Fault-Tolerant Tracking Observer-Based Controller Design for DFIG-Based Wind Turbine Affected by Stator Inter-Turn Short Circuit

Abstract

1. Introduction

- A T-S fuzzy representation is proposed to describe the dynamic behavior of the DFIG subject to ITSC faults in a wide range of generator speed variation. This allows to use linear control theory for nonlinear systems and it simplifies the controller and observer gains design as well as the stability analysis.

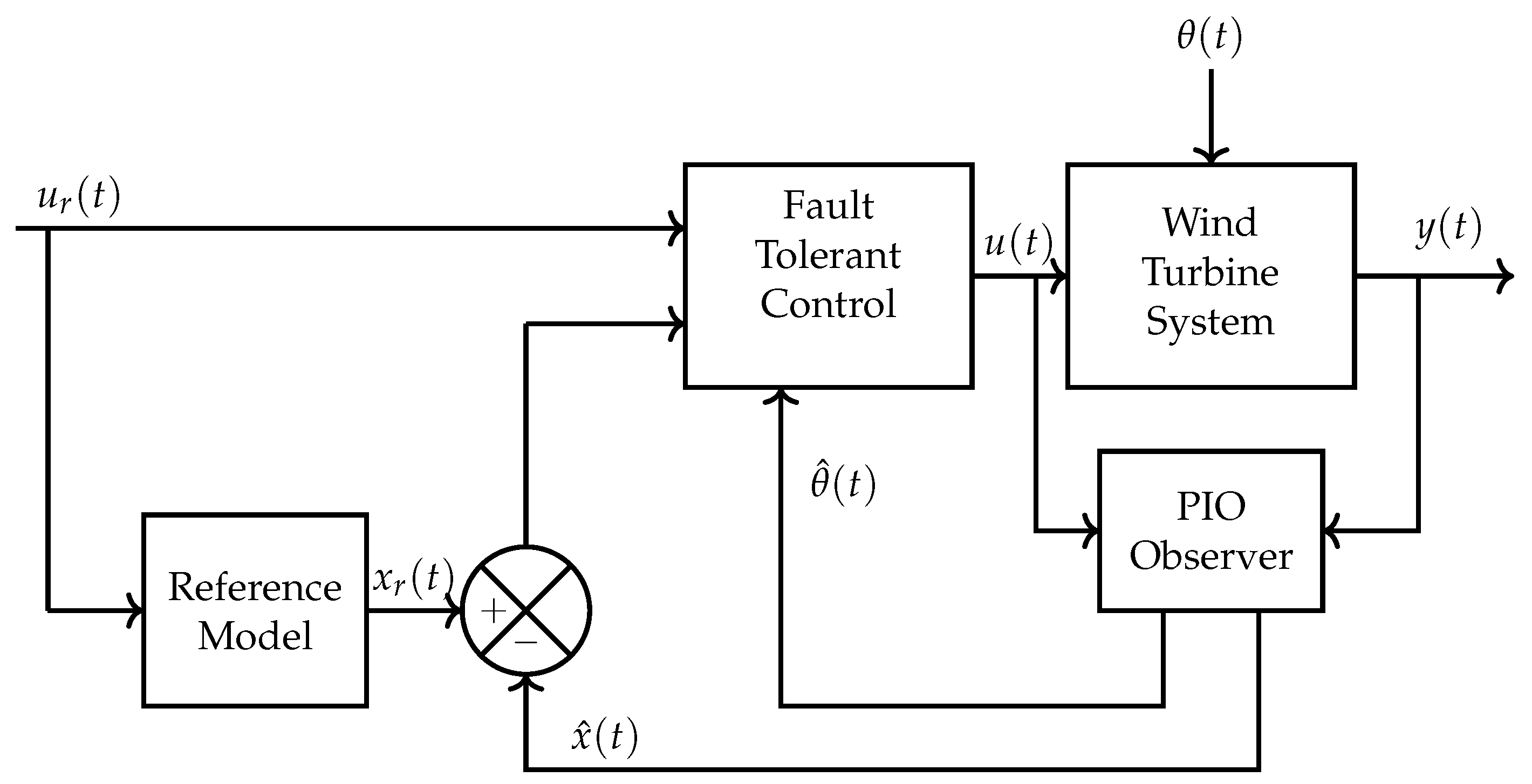

- A T-S fuzzy observer with unknown input is designed to achieve ITSC fault estimation and system state despite of wind speed variation.

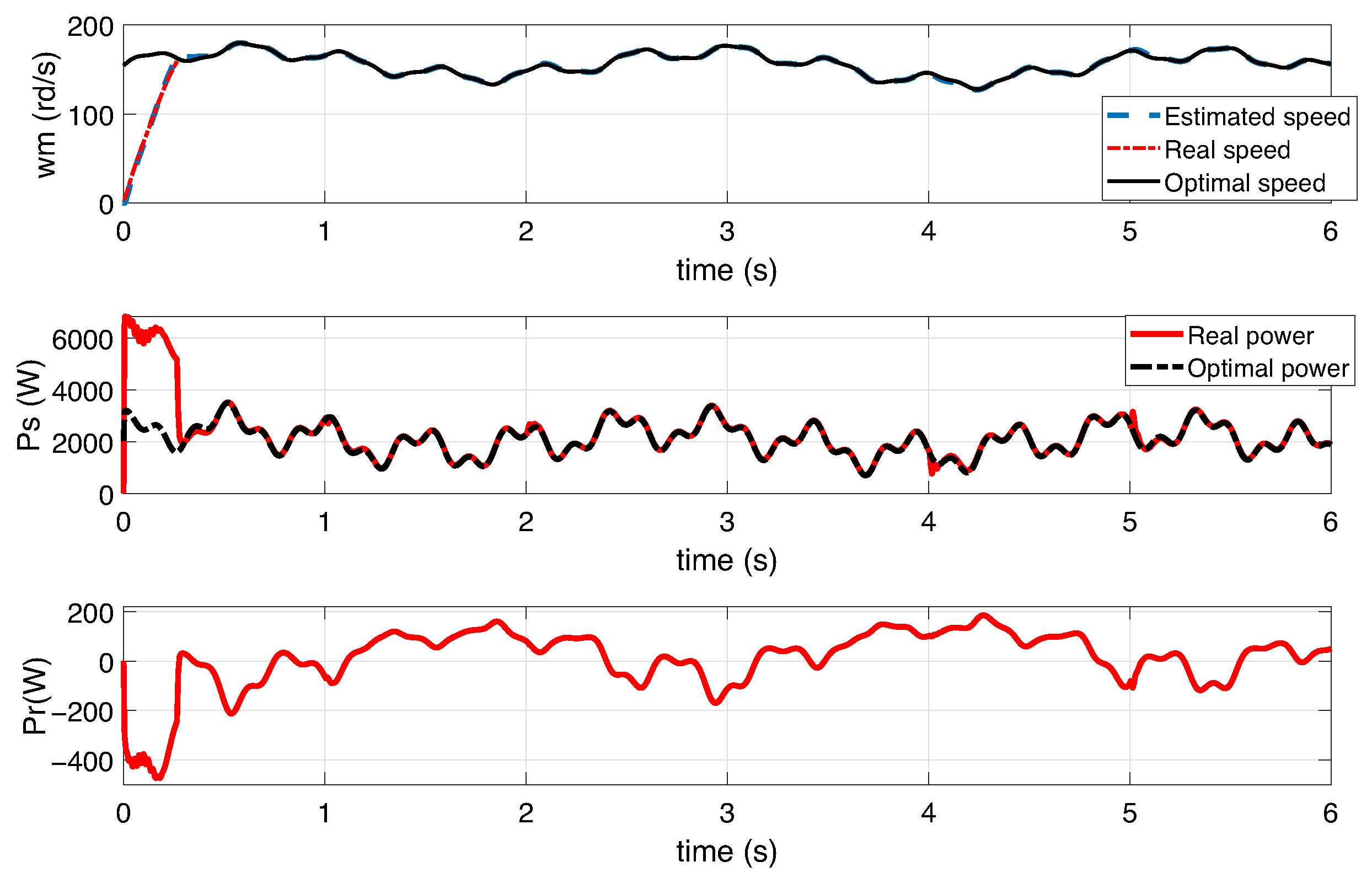

- A fault-tolerant control strategy based on optimal controller reconfiguration is proposed, which can compensate the ITSC fault and ensure the MPPT trajectory tracking performance. This allows to maintain the closed-loop system stable and ensures continuity of operation of the DFIG even in faulty mode.

Notations

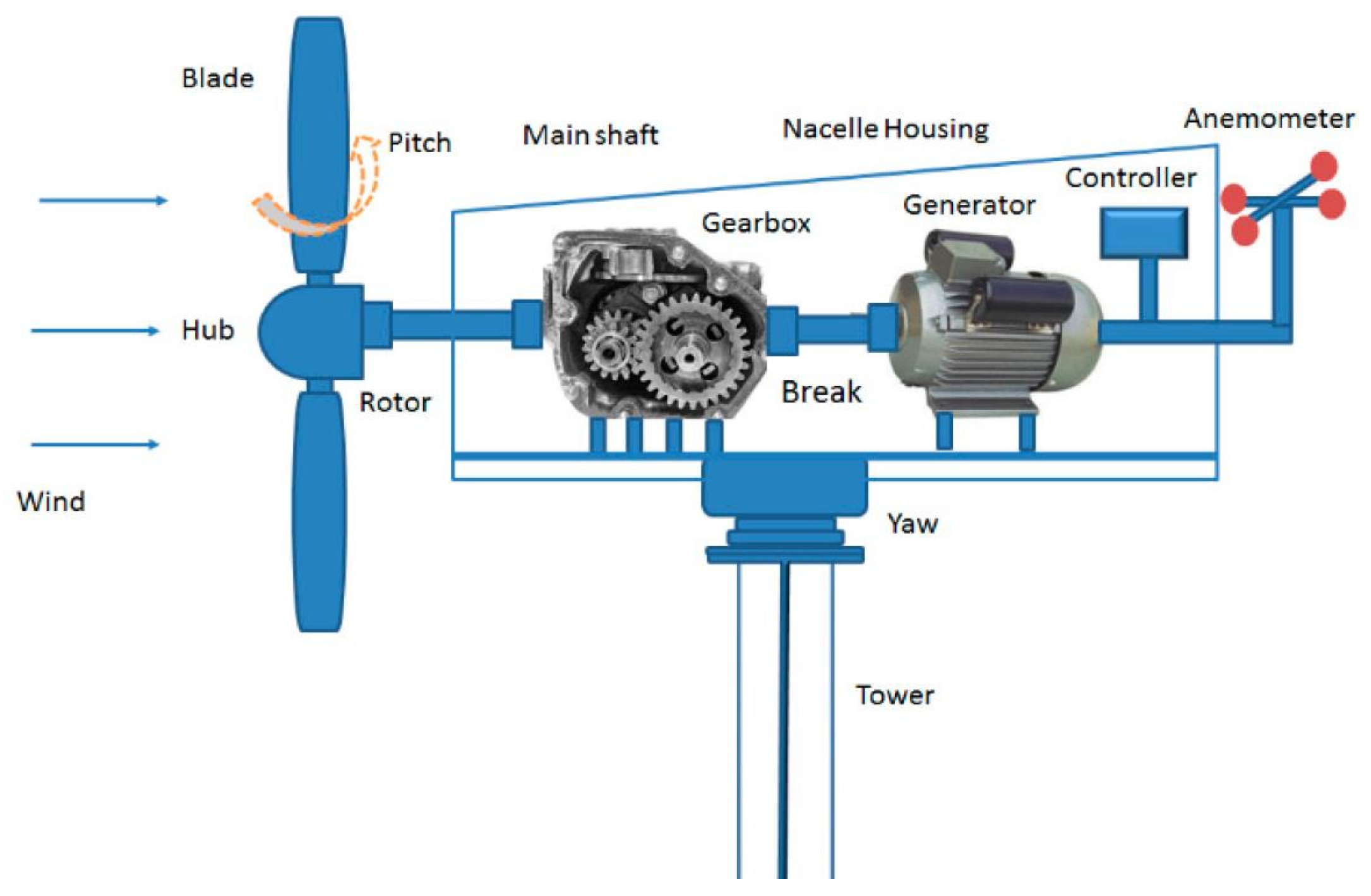

2. Modeling of a DFIG-Based Wind Energy Conversion System

2.1. Modeling of the Wind Turbine

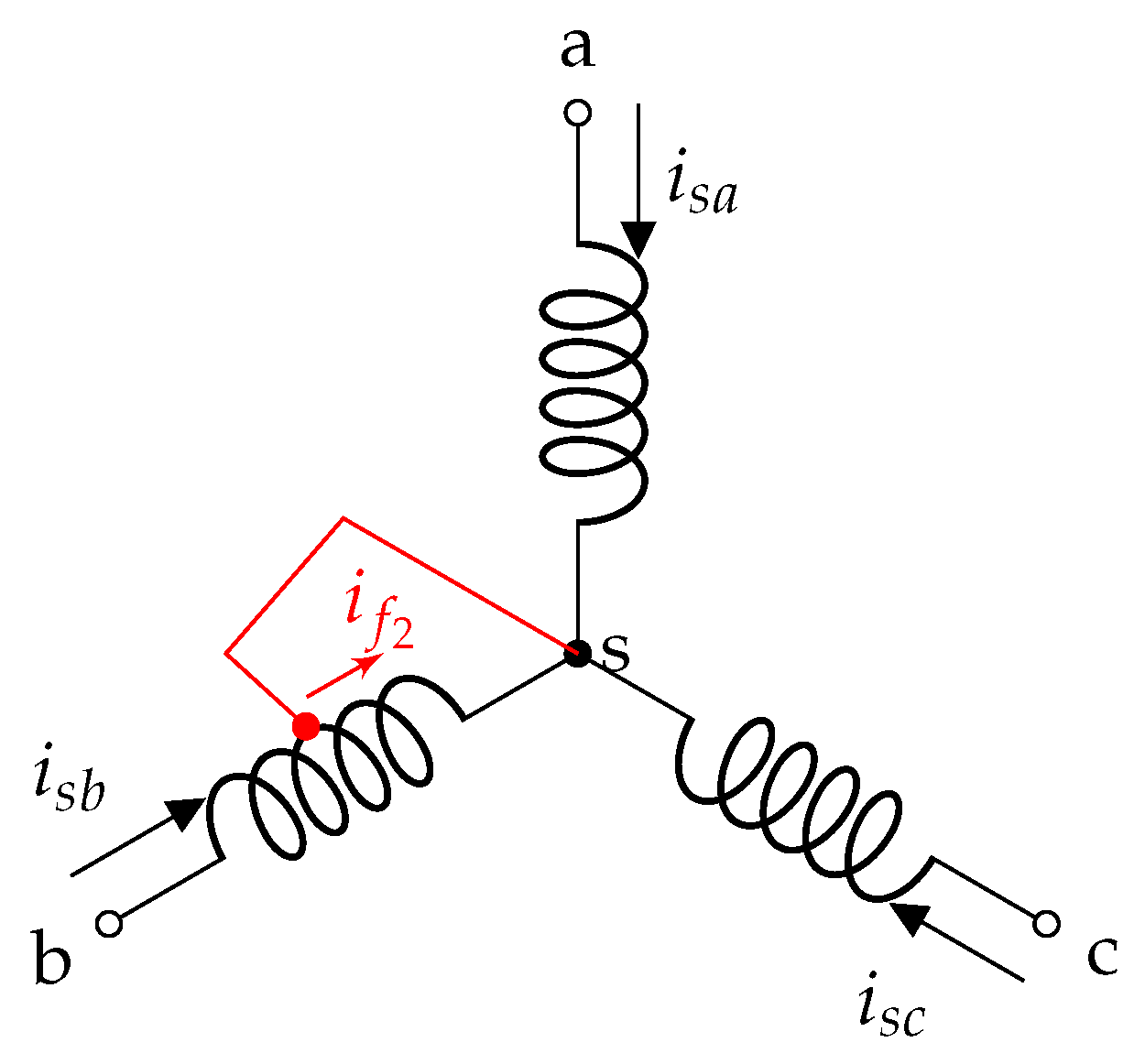

2.2. DFIG Model in the abc Reference Frame with ITSC Fault

2.3. DFIG Model in the d-q Reference Frame with ITSC Fault

2.4. State Space Model

2.5. T-S Fuzzy Model of the DFIG with ITSC Fault

3. Unknown Input T-S Observer Design for Stator Inter-Turn Short Circuit Fault

3.1. Indirect Field-Oriented Control Strategy

3.2. Unknown Input TS Observer Design

- matrix D and are full column ranks.

- rank(D) = rank()

4. Fault-Tolerant Controller Design Subject to ITSC Faults

- ensure a decoupling between torque and stator flux;

- compensate the effect of the ITSC fault and maintain normal operation of the machine even in faulty mode;

- maintain the optimal operation of the generator regardless of the variation of the wind speed.

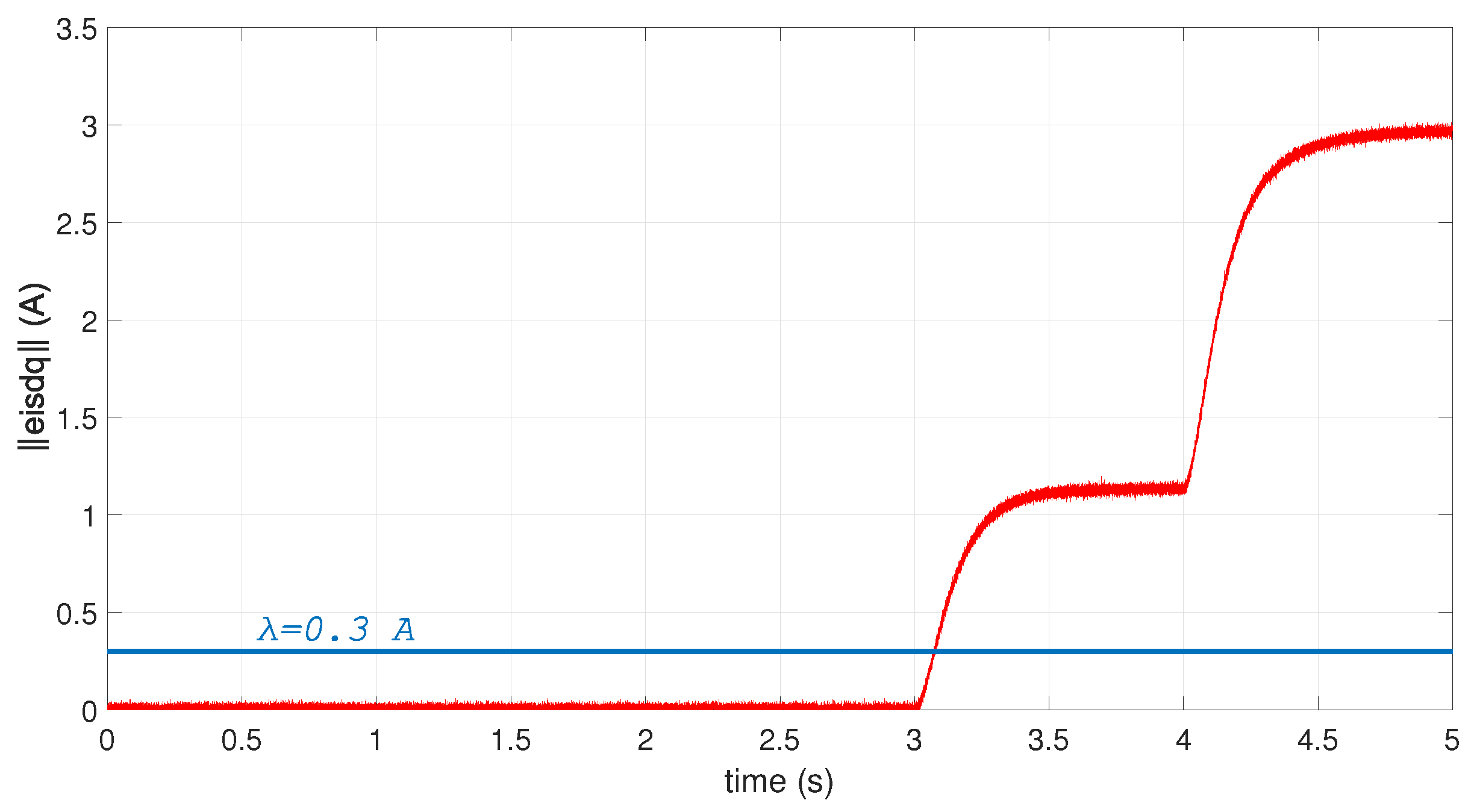

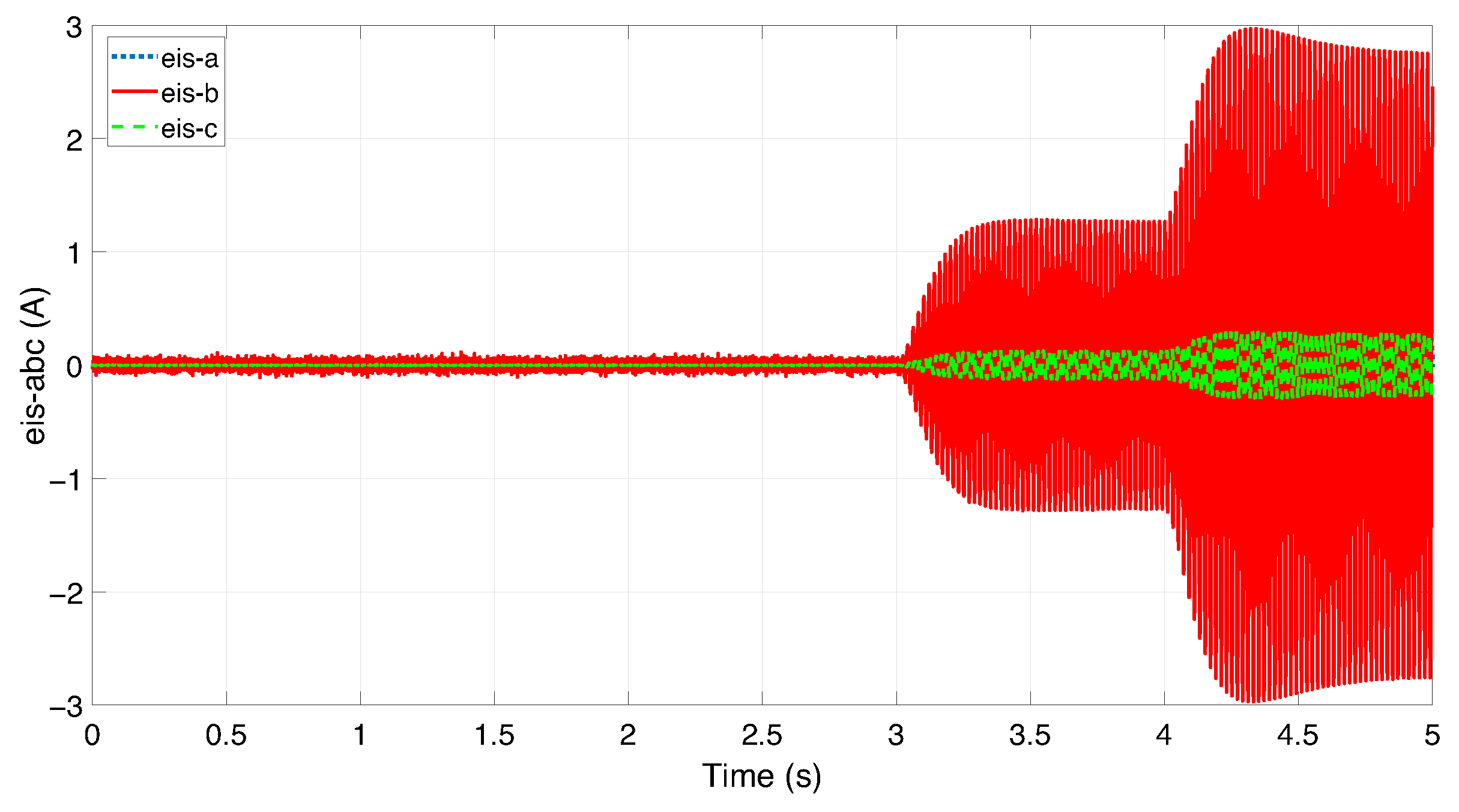

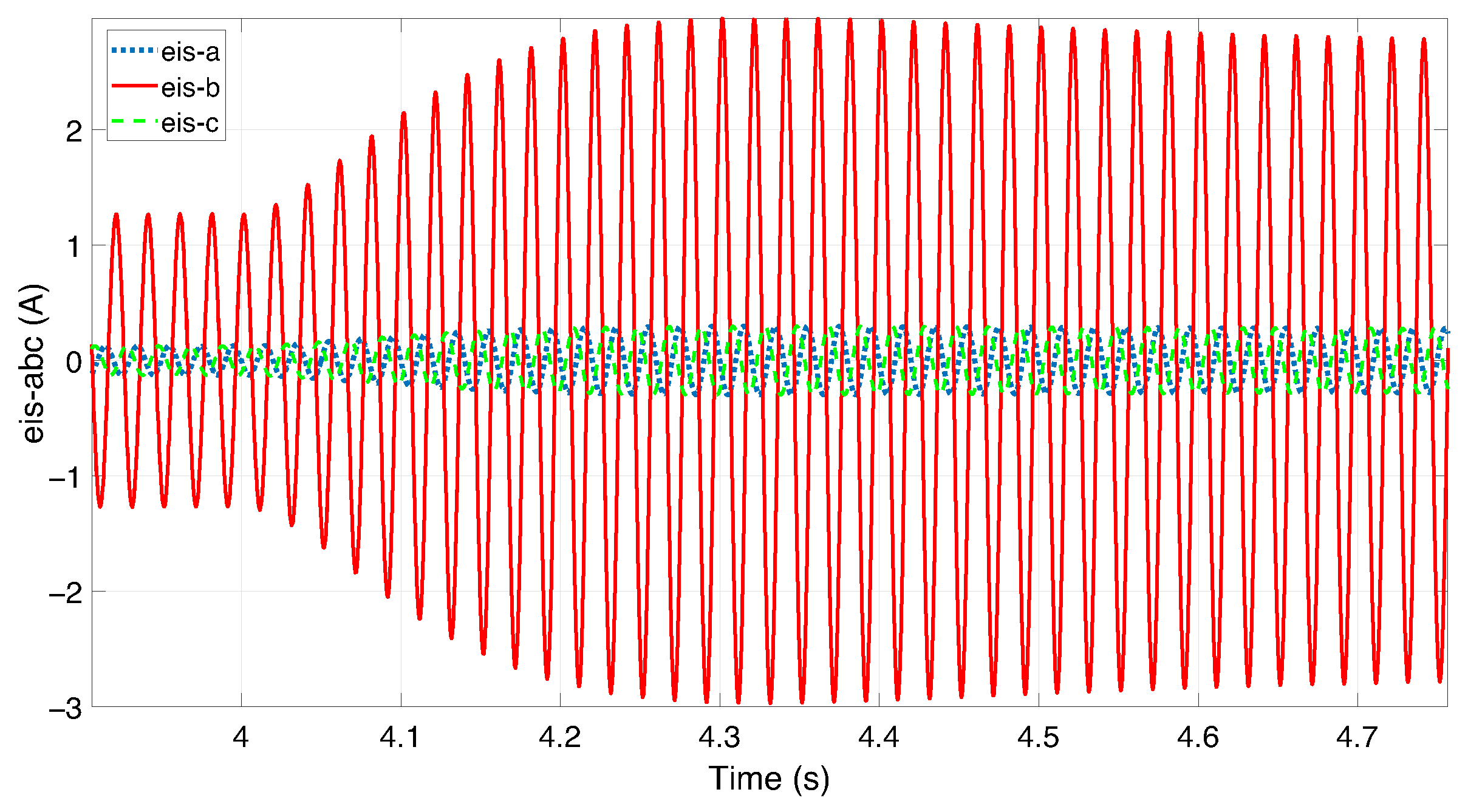

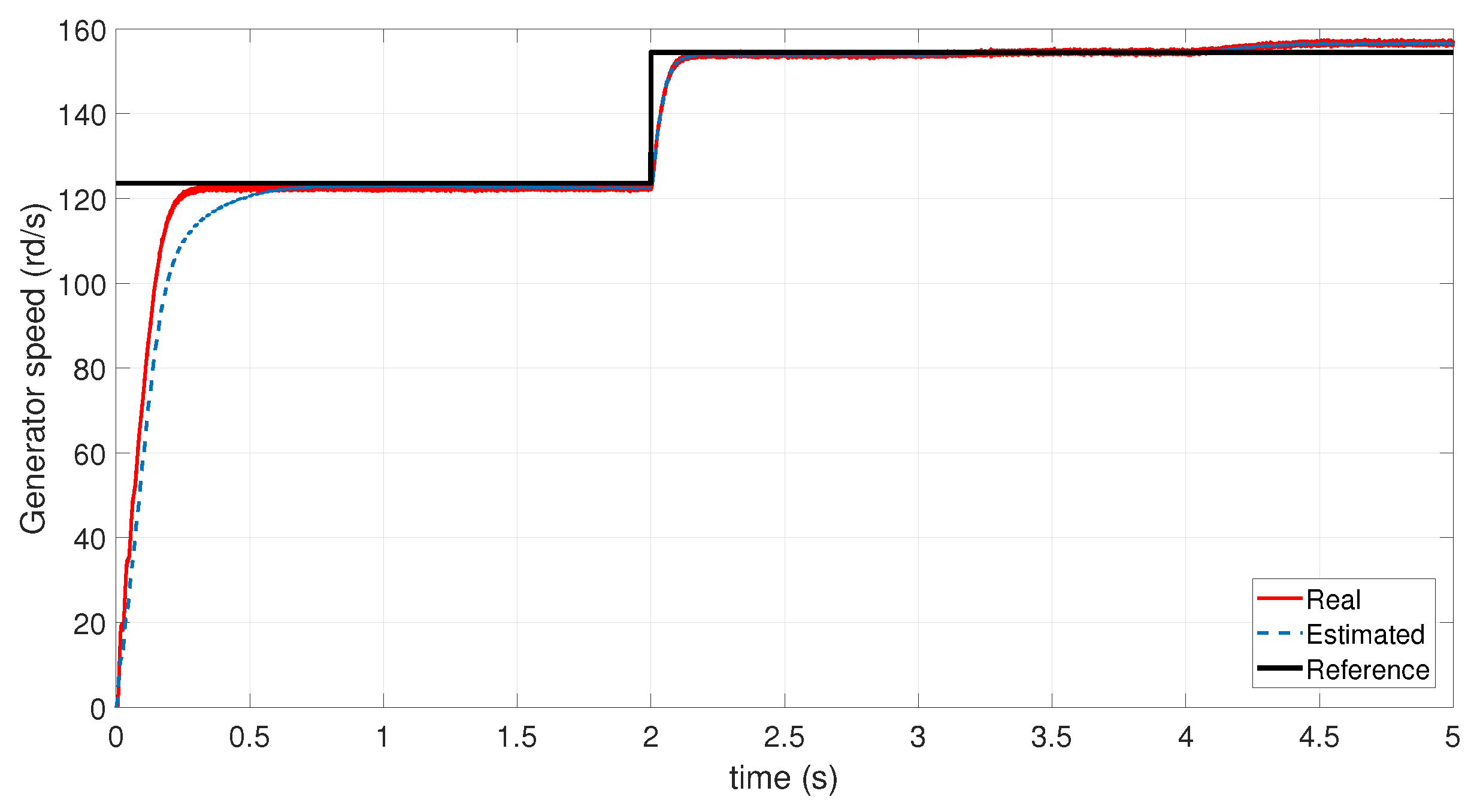

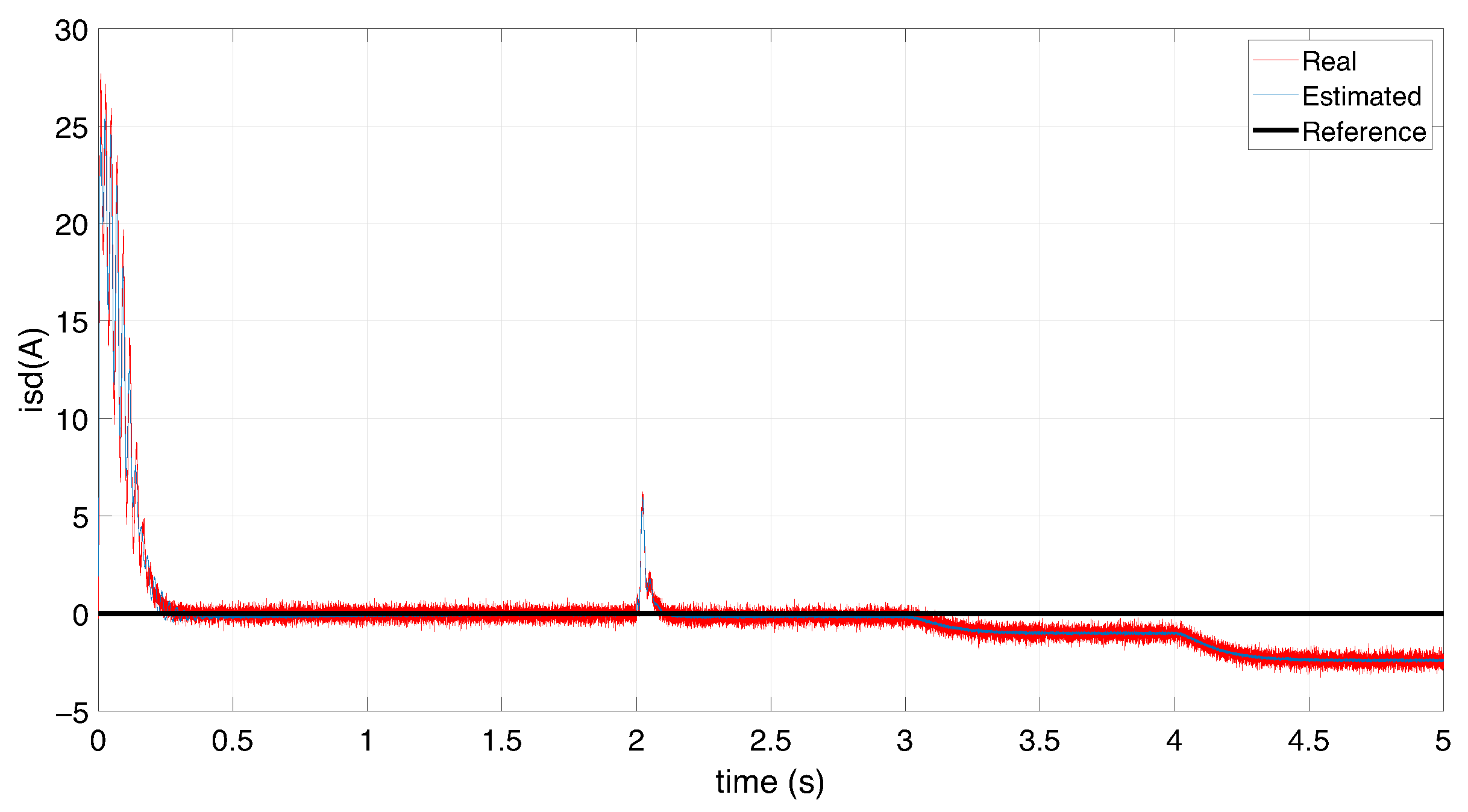

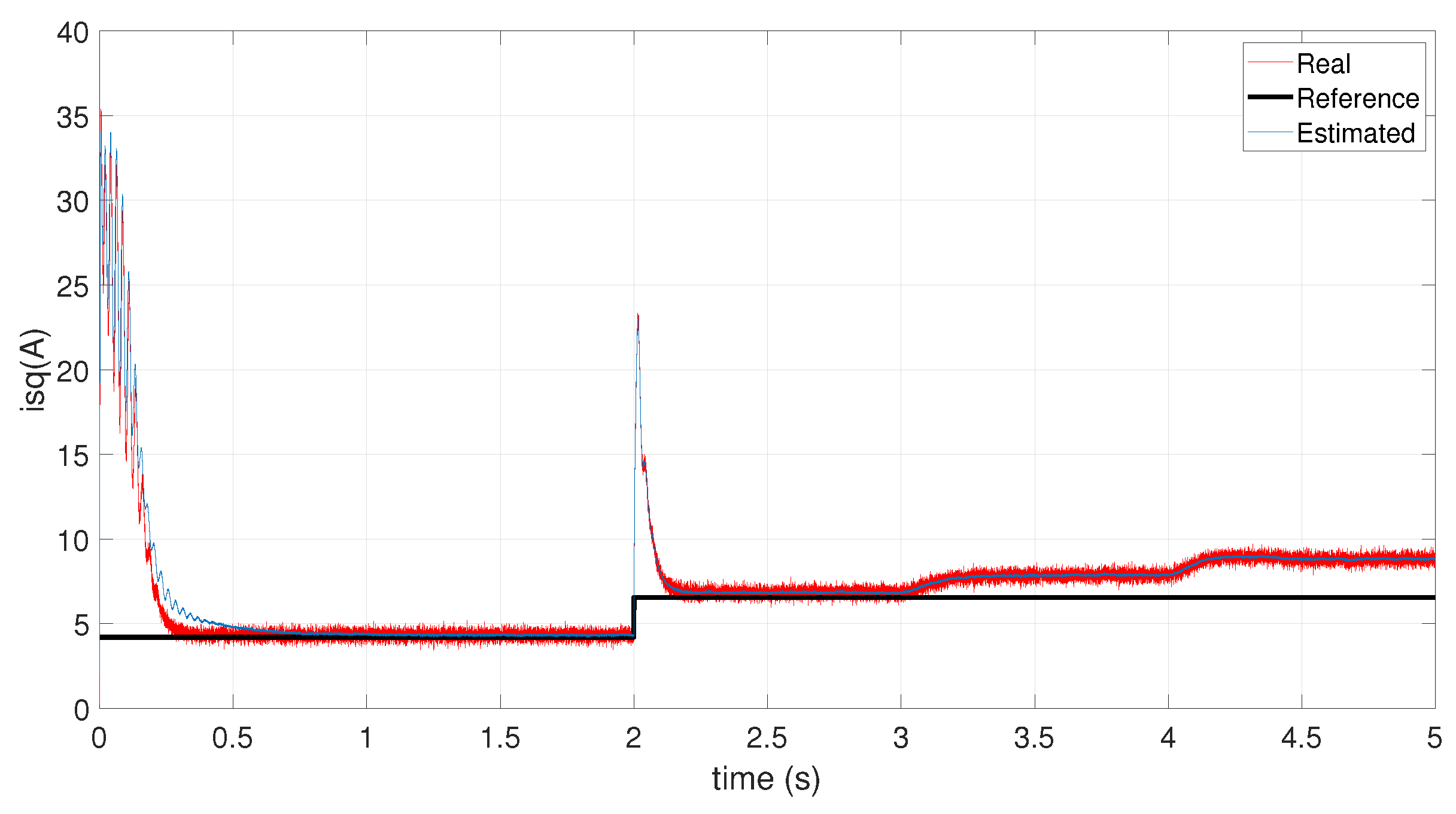

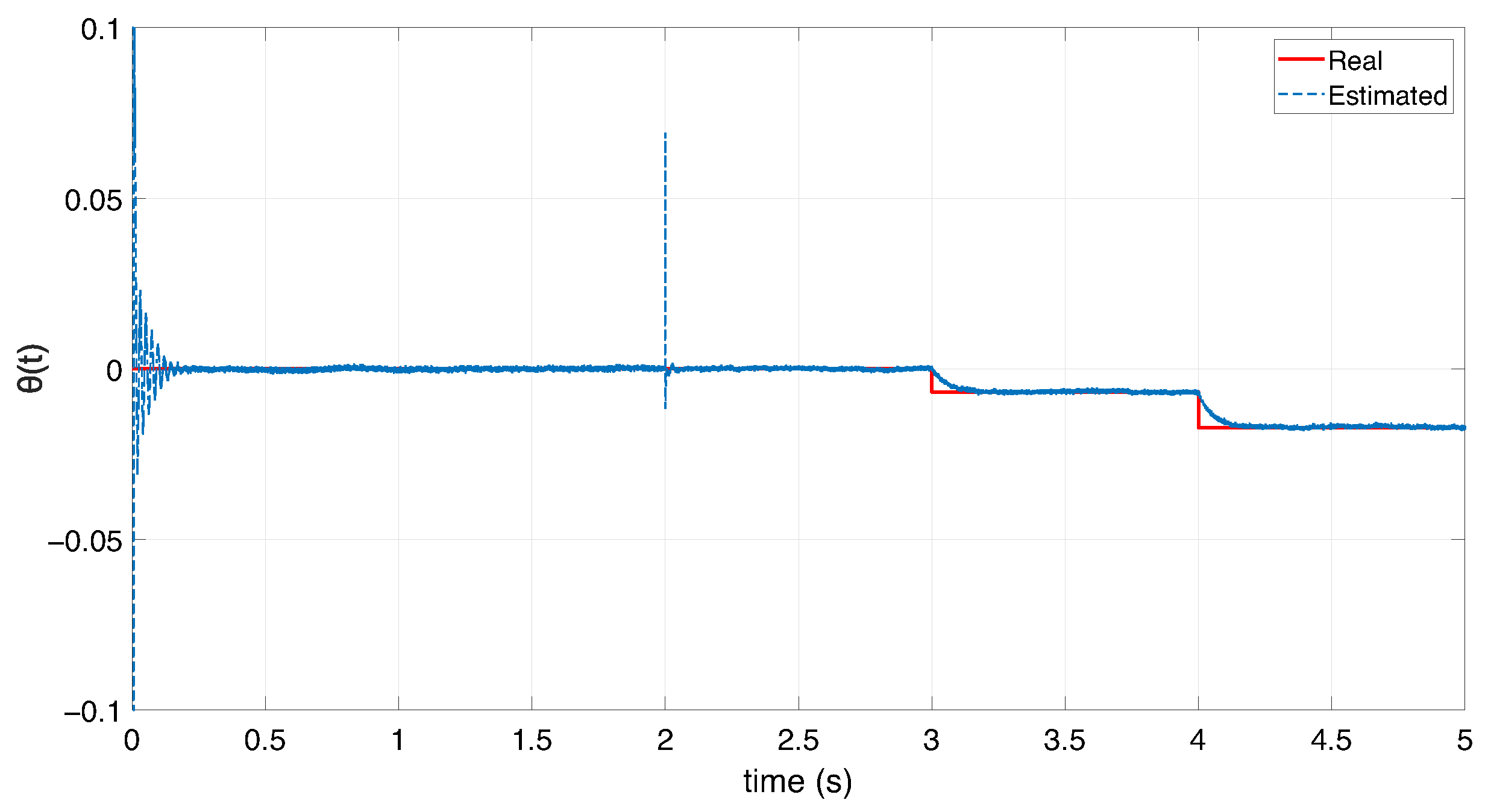

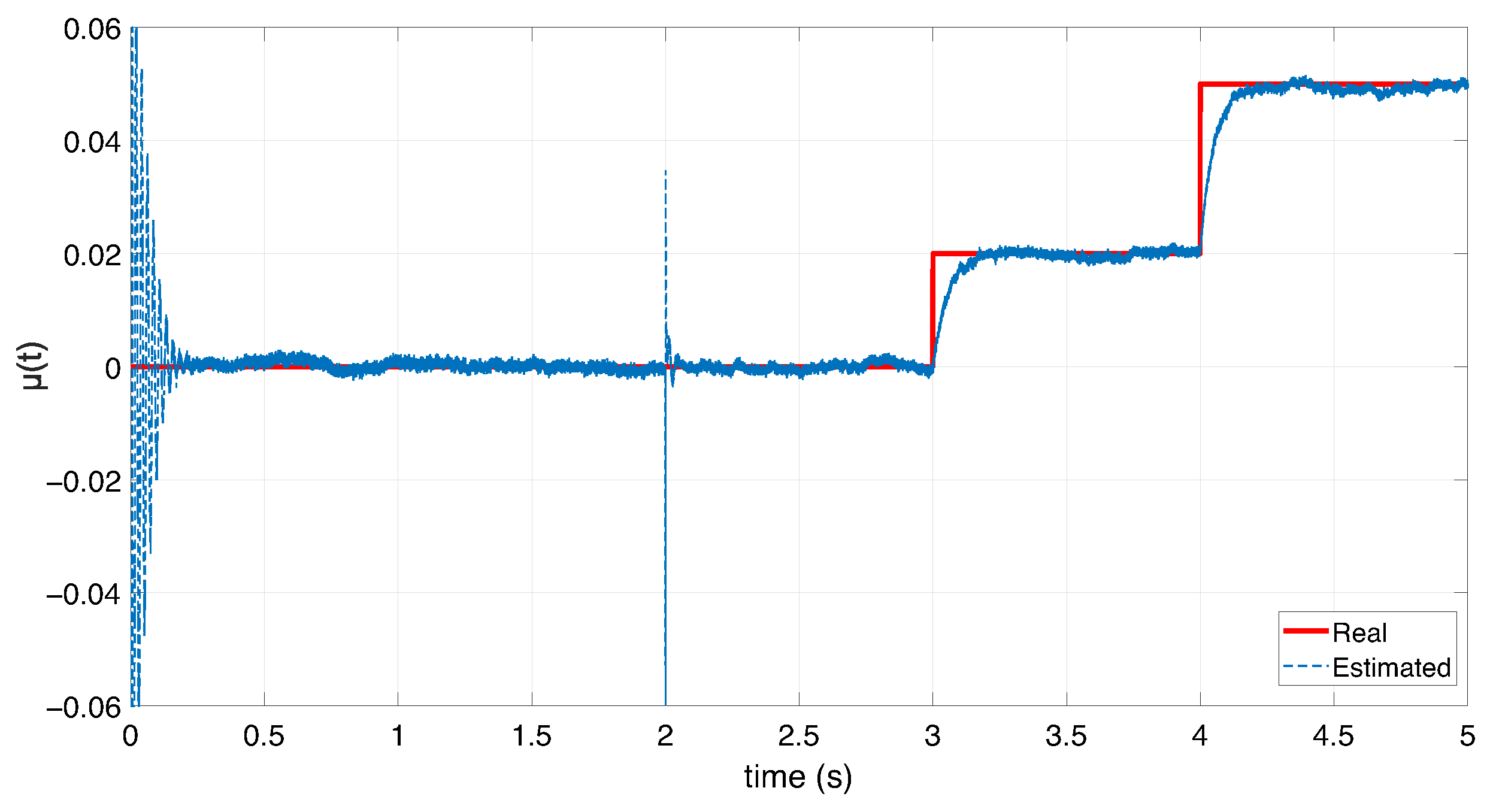

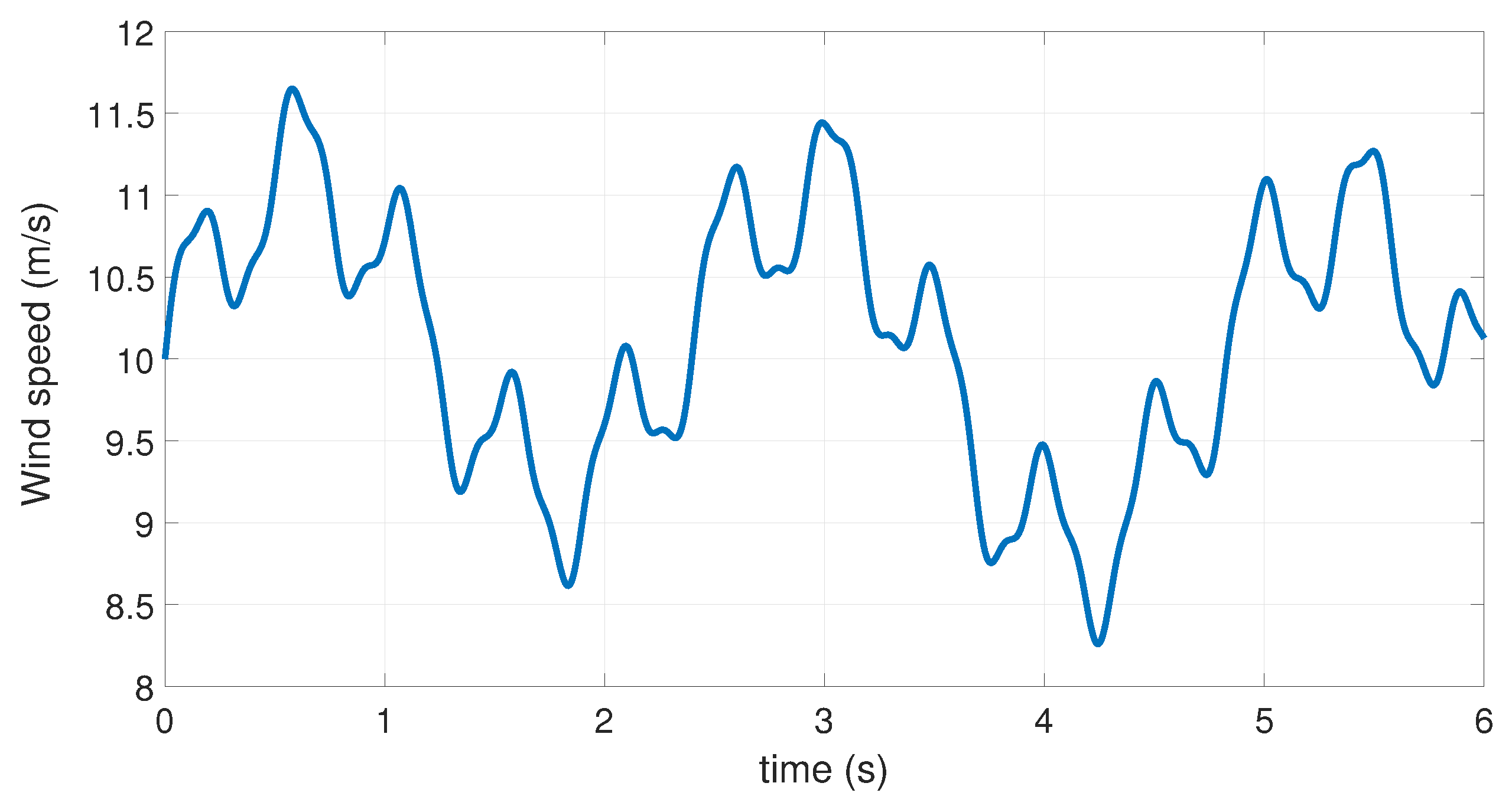

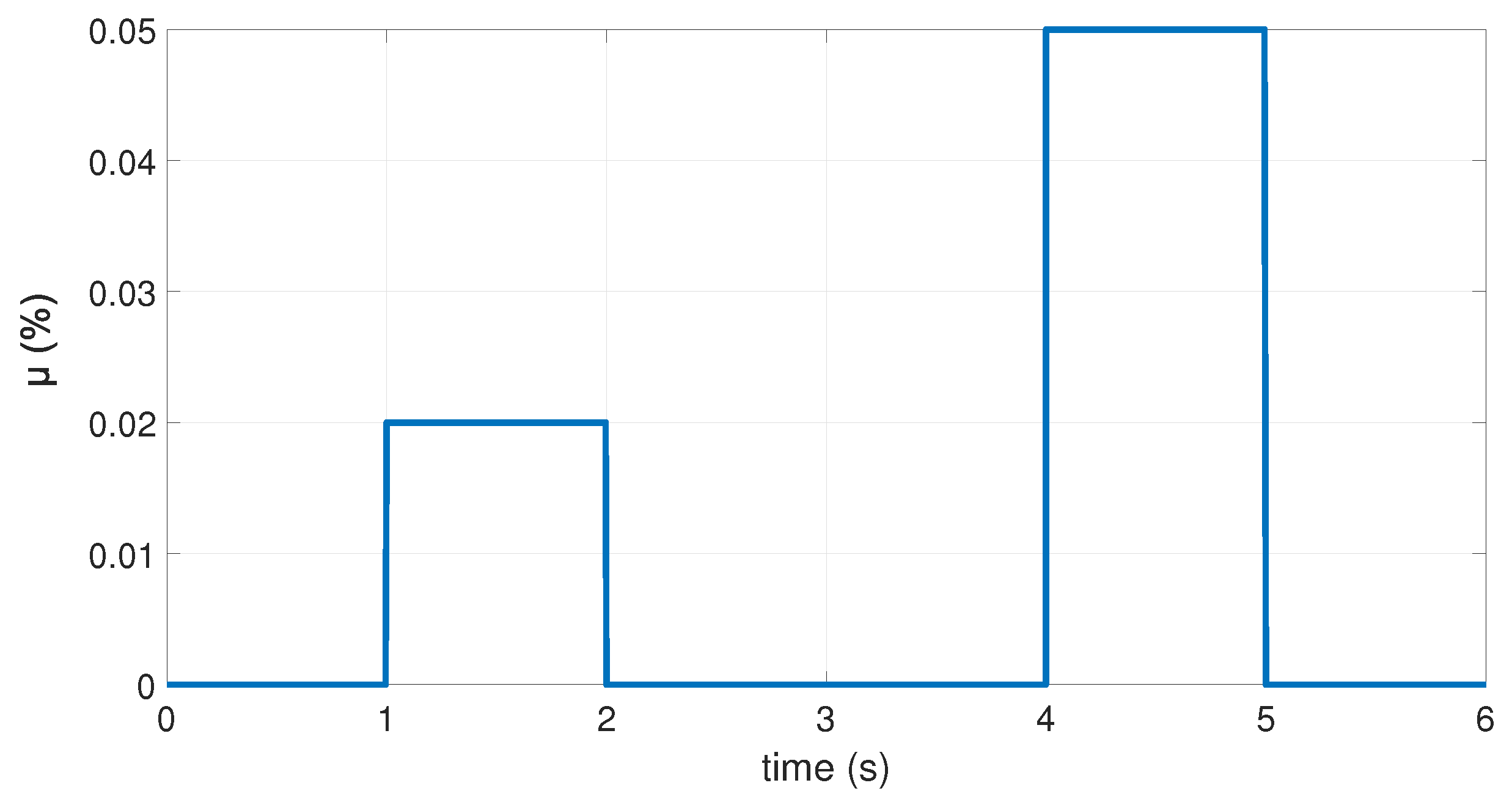

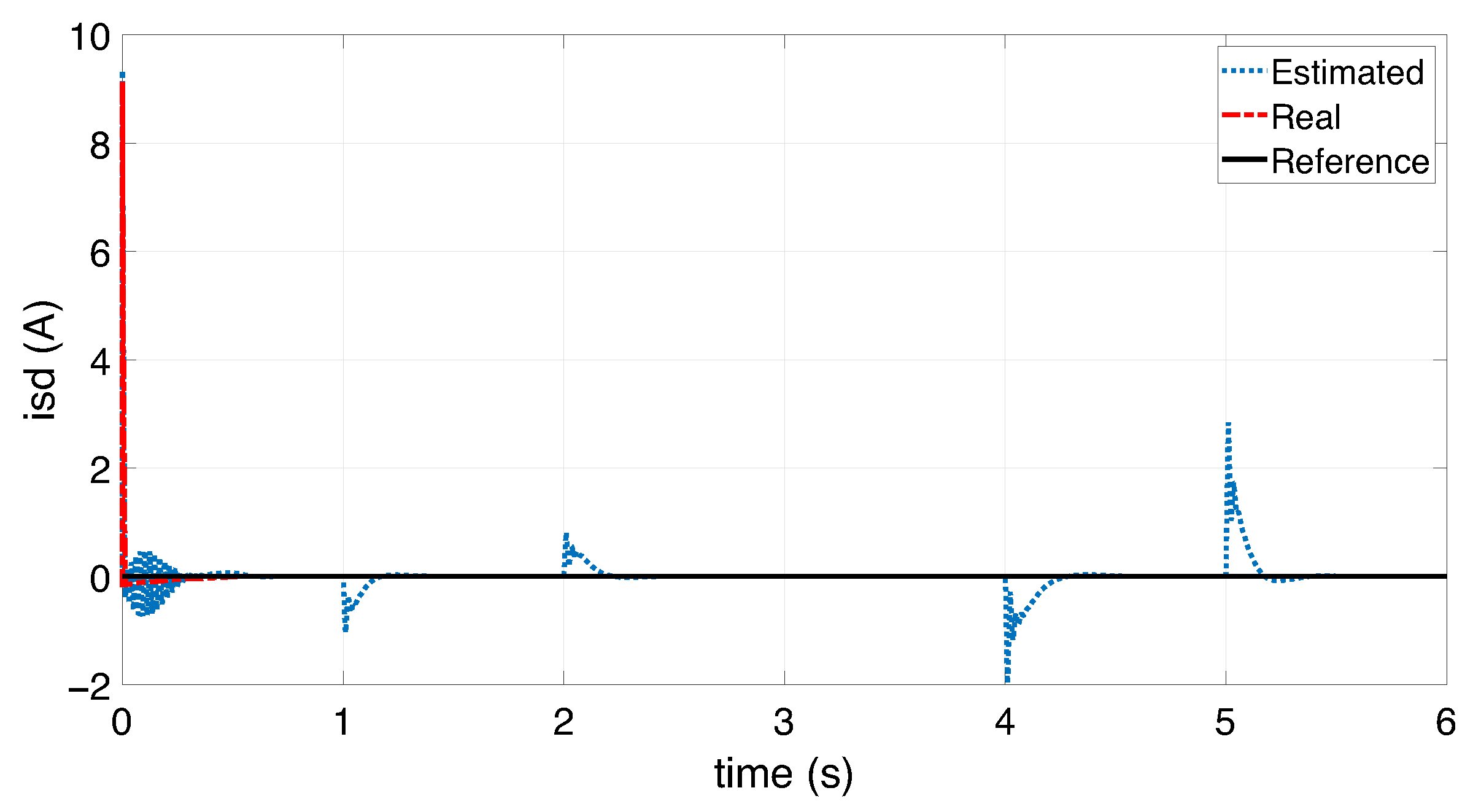

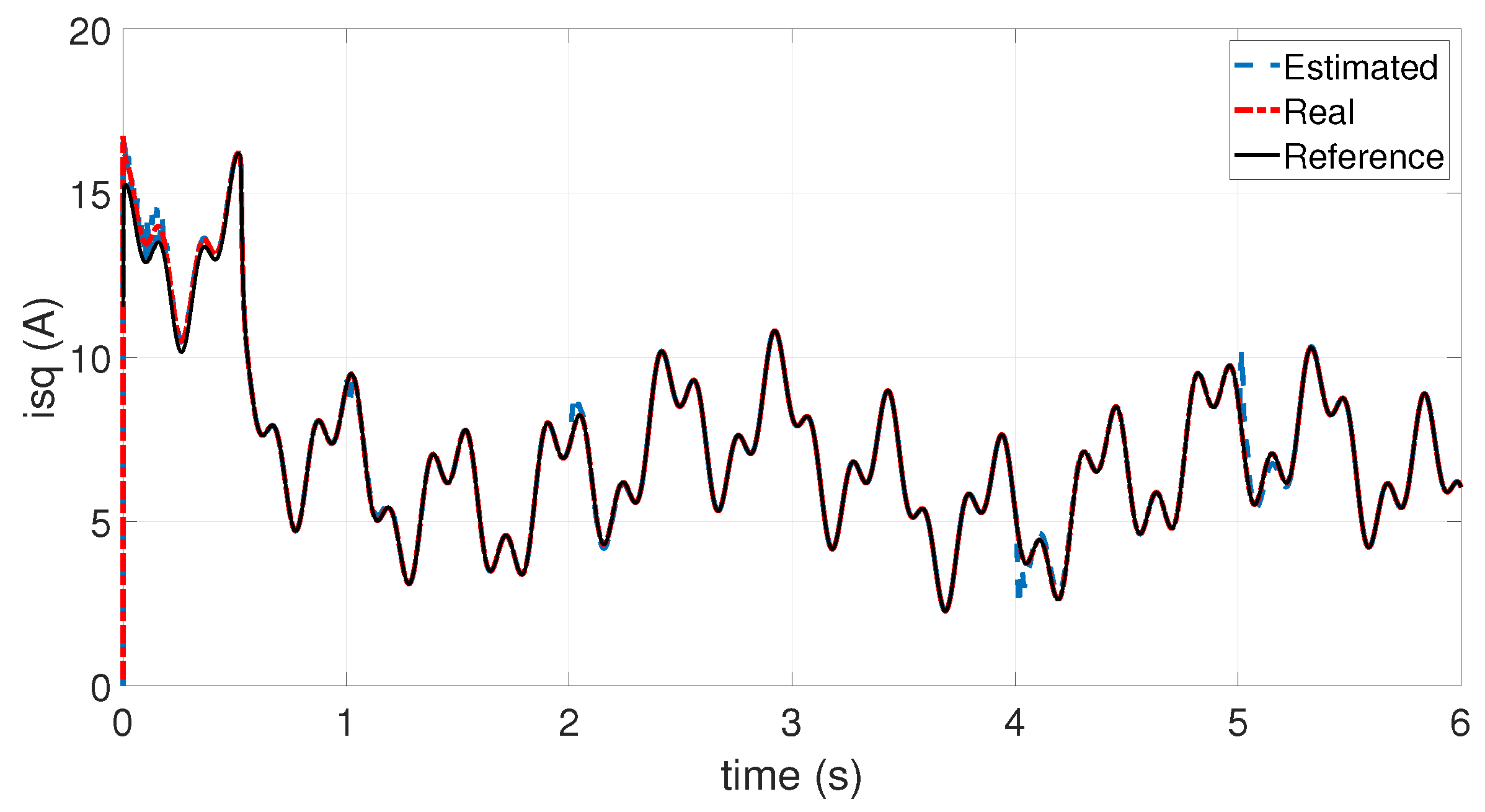

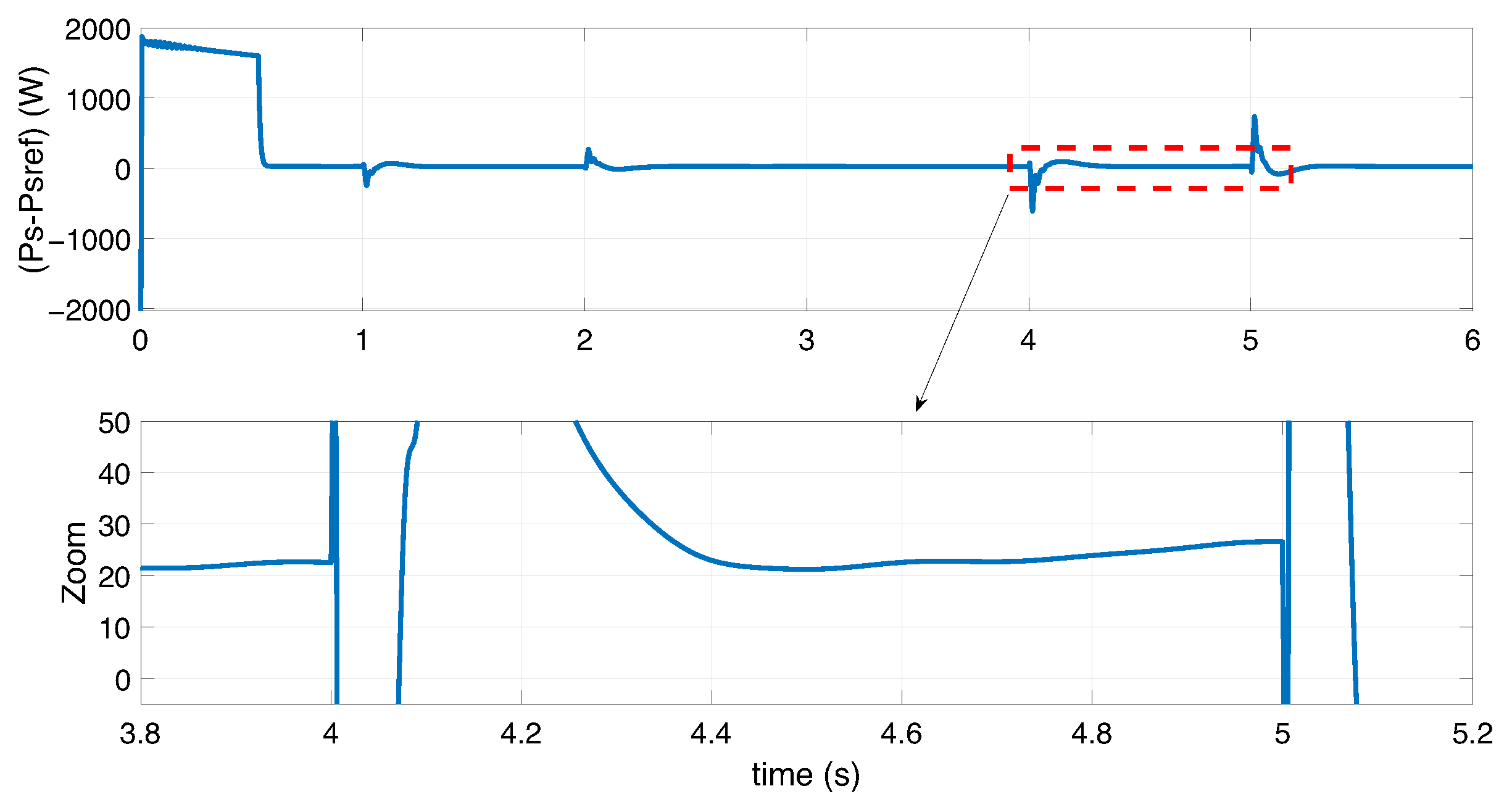

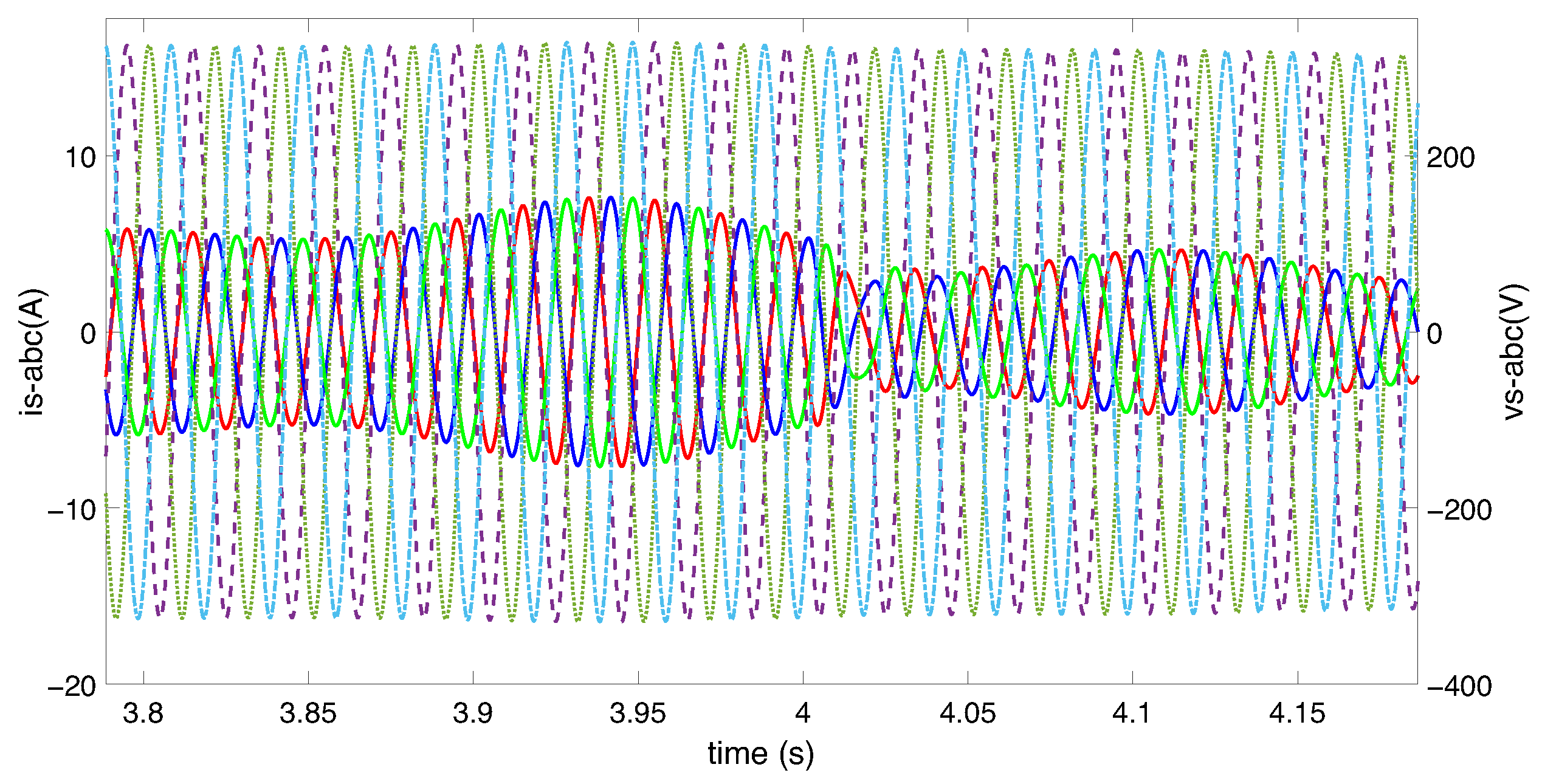

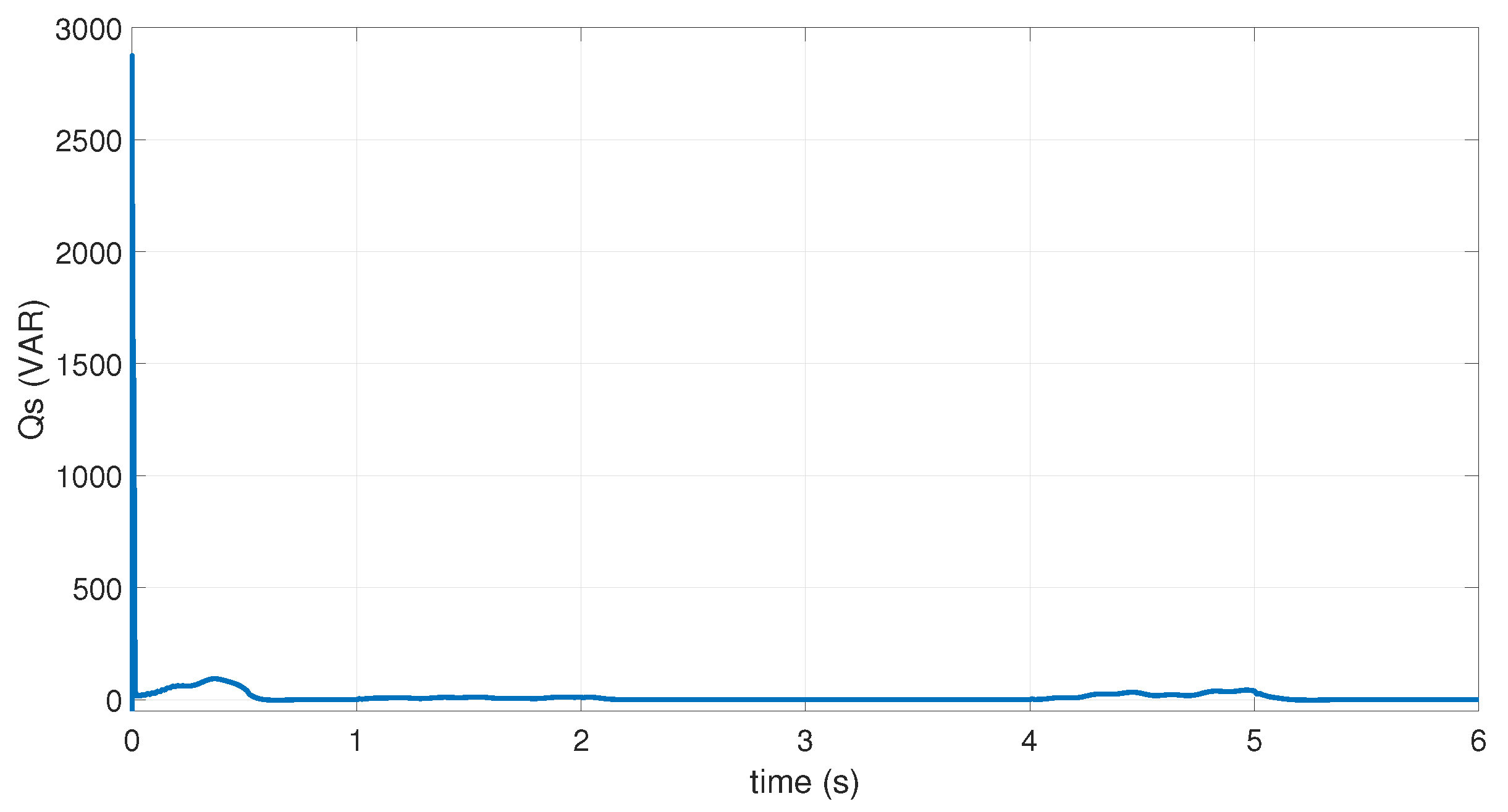

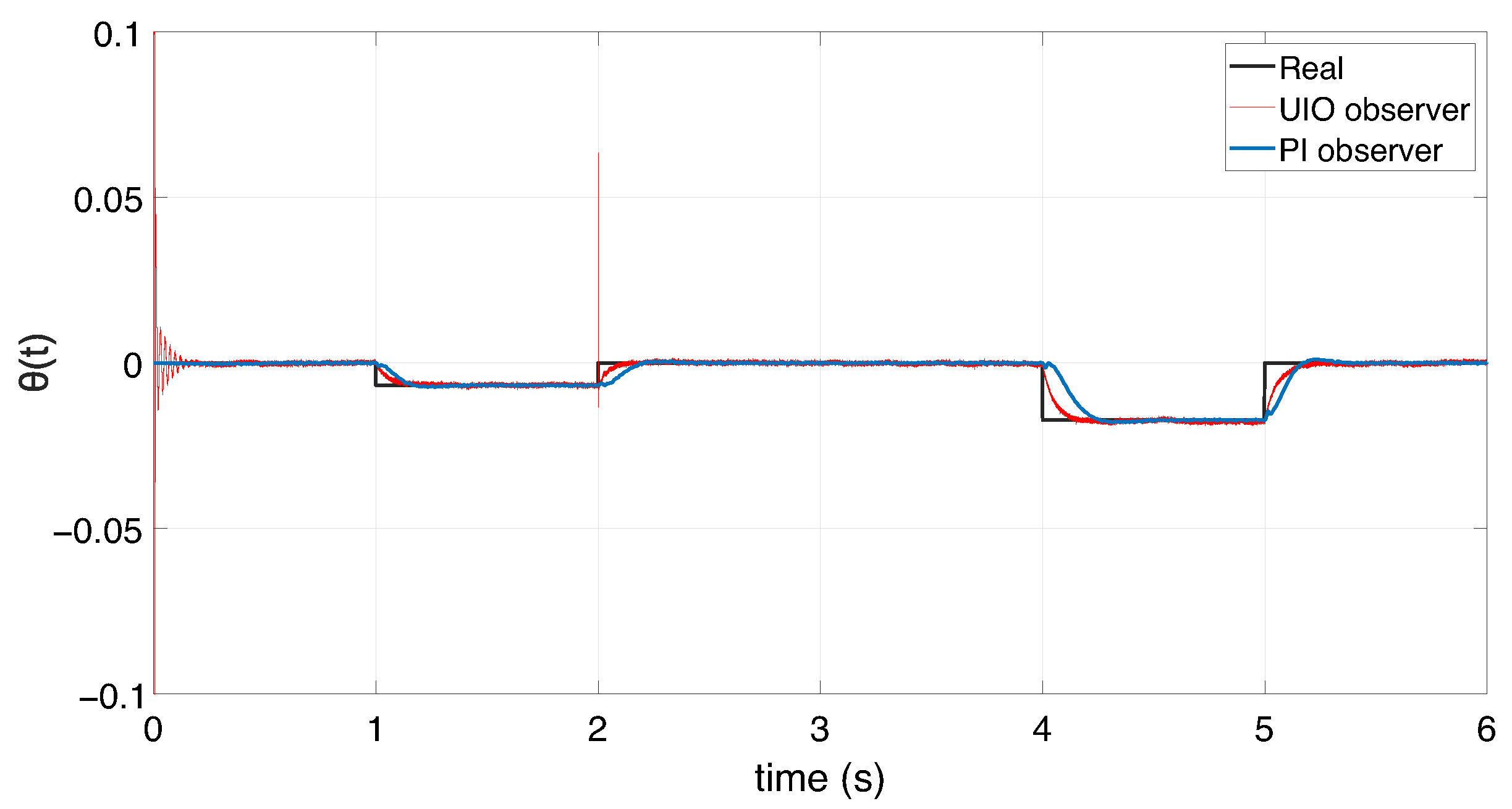

5. Simulation Results

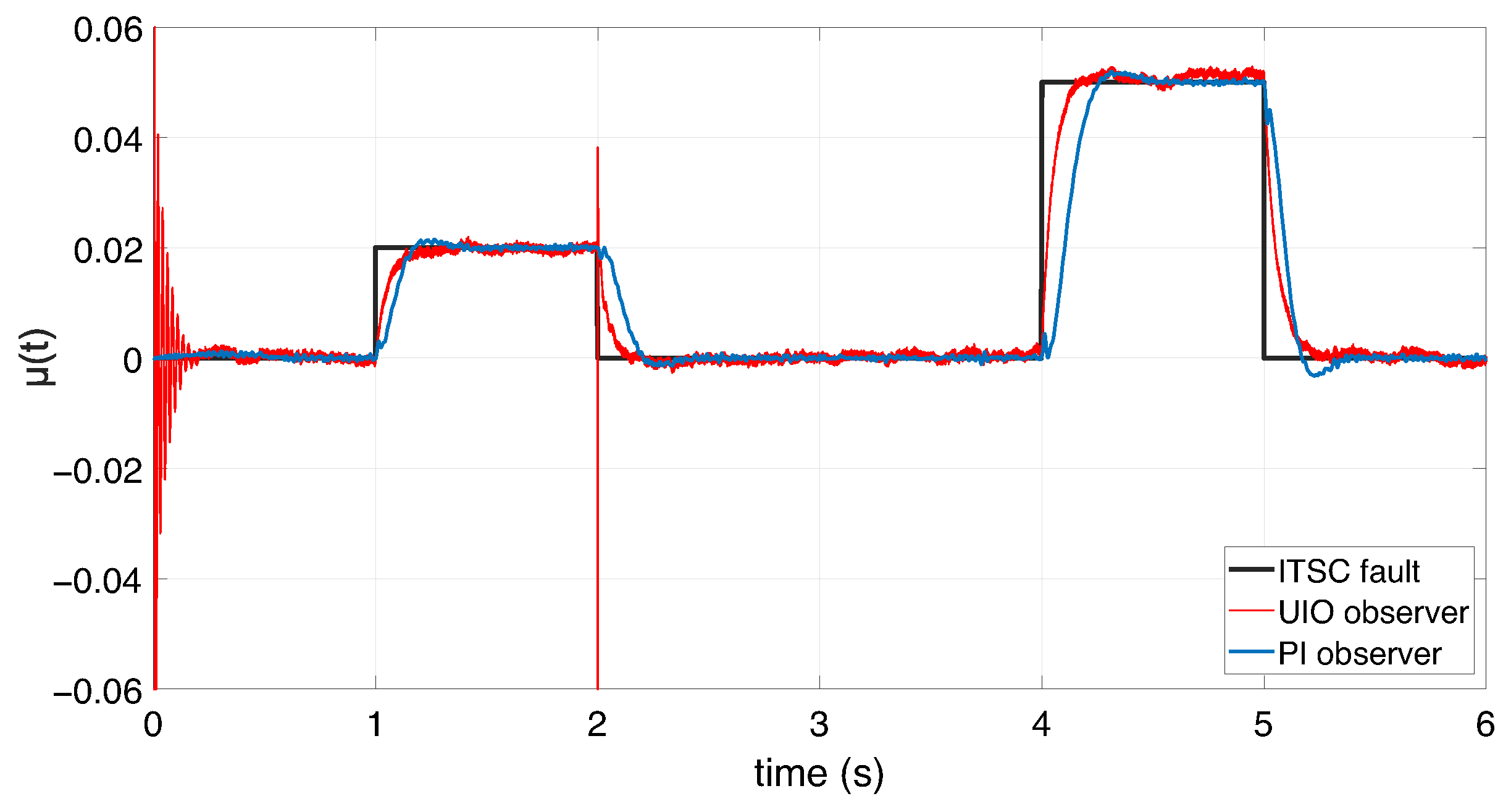

- For the ITSC fault, the UIO observer achieves a faster response time (0.215 s vs. 0.332 s) and a higher RMSE () compared to the PI observer (), but no overshoot is recorded for the UIO. This suggests that the UIO reacts quickly but with slightly more steady-state error.

- Under the ITSC fault, the UIO shows both faster response time (0.131 s vs. 0.221 s) and higher overshoot ( vs. ), while its RMSE () is significantly greater than that of the PI observer ().

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Acronyms

| FDD | Fault Detection and Diagnosis |

| FSFTC | Fuzzy Scheduler Fault-Tolerant Control |

| FTC | Fault-Tolerant Control |

| DFIG | Doubly Fed Induction Generator |

| ITSC | Inter-Turn Short Circuit |

| LMI | Linear Matrix Inequalities |

| MPPT | Maximum Power Point Tracking |

| PIO | Proportional Integral Observer |

| PMIO | Proportional Multiple Integral Observer |

| T-S | Takagi–Sugeno |

| UIO | Unknown Input Observer (UIO) |

References

- Vardhan, A.; Sinha, U. Control strategies and performance analysis of doubly fed induction generator for grid-connected wind energy conversion system. Electr. Eng. 2024, 106, 1203–1224. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B.; Sen, P.; Kouro, S.; Narimani, M. High-power wind energy conversion systems: State-of-the-art and emerging technologies. Proc. IEEE 2015, 103, 740–788. [Google Scholar] [CrossRef]

- Zhou, N.; Sun, F.; Wang, Q.; Meng, X. A flexible power control strategy for rotor-side converter of DFIG under unbalanced grid voltage sags. Int. J. Electr. Power Energy Syst. 2017, 90, 64–75. [Google Scholar] [CrossRef]

- Gao, Z.; Liu, X. An overview on fault diagnosis prognosis and resilient control for wind turbine systems. Processes 2021, 9, 300. [Google Scholar] [CrossRef]

- Bebars, A.; Eladl, A.; Abdulsalam, G.; Badran, E. Internal electrical fault detection techniques in DFIG-based wind turbines: A review. Prot. Control Mod. Power Syst. 2022, 7, 1–22. [Google Scholar] [CrossRef]

- Ma, K.; Soltani, M.; Hajizadeh, A.; Zhu, J.; Chen, Z. Active power optimisation for wind farms under generator inter-turn short-circuit fault. IET Renew. Power Gener. 2020, 14, 2079–2088. [Google Scholar] [CrossRef]

- Badihi, H.; Zhang, Y.; Hong, H. Wind turbine fault diagnosis and fault-tolerant torque load control against actuator faults. IEEE Trans. Control Syst. Technol. 2014, 23, 1351–1372. [Google Scholar] [CrossRef]

- Cheng, F.; Peng, Y.; Qu, L.; Qiao, W. Current-based fault detection and identification for wind turbine drivetrain gearboxes. IEEE Trans. Ind. Appl. 2016, 53, 878–887. [Google Scholar] [CrossRef]

- Afshar, M.; Abdi, S.; Mortazavizadeh, A.; Fajri, P.; Ebrahimi, M. A New Stator Winding Inter-Turn Short Circuit Fault Detection Method for Brushless Doubly Fed Induction Machine. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 223–228. [Google Scholar]

- Bilal, H.; Sambatra, E.; Heraud, N.; Razafimahenina, J.; Dyagileva, S. Detection of inter-turn short-circuit on a doubly fed induction machine with dq axis representation-application to different power levels. Prog. Electromagn. Res. B 2022, 95, 23–40. [Google Scholar] [CrossRef]

- Lu, Q.; Breikin, T.; Wang, H. Modelling and fault diagnosis of stator inter-turn short circuit in doubly fed induction generators. IFAC Proc. Vol. 2011, 44, 1013–1018. [Google Scholar] [CrossRef]

- Lu, Q.; Breikin, T. Fault detection for stator inter-turn short circuit in doubly fed induction generators using adaptive observers. Int. J. Adv. Mechatron. Syst. 2011, 3, 44–53. [Google Scholar] [CrossRef]

- Ma, K.; Zhu, J.; Soltani, M.; Hajizadeh, A.; Chen, Z. Inter-Turn Short-Circuit Fault Ride-Through for DFIG Wind Turbines. IFAC-PapersOnLine 2020, 53, 12757–12762. [Google Scholar] [CrossRef]

- Idrissi, I.; Bachtiri, R.E.; Chafouk, H.; Khanfara, M. Fault diagnosis of stator inter-turn short circuit in doubly fed induction generator of wind turbine. In Proceedings of the 2019 6th international conference on control, decision and information technologies (CoDIT), Paris, France, 23–26 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1313–1318. [Google Scholar]

- Mellah, H.; Arslan, S.; Sahraoui, H.; Hemsas, K. The effect of stator inter-turn short-circuit fault on dfig performance using fem. Eng. Technol. Appl. Sci. Res. 2022, 12, 8688–8693. [Google Scholar] [CrossRef]

- Rehman, A.; Chen, Y.; Zhao, Y.; Cheng, Y.; Zhao, Y.; Tanaka, T. Detection of rotor inter-turn short circuit fault in doubly-fed induction generator using FEM simulation. In Proceedings of the 2018 IEEE 2nd International Conference on Dielectrics (ICD), Budapest, Hungary, 1–5 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Rodríguez, J.; Hernández-De-León, H.; Marín, J.; Santiago, A.; Gómez, E.; Zapata, B.; Guzmán-Rabasa, J. Fault Diagnosis for Takagi-Sugeno Model Wind Turbine Pitch System. IEEE Access 2024, 12, 25296–25308. [Google Scholar] [CrossRef]

- Kamal, E.; Aitouche, A.; Abbes, D. Robust fuzzy scheduler fault tolerant control of wind energy systems subject to sensor and actuator faults. Int. J. Electr. Power Energy Syst. 2014, 55, 402–419. [Google Scholar] [CrossRef]

- Kamal, E.; Aitouche, A. Robust fault tolerant control of DFIG wind energy systems with unknown inputs. Renew. Energy 2013, 56, 2–15. [Google Scholar] [CrossRef]

- Sami, M.; Patton, R. An FTC approach to wind turbine power maximisation via TS fuzzy modelling and control. IFAC Proc. Vol. 2012, 45, 349–354. [Google Scholar] [CrossRef]

- Ouyessaad, H.; Chafouk, H.; Lefebvre, D. Doubly fed induction generator fault diagnosis using unknown input Takagi-Sugeno observer. In Proceedings of the 2013 International Conference on Control, Decision and Information Technologies (CoDIT), Hammamet, Tunisia, 6–8 May 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 530–535. [Google Scholar]

- Sayahi, Y.; Allouche, M.; Ghamgui, M.; Moreau, S.; Mehdi, D. Contribution to the Sensors Faults Diagnosis of a Variable Speed Wind Turbine: Multimodel Approach. In Proceedings of the 2023 IEEE 11th International Conference on Systems and Control (ICSC), Sousse, Tunisia, 18–20 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 427–432. [Google Scholar]

- Chen, Z.; Guerrero, J.M.; Blaabjerg, F. A review of the state of the art of power electronics for wind turbines. IEEE Trans. Power Electron. 2009, 24, 1859–1875. [Google Scholar] [CrossRef]

- Allouche, M.; Dahech, K.; Gaubert, J.P. Maximum Power Point Tracking control of a variable speed wind turbine via a TS fuzzy model-based approach. J. Intell. Fuzzy Syst. 2024, 46, 8529–8541. [Google Scholar]

| Parameters | Values |

|---|---|

| R | 1.483 m |

| kg/m3 | |

| mH | |

| mH | |

| mH | |

| p | |

| G | |

| Fault Type | Threshold (A) | Detection Time (s) |

|---|---|---|

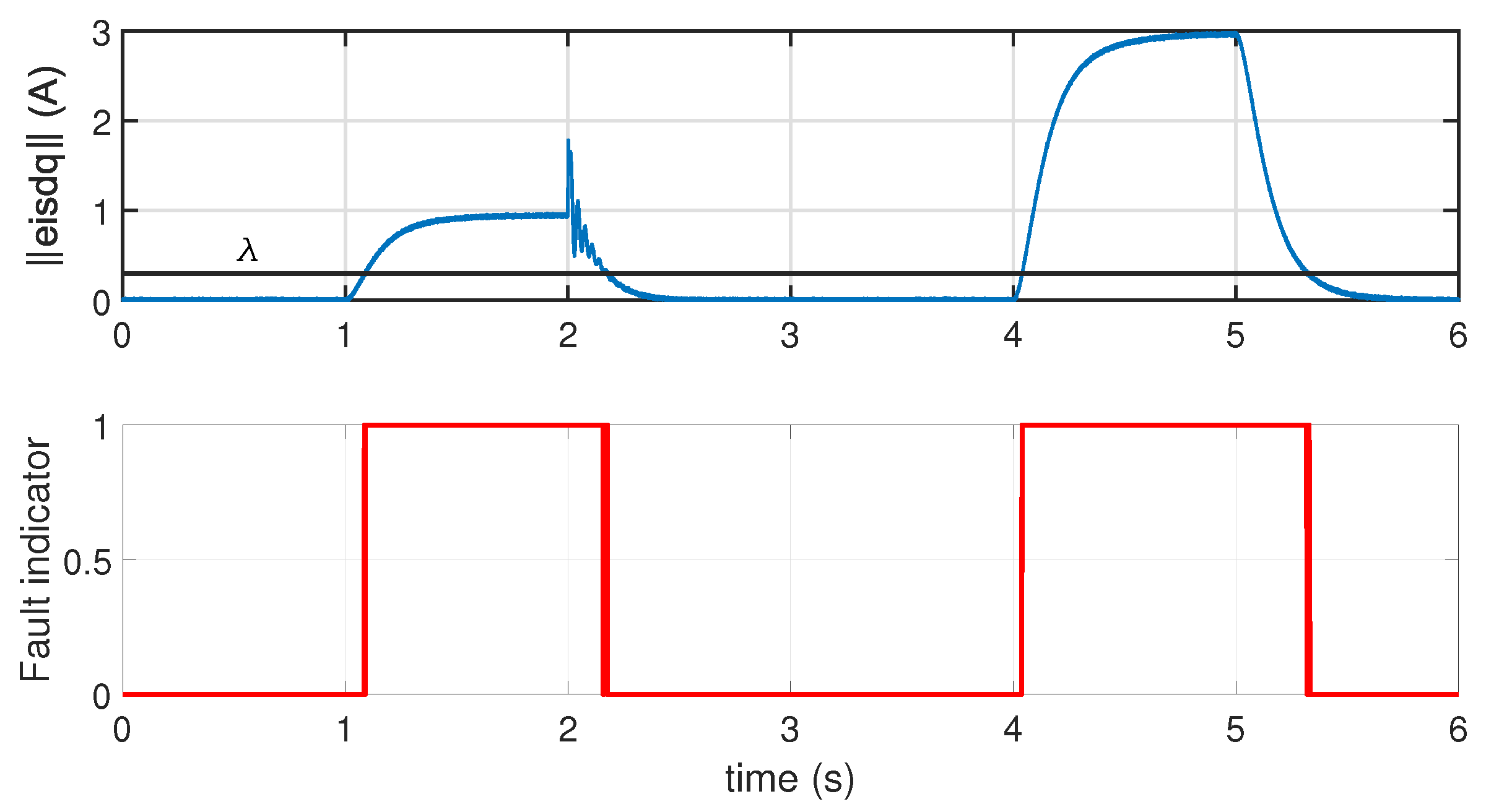

| 2% ITSC fault | 0.3 | 0.091 |

| State Variable | RMSE | MAE | Max |

|---|---|---|---|

| d-axis stator current | 0.1417 | 0.1130 | 0.7063 |

| q-axis stator current | 0.1418 | 0.1131 | 0.6987 |

| Generator speed | 0.1523 | 0.1214 | 0.8154 |

| Fault Level | UIO Observer | PI Observer | ||||

|---|---|---|---|---|---|---|

| (s) | (%) | RMSE (%) | (s) | (%) | RMSE (%) | |

| 2% ITSC fault | 0.215 | — | 0.852 | 0.332 | 7 | 0.435 |

| 5% ITSC fault | 0.131 | 5.4 | 1.126 | 0.221 | 4 | 0.115 |

| Fault Type | Threshold (A) | Detection Time (s) |

|---|---|---|

| 2% ITSC fault | 0.3 | 0.091 |

| 5% ITSC fault | 0.3 | 0.042 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayahi, Y.; Allouche, M.; Ghamgui, M.; Moreau, S.; Tadeo, F.; Mehdi, D. Fault-Tolerant Tracking Observer-Based Controller Design for DFIG-Based Wind Turbine Affected by Stator Inter-Turn Short Circuit. Symmetry 2025, 17, 1343. https://doi.org/10.3390/sym17081343

Sayahi Y, Allouche M, Ghamgui M, Moreau S, Tadeo F, Mehdi D. Fault-Tolerant Tracking Observer-Based Controller Design for DFIG-Based Wind Turbine Affected by Stator Inter-Turn Short Circuit. Symmetry. 2025; 17(8):1343. https://doi.org/10.3390/sym17081343

Chicago/Turabian StyleSayahi, Yossra, Moez Allouche, Mariem Ghamgui, Sandrine Moreau, Fernando Tadeo, and Driss Mehdi. 2025. "Fault-Tolerant Tracking Observer-Based Controller Design for DFIG-Based Wind Turbine Affected by Stator Inter-Turn Short Circuit" Symmetry 17, no. 8: 1343. https://doi.org/10.3390/sym17081343

APA StyleSayahi, Y., Allouche, M., Ghamgui, M., Moreau, S., Tadeo, F., & Mehdi, D. (2025). Fault-Tolerant Tracking Observer-Based Controller Design for DFIG-Based Wind Turbine Affected by Stator Inter-Turn Short Circuit. Symmetry, 17(8), 1343. https://doi.org/10.3390/sym17081343