A Microstructural Study of Cu-10Al-7Ag Shape Memory Alloy in As-Cast and Quenched Conditions

Abstract

1. Introduction

2. Materials and Methods

3. Results

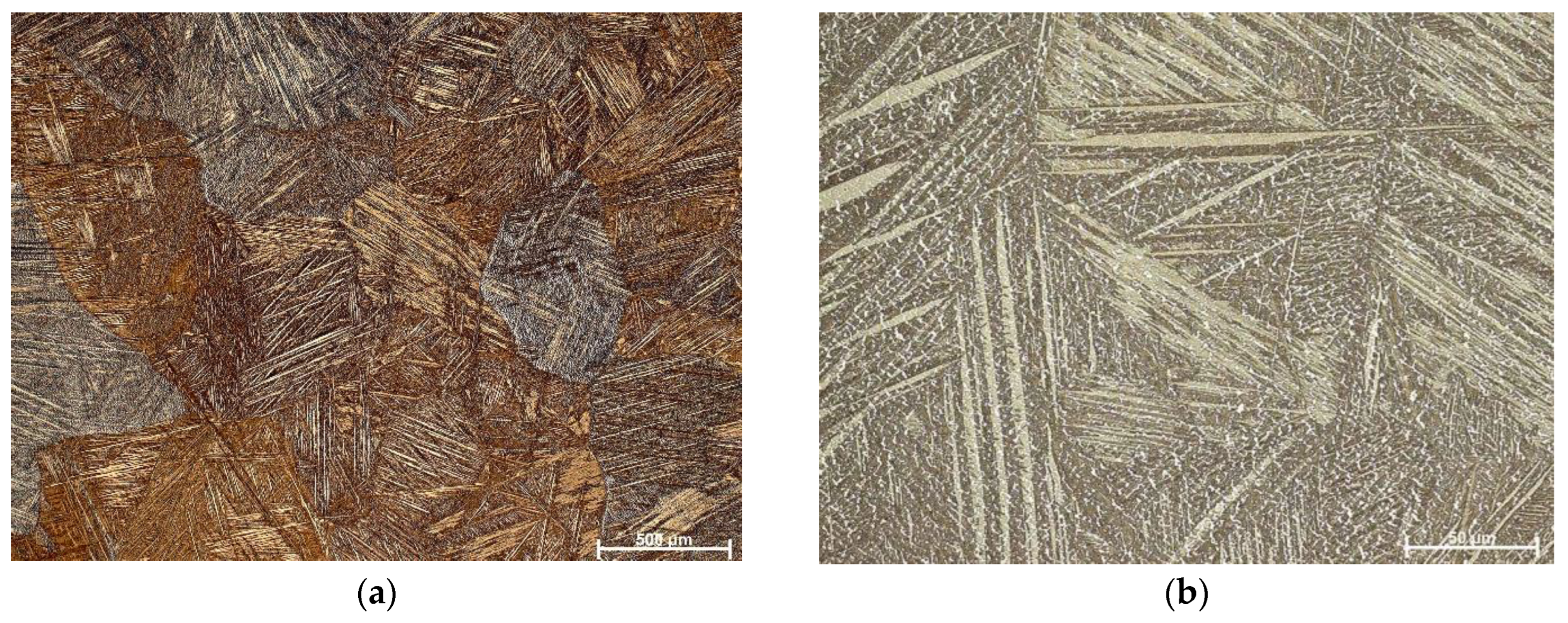

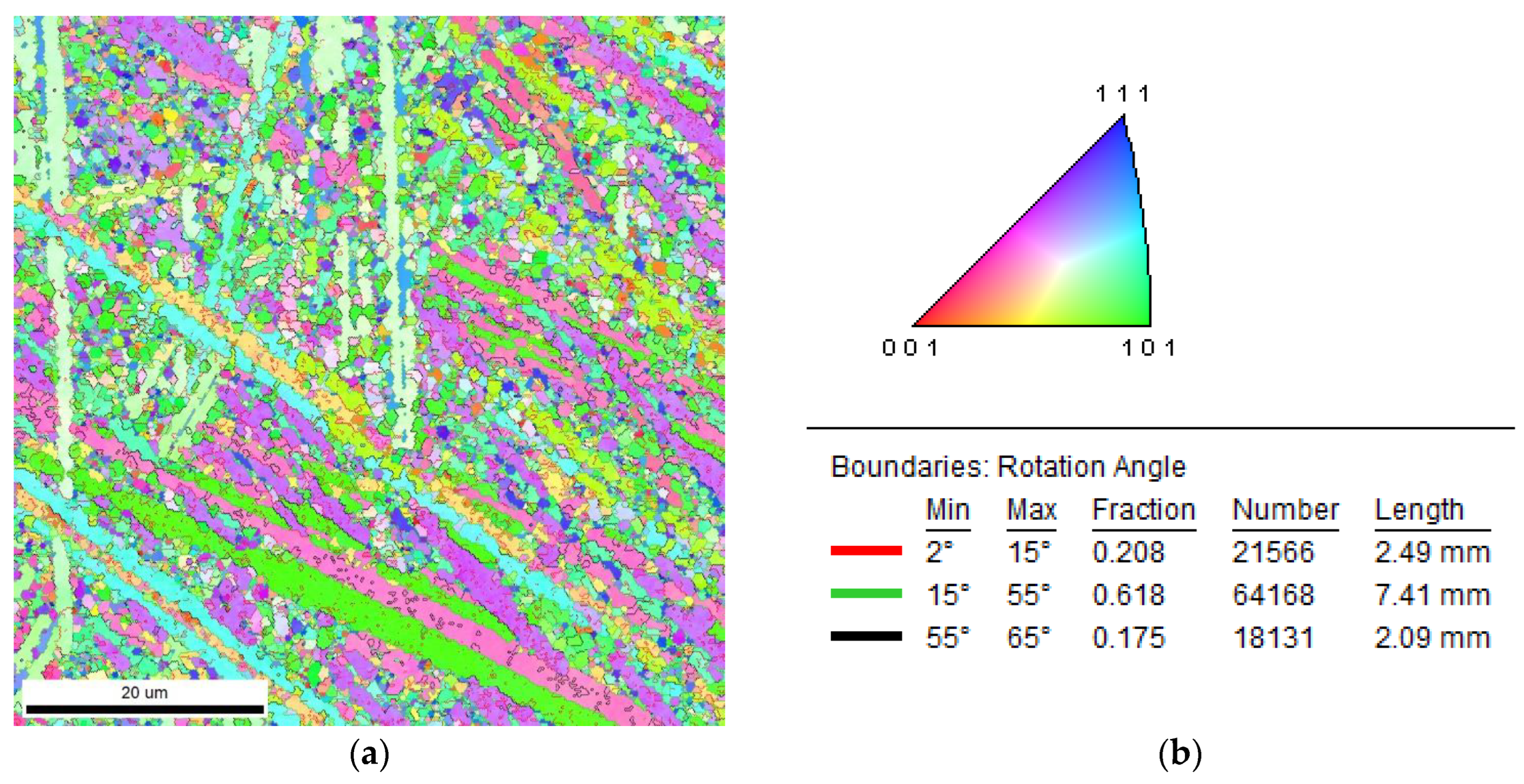

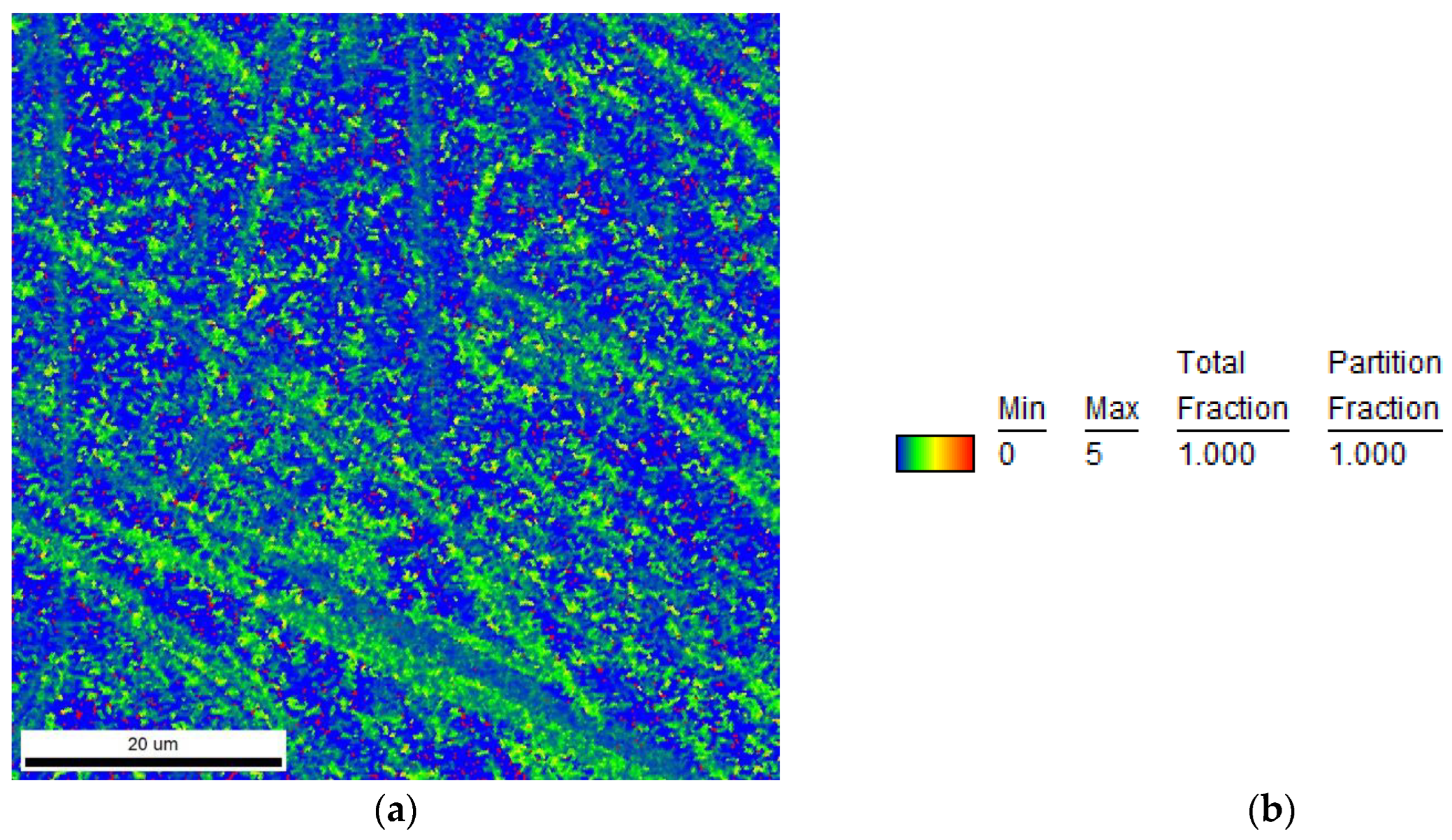

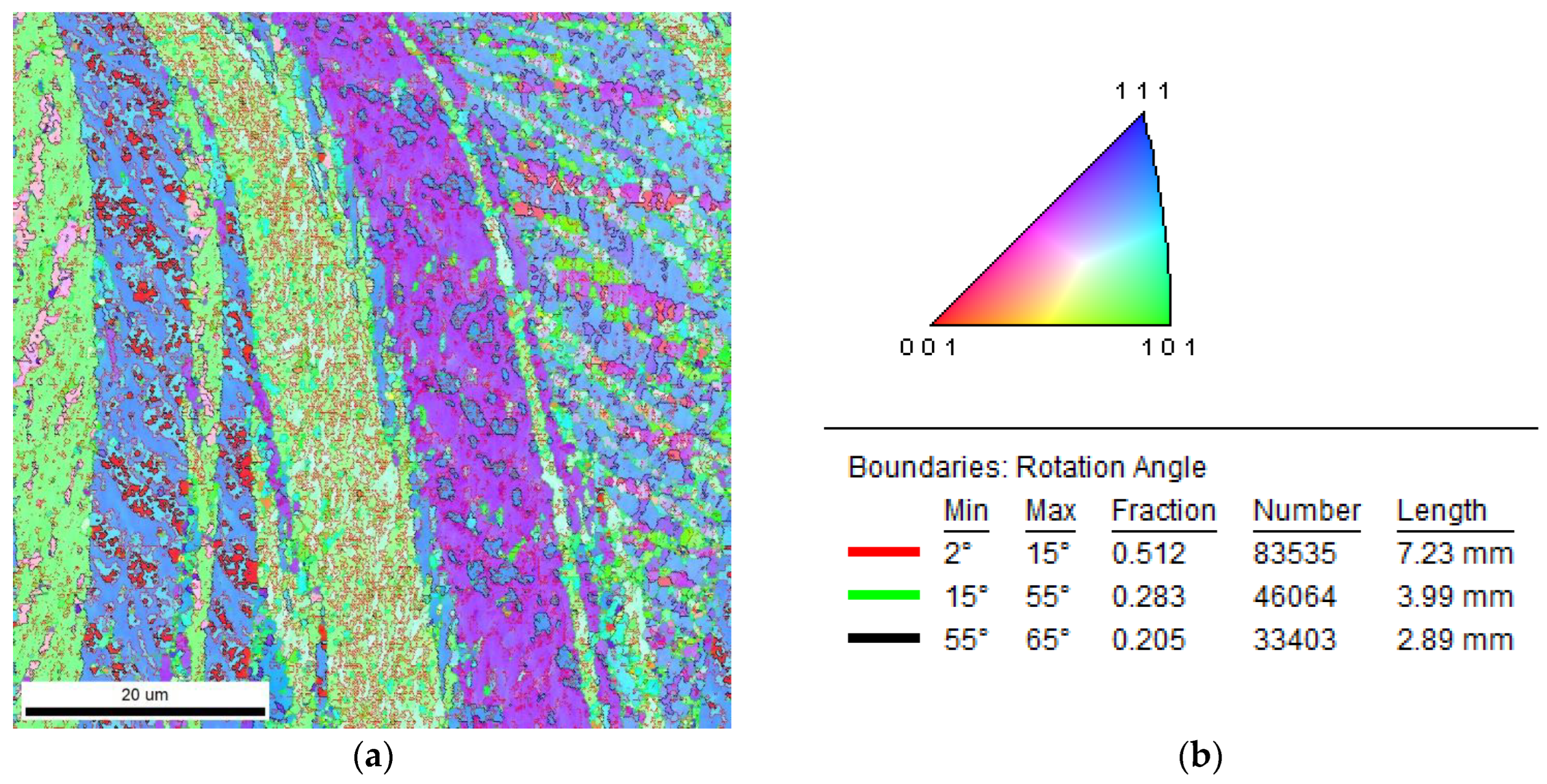

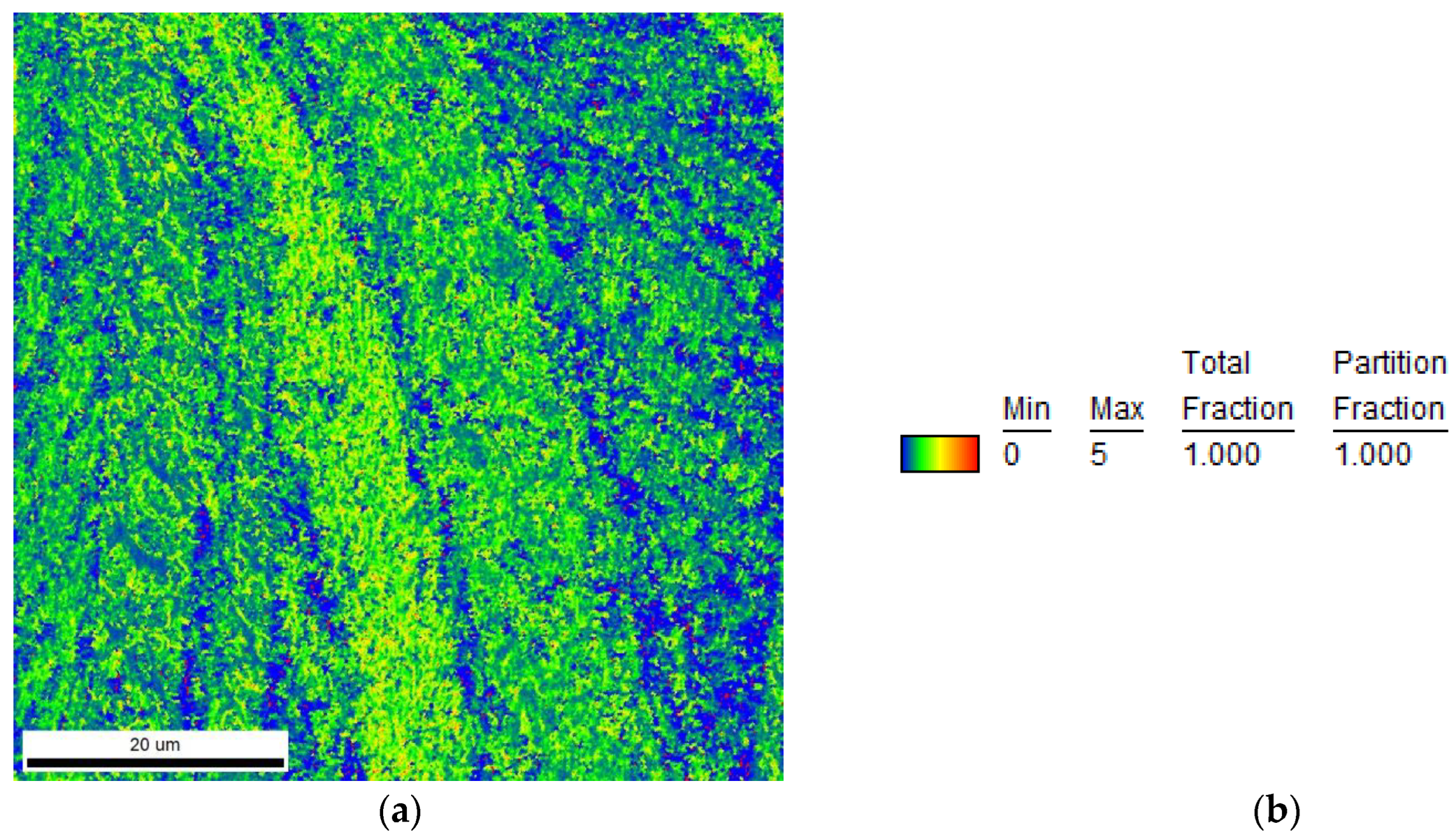

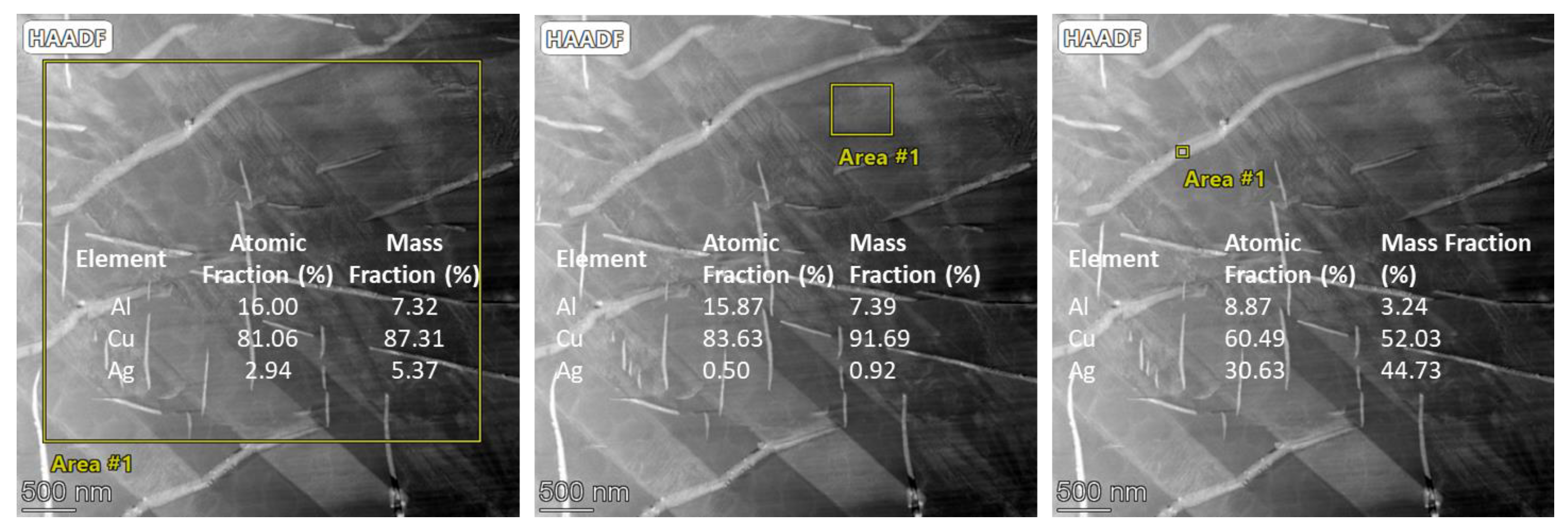

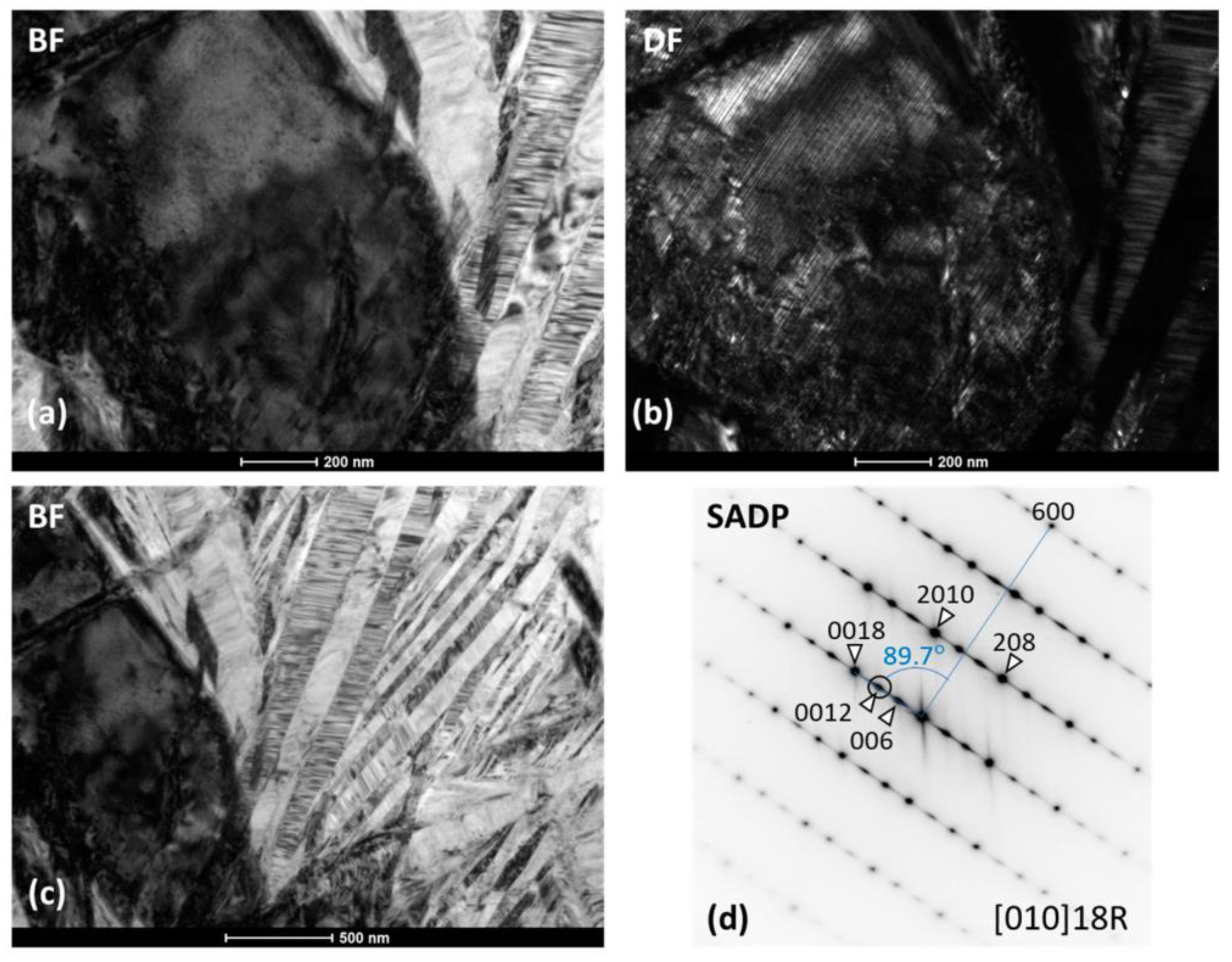

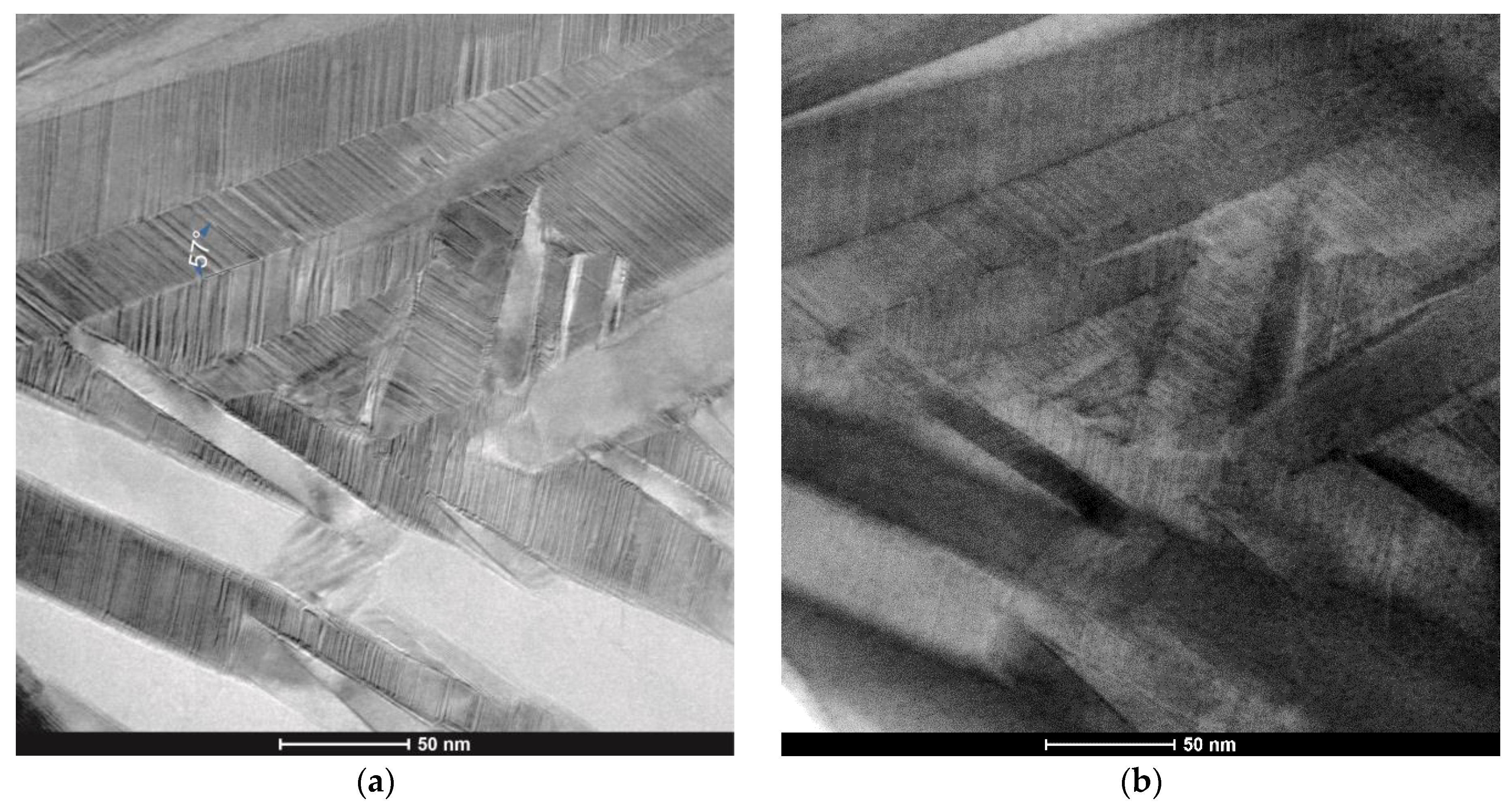

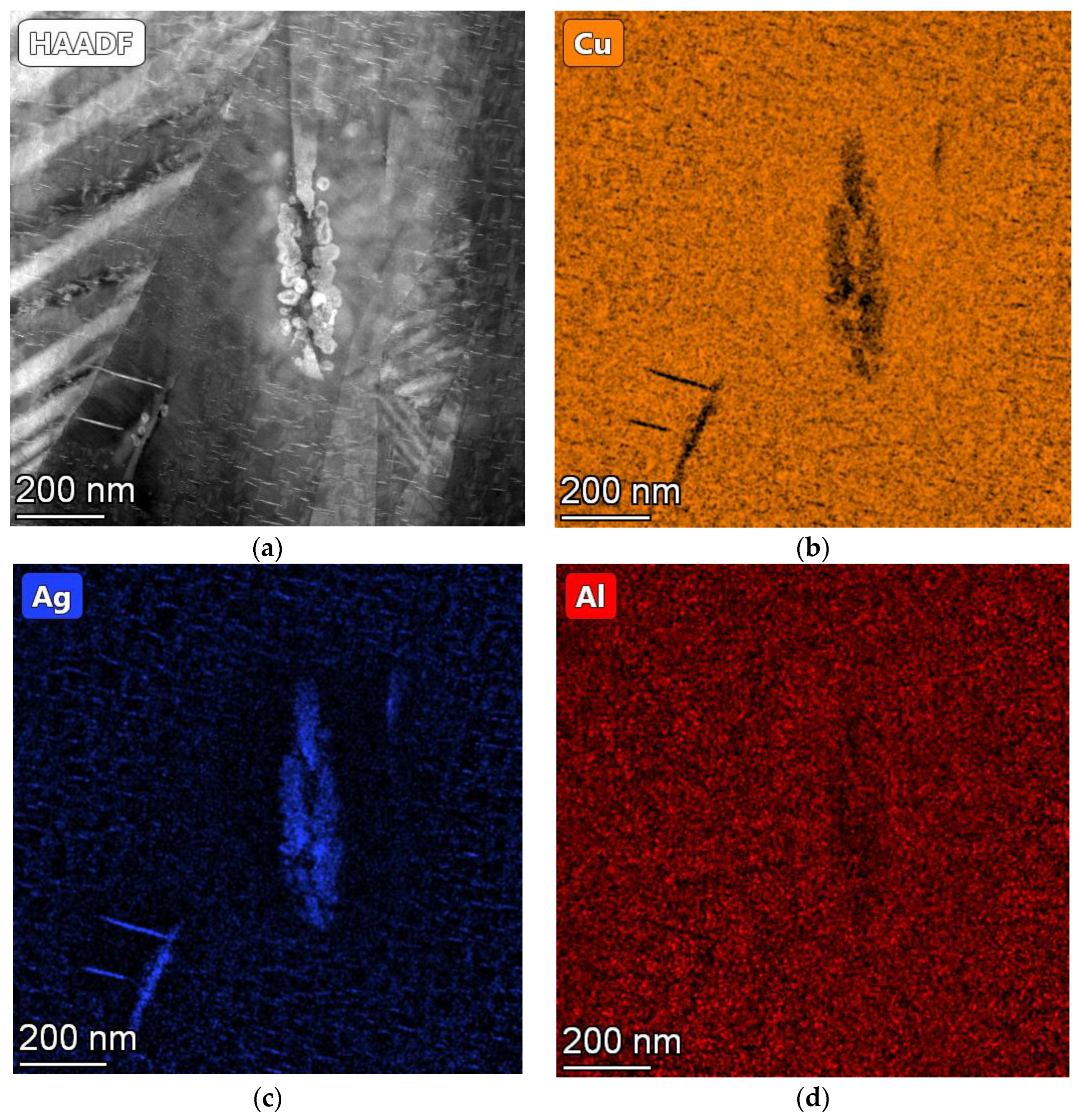

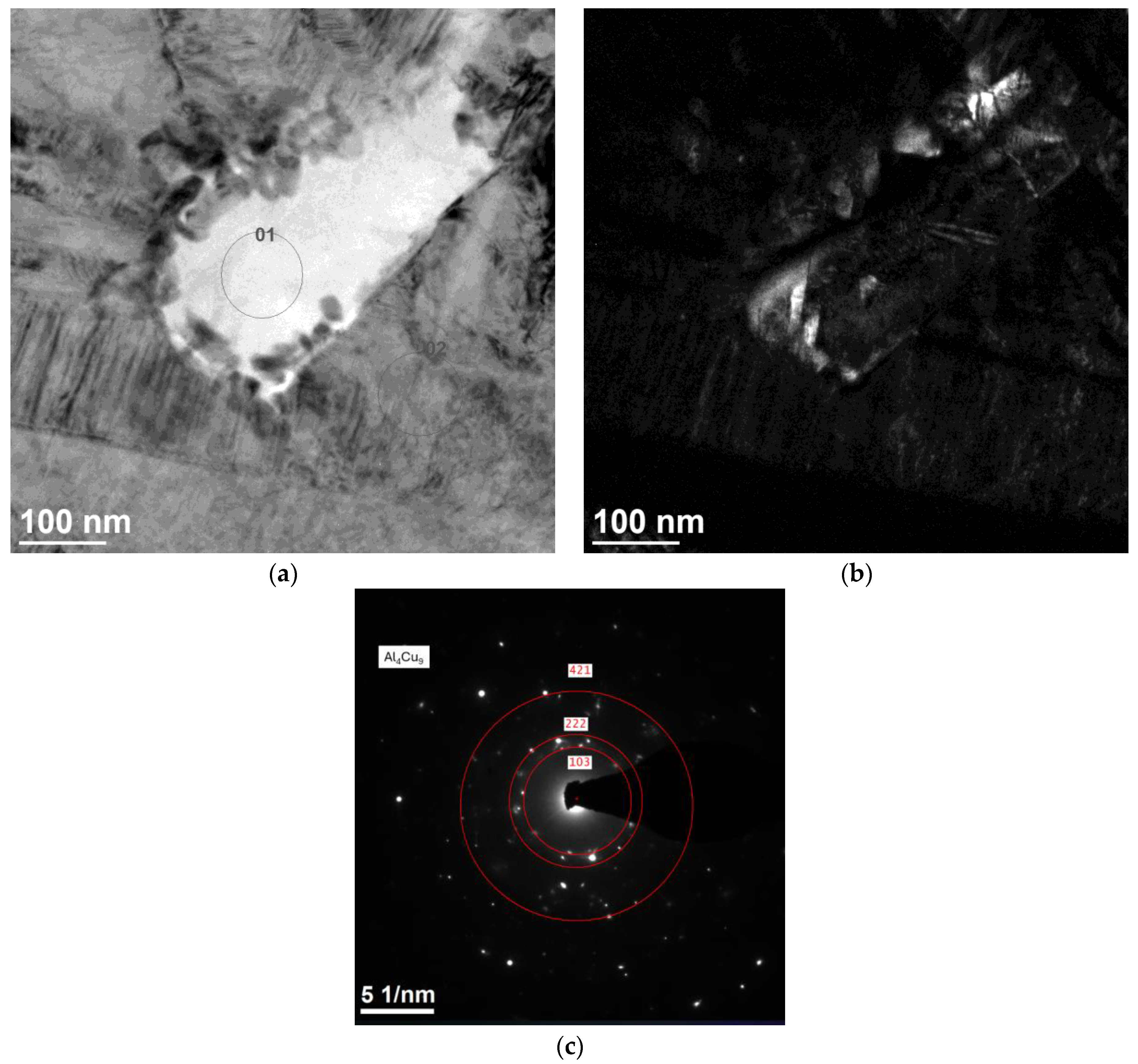

3.1. Microstructure of the Cu-10Al-7Ag SMA Alloy

3.2. Effect of Quenching on the Alloy Hardness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mazzer, E.M.; da Silva, M.R.; Gargarella, P. Revisiting Cu-Based Shape Memory Alloys: Recent Developments and New Perspectives. J. Mater. Res. 2022, 37, 162–182. [Google Scholar] [CrossRef]

- Silva, R.A.G.; Adorno Ii, A.T.; Carvalho Ii, T.M.; Ii, A.G.M.; Ii, C.M.A.S. Precipitation Reaction in Alpha-Cu-Al-Ag Alloys. Rev. Matéria V 2011, 16, 747–753. [Google Scholar] [CrossRef]

- Grgurić, T.H.; Manasijević, D.; Kožuh, S.; Ivanić, I.; Anžel, I.; Kosec, B.; Bizjak, M.; Bajsić, E.G.; Balanović, L.; Gojić, M. The Effect of the Processing Parameters on the Martensitic Transformation of Cu-Al-Mn Shape Memory Alloy. J. Alloys Compd. 2018, 765, 664–676. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Reconciling Viability and Cost-Effective Shape Memory Alloy Options—A Review of Copper and Iron Based Shape Memory Metallic Systems. Eng. Sci. Technol. Int. J. 2016, 19, 1582–1592. [Google Scholar] [CrossRef]

- Ren, C.X.; Wang, Q.; Hou, J.P.; Zhang, Z.J.; Yang, H.J.; Zhang, Z.F. Exploring the Strength and Ductility Improvement of Cu–Al Alloys. Mater. Sci. Eng. A 2020, 786, 139441. [Google Scholar] [CrossRef]

- Najah, S.; Al-Humairi, S. Cu-Based Shape Memory Alloys: Modified Structures and Their Related Properties. In Recent Advancements in the Metallurgical Engineering and Electrodeposition; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Dobrzański, L.A.; Dobrzański, L.B.; Dobrzańska-Danikiewicz, A.D.; Dobrzańska, J. Nitinol Type Alloys General Characteristics and Applications in Endodontics. Processes 2022, 10, 101. [Google Scholar] [CrossRef]

- Silva, R.A.G.; Paganotti, A.; Adorno, A.T.; Santos, C.M.A.; Carvalho, T.M. Characteristics of the Cu-18.84 at.%Al-10.28 at.%Mn-1.57 at.%Ag Alloy after Slow Cooling from High Temperatures. J. Therm. Anal. Calorim. 2015, 121, 1233–1238. [Google Scholar] [CrossRef]

- Mallik, U.S.; Sampath, V. Effect of Alloying on Microstructure and Shape Memory Characteristics of Cu–Al–Mn Shape Memory Alloys. Mater. Sci. Eng. A 2008, 481–482, 680–683. [Google Scholar] [CrossRef]

- Santos, C.M.A.; Adorno, A.T.; Oda, N.Y.; Sales, B.O.; Silva, L.S.; Silva, R.A.G. Phase Transformations and Aging of the Cu72.9Al15.0Mn10.5Ag1.6 Alloy. J. Alloys Compd. 2016, 685, 587–592. [Google Scholar] [CrossRef]

- Liverić, L.; Holjevac Grgurić, T.; Mandić, V.; Chulist, R. Influence of Manganese Content on Martensitic Transformation of Cu-Al-Mn-Ag Alloy. Materials 2023, 16, 5782. [Google Scholar] [CrossRef]

- Liverić, L.; Grgurić, T.H.; Bajsić, E.G.; Kršulja, M. Effect of Silver Addition on Cu-Based Shape Memory Alloys. Chem. Biochem. Eng. Q. 2023, 37, 153–161. [Google Scholar] [CrossRef]

- Silva, R.A.G.; Paganotti, A.; Gama, S.; Adorno, A.T.; Carvalho, T.M.; Santos, C.M.A. Investigation of Thermal, Mechanical and Magnetic Behaviors of the Cu-11%Al Alloy with Ag and Mn Additions. Mater. Charact. 2013, 75, 194–199. [Google Scholar] [CrossRef]

- Santos, C.M.A.; Adorno, A.T.; Paganotti, A.; Silva, C.C.S.; Oliveira, A.B.; Silva, R.A.G. Phase Stability in the Cu-9 Wt%Al-10 Wt%Mn-3 Wt%Ag Alloy. J. Phys. Chem. Solids 2017, 104, 145–151. [Google Scholar] [CrossRef]

- Pilz, C.B.; Matsumura, E.L.; Paganotti, A.; Cornejo, D.R.; Silva, R.A.G. Microstructure and Phase Stability of CuAlMnAgZr Multicomponent Alloys. Mater. Chem. Phys. 2020, 241, 122343. [Google Scholar] [CrossRef]

- Velazquez, D.; Romero, R. Spinodal Decomposition and Martensitic Transformation in Cu–Al–Mn Shape Memory Alloy. J. Therm. Anal. Calorim. 2017, 130, 2007–2013. [Google Scholar] [CrossRef]

- Zárubová, N.; Novák, V. Phase Stability of CuAlMn Shape Memory Alloys. Mater. Sci. Eng. A 2004, 378, 216–221. [Google Scholar] [CrossRef]

- Qian, S.; Geng, Y.; Wang, Y.; Pillsbury, T.E.; Hada, Y.; Yamaguchi, Y.; Fujimoto, K.; Hwang, Y.; Radermacher, R.; Cui, J.; et al. Elastocaloric Effect in CuAlZn and CuAlMn Shape Memory Alloys under Compression. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150309. [Google Scholar] [CrossRef] [PubMed]

- Suru, M.G.; Lohan, N.M.; Pricop, B.; Mihalache, E.; Mocanu, M.; Bujoreanu, L.G. Precipitation Effects on the Martensitic Transformation in a Cu-Al-Ni Shape Memory Alloy. J. Mater. Eng. Perform. 2016, 25, 1562–1569. [Google Scholar] [CrossRef]

- Fernández, J.; Isalgue, A.; Franch, R. Effect of Thermal Cycling on CuAlAg Shape Memory Alloys. Mater. Today Proc. 2015, 2, S805–S808. [Google Scholar] [CrossRef]

- Ferreira, R.O.; Silva, L.S.; Silva, R.A.G. Thermal Behavior of As-Annealed CuAlMnAgZr Alloys. J. Therm. Anal. Calorim. 2021, 146, 595–600. [Google Scholar] [CrossRef]

- Adorno, A.T.; Benedetti, A.V.; Da Silva, R.A.G.; Blanco, M. Influence of the Al Content on the Phase Transformations in Cu-Al-Ag Alloys. Eclet. Quim. 2003, 28, 33–38. [Google Scholar] [CrossRef]

- Seifollahzadeh, P.; Alizadeh, M.; Szabó, Á.; Gubicza, J.; El-Tahawy, M. Microstructure and Mechanical Behavior of Cu–Al–Ag Shape Memory Alloys Processed by Accumulative Roll Bonding and Subsequent Annealing. Crystals 2022, 12, 1167. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Fernandez, J.; Zhang, X.M. TEM Study on the Microstructure of Cu-Al-Ag Shape Memory Alloys. Mater. Sci. Eng. A 2006, 438–440, 726–729. [Google Scholar] [CrossRef]

- Silva, R.A.G.; MacHado, E.S.; Adorno, A.T.; Magdalena, A.G.; Carvalho, T.M. Completeness of B-Phase Decomposition Reaction in Cu-Al-Ag Alloys. J. Therm. Anal. Calorim. 2012, 109, 927–931. [Google Scholar] [CrossRef]

- Krishna, T.S.V.; Rao, D.S. Effect of Aluminium on Microstructure and Shape Memory Effect in Cu-Al-Ag-Mn Shape Memory Alloys. Aust. J. Mech. Eng. 2022, 1–17. [Google Scholar] [CrossRef]

- Manasijevićmanasijević, D.; Holjevac, T.; Grgurić, G.; Balanovićbalanović, L.; Stamenković, U.S.; Gorgievski, M.; Gojićgojić, M. Effect of Mn Content on the Microstructure and Phase Transformation Temperatures of the Cu-Al-Mn-Ag Shape Memory Alloys. Chem. Biochem. Eng. Q. 2020, 58, 293–299. [Google Scholar] [CrossRef]

- Izadinia, M.; Dehghani, K. Structure and Properties of Nanostructured Cu-13.2Al-5.1Ni Shape Memory Alloy Produced by Melt Spinning. Trans. Nonferrous Met. Soc. China 2011, 21, 2037–2043. [Google Scholar] [CrossRef]

- Gurau, G.; Gurau, C.; Fernandes, F.M.B.; Silva, R.J.C.; Marin, F. Using High Speed High Pressure Torsion for Cu–13Al–4Ni Shape Memory Alloy Processing. Trans. Indian Inst. Met. 2021, 74, 2459–2469. [Google Scholar] [CrossRef]

- Shafeeq, M.M.; Gupta, G.K.; Malik, M.M.; Sampath, V.; Modi, O.P. Influence of Quenching Methods on Martensitic Transformation and Mechanical Properties of P/M Processed Cu–Al–Ni–Ti Shape Memory Alloys. Powder Metall. 2016, 59, 271–280. [Google Scholar] [CrossRef]

- Yi, J.; Wan, L.; Shu, T.; Zhang, X.; Liu, F.; Cheng, G.J. Unleashing Multi-Scale Mechanical Enhancement in NiTi Shape Memory Alloy via Annular Intra-Laser Deposition with Homogenized Ti2Ni Nanoprecipitates. Acta Mater 2024, 262, 119418. [Google Scholar] [CrossRef]

- Suresh, K.S.; Bhaumik, S.K.; Suwas, S. Effect of Thermal and Thermo-Mechanical Cycling on the Microstructure of Ni-Rich NiTi Shape Memory Alloys. Mater. Lett. 2013, 99, 150–153. [Google Scholar] [CrossRef]

- Silva, R.A.G.; Paganotti, A.; Jabase, L.; Adorno, A.T.; Carvalho, T.M.; Santos, C.M.A. Ag-Rich Precipitates Formation in the Cu–11%Al–10%Mn–3%Ag Alloy. J. Alloys Compd. 2014, 615, S160–S162. [Google Scholar] [CrossRef]

- Canbay, C.A.; Karaduman, O.; Ünlü, N.; Baiz, S.A.; Özkul, İ. Heat Treatment and Quenching Media Effects on the Thermodynamical, Thermoelastical and Structural Characteristics of a New Cu-Based Quaternary Shape Memory Alloy. Compos. B Eng. 2019, 174, 106940. [Google Scholar] [CrossRef]

- Ge, Y.; Vronka, M.; Veřtát, P.; Karlik, M.; Hannula, S.P.; Heczko, O. Deformation Twinning with Different Twin-Boundary Mobility in 2H Martensite in Cu–Ni–Al Shape Memory Alloy. Acta Mater. 2022, 226, 117598. [Google Scholar] [CrossRef]

- Sedlák, P.; Seiner, H.; Landa, M.; Novák, V.; Šittner, P.; Mañosa, L. Elastic Constants of Bcc Austenite and 2H Orthorhombic Martensite in CuAlNi Shape Memory Alloy. Acta Mater. 2005, 53, 3643–3661. [Google Scholar] [CrossRef]

- Kožuh, S.; Gojić, M.; Ivanić, I.; Holjevac Grgurić, T.; Kosec, B.; Anžel, I. The Effect of Heat Treatment on the Microstructure and Mechanical Properties of Cu-Al-Mn Shape Memory Alloy. Kem. U Ind. 2018, 67, 11–17. [Google Scholar] [CrossRef]

- Jain, A.K.; Hussain, S.; Kumar, P.; Pandey, A.; Dasgupta, R. Effect of Varying Al/Mn Ratio on Phase Transformation in Cu–Al–Mn Shape Memory Alloys. Trans. Indian Inst. Met. 2016, 69, 1289–1295. [Google Scholar] [CrossRef]

- Silva, R.A.G.; Gama, S.; Paganotti, A.; Adorno, A.T.; Carvalho, T.M.; Santos, C.M.A. Effect of Ag Addition on Phase Transitions of the Cu-22.26 at.%Al-9.93 at.%Mn Alloy. Thermochim. Acta 2013, 554, 71–75. [Google Scholar] [CrossRef]

- Gholami-Kermanshahi, M.; Wu, Y.Y.; Lange, G.; Chang, S.H. Effect of Alloying Elements (Nb, Ag) on the Damping Performance of Cu–Al–Mn Shape Memory Alloys. J. Alloys Compd. 2023, 930, 167438. [Google Scholar] [CrossRef]

- Taha, A.S.; Hammad, F.H. Application of the Hall-Petch Relation to Microhardness Measurements on Al, Cu, Al-MD 105, and Al-Cu Alloys. Phys. Status Solidi A 1990, 119, 455–462. [Google Scholar] [CrossRef]

- Ćorić -Mladen Franz, D. Properties of Thermally Treated CuZn27Al3 Shape Memory Alloy. Stroj. Vestn. J. Mech. Eng. 2009, 55, 623–632. [Google Scholar]

- Adorno, A.T.; Silva, R.A.G. Isothermal Decomposition Kinetics in the Cu–9%Al–4%Ag Alloy. J. Alloys Compd. 2004, 375, 128–133. [Google Scholar] [CrossRef]

| Al | Cu | Ag | |

|---|---|---|---|

| Point 1 | 9.21 ± 0.20 | 80.87 ± 0.55 | 6.78 ± 0.24 |

| Point 2 | 10.28 ± 0.42 | 81.51 ± 0.63 | 8.21 ± 0.52 |

| Al | Cu | Ag | |

|---|---|---|---|

| Point 1 | 9.70 ± 1.11 | 80.41 ± 1.70 | 9.89 ± 1.42 |

| Point 2 | 10.30 ± 0.90 | 81.2 ± 1.10 | 8.50 ± 1.05 |

| Hardness | HV | |||||

|---|---|---|---|---|---|---|

| Cu-10Al-7Ag Alloy | 1 | 2 | 3 | 4 | 5 | Average |

| As-cast state | 225.68 | 287.79 | 323.21 | 278.72 | 323.34 | 278.85 |

| Quenched state | 186.57 | 250.05 | 184.20 | 222.53 | 181.80 | 210.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liverić, L.; Sitek, W.; Snopiński, P.; Maziarz, W.; Grgurić, T.H. A Microstructural Study of Cu-10Al-7Ag Shape Memory Alloy in As-Cast and Quenched Conditions. Symmetry 2024, 16, 545. https://doi.org/10.3390/sym16050545

Liverić L, Sitek W, Snopiński P, Maziarz W, Grgurić TH. A Microstructural Study of Cu-10Al-7Ag Shape Memory Alloy in As-Cast and Quenched Conditions. Symmetry. 2024; 16(5):545. https://doi.org/10.3390/sym16050545

Chicago/Turabian StyleLiverić, Lovro, Wojciech Sitek, Przemysław Snopiński, Wojciech Maziarz, and Tamara Holjevac Grgurić. 2024. "A Microstructural Study of Cu-10Al-7Ag Shape Memory Alloy in As-Cast and Quenched Conditions" Symmetry 16, no. 5: 545. https://doi.org/10.3390/sym16050545

APA StyleLiverić, L., Sitek, W., Snopiński, P., Maziarz, W., & Grgurić, T. H. (2024). A Microstructural Study of Cu-10Al-7Ag Shape Memory Alloy in As-Cast and Quenched Conditions. Symmetry, 16(5), 545. https://doi.org/10.3390/sym16050545