4.2. Results and Discussion

The case mentioned by Lee has been adopted by most scholars as the test standard of most Petri net algorithms. The classic algorithm and recently proposed graph search algorithms based on Petri nets are used as a comparison to verify the superiority of the algorithm. The five algorithms referenced in [

24,

25,

26,

27,

28] are all graph-based scheduling methods utilizing Petri nets models. L1, DWS, and HFBS are heuristic-driven search algorithms based on firing sequence enumeration. ACAS and WGA incorporate adaptive control strategies and weighted evaluation metrics to improve scheduling outcomes. NSGA-II is a widely adopted multi-objective evolutionary algorithm. In contrast, the proposed TPGA approach integrates a time Petri nets model with a genetic algorithm framework, leveraging token dynamics to handle both static and dynamic scheduling under uncertainty.

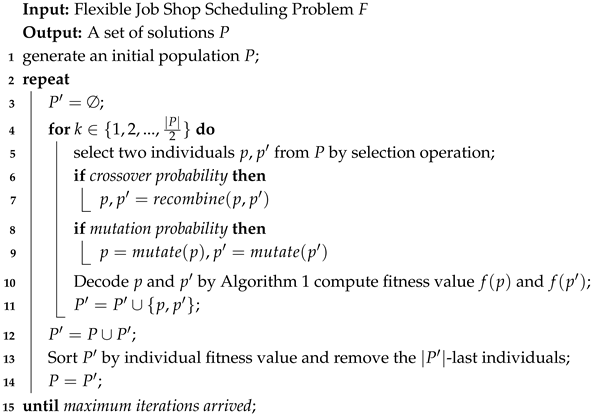

In the comparative experiments, a set of predefined production tasks and workflows for flexible job shop systems are used as benchmark cases. Each task consists of a sequence of operations, and every operation has an associated work time. The performance metric reported in

Table 5 is the total completion time (makespan) required to finish all tasks in each case, measured in time units. A lower value indicates better scheduling performance.

From the comparative experimental results, it can be seen that with the minimum completion time as the optimization goal, the TPGA has obtained a better solution in the three cases. The stability of the TPGA’s results across repeated calculations indicates its ability to consistently provide superior solutions. The experimental results prove that the Petri nets method proposed in this article can accurately describe the manufacturing process of the flexible job shop, and the TPGA can effectively search for an excellent scheduling scheme on the Petri nets model. The effectiveness of the model and the proposed algorithm is verified.

In traditional flexible job shop scheduling problems, machine constraints typically account only for processing time. However, in real manufacturing settings, machines incur additional setup time when transitioning between different jobs for processing. These time constraints were not considered in the LD3, LD4a, and LD4b cases. In order to further demonstrate that the TPGA can still address the actual manufacturing scenario with multiple time constraints, we produced a simulation dataset with multiple time constraints for experiments.

We set up experimental cases of different scales in process manufacturing scenarios, discrete manufacturing scenarios and hybrid manufacturing scenarios. The size of the experimental case was determined by the number of job types and the number of machine types in the job shop. The job shop in the experimental case was modeled by the Petri nets modeling method proposed in this article, and the TPGA was used on the model to address the flexible job shop scheduling problem. In order to evaluate the performance of the TPGA, the greedy iterative algorithms SJF and HRN were used to address the flexible job shop scheduling problem on the established model.

After multiple tests with a population size of 300, the algorithm typically required 30 to 60 iterations to obtain a stable and improved solution. The maximum number of iterations was set to 100, and the algorithm running time was about 150 s.

In a process manufacturing scenario, jobs are processed by different types of machines in a job shop in a fixed sequence. In the small-scale case, the job shop has five types of machines and four types of jobs, and each job is processed by three to five operations. In the medium-scale case, the job shop has eight types of machines, six types of jobs, and each type of jobs is processed by six to eight operations. In a large-scale case, the job shop has ten types of machines, ten types of jobs, and each type of job is processed by seven to ten operations. In the experimental case, five of each type of jobs need to be produced, and there are three of each type of machine in the job shop. The experimental results are shown in

Table 6. In the process manufacturing scenario, the TPGA has achieved a better scheduling results across all scales. Due to the low complexity of process manufacturing operations, changes in the scale of the job shop have little impact on the TPGA’s performance. As shown in

Figure 3, in the process manufacturing scenario, the performance of the TPGA is improved by an average of 20% compared with the greedy iterative algorithm.

In a discrete manufacturing scenario, a job consists of two to three components. Each component is completed in a fixed processing sequence, and finally, the assembly machine combines the components into a complete job. In the small-scale case, the job shop has five types of machines, four types of jobs, and the components of the jobs are processed by three to five operations. In the medium-scale case, the job shop has eight types of machines, six types of jobs, and the components of the jobs are processed by four to six operations. In a large-scale case, the job shop has ten types of machines, ten types of jobs, and the parts of the jobs are processed by five to eight operations. In the experimental case, five of each job type need to be produced. There are three processing machines of each type in the job shop, and the number of assembly machines is five. The experimental results are shown in

Table 6. In the discrete manufacturing scenario, the TPGA still obtains better results at various scales, but with the increase in the job shop scale, the solution efficiency and quality of the TPGA decrease. This is because discrete manufacturing operations are relatively complex, and the scale of the job shop has a greater impact on the solution space of the algorithm. As shown in

Figure 3, compared with the greedy iterative algorithm, the performance of the TPGA is improved by an average of 15% in the discrete manufacturing scenario.

In a hybrid manufacturing scenario, the job shop has both the above-mentioned process manufacturing jobs and discrete manufacturing jobs. In the experimental case, the number of jobs in the two processing processes is the same, there are three processing machines of each type in the workshop, and the number of assembly machines is five. The experimental results are shown in

Table 6. In hybrid scenarios, job shop scheduling exhibits higher complexity. The performance of the HRN algorithm fluctuates significantly at different scales, whereas the TPGA consistently achieves better scheduling results across various scales. As shown in

Figure 3, compared with the greedy iterative algorithm, the performance of TPGA is improved by 18% on average in the discrete manufacturing scenario.

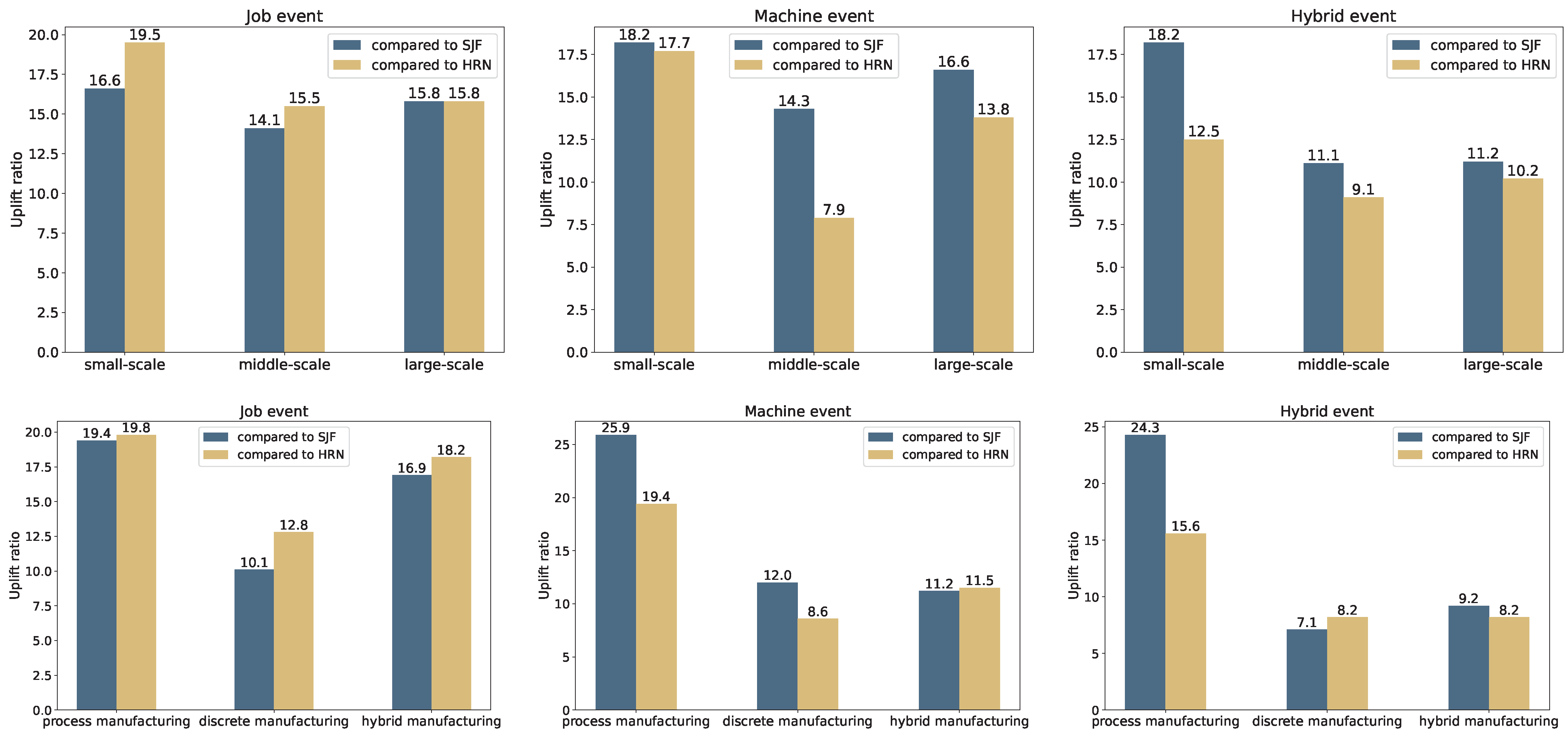

In order to verify the dynamic scheduling performance of the algorithm proposed in this paper, we add random dynamic events to different scales of process manufacturing, discrete manufacturing, and hybrid manufacturing cases. Dynamic events are divided into three categories: job events, machine events, and hybrid events.

Job events are those events which temporarily add the jobs to the job shop. Select 3–6 types of jobs from the existing pool of six types to increase their number. The incremented count ranges randomly between 4 and 6. Machine events are used to reduce the number of machines at the job shop workstations. Random machine events are introduced across the five types of machines in the workshop, where the number of faults for each machine type is random. At least three machines of each type are kept available. Hybrid events refer to job events and machine events occurring simultaneously. These events add tasks for 3–6 types of jobs in the workshop, introducing random task quantities ranging from three to six, implementing random machine events across the five types of machines, and randomizing the number of faults for each machine type. A minimum of four machines for each type is ensured to remain operational.

Machine events lead to changes in the job shop’s job processing capabilities and require dynamic adjustment of the scheduling plan. Job events simulate random job insertion events that occur in the real job shop and randomizing the number of faults for each machine type. A minimum of four machines for each type is ensured to remain operational. The TPGA employs event-driven rescheduling to adapt the scheduling method to dynamic events and utilizes a complete rescheduling strategy for all unprocessed and new jobs.

The experimental results of the dynamic scheduling case of the hybrid manufacturing job shop are shown in

Table 7. All algorithms were run 10 times continuously in process manufacturing and discrete manufacturing scenarios, respectively, and the average values were used for comparison. The TPGA achieves the best scheduling results for three dynamic events in different scenarios. In the dynamic flexible job shop case study, three manufacturing types (process, discrete, and hybrid) and three scales (small, medium, large) were considered.

Figure 4 shows the efficiency improvement of the proposed algorithm over SJF and HRN under three dynamic event types: job, machine, and hybrid events. The first row presents results by manufacturing scale, and the second row by manufacturing type. Captions and legends clearly distinguish the dynamic event types. Compared to the greedy iterative algorithm, the proposed method improves average performance by 23% in process manufacturing. The discrete manufacturing flexible job shop has higher job complexity, and the dynamic scheduling performance of the TPGA in this scenario is improved by an average of 10%. The hybrid manufacturing job shop has both features of process manufacturing and discrete manufacturing. The TPGA improves the dynamic scheduling problem results of hybrid manufacturing flexible job shop by an average of 13% compared with the greedy iterative algorithm. As shown in

Figure 4, the TPGA has superior performance compared with the greedy iterative algorithm in solving the small-scale flexible job shop dynamic scheduling problem.

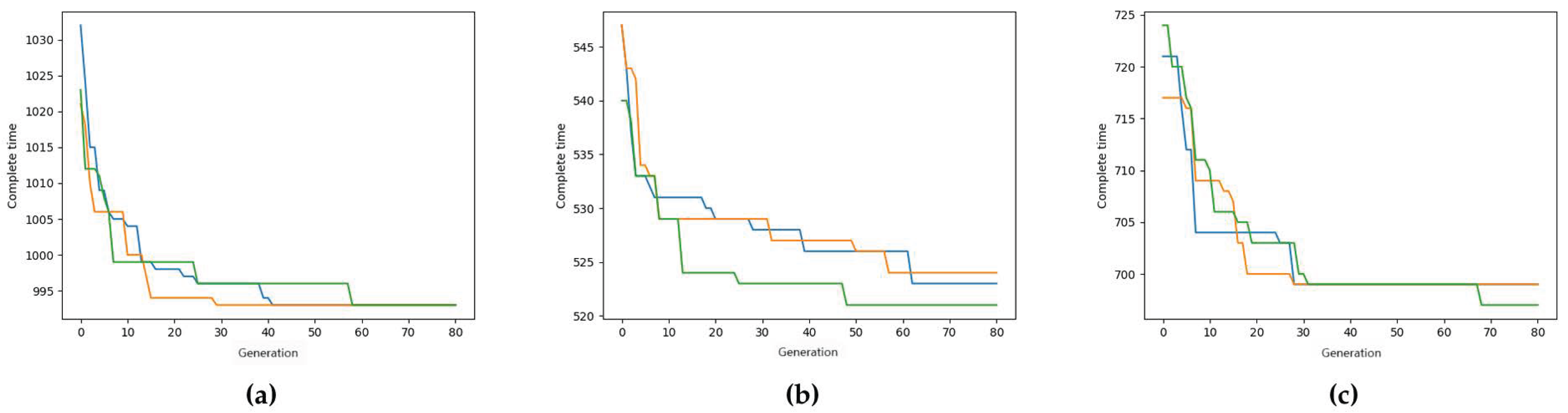

In addition, we have also conducted some experiments to test the convergence speed of the proposed algorithm. In the experiment, 100 flexible job shop scenarios were generated through simulation. All cases were tested using the Time Petri Nets Improved Genetic Algorithm. The algorithm includes three main parameters: population size, crossover probability, and mutation probability. During testing, two parameters were fixed while the third was varied. Representative cases were selected to visualize the impact of parameter adjustments on algorithm performance.

Figure 5 displays the convergence curves of completion time across generations for selected representative cases. Each colored line corresponds to a different parameter setting. The curves demonstrate that completion time decreases with generations and stabilizes, indicating the algorithm’s ability to converge toward optimal or near-optimal solutions over iterations.

From these experiments, we can see that the proposed algorithm is very effective for solving dynamic and static scheduling problems of multiple time-constrained flexible job shops in hybrid manufacturing mode. The TPGA has the advantages of good adaptability and strong search ability in various scenarios. It can produce better results in both simple and complex scenarios.