1. Introduction

Recent advances in sheet metal forming (SMF) have primarily focused on improving the ability to shape materials, creating more complex designs, and streamlining production processes [

1]. One notable trend is the growing adoption of nontraditional forming techniques, such as hydroforming, which are particularly effective for lightweight materials used in the automotive and aerospace industries. To meet the challenging demands for improved performance, reduced energy consumption, and higher safety standards, advanced materials like high-strength steels and lightweight alloys are increasingly being utilized [

2]. Key process parameters such as the radius of the punch nose, the temperature of the blank, and the applied blank holding force play a critical role in determining product quality [

3]. Researchers are working to address common challenges like spring-back, wrinkling, and tearing through experimental methods and advanced simulations. Computer-aided engineering (CAE) tools, particularly those based on finite element analysis (FEA), are now essential in designing tools and optimizing processes. Additionally, there is a growing emphasis on the environmental sustainability of SMF, with a particular focus on tribology [

4].

Hydroforming is an advanced metal forming process that stands out for its ability to produce complex components with fewer operations, lighter weights, and improved stiffness [

5]. This technology has seen rapid growth, especially in the automotive and aerospace industries, where materials like aluminum and titanium alloys are highly sought after. Significant strides have been made in shell, tube, and sheet hydroforming, with ongoing research focusing on innovative techniques and process optimization to enhance both performance and efficiency [

6].

The effectiveness of hydroforming depends on key factors such as the material’s properties, preform geometry, lubrication, and precise control of the process [

7]. While the technology offers clear advantages, it is still relatively new, with researchers addressing limitations and exploring its potential for broader applications. Studies have shown that hydroforming improves metal flow and minimizes thinning in critical areas, outperforming conventional deep drawing methods [

8,

9,

10]. Tools like forming limit diagrams (FLDs) and simulations are essential for predicting formability, while factors such as axial feed conditions and temperature significantly affect fracture behavior and material performance, especially for aluminum alloys [

11,

12,

13,

14].

Finite element (FE) simulations play a crucial role in designing and optimizing hydroforming processes, providing accurate predictions for spring-back and final component shapes [

15,

16]. Advanced models, like the 3D nonlinear FE approach developed by Achuthankutty et al. [

17], effectively simulate material flow in sheet hydroforming using the arbitrary Lagrangian-Eulerian (ALE) method. These advancements highlight hydroforming’s potential to enhance formability and precision for various materials, supporting its broader adoption across industries.

Shell hydroforming (SHF) enables the efficient production of thin-walled, complex components with a uniform thickness and high surface quality [

18,

19]. Researchers have focused on optimizing parameters like fluid pressure and blank size through finite element simulations and experimental studies [

20]. Recent innovations include lower-pressure hydroforming for tubular components, double-sided pressure hydroforming for sheets, and dieless hydroforming for ellipsoidal shells. Warm forming methods have further improved the formability of high-strength aluminum alloys, though challenges with surface quality persist [

19].

SHF, also known as integral hydro bulge forming (IHBF) technology, is especially suited for producing thin, large elliptical pressure vessel heads in small batches or with varying dimensions. Improved forming stability can be achieved using a high-stiffness ring with a fixed boundary and increased thickness [

21]. An innovative approach using circular plates with different thicknesses has shown better formability than conventional deep drawing, enabling the production of semi-ellipsoid shells with specific thickness ratios and minimal thinning [

22]. The process begins with plastic deformation at the center of a flat blank, where the radius is infinite, and continues outward toward regions with larger curvatures. This sequence is repeated until the shell reaches a uniform spherical shape or fractures [

23]. Further research into shell hydroforming has explored spherical shells with different preform types. Zhang et al. [

24] studied deformation behaviors and roundness issues, offering valuable insights into shaping complex geometries.

Building on previous advancements, our current research focuses on the numerical modeling and experimental evaluation of the shell hydroforming process, specifically for AA5052 aluminum alloy. Known for its excellent formability and impressive strength-to-weight ratio, AA5052 is a popular choice in automotive, marine, and aerospace applications [

25,

26].

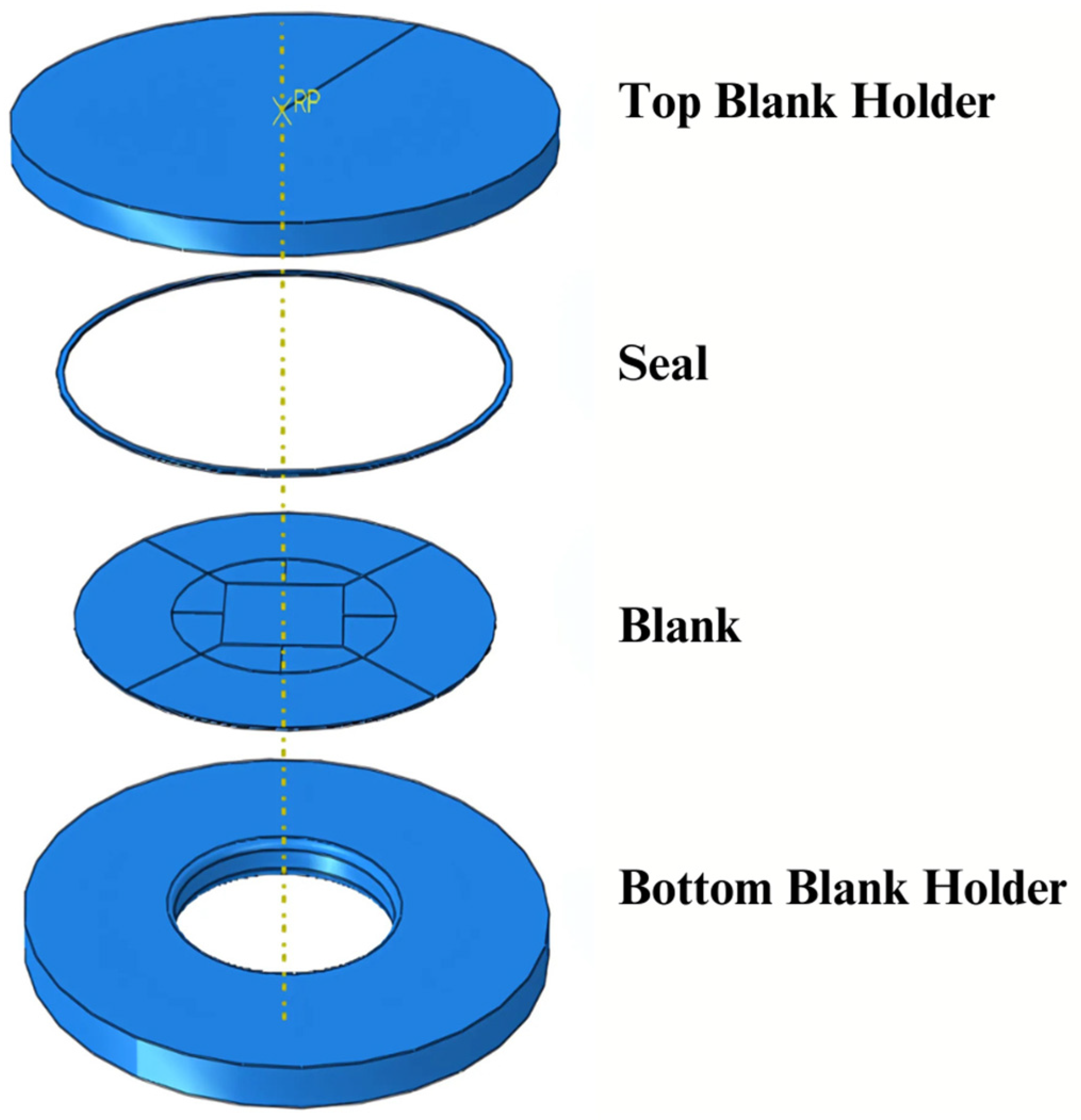

Figure 1 illustrates the shell hydroforming process, showcasing its mechanisms and potential for efficiently producing complex structures.

While several studies have explored SHF for forming aluminum alloys, most focus on general behavior under fixed loading conditions or do not incorporate a validated numerical model combined with optimization techniques. For instance, Zhang et al. [

24] investigated deformation and roundness in spherical shells but did not address thinning control or process optimization. Similarly, studies using AA5XXX series alloys often concentrate on sheet or tube hydroforming, with limited application to dieless shell forming scenarios. The current study distinguishes itself by targeting AA5052, a widely used alloy in lightweight applications, and integrating experimental validation, FE modeling, and multi-objective optimization, specifically aiming to minimize thinning while achieving a target dome height. This combination, especially in a dieless forming set-up, is not addressed in the prior SHF literature, making the present work a significant contribution to the advancement of SHF for AA5XXX alloys.

Despite significant advancements in hydroforming, particularly in tube and sheet hydroforming, shell hydroforming (SHF) remains relatively underexplored, especially in terms of process optimization, deformation prediction, and defect control. Existing studies often rely on traditional die-based methods, which are costly and inflexible, making them unsuitable for low-volume production or complex geometries. Additionally, the absence of robust numerical models and validated experimental data in SHF limits the ability to predict key outcomes such as thinning, the dome height, and wrinkle formation with high accuracy.

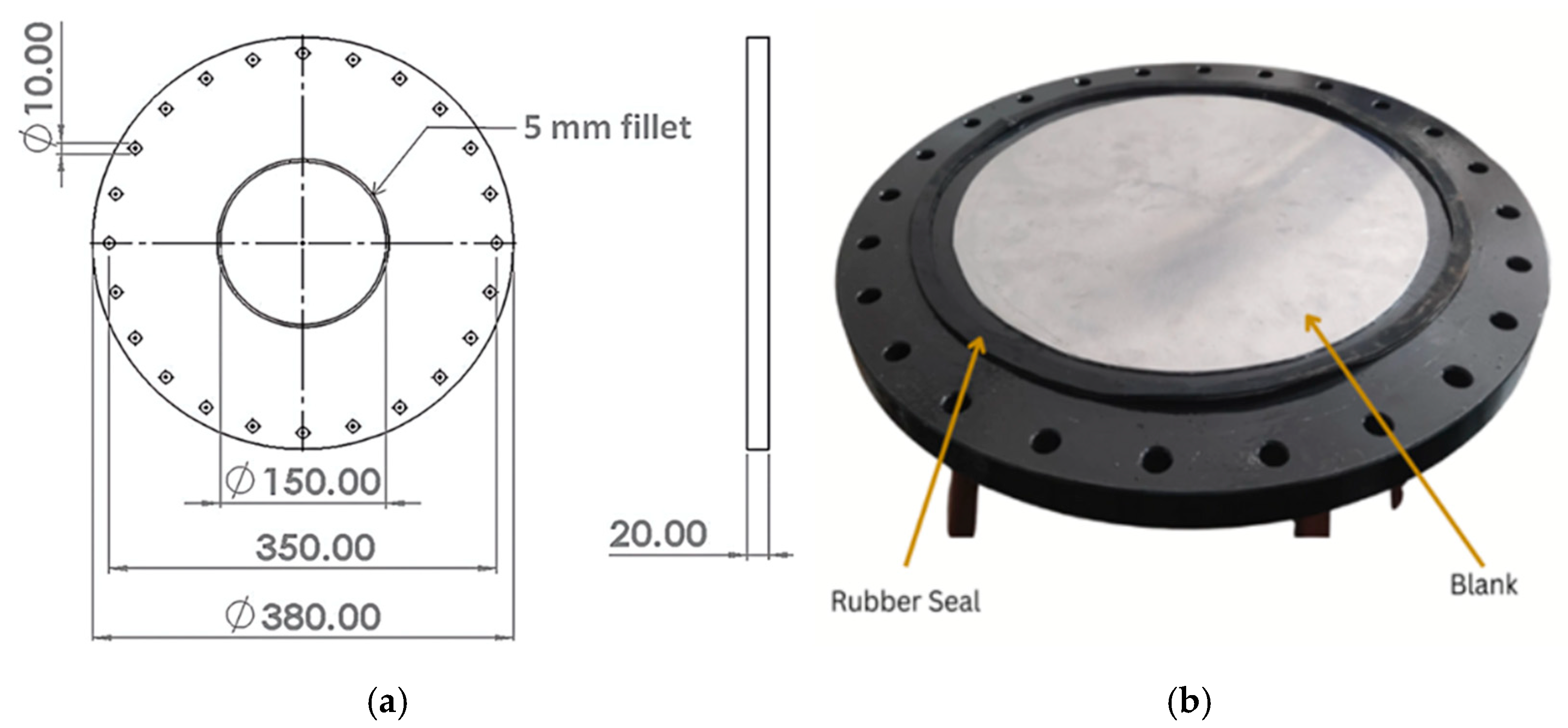

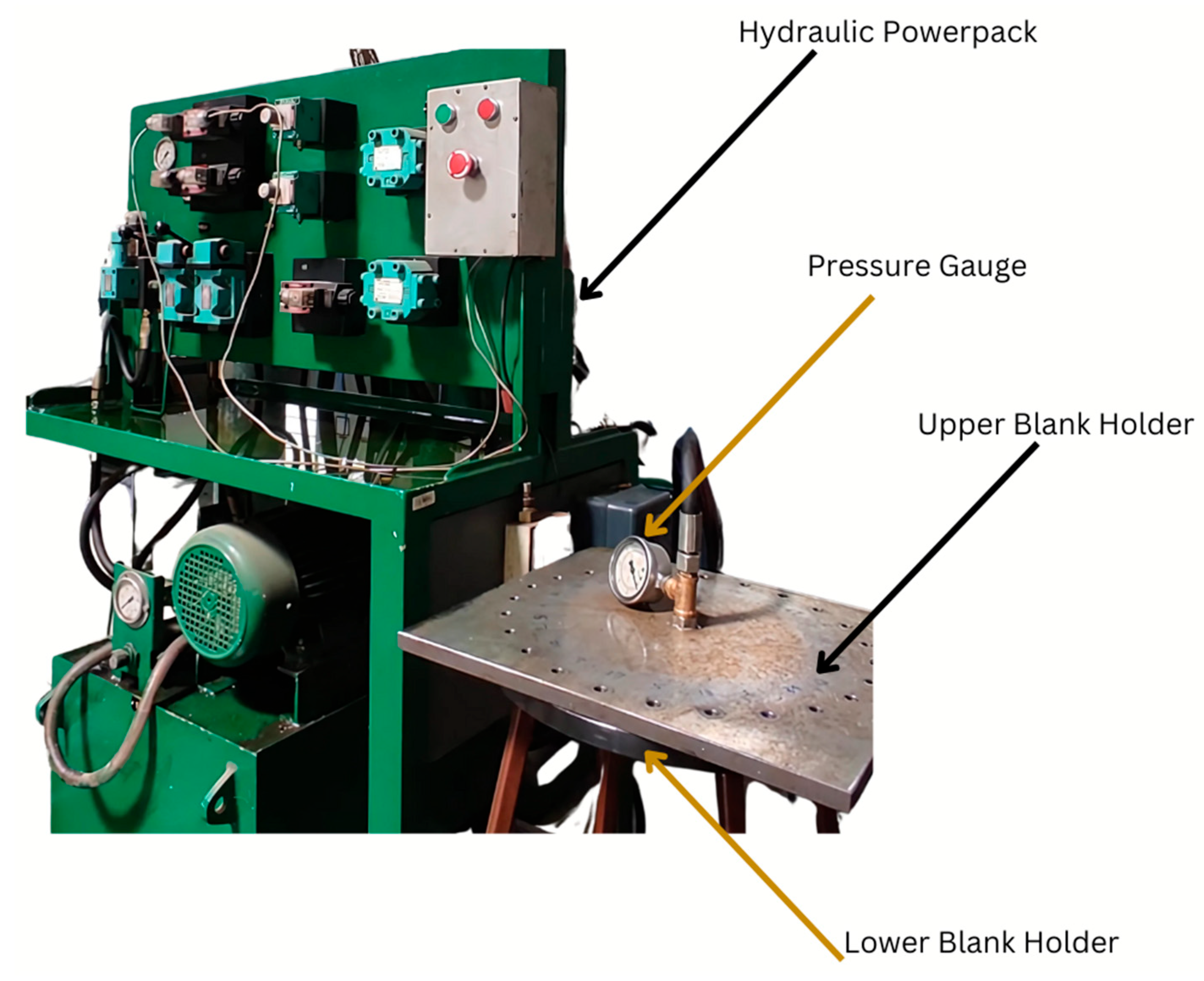

This study addresses these gaps by designing and fabricating a custom experimental SHF set-up, eliminating the need for expensive dies and enabling cost-effective exploration of forming behavior; developing and validating a 3D finite element (FE) model that accurately predicts material flow, thickness variation, and deformation patterns, including wrinkling; introducing a process window to classify failure zones (e.g., bursting, tearing, and incomplete forming), thus guiding safe process design; analyzing the influence of the hydrostatic stress and strain rate, providing insight into void nucleation and growth control, an area rarely quantified in SHF studies; and implementing a response surface methodology (RSM)-based multi-objective optimization approach to identify optimal process parameters for achieving the maximum dome height with minimal thinning which surpasses the predictive capabilities of simpler methods, like the Taguchi method.

This work contributes a comprehensive and validated framework for understanding, predicting, and optimizing shell hydroforming processes. By bridging experimental findings with advanced simulation and optimization, this study offers practical solutions for producing lightweight, complex shell structures without traditional dies. These contributions are particularly relevant for aerospace, automotive, and custom component manufacturing, where precision forming of thin-walled shells is critical.

3. Results and Discussions

3.1. Experimental Results

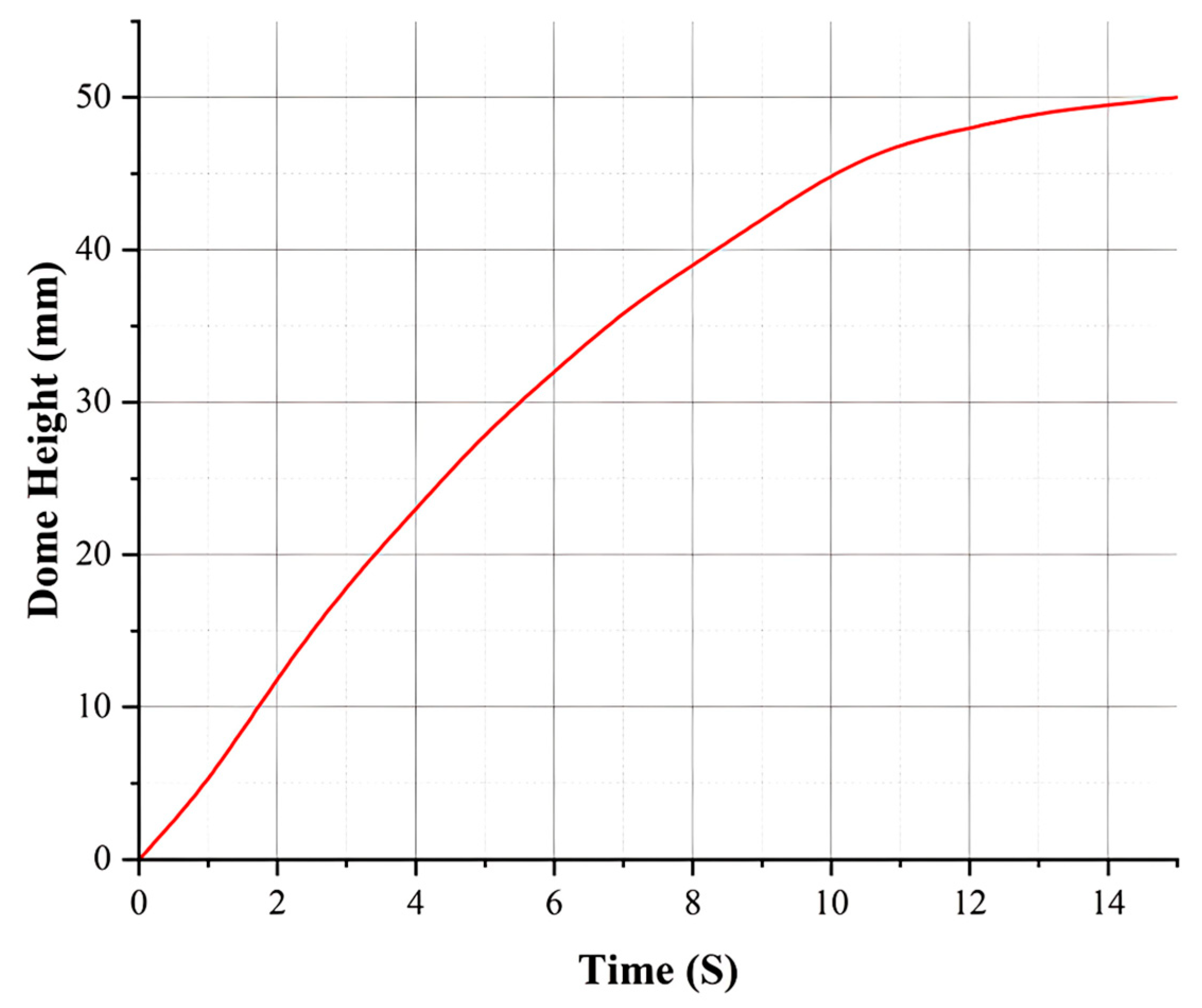

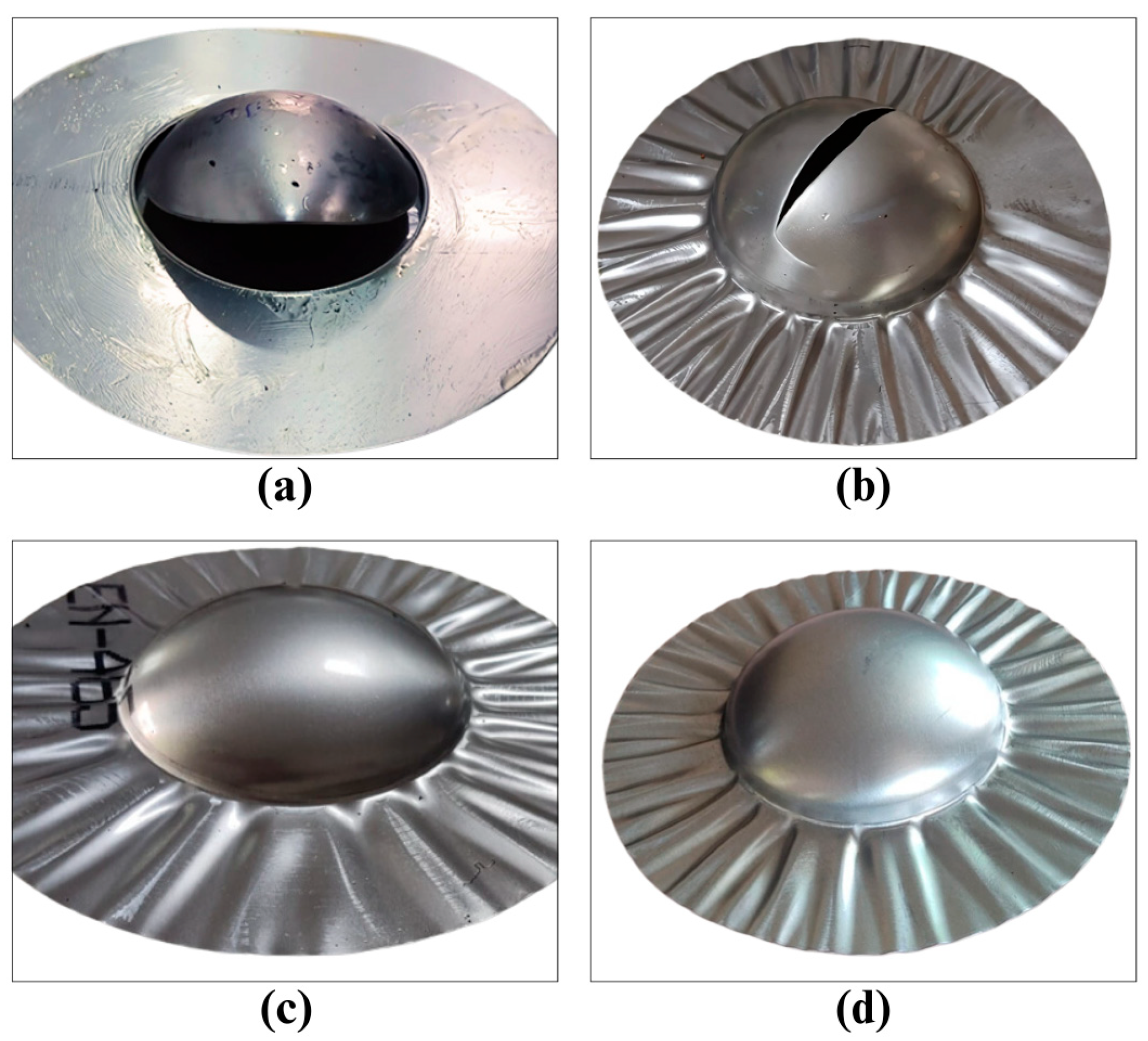

The experiments were aimed at achieving a dome height of 50 mm, with the sheet thickness set to 1.2 mm. Optimal forming conditions were reached with a BHF of 340 kN and an IP of 5.5 MPa, which successfully produced fully formed components (as shown in

Figure 6d). However, increasing the BHF to 380 kN restricted material flow, resulting in tearing at an IP of 4.8 MPa (illustrated in

Figure 6a). On the other hand, reducing the BHF below 140 kN led to oil leakage along the edges of the blank at an IP of 3 MPa, with the leakage becoming more pronounced at a 100 kN BHF.

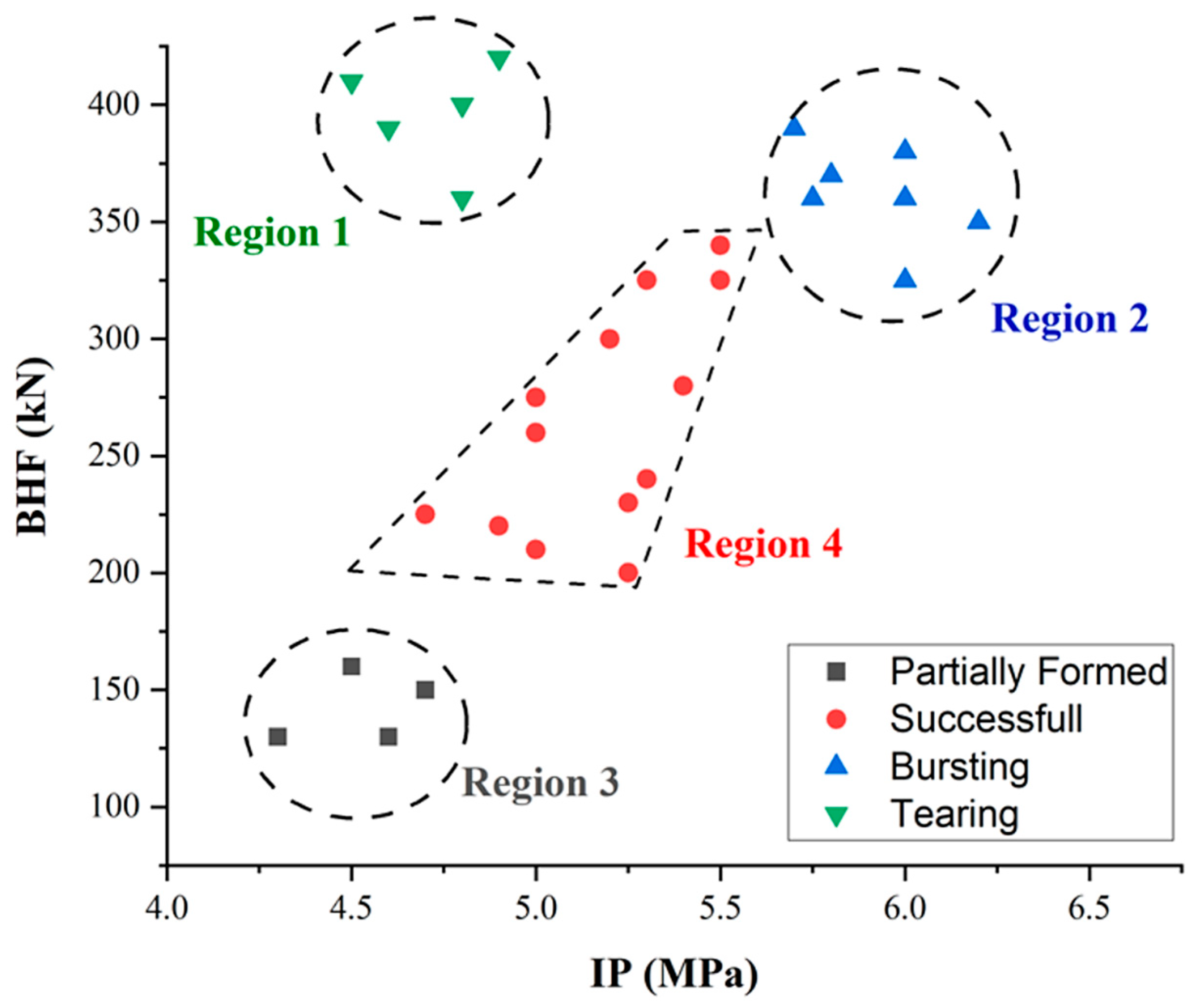

A process window, shown in

Figure 7, was developed based on various trials. The regions within the process window were categorized as follows:

Region 1: A high BHF combined with low IP caused failures near the die hole entry, as shown in

Figure 6a.

Region 2: A high BHF and high IP led to bursting at the dome apex (

Figure 6b).

Region 3: A low BHF and IP resulted in dome heights below 45 mm (

Figure 6c).

Region 4: Optimal forming conditions achieved dome heights between 45 mm and 55 mm (

Figure 6d).

Figure 7.

Process window for shell hydroforming process for varying BHF and IP.

Figure 7.

Process window for shell hydroforming process for varying BHF and IP.

Wrinkles were observed symmetrically around the dome periphery, caused by circumferential compressive stresses pulling the material into the die. The symmetric formation of wrinkles aligns with the radial geometry and boundary conditions applied during the process. These wrinkles were eliminated during post-processing by trimming the excess material, ensuring a clean component (see

Figure 8).

The final formed component achieved a height of 50 mm (

Figure 8) under a BHF of 340 kN and an IP of 5.5 MPa. A detailed thickness distribution assessment was conducted by sectioning the dome and measuring the thinning percentage from the apex to the base at 10 evenly spaced locations (

Table 5). The results revealed a minimum thickness of 0.87 mm at the apex and a maximum thickness of 1.12 mm at the base, resulting in a thickness variation of 25% across the shell.

3.2. Numerical Results

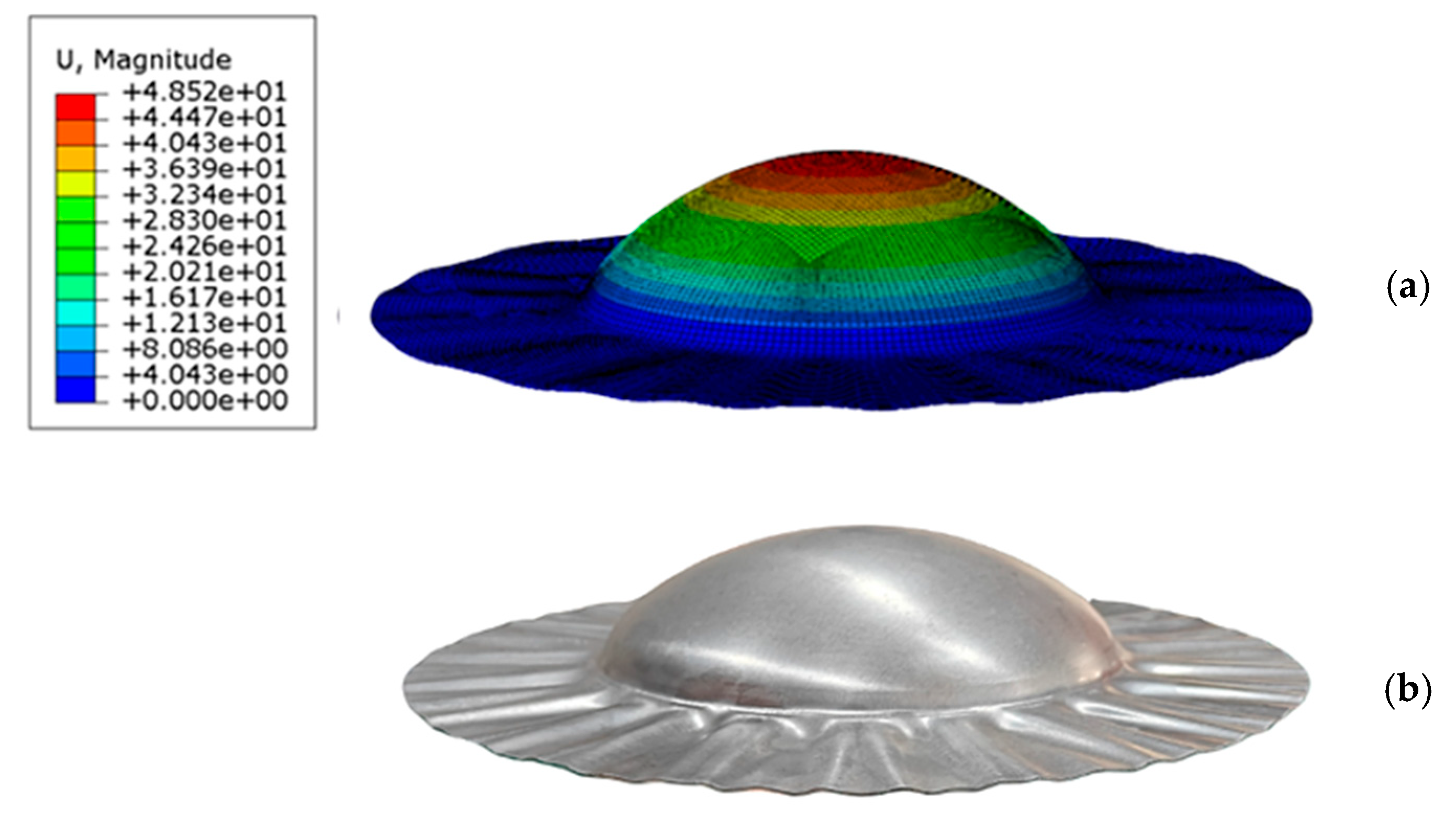

The finite element simulation, developed with axisymmetric boundary conditions and a symmetric internal pressure of 5.5 MPa, accurately replicated the deformation behavior observed in the experiments. The simulation set-up mirrored the experimental parameters, including a friction coefficient of 0.08 and a blank holding force of 340 kN. As shown in

Figure 9, the simulation results closely matched the experimental observations, with wrinkle formation occurring symmetrically along the outer region of the dome, consistent with the actual shell hydroforming (SHF) components.

The simulation revealed a maximum height of 48.52 mm under the same experimental conditions (

Table 6). The wrinkle formation, observed in the experiment, was also replicated in the simulation. Thickness distribution measurements were taken at identical locations for both the simulation and the experiment. A comparison of these results is presented in

Figure 10.

The distribution of von Mises stress and equivalent plastic strain (

Figure 11 and

Figure 12) showed clear radial symmetry, with higher concentrations near the apex and a lower die fillet, consistent with expectations for a symmetric pressure-driven forming process.

Locations 8 and 9 (marked in

Figure 8) had the maximum thickness since these regions retained more material due to material flow during the forming process. However, these same locations exhibited the lowest von Mises stress and equivalent plastic strain.

During the initial forming stages, the blank began to wrap around the fillet area. By the end of the forming process, the blank was fully wrapped around the fillet, which halted further material flow. This explains the significant stretching observed at position 10, where the material underwent considerable deformation.

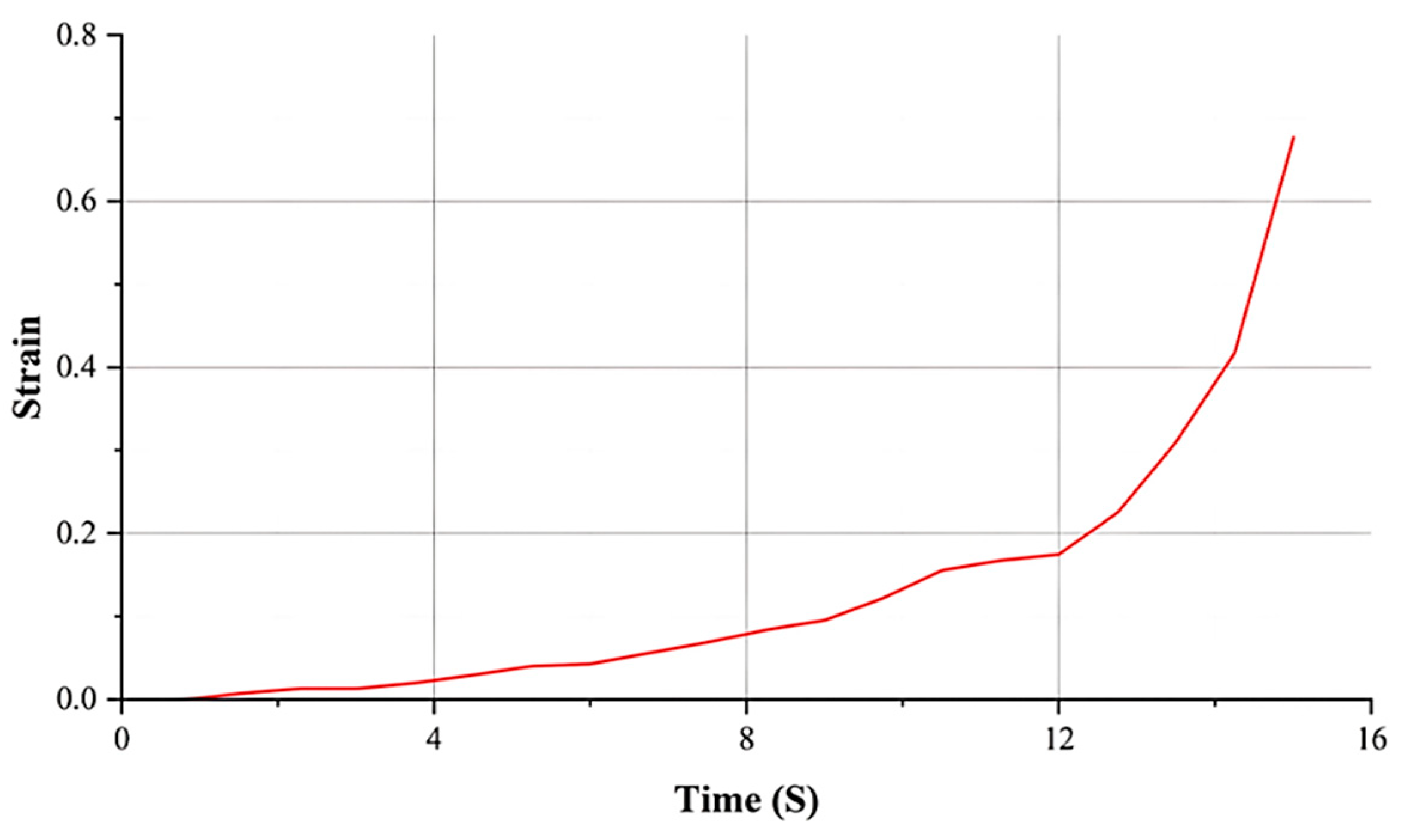

The strain rate history was analyzed at the dome’s apex throughout the hydroforming process. Using the slope of the strain–time curve (

Figure 13), the strain rate was determined. The results revealed strain rates across three time intervals: 0.0086 s

−1 from 0 to 5 s, 0.025 s

−1 from 5 to 10 s, and 0.1 s

−1 from 10 to 15 s. Higher strain rates increased the flow stress due to strain rate sensitivity, which is a critical property of materials like AA5052. This material exhibits high strain rate sensitivity, which significantly impacts its formability and strength. These findings emphasize the need to monitor and control strain rates during the hydroforming process to achieve the best possible forming results.

The hydrostatic stress and strain were analyzed in detail to understand their impact on volumetric deformation behavior during the shell hydroforming process. Hydrostatic stress is calculated as the average of the principal stresses (S

11, S

22, and S

33) using the following formula:

In this study, the hydrostatic stress at the dome’s apex was found to be 160 MPa, indicating uniform tensile pressure during deformation. This tensile stress influences the material’s behavior, especially at higher strain rates. At a strain rate of during the final stage, the strain rate sensitivity increases the material’s flow stress. While tensile hydrostatic stress generally promotes void formation, an elevated strain rate limits the time available for void growth, helping delay failure and maintain deformation uniformity. This interplay between tensile hydrostatic stress and strain rate sensitivity minimizes significant defects, such as premature void expansion or cracking, ensuring controlled material deformation.

The hydrostatic strain (

ε∗) gives insights into volumetric deformation behavior and is calculated as the average of the normal strains (LE

11, LE

22, and LE

33) using the following formula:

In this case, the hydrostatic strain was minimal, being ε∗ = 0.001, indicating that the deformation was primarily dominated by shape changes rather than volumetric changes. This result shows that the material underwent geometric distortion. Additionally, the shear strain (LE12) was observed, with a value of LE12 = 0.1, which plays a significant role in localized deformation mechanisms, enabling the formation of complex geometries. The combination of minimal hydrostatic strain and noticeable shear strain indicates that the deformation was largely driven by shape transformation, with localized shearing enhancing the material’s ability to respond to forming stresses.

These findings emphasize the intricate balance between hydrostatic stress, strain rate sensitivity, and shear strain in shaping the material’s deformation behavior. Tensile hydrostatic stress plays a significant role in driving material expansion, while minimal volumetric strain and significant shear strain contribute to maintaining controlled deformation. At higher strain rates, the tensile hydrostatic stress, combined with the strain rate sensitivity, limits void growth and delays failure, ensuring a defect-free process. This insight is critical for optimizing hydroforming processes, particularly for strain rate-sensitive materials like aluminum alloys, where precise control of stress and strain conditions is essential for achieving optimal formability and strength.

3.3. Optimization Results

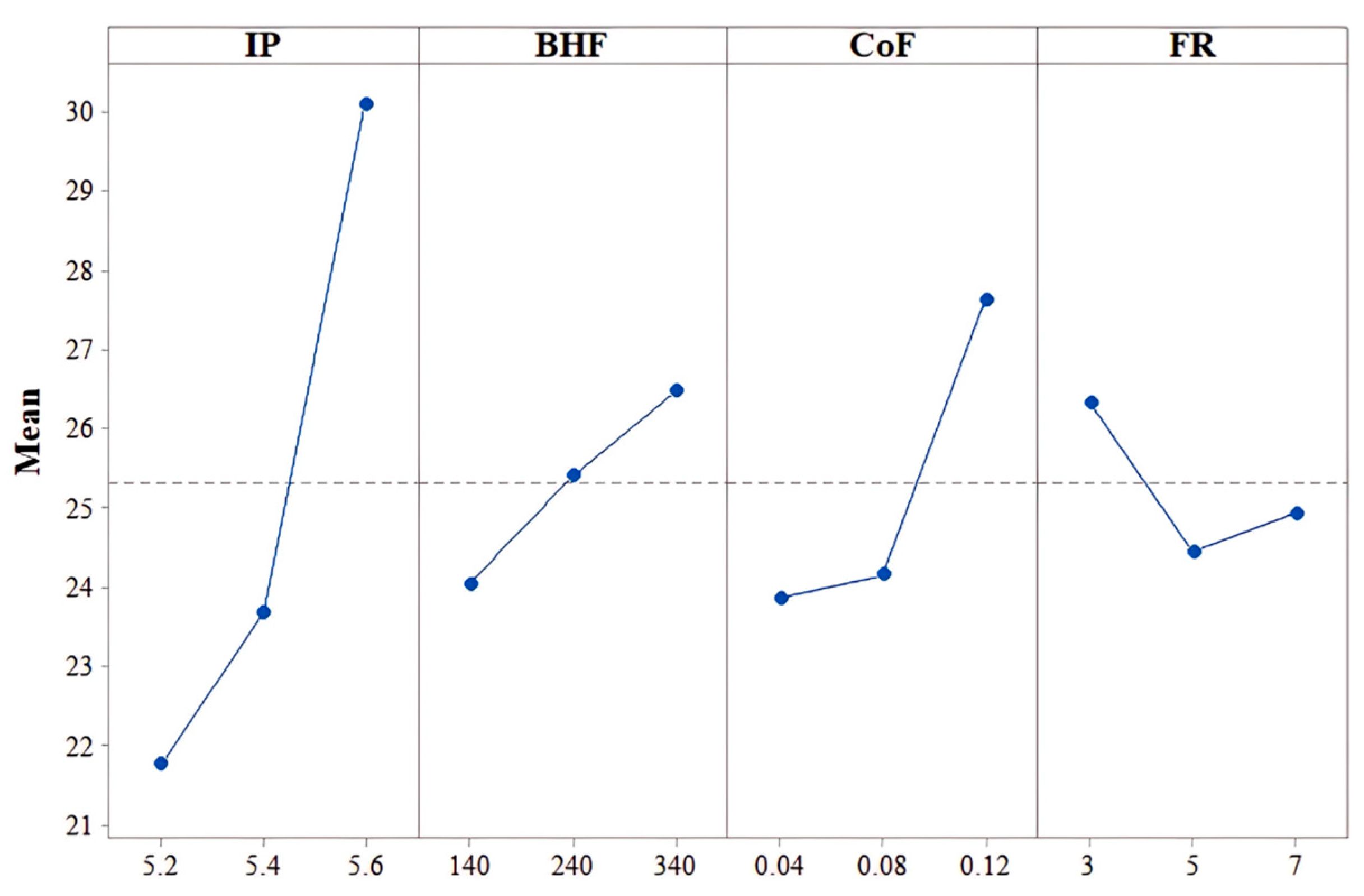

Figure 14 presents the main effect plot on the thinning percentage, whereas

Figure 15 illustrates the main effect plot for the dome height.

In the thinning percentage plot, it can be observed that the IP had a significant impact, with higher pressure values leading to increased thinning. The BHF also affected thinning, though to a lesser extent, with an increasing trend. The CoF exhibited a rise in thinning as its value increased, indicating that frictional resistance plays a role in material flow restriction. Additionally, the FR showed a slight decrease in thinning with an increase in its value.

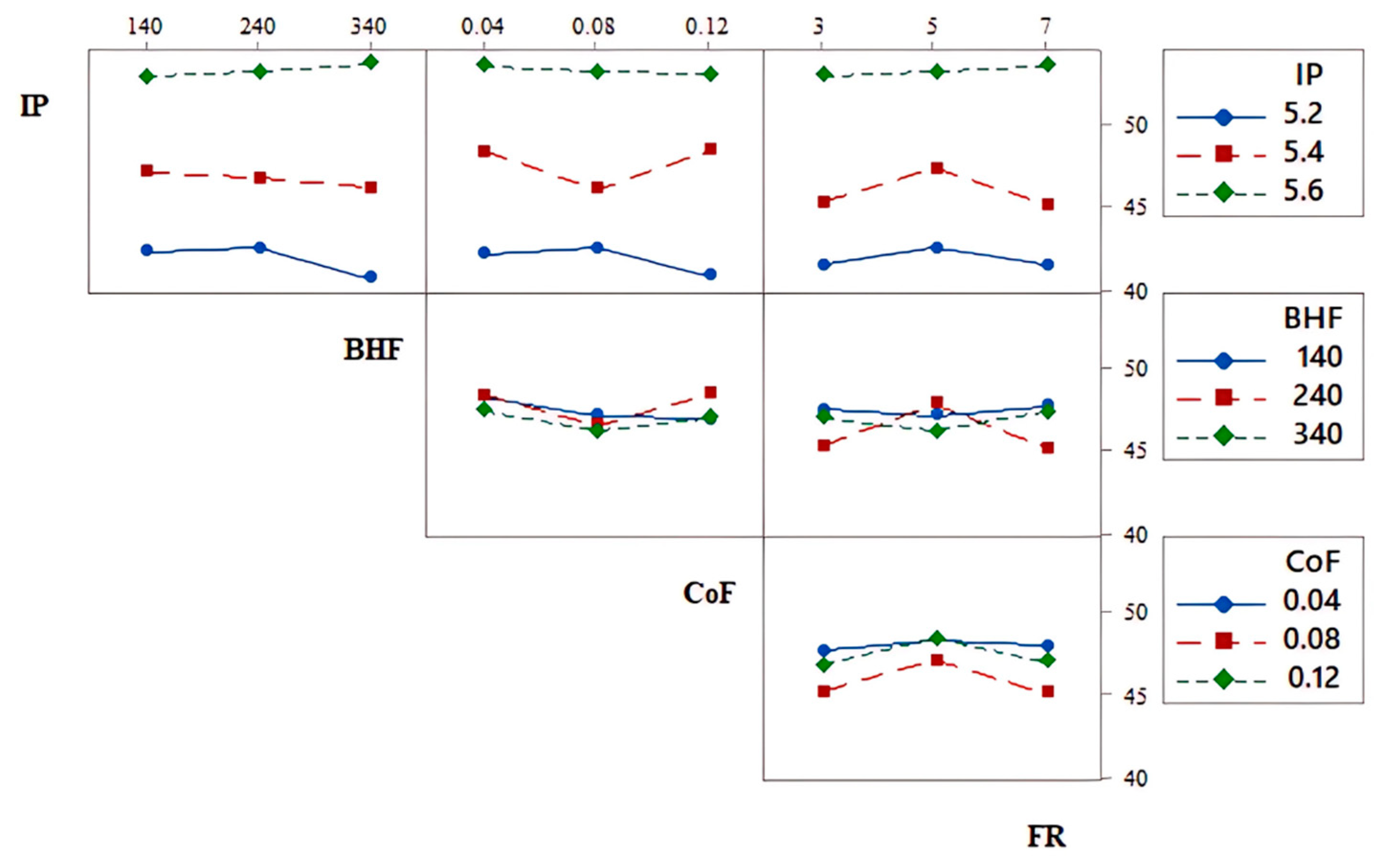

In the dome height plot, the IP again showed a dominant effect, with increased pressure resulting in a higher dome height. The BHF and CoF did not show substantial changes in dome height, while the effect of the FR was marginal.

The results showed that internal pressure had the most dominant effect on thinning and the dome height, reinforcing its role in driving symmetric deformation. The influence of other parameters such as the BHF and CoF was consistent across the axisymmetric geometry.

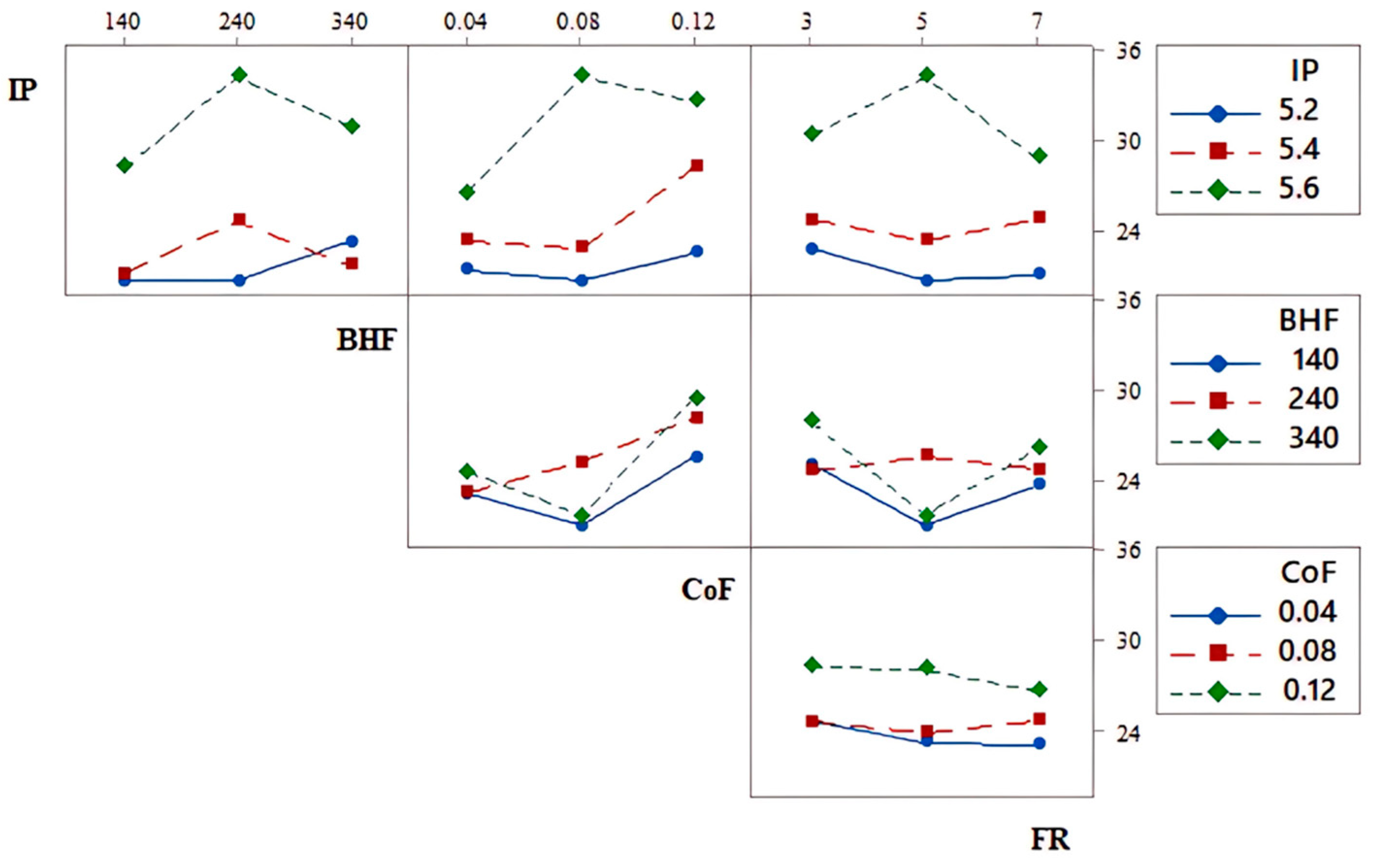

Interaction plots were used to understand the combined effect of two or more input parameters on the output responses in hydroforming processes. These plots visualize how changes in one parameter impacted the response when another parameter was varied, offering insights into parameter interactions that influence thinning and the dome height. The interaction plots for the SHF are shown in

Figure 16 and

Figure 17. The plots highlight the interactions among the IP, BHF, CoF, and FR and the responses of the thinning percentage and dome height. For the thinning percentage, the interaction between the IP and BHF significantly influenced the response, with a higher IP and higher BHF resulting in increased thinning. The interaction between the CoF and FR shows that increasing the CoF tends to increase thinning, while varying the FR has minimal impact. The interaction between the IP and CoF also indicates that thinning is more pronounced at higher CoF levels when the pressure is increased.

The regression equations derived for the thickness reduction and dome height are as follows:

The optimization was carried out by setting the following objectives:

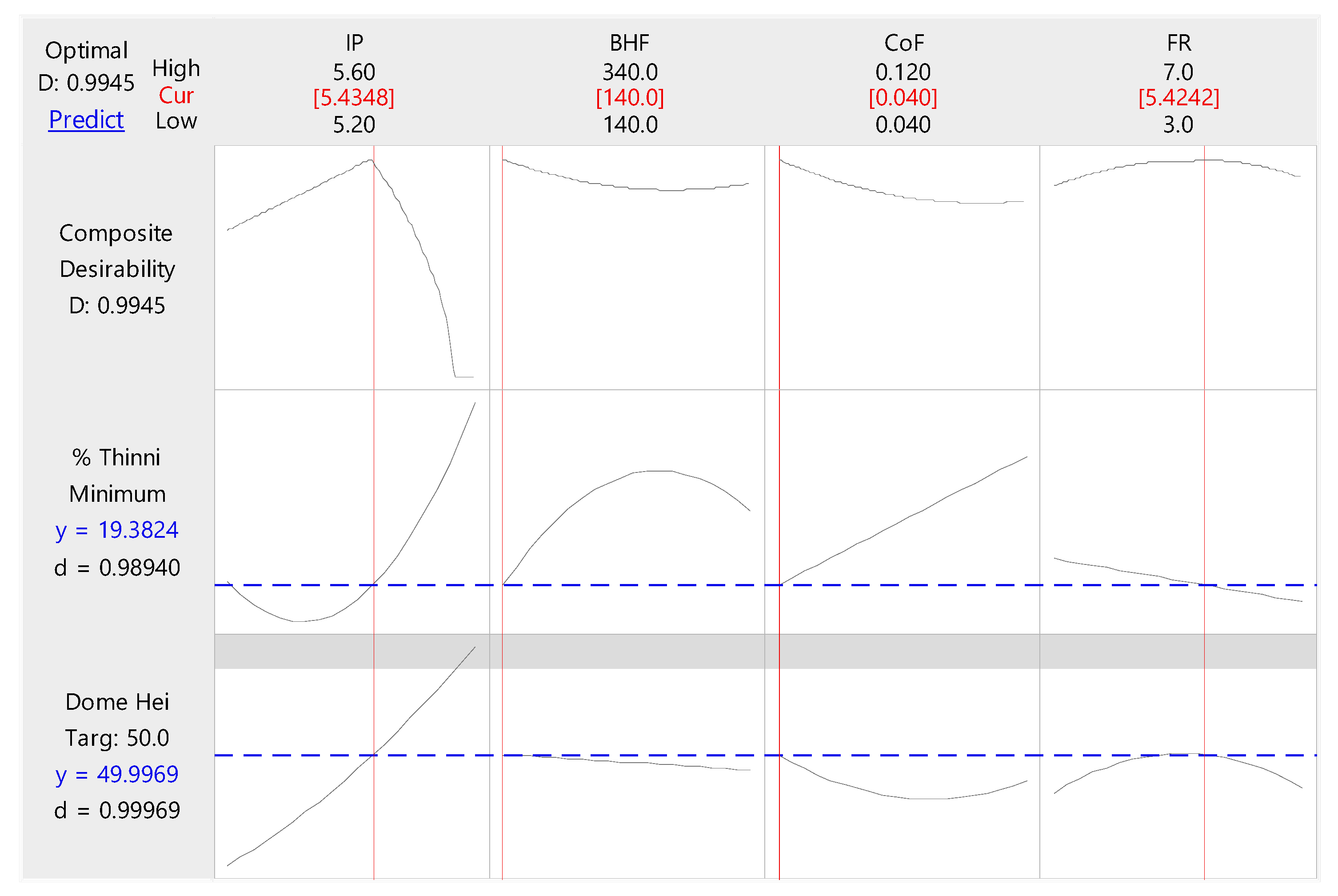

The optimization procedure involved the use of desirability functions, which combine multiple objective functions into a single performance metric. A composite desirability value closer to one indicates a better combination of process parameters. The optimal set of parameters was determined by maximizing this composite desirability.

The optimal parameters obtained from the optimization analysis were an IP of 5.43 MPa, a BHF of 140 kN, a CoF of 0.04, and an FR of 5.42 mm. These parameters ensured that the forming process was efficient while minimizing thinning and achieving the desired dome height. As a result of the optimization, the optimal output parameters achieved were a dome height of 50 mm, meeting the target specification, and a thinning percentage of 19.38%, indicating a well-balanced and efficient forming process.

Figure 18 shows the optimization plot.

The composite desirability achieved was 0.9945, indicating a high level of optimization efficiency. The optimization plot is shown in

Figure 18, illustrating the response surfaces and desirability contours for the SHF.

The optimized input parameters were then fed into simulations, and the resulting outputs were compared with the predictions. The FE analysis predicted a dome height of 51.58 mm and a thinning percentage of 19.6%, resulting in percentage errors of 3.08% and 1.12% respectively. This low error percentage indicates the reliability of the optimization process and the accuracy of the response surface models used.