The Sustainable Allocation of Earth-Rock via Division and Cooperation Ant Colony Optimization Combined with the Firefly Algorithm

Abstract

1. Introduction

- (1)

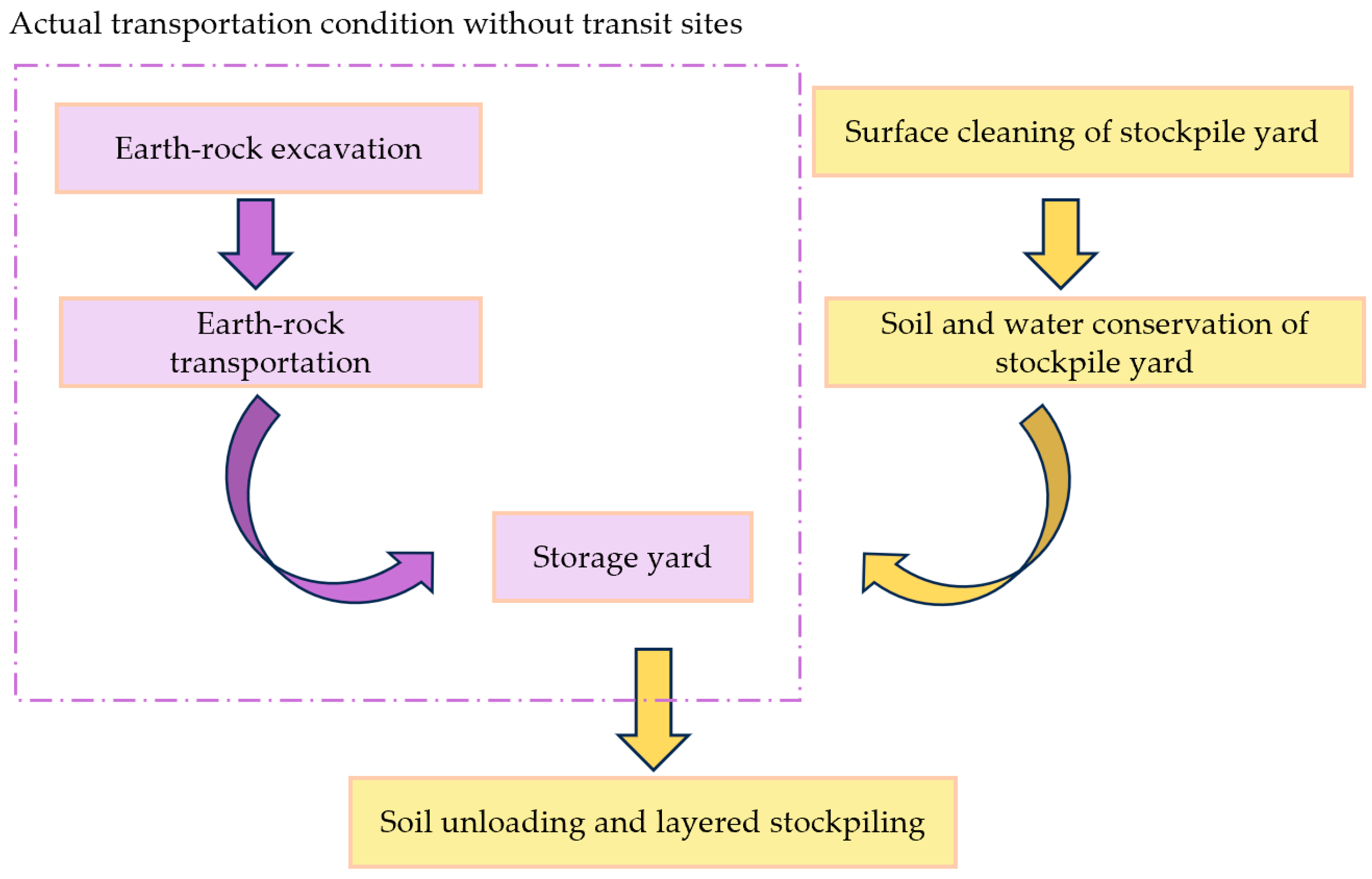

- From the perspective of economic and environmental benefits, to analyze the characteristics of large-scale waterway project earth-rock allocation, an allocation model without a transfer yard was established and simplified at the same time to reduce the cost of the transfer yard involved in site leasing, etc. In building the model, we also considered land acquisition project approval time, the project characteristics of the separation of earth-rock allocation independently, and the topsoil, covering a variety of constraints to build a more comprehensive and practical model.

- (2)

- An optimized sustainable earth-rock allocation model integrating an improved ant colony algorithm and firefly algorithm is proposed, adopting a two-stage hybrid optimization framework. The improved ant colony algorithm is tailored to the characteristics of earth-rock in the improved model to separate and allocate independently, and improves the local search efficiency. The firefly algorithm strengthens global optimization capability, and balances the algorithm’s convergence accuracy and stability through the adaptive parameter adjustment mechanism. The remainder of the paper is organized as follows. Section 2 introduces the earth-rock allocation model. The earth-rock allocation optimization algorithm is proposed in Section 3. Section 4 provides engineering applications, followed by conclusions.

2. Related Works

- Earth-rock allocation background

- 2.

- Project background

- 3.

- Technical background

3. Earth-Rock Allocation Model

3.1. Problem Analysis

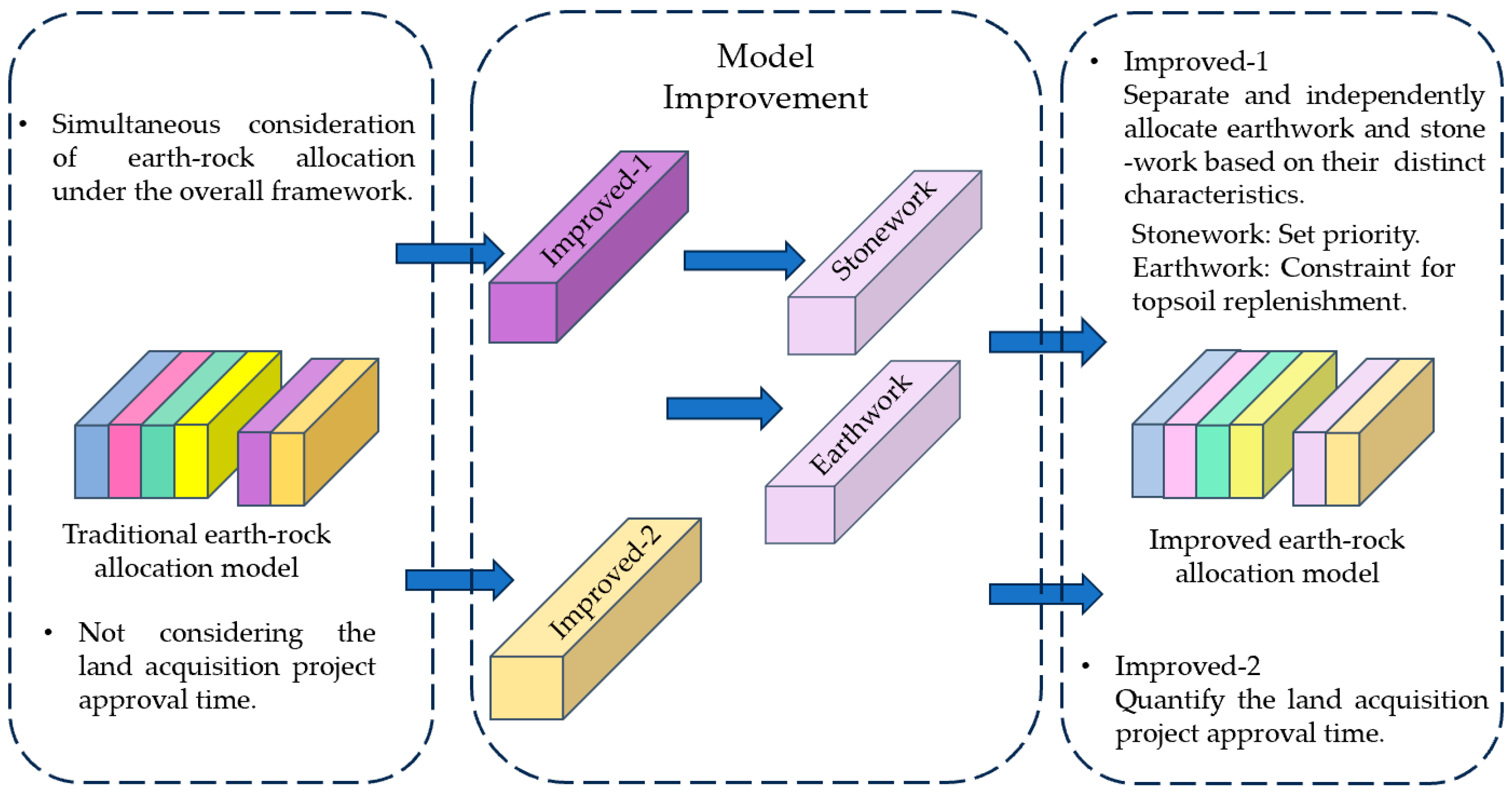

- The model considers independent allocation based on project characteristics, and allocates earthwork and stonework separately, optimizing them according to their specific characteristics. Firstly, given that the unit price of stonework is higher, priority should be given to stonework blending when the transportation distance is shorter. Secondly, according to the soil layer thickness requirements of the relevant standards or specifications for environmental restoration projects, the amount of earthwork is constrained according to the footprint of the stockpile at the later stage of construction, to ensure the effective replenishment of topsoil in the greening area while meeting the needs of the project, thereby promoting environmental protection and ecological restoration.

- Previously, the earth-rock allocation problem did not consider the land requisition project approval timeline, but a reasonable arrangement of the time can reduce the project stagnation period and avoid the waste of manpower, material resources, and other resources caused by timing delays. Therefore, the land requisition project approval time constraint is added to the model to improve the overall efficiency and compliance of the project.

3.2. Modeling

3.3. Constraints

- ①

- Balance constraint for supply and reception:

- ②

- Capacity constraint for stacking:

- ③

- Time constraint for land requisition project approval:

- ④

- Constraint for stonework near priority:

- ⑤

- Constraint for topsoil overlay:

- ⑥

- Zero constraints for excavation quantity at the end of allocation:

- ⑦

- Constraint for non-negative variables:

4. Earth-Rock Allocation Optimization Algorithm

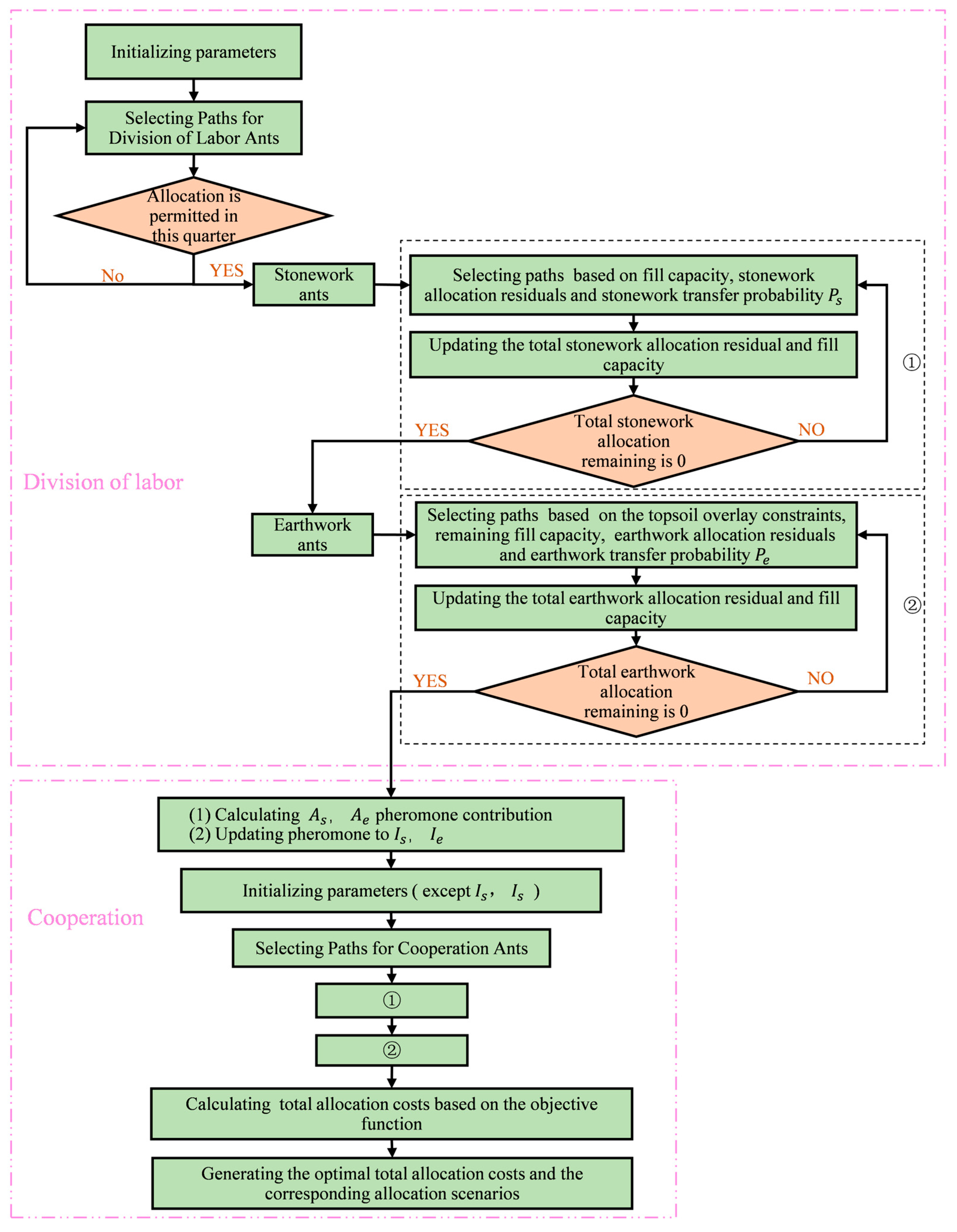

4.1. Evolution from ACO to DC-ACO

4.1.1. ACO

4.1.2. DC-ACO

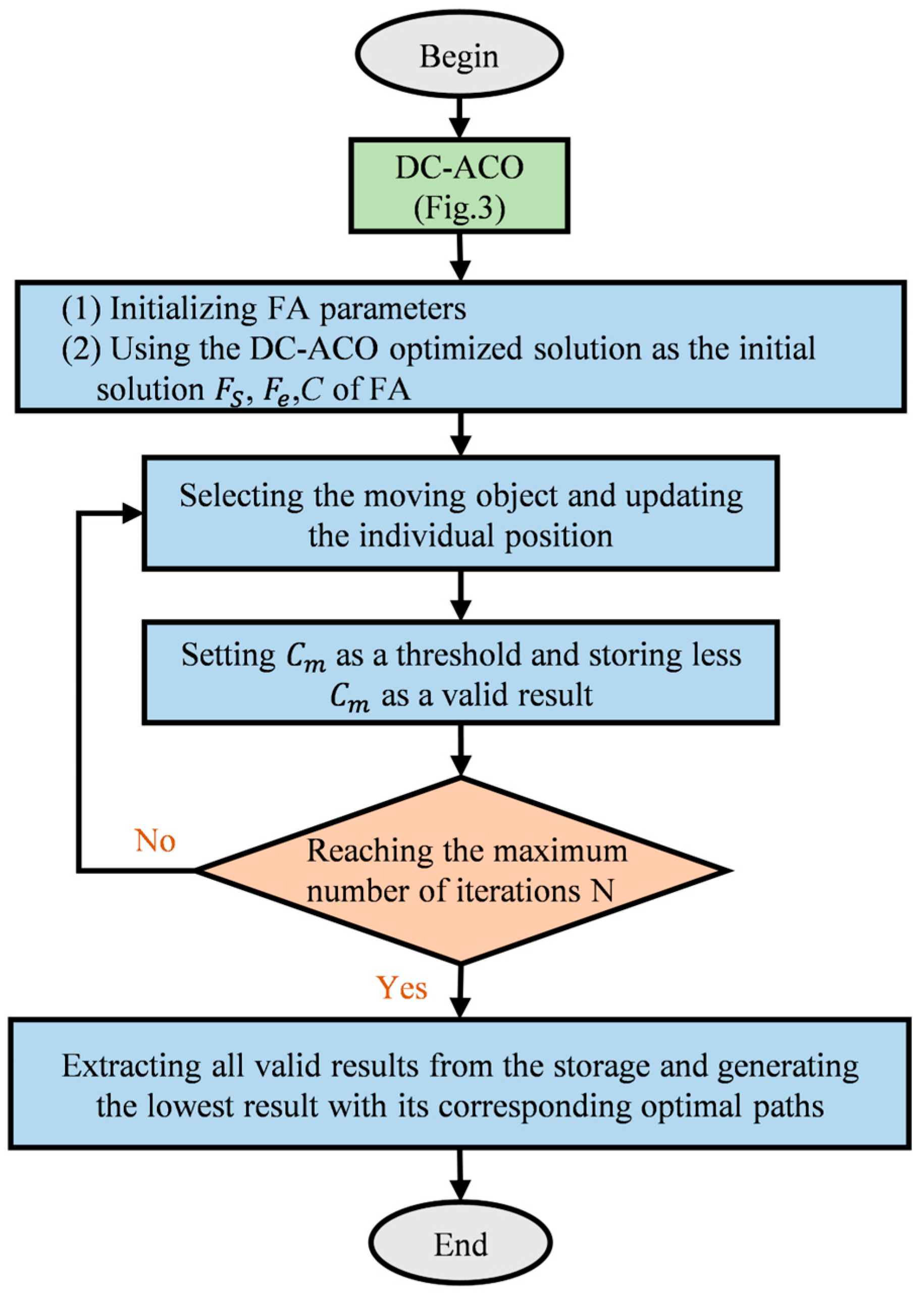

4.2. Evolution from DC-ACO to DC-FACO

4.2.1. FA

4.2.2. DC-FACO

4.2.3. DC-FACO-Based Earth-Rock Allocation Process

5. Engineering Applications

5.1. Engineering General Situation

5.2. Comparative Analysis of the Results of Different Algorithms

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACO | Ant Colony Optimization |

| FA | Firefly Algorithm |

| DC-ACO | Division and Cooperation Ant Colony Optimization |

| DC-FACO | Division and Cooperation Ant Colony Optimization combined with Firefly Algorithm |

Appendix A

Appendix A.1

| Algorithm A1 DC-ACO |

| INPUT (Problem Parameters): stone_total, earth_total, capacity_stone, capacity_earth, distance, stone_price, earth_price, quarters_constraint, min_earth_ratio, area, max_stone_per_quarter, max_earth_per_quarter INPUT (Algorithm Parameters): num_ants OUTPUT: allocation_stone, allocation_earth, mini_cost # --------------------------------------------------- 1. Preprocessing Calculation: Calculate the minimum earthwork volume: min_earth = min_earth_ratio × 1.08 × 10−4 × area Initialize the pheromone matrix: pheromone = ones (3 × 12 × 4) 2. Clustering Ant Colony Optimization: for epoch in 1 to 50: # Stonework Ant Allocation for run in 1 to 100: for ant in 1 to num_ants/2: P(src,dest, q) ∝ (pheromone^) × (1/(distance × stone_price))^ Satisfying constraints: - quarters_constraint[dest,q] = 1 - Σstone_alloc[src, dest, :] ≤ capacity_stone[dest] - Σstone_alloc[:, :, q] ≤ max_stone_per_quarter # Earthwork Ant Allocation for ant in 1 to num_ants/2: if q = 4: earth_alloc[3, dest, 4] = min_earth[dest] P(src, dest, q) ∝ (pheromone^) × (1/(distance × earth_price))^ Satisfying constraints: - quarters_constraint[dest,q] = 1 - Σearth_alloc[src, dest, :] ≥ min_earth[dest] - Σearth_alloc[:, :, q] ≤ max_earth_per_quarter # Compute cost and update optimal solution cost = transport_cost + 26.34 × total_volume solutions.append ((stone_alloc, earth_alloc, cost)) # Pheromone update pheromone *= (1-) pheromone += Σ(/solution_cost) for top 10% solutions 3. Post-Optimization for Entire Ant Colony: ants = [non-dominated solutions from solutions] for i in ants: for j in ants: if cost_j < cost_i: Pheromone Concentration Update: beta = × exp(- × distance(i, j)^2) stone_alloc_i += × (stone_alloc_j − stone_alloc_i) earth_alloc_i += × (earth_alloc_j − earth_alloc_i) Global Optimum Update: mini_cost = min(ants.costs) |

Appendix A.2

| Algorithm A2 DC-FACO |

| NPUT (Problem Parameters): stone_total, earth_total, capacity_stone, capacity_earth, distance, stone_price, earth_price, quarters_constraint, min_earth_ratio, area, max_stone_per_quarter, max_earth_per_quarter INPUT (Algorithm Parameters): num_ants, num_fireflies OUTPUT: best_earth_allocation, best_stone_allocation, best_cost # --------------------------------------------------- 1. Preprocessing Calculation: Calculate the minimum earthwork volume: min_earth = min_earth_ratio × 1.08 × 10−4 × area Initialize the pheromone matrix: pheromone = ones (3 × 12 × 4) 2. Clustering Ant Colony Optimization: for epoch in 1 to 50: # Stonework Ant Allocation for run in 1 to 100: for ant in 1 to num_ants/2: P(src, dest, q) ∝ (pheromone^) × (1/(distance × stone_price))^ Satisfying constraints: - quarters_constraint[dest ,q] == 1 - Σstone_alloc[src, dest, :] ≤ capacity_stone[dest] - Σstone_alloc[:, :, q] ≤ max_stone_per_quarter # Earthwork Ant Allocation for ant in 1 to num_ants/2: if q == 4: earth_alloc[3, dest, 4] = min_earth[dest] P(src, dest, q) ∝ (pheromone^) × (1/(distance×earth_price))^ Satisfying constraints: - quarters_constraint[dest,q]==1 - Σearth_alloc[src, dest, :] ≥ min_earth[dest] - Σearth_alloc[:, :, q] ≤ max_earth_per_quarter # Compute cost and update optimal solution cost = transport_cost + 26.34 × total_volume solutions.append((stone_alloc, earth_alloc, cost)) # Pheromone update pheromone *= (1- ) pheromone += Σ(/solution_cost) for top 10% solutions 3. Post-Optimization for Entire Ant Colony: ants = [non-dominated solutions from solutions] for i in ants: for j in ants: if cost_j < cost_i: Pheromone Concentration Update: beta = × exp(- × distance(i,j)^2) stone_alloc_i += ×(stone_alloc_j − stone_alloc_i) earth_alloc_i += ×(earth_alloc_j − earth_alloc_i) Global Optimum Update: mini_cost = min(ants.costs) # --------------------------------------------------- 4. FA Preprocessing calculations: firefly_stone_positions = allocation_stone, firefly_earth_positions = allocation_earth, firefly_costs = min_cost 5. FA master cycle: for iter in 1 to max_generations: Calculate the cost of all fireflies: Cost = transport_cost + 26.34 × total_volume # Firefly attraction rules for f1 in 1 to num_fireflies: for f2 in 1 to num_fireflies: if cost[f1] > cost[f2]: stone_dist = ||stone_alloc[f1]- − stone_alloc[f2]||_Frobenius earth_dist = ||earth_alloc[f1] − earth_alloc[f2]||_Frobenius β_stone = exp(−gamma * stone_dist) β_earth = exp(−gamma * earth_dist) stone_allocation[f1] = β_stone * (stone_allocation [f2] − stone_allocation [f1]) + α* rand earth_allocation [f1] = β_earth * (earth_allocation [f2] − earth_allocation [f1]) + α* rand stone_allocation [f1] = max(0, stone_ allocation) earth_ allocation [f1] = max(0, earth_ allocation) # Record the solutions that satisfy the threshold if current best cost < threshold: below_threshold_results.append= stone_allocation [f1], earth_allocation [f1] else: iscard 6. Statistical results to find the optimal solution below_threshold_values = [result[2] for result in below_threshold_results] best_cost= argmin(below_threshold_values) best_stone_allocation = below_threshold_results[best_cost] best_earth_allocation = below_threshold_results[best_cost] |

References

- Xiong, X.Y.; Zhao, F.; Su, L.J.; Xu, J.X. Earthwork balance and plan of a large-scale hydropower project. Yangtze River 2011, 42, 41–43. [Google Scholar] [CrossRef]

- Aizez, I.; Akejiang, S. Analysis of problems existing in earth-rock balance and material allocation of water conservancy and hydropower projects in Xinjiang. China Rural. Water Hydropower 2012, 04, 139–141+144. [Google Scholar]

- Jiang, S.Y.; Li, X.W.; Dong, S.; Shen, M. Study on allocation balance of faced rock-fill dam earth-rock work based on large scale system theory. Water Resour. Power 2013, 31, 128-1. [Google Scholar]

- Huang, L.; Zuo, S.; Yu, B.; Chen, S. Optimization of the earthwork excavation-filling balance and allocation for the upper reservoir of a pumped storage power station. J. Energy Storage 2024, 83, 110722. [Google Scholar] [CrossRef]

- Katebi, A.; Pishvaee, M.S.; Mohebalizadeh, A.; Pazhuhandeh, A.; Katebi, B. Towards Developing a Robust Optimization Model of Earthwork Allocations in Roadway Projects. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 47, 2507–2520. [Google Scholar] [CrossRef]

- Yu, J.; Huang, Y.; Xing, L.; Li, M. Earthwork allocation optimisation based on cut-fill matching and transportation path planning. Int. J. Autom. Control 2024, 18, 588–603. [Google Scholar] [CrossRef]

- Li, D.H.; Shao, X.F.; Shen, C. Study on optimization of the green construction scheme of earthwork projects based on Value engineering. Joumal Jiangsu Univ. Sci. Technol. (Nat. Sci. Ed.) 2019, 33, 114–118. [Google Scholar]

- Qian, L.Y.; Bao, X.Y. On the optimal allocation of earthwork in railway subgrade based on green construction. J. Eng. Stud. 2019, 11, 64–74. [Google Scholar] [CrossRef]

- Huang, B.H.; Zhao, Y.; Lu, R.; Zheng, J.Q.; Xu, B.S. Earthwork allocation method based on ant colony algorithm. J. Civ. Eng. Manag. 2019, 36, 72–77+84. [Google Scholar] [CrossRef]

- Zhao, Y.; Jia, Z.; Zhang, J.W.; Cao, K.; Chen, C. Research on earthwork allocation of face rockfill dam based on particle swarm optimization and genetic algorithm. J. North China Univ. Water Resour. Electr. Power (Nat. Sci. Ed.) 2022, 43, 54–59+68. [Google Scholar]

- Deng, N.; Li, X.; Su, Y. Optimization of Earthwork Allocation Path as Vehicle Route Problem Based on Genetic Algorithm. In Proceedings of the E3S Web of Conferences 2020, Changchun, China, 20–22 March 2020; p. 16504057. [Google Scholar]

- Wang, K.S.; Wang, C.X.; Xie, M.L.; Cheng, W.; Huang, Y. A Hybrid Algorithm Based on Genetic Algorithm and Tabu Search Algorithm for Earth and Rock Allocation Modeling. Constr. Econ. 2024, 45 (Suppl. S2), 215–220. [Google Scholar]

- Li, A.; Li, Y.; Yao, B.W.; Li, Y.L.; Jiang, L.P. Optimal Allocation Model of Earthwork and Its Application Based on Dynamic Path Planning. Henan Sci. 2025, 1–7. Available online: http://kns.cnki.net/kcms/detail/41.1084.N.20250226.0901.006.html (accessed on 12 June 2025).

- Liu, Y.; Song, J.; Wen, J.Y. An optimizing algorithm of static task scheduling problem based on hybrid genetic algorithm. High Technol. Lett. 2016, 22, 170–176. [Google Scholar]

- Wang, F.; Chun, W.; Wu, W. Application of simulated annealing algorithm in multi-objective allocation optimization of urban water resources. Desalination Water Treat. 2023, 314, 304–313. [Google Scholar] [CrossRef]

- Zuo, G.; Jia, Z.; Wu, Z.; Shi, J.; Wang, G. A Q-learning guided dual population genetic algorithm for distributed permutation flow shop scheduling problem with machine having fuzzy processing efficiency. Expert Syst. Appl. 2025, 285, 127882. [Google Scholar] [CrossRef]

- Liu, C.; Wu, L.; Xiao, W.; Li, G.; Xu, D.; Guo, J.; Li, W. An improved heuristic mechanism ant colony optimization algorithm for solving path planning. Knowl.-Based Syst. 2023, 271, 110540. [Google Scholar] [CrossRef]

- Zhao, J.H.; Lu, Y.M.; Cai, B. Multi-Satellite and Multi-Objective Mission Scheduling Based on Improved Genetic and Firefly Algo-rithms. Comput. Simul. 2023, 40, 57–63+82. [Google Scholar]

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhang, Y.; Dai, X.; Zhang, S. A modified reptile search algorithm for nu-merical optimization problems. Comput. Intell. Neurosci. 2022, 2022, 9752003. [Google Scholar] [CrossRef]

- Yao, L.; Li, G.; Yuan, P.; Yang, J.; Tian, D.; Zhang, T. Reptile search algorithm considering different flight heights to solve engineering optimization design problems. Biomimetics 2023, 8, 305. [Google Scholar] [CrossRef]

- Sasmal, B.; Hussien, A.G.; Das, A.; Dhal, K.G.; Saha, R. Reptile search algorithm: Theory, vari-ants, applications, and performance evaluation. Arch. Comput. Methods Eng. 2024, 31, 521–549. [Google Scholar] [CrossRef]

- Natarajan, R.; Megharaj, G.; Marchewka, A.; Divakarachari, P.B.; Hans, M.R. Energy and distance based multi-objective red fox optimization algorithm in wireless sensor network. Sensors 2022, 22, 3761. [Google Scholar] [CrossRef] [PubMed]

- Chellapraba, B.; Manohari, D.; Periyakaruppan, K.; Kavitha, M.S. Oppositional Red Fox Optimization Based Task Scheduling Scheme for Cloud Environment. Comput. Syst. Sci. Eng. 2023, 45, 484. [Google Scholar] [CrossRef]

- Zhou, X.; Ma, H.; Gu, J.; Chen, H.; Deng, W. Parameter adaptation-based ant colony optimization with dynamic hybrid mechanism. Eng. Appl. Artif. Intell. 2022, 114, 105139. [Google Scholar] [CrossRef]

- Patle, B.K.; Pandey, A.; Jagadeesh, A.; Parhi, D.R. Path planning in uncertain environment by using firefly algorithm. Def. Technol. 2018, 14, 691–701. [Google Scholar] [CrossRef]

| Fillings | K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 | K11 | K12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Names | |||||||||||||

| Occupany area (hm2) | 2.2 | 8.3 | 12.4 | 6.2 | 3.5 | 9.7 | 6.5 | 1.5 | 4.1 | 63.7 | 10.2 | 89.1 | |

| Average transportation distance (km) | 0.2 | 0.6 | 0.9 | 0.4 | 0.9 | 0.3 | 0.4 | 0.4 | 0.2 | 4.6 | 4.8 | 5.1 | |

| Design capacity (million m3) | 12.7 | 53.7 | 76.7 | 36.1 | 10.2 | 72.6 | 31.1 | 4.9 | 17.6 | 877.4 | 506.0 | 453.9 | |

| Fillings | K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 | K11 | K12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Names | |||||||||||||

| Q1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | |

| Q2 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | |

| Q3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Q4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Quarters | Q1 | Q2 | Q3 | Q4 | ||||

|---|---|---|---|---|---|---|---|---|

| Fillings | S | E | S | E | S | E | S | E |

| K1 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 7.4100 | 4.5730 | 0.0000 | 0.7170 |

| K2 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 47.4900 | 3.5101 | 0.0000 | 2.6999 |

| K3 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 51.2600 | 21.4117 | 0.0000 | 4.0283 |

| K4 | 25.2300 | 8.8699 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 2.0001 |

| K5 | 8.5200 | 0.5525 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 1.1275 |

| K6 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 13.8400 | 18.0595 | 37.5600 | 3.1405 |

| K7 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.7080 | 26.1800 | 2.1060 |

| K8 | 3.5300 | 0.3766 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.4967 |

| K9 | 14.3300 | 0.7437 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 1.3132 |

| K10 | 68.3800 | 74.2098 | 36.7000 | 84.7526 | 0.0000 | 36.4902 | 0.0000 | 34.9631 |

| K11 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 3.2918 |

| K12 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 28.8684 |

| Quarters | Q1 | Q2 | Q3 | Q4 | ||||

|---|---|---|---|---|---|---|---|---|

| Fillings | S | E | S | E | S | E | S | E |

| K1 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 10.0900 | 1.8930 | 0.0000 | 0.7170 |

| K2 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 47.2300 | 3.7601 | 0.0000 | 2.6999 |

| K3 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 61.3000 | 11.3717 | 0.0000 | 4.0283 |

| K4 | 31.5700 | 2.5299 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 2.0001 |

| K5 | 8.3000 | 0.2725 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 1.1275 |

| K6 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 1.3800 | 0.4895 | 67.5900 | 3.1405 |

| K7 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 27.7600 | 2.1060 |

| K8 | 3.5350 | 0.3716 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.4967 |

| K9 | 14.8600 | 0.1137 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 1.3132 |

| K10 | 61.2350 | 81.4648 | 5.0900 | 84.7525 | 0.0000 | 67.2382 | 0.0000 | 34.9631 |

| K11 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 3.2918 |

| K12 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 28.8684 |

| Quarters | Q1 | Q2 | Q3 | Q4 | ||||

|---|---|---|---|---|---|---|---|---|

| Fillings | S | E | S | E | S | E | S | E |

| K1 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 10.5300 | 1.4530 | 0.0000 | 0.7170 |

| K2 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 47.4900 | 3.5101 | 0.0000 | 2.6999 |

| K3 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 61.3200 | 11.3517 | 0.0000 | 4.0283 |

| K4 | 32.7300 | 1.3699 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 2.0001 |

| K5 | 8.5400 | 0.5325 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 1.1275 |

| K6 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.6600 | 0.0595 | 68.7400 | 3.1405 |

| K7 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 27.5700 | 2.1060 |

| K8 | 3.7400 | 0.1666 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.4967 |

| K9 | 15.2100 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 1.3132 |

| K10 | 59.7800 | 82.6835 | 4.1300 | 84.7535 | 0.0000 | 68.3782 | 0.0000 | 34.9631 |

| K11 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 3.2918 |

| K12 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 28.8684 |

| Algorithm | ACO | DC-ACO | DC-FACO |

|---|---|---|---|

| Optimal function value (million CNY) | 2.80712 × 104 | 2.80356 × 104 | 2.80350 × 104 |

| Worst value (million CNY) | 2.80712 × 104 | 2.80399 × 104 | 2.80371 × 104 |

| Average value (million CNY) | 2.80712 × 104 | 2.80375 × 104 | 2.80361 × 104 |

| Standard deviation | 0.00000 | 1.1668 | 0.5272 |

| Algorithm | Standard Deviation | CV | Stability |

|---|---|---|---|

| ACO | 0.0000 | 0.0000 | Excellent |

| DC-ACO | 1.2276 | 0.0044 | Mediocre |

| DC-FACO | 0.5220 | 0.0018 | Better |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Lu, J.; Gao, H.; Li, D. The Sustainable Allocation of Earth-Rock via Division and Cooperation Ant Colony Optimization Combined with the Firefly Algorithm. Symmetry 2025, 17, 1029. https://doi.org/10.3390/sym17071029

Li L, Lu J, Gao H, Li D. The Sustainable Allocation of Earth-Rock via Division and Cooperation Ant Colony Optimization Combined with the Firefly Algorithm. Symmetry. 2025; 17(7):1029. https://doi.org/10.3390/sym17071029

Chicago/Turabian StyleLi, Linna, Junyi Lu, Han Gao, and Dan Li. 2025. "The Sustainable Allocation of Earth-Rock via Division and Cooperation Ant Colony Optimization Combined with the Firefly Algorithm" Symmetry 17, no. 7: 1029. https://doi.org/10.3390/sym17071029

APA StyleLi, L., Lu, J., Gao, H., & Li, D. (2025). The Sustainable Allocation of Earth-Rock via Division and Cooperation Ant Colony Optimization Combined with the Firefly Algorithm. Symmetry, 17(7), 1029. https://doi.org/10.3390/sym17071029