Abstract

This study investigates the microstructural evolution and mechanical response of an additively manufactured (PBF-LB/M) AlSi10Mg alloy subjected to severe plastic deformation via two passes of twist channel angular pressing (TCAP). Processing was conducted using Route Bc, with the first pass at 150 °C and the second at 250 °C. For the first time, the evolution from the initial hierarchical AM structure to a refined state was characterized in high-fidelity detail using a novel EBSD detector. The two-pass process transformed the initial structure into a heterogeneous, bimodal microstructure existing in a non-equilibrium state, characterized by a high fraction of low-angle grain boundaries (63%) and significant internal lattice distortion. The mechanical properties were dictated by the processing temperature: a single pass at 150 °C induced work hardening, increasing the yield strength from 450 MPa to 482 MPa. Conversely, the second pass at an elevated temperature of 250 °C promoted significant dynamic recovery. This led to a decrease in yield strength to 422 MPa but concurrently resulted in a substantial increase in ultimate compressive strength to 731 MPa.

1. Introduction

The development of laser powder bed fusion (PBF-LB/M) has transformed the manufacturing of metallic components, enabling the fabrication of near-net-shape geometries from high-strength materials such as titanium [1], aluminum [2], magnesium [3], copper [4], or stainless steels [5]. The PBF-LB/M process is governed by complex, non-equilibrium physical phenomena. Extreme thermal gradients and fluid flow within the melt pool result in a unique and highly heterogeneous microstructure [6]. For example, the microstructure of the PBF-LB/M AlSi10Mg alloy is fundamentally anisotropic, characterized by a hierarchical structure that includes macro-scale melt pool boundaries, columnar grains that grow directly from the layer below along the direction of the temperature gradient, and a fine-scale cellular–dendritic network. Within this network, the α-Al matrix exists as a supersaturated solid solution, with eutectic Si segregated from the cell boundaries [7,8]. From a crystallographic perspective, this initial state differs significantly from the statistical isotropy of conventionally processed materials, possessing a low-symmetry configuration that leads to a strong directionality in its mechanical properties—a significant limitation for its use in structurally demanding applications [9,10].

To address these inherent microstructural issues, a variety of post-processing strategies are commonly employed. The most conventional are thermal treatments adapted from traditional casting metallurgy, such as a complete T6 cycle involving solution heat treatment and artificial aging [11,12,13,14,15]. Although these methods are effective at relieving the substantial residual stresses inherent to the PBF-LB/M process, they present a significant performance trade-off. The required high-temperature solution heat treatment stage (typically >500 °C for PBF-LB/M AlSi10Mg) leads to the dissolution of the fine continuous Si network and the coarsening of Si particles [16,17,18]. This process destroys the main strengthening mechanism of the as-built state—grain boundary strengthening from the fine Al/Si cellular architecture [19,20]. Subsequent aging precipitates Si in the form of discrete, often coarse particles that provide less effective strengthening [21], resulting in a pronounced decrease in yield and tensile strength compared to the as-built condition. Furthermore, these thermal treatments are largely unable to change the macro-scale textural anisotropy inherited from the additive manufacturing process [22].

While heat treatments are common for PBF-LB/M AlSi10Mg alloy, severe plastic deformation (SPD) offers a fundamentally different pathway by mechanically re-engineering the material’s internal structure. A widely investigated foundational SPD method is equal channel angular pressing (ECAP) [23,24]. This process involves pressing a billet through a die containing two intersecting channels of identical cross-section. The deformation is ideally constrained to a single shear plane, which imparts a well-defined monoclinic symmetry to the deformation field. By re-inserting the billet for multiple passes—often with rotations according to processing routes (e.g., A, Bc, C)—it is possible to accumulate strain and develop a homogeneous ultrafine-grained microstructure [25,26]. The evolution of the final crystallographic texture is therefore a direct and predictable result of this underlying process symmetry.

This study employs a more advanced SPD technique, twist channel angular pressing (TCAP), which is specifically designed to break the simple symmetry of the ECAP process and impose a more complex deformation state [27,28]. The critical advantage of TCAP lies in its unique “shear-then-twist” sequence, which imposes a severe, three-dimensional, and non-monotonic strain path within a single pass. The process begins with an intense, simple shear deformation at the channel intersection, identical to ECAP. However, the critical design modification is the helical twist machined into the exit channel [29,30,31]. As the already-sheared material is extruded through this channel, a secondary, severe torsional deformation is superimposed. This “shear-then-twist” sequence is the key to the process’s efficacy. The abrupt change in deformation mode from planar shear to torsion forces the material to activate a wider and more varied combination of crystallographic slip systems than is possible during the simple shear of ECAP [32]. We hypothesize that this complex, three-dimensional strain path is uniquely advantageous for processing additively manufactured materials, as it is more effective at fragmenting the coarse-grain structure and randomizing the strong crystallographic texture.

The novelty of this investigation is therefore twofold. First, we investigate the response of the complex, low-symmetry microstructure of an additively manufactured alloy to this unique shear-then-twist deformation—a combination that remains largely unexplored. Second, we recognize that the quantitative characterization of such a complex material, both in its initial state and after severe deformation, presents a significant measurement challenge. To overcome this, we conducted a detailed investigation using the cutting-edge eWARP™ electron backscatter diffraction (EBSD) detector. The exceptional acquisition speed and high signal-to-noise ratio of this advanced system are essential for achieving high-fidelity orientation mapping. This allowed us to accurately resolve sub-micron cellular features and quantify lattice distortion fields and geometrically necessary dislocation densities, features that conventional detectors fail to capture with sufficient accuracy in such highly strained, fine-scale materials.

By combining an advanced asymmetric deformation process with state-of-the-art characterization, this work aims to provide a clear analysis of the structure–property relationships governing the evolution of PBF-LB/M AlSi10Mg under severe, non-monotonic strain. The objective is to directly correlate high-fidelity microstructural data with the macroscopic mechanical response, thereby providing new insights into how engineered, symmetry-breaking deformation paths can be used to optimize the performance and reliability of additively manufactured alloys for advanced engineering applications.

2. Materials and Methods

2.1. Material and PBF-LB/M Fabrication

The starting material for this investigation was a virgin gas-atomized AlSi10Mg powder with a spherical morphology and a particle size distribution characterized by D10 = 22.5 µm, D50 = 38.1 µm, and D90 = 59.8 µm, as determined by laser diffraction. The nominal chemical composition of the powder, provided by the manufacturer, is detailed in Table 1.

Table 1.

Nominal chemical composition of the AlSi10Mg powder used in this study (wt.%).

Rectangular billets, with a cross-section of 14.25 mm × 14.25 mm and a length of 50 mm, were fabricated from the powder using a TruPrint 1000 PBF-LB/M system from Trumpf (Ditzingen, Germany) equipped with a fibre laser. The processing was conducted under a high-purity argon atmosphere to mitigate oxidation. The start of the SLM process was then delayed until the oxygen content in the printing chamber dropped below 0.02%. The fabrication parameters were set as follows: a laser power of 275 W, a scan speed of 1400 mm/s, a layer thickness of 20 µm, and a hatch spacing of 100 µm. A standard scan strategy involving a 67° rotation of the scan vectors between consecutive layers was implemented to reduce texture development during the build process. Following fabrication, the billets were carefully separated from the build platform.

2.2. Twist Channel Angular Pressing (TCAP)

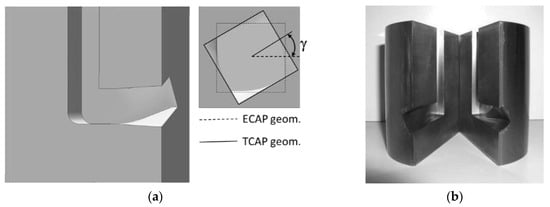

The twist equal channel angular pressing (ECAP) die was designed for this study, as shown schematically in Figure 1. The die has a channel intersection angle (Φ) of 90° and an outer arc of curvature (Ψ) of 30°. The channel maintains a constant square cross-section of 14.25 mm × 14.25 mm throughout its length. The key design feature is the geometry of the exit channel, which was machined to incorporate a 30° twist, imparting an additional torsional strain component to the billet during extrusion.

Figure 1.

Schematic of the equal channel angular pressing (ECAP) die (a). The illustration shows the overall geometry of the die and provides a detailed view of the twist (helical) channel section, using an example with a twist angle (γ) of 30° [33]; (b) a photograph showing the die configuration used in this study.

The ECAP process was performed using a LabTest 5.2000CT (Labortech, Opava, Czech Republic) hydraulic press controlled by Test Emotion software. Before processing, each billet was coated with Nicro-Thermocup 1200 lubricant to minimize friction with the die walls. The billet, in its as-built condition, directly resulting from the additive manufacturing process, did not receive post-build heat treatment. Subsequently, it was placed in the ECAP die. The die–billet assembly was then heated to the specified deformation temperature and allowed to equilibrate for a holding time of 10 min before the deformation process began. A two-pass procedure following the Bc route was employed, the first pass being conducted at 150 °C and the second at 250 °C. The temperature was continuously monitored using a NiCr-Ni thermocouple. Once the target temperature stabilized, the billet was pressed through the die at a constant ram speed of 1 mm/s.

2.3. Microstructural Characterization

The microstructures of the as-built and TCAP-processed samples were examined on the cross-sectional plane, which is perpendicular to the extrusion axis and contains the normal direction (ND) and the transverse direction (TD). For microstructural analysis, the samples were first sectioned using a semi-automatic cut-off machine and then mounted in an epoxy resin. Subsequently, they underwent a mechanical grinding and polishing procedure. This included grinding with successive grades of SiC paper up to 1200 grit, followed by polishing with 3 µm and 1 µm diamond suspensions. A final polishing step was performed using a 0.04 µm colloidal silica suspension to achieve a deformation-free surface suitable for high-resolution electron microscopy.

To reveal the microstructure details, samples were etched with a solution of 190 mL of distilled water, 2 mL of hydrofluoric acid, 3 mL of hydrochloric acid, and 5 mL of nitric acid for 40–60 s (Keller’s reagent).

Light microscopy observations were performed using an Axio Observer Z1 inverted microscope. The microstructure of the as-built sample was analyzed by electron backscatter diffraction (EBSD) using a Zeiss Supra 35 scanning electron microscope (Carl Zeiss NTS GmbH, Oberkochen, Germany) equipped with an EDAX NT EBSD detector.

A detailed crystallographic analysis of the sample processed ECAP was conducted using electron backscatter diffraction (EBSD) on a Thermo Fisher (Thermo Fisher, Waltham, MA, USA) Scientific Apreo 2S field emission scanning electron microscope (FEG-SEM). This microscope is equipped with a Bruker eWARP direct detection detector, which is known for its speed in EBSD imaging.

The EBSD scan was performed at an acceleration voltage of 10 kV and a probe current of 13 nA. For the EBSD mapping, step sizes of 40 nm (measurement area of 16,800 μm2) and 20 nm (measurement area of 4428 μm2; see Figure S1 in the Supplementary Materials) were employed. These sizes were selected to balance the acquisition time with the need for adequate spatial resolution, especially considering the ultrafine-grained structure and the expected high strain of the material. This approach allowed for the precise capturing of grain boundaries and intra-granular orientation gradients. The effective spatial resolution for orientation mapping was approximately 20 nm, with an indexing success rate of about 80%.

EBSD data were analyzed to create inverse pole figure (IPF) orientation maps and grain boundary maps, distinguishing low-angle boundaries (2–15°) from high-angle boundaries (greater than 15°). The average grain size was determined as the area-weighted equivalent circle diameter (ECD). In addition, local misorientation maps, particularly kernel average misorientation (KAM), were generated to qualitatively assess the distribution of geometrically necessary dislocations and the degree of localized plastic strain.

2.4. Mechanical Properties

The mechanical properties of the material in its as-built and TCAP-processed states were evaluated through uniaxial compression tests. Sub-sized cylindrical compression samples, with a diameter of 6 mm and a height of 9 mm, were machined from the center of the billets. Uniaxial compression tests were performed with the compression axis oriented parallel to the extrusion direction of the material.

The tests were conducted at room temperature using a universal testing machine (Zwick Z20, ZwickRoell, Ulm, Germany) at a quasi-static strain rate of 10−3 s−1. The load and displacement data were continuously recorded to generate engineering stress–strain curves, from which the yield strength was determined (at 0.2% plastic strain), and ultimately, compressive strength values were determined. To ensure statistical reliability, a minimum of three tests were performed for each material condition.

The strain hardening exponent (n) was calculated from true stress-true strain data obtained during uniaxial compression tests. The calculation is based on the Hollomon power-law equation, σtrue = K(εtrue)n, which describes the plastic deformation region of the curve. Taking the natural logarithm of this equation, we derived a linear relationship: ln(σtrue) = ln(K) + nln(εtrue). The strain hardening exponent ‘n’ was then determined as the slope of the best-fit line from a linear regression of the ln(σ_true) versus ln(ε_true) plot.

3. Results

3.1. Microstructure in As-Built Condition

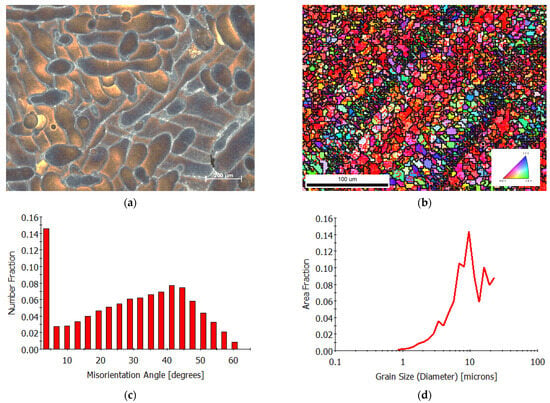

The as-built microstructure of the AlSi10Mg alloy, presented in Figure 2a, reveals a characteristic pattern of overlapping/discontinuous laser scan traces. The phase analysis by XRD (Supplementary Figure S2) confirms that the material is composed of the α-Al phase. The lack of detectable crystalline silicon indicates a high degree of solute supersaturation in the aluminum matrix, which is a well-established outcome of the kinetic solute trapping driven by the high cooling rates (>105 K/s) during LPBF.

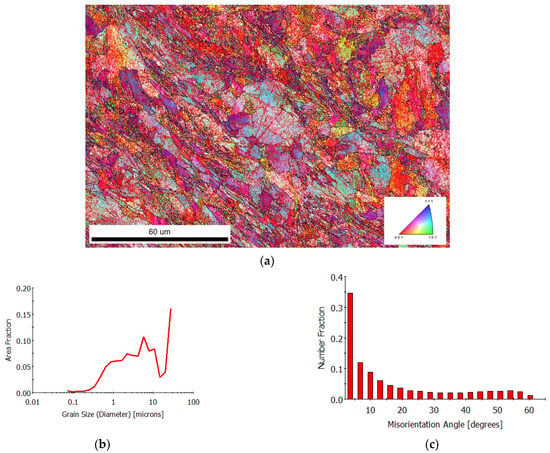

Figure 2.

Hierarchical microstructure of the as-built PBF-LB/M AlSi10Mg alloy in the X-Y build plane: (a) Optical micrograph revealing the characteristic discontinuous melt pools resulting from the laser scan strategy, which includes a 67° rotation between successive layers; (b) large-area EBSD inverse pole figure (IPF) map showing a bimodal distribution of equiaxed grains. Larger grains are visible in the scan track interiors, while finer grains are concentrated at the melt pool (scan track) boundaries. Red lines—LAGBs, black lines—HAGBs; (c) histogram of grain boundary misorientation distribution; (d) histogram of grain size distribution.

The grain microstructure of the as-built material was characterized by EBSD. Figure 2b presents a representative inverse pole figure (IPF) map from the X–Y plane, which reveals a heterogeneous microstructure directly correlated with the laser scan tracks from the manufacturing process. The microstructure exhibits a bimodal grain distribution. A network of fine, equiaxed grains is observed at the melt pool boundaries. The formation of these grains is characteristic of the high cooling rates and repeated thermal cycling at the edges of the laser track, which promotes a high rate of nucleation. In contrast, the interior of the melt pools is composed of larger grains that are the result of competitive growth. These grains exhibit a strong preferential orientation, leading to the development of a <100> crystallographic texture. This texture is aligned with the primary heat flow direction and is consistent with the preferred solidification growth mode for face-centered cubic (FCC) aluminum alloys.

Statistical data (Figure 2c) confirm the prevalence of HAGBs, which account for 76% of the total boundary fraction. These HAGBs delineate the primary equiaxed grains across the microstructure, including both the fine grains at melt pool peripheries and the larger grains in the interior. Conversely, LAGBs constitute the remaining 24%. These LAGBs are concentrated primarily within the larger grains, forming the cellular substructure (Al/Si network). Overall, the as-built microstructure exhibits an average grain size of ~10.8 μm (Figure 2d).

Next, a high-resolution EBSD scan was performed to analyze the microstructure of the as-built AlSi10Mg alloy sample in more detail. The resulting IPF map (Figure 3a) clearly shows that the large grains are composed of a very fine (approx. 400 nm) cellular–dendritic network. This substructure is a direct consequence of the extremely high cooling rates (105–106 K/s) experienced during solidification, which kinetically trap the solute (Si) at the advancing solidification front, forming the Si cell walls. A point-to-point misorientation analysis across this network (see the line in Figure 3a) reveals that the misorientation between adjacent cells is minimal, typically less than 2 degrees; Figure 3b. This confirms that these are, in fact, subgrains that share a nearly identical crystallographic orientation with the parent grain in which they reside.

Figure 3.

(a) High-resolution IPF-EBSD map resolving the fine cellular substructure within a grain, characterized by very low misorientation angles between adjacent cells. Red lines—LAGBs, black lines—HAGBs; (b) results of the point-to-point misorientation along the “rainbow” line visible in (a); (c) KAM map revealing the concentration of geometrically necessary dislocations (GNDs) along the cellular walls.

The corresponding KAM map (Figure 3c) visualizes the local lattice distortion. The map indicates a relatively low overall strain but shows a clear pattern of geometrically necessary dislocations (GNDs) accumulating at the cell boundaries (green areas). This GND network does not arise from external plastic deformation but is formed during cooling to accommodate the thermal stresses inherent to the PBF-LB/M process. The dense cellular network, pinned by a high density of GNDs, is the primary microstructural feature responsible for the exceptionally high strength of the as-built AlSi10Mg alloy [34,35].

3.2. Effect of Twist Channel Angular Pressing (TCAP) on the Microstructure

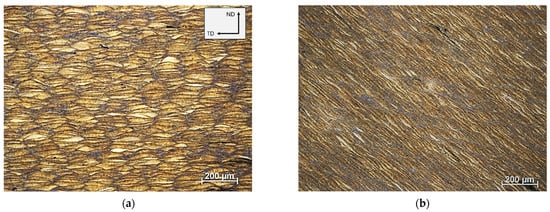

After the first pass of ECAP, the material undergoes a pronounced microstructural transformation, as depicted in Figure 4a. This evolution is primarily governed by the shear imposed along the intersecting channels. The microstructure develops a characteristic banded morphology, with elongated features aligned parallel to the ND plane. While the use of a helical die introduces an additional torsional component, its influence remains subordinate during the initial pass, with shear strain playing the decisive role in microstructural refinement. The transformed structure consists of two distinct constituents, both originating from the heterogeneous microstructure of the as-built material, now undergoing reorganization and partial subdivision in response to the imposed strain.

Figure 4.

Light microscope images illustrating the microstructural state of the AlSi10Mg alloy sample after a first (a) and second pass (b) using the ECAP die with a 30-degree twist outer channel. The cumulative effect of two passes through this specific die, imposing both shear and continuous torsional strain, leads to a further advanced and distinct microstructural evolution. It should be noted here that the second pass was conducted via Route Bc, which involves a billet rotation of 90 degrees after the first ECAP pass. The vertical and horizontal axes of the figure correspond to the normal direction (ND) and transverse direction (TD), respectively.

- Deformed Melt Pool Structures: The lighter, lenticular (lens-shaped) regions represent the interiors of the original melt pools, which have been plastically deformed. It is critical to note that these are not individual grains; rather, each elongated “fish-scale” structure is a multi-grained region that has been subjected to intense shear. The interiors of these structures consist of the α-Al matrix and the Si network.

- Melt Pool Boundaries: A dark, continuous, and interconnecting network delineates the deformed melt pool structures. These correspond to the original melt pool boundaries from the SLM process. Their preferential response to chemical etching, which results in the dark contrast, is attributed to the segregation of the Si-rich eutectic phase that occurs at these interfaces during the rapid solidification inherent to the additive manufacturing process. After the first ECAP pass, these boundaries are stretched, thinned, and reoriented to trace the material’s flow lines. By forming a continuous network that encapsulates the deformed melt pools.

Next, a quantitative analysis was performed to characterize the extent of microstructural deformation. The deformed melt pool structures exhibit significant anisotropy, with an average thickness of approximately 16 µm when measured along the normal direction (ND). In contrast, the average width of these structures, measured along the transverse direction (TD), is substantially larger, at approximately 150 µm. This dimensional disparity yields a high aspect ratio (width-to-thickness) of approximately 9.4:1, quantitatively confirming the severe flattening and elongation of the initial microstructural features.

Following the second ECAP pass, the material’s microstructure displays a significant evolution from its state after the first ECAP pass (Figure 4b). This is a direct consequence of the strain path, specifically Route Bc, which involves a 90° rotation of the billet about its longitudinal axis between consecutive pressings. This fundamentally alters the orientation of the workpiece relative to the die’s shear plane. As a result, the shear strain in the second pass is imposed on a new set of crystallographic planes, which are essentially orthogonal to those activated during the initial pass. This leads to a “cross-shearing” effect where the new deformation bands intersect and transect the previously formed lamellar structure. Visually, this mechanistic change results in the reorientation of the dominant lamellar features to an inclination of approximately 45° relative to the transverse direction, as seen in the second micrograph. The “melt pool structures” are visibly finer and more elongated than after the single pass, which reflects an enhanced level of microstructure refinement. The average widths of melt pool structures, measured along the (TD) and (ND), are 14.2 μm and 12.5 μm, respectively.

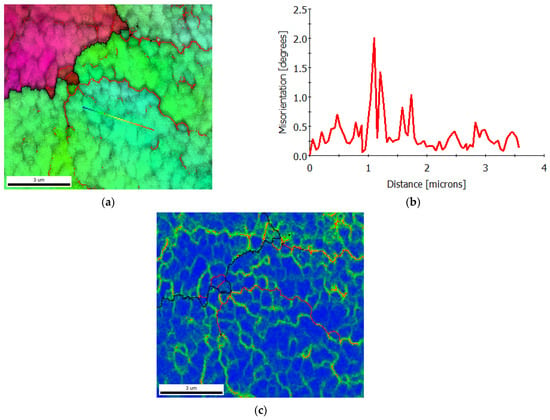

Following the initial characterization of the overall deformed morphology via light microscopy, a more detailed, quantitative analysis of the microstructure was performed using EBSD (Figure 5 and Table 2). For this analysis, characterization was performed exclusively on the specimen subjected to two ECAP passes.

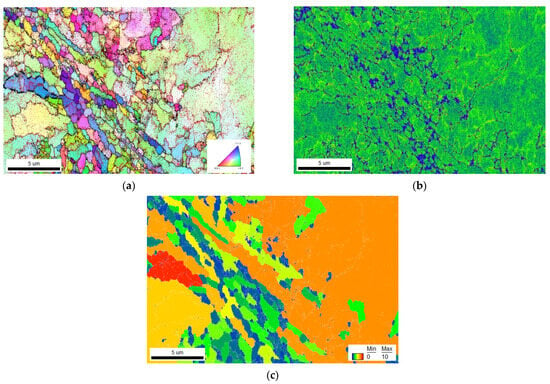

Figure 5.

High-resolution IPF-EBSD map presenting the microstructure of AlSi10Mg alloy after 2 ECAP passes: (a) IPF-Z map showing the deformed microstructure. Red lines–LAGBs and black lines—HAGBs. The vertical and horizontal axes of the figure correspond to the normal direction (ND) and transverse direction (TD), respectively; (b) histogram of grain size distribution; (c) histogram of grain boundary misorientation distribution.

Table 2.

Summary of key microstructural parameters from EBSD analysis.

Figure 5a presents the inverse pole figure (IPF) map referenced to the sample’s normal (Z) direction, which utilizes a color code (see the inset in the right corner of the image) to visualize the spatial distribution of crystallographic orientations. The alignment of the microstructure is approximately 45°, which is in good agreement with the light microscopy observations. The IPF-Z map reveals a highly heterogeneous microstructure composed of a sheared, elongated substructure alongside regions of fine, probably dynamically recrystallized (DRX) grains. It is also visible that the original grains have been severely deformed, as significant intragranular color gradients are visible. These gradients indicate substantial lattice distortion and the formation of extensive dislocation substructures, a common feature of plastically deformed metals.

In aluminum alloys subjected to severe plastic deformation, the accommodation of intense strain is primarily achieved through localized shear. This results in the formation of microdeformation bands (MSBs) [36]. As shown in Figure 5a, these MSBs are crystallographically distinct, delineated by sharp orientation gradients with respect to the surrounding, less-deformed matrix grains, as evidenced by the distinct color changes in the IPF map. The localized strain energy within these bands provides the necessary driving force for dynamic recrystallization (DRX), leading to the nucleation of arrays of ultrafine, equiaxed grains.

Quantitative analysis of the grain size distribution, presented in Figure 5b, statistically confirms the heterogeneous microstructure observed in the micrographs. The distribution is clearly bimodal, reflecting the two main structural constituents of the material. The first mode represents the population of refined grains, as evidenced by the wide distribution spanning approximately 0.5 to 10 μm, with a notable peak centered around 5–7 μm. This confirms that substantial grain refinement was achieved. The second distinct mode corresponds to the coarse grains that remained deformed, represented by the sharp peak for diameters greater than 20 μm.

This bimodal grain architecture is a characteristic outcome of incomplete dynamic recrystallization across the material volume. Although the calculated area-weighted average grain diameter is ~9 μm, the bimodal distribution more accurately reveals the coexistence of newly formed, strain-free ultrafine grains alongside persistent, highly deformed regions of the parent grain structure.

The histogram of grain boundary misorientation, presented in Figure 5c, reveals that low-angle grain boundaries (LAGBs) constitute 63% of the boundary population. This prevalence of LAGBs signifies that the microstructure exists in a non-equilibrium state, characterized by a high density of dislocation substructures and subgrains that have not yet fully evolved into new grains delineated by HAGBs [37]. Such a condition is characteristic of an intermediate stage of severe plastic deformation, occurring before the microstructure reaches a steady-state condition that is typically associated with a higher HAGB fraction.

A detailed characterization of the UFG microstructure, performed with a 20 nm step size (Figure 6), reveals a complex, hierarchical boundary network. The IPF-Z map in Figure 6a reveals a deformed, banded microstructure. Within this structure, the original parent grains are subdivided by deformation bands separated by geometrically necessary boundaries (GNBs). These GNBs are formed to accommodate the lattice misorientations that result from glide on different slip system combinations in neighboring regions [38]. Microscopically, such boundaries appear as ‘dense dislocation walls’, ‘deformation bands’, and ‘microbands’, and they collectively define the primary deformation structure [39]. With continued strain, some of these GNBs evolve into high-angle grain boundaries (HAGBs) by the gradual accumulation of misorientation. This transformation is typically limited to GNBs located along the original parent grain boundaries.

Figure 6.

(a) High-resolution inverse pole figure (IPF) map presenting a detailed characterization of a representative region within the AlSi10Mg alloy microstructure after two ECAP passes. The color of each grain corresponds to the crystallographic orientation parallel to the map normal (Z-axis). Grain boundaries are superimposed, with low-angle grain boundaries (2° < θ < 15°) shown in red and high-angle grain boundaries (θ > 15°) in black; (b) the corresponding KAM map; (c) grain orientation spread map.

The vast network of LAGBs that dominates the interiors of deformation bands is composed of a different type, known as incidental dislocation boundaries (IDBs) [40]. These short, interconnecting IDBs are created by the statistical trapping and mutual entanglement of glide dislocations, which organizes them into a fine, cell-like structure (see the green grain delineated by the black dashed line in Figure 6a). Compared to GNBs, these IDBs are more likely to remain as low-angle boundaries and require further straining to evolve into HAGBs.

The KAM map (Figure 6b) reveals substantial GNDs, with the average KAM value rising from 0.48° in the as-built condition to 1.2° after two ECAP passes. This significant increase in GND density is a direct consequence of the plastic deformation inhomogeneity within the material’s hierarchical microstructure, which is primarily caused by the strain incompatibility between the soft α-Al matrix and the harder, Si-rich cellular network inherited from the PBF-LB/M process [7,8,41,42,43,44]. To preserve lattice compatibility across the interfaces between these microstructure constituents, a high density of GNDs is generated [45]. These dislocations play a multifaceted role in the microstructural evolution; they organize into geometrically necessary boundaries (GNBs), but they can also be trapped or interact in a statistically random manner, similar to statistically stored dislocations (SSDs), contributing to the formation of cell walls with the character of incidental dislocation boundaries (IDBs). The continuous accumulation of these GNDs within the evolving subgrain boundaries—a process templated by the Al/Si cellular network—facilitates their progressive rotation, increasing their misorientation and ultimately driving the transformation of LAGBs into new, refined HAGBs through dynamic recrystallization. The GOS map, shown in Figure 6c, visualizes this phenomenon. It reveals a bimodal microstructure characteristic of incomplete dynamic recrystallization [46]. The remnant parent grains, which are heavily deformed, are identified by high GOS values (appearing as yellow and orange regions). This signifies substantial internal lattice distortion and stored energy. In contrast, a population of fine, equiaxed grains is clearly distinguished by very low GOS values (<1°), rendered in blue. The low internal misorientation of these grains indicates that they possess a significantly reduced dislocation density. Their presence provides direct evidence of dynamic recrystallization [47,48], in which new strain-free grains have nucleated from the deformed matrix.

3.3. Effect of Twist Equal Channel Angular Pressing on the Mechanical Properties of PBF-LB/M AlSi10Mg Alloy

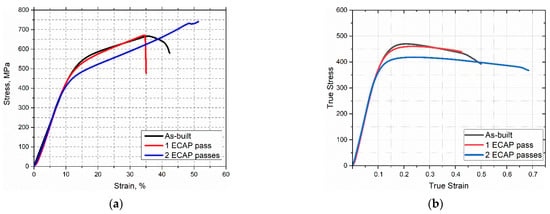

The mechanical response of the as-built and ECAP-processed AlSi10Mg samples under compressive loading is illustrated by the true stress–strain curves in Figure 7. A summary of the key mechanical properties derived from these curves, including the 0.2% offset yield strength (YS), ultimate compressive strength (UCS), and the strain hardening exponent (n), is presented in Table 3.

Figure 7.

Uniaxial compression: (a) engineering stress–strain curves; (b) true stress–strain curves.

Table 3.

Compressive mechanical properties of AlSi10Mg samples before and after ECAP processing.

The as-built AlSi10Mg sample presents a yield strength of 450 MPa and an ultimate compressive strength of 670 MPa. The high strength of the as-built sample is derived primarily from its unique and fine cellular dislocation structure formed during rapid solidification [34,44,49]. Although composed of low-angle boundaries, these dense cellular walls effectively impede dislocation motion. The true stress–strain curve for this condition reveals a distinct peak stress of ~470 MPa, followed by gradual flow softening, likely due to the progressive breakdown of the initial cell structure during deformation. The initial strain hardening exponent (n = 0.25) is consistent with values reported in the literature [50].

Following a single ECAP pass at 150 °C, the material exhibits a slight enhancement in its mechanical properties. The YS increases by approximately 7% to 482 MPa, with the UCS reaching 682 MPa. This strengthening is attributed to the combined effects of increased dislocation density and significant grain refinement induced by the severe plastic deformation. The newly created grain and subgrain boundaries act as effective obstacles to dislocation motion. The true stress–strain curve for this condition shows pronounced strain hardening up to a peak stress of ~480 MPa, after which flow softening becomes dominant, similar to the as-built state. This initial hardening capacity is slightly enhanced, as quantified by an increase in the strain hardening exponent (n) to 0.27.

A second ECAP pass at an elevated temperature of 250 °C altered the mechanical response, resulting in a decreased yield strength of 422 MPa. This softening is attributed to the prevalence of thermally activated restoration mechanisms, namely dynamic recovery (DRV) and dynamic recrystallization (DRX) [51,52]. The true stress–strain curve for this condition is distinct, exhibiting a pronounced regime of near steady-state flow that extends to a true strain of approximately 0.4 before the onset of flow softening.

This macroscopic behavior is a direct manifestation of the underlying microstructural evolution and is quantitatively supported by the reduction in the strain hardening exponent (n) to 0.25. Restoration processes at 250 °C produce a recovered microstructure with a lower initial dislocation density and well-defined subgrains, which diminishes the capacity for subsequent storage of dislocations. The steady-state flow regime is therefore interpreted as a dynamic equilibrium where the rate of dislocation generation is balanced by the rate of annihilation at the high density of grain and subgrain boundaries, which serve as efficient sinks [53,54]. This equilibrium precludes significant work hardening, leading to the observed flow characteristics.

A notable characteristic of the mechanical response is also the limited post-yield strain hardening observed across all material states, despite their high initial yield strengths. This apparent discrepancy can be reconciled by considering the dual role of the refined microstructure. The very same features responsible for the high strength—namely, the dense network of cellular walls, subgrain boundaries, and high-angle grain boundaries—also inherently limit the material’s capacity for further dislocation storage [55,56], which is the primary mechanism of strain hardening. The as-built and ECAP-processed microstructures are probably already in a state approaching dislocation saturation. During subsequent plastic deformation, the numerous grain and subgrain boundaries act not only as barriers to dislocation motion but also as highly efficient sinks for their annihilation [57]. Consequently, a dynamic equilibrium is rapidly established where the rate of dislocation generation is effectively balanced by the rate of their annihilation. This results in a low net accumulation of dislocations within the grain interiors, manifesting macroscopically as a diminished strain hardening response, which presents as either steady-state flow or flow softening.

4. Conclusions

In this article, the microstructural and mechanical evolution of a PBF-LB/M AlSi10Mg alloy subjected to a complex, non-monotonic strain path via twist equal channel angular pressing was investigated. The key findings are as follows:

- The as-built PBF-LB/M alloy possessed a unique hierarchical microstructure, with its high initial yield strength (450 MPa) attributed to a fine cellular network. High-resolution EBSD confirmed that this network consisted of low-angle subgrain boundaries containing a high density of geometrically necessary dislocations.

- Two passes of TCAP via Route Bc produced a heterogeneous microstructure with a bimodal grain size distribution. The refined structure existed in a non-equilibrium state, characterized by a high fraction of low-angle grain boundaries (63%) and significant internal lattice distortion.

- The mechanical response was dictated by the processing temperature. A single TWIST ECAP pass at 150 °C induced work hardening, increasing the yield strength to 482 MPa. The second pass at an elevated temperature of 250 °C promoted dynamic recovery, which, despite further grain refinement, led to a decrease in yield strength to 422 MPa but an increase in ultimate compressive strength to 731 MPa.

This study demonstrated the feasibility of applying the TCAP process to LPBF-processed alloys. Looking ahead, future work should focus on exploring multi-pass TCAP at varied temperatures and investigating other severe plastic deformation (SPD) routes to further refine the microstructure and mechanical properties of the additively manufactured materials. Such advancements could pave the way for their use in high-performance components across various demanding applications, ultimately overcoming current limitations and expanding the utility of LPBF-processed alloys.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/sym17081289/s1, Figure S1. IPF-Z map of the AlSi10Mg alloy sample subjected to 2 ECAP pressings. The map was collected using a 20 nm step size; Figure S2. X-ray diffraction pattern for AlSi10Mg alloy samples in as-built and after 2 ECAP pressing conditions.

Author Contributions

P.S.: conceptualization, methodology, validation, formal analysis, resources, data curation, writing—original draft, visualization, supervision, project administration, founding acquisition; A.A.: data curation, investigation. O.H.: data curation, investigation. J.H.: data curation, resources. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the National Science Centre, Poland, based on the decision number 2021/43/D/ST8/01946. This paper was completed in connection with the project “Innovative and additive technologies for sustainable energy industry”, registration no. CZ.02.01.01/00/23_021/0010117, financed by the Structural Funds of the European Union.

Data Availability Statement

Data are contained within the article and Supplementary Materials.

Acknowledgments

The authors would like to thank Laurie Palasse from Bruker company for performing the EBSD analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Al-Rubaie, K.S.; Melotti, S.; Rabelo, A.; Paiva, J.M.; Elbestawi, M.A.; Veldhuis, S.C. Machinability of SLM-Produced Ti6Al4V Titanium Alloy Parts. J. Manuf. Process 2020, 57, 768–786. [Google Scholar] [CrossRef]

- Huang, N.; Luo, Q.; Bartles, D.; Simpson, T.; Beese, A. Effect of heat treatment on microstructure and mechanical properties of AlSi10Mg fabricated using laser powder bed fusion. Mater. Sci. Eng. A 2024, 895, 146228. [Google Scholar] [CrossRef]

- Chen, J.; Chen, B. Progress in Additive Manufacturing of Magnesium Alloys: A Review. Materials 2024, 17, 3851. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, G.; Xiao, Z.; Zhang, Y.; Zhou, Y.; Liu, X.; Li, W.; Xu, J. Microstructures and Mechanical Properties of Pure Copper Manufactured by High-Strength Laser Powder Bed Fusion. Opt. Laser Technol. 2025, 182, 112134. [Google Scholar] [CrossRef]

- Jiang, R.; Yang, Y.; Wang, H.; Liu, Z.; Liu, L.; Du, J.; Tang, T.; Ye, Z.; Li, Q.; Yan, X.; et al. Effects of Remelting Scan Strategy on the Overlapping Quality of 316L Stainless Steel Fabricated by Multi-Laser Powder Bed Fusion. Mater. Sci. Eng. A 2025, 923, 147725. [Google Scholar] [CrossRef]

- Xiong, Z.H.; Liu, S.L.; Li, S.F.; Shi, Y.; Yang, Y.F.; Misra, R.D.K. Role of Melt Pool Boundary Condition in Determining the Mechanical Properties of Selective Laser Melting AlSi10Mg Alloy. Mater. Sci. Eng. A 2019, 740–741, 148–156. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Tan, Z.; Xiong, D.B.; Guo, Q. Stress Relaxation and the Cellular Structure-Dependence of Plastic Deformation in Additively Manufactured AlSi10Mg Alloys. Int. J. Plast. 2020, 127, 102640. [Google Scholar] [CrossRef]

- Wang, P.; Rabori, A.S.; Dong, Q.; Ravkov, L.; Balogh, L.; Fallah, V. The Role of Cellular Structure, Non-Equilibrium Eutectic Phases and Precipitates on Quasi-Static Strengthening Mechanisms of as-Built AlSi10Mg Parts 3D Printed via Laser Powder Bed Fusion. Mater. Charact. 2023, 198, 112730. [Google Scholar] [CrossRef]

- Jokelainen, T.; Iso-Junno, T.; Järvenpää, A.; Mustakangas, A.; Keskitalo, M.; Mäntyjärvi, K. Formability of Selective Laser Melted AlSi10Mg. AIP Conf. Proc. 2019, 2113, 150011. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, C.; Zhou, X.; Shen, Z.; Liu, W. Microstructure of Selective Laser Melted AlSi10Mg Alloy. Mater. Des. 2019, 168, 107677. [Google Scholar] [CrossRef]

- Di Egidio, G.; Ceschini, L.; Morri, A.; Martini, C.; Merlin, M. A Novel T6 Rapid Heat Treatment for AlSi10Mg Alloy Produced by Laser-Based Powder Bed Fusion: Comparison with T5 and Conventional T6 Heat Treatments. Metall. Mater. Trans. B 2022, 53, 284–303. [Google Scholar] [CrossRef]

- Chen, S.Q.; Huang, X.Y.; Shuai, L.F.; Wu, G.L.; Huang, T.L.; Huang, X.X. Annealing Behavior of AlSi10Mg Alloy Fabricated by Laser Powder Bed Fusion. J. Phys. Conf. Ser. 2023, 2635, 012036. [Google Scholar] [CrossRef]

- Yaru, L.; Tiejun, M.; Tounan, J.; Bo, Z.; Le, Y.; Wenhang, Y.; Hanguang, F. Aging Temperature Effects on Microstructure and Mechanical Properties for Additively Manufactured AlSi10Mg. Mater. Sci. Technol. 2023, 39, 1223–1236. [Google Scholar] [CrossRef]

- Vishnu, V.; Prabhu, T.R.; Vineesh, K.P. Effect of Hard Anodizing and T6 Heat Treatment on the Dry Sliding Wear Behavior of AlSi10Mg Fabricated by Direct Metal Laser Sintering. Wear 2025, 564–565, 205677. [Google Scholar] [CrossRef]

- Lehner, P.; Blinn, B.; Zhu, T.; Al-Zuhairi, A.; Smaga, M.; Teutsch, R.; Beck, T. Influence of the As-Built Surface and a T6 Heat Treatment on the Fatigue Behavior of Additively Manufactured AlSi10Mg. Int. J. Fatigue 2024, 187, 108479. [Google Scholar] [CrossRef]

- Rubben, T.; Revilla, R.I.; De Graeve, I. Effect of Heat Treatments on the Anodizing Behavior of Additive Manufactured AlSi10Mg. J. Electrochem. Soc. 2019, 166, C42–C48. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in Microstructure of Selectively Laser Melted AlSi10Mg Alloy with Heat Treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Casati, R.; Nasab, M.H.; Coduri, M.; Tirelli, V.; Vedani, M. Effects of Platform Pre-Heating and Thermal-Treatment Strategies on Properties of Alsi10mg Alloy Processed by Selective Laser Melting. Metals 2018, 8, 954. [Google Scholar] [CrossRef]

- Heilgeist, S.; Heine, B.; Merkel, M.; Hitzler, L.; Javanbakht, Z.; Öchsner, A. The Influence of Post-Heat Treatments on the Tensile Strength and Surface Hardness of Selectively Laser-Melted AlSi10Mg. Materwiss Werksttech 2019, 50, 546–552. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, Precipitates and Hardness of Selectively Laser Melted AlSi10Mg Alloy before and after Heat Treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, S.; Wang, Z.; Li, D.; Cui, X.; Xu, J. Effect of Cooling Rates and Heat Treatment Time on Si Phase of AlSi10Mg Alloy Manufactured by Selective Laser Melting: Microstructure Evolution and Strengthening Mechanism. J. Alloys Compd. 2024, 1007, 176494. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post Heat Treatment of Additive Manufactured AlSi10Mg: On Silicon Morphology, Texture and Small-Scale Properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-Five Years of Ultrafine-Grained Materials: Achieving Exceptional Properties through Grain Refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Beytüt, H.; Özbeyaz, K.; Temiz, Ş. A Novel Hybrid Die Design for Enhanced Grain Refinement: Vortex Extrusion–Equal-Channel Angular Pressing (Vo-CAP). Appl. Sci. 2025, 15, 359. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Langdon, T.G. The Fundamentals of Nanostructured Materials Processed by Severe Plastic Deformation. JOM 2004, 56, 58–63. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Snopińśki, P.; Tański, T.; Matus, K.; Rusz, S. Microstructure, Grain Refinement and Hardness of Al–3%Mg Aluminium Alloy Processed by ECAP with Helical Die. Arch. Civ. Mech. Eng. 2019, 19, 287–296. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Prilepo, D.; Kulagin, R.; Grishaev, V.; Abramova, O.; Varyukhin, V.; Kulakov, M. Planar Twist Extrusion versus Twist Extrusion. J. Mater. Process. Technol. 2011, 211, 522–529. [Google Scholar] [CrossRef]

- Hilšer, O.; Rusz, S.; Maziarz, W.; Dutkiewicz, J.; Tański, T.; Snopiński, P.; Džugan, J. Structure and Properties of AZ31 Magnesium Alloy after Combination of Hot Extrusion and ECAP. Acta Metall. Slovaca 2017, 23, 222–228. [Google Scholar] [CrossRef]

- Masouleh, M.K.; Mirzakhani, A.; Abdian, M.; Assempour, A. Effects of Temperature and Pass Number on Mechanical Properties, Microstructure, and Texture Evolution in Pure Magnesium Processed via a Geometrically Optimized TCAP Method. Results Eng. 2025, 27, 106138. [Google Scholar] [CrossRef]

- Bednarczyk, I.; Dobkowska, A.; Hilšer, O.; Rusz, S.; Pastrňák, M.; Čada, R.; Jabłońska, M.; Tkocz, M.; Kowalczyk, K.; Palgan, D.; et al. Influence of Temperature and Number of Passes during Twist Channel Angular Pressing (TCAP) on the Microstructural, Mechanical, and Corrosion Properties of Mg–4Li–Ca. Arch. Civ. Mech. Eng. 2024, 24, 89. [Google Scholar] [CrossRef]

- Macháčková, A. Decade of Twist Channel Angular Pressing: A Review. Materials 2020, 13, 1725. [Google Scholar] [CrossRef] [PubMed]

- Hilser, O.; Pastrnak, M.; Rusz, S.; Hana Krupova, P.S. Finite element analysis of twist channel angular pressing. MM Sci. J. 2023, 6314–6318. [Google Scholar] [CrossRef]

- Chen, B.; Moon, S.K.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Strength and Strain Hardening of a Selective Laser Melted AlSi10Mg Alloy. Scr. Mater. 2017, 141, 45–49. [Google Scholar] [CrossRef]

- Zhang, X.X.; Andrä, H.; Harjo, S.; Gong, W.; Kawasaki, T.; Lutz, A.; Lahres, M. Quantifying Internal Strains, Stresses, and Dislocation Density in Additively Manufactured AlSi10Mg during Loading-Unloading-Reloading Deformation. Mater. Des. 2021, 198, 109339. [Google Scholar] [CrossRef]

- Paul, H.; Driver, J.H.; Tarasek, A.; Wajda, W.; Miszczyk, M.M. Mechanism of Macroscopic Shear Band Formation in Plane Strain Compressed Fine-Grained Aluminium. Mater. Sci. Eng. A 2015, 642, 167–180. [Google Scholar] [CrossRef]

- Atefi, S.; Parsa, M.H.; Ahmadkhaniha, D.; Zanella, C.; Jafarian, H.R. A Study on Microstructure Development and Mechanical Properties of Pure Copper Subjected to Severe Plastic Deformation by the ECAP-Conform Process. J. Mater. Res. Technol. 2022, 21, 1614–1629. [Google Scholar] [CrossRef]

- Gholizadeh, R.; Terada, D.; Shibata, A.; Tsuji, N. Strain-Dependence of Deformation Microstructures in Ultra-Low-C IF Steel Deformed to High Strains by Torsion at Elevated Temperatures. Nano Mater. Sci. 2020, 2, 83–95. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, Q.; Wang, S. Dislocation Structure Evolution Pathway in Surface and Bulk Regions of Ni Deformed in Tension: A Comparison. Philos. Mag. 2025, 200, 1–17. [Google Scholar] [CrossRef]

- Jodi, D.E.; Kitashima, T.; Singh, A.; Watanabe, M. High-Temperature Microstructural Stability of Pure Ni Fabricated by Laser Powder Bed Fusion Using Gaussian and Flat-Top Beam Profiles. Mater. Charact. 2023, 200, 112897. [Google Scholar] [CrossRef]

- Snopiński, P.; Hilšer, O.; Hajnyš, J. Tuning the Defects Density in Additively Manufactured Fcc Aluminium Alloy via Modifying the Cellular Structure and Post-Processing Deformation. Mater. Sci. Eng. A 2023, 865, 144605. [Google Scholar] [CrossRef]

- Karthik, G.M.; Kim, E.S.; Zargaran, A.; Sathiyamoorthi, P.; Jeong, S.G.; Kim, H.S. Role of Cellular Structure on Deformation Twinning and Hetero-Deformation Induced Strengthening of Laser Powder-Bed Fusion Processed CuSn Alloy. Addit. Manuf. 2022, 54, 102744. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Li, J.; Odeshi, A.; Mohammadi, M. Deformation Mechanism during Dynamic Loading of an Additively Manufactured AlSi10Mg_200C. Mater. Sci. Eng. A 2018, 722, 263–268. [Google Scholar] [CrossRef]

- Roth, C.C.; Tancogne-Dejean, T.; Mohr, D. Plasticity and Fracture of Cast and SLM AlSi10Mg: High-Throughput Testing and Modeling. Addit. Manuf. 2021, 43, 101998. [Google Scholar] [CrossRef]

- Snopiński, P. Exploring Microstructure Refinement and Deformation Mechanisms in Severely Deformed LPBF AlSi10Mg Alloy. J. Alloys Compd. 2023, 941, 168984. [Google Scholar] [CrossRef]

- Li, N.; Qiao, S.; Gao, X.; Wang, F.; Wen, X.; Xia, Z.; Wang, Y.; Liu, S.; Jiang, J.; Yuan, C.; et al. Unraveling Dynamic Recrystallization Mechanisms in Ni-Based Wrought Superalloy GH4698 through Comprehensive EBSD Analysis. Mater. Lett. 2025, 378, 137613. [Google Scholar] [CrossRef]

- Yang, Q.; Wojcik, T.; Kozeschnik, E. Continuous Dynamic Recrystallization and Deformation Behavior of an AA1050 Aluminum Alloy during High-Temperature Compression. Metals 2024, 14, 889. [Google Scholar] [CrossRef]

- Lejček, P.; Školáková, A.; Molnárová, O.; Habr, S.; Čapek, J.; Čepová, M.; Málek, P. Development of Microstructure in Aluminum Single Crystal During Complex Shearing of Extruded Tube. Metall. Mater. Trans. A 2024, 55, 3407–3421. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Baxter, C.; Amirkhiz, B.S.; Mohammadi, M. Strengthening Mechanisms in Direct Metal Laser Sintered AlSi10Mg: Comparison between Virgin and Recycled Powders. Addit. Manuf. 2018, 23, 108–120. [Google Scholar] [CrossRef]

- Snopiński, P.; Matus, K.; Tatiček, F.; Rusz, S. Overcoming the Strength-Ductility Trade-off in Additively Manufactured AlSi10Mg Alloy by ECAP Processing. J. Alloys Compd. 2022, 918, 165817. [Google Scholar] [CrossRef]

- Feng, X.; Wang, Y.; Huang, Q.; Liu, H.; Zhang, Z. The Dynamic Recrystallization Microstructure Characteristics and the Effects on Static Recrystallization and Mechanical Properties of Al–Mg–Si Alloy. Mater. Sci. Eng. A 2024, 899, 146454. [Google Scholar] [CrossRef]

- Wei, D.; Han, L.; Lv, Z.; Wang, G.; Zhao, G. Investigation of Constitutive Models and Microstructure Evolution during Hot Deformation and Solution Treatment of Al–Zn–Mg–Cu Alloy. J. Mater. Res. Technol. 2024, 32, 1028–1045. [Google Scholar] [CrossRef]

- Yasnikov, I.S.; Kaneko, Y.; Uchida, M.; Vinogradov, A. The Grain Size Effect on Strain Hardening and Necking Instability Revisited from the Dislocation Density Evolution Approach. Mater. Sci. Eng. A 2022, 831, 142330. [Google Scholar] [CrossRef]

- Kubin, L.; Devincre, B.; Hoc, T. Modeling Dislocation Storage Rates and Mean Free Paths in Face-Centered Cubic Crystals. Acta Mater. 2008, 56, 6040–6049. [Google Scholar] [CrossRef]

- Wang, Z.; Tao, S.; Jian, T.; Jiang, B. Grain Boundary-Induced Stress Localization during Compression Deformation of Polycrystalline 316L Stainless Steel. Appl. Phys. A 2024, 130, 870. [Google Scholar] [CrossRef]

- Bouaziz, O.; Estrin, Y.; Bréchet, Y.; Embury, J.D. Critical Grain Size for Dislocation Storage and Consequences for Strain Hardening of Nanocrystalline Materials. Scr. Mater. 2010, 63, 477–479. [Google Scholar] [CrossRef]

- Záležák, T.; Gadelmeier, C.; Gamanov, S.; Glatzel, U.; Inui, H.; George, E.; Dlouhý, A. Creep strength variations related to grain boundaries in the equiatomic CoCrFeMnNi high-entropy alloy. Scr. Mater. 2024, 249, 116165. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).