The Influence of Grain Structure on Mechanical Properties of LPBF AlSi10Mg Alloy Obtained via Conventional and KOBO Extrusion Process

Abstract

1. Introduction

2. Methodology

2.1. Material Fabrication via Laser Powder Bed Fusion (LPBF)

2.2. Post-Processing via Conventional and KOBO Extrusion

2.3. Metallographic Preparation and Microstructural Characterization

2.4. Mechanical Properties Characterization

3. Results

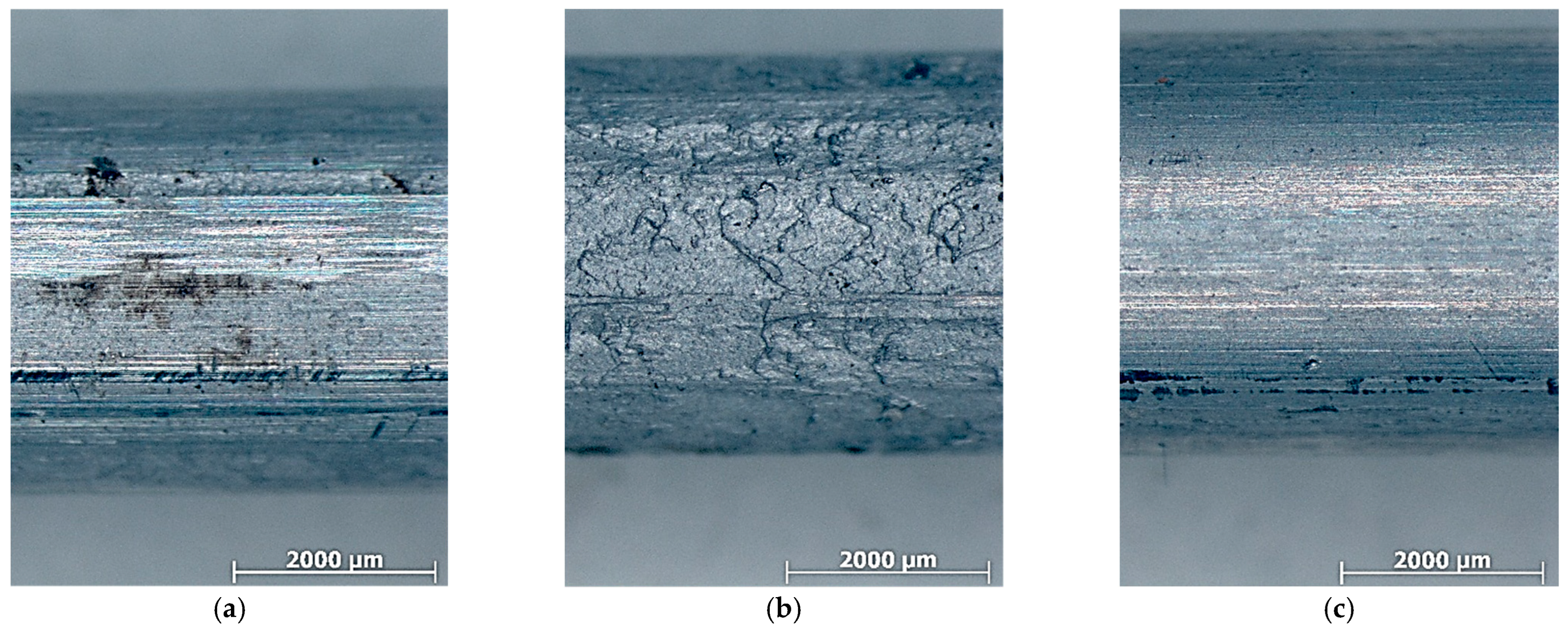

3.1. External Surface Observations

3.2. Cellular Network Fragmentation

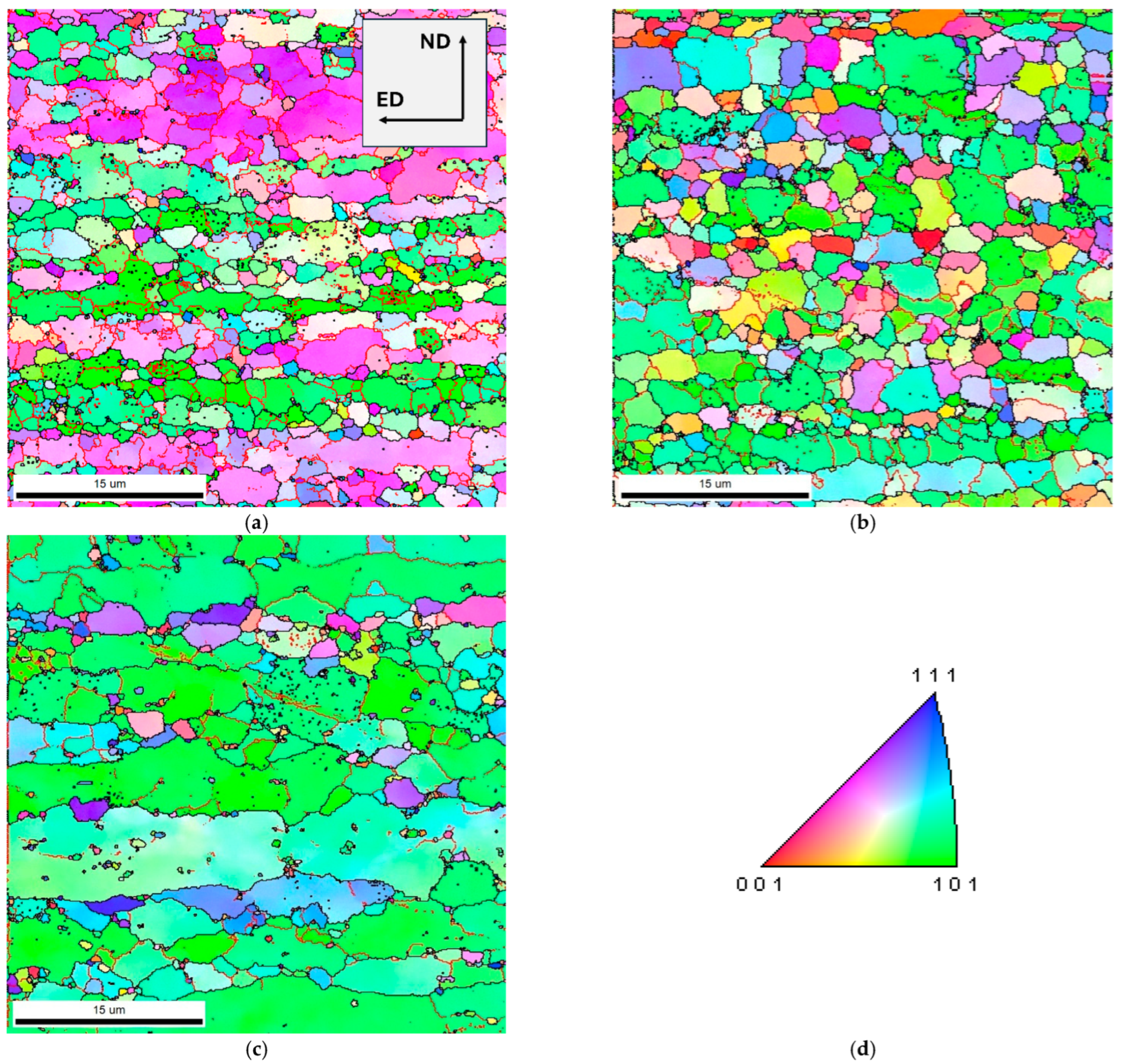

3.3. Analysis of the Grain Microstructure

3.4. Mechanical Properties

4. Conclusions

- Post-processing via extrusion substantially densified the LPBF AlSi10Mg alloy, eliminating the majority of the initial porosity inherent to the additive manufacturing process.

- The degree of eutectic Si particle refinement was highly sensitive to the specific extrusion parameters. Conventional extrusion at 350 °C (CE-350) yielded the highest degree of Si particle refinement, resulting in a mean particle area of ≈0.18 µm2. In contrast, KOBO extrusion at the same nominal temperature (KOBO-350) led to significant particle coarsening, yielding a mean Si particle area of ≈0.47 µm2.

- The resulting grain structure varied markedly with the applied extrusion conditions. CE-350 sample possessed the finest microstructure (average grain width ≈ 1.9 µm). In contrast, KOBO extrusion yielded microstructures, with average widths of ≈3.4 µm after room-temperature processing (KOBO-RT) and ≈6.3 µm after processing at 350 °C (KOBO-350).

- Extrusion significantly enhanced the ductility of the LPBF AlSi10Mg alloy (elongations exceeding 14% compared to 2.4% as-built), albeit accompanied by a reduction in yield strength. Conventional extruded (CE-350) sample demonstrated the most advantageous property combination within this study, delivering the maximum elongation (18.1%) and a yield strength (186 MPa) superior to that of the materials processed by the KOBO method under the investigated parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- O’Keeffe, M.; Hyde, B.G. Crystal Structures. In Crystallography and Crystal Defects; Courier Dover Publications: New York, NY, USA, 2012; pp. 85–122. ISBN 9781119961468. [Google Scholar]

- Marcos, C. Relationship Between Symmetry and Physical Properties. In Crystallography: Introduction to the Study of Minerals; Marcos, C., Ed.; Springer Nature: Cham, Switzerland, 2022; pp. 251–262. ISBN 978-3-030-96783-3. [Google Scholar]

- Qamar, S.Z.; Chekotu, J.C.; Al-Maharbi, M.; Alam, K. Shape Complexity in Metal Extrusion: Definitions, Classification, and Applications. Arab. J. Sci. Eng. 2019, 44, 7371–7384. [Google Scholar] [CrossRef]

- Marín, M.M.; Camacho, A.M.; Pérez, J.A. Influence of the Temperature on AA6061 Aluminum Alloy in a Hot Extrusion Process. Procedia Manuf. 2017, 13, 327–334. [Google Scholar] [CrossRef]

- Wagiman, A.; Mustapa, M.S.; Asmawi, R.; Shamsudin, S.; Lajis, M.A.; Mutoh, Y. A Review on Direct Hot Extrusion Technique in Recycling of Aluminium Chips. Int. J. Adv. Manuf. Technol. 2020, 106, 641–653. [Google Scholar] [CrossRef]

- Korkolis, Y.P.; Schindler, P.; Henn, E.; Gebhard, J.; Stommel, M.; Tekkaya, A.E. Hot Extrusion of Aluminium-Polymer Profiles with Axially-Graded Cross-Sections. CIRP Annals 2025. [Google Scholar] [CrossRef]

- Meng, S.; Xiao, H.; Song, J.; Bi, G.; Wang, Q.; Wang, Z.; Yu, H.; Liu, H. Research Progress and Future Prospects on High Speed Extrudable Magnesium Alloys: A Review. J. Mater. Res. Technol. 2024, 30, 9007–9019. [Google Scholar] [CrossRef]

- Kuang, F.; Pan, Y.; Zhang, J.; Wu, X.; Lu, X. Microstructure, Mechanical Properties, and Strengthening Mechanism of High Performance Ti-6Al-4V Alloy by Pressureless Sintering and Hot Extrusion. J. Alloys Compd. 2023, 951, 169990. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, R.; Zhou, Y.; Zhou, G.; Li, D.; Zhao, Z.; Peng, Y.; Huang, D. Investigation on Microstructural Evolution of Spray Formed Al-Zn-Mg-Cu Alloy during Hot Extrusion Processes and Subsequent Solution Treatment. J. Alloys Compd. 2025, 1014, 178387. [Google Scholar] [CrossRef]

- Tang, W.; Huang, S.; Zhang, S.; Li, D.; Peng, Y. Influence of Extrusion Parameters on Grain Size and Texture Distributions of AZ31 Alloy. J. Mater. Process Technol. 2011, 211, 1203–1209. [Google Scholar] [CrossRef]

- Jiang, X.; Galano, M.; Audebert, F. Extrusion Textures in Al, 6061 Alloy and 6061/SiCp Nanocomposites. Mater. Charact. 2014, 88, 111–118. [Google Scholar] [CrossRef]

- Moazami, M.R.; Razaghian, A.; Mirzadeh, H.; Emamy, M. Tailoring the Mechanical Properties of Hypereutectic in Situ Al–Mg2Si Composites via Hybrid TiB2 Reinforcement and Hot Extrusion. Arch. Civil. Mech. Eng. 2022, 22, 87. [Google Scholar] [CrossRef]

- Ding, C.; Hao, H.; Lu, Z.; Yu, C.; Wu, X.; Yu, P.; Ye, S. Fabrication of Hypereutectic Al–Si Alloy with Improved Mechanical and Thermal Properties by Hot Extrusion. Mater. Charact. 2023, 202, 113026. [Google Scholar] [CrossRef]

- Zribi, Z.; Ktari, H.H.; Herbst, F.; Optasanu, V.; Njah, N. EBSD, XRD and SRS Characterization of a Casting Al-7wt%Si Alloy Processed by Equal Channel Angular Extrusion: Dislocation Density Evaluation. Mater. Charact. 2019, 153, 190–198. [Google Scholar] [CrossRef]

- Jin, S.; Wang, A.; Wang, K.; Li, W.; Wan, B.; Zhai, T. Significant Strengthening Effect in Ultra-Fine Grained Al Alloy Made by Fast Solidification and Hot Extrusion Processes. J. Mater. Res. Technol. 2022, 16, 1761–1769. [Google Scholar] [CrossRef]

- Ke, D.; Hengcheng, L.; Qiumin, J.; Yun, T. Effect of Hot Extrusion on Mechanical Properties and Microstructure of near Eutectic Al–12.0%Si–0.2%Mg Alloy. Mater. Sci. Eng. A 2010, 527, 6887–6892. [Google Scholar] [CrossRef]

- Noga, P.; Skrzekut, T.; Wędrychowicz, M. Microstructure and Mechanical Properties of Al-Si Alloys Produced by Rapid Solidification and Hot Extrusion. Materials 2023, 16, 5223. [Google Scholar] [CrossRef]

- Geenen, K.; Röttger, A.; Theisen, W. Corrosion Behavior of 316L Austenitic Steel Processed by Selective Laser Melting, Hot-Isostatic Pressing, and Casting. Mater. Corros. 2017, 68, 764–775. [Google Scholar] [CrossRef]

- Chadha, K.; Tian, Y.; Spray, J.; Aranas, C. Microtextural Characterization of Additively Manufactured SS316L After Hot Isostatic Pressing Heat Treatment. Met. Mater. Int. 2022, 28, 237–249. [Google Scholar] [CrossRef]

- Santos Macías, J.G.; Zhao, L.; Tingaud, D.; Bacroix, B.; Pyka, G.; van der Rest, C.; Ryelandt, L.; Simar, A. Hot Isostatic Pressing of Laser Powder Bed Fusion AlSi10Mg: Parameter Identification and Mechanical Properties. J. Mater. Sci. 2022, 57, 9726–9740. [Google Scholar] [CrossRef]

- Snopiński, P.; Matus, K.; Łagoda, M.; Appiah, A.N.S.; Hajnyš, J. Engineering an Ultra-Fine Grained Microstructure, Twins and Stacking Faults in PBF-LB/M Al-Si Alloy via KoBo Extrusion Method. J. Alloys Compd. 2024, 970, 172576. [Google Scholar] [CrossRef]

- Bochniak, W.; Marszowski, K.; Korbel, A. Theoretical and Practical Aspects of the Production of Thin-Walled Tubes by the KOBO Method. J. Mater. Process Technol. 2005, 169, 44–53. [Google Scholar] [CrossRef]

- Bochniak, W.; Korbel, A.; Ostachowski, P.; Łagoda, M. Plastic Flow of Metals under Cyclic Change of Deformation Path Conditions. Arch. Civil. Mech. Eng. 2018, 18, 679–686. [Google Scholar] [CrossRef]

- Bochniak, W.; Ostachowski, P.; Korbel, A.; Łagoda, M. Potential of the KOBO Extrusion Process for Nonferrous Metals in the Form of Solids and Chips. Int. J. Adv. Manuf. Technol. 2023, 127, 733–750. [Google Scholar] [CrossRef]

- Pieła, K.; Błaż, L.; Bochniak, W.; Ostachowski, P.; Łagoda, M.; Żabiński, P.; Jaskowski, M.; Kiper, M.; Polkowska, A. Self-Hardening of Low-Alloyed Zinc for Biodegradable Application. J. Alloys Compd. 2019, 810, 151883. [Google Scholar] [CrossRef]

- Snopiński, P.; Król, M.; Pagáč, M.; Petrů, J.; Hajnyš, J.; Mikuszewski, T.; Tański, T. Effects of Equal Channel Angular Pressing and Heat Treatments on the Microstructures and Mechanical Properties of Selective Laser Melted and Cast AlSi10Mg Alloys. Arch. Civil. Mech. Eng. 2021, 21, 92. [Google Scholar] [CrossRef]

- Snopiński, P. Exploring Microstructure Refinement and Deformation Mechanisms in Severely Deformed LPBF AlSi10Mg Alloy. J. Alloys Compd. 2023, 941, 168984. [Google Scholar] [CrossRef]

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Panda, B.K.; Sahoo, S.; Siva Kumar, C.; Kumar Nath, A. Multiscale Modelling of Microstructure Evolution, and Local Solidification Behaviours of the AlSi10Mg Build Component in Laser Powder Bed Fusion Process. Opt. Laser Technol. 2025, 180, 111446. [Google Scholar] [CrossRef]

- Rafieazad, M.; Chatterjee, A.; Nasiri, A.M. Effects of Recycled Powder on Solidification Defects, Microstructure, and Corrosion Properties of DMLS Fabricated AlSi10Mg. JOM 2019, 71, 3241–3252. [Google Scholar] [CrossRef]

- Panda, B.K.; Sahoo, S.; Kumar, C.S.; Nath, A.K. Investigating the Microstructural and Mechanical Characteristics of Laser Additive-Manufactured AlSi10Mg Specimens Through Experimental and Phase-Field Modeling Approaches. Adv. Eng. Mater. 2024, 26, 2301784. [Google Scholar] [CrossRef]

- Hu, L.; Li, Y.; Wei, Q.; Wang, A.; Wang, Y.; Cui, Y.; Wang, H.; Chen, Z. Microstructure Evolution in AlSi10Mg Alloy Fabricated by Laser-Based Directed Energy Deposition. Vacuum 2024, 228, 113478. [Google Scholar] [CrossRef]

- Van Cauwenbergh, P.; Samaee, V.; Thijs, L.; Nejezchlebová, J.; Sedlák, P.; Iveković, A.; Schryvers, D.; Van Hooreweder, B.; Vanmeensel, K. Unravelling the Multi-Scale Structure–Property Relationship of Laser Powder Bed Fusion Processed and Heat-Treated AlSi10Mg. Sci. Rep. 2021, 11, 6423. [Google Scholar] [CrossRef]

- Landau, P.; Saffar, T.; Orion, I.; Girshevitz, O.; Tiferet, E. Helium Bubble Formation in Additive Manufactured L-PBF AlSi10Mg. J. Nucl. Mater. 2023, 582, 154473. [Google Scholar] [CrossRef]

- Chen, S.Q.; Huang, X.Y.; Shuai, L.F.; Wu, G.L.; Huang, T.L.; Huang, X.X. Annealing Behavior of AlSi10Mg Alloy Fabricated by Laser Powder Bed Fusion. J. Phys. Conf. Ser. 2023, 2635, 012036. [Google Scholar] [CrossRef]

- Alparslan, C.; Bayraktar, Ş. An Experimental Study on Microstructural, Mechanical and Machinability Properties of As-Cast and Heat-Treated Al-7Si-Mg Alloy. Silicon 2024, 16, 3971–3985. [Google Scholar] [CrossRef]

- Diyoke, G.; Rath, L.; Chafle, R.; Ben Khalifa, N.; Klusemann, B. Numerical Simulation of Friction Extrusion: Process Characteristics and Material Deformation Due to Friction. Int. J. Mater. Form. 2024, 17, 26. [Google Scholar] [CrossRef]

- Zhu, H.; Sun, J.; Guo, Y.; Xu, X.; Huang, Y.; Jiang, Z.; Wu, G.; Li, J.; Liu, W. Effects of Post Heat Treatment on the Microstructure and Mechanical Properties of Selective Laser Melted AlSi10Mg Alloys. Mater. Sci. Eng. A 2024, 894, 146195. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Yuan, S.-Y.; Peng, C.-H. A Reciprocating Extrusion Process for Producing Hypereutectic Al–20wt.% Si Wrought Alloys. Mater. Sci. Eng. A 1998, 252, 212–221. [Google Scholar] [CrossRef]

- Ferro, P.; Fabrizi, A.; Berto, F.; Savio, G.; Meneghello, R.; Rosso, S. Defects as a Root Cause of Fatigue Weakening of Additively Manufactured AlSi10Mg Components. Theor. Appl. Fract. Mech. 2020, 108, 102611. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, J.; Zhao, Y.; Wang, Z.; Song, H.; Gao, M. Effect of Processing Parameters on Solidification Defects Behavior of Laser Deposited AlSi10Mg Alloy. Vacuum 2019, 167, 471–478. [Google Scholar] [CrossRef]

- Wu, Z.; Wu, S.; Gao, X.; Lin, Y.; Xue, Y.; Withers, P.J. The Role of Internal Defects on Anisotropic Tensile Failure of L-PBF AlSi10Mg Alloys. Sci. Rep. 2023, 13, 14681. [Google Scholar] [CrossRef]

- Chen, L.; Chen, G.; Tang, J.; Zhao, G.; Zhang, C. Evolution of Grain Structure, Micro-Texture and Second Phase during Porthole Die Extrusion of Al–Zn–Mg Alloy. Mater. Charact. 2019, 158, 109953. [Google Scholar] [CrossRef]

- Liu, M.; Wang, P.; Lu, G.; Huang, C.-Y.; You, Z.; Wang, C.-H.; Yen, H.-W. Deformation-Activated Recrystallization Twin: New Twinning Path in Pure Aluminum Enabled by Cryogenic and Rapid Compression. iScience 2022, 25, 104248. [Google Scholar] [CrossRef] [PubMed]

- Hadadzadeh, A.; Amirkhiz, B.S.; Li, J.; Odeshi, A.; Mohammadi, M. Deformation Mechanism during Dynamic Loading of an Additively Manufactured AlSi10Mg_200C. Mater. Sci. Eng. A 2018, 722, 263–268. [Google Scholar] [CrossRef]

- Kan, W.H.; Nadot, Y.; Foley, M.; Ridosz, L.; Proust, G.; Cairney, J.M. Factors That Affect the Properties of Additively-Manufactured AlSi10Mg: Porosity versus Microstructure. Addit. Manuf. 2019, 29, 100805. [Google Scholar] [CrossRef]

- Roth, C.C.; Tancogne-Dejean, T.; Mohr, D. Plasticity and Fracture of Cast and SLM AlSi10Mg: High-Throughput Testing and Modeling. Addit. Manuf. 2021, 43, 101998. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective Laser Melting of AlSi10Mg: Influence of Post-Processing on the Microstructural and Tensile Properties Development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch Relation and Boundary Strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About Metastable Cellular Structure in Additively Manufactured Austenitic Stainless Steels. Addit. Manuf. 2021, 38, 101804. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Eckert, J. Formation of Metastable Cellular Microstructures in Selective Laser Melted Alloys. J. Alloys Compd. 2017, 707, 27–34. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular Cellular Segregation Network Structure Strengthening 316L Stainless Steel Prepared by Selective Laser Melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Dang, B.; Zhang, X.; Chen, Y.Z.; Chen, C.X.; Wang, H.T.; Liu, F. Breaking through the Strength-Ductility Trade-off Dilemma in an Al-Si-Based Casting Alloy. Sci. Rep. 2016, 6, 30874. [Google Scholar] [CrossRef]

- Liu, M.; Zheng, R.; Xiao, W.; Li, J.; Li, G.; Peng, Q.; Ma, C. Bulk Nanostructured Al-Si Alloy with Remarkable Improvement in Strength and Ductility. Scr. Mater. 2021, 201, 113970. [Google Scholar] [CrossRef]

- Ding, C.; Yu, P. Effect of Extrusion Temperatures on the Microstructures, Mechanical Properties and Thermal Properties of PM Al-20Si Alloy. J. Alloys Compd. 2022, 903, 163979. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Abedi, H.R.; Abou-Ras, D.; Kawasaki, M.; Zhilyaev, A.P. Evolution of Microstructure and Mechanical Properties in a Hypoeutectic Al-Si-Mg Alloy Processed by Accumulative Back Extrusion. Mater. Sci. Eng. A 2016, 651, 269–279. [Google Scholar] [CrossRef]

- Li, J.; Sun, J.; Qian, G.; Shi, L. Defect-Induced Cracking and Fine Granular Characteristics in Very-High-Cycle Fatigue of Laser Powder Bed Fusion AlSi10Mg Alloy. Int. J. Fatigue 2022, 158, 106770. [Google Scholar] [CrossRef]

- Poole, W.J.; Charras, N. An Experimental Study on the Effect of Damage on the Stress–Strain Behaviour for Al–Si Model Composites. Mater. Sci. Eng. A 2005, 406, 300–308. [Google Scholar] [CrossRef]

- Di Egidio, G.; Tonelli, L.; Zanni, M.; Carosi, D.; Morri, A.; Ceschini, L. Direct Artificial Aging of the PBF-LB AlSi10Mg Alloy Designed to Enhance the Trade-off between Strength and Residual Stress Relief. J. Alloys Metall. Syst. 2024, 5, 100063. [Google Scholar] [CrossRef]

- Huang, M.; Zhai, P.; Morozov, S.I.; Goddard, W.A.; Li, G.; Zhang, Q. Engineering Twin Boundaries for Enhancing Strength and Ductility of Thermoelectric Semiconductor PbTe. J. Alloys Compd. 2023, 959, 170429. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Wang, Z.; Zhang, W.; Sun, W. Effect of Cold Rolling Degree on Texture Evolution, Eccentricity, and Yielding Anisotropy of GH4145 Alloy Tubes. Mater. Sci. Eng. A 2022, 832, 142464. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Laser Power | 175 W |

| Layer Thickness | 20 μm |

| Scanning Speed | 1400 mm/s |

| Scan Rotation | 67° |

| Sample | KOBO-350 | KOBO-RT | CE-350 |

|---|---|---|---|

| Post-processing Method | KOBO Extrusion | KOBO Extrusion | Conventional Extrusion |

| Extrusion Temperature | 350 °C | Room Temperature (~20 °C) | 350 °C |

| Die Oscillation Frequency | 5 Hz | 5 Hz | N/A |

| Die Twist Angle | ±8° | ±8° | N/A |

| Billet Heating Duration/Method | 15 min in press container | N/A | 15 min in press container |

| As-Built | CE-350 | KOBO-RT | KOBO-350 | |

|---|---|---|---|---|

| Hardness, HV0.3 | 117 ± 2 | 76 ± 1.7 | 72 ± 1.9 | 61 ± 1.2 |

| Yield strength (YS), [MPa] | 255 ± 3 | 186 ± 3 | 133 ± 3 | 114 ± 3 |

| Tensile strength (TS), [MPa] | 422 ± 4 | 285 ± 3 | 238 ± 4 | 215 ± 4 |

| Elongation, % | 2.4 ± 0.1 | 18.1 ± 0.2 | 14.8 ± 0.2 | 14.1 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snopiński, P.; Ostachowski, P.; Matus, K.; Żaba, K. The Influence of Grain Structure on Mechanical Properties of LPBF AlSi10Mg Alloy Obtained via Conventional and KOBO Extrusion Process. Symmetry 2025, 17, 709. https://doi.org/10.3390/sym17050709

Snopiński P, Ostachowski P, Matus K, Żaba K. The Influence of Grain Structure on Mechanical Properties of LPBF AlSi10Mg Alloy Obtained via Conventional and KOBO Extrusion Process. Symmetry. 2025; 17(5):709. https://doi.org/10.3390/sym17050709

Chicago/Turabian StyleSnopiński, Przemysław, Paweł Ostachowski, Krzysztof Matus, and Krzysztof Żaba. 2025. "The Influence of Grain Structure on Mechanical Properties of LPBF AlSi10Mg Alloy Obtained via Conventional and KOBO Extrusion Process" Symmetry 17, no. 5: 709. https://doi.org/10.3390/sym17050709

APA StyleSnopiński, P., Ostachowski, P., Matus, K., & Żaba, K. (2025). The Influence of Grain Structure on Mechanical Properties of LPBF AlSi10Mg Alloy Obtained via Conventional and KOBO Extrusion Process. Symmetry, 17(5), 709. https://doi.org/10.3390/sym17050709