In this section, the reliability sampling design is investigated under different setups and considerations. In

Section 3.1, the case of the fixed termination time

T is considered. The minimum sample size is determined to reach the given power level of the hypothesis testing procedure. In

Section 3.2, the case of the unfixed number of inspection intervals and fixed termination time

T is considered. The minimum number of inspection intervals and sample sizes are determined to reach the given power of the level

α testing procedure, and the total cost can be minimized. In

Section 3.3, the case of an unfixed number of inspection intervals and unfixed interval length is considered. The minimum number of inspection intervals and the corresponding sample sizes and equal lengths of the intervals are determined so that the given power of the level

α testing procedure can be reached and the total cost of the experiment can be minimized.

3.1. The Determination of the Minimum Sample Size

In this subsection, we need to determine the sample size

n to attain the prespecified power 1-

β or the probability of type II error

β at

under the level of significance

α for a fixed

m and

T. For a fixed number of inspection intervals, we assigned the power in Equation (9) to be 1-

β. Then, we have

. The minimum required sample size to reach the given power is obtained by solving the equation of

. Then, the formula for the minimum required sample size can be obtained as

The minimum required sample sizes for testing

are tabulated in

Table 1,

Table 2 and

Table 3 at

β = 0.25, 0.20 and 0.15 under

α = 0.01, 0.05 and 0.1, respectively; for

c1 = 0.825, 0.850, 0.875, 0.90, 0.925, 0.95, 0.96, 0.975 and 0.98,

m = 5, 6, 7 and 8 and

p = 0.05, 0.075 and 0.1, with

L = 0.3 and

T = 3.0. For example, the user wants to conduct a level 0.05 hypothesis testing of

under the power of 0.8 at

c1 = 0.95,

p = 0.05 and

m = 8, so the minimum required sample size is 7 from

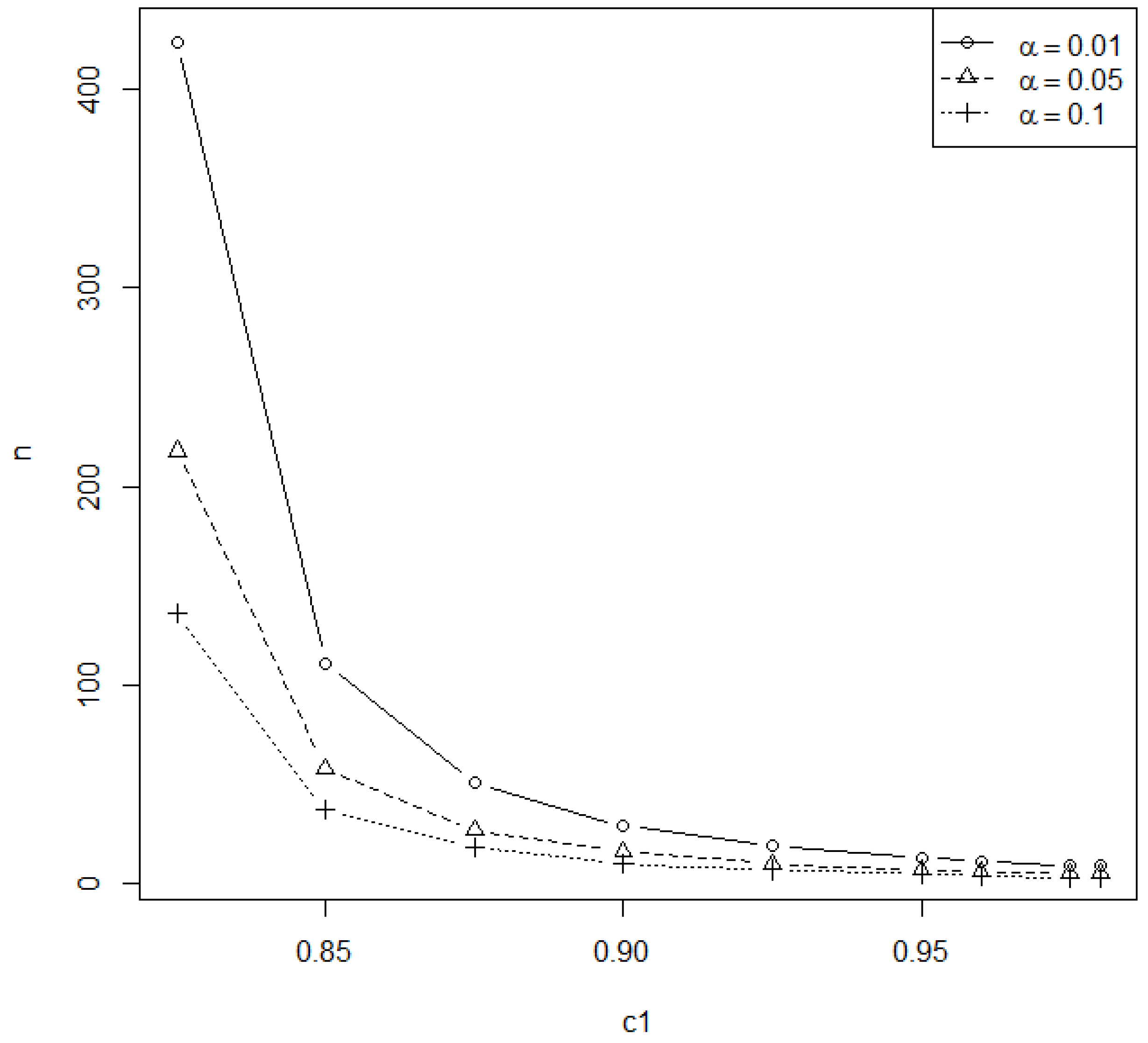

Table 2. The minimum required sample sizes are also displayed in

Figure 1,

Figure 2,

Figure 3 and

Figure 4 for some typical cases. Observed in

Figure 1,

Figure 2,

Figure 3 and

Figure 4, we find that (1) the minimum sample size

n is a decreasing function of

c1 for fixed

α,

β,

m and

p; (2) the minimum sample size is a decreasing function of the level of significance for fixed

β,

m and

p; (3) the minimum sample size is a nondecreasing function of

m at

α = 0.05 for a fixed

β = 0.2 and

p = 0.05; (4) the minimum sample size is a nonincreasing function of the removal percentage

p for fixed

α,

β and

m and (5) the minimum sample size is a decreasing function of power 1-

β at

α = 0.05 for fixed

m = 5 and

p = 0.05.

3.2. The Determination of Optimal m and n When the Termination Time Is Fixed

The smaller the number of inspection intervals

m, the more convenient for experimenters to collect a progressive type I interval sample. There must be an upper limit

m0 for

m specified by the experimenters (The default value of

m0 is 100). In this subsection, the case of the fixed termination time is considered. For this case, the algorithm for searching the optimal (

m,

n) is presented so that the total experimental cost is minimized for the testing procedure in Wu and Lin [

15] under progressive type I interval censoring. Using the cost structure in Huang and Wu [

19], the following costs are considered:

Ca: The cost of installing all test units;

Cs: The cost for per test unit in the sample;

CI: The cost for the use of the inspection equipment;

Co: The cost for operating the equipment per unit of experimental time.

Integrating all these costs, we have the total cost of

where

n is determined in Equation (10).

The Algorithm 1 using the numeration method to search the optimal (

m,

n) is given as follows:

| Algorithm 1: |

| Step 1: Give the preassigned values of c0, c1, α, β, p, T, L and m0 (the default value is 100) and the four costs Ca = aCo, Cs = bCo, CI = cCo and Co by the experimenters. |

| Step 2: Set m = 1. |

| Step 3: Compute the sample size n in Equation (10) as n’(m) and then compute the corresponding total cost TC(m, n’(m)), as in Equation (11). |

| Step 4: If m ≥ m0, then go to Step 5; otherwise, m = m + 1, and go to Step 3. |

| Step 5: The optimal solution of m* is the minimum m value with the minimum total cost TC(m, n’(m)). Then, the corresponding sample size n* = n’(m*) is obtained. |

| Step 6: Calculate the critical value of by replacing m = m* and n = m*. |

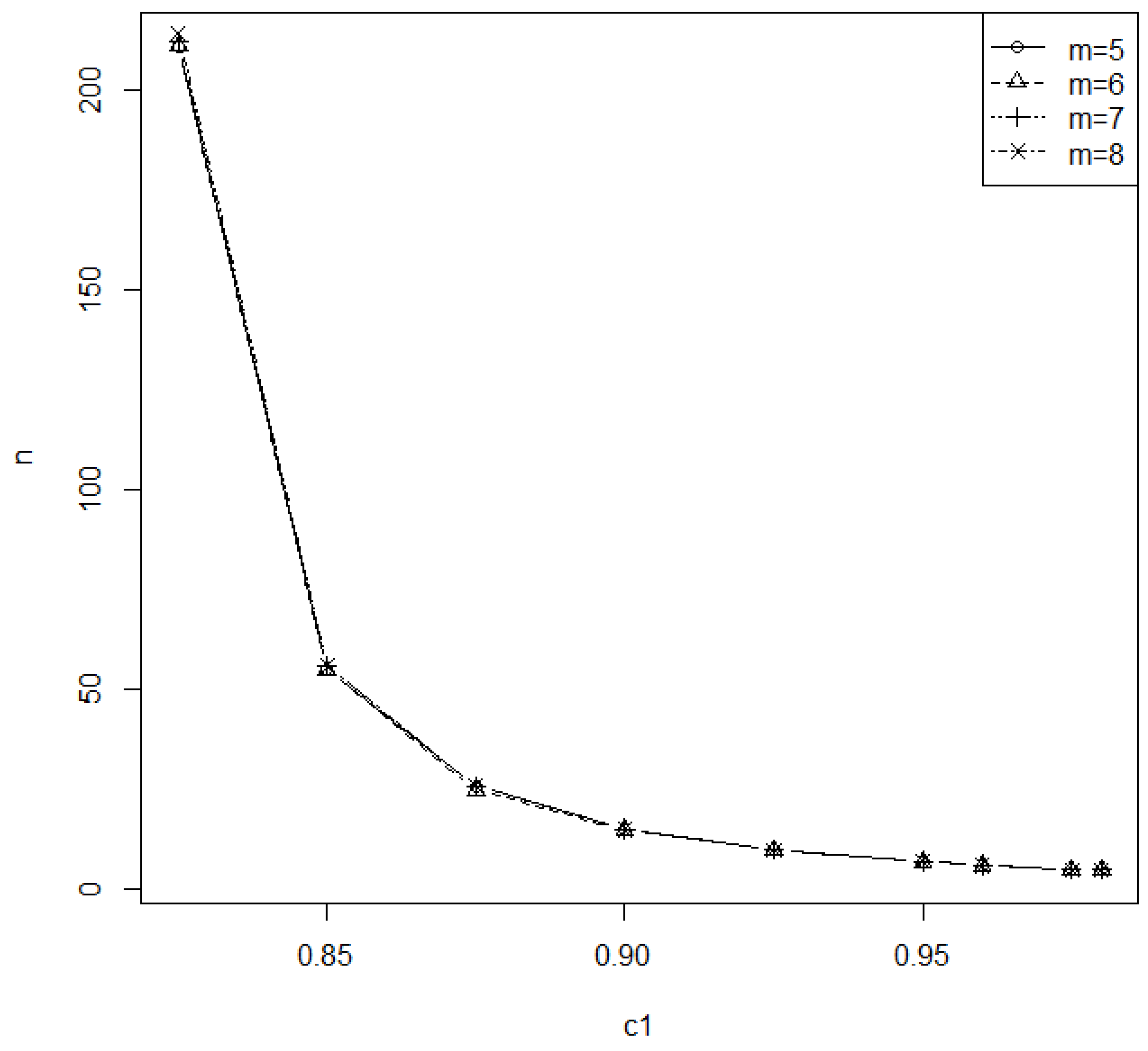

Consider

Co = 1 and

a =

b =

c = 1 and testing for

. When

β = 0.15,

α= 0.01,

p = 0.05,

= 1.97,

c1 = 0.825,

m0 = 20,

L = 0.3 and

T = 3.0, the curve of the total cost versus

m = 2:

m0 is plotted in

Figure 5a. From this figure, it can be seen that the total cost curve is a convex curve, and the minimum number of inspection intervals is

m = 5, with a minimum total cost of 424. For another setup of parameters

β = 0.25,

α = 0.1,

p = 0.1,

= 1.97,

c1 = 0.90,

m0 = 20,

L = 0.3 and

T = 3.0, the plot of

m = 2:

m0 against its corresponding total cost is made in

Figure 5b. This figure also shows that it is a convex curve with some flats, and the minimum number of inspection intervals is

m = 3, with a minimum total cost of 17.

Consider the case of

β = 0.25, 0.20 and 0.15,

α = 0.01, 0.05 and 0.1;

L = 0.3;

T = 3.0;

p = 0.05, 0.075 and 0.1 and testing

. The required inspection intervals

m* and sample size

n* to yield the minimum total cost

TC(

m*,

n*) under

m0 = 20 are tabulated in

Table 4 and

Table 5 for

c1 = 0.825 and 0.850 and

c1 = 0.875 and 0.90, respectively. We also tabulated the related critical values in these two tables. Suppose that the experimenters would like to conduct a level 0.05 test for the case of 1-

β = 0.8 at

c1 = 0.90,

p = 0.05 and

m0 = 20. We can find the minimum number of inspection intervals to be three, with the minimum total cost 23 from

Table 5. At the same time, the corresponding required sample size can be 16, with the critical value 0.71592.

We have the following findings from

Table 4 and

Table 5: (1) the minimum required sample size is a nonincreasing function of the level of significance for fixed

β and

p; (2) the minimum required sample size is a nonincreasing function of

c1 for fixed

α,

β and

p; (3) the minimum required sample size increases when the probability of type II error

β decreases; (4) the minimum inspection intervals decrease when

c1 increases for any combination of

α,

β and

p; (5) the minimum inspection intervals increases when the probability of type II error

β decreases; (6) the minimum total cost increases when the removal probability

p decreases for fixed

α,

β and

c1 are fixed; (7) the minimum total cost decreases when

c1 increases for any combination of

α,

β and

p and (8) the minimum total cost increases when the probability of type II error

β decreases.

3.3. The Determination of Optimal m, t and n for the Unfixed Total Life Test Time T

In this subsection, the case of the fixed termination time

T and unfixed equal interval length

t is considered. The algorithm for searching the optimal (

m,

t,

n) is presented so that the total experimental cost is minimized for the testing procedure based on Wu and Lin [

15] under progressive type I interval censoring.

The total cost is

where

n is determined in Equation (10).

The Algorithm 2 using the numeration method to search the optimal (

m,

t,

n) is given as follows:

| Algorithm 2: |

| Step 1: Give the preassigned values of c0, c1, α, β, p, T, L and m0 (the default value is 100) and the four costs Ca = aCo, Cs = bCo, CI = cCo and Co by the experimenters. |

| Step 2: Set m = 1. |

| Step 3: Find the optimal solution t*, such that TC(m,t,n) is minimized. Compute the sample size n in Equation (10) as n′(m,t*), and then, compute the corresponding total cost TC(m,t*, n’(m,t*)), as in Equation (12). |

| Step 4: If m ≥ m0, then go to Step 5; otherwise, m = m+1, and go to Step 3. |

| Step 5: The optimal solution of m* is the minimum m value with the minimum total cost TC(m, n’(m)). Then, the corresponding sample size n* = n’(m*) is obtained. |

| Step 6: Calculate the critical value of by replacing m = m* and n = m*. |

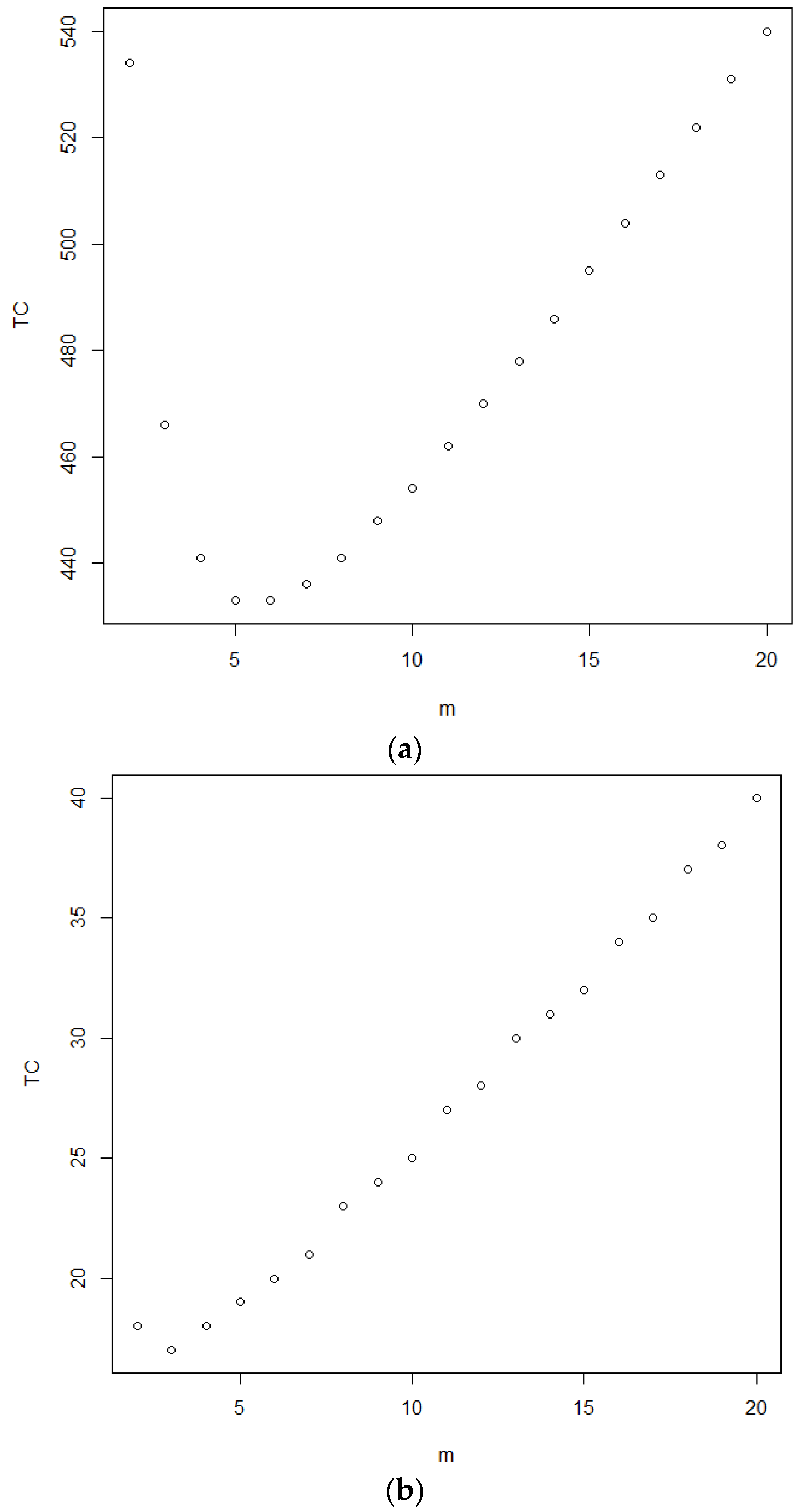

Consider the cost structure

Co = 1 and

a =

b =

c = 1 and the testing for

. When

β = 0.25,

α = 0.01,

p = 0.05,

= 1.97,

c1 = 0.825,

m0 = 20,

L = 0.3 and

T = 3.0, the curve of total cost versus

m = 2:

m0 is plotted in

Figure 6a. It can be seen that the total cost curve is a convex curve, and the minimum number of inspection intervals is

m = 6, with a minimum total cost of 423.1605. For another set up of parameters:

β = 0.15,

α = 0.1,

p = 0.1 and

c1 = 0.90, the plot of the total cost curve with

m = 1:

m0 is made in

Figure 6b. It can be seen that the total cost curve is a concave upward curve, and the minimum number of inspection intervals is

m = 3, with a minimum total cost of 16.8.

Consider the case of

β = 0.25, 0.20 and 0.15;

α = 0.01, 0.05 and 0.1;

L = 0.3;

T = 3.0;

p = 0.05, 0.075 and 0.1 and

c0 = 0.8. The minimum suggested number of inspection intervals

m*, optimal equal interval length

t* and sample size

n* to attain the minimum total cost

TC(

m*,

t*,

n*) under

m0 = 20 are tabulated in

Table 6 and

Table 7 for

c1 = 0.825 and 0.850 and

c1 = 0.875 and 0.90, respectively. We also list the critical values

in these two tables. If the experimenters would like to conduct a level 0.05 test under the conditions of

β = 0.8,

c1 = 0.825,

p = 0.05 and

m0 = 20, the optimal values of (

m*,

t*,

n*) can be found as (5,0.55,214) from

Table 6. From this table, you can also find the minimum total cost as TC = 222.744 and the corresponding critical value as 0.7759.

A software program to find the optimal setup for the sampling design proposed in

Section 3.1,

Section 3.2 and

Section 3.3 for any combination of parameters was built by the authors for practical use.

From

Table 6 and

Table 7, we have the following findings: (1) the minimum required sample size is a decreasing function of the level of significance for fixed

β and

p; (2) the minimum required sample size is a decreasing function of

c1 for fixed

α,

β and

p; (3) the minimum required sample size increases when the probability of a type II error

β decreases; (4) the minimum number of inspection intervals decreases when

c1 increases for any combinations of

α,

β and

p; (5) the minimum number of inspection intervals increases when the probability of a type II error

β decreases; (6) the minimum total cost decreases when

c1 increases for fixed

α,

β and

p; (7) the minimum total cost increases when the probability of a type II error

β decreases and (8) the minimum total cost is a nonincreasing function of the removal probability

p for fixed

α,

β and

c1.

3.4. Example

For the aims of the illustration, the data in Caroni [

20] is used to illustrate our proposed sampling design. The data of the failure times of

n = 25 ball bearing are given as follows (number of cycles in 1000 times): 0.1788, 0.2892, 0.3300, 0.4152, 0.4212, 0.4560, 0.4848, 0.5184, 0.5196, 0.5412, 0.5556, 0.6780, 0.6780, 0.6780, 0.6864, 0.6864, 0.6888, 0.8412, 0.9312, 0.9864, 1.0512, 1.0584, 1.2792, 1.2804, 1.7340.

The Gini test (see Gail and Gastwirth [

21]) is a scale-free goodness-of-fit test for distribution that can be transformed into an exponential distribution. The testing procedures in Jäntschi [

22] and Jäntschi [

23] are more general procedures as alternatives to the Gini test. We use the Gini test with the maximum

p-value to determine the parameter δ for this example. We conduct the Gini test as follows: In the first step, the null hypothesis is set up as

. Secondly, we sort the data in order as

U(1) = 0.1788,

U(2) = 0.2892,… and

U(25) = 1.7340. We calculate the Gini test statistic

, where

. The limiting distribution of

is a standard normal distribution when the sample size is large enough. Let

z be the realization of

Z, and then, the

p-value is obtained as

. The higher the

p-value, the better fit of the data to the Weibull distribution. From Wu and Lin [

15], the value of δ is determined as δ = 1.97, since it has the largest

p-value = 0.9882 for the Gini test. With a high

p-value, we conclude that the data fits the Weibull distribution very well. We then used this example to illustrate

Section 3.1,

Section 3.2 and

Section 3.3.

For

Section 3.1, we considered the case of

L = 0.05,

T = 0.5,

m = 5 and

p = 0.05 for testing

with a significance level

α = 0.05 and the power level 1-

β = 0.75 at

c1 = 0.975. After running our software, the minimum sample size was determined to be

n = 20, and the critical value was obtained as

= 0.7002605.

Then, the hypothesis test was conducted as follows:

Step 1: We took a random sample of size n = 20 from the dataset. The progressive type I interval censored sample (X1,X2,…,X5) = (0,1,1,1,2) was collected at the time points (t1,t2,…,t5) = (0.1,0.2,0.3,0.4,0.5) under the progressive censoring scheme of (R1,R2,…,R5) = (1,2,0,2,10).

Step 2: Based on the progressive type I interval censored sample given in step 1, the MLE of k was found to be = 1.382812 by solving Equation (6).

Step 3: The value of test statistic = 1 − 1.382812 × 0.05 = 0.9308594 was computed.

Step 4: Due to the result of = 0.9308594 > = 0.7002605, we concluded it supported the alternative hypothesis and claimed that the lifetime performance index exceeded the desired level.

From

Section 3.2, the same consideration of parameters and cost setup as the previous paragraph was considered. After running our software, the minimum number of inspection intervals and the related sample size were determined to be

m* = 1 and

n*= 19, with the critical value as

= 0.7228799 and a minimum total cost of 21.5 units.

The, a hypothesis test about was conducted as follows:

Step 1: A random sample of size n = 19 was taken from the dataset. The progressive type I interval censored sample (X1) = (5) was collected at the time point (t1) = (0.5) under the progressive censoring scheme of (R1) = (14).

Step 2: Using the progressive type I interval censored sample collected in step 1, the MLE of k was found to be = 1.196398 by solving Equation (6).

Step 3: Computing the test statistic, = 1 − 0.196398 × 0.05 = 0.9401801.

Step 4: We observed that = 0.9401801 > = 0.7228799. Thus, it supported the alternative hypothesis and claimed that the lifetime performance index exceeded the desired level.

For

Section 3.3, the case of unfixed

m and

t was considered. Based on the same setup with the previous two cases, the optimal sampling design with (

m*,

n*,

t*) = (2,12,0.42) was found from the output of our software. The critical value

= 0.7063278 and the minimum total cost of TC = 15.834 units could also be found from the output.

The testing procedure of was conducted as follows:

Step 1: A random sample of size n = 12 was taken from the dataset. The progressive type I interval censored sample was (X1,X2) = (3,6) at the time points (t1,t2) = (042,0.84) under the progressive censoring schemes of (R1,R2) = (0,3).

Step 2: Based on the progressive type I interval censored sample given in step 1, the MLE of k was found to be = 1.875922 by solving Equation (6).

Step 3: The test statistic was = 1 − 1.875922 × 0.05 = 0.9062039.

Step 4: we observed that = 0.9062039 > = 0.7063278. Based on this observation, the same claim was made with the previous two cases.