Transient Dynamic Analysis of Composite Vertical Tail Structures Under Transportation-Induced Vibration Loads

Abstract

1. Introduction

2. Materials and Testing

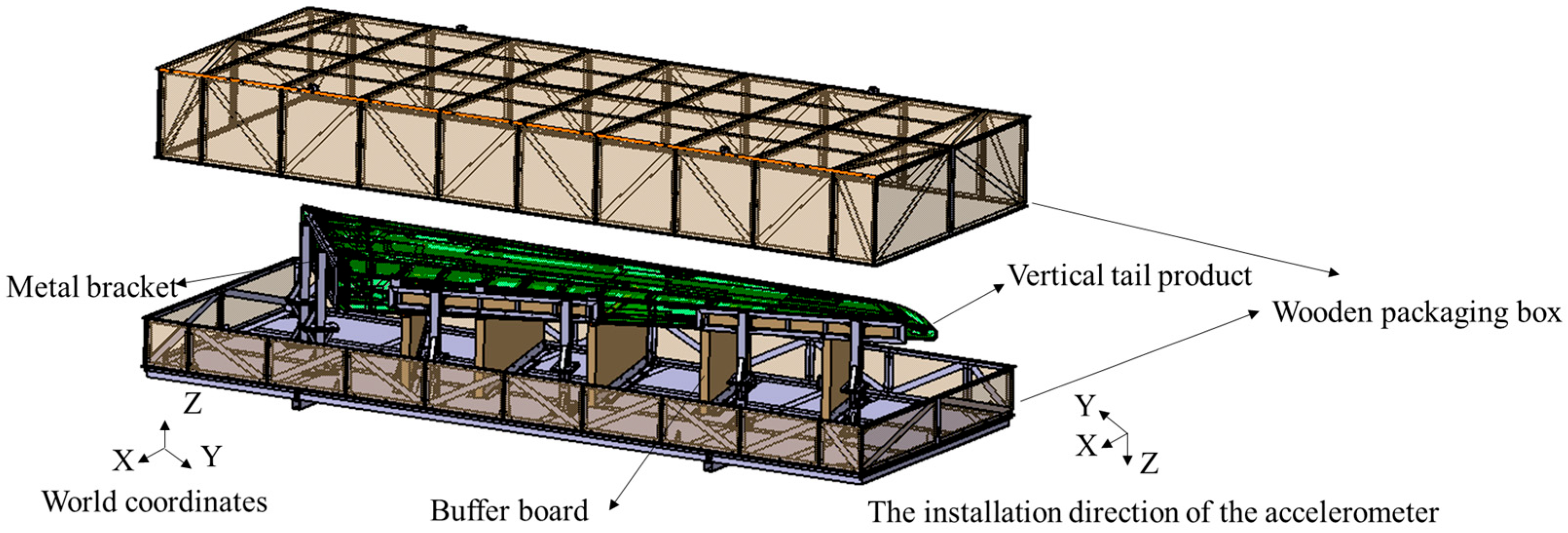

2.1. Geometry Models

2.2. Material Properties

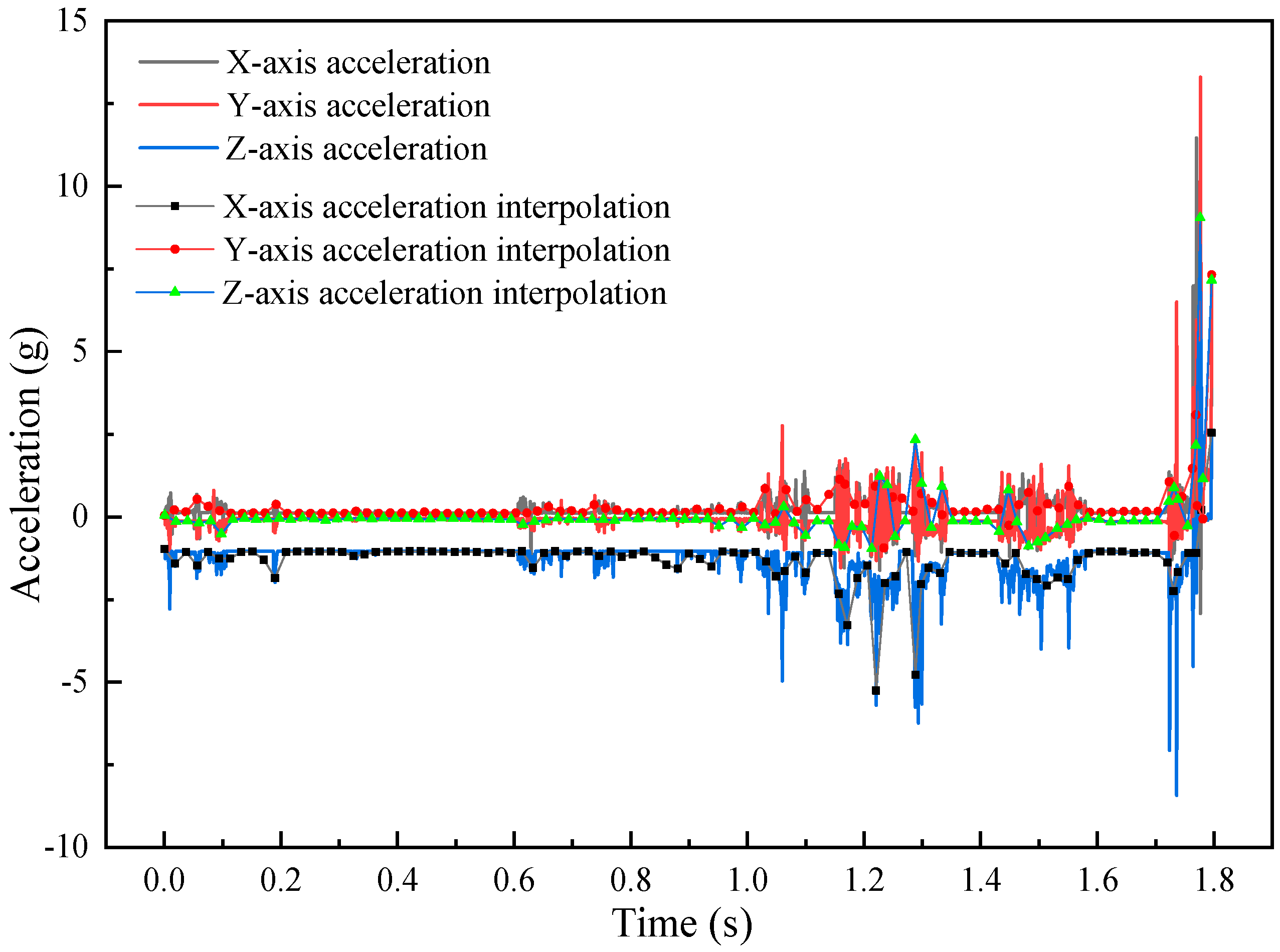

2.3. Transportation Vibration and Shock Testing

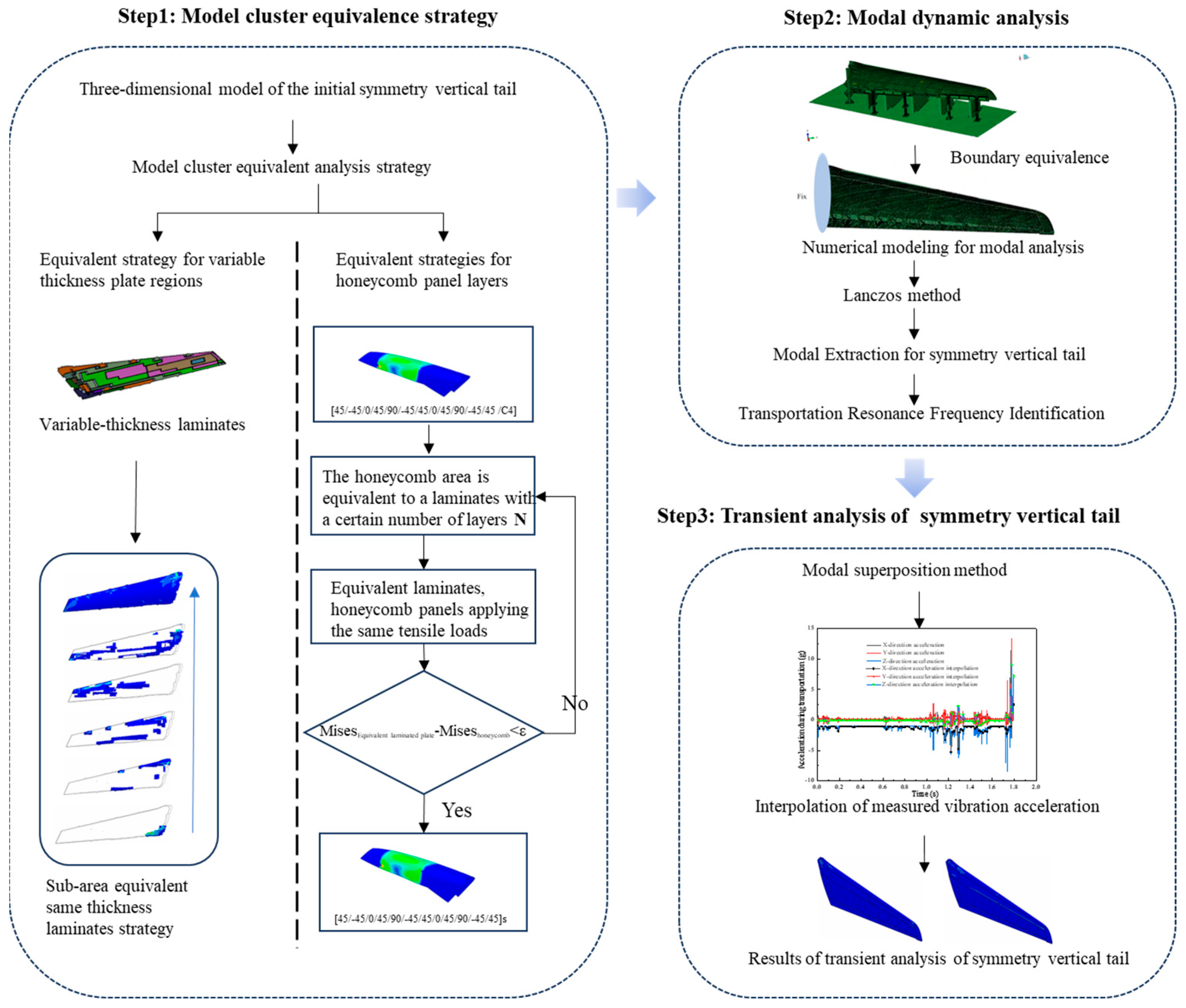

3. Methods and Numerical Modeling

4. Results and Discussion

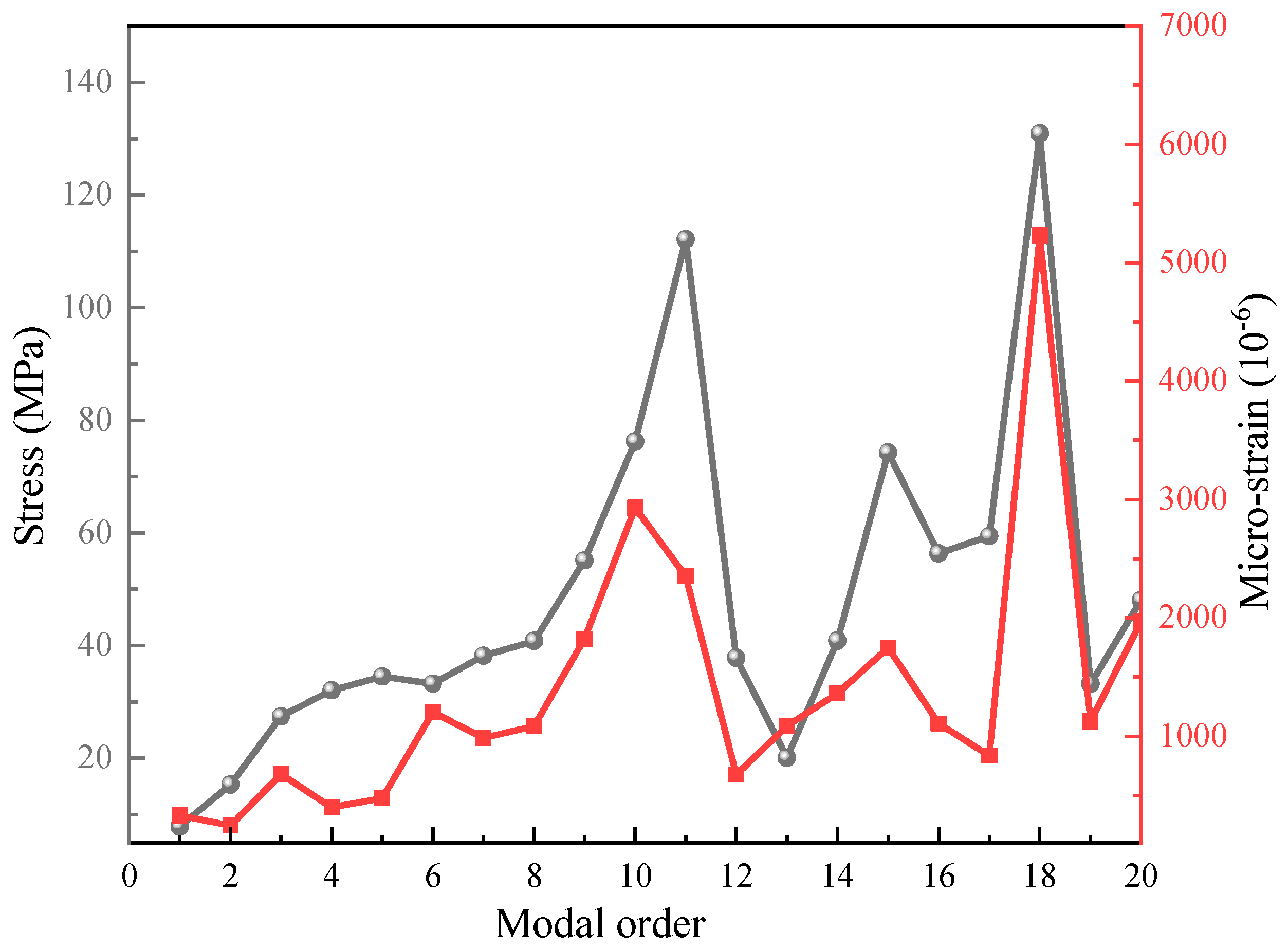

4.1. Modal Analysis

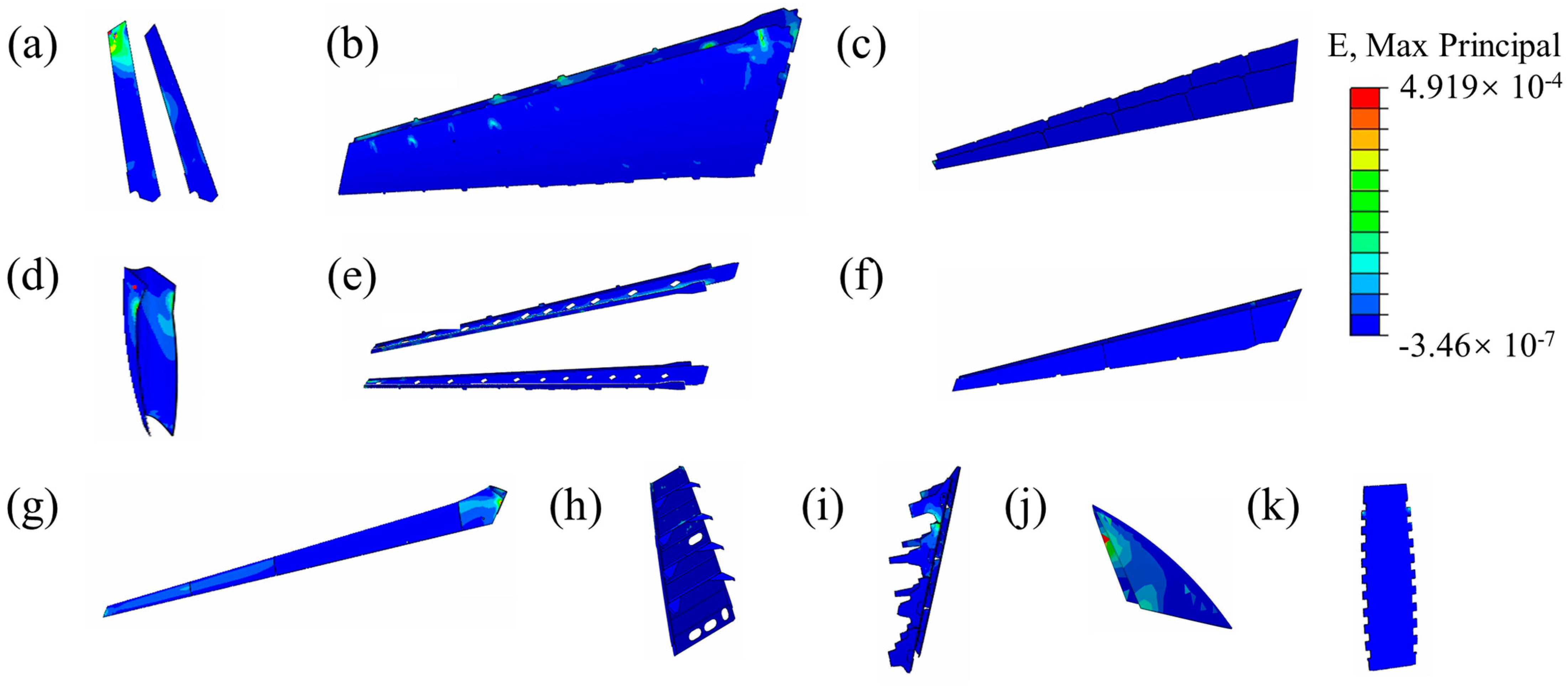

4.2. Transient Dynamics Analysis of SVT

- (1)

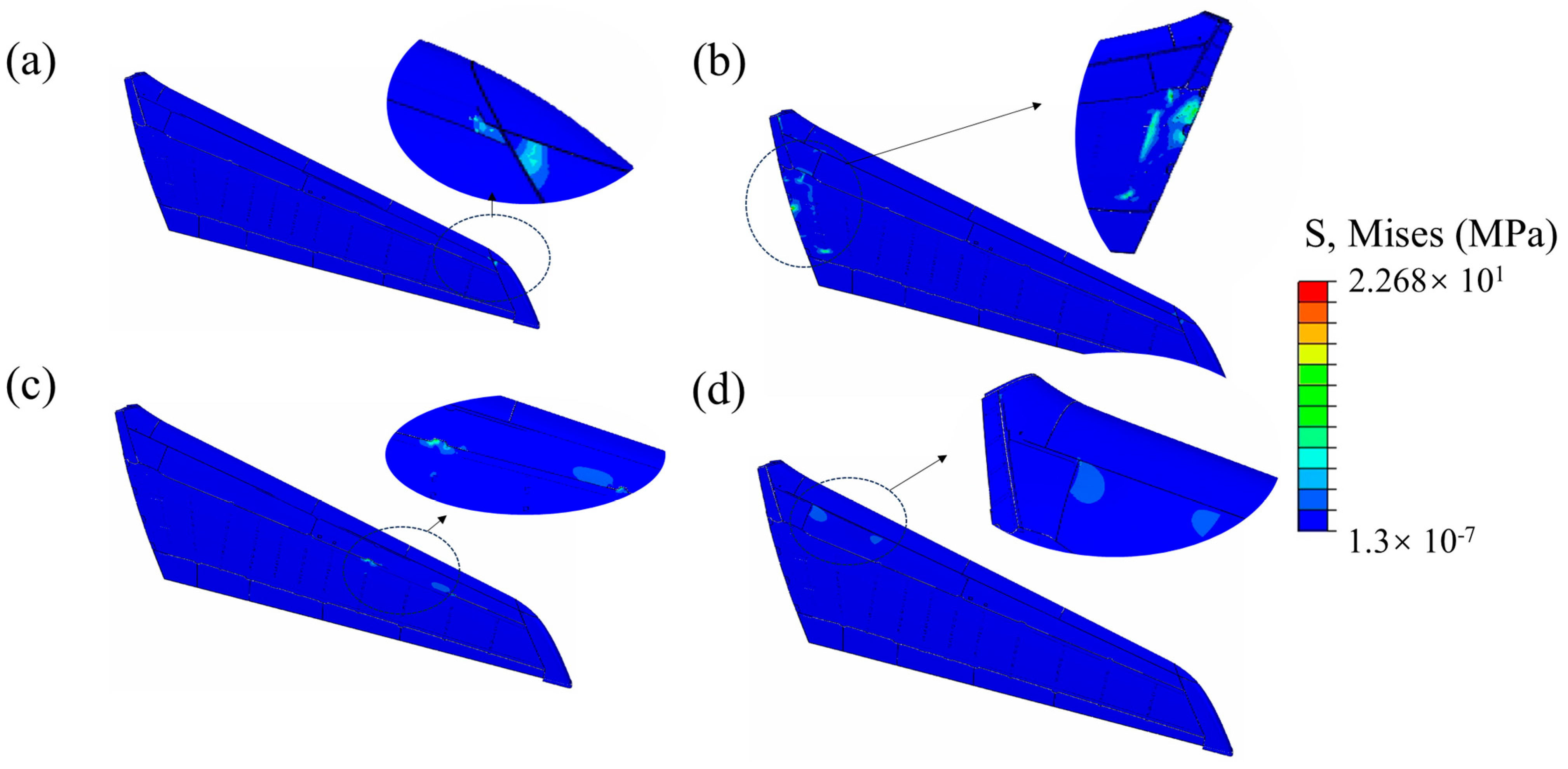

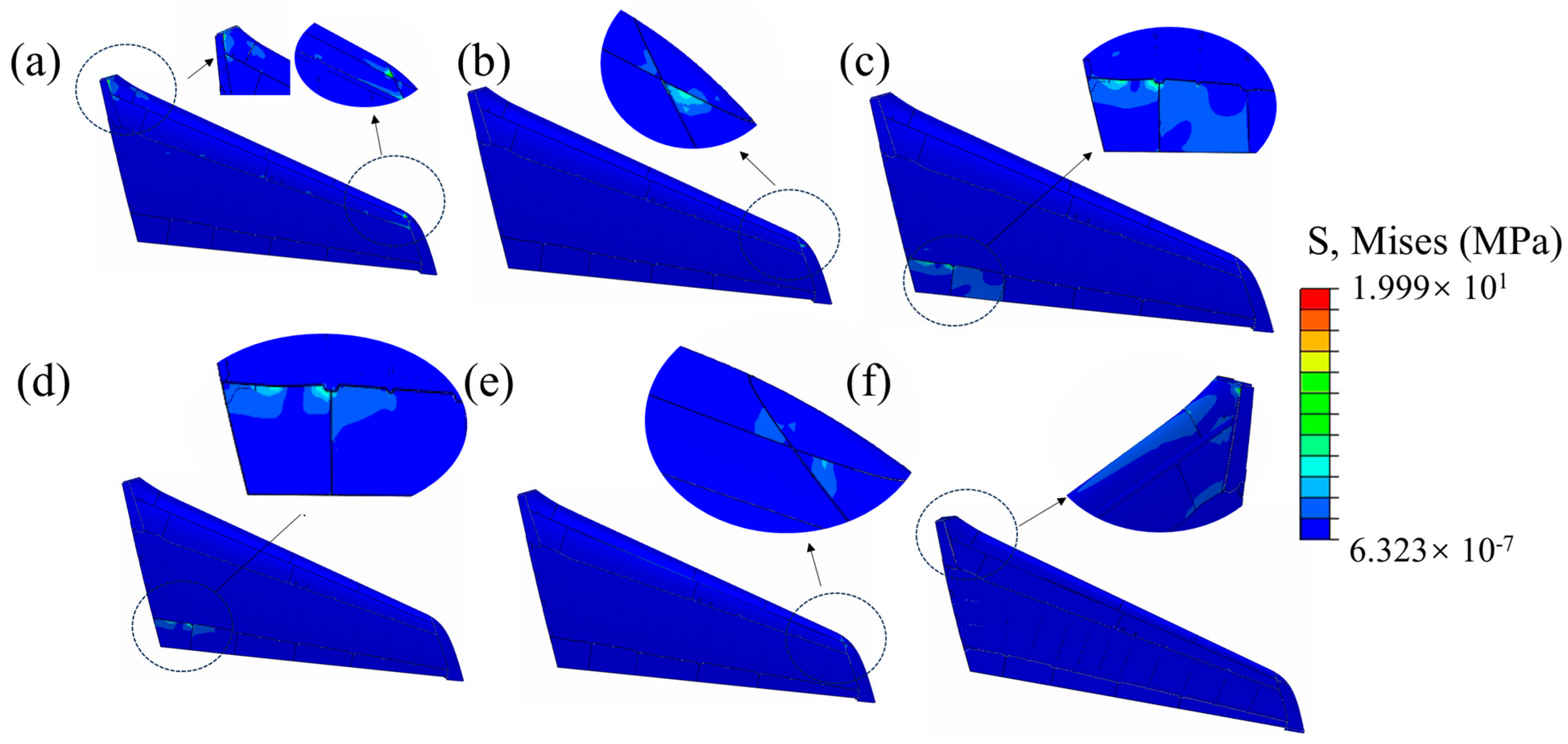

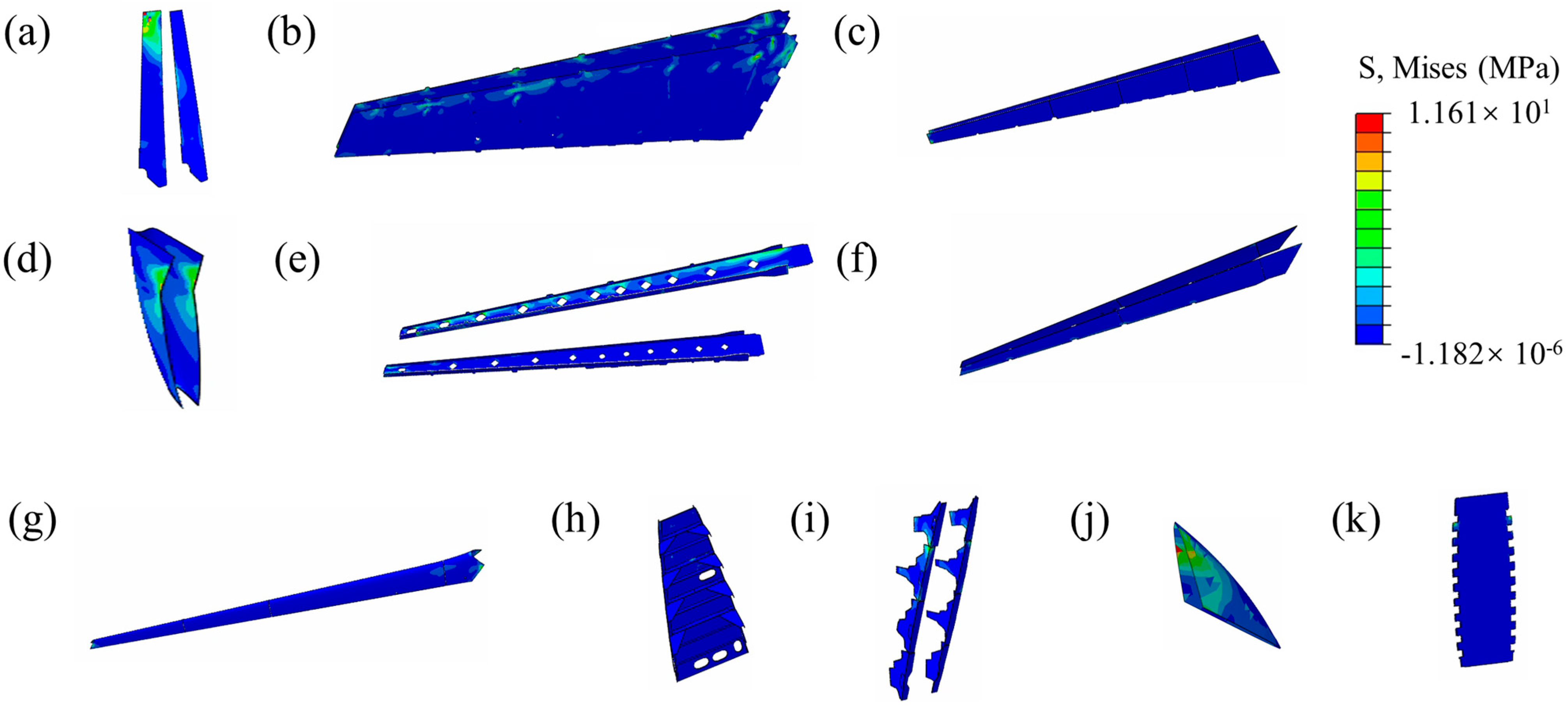

- Stress–strain response to transportation shock

- (2)

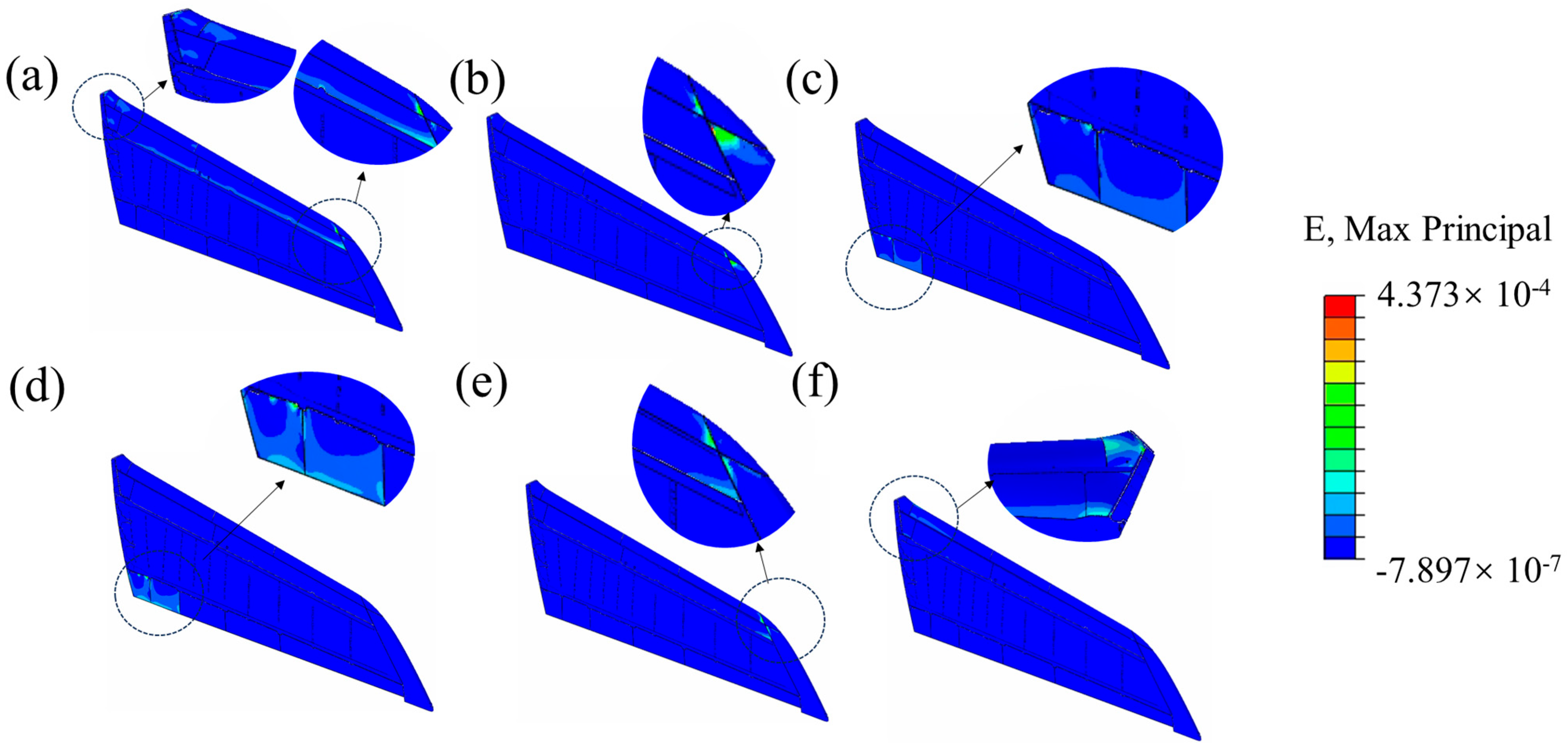

- Interlaminar stress–strain response of typical substructures

- ⮚

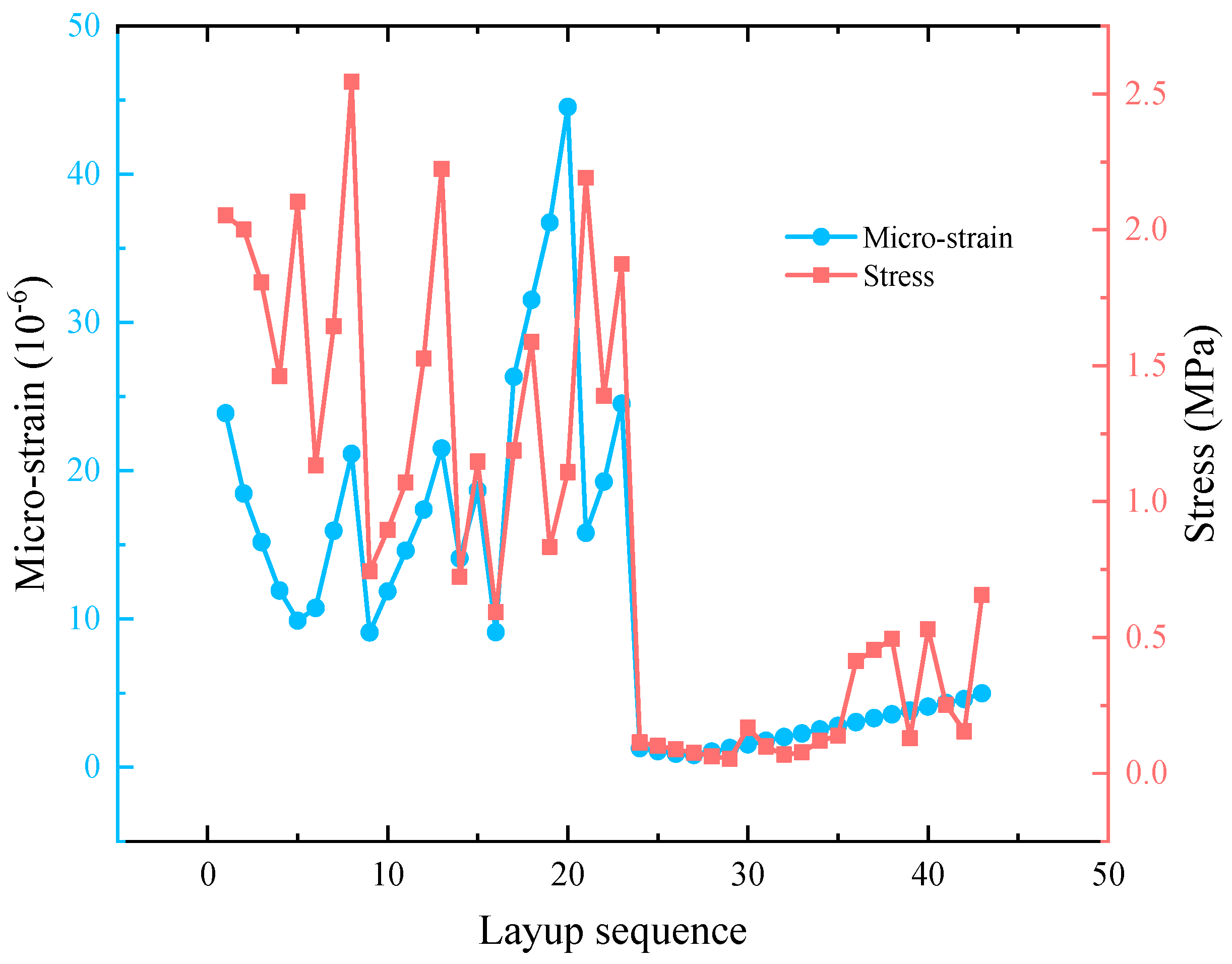

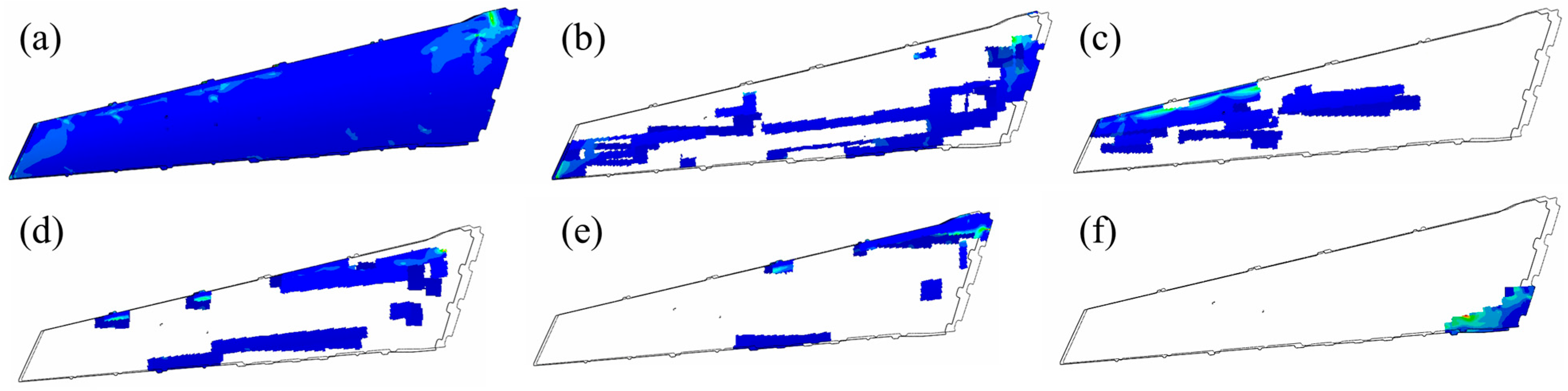

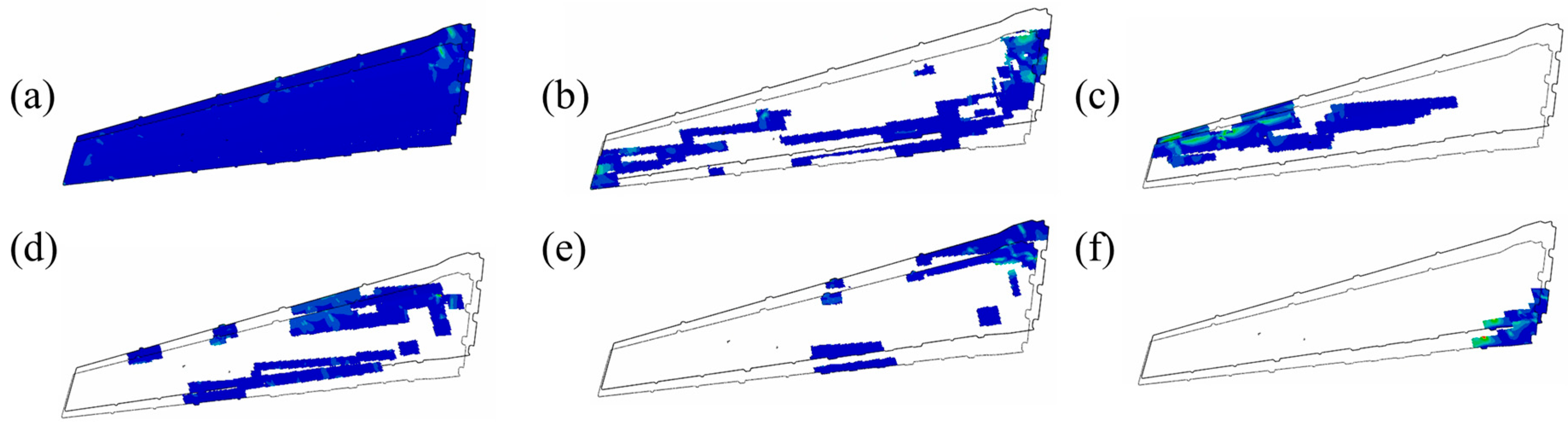

- Interlaminar stress–strain behavior of PCL

- ⮚

- Interlaminar stress–strain behavior in VTL

- ⮚

- Interlaminar stress–strain behavior in HEL

5. Conclusions

- (1)

- The spatial-temporal reconstruction of 100 equivalent acceleration nodes enabled quantitative determination of stress–strain distribution patterns. The SVT dynamic response characterization reveals the critical stress concentration zones, which is helpful to the optimal packaging design and the safe transportation. The SVT vibration modal analysis identified four resonant frequency bands (39.906 Hz, 42.094 Hz, 47.225 Hz, and 59.981 Hz) requiring mitigation of stress concentration.

- (2)

- The transient response assessment obtained using the modal superposition method showed that the peak equivalent stress (11.61 MPa) during transportation is 82% below the threshold stress of land transportation standards. This indicates that the existing packaging solution has sufficient safety margins. Further analysis of the distribution characteristics of typical structural components reveals that by optimizing the stiffness distribution of the cushioning pads in the upper part of the SVT, the stress level in the critical region can be further reduced, which provides a clear direction for packaging improvement.

- (3)

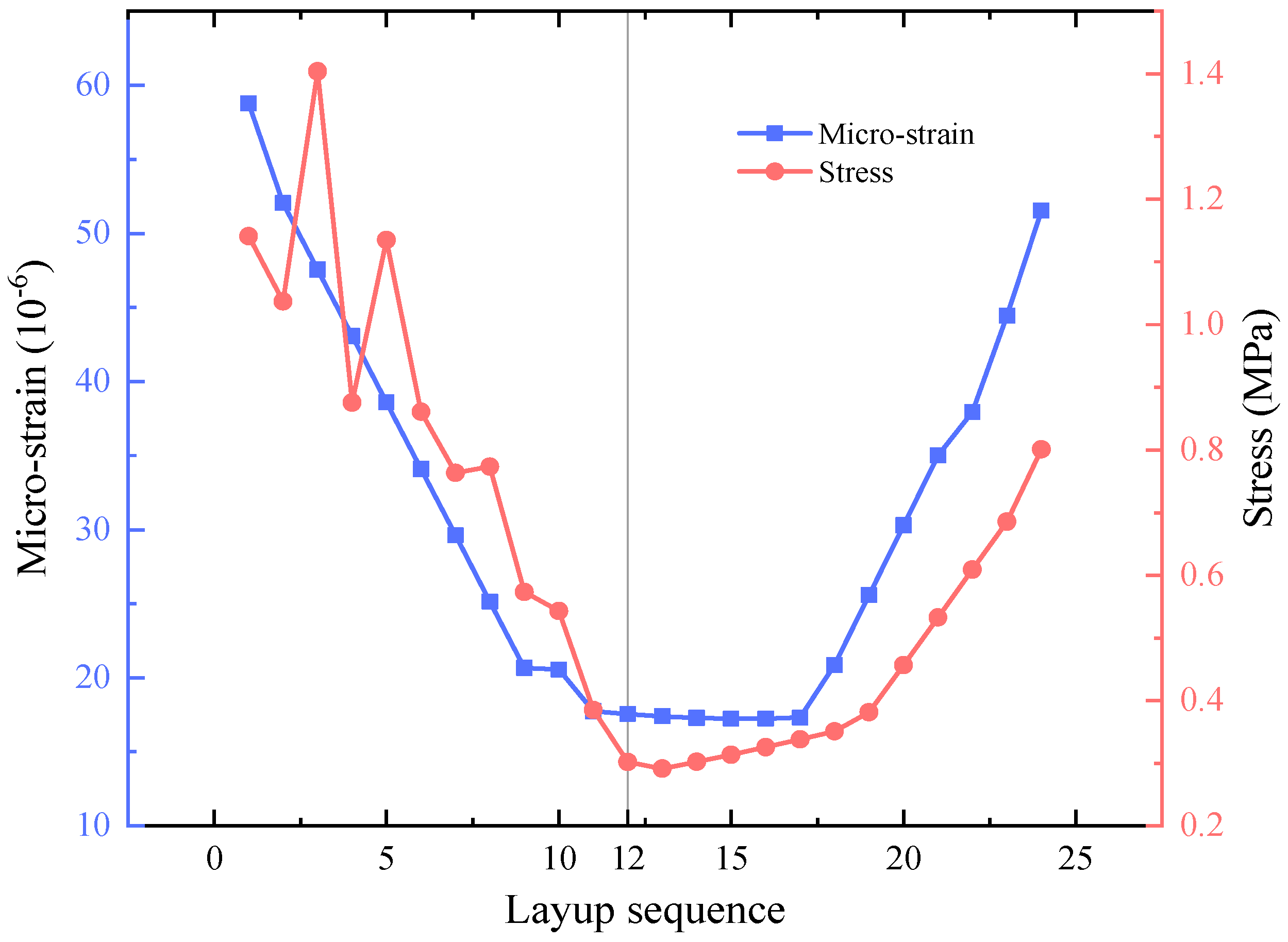

- The stress distribution of a typical composite structure showed a quasi-periodic evolution pattern concerning the layup angle, while the strain response shows non-monotonic characteristics due to the stress redistribution effect of the variable-thickness design. This heterogeneous response mechanism reveals the physical nature of variable-thickness layups to effectively reduce the stress concentration effect and inhibit the strain development by improving the stress transfer path, which provides new theoretical support for the impact-resistant design of composite structures.

- (4)

- The established “load reconstruction-modal synthesis-transient solution” framework can provide fundamental understanding of composite structure transport dynamics, delivers a complete workflow for aviation packaging design, reduces computational costs through model group equivalence, and offers direct applicability to other aerospace transport systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Paternoster, A.; Vanlanduit, S.; Springael, J.; Braet, J. Measurement and Analysis of Vibration and Shock Levels for Truck Transport in Belgium with Respect to Packaged Beer during Transit. Food Packag. Shelf Life 2018, 15, 134–143. [Google Scholar] [CrossRef]

- Gobbato, M.; Conte, J.P.; Kosmatka, J.B.; Farrar, C.R. A Reliability-Based Framework for Fatigue Damage Prognosis of Composite Aircraft Structures. Probabilistic Eng. Mech. 2012, 29, 176–188. [Google Scholar] [CrossRef]

- Lu, F.; Ishikawa, Y.; Shiina, T.; Satake, T. Analysis of Shock and Vibration in Truck Transport in Japan. Packag. Technol. Sci. 2008, 21, 479–489. [Google Scholar] [CrossRef]

- Kuriakose, V.M.; Sreehari, V.M. Experimental Investigation on the Enhancement of Vibration and Flutter Characteristics of Damaged Composite Plates Using Piezoelectric Patches. Compos Struct. 2021, 275, 114518. [Google Scholar] [CrossRef]

- Pagani, A.; Enea, M.; Carrera, E. Component-Wise Damage Detection by Neural Networks and Refined FEs Training. J. Sound Vib. 2021, 509, 116255. [Google Scholar] [CrossRef]

- Luo, L.; Liu, D.; Jiang, Z.; Cheng, D. Research on the Design and Damping Control of Rocket Maritime Transportation Device. J. Phys. Conf. Ser. 2024, 2775, 012023. [Google Scholar] [CrossRef]

- Lepine, J.; Rouillard, V.; Sek, M. On the Use of Machine Learning to Detect Shocks in Road Vehicle Vibration Signals. Packag. Technol. Sci. 2017, 30, 387–398. [Google Scholar] [CrossRef]

- Kitazawa, H.; Li, L.; Hasegawa, N.; Rattanakaran, J.; Saengrayap, R. Evaluation of Shock-Proof Performance of New Cushioning System for Portable Packaging of Apples. Environ. Control. Biol. 2018, 56, 167–172. [Google Scholar] [CrossRef]

- Hasegawa, K. Analysis of Vibration and Shock Occurring in Transport Systems. Packag. Technol. Sci. 1989, 2, 69–74. [Google Scholar] [CrossRef]

- Rouillard, V.; Richmond, R. A Novel Approach to Analysing and Simulating Railcar Shock and Vibrations. Packag. Technol. Sci. 2007, 20, 17–26. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.P.; Joneson, E. Measurement and Analysis of US Truck Vibration for Leaf Spring and Air Ride Suspensions, and Development of Tests to Simulate These Conditions. Packag. Technol. Sci. 2006, 19, 309–323. [Google Scholar] [CrossRef]

- Griffiths, K.R.; Hicks, B.J.; Keogh, P.S.; Shires, D. Wavelet Analysis to Decompose a Vibration Simulation Signal to Improve Pre-Distribution Testing of Packaging. Mech. Syst. Signal Process 2016, 76–77, 780–795. [Google Scholar] [CrossRef]

- Fan, Y.; Xu, B.; Wang, J.; Wu, J.; Liu, Z.; Cai, L. Transport Vibration and Shock Characteristics of A 110 KV/40MVA Vehicular Mobile Transformer. IEEJ Trans. Electr. Electron. Eng. 2022, 17, 1110–1120. [Google Scholar] [CrossRef]

- Paternoster, A.; Vanlanduit, S.; Springael, J.; Braet, J. Vibration and Shock Analysis of Specific Events during Truck and Train Transport of Food Products. Food Packag. Shelf Life 2018, 15, 95–104. [Google Scholar] [CrossRef]

- Hu, R.Z.; Liu, L.; Liu, E.J.; Tu, J.; Yao, X.H.; Song, P.; Zhang, D.Y.; Huang, Z.H.; Chen, T. Biomimetic Hierarchical Composites Inspired by Natural Pomelo Peel for Mechanical-Damage Resistance and Storage of Fruits. Chem. Eng. J. 2024, 485, 149853. [Google Scholar] [CrossRef]

- Lee, W.; Kim, J.; Park, C. Topology Optimization for Polymeric Foam Shock-Absorbing Structure Using Hybrid Cellular Automata. Int. J. Autom. Technol. 2014, 8, 365–375. [Google Scholar] [CrossRef]

- Qu, D.; Liu, X.; Liu, G.; Bai, Y.; He, T. Analysis of Vibration Isolation Performance of Parallel Air Spring System for Precision Equipment Transportation. Meas. Control. 2019, 52, 291–302. [Google Scholar] [CrossRef]

- Huang, X.; Su, J.; Ren, L.; Hua, H. Development of Curved Beam Periodic Structure in Broadband Resonance Suppression for Cylindrical Shell Structure. JVC/J. Vib. Control. 2017, 23, 1267–1284. [Google Scholar] [CrossRef]

- Li, Y.; Wang, K.; Yang, H.; Sun, Y.; Zhang, H.; Xiao, K.; Li, Z.; Li, D.; Li, J. Solid-Liquid Triboelectric Nanogenerator Based Self-Sensing Vibration Device. Nano Energy 2024, 131, 110211. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, K.; Chen, M.Z.Q. Semi-Active Suspensions with Low-Order Mechanical Admittances Incorporating Inerters. In Proceedings of the 2015 27th Chinese Control and Decision Conference, CCDC 2015, Qingdao, China, 23–25 May 2015. [Google Scholar]

- He, F.; Du, J.; Liu, Y. The Bio-Inspired Spider Web Dynamic Vibration Absorber Applied to the transverse-Torsional-Axial Vibration in Rotor Systems. Mech. Syst. Signal Process 2025, 237, 112993. [Google Scholar] [CrossRef]

- Kakou, P.; Barry, O. Simultaneous Vibration Reduction and Energy Harvesting of a Nonlinear Oscillator Using a Nonlinear Electromagnetic Vibration Absorber-Inerter. Mech. Syst. Signal Process 2021, 156, 107607. [Google Scholar] [CrossRef]

- Joubaneh, E.F.; Barry, O.R. On the Improvement of Vibration Mitigation and Energy Harvesting Using Electromagnetic Vibration Absorber-Inerter: Exact H2 Optimization. J. Vib. Acoust. 2019, 141, 061007. [Google Scholar] [CrossRef]

- Liu, C.; Chen, L.; Lee, H.P.; Yang, Y.; Zhang, X. A Review of the Inerter and Inerter-Based Vibration Isolation: Theory, Devices, and Applications. J. Franklin Inst. 2022, 359, 7677–7707. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Ryu, C.-H.; Kim, H.-S.; Choi, Y.-J. A Study on the Free Drop Impact of a Cask Using Commercial FEA Codes. Nucl. Eng. Des. 2005, 235, 2219–2226. [Google Scholar] [CrossRef]

- Bernad, C.; Laspalas, A.; González, D.; Liarte, E.; Jiménez, M.A. Dynamic Study of Stacked Packaging Units by Operational Modal Analysis. Packag. Technol. Sci. 2010, 23, 121–133. [Google Scholar] [CrossRef]

- Kim, W.-J.; Kum, D.-H.; Park, S.-H. Effective Design of Cushioning Package to Improve Shockproof Characteristics of Large-Sized Home Appliances. Mech. Based Des. Struc. 2009, 37, 1–14. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, X. Study on Damage Analysis and Random Vibration Detection of Transportation Goods. In Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2018; Volume 477. [Google Scholar]

- Pan, X.; Lin, Y.; Liu, X.; Han, Y. Design and Implementation of a Vibration Measurement and Analysis System for Spacecraft Road Transportation. In Proceedings of the 6th International Conference on Traffic Engineering and Transportation System (ICTETS 2022), Guangzhou, China, 23–25 September 2022; p. 1259101. [Google Scholar] [CrossRef]

- Wunderlich, T.F.; Dähne, S.; Reimer, L.; Schuster, A. Global Aerostructural Design Optimization of More Flexible Wings for Commercial Aircraft. J. Aircr. 2021, 58, 6. [Google Scholar] [CrossRef]

- Kennedy, G.J.; Martinsy, J.R.R.A. A Comparison of Metallic and Composite Aircraft Wings Using Aerostructural Design Optimization. In Proceedings of the 12th AIAA Aviation Technology, Integration and Operations (ATIO) Conference and 14th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Indianapolis, IN, USA, 17–19 September 2012. [Google Scholar]

- Ma, Y.; Abouhamzeh, M.; Elham, A. Geometrically Nonlinear Coupled Adjoint Aerostructural Optimization of Natural-Laminar-Flow Strut-Braced Wing. J. Aircr. 2023, 60, 3. [Google Scholar] [CrossRef]

- Krupa, E.P.; Cooper, J.E.; Pirrera, A.; Nangia, R. Improved Aerostructural Performance via Aeroservoelastic Tailoring of a Composite Wing. Aeronaut. J. 2018, 122, 1442–1474. [Google Scholar] [CrossRef]

- Brooks, T.R.; Martins, J.R.R.A.; Kennedy, G.J. Aerostructural Tradeoffs for Tow-Steered Composite Wings. J Aircr. 2020, 57, 5. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, X.; He, Y.; Yang, S.; Chen, S.; Zhang, S.; Zhou, D. CFRP Barely Visible Impact Damage Inspection Based on an Ultrasound Wave Distortion Indicator. Compos. B Eng. 2019, 168, 152–158. [Google Scholar] [CrossRef]

- Wanhill, R.J.H.; Molent, L.; Barter, S.A. Milestone Case Histories in Aircraft Structural Integrity. In Comprehensive Structural Integrity; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural Fiber–Reinforced Composites: A Review on Material, Manufacturing, and Machinability. J. Thermoplast. Compos. Mater. 2021, 34, 089270571984454. [Google Scholar] [CrossRef]

- Nauman, S. Piezoresistive Sensing Approaches for Structural Health Monitoring of Polymer Composites—A Review. Eng 2021, 2, 197–226. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Lee, J.; Megat-Yusoff, P.S.M.; Hussain, S.Z.; Sharif, T.; Choudhry, R.S. Multiscale Damage Modelling of Notched and Un-Notched 3D Woven Composites with Randomly Distributed Manufacturing Defects. Compos Struct. 2023, 318, 117109. [Google Scholar] [CrossRef]

- Mendoza, E.A.; Prohaska, J.P.; Kempen, C.; Esterkin, Y.; Sunjian, S. Fiber Optic Acousto-Ultrasound Condition Monitoring System for Advanced Structures. In Proceedings of the SHMII 2015—7th International Conference on Structural Health Monitoring of Intelligent Infrastructure, Torino, Italy, 1–3 July 2015. [Google Scholar]

- Shipunov, G.S.; Baranov, M.A.; Nikiforov, A.S.; Golovin, D.V.; Tihonova, A.A. Study Smart-Layer Effect on the Physical and Mechanical Characteristics of the Samples from Polymer Composite Materials under Quasi-Static Loading. PNRPU Mech. Bull. 2020, 2020, 188–200. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Zhong, S.; Lee, T.L.; Fancey, K.S.; Mi, J. Non-Destructive Testing and Evaluation of Composite Materials/Structures: A State-of-the-Art Review. arXiv 2020, arXiv:2002.12201. [Google Scholar] [CrossRef]

- Huang, S.; Geng, Y.; Han, Y.; Gu, M. Design of Shocks & Vibrations Monitoring System for Long Distance Transportation in Confined Spaces. In Proceedings of the 2023 China Automation Congress (CAC), Chongqing, China, 17–19 November 2023; pp. 4886–4892. [Google Scholar]

- ASTM D4169-23; Standard Practice for Performance Testing of Shipping Containers and Systems. ASTM International: West Conshohocken, PA, USA, 2023.

- Kumar, M.; Kar, V.R.; Chandravanshi, M.L. Free Vibration Analysis of Sandwich Composite Plate with Honeycomb Core. Mater. Today Proc. 2022, 56, 931–935. [Google Scholar] [CrossRef]

- Rezaiee-Pajand, M.; Sarmadi, H.; Entezami, A. A Hybrid Sensitivity Function and Lanczos Bidiagonalization-Tikhonov Method for Structural Model Updating: Application to a Full-Scale Bridge Structure. Appl. Math. Model. 2021, 89, 860–884. [Google Scholar] [CrossRef]

- Tieming, X.; Shuiting, Z.; Liao, Y. Free Modal Analysis for Spiral Bevel Gear Wheel Based on the Lanczos Method. Open Mech. Eng. J. 2015, 9, 637–645. [Google Scholar] [CrossRef]

- Dassault Systèmes. Abaqus Analysis User’s Guide: Analysis Volume; Dassault Systèmes: Paris, France, 2021. [Google Scholar]

| Name | ρ/(kg/m3) | E/(N/m2) | v |

|---|---|---|---|

| Metal | 2.7 × 103 | 6.9 ×1010 | 0.33 |

| Flakeboard | 4 × 102 | 9.8 × 109 | 0.35 |

| Bufferboard | 1 × 103 | 6.1 × 106 | 0.49 |

| Name | Stacking Sequence |

|---|---|

| Plain composite laminates (PCL) | [45/−45/0/45/90/−45/45/0/−45/90/45/−45/−45/−45/−45/−45/45] |

| Variable-thickness laminates (VTL) | [45/90/90/−45/0/−45/0/−45/45/45/90/−45/−45/−45/013/−45/05/−45/0/0/45/0/0/45/−45/−45/45] |

| Aramid honeycomb sandwich | [45/−45/0/45/90/−45/45/0/45/90/−45/45] |

| Name | Ex/GPa | Ey/GPa | Ez/GPa | Gxy/GPa | Gxz/GPa | Gyz/GPa | Vxy |

|---|---|---|---|---|---|---|---|

| CFRP | 120 | 8.9 | 8.9 | 4.53 | 4.53 | 4.53 | 0.32 |

| Name | XT/MPa | XC/MPa | YT/MPa | YC/MPa | ZT/MPa | ZC/MPa | Sxy/MPa | Sxz/MPa | Syz/MPa |

|---|---|---|---|---|---|---|---|---|---|

| CFRP | 2380 | 1236 | 216 | 133 | 216 | 133 | 133 | 86 | 200 |

| Name | Grid Material Thickness/mm | Grid Length/mm | T-Directional Modulus/MPa | L-Directional Modulus/MPa | W-Directional Modulus/MPa | L-Directional Shear Strength/MPa | W-Directional Shear Strength/MPa |

|---|---|---|---|---|---|---|---|

| Aramid honeycomb | 0.084 | 2.75 | 4.48 | 15.17 | 31.03 | 0.62 | 0.66 |

| Modal Order | Frequency (Hz) | Effective Mass Fraction | |||||

|---|---|---|---|---|---|---|---|

| X-Flat | Y-Flat | Z-Flat | X-Turn | Y-Turn | Z-Turn | ||

| 1 | 9.0452 | 1.34 × 10−7 | 1.65 × 10−8 | 4.34 × 10−2 | 5.31 × 105 | 5.85 × 107 | 18.693 |

| 2 | 16.476 | 1.34 × 10−2 | 9.52 × 10−3 | 9.42 × 10−8 | 1.8007 | 140.01 | 1.78 × 107 |

| 3 | 24.901 | 9.64 × 10−8 | 9.00 × 10−10 | 1.77 × 10−2 | 1.58 × 105 | 2.60 × 107 | 7.3503 |

| 4 | 25.256 | 2.87 × 10−5 | 6.35 × 10−7 | 2.86 × 10−5 | 252.99 | 41,797 | 1867.4 |

| 5 | 25.759 | 1.27 × 10−6 | 1.56 × 10−6 | 1.28 × 10−3 | 4052.4 | 1.59 × 106 | 3374.5 |

| 6 | 29.389 | 8.32 × 10−5 | 1.86 × 10−5 | 8.35 × 10−3 | 1.52 × 105 | 1.20 × 107 | 56,150 |

| 7 | 31.573 | 6.12 × 10−5 | 5.08 × 10−5 | 3.38 × 10−2 | 7.43 × 105 | 4.95 × 107 | 1.03 × 105 |

| 8 | 32.691 | 3.76 × 10−6 | 1.65 × 10−7 | 4.56 × 10−2 | 7.53 × 105 | 6.55 × 107 | 659.21 |

| 9 | 36.57 | 1.79 × 10−5 | 8.20 × 10−6 | 1.40 × 10−2 | 4.69 × 105 | 2.16 × 107 | 23,295 |

| 10 | 37.039 | 1.82 × 10−6 | 1.03 × 10−5 | 6.62 × 10−3 | 1.89 × 105 | 1.00 × 107 | 13,985 |

| 11 | 39.906 | 1.08 × 10−5 | 1.31 × 10−6 | 4.72 × 10−2 | 2.47 × 105 | 6.60 × 107 | 67.868 |

| 12 | 42.094 | 1.54 × 10−5 | 5.44 × 10−7 | 0.26379 | 3.59 × 106 | 3.86 × 108 | 290.97 |

| 13 | 45.362 | 1.37 × 10−6 | 2.00 × 10−8 | 2.20 × 10−3 | 27,981 | 3.14 × 106 | 34.003 |

| 14 | 45.434 | 1.76 × 10−6 | 5.70 × 10−8 | 4.41 × 10−3 | 56,916 | 6.31 × 106 | 9.7166 |

| 15 | 47.225 | 7.21 × 10−7 | 3.96 × 10−6 | 3.39 × 10−4 | 3790.3 | 5.00 × 105 | 723.14 |

| 16 | 53.528 | 6.71 × 10−4 | 3.16 × 10−4 | 3.23 × 10−4 | 12,441 | 4.99 × 105 | 9.97 × 105 |

| 17 | 55.737 | 1.46 × 10−3 | 9.56 × 10−4 | 3.77 × 10−5 | 456.57 | 52,979 | 2.66 × 106 |

| 18 | 59.981 | 5.45 × 10−5 | 1.79 × 10−5 | 7.80 × 10−5 | 588.49 | 1.08 × 105 | 35,943 |

| 19 | 65.175 | 2.19 × 10−5 | 8.42 × 10−6 | 1.68 × 10−3 | 168.09 | 1.97 × 106 | 18,513 |

| 20 | 65.524 | 2.26 × 10−5 | 1.69 × 10−5 | 1.14 × 10−4 | 35,069 | 2.38 × 105 | 34,218 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, W.; Yang, W.; Li, S.; Wang, D.; Yu, W.; Xing, Z.; Pang, L.; Lei, Z.; Wang, Y. Transient Dynamic Analysis of Composite Vertical Tail Structures Under Transportation-Induced Vibration Loads. Symmetry 2025, 17, 1182. https://doi.org/10.3390/sym17081182

Zheng W, Yang W, Li S, Wang D, Yu W, Xing Z, Pang L, Lei Z, Wang Y. Transient Dynamic Analysis of Composite Vertical Tail Structures Under Transportation-Induced Vibration Loads. Symmetry. 2025; 17(8):1182. https://doi.org/10.3390/sym17081182

Chicago/Turabian StyleZheng, Wei, Wubing Yang, Sen Li, Dawei Wang, Weidong Yu, Zhuang Xing, Lan Pang, Zhenkun Lei, and Yingming Wang. 2025. "Transient Dynamic Analysis of Composite Vertical Tail Structures Under Transportation-Induced Vibration Loads" Symmetry 17, no. 8: 1182. https://doi.org/10.3390/sym17081182

APA StyleZheng, W., Yang, W., Li, S., Wang, D., Yu, W., Xing, Z., Pang, L., Lei, Z., & Wang, Y. (2025). Transient Dynamic Analysis of Composite Vertical Tail Structures Under Transportation-Induced Vibration Loads. Symmetry, 17(8), 1182. https://doi.org/10.3390/sym17081182