Creep Behavior and Deformation Mechanism of Aluminum Alloy: Integrating Multiscale Simulation and Experiments

Abstract

1. Introduction

2. Experiments

3. Multiscale Simulation Method

3.1. Phase Field Method

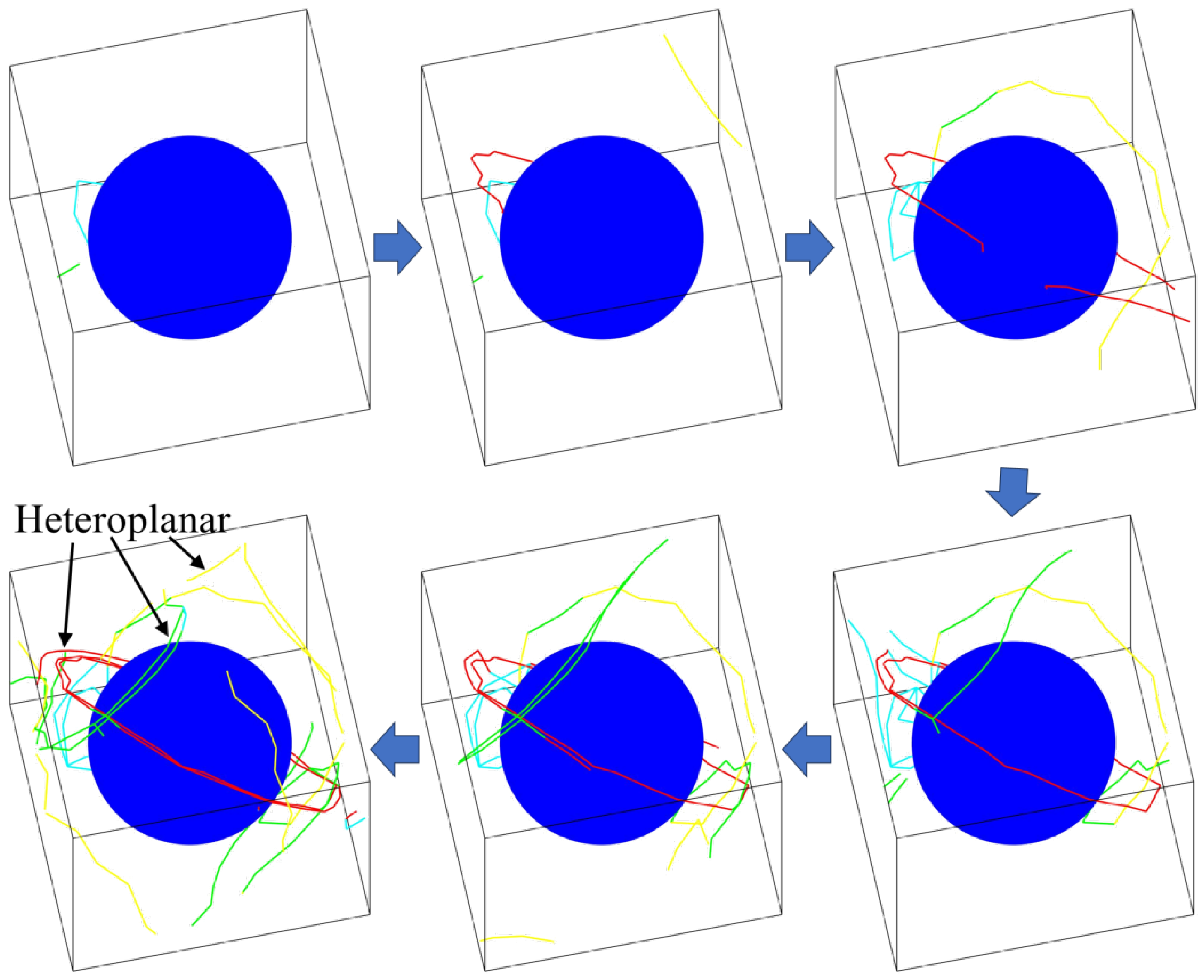

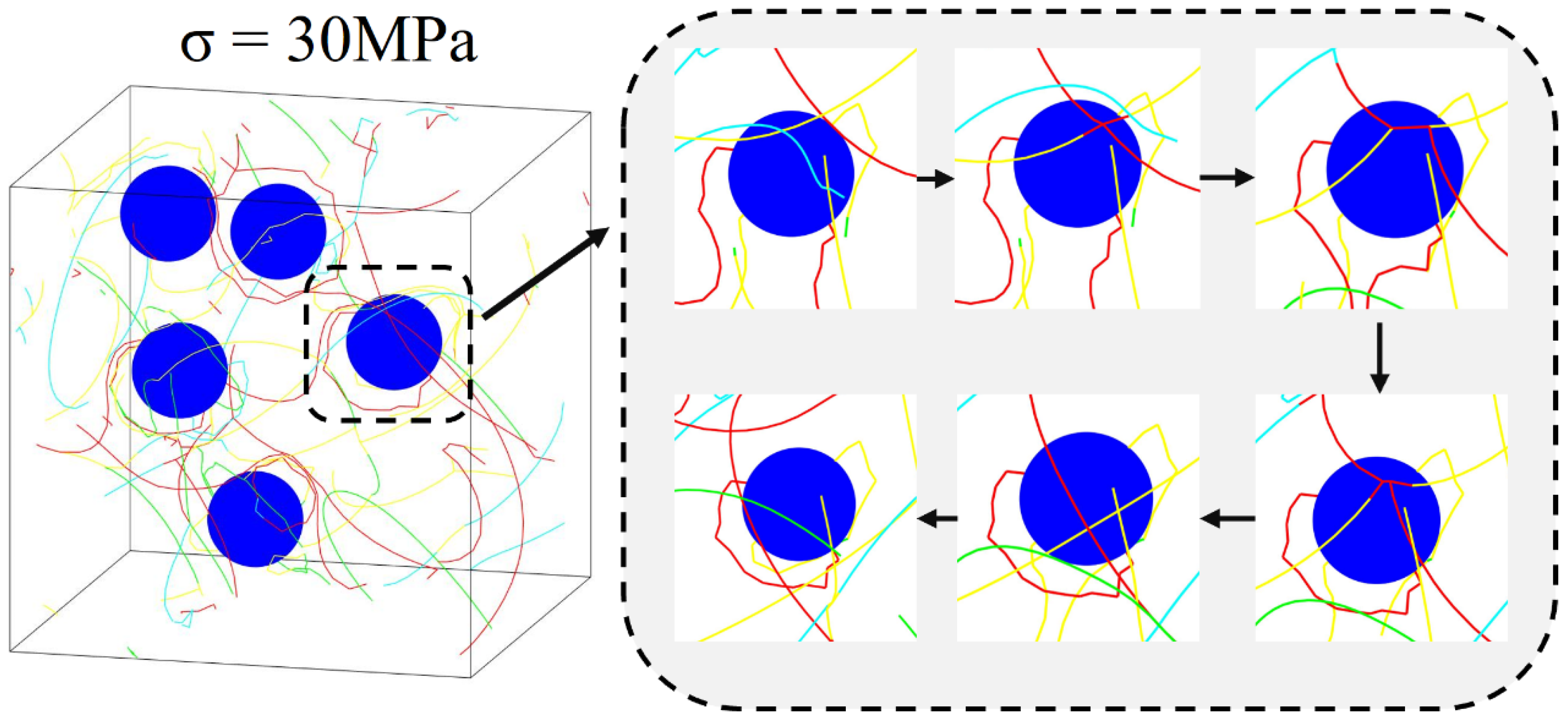

3.2. Dislocation Dynamics Simulation

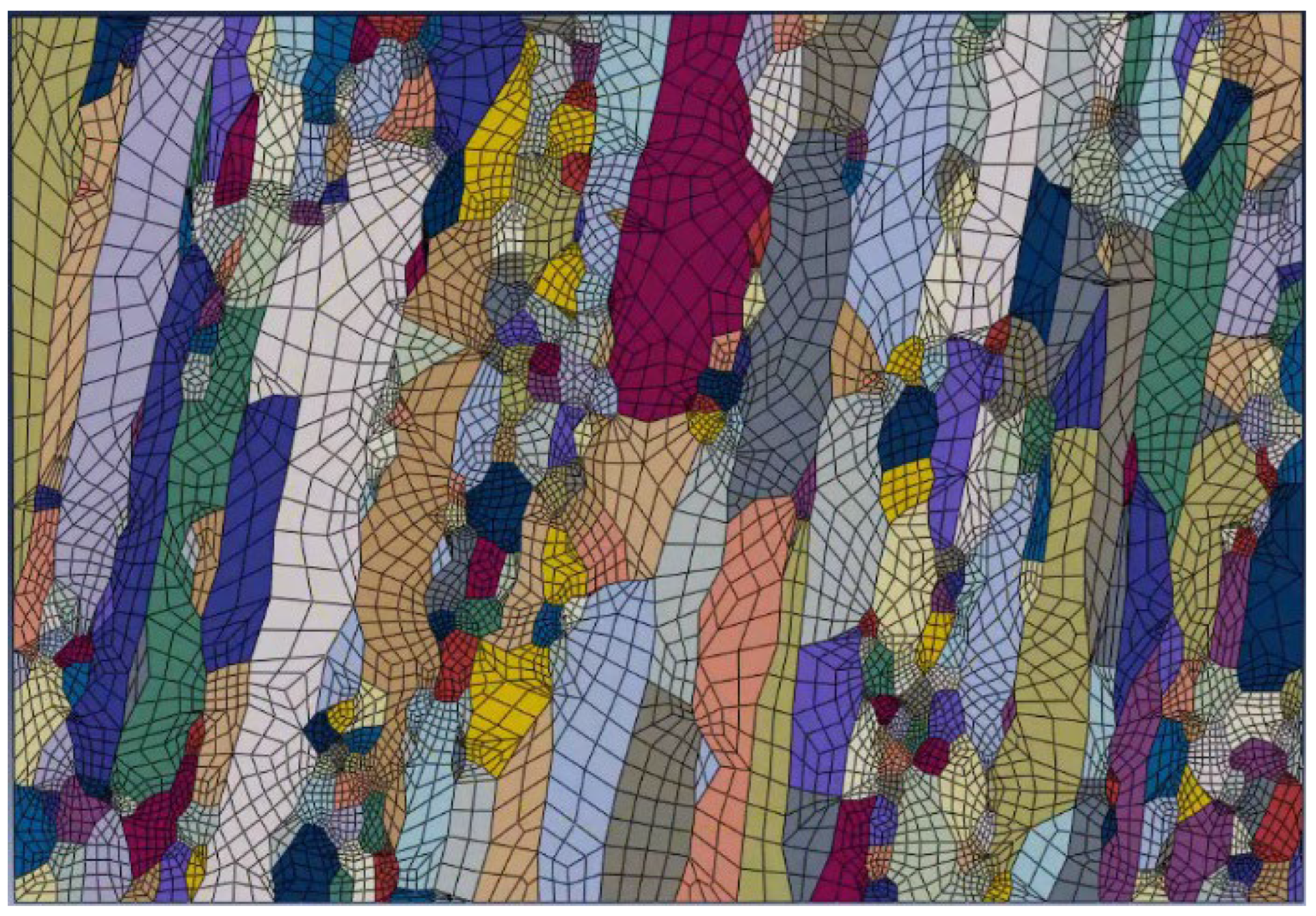

3.3. Crystal Plastic Finite Element Method

4. Results and Discussion

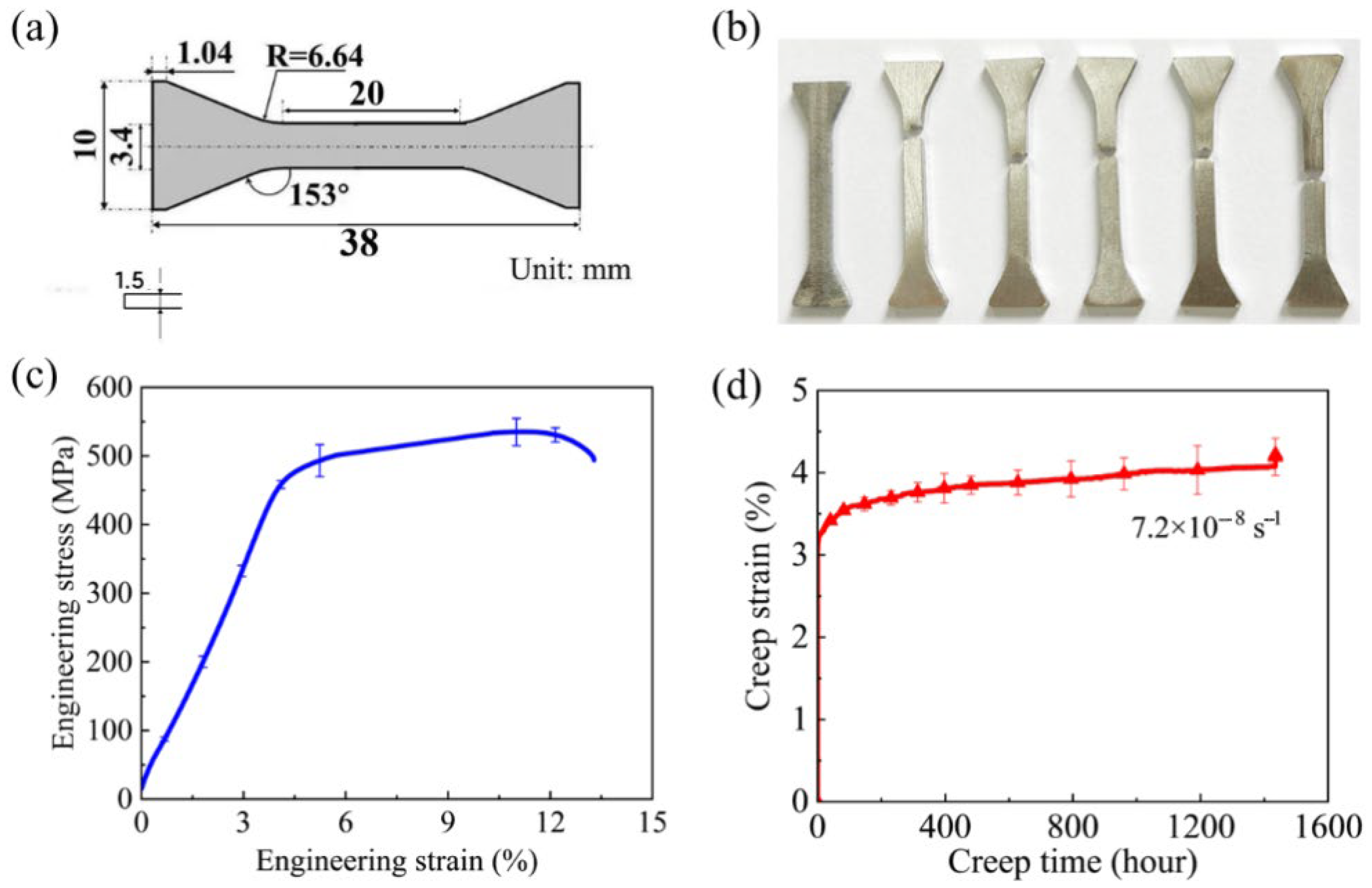

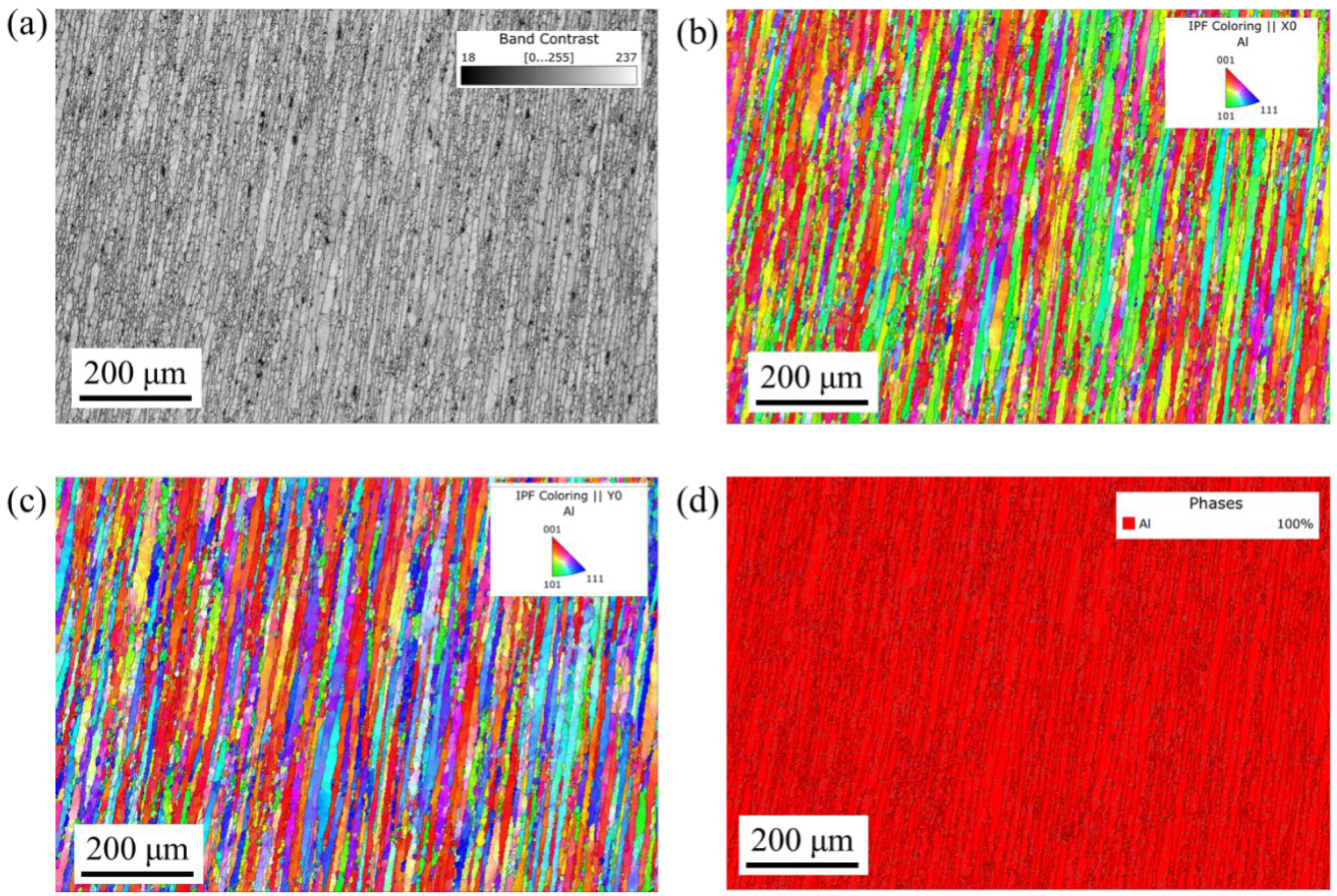

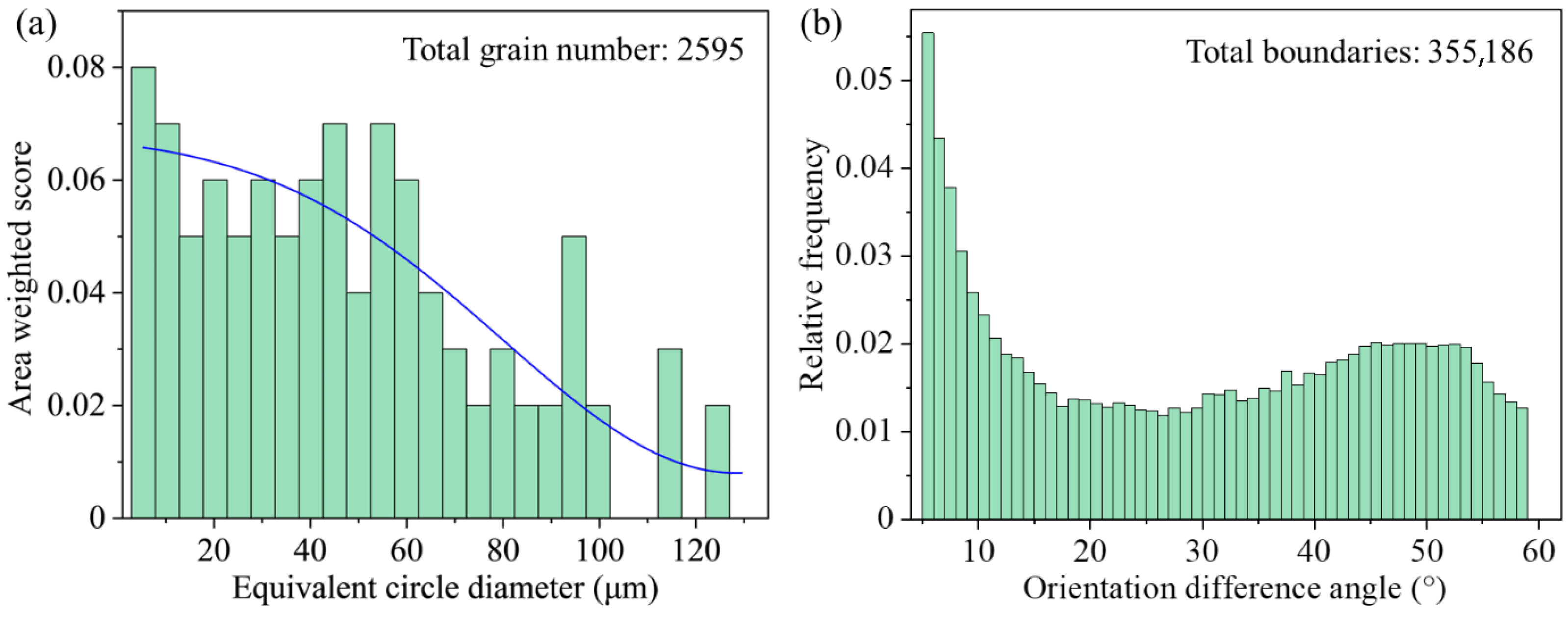

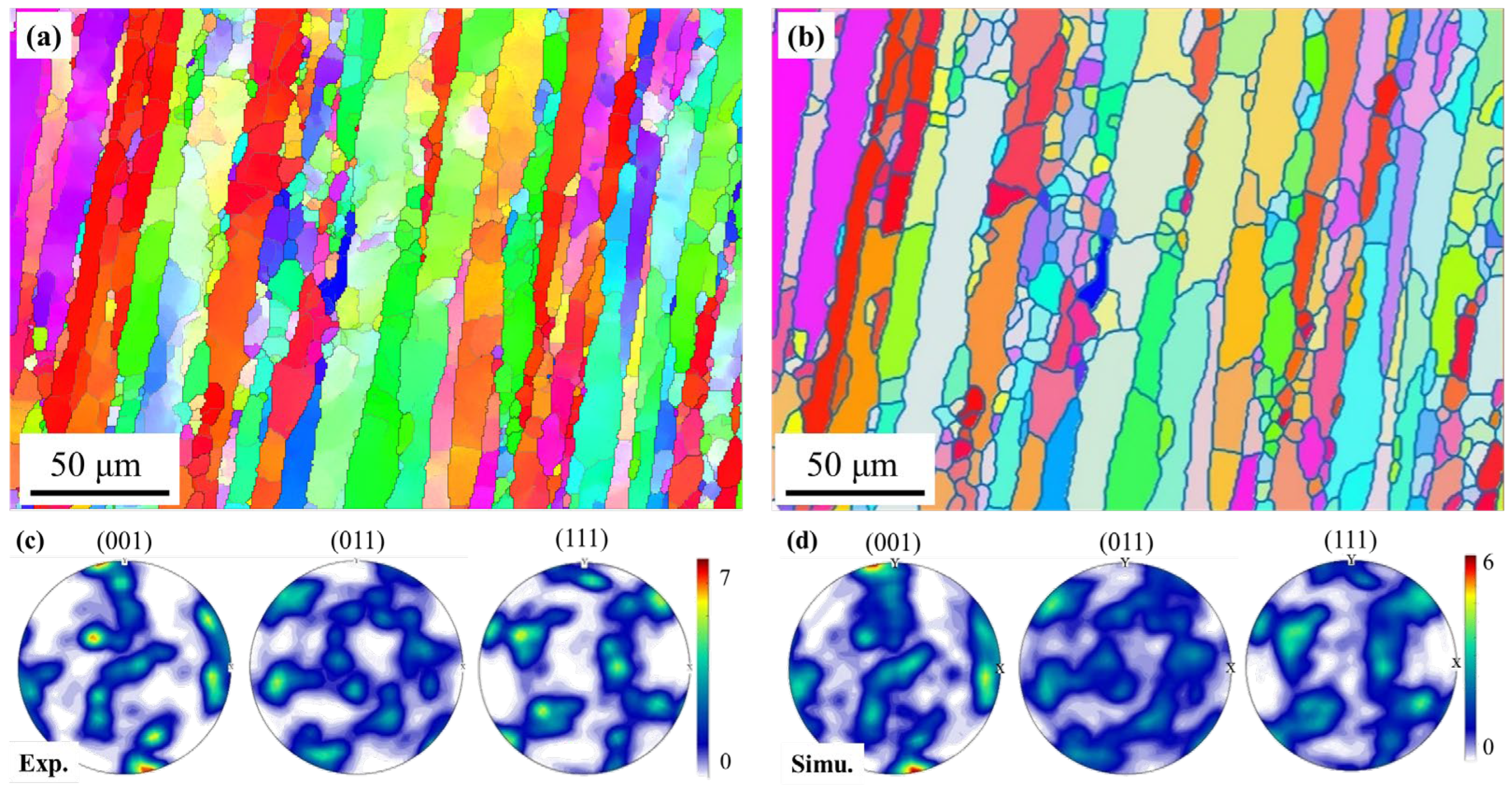

4.1. Mechanical Properties and Microstructure

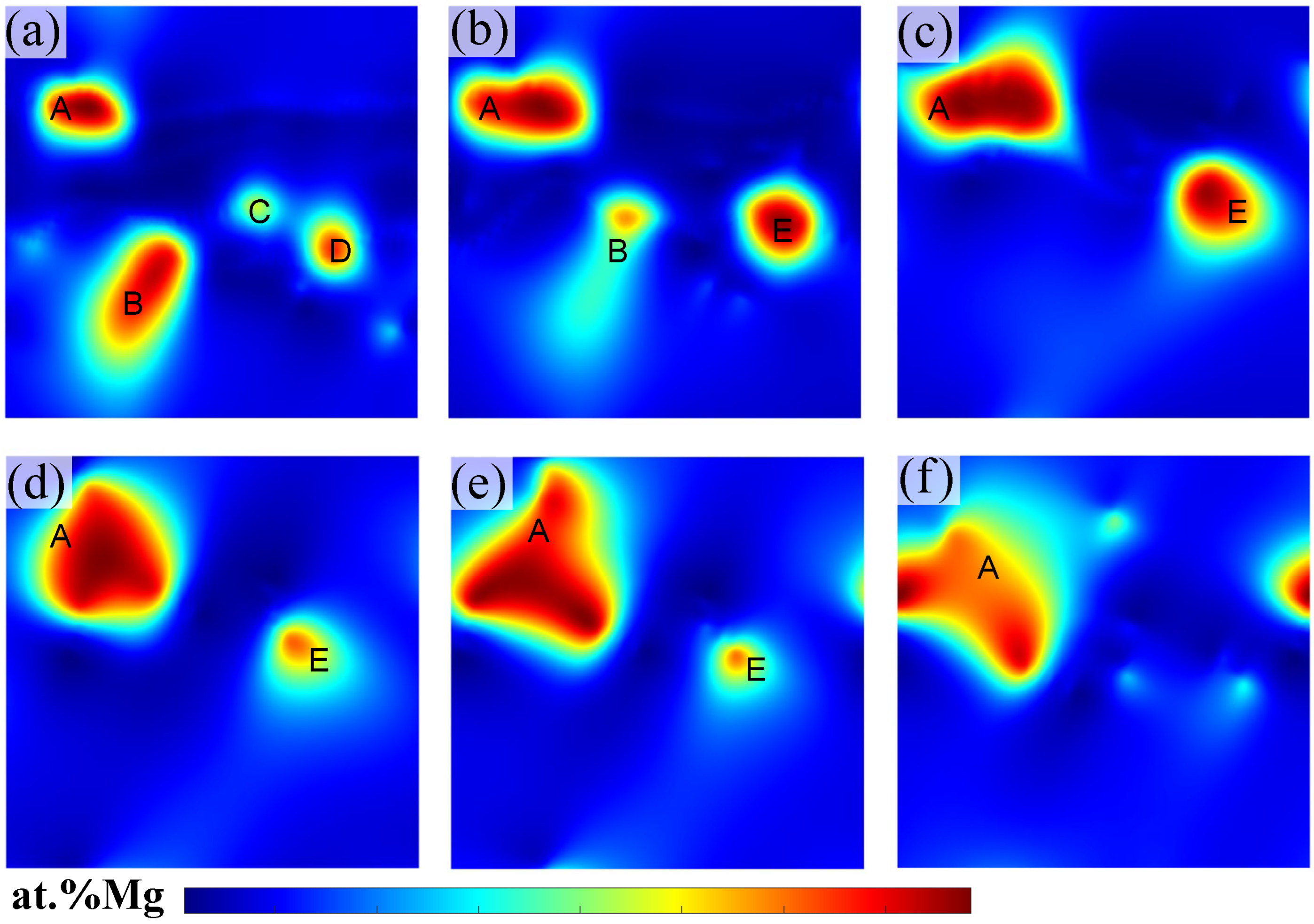

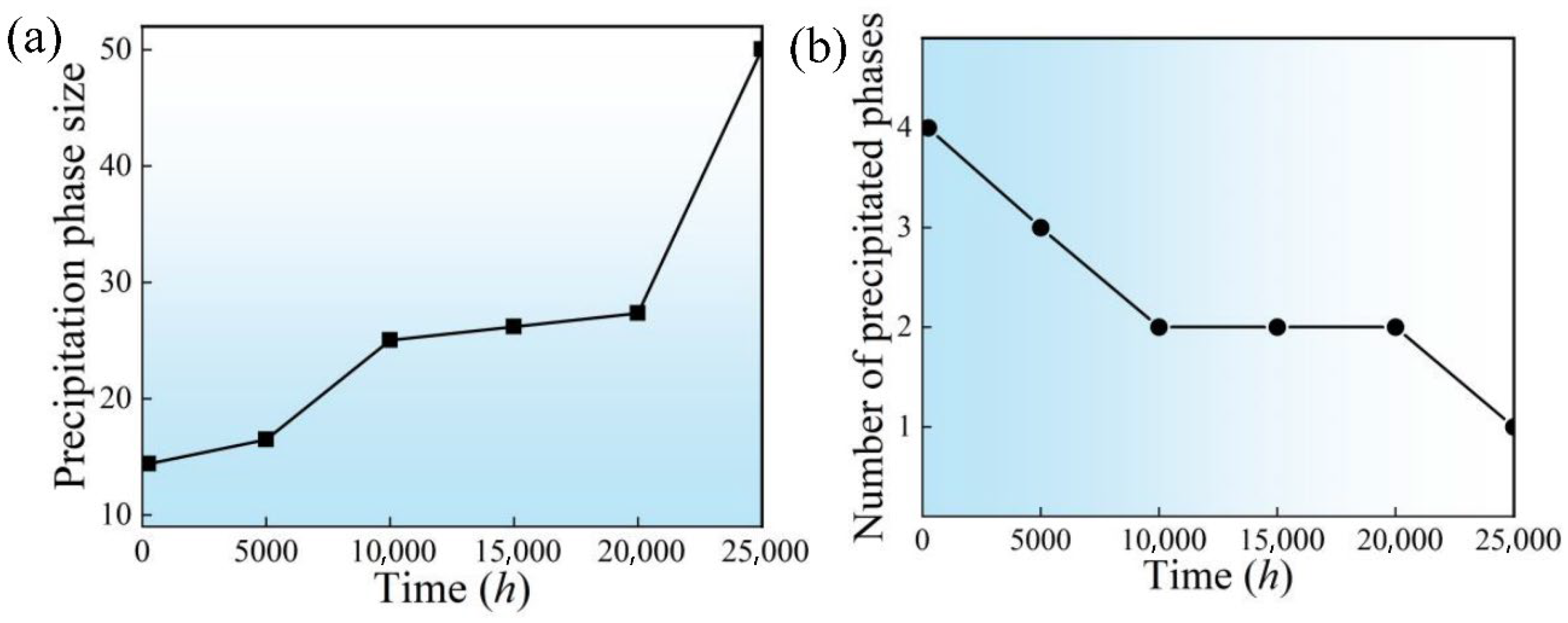

4.2. Evolution of Precipitate

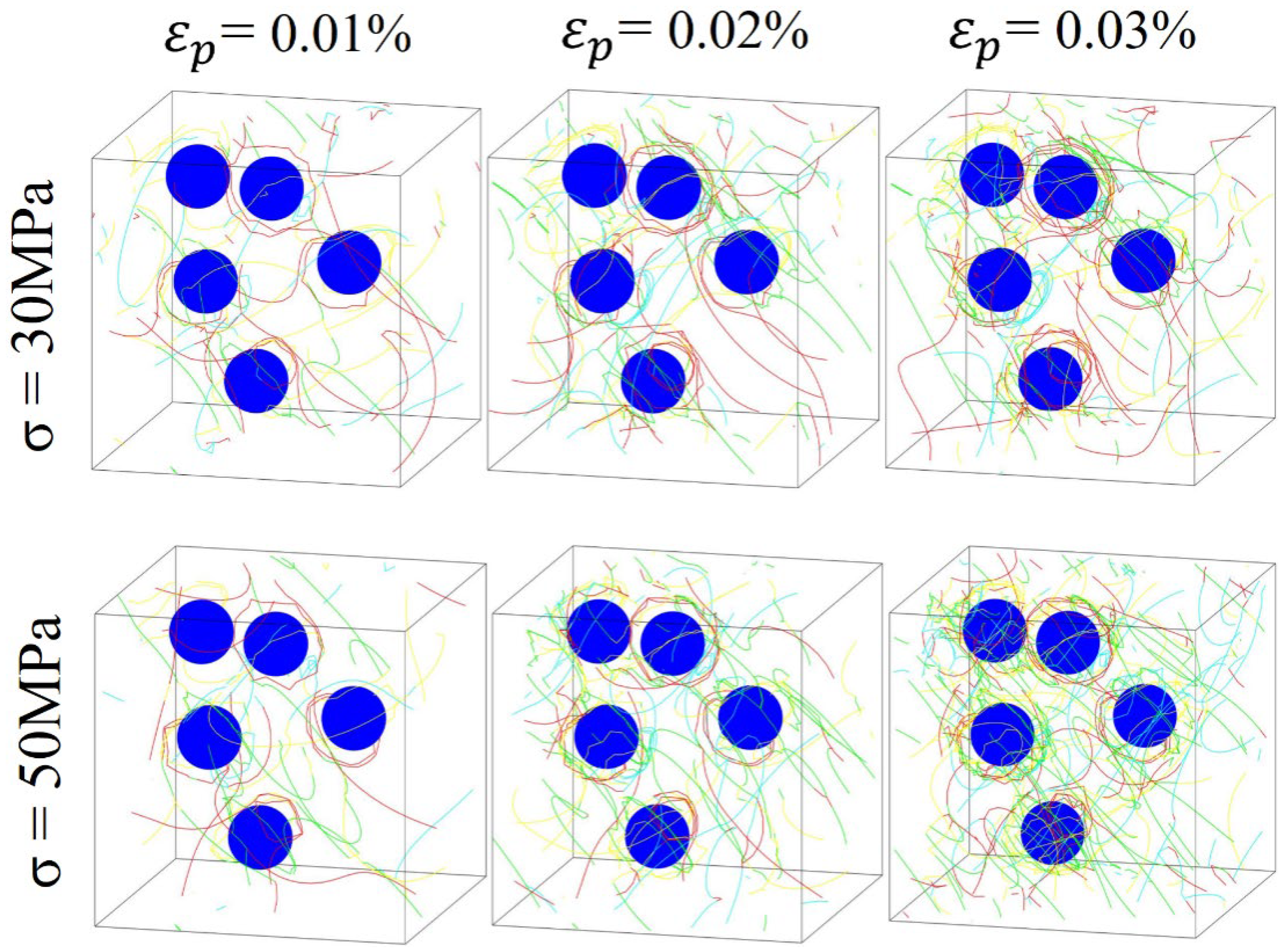

4.3. Interaction Between Precipitate and Dislocation

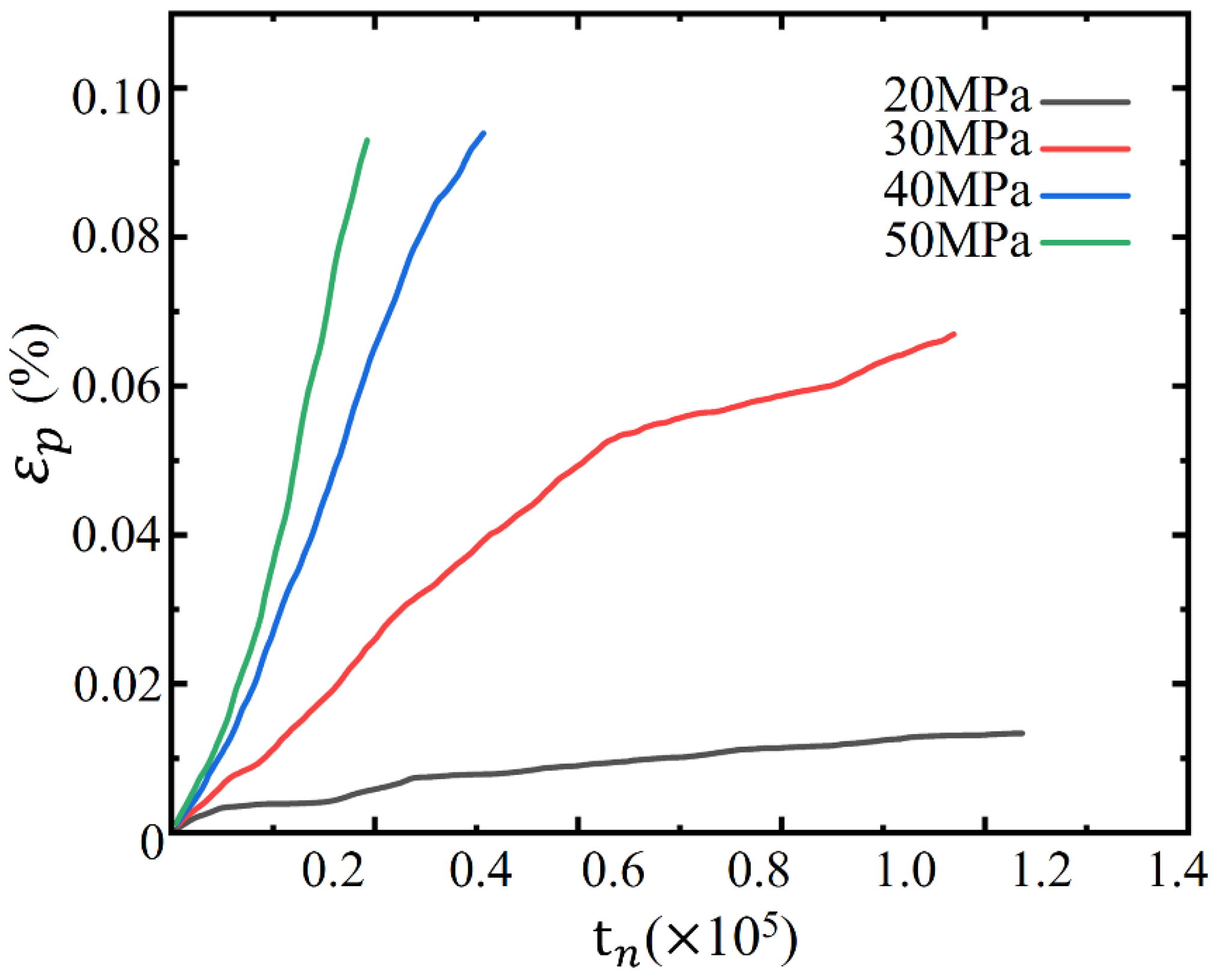

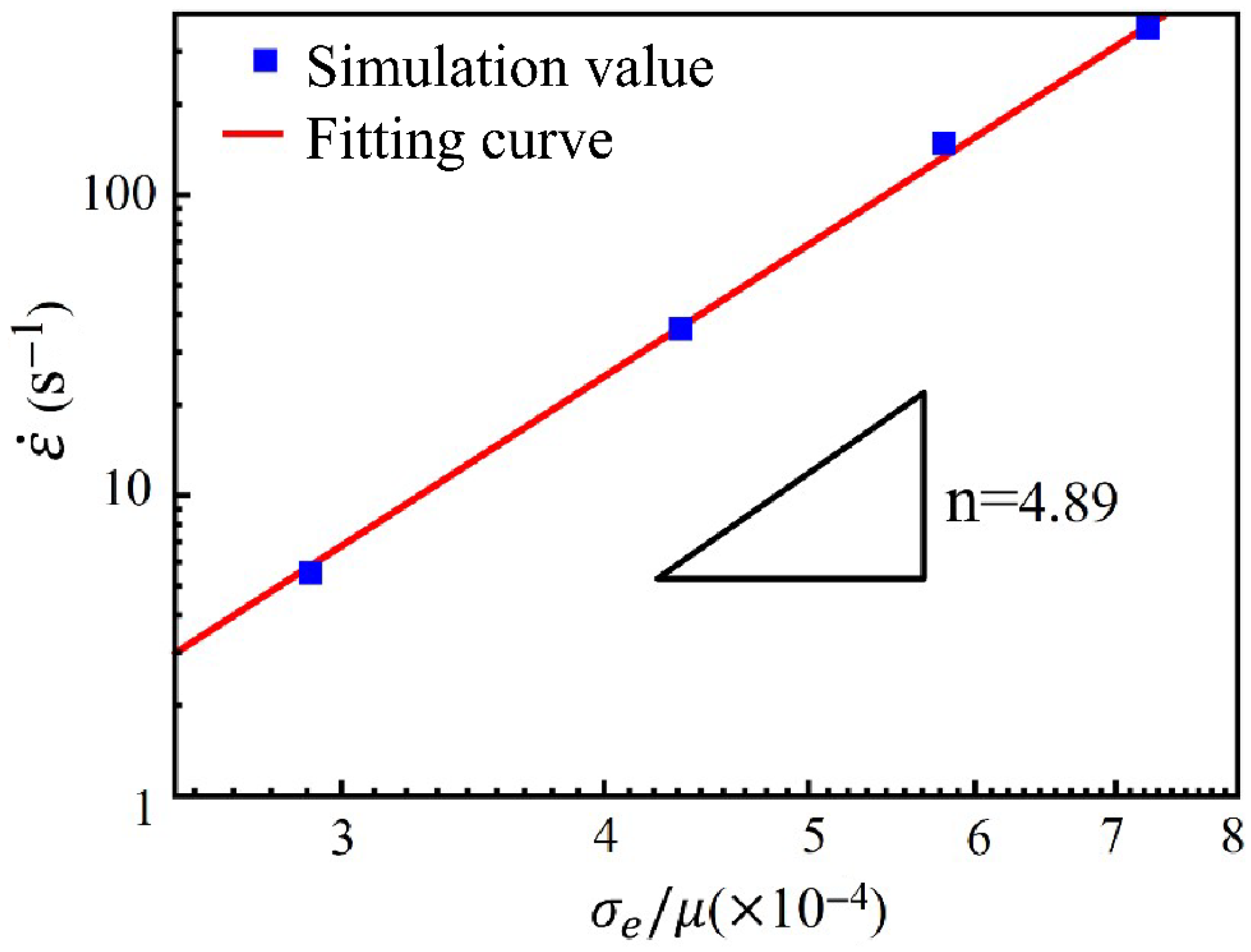

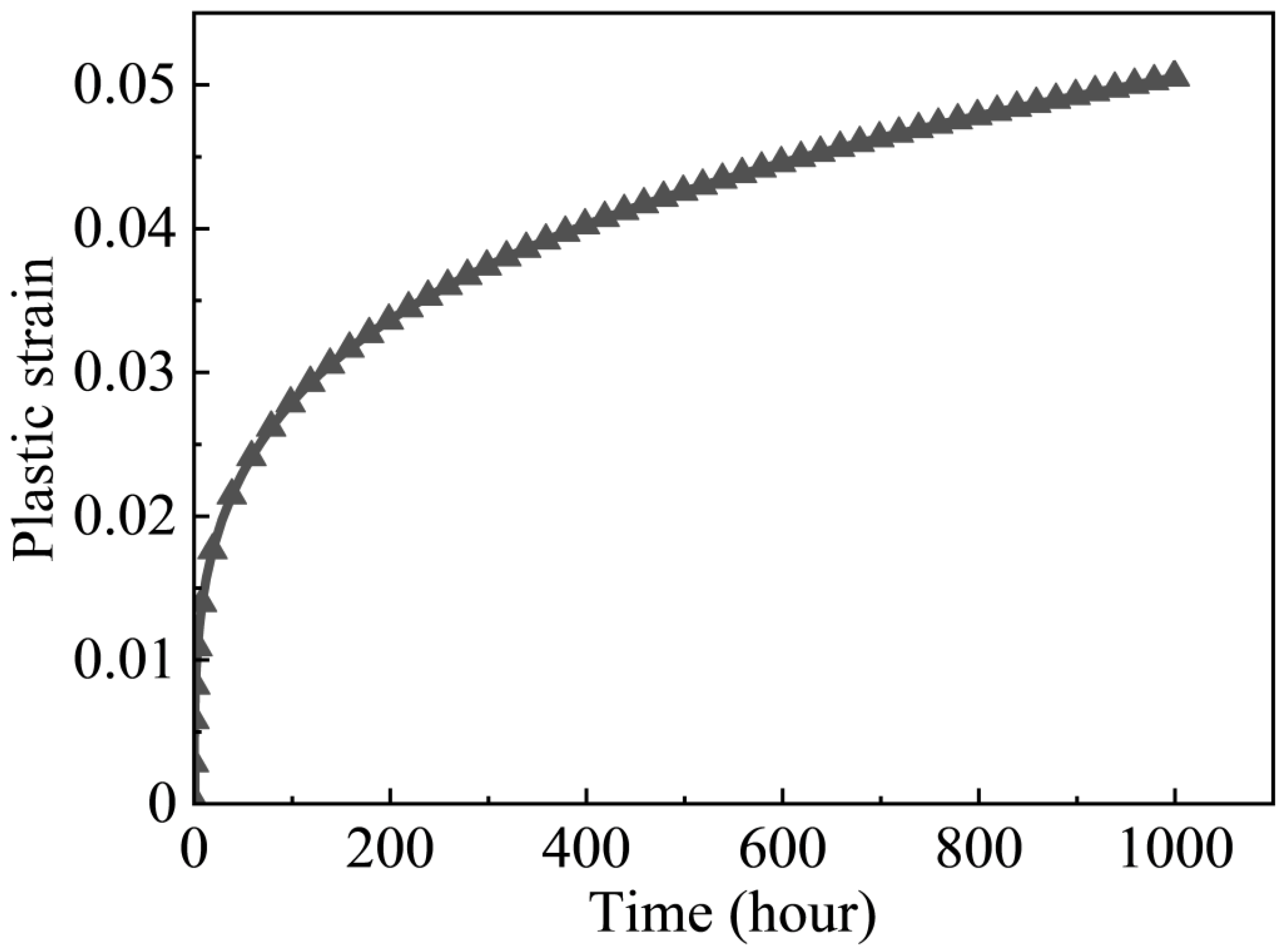

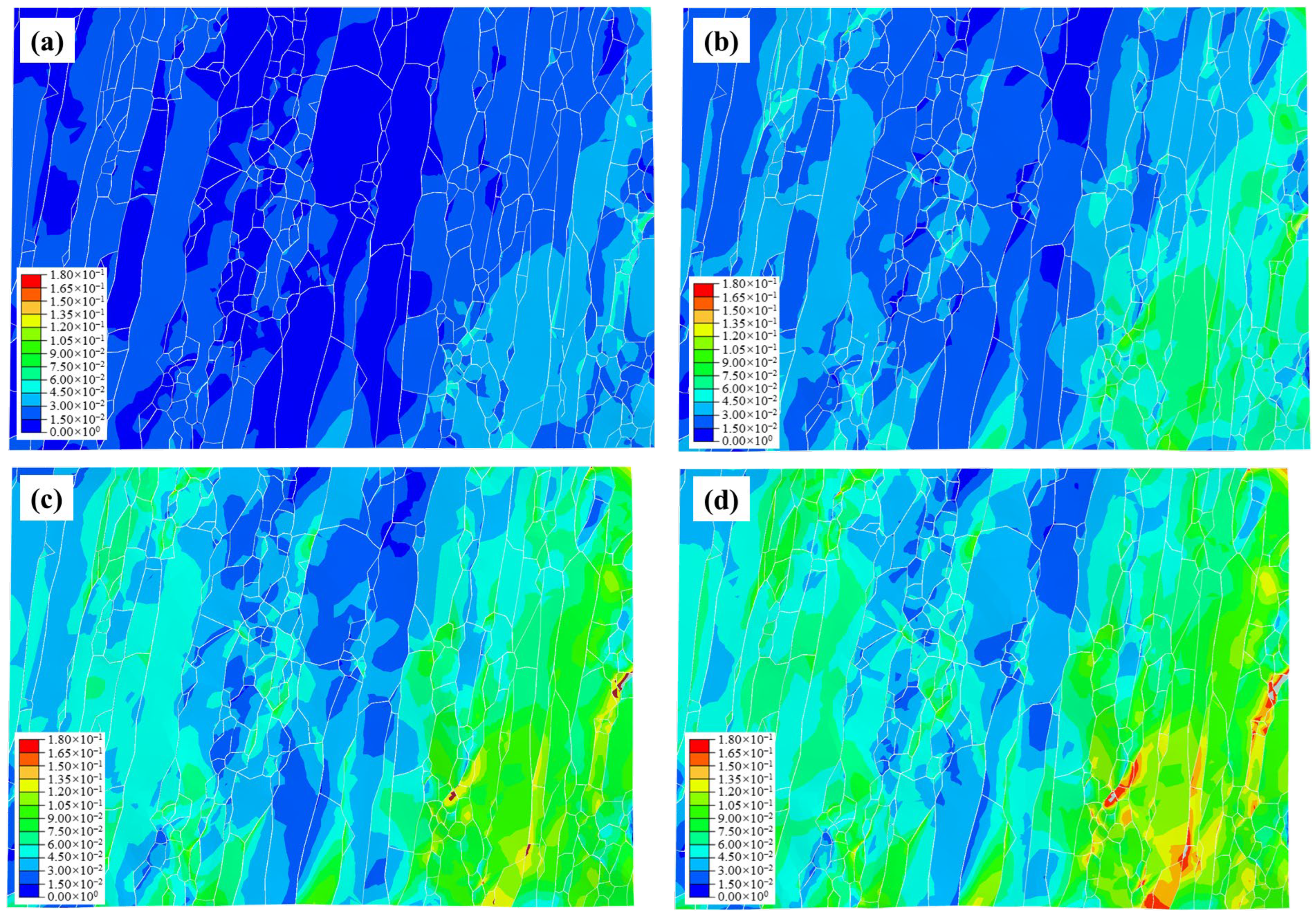

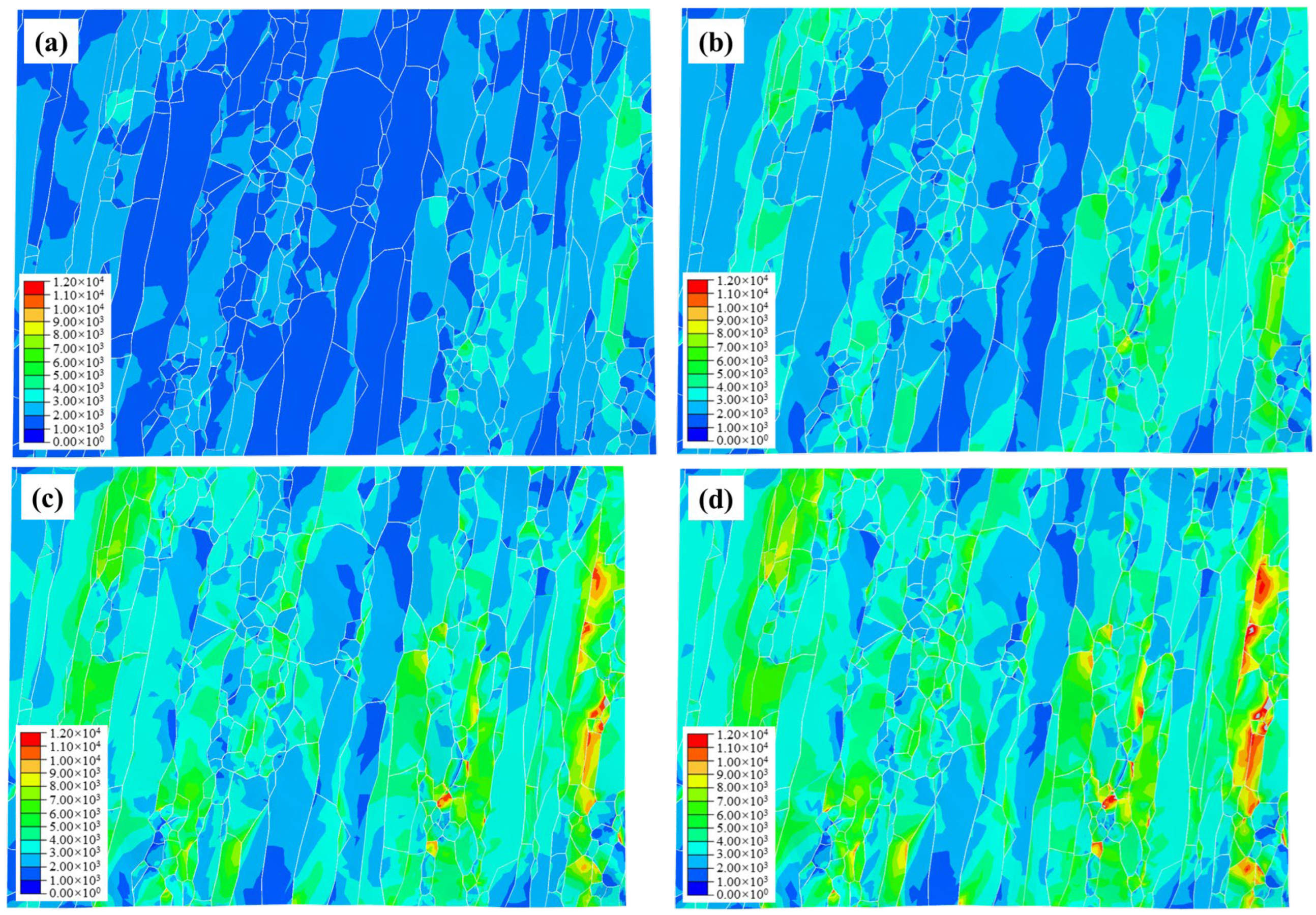

4.4. Deformation Behavior and Mechanism

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bardiani, J.; Bertagna, S.; Braidotti, L.; Marinò, A.; Bucci, V.; Sbarufatti, C.; Manes, A. Creep assessment of thermoplastic materials for non-structural components in marine engines. Compos. Part B Eng. 2024, 287, 111800. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Song, Y. Creep behavior of titanium alloy used in deep-sea pressure shell considering tensile/compressive asymmetry: Experiments and numerical modeling. Ocean Eng. 2023, 288, 116095. [Google Scholar] [CrossRef]

- Lin, Y.C.; Jiang, Y.-Q.; Chen, X.-M.; Wen, D.-X.; Zhou, H.-M. Effect of creep-aging on precipitates of 7075 aluminum alloy. Mater. Sci. Eng. A 2013, 588, 347–356. [Google Scholar] [CrossRef]

- Fernández, R.; González-Doncel, G. Understanding the creep fracture behavior of aluminum alloys and aluminum alloy metal matrix composites. Mater. Sci. Eng. A 2011, 528, 8218–8225. [Google Scholar] [CrossRef]

- Ma, Z.; Zhan, L.; Liu, C.; Xu, L.; Xu, Y.; Ma, P.; Li, J. Stress-level-dependency and bimodal precipitation behaviors during creep ageing of Al-Cu alloy: Experiments and modeling. Int. J. Plast. 2018, 110, 183–201. [Google Scholar] [CrossRef]

- Xie, D.; Feng, R.; Liaw, P.K.; Bei, H.; Gao, Y. Long-term tensile creep behavior of a family of FCC-structured multi-component equiatomic solid solution alloys. Scr. Mater. 2022, 212, 114556. [Google Scholar] [CrossRef]

- Saitova, R.; Arutyunyan, A.; Altenbach, H. High temperature creep and embrittlement in metals and alloys under conditions of the long-term usage. Acta Mech. 2024, 235, 6033–6055. [Google Scholar] [CrossRef]

- Lin, Y.C.; Jiang, Y.-Q.; Zhang, X.-C.; Deng, J.; Chen, X.-M. Effect of creep-aging processing on corrosion resistance of an Al–Zn–Mg–Cu alloy. Mater. Des. 2014, 61, 228–238. [Google Scholar] [CrossRef]

- Xu, L.; Zhan, L.; Xu, Y.; Liu, C.; Huang, M. Thermomechanical pretreatment of Al-Zn-Mg-Cu alloy to improve formability and performance during creep-age forming. J. Mech. Work. Technol. 2021, 293, 117089. [Google Scholar] [CrossRef]

- Petkov, M.P.; Elmukashfi, E.; Tarleton, E.; Cocks, A.C.F. Evaluation of local stress state due to grain-boundary sliding during creep within a crystal plasticity finite element multi-scale framework. Int. J. Mech. Sci. 2021, 211, 106715. [Google Scholar] [CrossRef]

- Lu, W.; Chen, Y.; Zhang, W.; Tan, F.; Li, J.; Liu, B.; Liaw, P.K.; Fang, Q. A hierarchical multiscale crystal plasticity model for refractory multi-principal element alloys. Int. J. Mech. Sci. 2024, 271, 109140. [Google Scholar] [CrossRef]

- Yin, Q.; Wang, J.D.; Wen, Z.X.; Shi, Q.Y.; Lian, Y.D.; Yue, Z.F. Creep-fatigue behavior of nickel-based single crystal superalloy with different orientations: Experimental characterization and multi-scale simulation. Mater. Sci. Eng. A 2023, 886, 145667. [Google Scholar] [CrossRef]

- Vo, N.Q.; Liebscher, C.H.; Rawlings, M.J.S.; Asta, M.; Dunand, D.C. Creep properties and microstructure of a precipitation-strengthened ferritic Fe–Al–Ni–Cr alloy. Acta Mater. 2014, 71, 89–99. [Google Scholar] [CrossRef]

- Griffiths, S.; Croteau, J.R.; Rossell, M.D.; Erni, R.; De Luca, A.; Vo, N.Q.; Dunand, D.C.; Leinenbach, C. Coarsening- and creep resistance of precipitation-strengthened Al–Mg–Zr alloys processed by selective laser melting. Acta Mater. 2020, 188, 192–202. [Google Scholar] [CrossRef]

- Rakhmonov, J.U.; Milligan, B.; Bahl, S.; Ma, D.; Shyam, A.; Dunand, D.C. Progression of creep deformation from grain boundaries to grain interior in Al-Cu-Mn-Zr alloys. Acta Mater. 2023, 250, 118886. [Google Scholar] [CrossRef]

- Yi, M.; Zhang, P.; Deng, S.; Xue, H.; Yang, C.; Liu, F.; Chen, B.; Wu, S.; Lu, H.; Tan, Z.; et al. Atomic-scale compositional complexity ductilizes eutectic phase towards creep-resistant Al-Ce alloys with improved fracture toughness. Acta Mater. 2024, 276, 120133. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, L.; Zhan, L.; Yu, H.; Huang, M. Creep Mechanisms of an Al–Cu–Mg Alloy at the Macro- and Micro-Scale: Effect of the S′/S Precipitate. Materials 2019, 12, 2907. [Google Scholar] [CrossRef]

- Hu, Y.; Jiang, J.; Lei, M.; Song, M.; Nikbin, K. Predicting virtual creep crack growth in a simulated titanium aluminide alloy microstructure containing voids, precipitates, and grain/grain boundary distortions. Eng. Fract. Mech. 2021, 262, 108171. [Google Scholar] [CrossRef]

- Jiang, Q.; Deshpande, A.; Dasgupta, A. Multi-scale Crystal Viscoplasticity Approach for Estimating Anisotropic Steady-State Creep Properties of Single-Crystal SnAgCu Alloys. Int. J. Plast. 2022, 153, 103271. [Google Scholar] [CrossRef]

- Li, K.-S.; Wang, R.-Z.; Wang, J.; Xu, L.; Liu, L.-Q.; Zhang, X.-C.; Tu, S.-T. Investigation of creep-fatigue crack initiation by using an optimal dual-scale modelling approach. Int. J. Fatigue 2023, 172, 107621. [Google Scholar] [CrossRef]

- Li, K.-S.; Cheng, L.-Y.; Xu, Y.; Wang, R.-Z.; Zhang, Y.; Zhang, X.-C.; Tu, S.-T.; Miura, H. A dual-scale modelling approach for creep-fatigue crack initiation life prediction of holed structure in a nickel-based superalloy. Int. J. Fatigue 2022, 154, 106522. [Google Scholar] [CrossRef]

- Sattar, M.; Othman, A.R.; Kamaruddin, S.; Akhtar, M.; Khan, R. Limitations on the computational analysis of creep failure models: A review. Eng. Fail. Anal. 2022, 134, 105968. [Google Scholar] [CrossRef]

- Kassner, M.E.; Pérez-Prado, M.-T. Five-power-law creep in single phase metals and alloys. Prog. Mater. Sci. 2000, 45, 1–102. [Google Scholar] [CrossRef]

- Kale, C.; Srinivasan, S.; Hornbuckle, B.C.; Koju, R.K.; Darling, K.; Mishin, Y.; Solanki, K.N. An experimental and modeling investigation of tensile creep resistance of a stable nanocrystalline alloy. Acta Mater. 2020, 199, 141–154. [Google Scholar] [CrossRef]

- Omprakash, C.M.; Kumar, A.; Srivathsa, B.; Satyanarayana, D.V.V. Prediction of Creep Curves of High Temperature Alloys using θ -Projection Concept. Procedia Eng. 2013, 55, 756–759. [Google Scholar] [CrossRef]

- Liu, P.; Zong, Y.; Shan, D.; Guo, B. Relationship between constant-load creep, decreasing-load creep and stress relaxation of titanium alloy. Mater. Sci. Eng. A 2015, 638, 106–113. [Google Scholar] [CrossRef]

- Zhang, H.-M.; Qin, Y.-H.; Peng, J.; Zhang, W.-Y.; Li, J.-H.; Zha, M. Impressive creep resistance in an additively manufactured Al-Mg alloy enabled by multiscale microstructure tuning. Scr. Mater. 2025, 265, 116753. [Google Scholar] [CrossRef]

- Li, R.Z.; Xie, B.; Yang, X.G.; Fan, Y.S.; Sun, Y.T.; Shi, D.Q. Multi-scale modelling of rafting behaviour under complex stress states for Ni3Al superalloys. Int. J. Plast. 2022, 152, 103255. [Google Scholar] [CrossRef]

- Lv, Z.; Hu, D.; Liu, H.; Zhang, S.; Zhang, B.; You, W.; Wang, R. Creep behavior in coated nickel-based single crystal superalloys with interdiffusion effects: A multi-scale prediction framework. Chin. J. Aeronaut. 2025, in press. [Google Scholar] [CrossRef]

- Li, J.; Fang, Q.; Liu, B.; Liu, Y. Transformation induced softening and plasticity in high entropy alloys. Acta Mater. 2018, 147, 35–41. [Google Scholar] [CrossRef]

- Li, J.; Yi, X.; Liu, B.; Fang, Q.; Liaw, P.K. A phase field crystal model for real-time grain boundary formation and motion in complex concentration alloy. Acta Mater. 2024, 281, 120425. [Google Scholar] [CrossRef]

- Elder, K.R.; Provatas, N.; Berry, J.; Stefanovic, P.; Grant, M. Phase-field crystal modeling and classical density functional theory of freezing. Phys. Rev. B Condens. Matter Mater. Phys. 2007, 75, 064107. [Google Scholar] [CrossRef]

- Greenwood, M.; Ofori-Opoku, N.; Rottler, J.; Provatas, N. Modeling structural transformations in binary alloys with phase field crystals. Phys. Rev. B Condens. Matter Mater. Phys. 2011, 84, 064104. [Google Scholar] [CrossRef]

- Sills, R.B.; Kuykendall, W.P.; Aghaei, A.; Cai, W. Fundamentals of Dislocation Dynamics Simulations. In Multiscale Materials Modeling for Nanomechanics; Weinberger, C.R., Tucker, G.J., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 53–87. [Google Scholar] [CrossRef]

- Cai, W.; Arsenlis, A.; Weinberger, C.; Bulatov, V. A non-singular continuum theory of dislocations. J. Mech. Phys. Solids 2006, 54, 561–587. [Google Scholar] [CrossRef]

- Vattré, A.; Devincre, B.; Roos, A. Dislocation dynamics simulations of precipitation hardening in Ni-based superalloys with high γ′ volume fraction. Intermetallics 2009, 17, 988–994. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, L.; Tong, J. Discrete dislocation dynamics modelling of mechanical deformation of nickel-based single crystal superalloys. Int. J. Plast. 2012, 28, 141–158. [Google Scholar] [CrossRef]

- Yashiro, K.; Kurose, F.; Nakashima, Y.; Kubo, K.; Tomita, Y.; Zbib, H.M. Discrete dislocation dynamics simulation of cutting of γ′ precipitate and interfacial dislocation network in Ni-based superalloys. Int. J. Plast. 2006, 22, 713–723. [Google Scholar] [CrossRef]

- Liu, B.; Raabe, D.; Roters, F.; Arsenlis, A. Interfacial dislocation motion and interactions in single-crystal superalloys. Acta Mater. 2014, 79, 216–233. [Google Scholar] [CrossRef]

- Hu, S.Y.; Chen, L.Q. A phase-field model for evolving microstructures with strong elastic inhomogeneity. Acta Mater. 2001, 49, 1879–1890. [Google Scholar] [CrossRef]

- Demir, E.; Martinez-Pechero, A.; Hardie, C.; Tarleton, E. OXFORD-UMAT: An efficient and versatile crystal plasticity framework. Int. J. Solids Struct. 2025, 307, 113110. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Bronkhorst, C.A.; Anand, L. Crystallographic texture evolution in bulk deformation processing of FCC metals. J. Mech. Phys. Solids 1992, 40, 537–569. [Google Scholar] [CrossRef]

- Wronski, M.; Kumar, M.A.; Capolungo, L.; McCabe, R.J.; Wierzbanowski, K.; Tomé, C.N. Deformation behavior of CP-titanium: Experiment and crystal plasticity modeling. Mater. Sci. Eng. A 2018, 724, 289–297. [Google Scholar] [CrossRef]

- Skamniotis, C.; Grilli, N.; Cocks, A.C.F. Crystal plasticity analysis of fatigue-creep behavior at cooling holes in single crystal Nickel based gas turbine blade components. Int. J. Plast. 2023, 166, 103589. [Google Scholar] [CrossRef]

- Mao, H.; Zeng, C.; Zhang, Z.; Shuai, X.; Tang, S. The effect of lattice misfits on the precipitation at dislocations: Phase-field crystal simulation. Materials 2023, 166, 6307. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Voorhees, P.W. Ostwald ripening of spheroidal particles in multicomponent alloys. Acta Mater. 2018, 152, 327–337. [Google Scholar] [CrossRef]

- Liang, Z.; Xiao, S.; Li, Q.; Li, X.; Chi, D.; Zheng, Y.; Xu, L.; Xue, X.; Tian, J.; Chen, Y. Creep behavior and related phase precipitation of a creep-resistant Y2O3-bearing high Nb containing TiAl alloy. Mater. Charact. 2023, 198, 112767. [Google Scholar] [CrossRef]

- Arsenlis, A.; Rhee, M.; Hommes, G.; Cook, R.; Marian, J. A dislocation dynamics study of the transition from homogeneous to heterogeneous deformation in irradiated body-centered cubic iron. Acta Mater. 2012, 60, 3748–3757. [Google Scholar] [CrossRef]

- Slooff, F.A.; Zhou, J.; Duszczyk, J.; Katgerman, L. Constitutive analysis of wrought magnesium alloy Mg–Al4–Zn1. Scr. Mater. 2007, 57, 759–762. [Google Scholar] [CrossRef]

- Oruganti, R. A new approach to dislocation creep. Acta Mater. 2012, 60, 1695–1702. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, X.; Yang, X.; Li, W.; Aitken, Z.; Vastola, G.; Gao, H.; Zhang, Y.-W. Temperature-dependent, multi-mechanism crystal plasticity reveals the deformation and failure behaviour of multi-principal element alloys. J. Mech. Phys. Solids 2024, 185, 105549. [Google Scholar] [CrossRef]

- Naumenko, K.; Gariboldi, E. Experimental analysis and constitutive modeling of anisotropic creep damage in a wrought age-hardenable Al alloy. Eng. Fract. Mech. 2022, 259, 108119. [Google Scholar] [CrossRef]

- del Valle, J.A.; Pérez-Prado, M.T.; Ruano, O.A. Symbiosis between grain boundary sliding and slip creep to obtain high-strain-rate superplasticity in aluminum alloys. J. Eur. Ceram. Soc. 2007, 27, 3385–3390. [Google Scholar] [CrossRef]

- Wilshire, B.; Whittaker, M.T. The role of grain boundaries in creep strain accumulation. Acta Mater. 2009, 57, 4115–4124. [Google Scholar] [CrossRef]

), (

), ( ), (

), ( ), and (

), and ( ).

).

), (

), ( ), (

), ( ), and (

), and ( ).

).

), (

), ( ), (

), ( ), and (

), and ( ).

).

), (

), ( ), (

), ( ), and (

), and ( ).

).

), (

), ( ), (

), ( ), and (

), and ( ).

).

), (

), ( ), (

), ( ), and (

), and ( ).

).

), (

), ( ), (

), ( ), and (

), and ( ).

).

), (

), ( ), (

), ( ), and (

), and ( ).

).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, W.; Wu, J.; Liu, J.; Yi, X.; Zhang, Q.; Chen, Y.; Li, J.; Fang, Q. Creep Behavior and Deformation Mechanism of Aluminum Alloy: Integrating Multiscale Simulation and Experiments. Symmetry 2025, 17, 1146. https://doi.org/10.3390/sym17071146

Lu W, Wu J, Liu J, Yi X, Zhang Q, Chen Y, Li J, Fang Q. Creep Behavior and Deformation Mechanism of Aluminum Alloy: Integrating Multiscale Simulation and Experiments. Symmetry. 2025; 17(7):1146. https://doi.org/10.3390/sym17071146

Chicago/Turabian StyleLu, Weizheng, Jianguo Wu, Jiajun Liu, Xiaoai Yi, Qiyue Zhang, Yang Chen, Jia Li, and Qihong Fang. 2025. "Creep Behavior and Deformation Mechanism of Aluminum Alloy: Integrating Multiscale Simulation and Experiments" Symmetry 17, no. 7: 1146. https://doi.org/10.3390/sym17071146

APA StyleLu, W., Wu, J., Liu, J., Yi, X., Zhang, Q., Chen, Y., Li, J., & Fang, Q. (2025). Creep Behavior and Deformation Mechanism of Aluminum Alloy: Integrating Multiscale Simulation and Experiments. Symmetry, 17(7), 1146. https://doi.org/10.3390/sym17071146