and their hinterlands due to their distinct advantage of providing door-to-door services for medium- and short-distance transportation. However, several issues still hinder the further development of port collection and dispatching, such as high unloading rates, low scheduling efficiency, and resource waste. As an emerging economic mode, the sharing economy has a positive impact on the production and operational activities of enterprises through information sharing, resource sharing, and other effects [

1]. Integrating the concept of the sharing economy into port collection and dispatching systems to realize the low-carbon and intelligent transformation of ports has become an urgent issue, where the methods of resource sharing, digital matching, and intelligent scheduling can be used to promote cooperation and resource sharing among carriers and enhance the utilization rate of port resources and their operation efficiency.

A sharing economy is a set of practices that allow consumers to share the same products or services with others. This concept has evolved in recent times in many research domains, such as car, taxi, and bike sharing [

2,

3]. Regarding the issue of container truck sharing, some surveys of carriers showed that carriers are typically small in scale and often lack convenient ways to cooperate in actual operations. Moreover, carriers are reluctant to transfer transportation tasks to other carriers due to the risk of customer loss, which results in low enthusiasm for cooperation among carriers [

4]. The key challenge in container truck sharing lies in developing more effective cooperation mechanisms to foster long-term direct collaboration among carriers. In existing research, profit allocation and transportation task allocation have been considered to design cooperation mechanisms for carriers. However, the enthusiasm of heterogeneous carriers to cooperate has not been fully considered, and research on how the introduction of sharing and cooperation mechanisms affects the complexity of decision structures in the task-and-route optimization of container trucks remains insufficient. Therefore, it is urgent to explore a win–win cooperation mechanism from the perspective of the sharing economy mode. Additionally, a container truck scheduling optimization model based on information sharing should be designed to quantify profit spaces and reduce carbon emissions.

In existing research on external container truck scheduling, studies on the independent operations of carriers are typically based on a simple contractual relationship. In other words, carriers provide transportation services to customers and charge for the service. For example, there are studies focusing on minimizing the total cost or total time [

5,

6] as the objective by exploring route planning problems for container trucks. In multi-carrier cooperation, revenue allocation is a key factor affecting collaboration and sharing. Although many revenue allocation methods have been proposed, they often yield unsatisfactory results [

7]. Some surveys based on qualitative interviews and quantitative questionnaires show that the lack of cooperative models capable of coordinating multiple carriers is a key factor limiting cooperation among container truck carriers [

8]. Sharing of transportation task information among carriers helps small carriers to achieve economy-of-scale effects. However, large carriers are less enthusiastic to share their transportation tasks, and the attractiveness of participating in cooperation is relatively low [

9]. Some studies have suggested that carriers can achieve cooperation and reduce overall transportation costs by exchanging transportation tasks. However, this approach makes it difficult to ensure that all participating carriers benefit equally from cooperation [

10]. Introducing a profit compensation mechanism in carrier cooperation allows carriers to obtain compensation by sharing transportation tasks and earn profits by completing transportation tasks shared by other carriers [

11]. However, this cooperation model lacks centralized management by a third party, making it difficult to ensure the quality of transportation task completion. In addition, carriers must disclose important information to other carriers during the process of exchanging and sharing transportation tasks. Therefore, the confidentiality of customer information is crucial, as it can affect the stability of cooperation and the sustainability of sharing [

12]. Therefore, it has become an urgent issue to design effective cooperation mechanisms to tap into the enthusiasm of carriers to cooperate fully and establish a stable cooperation platform to improve the efficiency of collection and dispatching at ports.

Existing research on port container truck scheduling, while addressing multi-carrier cooperation, still lacks the deep integration of sharing economy concepts. The main shortcomings include the absence of efficient resource-sharing cooperation mechanisms, with existing collaborative models mostly being limited to simple transportation task exchanges, demonstrating poor systemic integration of core elements such as container trucks and transportation tasks, along with insufficient incentives for heterogeneous carriers. Research on the synergy between truck scheduling under carrier collaboration and low-carbon objectives remains inadequate, failing to harness the potential of the sharing economy in improving port drayage efficiency and facilitating a low-carbon transition.

This study introduces the concept of the sharing economy and conducts research from the perspective of system optimization. The main work and contributions are as follows. (1) A sharing and cooperation mechanism with dual elasticity in capacity and information is designed to enhance the enthusiasm of heterogeneous carriers to cooperate, integrate capacity resources and transportation tasks, and establish a green sharing platform (GSP). (2) A green and cooperative task-and-route optimization model for container trucks with heterogeneous carriers based on task sharing is formulated to minimize the carbon emissions of the system, considering the spatiotemporal matching of scattered transportation tasks and the coordination of the revenue situations among all participants in the GSP. (3) To address the increased computational complexity induced by carrier cooperation, a ring-increasing strategy is designed to refine the column generation algorithm to enhance the computational efficiency. Insights for management are presented from the perspectives of the capacity size shared by carriers, external market demand, task demand variability, mixed fleets, and profit allocation of the GSP. The optimization method presented in this study allows resources to be efficiently coordinated and enables transportation tasks to be matched better among heterogeneous carriers, providing valuable insights for promoting the green development of the port collection and dispatching system.

The remainder of this article is organized as follows.

Section 2 presents the relevant literature.

Section 3 presents the problem statement, proposes a cooperation mechanism, and develops the mathematical formulation.

Section 4 elaborates upon the solution methodology.

Section 5 discusses the algorithmic testing and case studies, offering managerial insights for sustainable operations of the GSP along with the research limitations.

Section 6 concludes the study.

3. Mathematical Model

3.1. Problem Statement

Many logistics companies conduct container drayage operations between a port and its hinterland regions, with each maintaining proprietary fleets of container trucks to procure and execute transportation tasks. These transportation tasks predominantly consist of two modalities: import and export operations, corresponding to outbound and inbound movements of full containers, with associated empty-container repositioning tasks. Conventional transportation processes for import containers involve a carrier obtaining a loaded container at the port terminal, conveying the container via truck to the consignee’s specified location, and subsequently returning empty to the port facility; export container transportation processes are conducted following the inverse sequence. This transportation paradigm inevitably involves substantial empty haul movements that do not generate revenue and elevated operational expenditures while concurrently exacerbating environmental issues. By optimally matching import and export transportation processes, a single truck can simultaneously complete both tasks with only one additional truck travel segment. The operational sequence involves the following: (1) a container is loaded at the port for outbound delivery to the customer; (2) the truck travels to another customer location; (3) an inbound container is transported back to the port. However, for most carriers, the acquired import and export container tasks exhibit significant temporal imbalances, making task matching particularly difficult for individual carriers. Consequently, reducing empty truck movements while maintaining cost efficiency poses substantial practical difficulties. The development of the sharing economy model provides a viable solution for individual carriers to overcome temporal imbalances in transportation tasks. Specifically, heterogeneous carriers with varying container truck fleet sizes and transportation task volumes can establish a green sharing platform through binding consortium agreements. Under these agreements, each participating carrier can elect to share either partial or entire fleets and transportation tasks, systemically rebalancing import–export flow asymmetries and achieving stable task matching equilibria. Compared with conventional import and export transportation processes, the sharing-economy-based operational model not only significantly reduces empty truck mileage but also combines one-way transportation processes, thereby enhancing both truck utilization efficiency and overall port collection and transport efficiency.

In summary, this study investigates the design of cooperation mechanisms among carriers from the perspective of a consortium of heterogeneous carriers based on the sharing economy paradigm. Focusing on the truck fleets and transportation tasks shared by participating carriers, it achieves effective matching of import–export transportation tasks and optimizes container truck routing, thereby ensuring that all carriers obtain economic benefits.

Considering the operational reality of container truck activities while maintaining generality, the following hypotheses are proposed: (1) Each transportation task for carriers consists of either one 40 ft container or two 20 ft containers [

5]. In international container transportation, the cargo capacity of a 40 ft container is approximately 2.2 times that of a 20 ft container, while the freight rate is only 1.2–1.5 times higher [

32]. Consequently, 40 ft containers dominate the market due to their significant economic advantage, and thus carriers typically configure their trucks for 40 ft container transportation. For the limited demand of 20 ft container transportation, carriers usually adopt a dual-container operation mode, simultaneously transporting two 20 ft containers to ensure the economic efficiency of transport via trucks. (2) After completing a task, trucks return to standby near the port, meaning that all tasks start from the port [

33]. Container transportation exhibits a distinct “hub-and-spoke” structure: the trucks’ operational pattern involves shuttling containers back and forth between the port and task locations. Given that task locations are typically geographically dispersed while the port’s position remains fixed, the port in usually designated as both the origin and destination of all transportation tasks in the truck dispatching system to optimize dispatch efficiency. (3) All transportation tasks are completed within one day, with each truck being limited to handling either a single task or one set of matched tasks per day [

34]. In terms of the transportation distance, trucks primarily handle short-to-medium-haul tasks, with one-way trip durations typically lasting several hours. Therefore, considering drivers’ working hour restrictions, container loading/unloading operations, and return trip requirements, each truck can normally only complete one set of transportation tasks per day. The parameters and variables are given in

Table 1.

3.2. Design of a Dual-Flexibility Sharing and Cooperation Mechanism

An investigation of the current literature reveals that transportation of empty and full containers at ports is typically carried out collaboratively by multiple carriers. These carriers often exhibit significant disparities in capacity resources and the ability to attract transportation tasks due to funding constraints, operational scales, and other factors. In other words, there is heterogeneity in both the number of container trucks and transportation tasks among these carriers. Therefore, we call them heterogeneous carriers. The transportation tasks often exhibit uncertainty in terms of quantity, geographical distribution, and time requirements, and there is asymmetry between import and export container transportation tasks, resulting in an imbalance between the supply of container trucks and the demand for transportation tasks. On the one hand, it can lead to idle trucks or excessively high unloaded rates when the capacity resources exceed the demand for transportation tasks, leading to a waste of resources and sunk costs. On the other hand, carriers need to charter container trucks from the external market to fulfill their tasks when the capacity resources are insufficient to meet the demand for transportation tasks. This not only exposes them to the risk of losing transportation tasks due to the inability to secure capacity resources in time but also reduces customer satisfaction, as service quality cannot be guaranteed. Therefore, a more stable and flexible transportation service, through introducing the concept of the sharing economy to implement platform-based resource management and optimization, is an effective way to address the imbalance between the supply of container trucks and the demand for transportation tasks.

Existing research has shown that while the concept of the sharing economy provides a theoretical foundation for transportation task sharing and matching, the strong heterogeneity of carriers, low levels of information sharing, and lack of effective profit distribution methods limit carriers’ enthusiasm to cooperate [

35]. To address this, a sharing and cooperation mechanism with dual elasticity in capacity and information among heterogeneous carriers is designed. In other words, carriers within the GSP can flexibly share both container trucks and transportation tasks to the GSP according to their own needs. This flexible sharing approach provides carriers with enough space for adjustment. The sharing and cooperation mechanism with dual elasticity is shown in

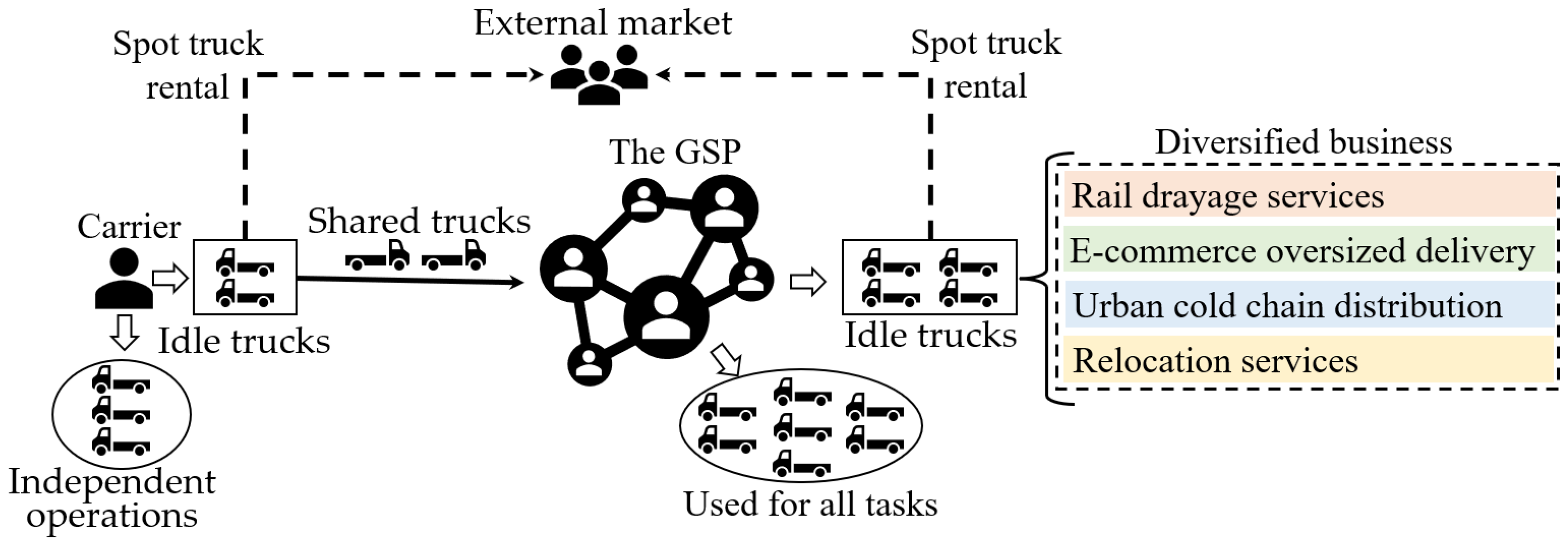

Figure 1.

As shown in

Figure 1, from the perspective of capacity resources, carriers can independently choose the number of container trucks to share on the GSP. The operating costs of the shared container trucks are covered by the GSP and, for revenues, the GSP provides subsidies for shared trucks to the carriers. Alternatively, carriers can independently operate a portion of their container trucks to complete the transportation tasks that are not shared, paying the operating costs themselves and obtaining the profit exclusively. From the perspective of information, carriers can also choose the number of transportation tasks to share with the GSP. The shared transportation tasks will be carried out by the GSP, and carriers are required to pay transportation fees for the shared transportation tasks to the GSP. In this case, carriers can earn a profit from the difference between the transportation fees charged by the GSP and the transportation fees charged to customers. On the other hand, carriers can retain the transportation tasks of important customers and independently carry them out to earn the full transportation fees from these customers for information protection.

To enhance carriers’ oversight of shared customer service quality, the GSP provides corresponding carriers with access permission, enabling real-time monitoring of transportation task execution status, including critical metrics such as progress, timeliness, and completion rates. Furthermore, the GSP implements a strict permission management system that prevents carriers from accessing other carriers’ business data. This design ensures both the confidentiality of customer information and the protection of carriers’ commercial interests, effectively mitigating carriers’ potential customer attrition risks.

3.3. Cost Accounting and Revenue Distribution Method Under the Dual-Flexibility Sharing and Cooperation Mechanism

This section initially formulates a cost accounting and revenue allocation method in the sharing and cooperation mechanism, aiming to maintain the GSP’s stability while enhancing carrier participation incentives.

- (1)

Cost accounting method in the sharing and cooperation mechanism

From the perspective of the GSP, the following four types of costs exist.

- a.

Fixed cost: This is incurred for maintaining the normal operation of the GSP.

- b.

Operating cost: This is incurred when the GSP dispatches container trucks to carry out transportation tasks, including both unloaded and heavy-load costs for container trucks [

36,

37].

- c.

Chartering expense: This is incurred when the GSP charters container trucks from the external market when its available container trucks are insufficient [

38].

- d.

Subsidy: This is incurred because the GSP should pay subsidies to carriers who share their container trucks. The number of container trucks that carriers share may be the benchmark for subsidies.

Therefore, the total cost of the GSP is expressed as follows [

39].

From the perspective of carriers, they should pay the operating costs of container trucks, as well as chartering expenses for obtaining additional container trucks from the external market in a shortage of trucks, when they operate some container trucks independently. In contrast, when carriers participate in the GSP and share their trucks and transportation tasks with the GSP, they need not pay operating costs. However, carriers should pay transportation fees to the GSP for these transportation tasks being carried out by the GSP. The transportation fees can be calculated using a linear function based on distances between the port and locations of transportation tasks [

5]. Therefore, the cost of carriers when participating in the GSP can be calculated as follows.

- (2)

Revenue allocation method in the sharing and cooperation mechanism

From the perspective of the GSP, two types of revenues exist. The first is transportation fees that can be charged by the GSP from carriers, as the GSP dispatches container trucks to carry out transportation tasks, which are shared by carriers when participating in the GSP. The second is the revenue from renting surplus container trucks of the GSP out to the external market. Therefore, the revenue of the GSP can be calculated as follows.

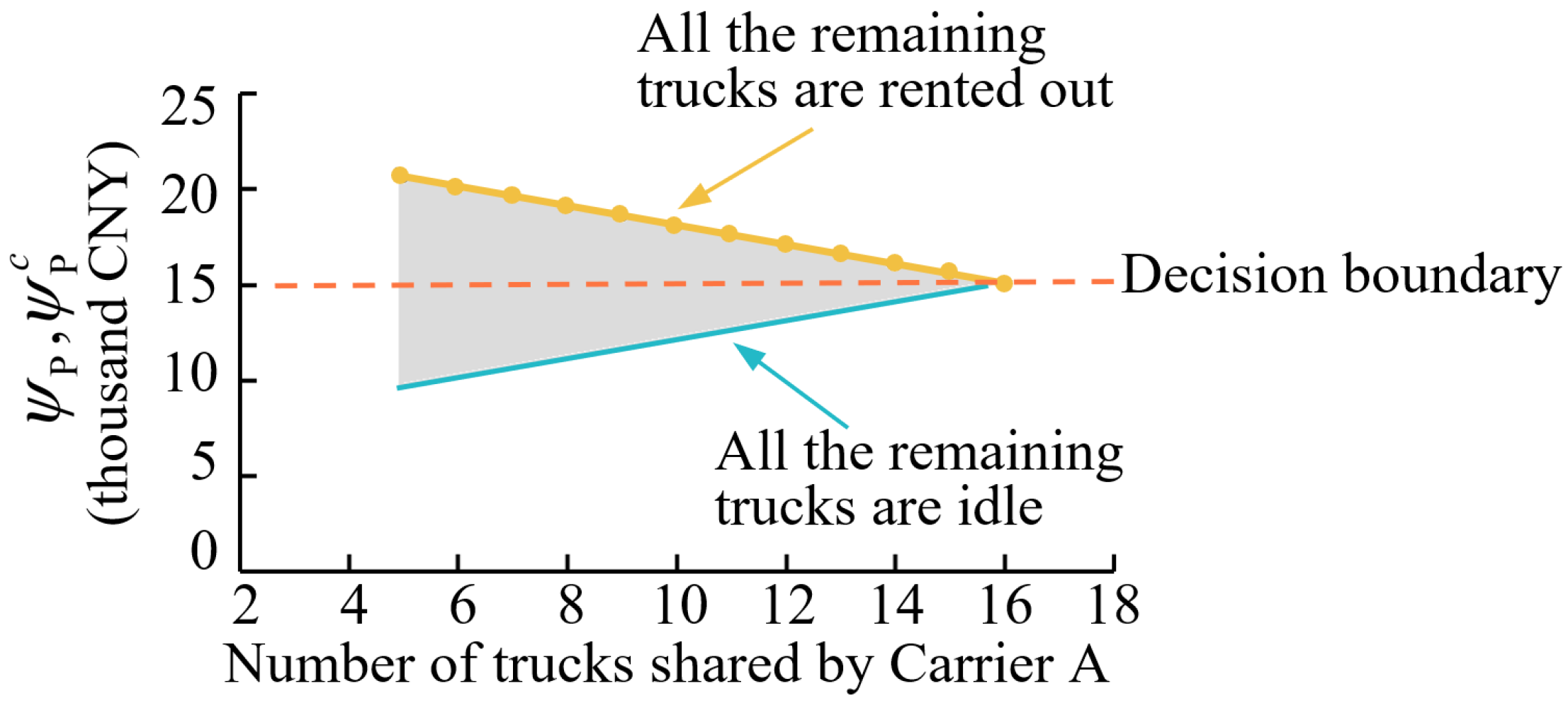

From the perspective of carriers, transportation fees are their only revenue for providing transportation services to customers. In contrast, they would have two other types of revenues when participating in the GSP, corresponding to their shared capacity resources and information with the GSP, respectively. The first is subsidies obtained by sharing container trucks, and the second is the bonus allocated by the GSP based on the transportation tasks shared with the GSP. Therefore, the revenue of carriers when participating in the GSP can be calculated using Equation (4), where the bonus proportion of carrier c is determined using Equation (5).

Since the GSP needs to allocate some revenues as the above bonus, the actual profit obtained by the GSP equals .

3.4. Green Cooperative Task-and-Route Optimization Model for Container Trucks

Carbon emissions predominantly come from fuel combustion during container truck driving. Higher fuel combustion results in more carbon emissions, and the fuel consumption is related to the driving distance of container trucks and load status [

40]. Therefore, under the scheduling of the GSP, the total carbon emissions generated by completing transportation tasks can be calculated using Equation (6).

Under the sharing and cooperation mechanism with dual elasticity, the GSP integrates the capacity resources and transportation tasks of heterogeneous carriers. Through the coordinated allocation of resources, the GSP aims to reduce carbon emissions and promote the healthy development of the sharing economy. Therefore, a green and cooperative task-and-route optimization model for container trucks with heterogeneous carriers based on task sharing is formulated, with the combination of import and export container transportation tasks and the routes of container trucks as the decision variables. The model is referred to as M1, and its objective function is the minimization of system carbon emissions under the unified scheduling of the GSP [

41], as shown in Equation (7).

M1 achieves the minimization of system carbon emissions while simultaneously ensuring that all parties participating in the GSP benefit. It guarantees the GSP’s profitability by maintaining positive residual profits after bonus distribution, as formalized in Equation (8).

M1 ensures carriers receive benefits by maintaining a positive difference between their total income and total expenditure, as specified in Equation (9).

To ensure customer satisfaction, the completion of all transportation tasks, which comprise both import and export transportation tasks, must be guaranteed in the GSP [

38]. The constraints are specified in detail in Equations (10)–(12).

The GSP does not have unlimited available container trucks. The number of trucks used to complete all transportation tasks must not exceed the GSP’s callable trucks, as formalized in Equation (13).

Each container truck corresponds to one route. Under each route, the truck may complete either a single transportation task or a combination of tasks. Consequently, there is a relationship between the route of a container truck and the task combination, as specified in Equation (14).

When executing import transportation tasks, container trucks must depart from the port; when handling export transportation tasks, they must return to the port [

42]. Consequently, each transportation task can only be assigned to one route, as formalized in Equations (15) and (16).

For each route, flow balance must be maintained at all visited locations. These nodes are categorized into two types: locations

n and locations

m, as formalized in Equations (17) and (18).

To address the time sensitivity of real-world operations, the latest acceptable service times for import and export containers are incorporated into truck route constraints. Specifically, in this study, deadlines are imposed for both container delivery and pickup completion. This approach balances carrier interests with carrier scheduling flexibility, as formalized in Equation (19).

The binary constraints of the decision variables are specified in Equations (20) and (21).

Detailed descriptions of the constraints are provided in

Table 2.

4. Design of a Column Generation Algorithm Embedded with a Ring-Increasing Strategy

Regarding the problem complexity, we define a pair of import and export container transportation tasks that satisfy the time window constraints as a task combination

,

,

. Transportation tasks that do not meet the combination conditions and are carried out individually are also regarded as a task combination, which is

or

. Thus, it can be deduced that the import and export container transportation tasks can be matched into, at most

different task combinations. To fulfill all transportation tasks from carriers, the GSP will select at least

task combinations from all possible combinations to form the final scheduling scheme. Given the dependency relationships among task combinations

,

, and

, once

are determined,

and

are also determined. Consequently, combinatorial analysis demonstrates that the number of feasible solutions equals

, where X denotes the number of task combinations

, i.e.,

. The problem is transformed into identifying the optimal combination among all feasible solutions that accomplishes all transportation tasks while minimizing the GSP’s carbon emissions. Furthermore, due to the complex structure introduced by profit distribution among carriers, the computational complexity of the problem grows exponentially with task volume. To address these challenges, we employ a column generation approach as the core algorithm. Through Dantzig–Wolfe decomposition, the model is divided into a route-based master problem and subproblems [

43]. To enhance the interaction efficiency between the master problem and subproblems, a ring-increasing strategy is designed based on the spatial coupling characteristics of transportation task locations. This strategy accelerates subproblem optimization, enabling higher-accuracy solutions, or potentially even exact solutions, to be obtained within shorter computation times. The notation used in the algorithm and their descriptions are presented in

Table 3.

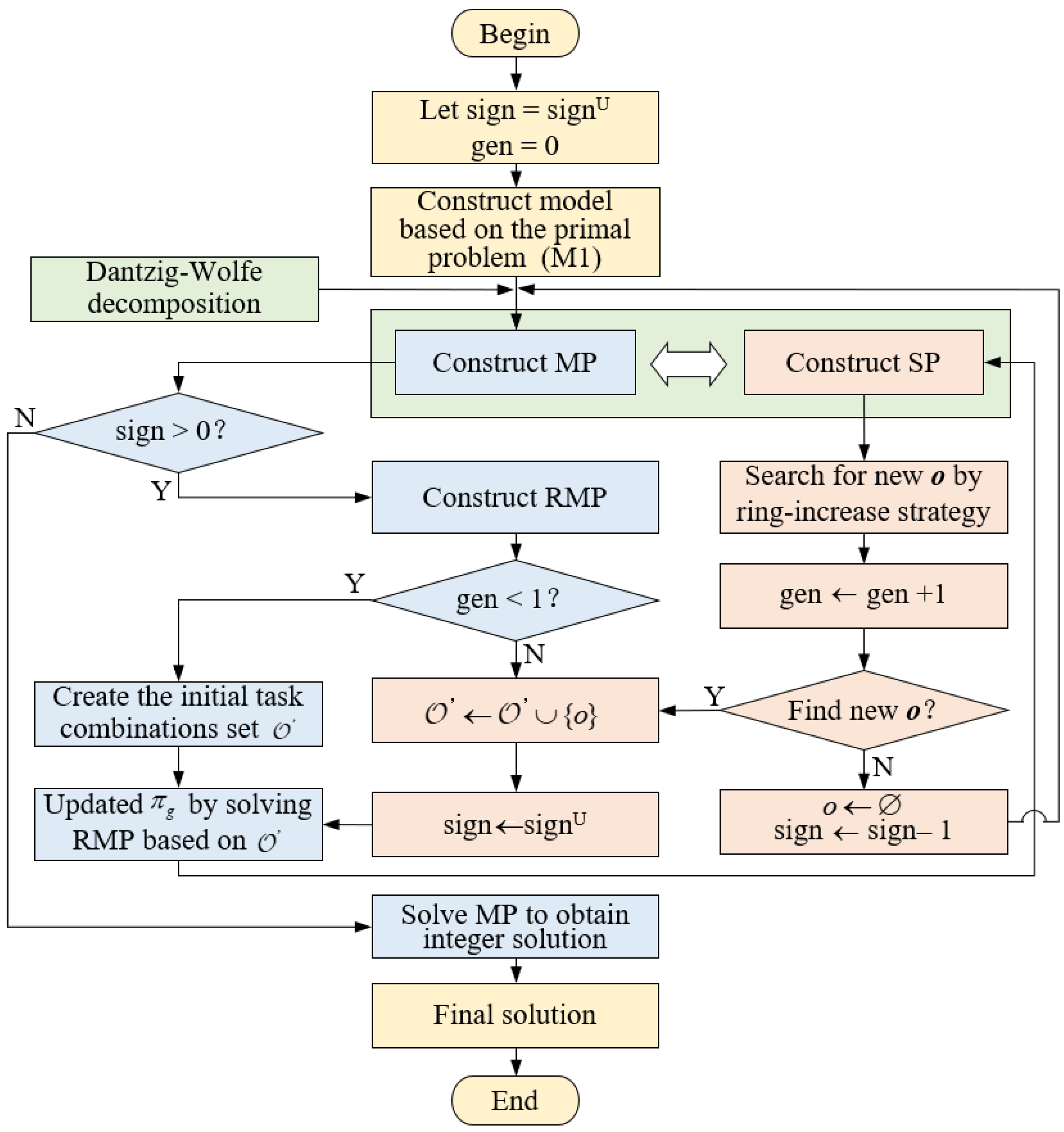

4.1. Algorithm Procedure

The procedure of the column generation algorithm based on the ring-increasing strategy (RCG) is as follows:

Step 1: Data initialization is conducted by inputting the transportation task sets and , along with fundamental parameters, including the GSP’s subsidy and transportation fees and .

Step 2: Using the Dantzig–Wolfe decomposition method, the original problem M1 is partitioned into a master problem (MP) and subproblems (SPs). The profit and transportation task constraints in the MP are relaxed, thereby transforming it into a restricted master problem (RMP).

Step 3: Based on the scenario where all transportation tasks are carried out individually, the initial task combination set for the RMP is constructed, and we let .

Step 4: Under the current task combination set , the RMP is solved using CPLEX to obtain the minimal carbon emissions and updated dual information . Then, the algorithm evaluates whether has decreased. If true, let ; otherwise, let .

Step 5: If , we perform Step 6; otherwise, we perform Step 7.

Step 6: By incorporating the dual information

, the ring-increasing strategy from

Section 4.3 is employed to search for a new task combination

o, and we let

. If

o satisfies

, the set

will be updated, and we let

; otherwise, we let

and perform Step 7.

Step 7: The updated task combination set is propagated to the MP, which is then solved to optimality using CPLEX. Then, we obtain the minimal carbon emissions, the corresponding container truck scheduling scheme, and the total profit allocation across all carriers, and end the process.

The procedure of the RCG is as

Figure 2.

4.2. Model Decomposition

Through the decomposition of the model, the master problem is transformed into a problem of finding a set of task combinations that can cover all transportation tasks while minimizing the carbon emissions of the system under the GSP, given all feasible task combinations. The subproblem is that of finding the task combinations that satisfy the time constraints of the primary problem, and the reduced carbon emissions are negative.

4.2.1. Master Problem and Restricted Master Problem

Let the set of feasible task combinations

o for the primary problem be denoted as

. The primary problem can then be transformed into a problem that involves finding a subset within

that minimizes carbon emissions while ensuring that the transportation tasks from all carriers are completed. The mathematical model of the master problem (MP) is as follows:

where Equation (22) is the objective function for minimizing the total carbon emissions under the unified scheduling of the GSP. Equation (23) places the restriction that all transportation tasks should be completed. Equation (24) represents the constraint that the number of container trucks used by the GSP must not exceed the total trucks available. Equation (25) is the binary constraint of the decision variables.

There will be a vast number of elements within

when the problem scale is large, making the master problem difficult to solve. The solution is initiated from a simple initial task combination set

by continuously adding feasible task combinations to

. This approach avoids the direct resolution of the master problem with set

. By relaxing Equations (8), (9), (23) and (25) in the MP, it is transformed into a linear programming problem to which the duality theory can be applied. The relaxed MP is referred to as the RMP, and its mathematical model is as follows:

4.2.2. Subproblem

To enrich the task combinations within

and enhance the quality of

, the subproblem is primarily used to search for task combinations that satisfy the condition of negative reduced carbon emissions. The model of the SP is as follows:

where

represents the reduced carbon emissions of task combination

o. Task combination

o is considered a valid task combination when

is negative.

is the dual variable of Equation (27) in the RMP, which may lead to a lower bound of the RMP, and its economic significance is the carbon emissions generated to fulfill transportation task

g. Assuming that transportation task

g is in task combination

o,

can be calculated according to Equation (31) when task combination

o contains only the transportation task

g.

When the task combination

o consists of two transportation tasks, one of which is transportation task

g,

can be calculated according to Equation (32).

Through continuous iterative optimization between the RMP and SP, it is considered that the RMP and MP have the same lower bound when no route with a negative can be found, and the column generation process is terminated. At this point, the best integer solution of the RMP is the final solution.

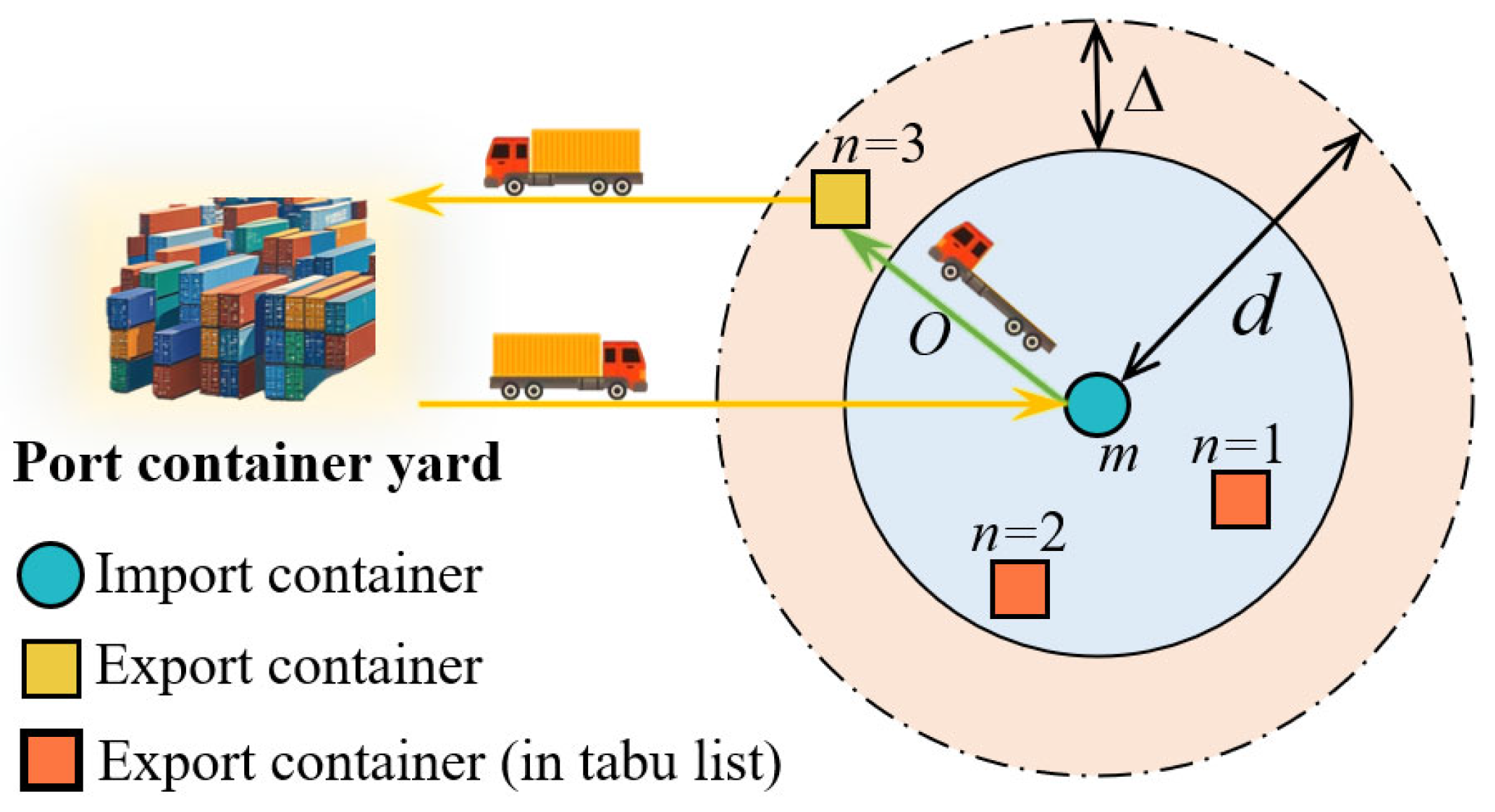

4.3. Ring-Increasing Strategy

It should be noted that

is constant in Equation (30), which is for calculating the reduced carbon emissions of

. In addition,

is influenced by

according to Equation (32). Therefore, the likelihood of

being negative is higher when the travel distance of the container truck from location

m to location

n in task combination

o is relatively short, which means that the value of

is small. Based on this, the ring-increasing strategy is designed to find the minimum task combination set

. The pseudocode of the algorithm is as Algorithm 1.

| Algorithm 1 Ring-increasing strategy |

![Symmetry 17 01437 i001 Symmetry 17 01437 i001]() |

To address the phenomenon of degeneracy in the column generation algorithm, the ring-increasing strategy introduces parameters

and

for early termination. When the algorithm fails to improve the incumbent optimal solution for

consecutive iterations, it terminates prematurely. This effectively mitigates the tailing-off effect and enhances the algorithm’s computational efficiency. Taking transportation task

m as an example, the pseudocode searches for transportation tasks of the export container within the radius range

centered on

m and forms a task combination with transportation task

m, as illustrated in

Figure 3.

6. Conclusions

For port collection and dispatching systems, existing research on vehicle routing problems under sharing has predominantly focused on simplistic task-exchange cooperation models. These approaches demonstrate limited systemic integration capabilities for core elements such as container trucks and transportation tasks, while cooperative mechanisms provide insufficient incentives for heterogeneous carriers. Therefore, this study proposed a dual-flexibility sharing and cooperation mechanism for heterogeneous carriers to enhance their participation willingness and collaboration stability in the GSP. Building upon this foundation, we established a green and cooperative task-and-route optimization model for container trucks with heterogeneous carriers based on task sharing, and designed a column generation algorithm embedded with a ring-increasing strategy to obtain an efficient solution for the asymmetric problem between import and export container transportation tasks. This integrated approach effectively harnesses the potential of the sharing economy to enhance port collection and distribution efficiency and accelerate low-carbon transitions in container logistics systems.

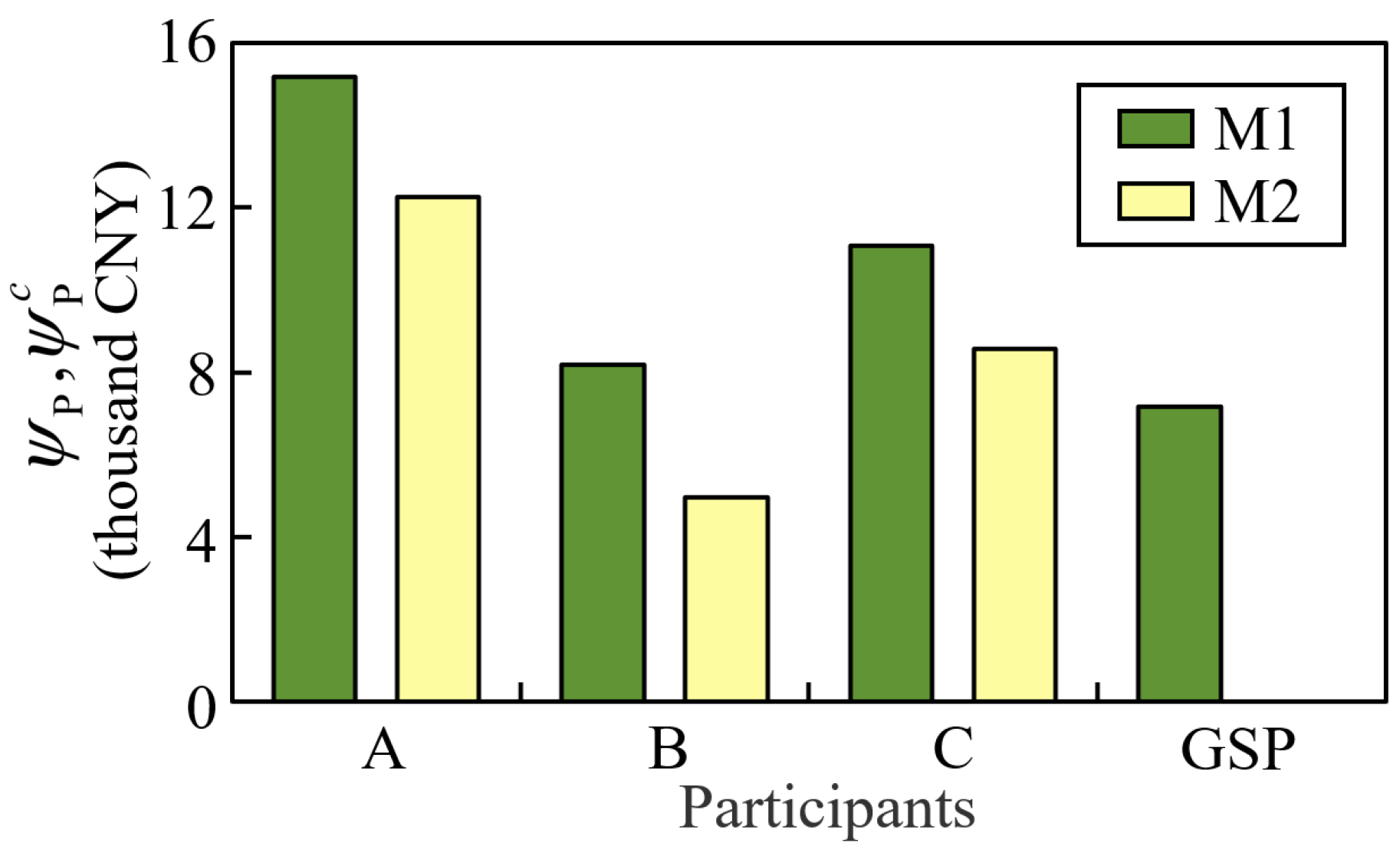

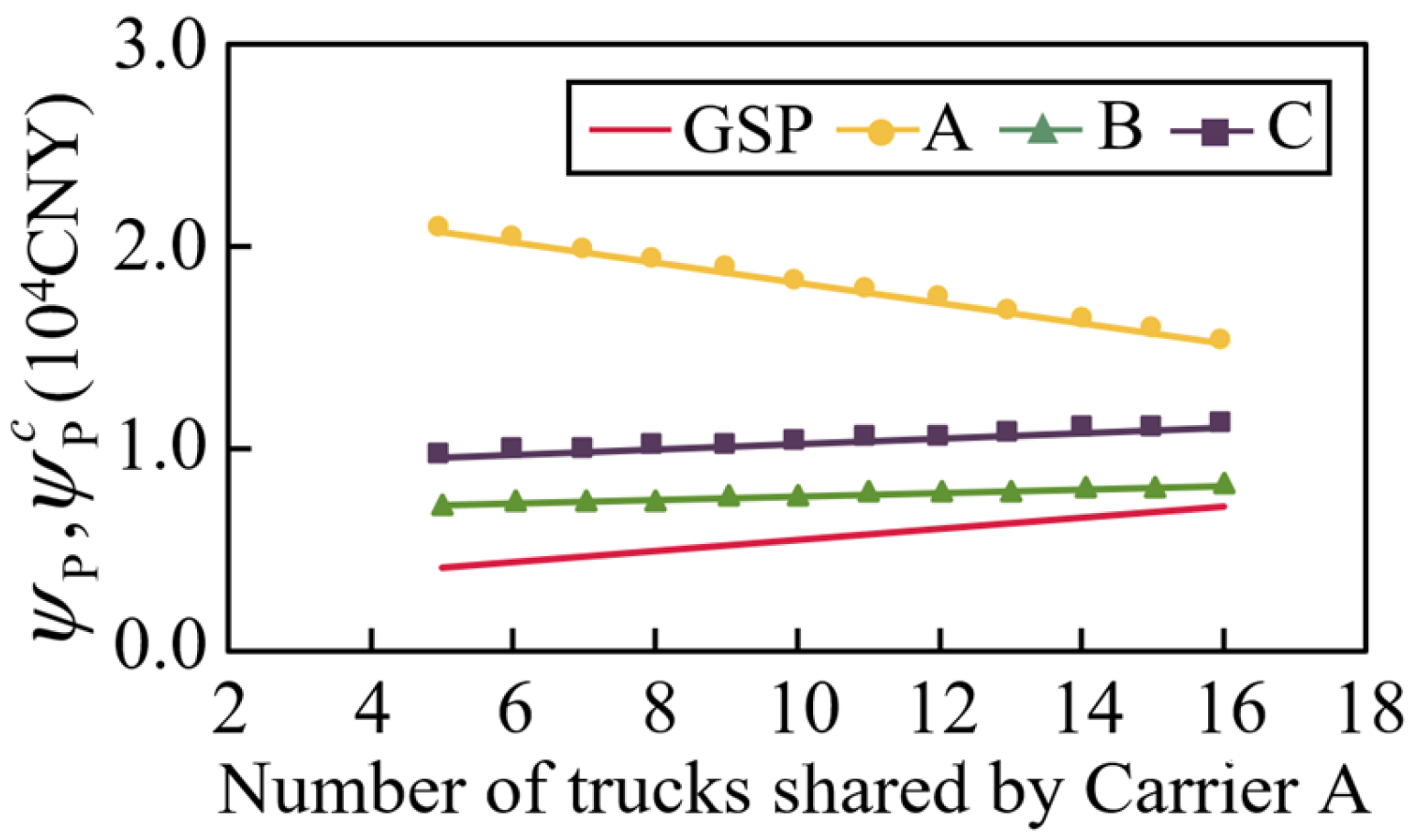

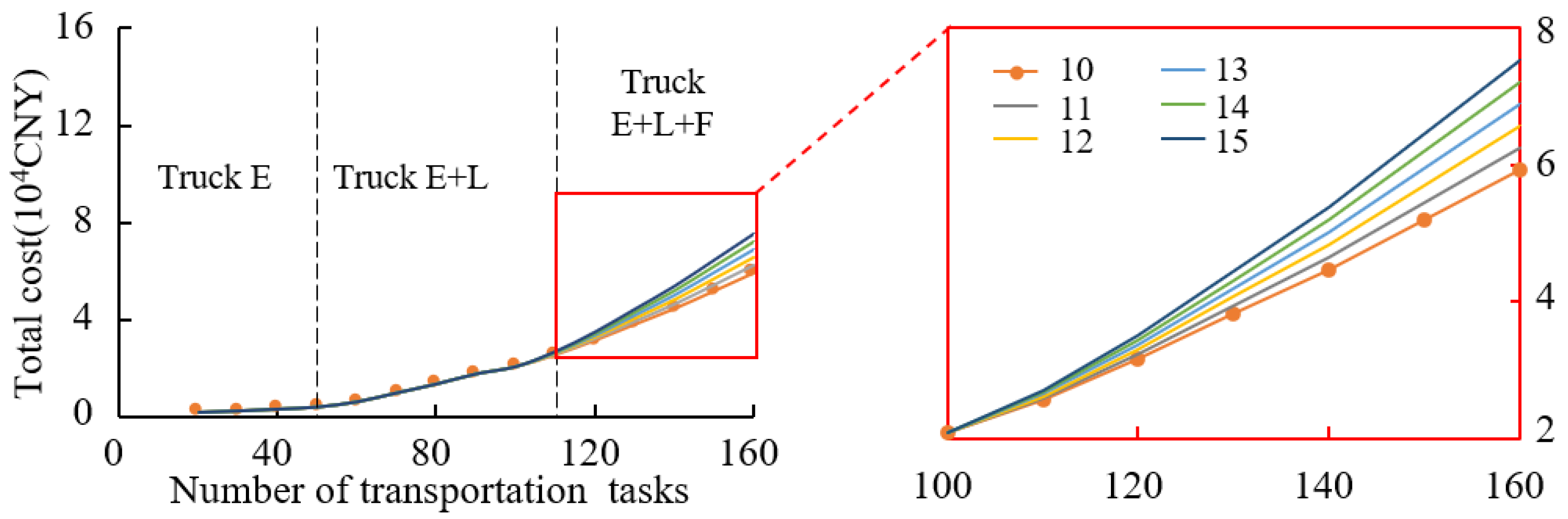

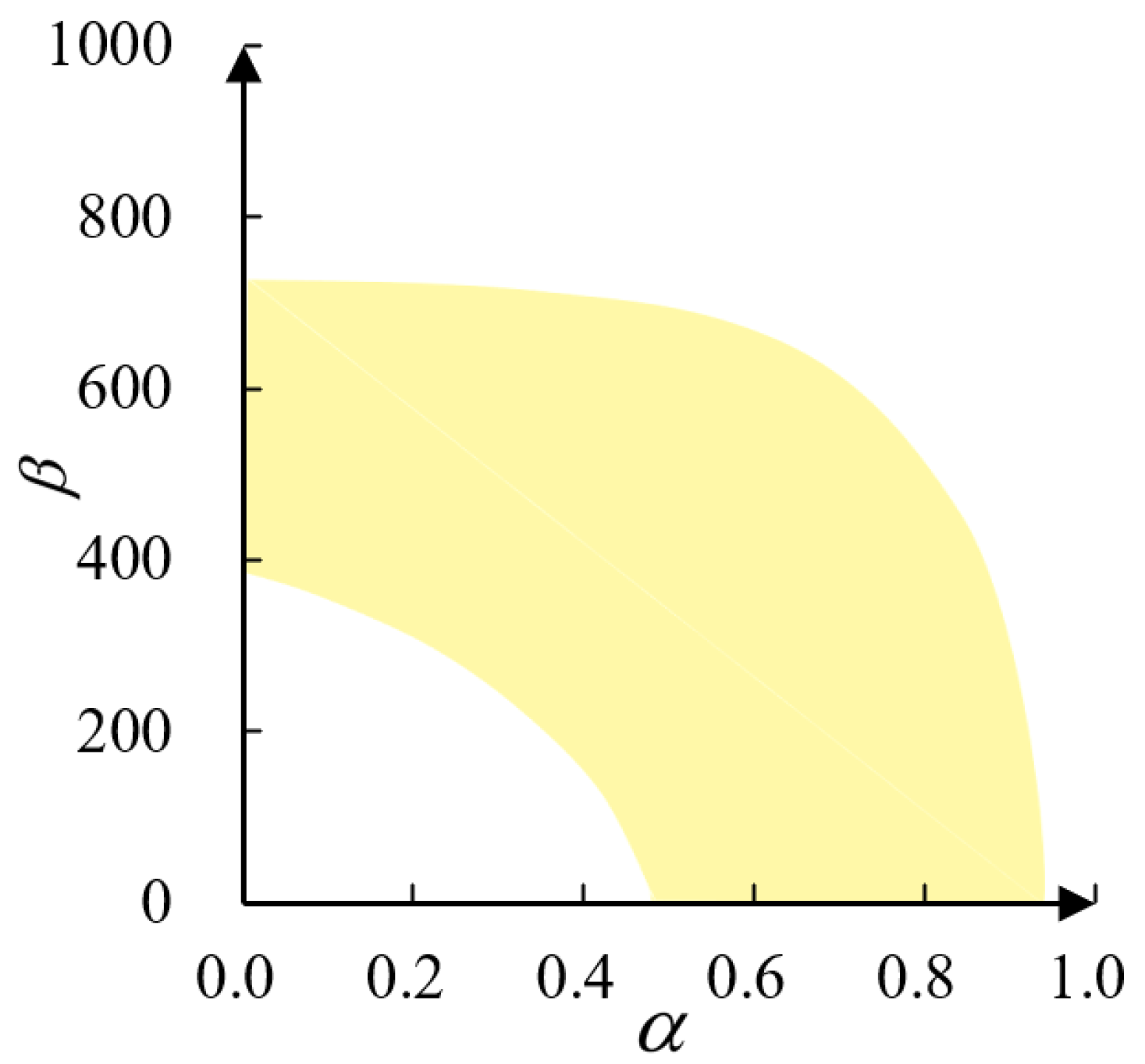

The methodology developed in this study extends the application of the sharing economy in port logistics, contributing to the enrichment of vehicle routing problems under sharing. Specifically, the proposed efficient algorithm addresses the increased computational complexity arising from profit allocation in multi-carrier collaboration, representing a novel approach for solving sharing-based vehicle scheduling problems. The case study yielded the following key quantitative findings. First, under identical transportation task volumes, the proposed optimization method reduced carbon emissions by 28–35% when compared with independent carrier operations, while simultaneously increasing profits for all cooperation participants by 23.6–65.3%. Second, adopting a more balanced approach to adjusting import and export transportation task volumes enabled the GSP to generate an additional CNY 205 in revenue per incremental task. The GSP managers can utilize this marginal gain as an incentive to encourage carriers to preferentially share their most suitable tasks, thereby creating a positive feedback loop that enhances overall system profitability. Third, the analysis examined the impacts of subsidy amounts and the proportion of the bonus on the profits of participants. The GSP can achieve a minimum 15% improvement in profit margins while ensuring that all participants benefit by optimizing these two parameters. The proposed method provides critical boundary conditions for designing cooperative mechanisms in the GSP.

In summary, the main contributions and work of this study include the following: the design of a dual-flexibility sharing and cooperation mechanism to enhance the willingness of heterogeneous carriers to collaborate and integrate trucks and transportation tasks; the establishment of a green and cooperative task-and-route optimization model for container trucks with heterogeneous carriers based on task sharing that considers the spatiotemporal matching of distributed transportation tasks and balances the profit levels of all participants; the development of a column generation algorithm embedded with a ring-increasing strategy to enhance computational efficiency by addressing the increased complexity caused by multi-carrier cooperation; through sensitivity analysis of key factors, the proposal of corresponding management insights that provide boundary conditions for GSP managers to maintain stable operations and profits while offering quantitative references for participating carriers regarding the effects of container trucks and task information sharing levels on profits.

Further research could be undertaken in the following directions. Firstly, the issue of information sharing within cooperation mechanisms is a critical consideration in research on the sharing economy, as it involves the protection of carriers’ sensitive data. Therefore, administrators of the GSP must maintain strict neutrality and treat all carriers equally to ensure its stable development. Further, the emergence of the GSP may raise monopoly concerns within governments. Thus, it is essential to establish proper relationships with governmental and regulatory bodies and formulate relevant agreements. Finally, stochastic and robust optimization frameworks demonstrate strong efficacy in handling uncertain information. These areas will constitute the primary focus of our future research.