First and Second Law Thermodynamic Analyses of Hybrid Nanofluid with Different Particle Shapes in a Microplate Heat Exchanger

Abstract

:1. Introduction

2. Numerical Method

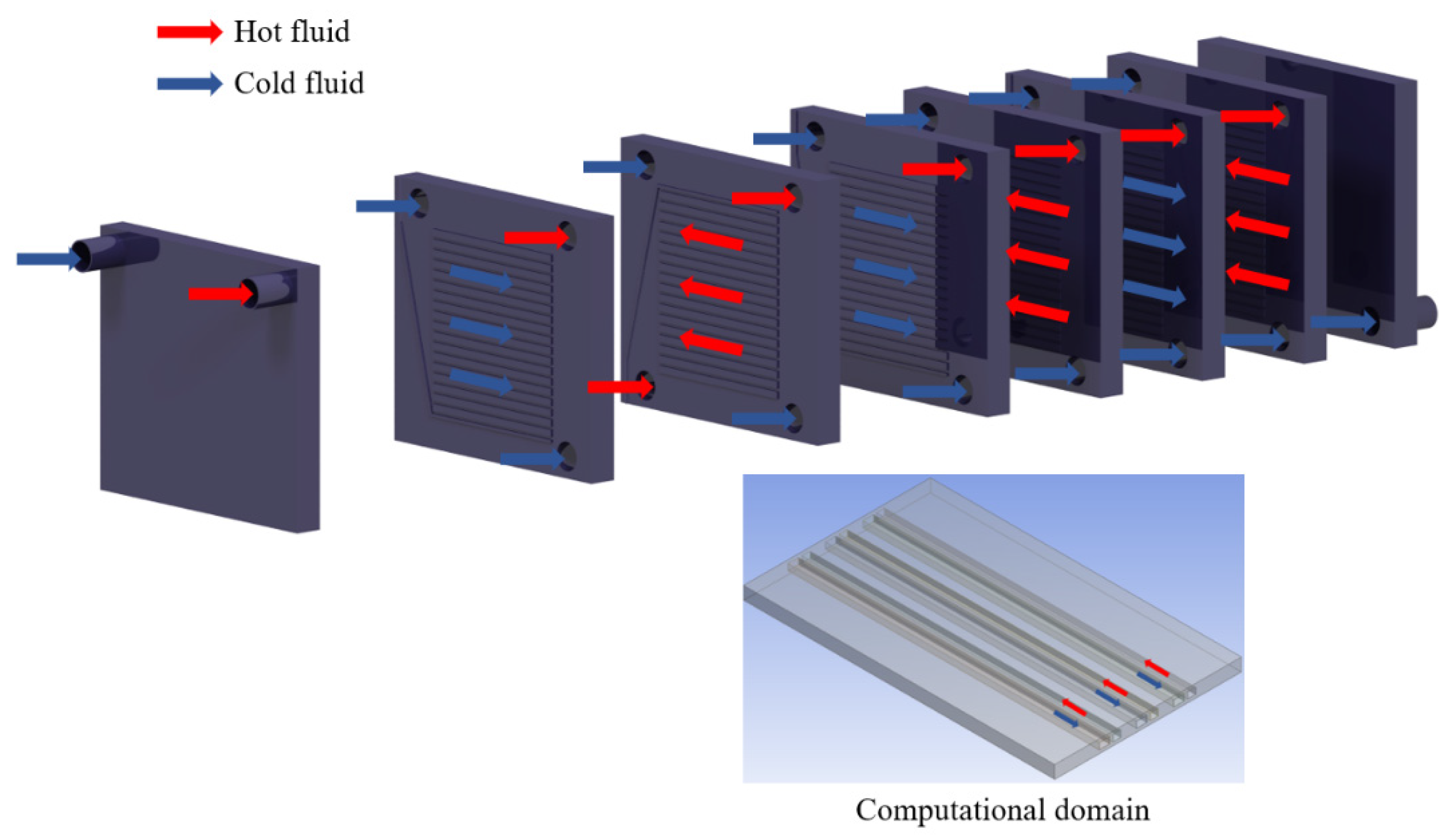

2.1. Computational Geometry and Boundary Conditions

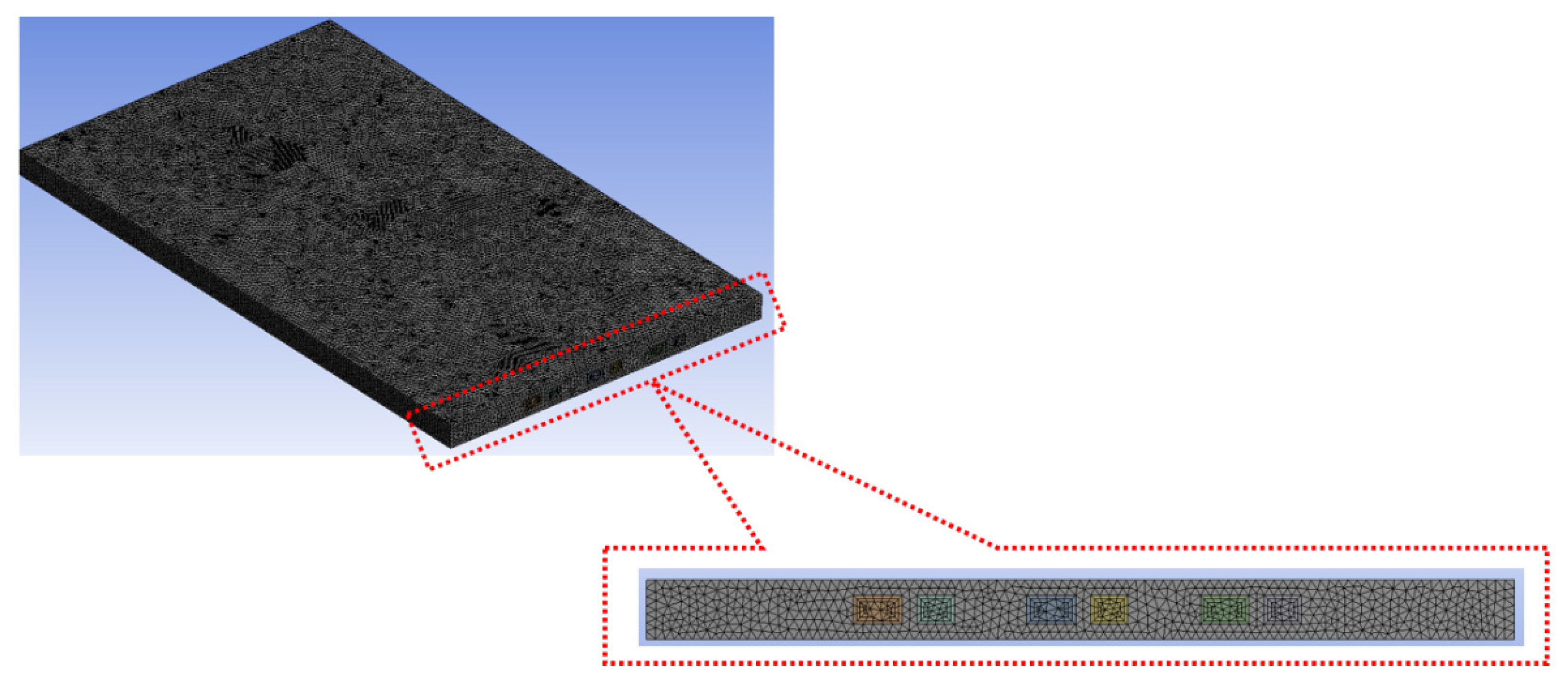

2.2. Governing Equation and Meshing

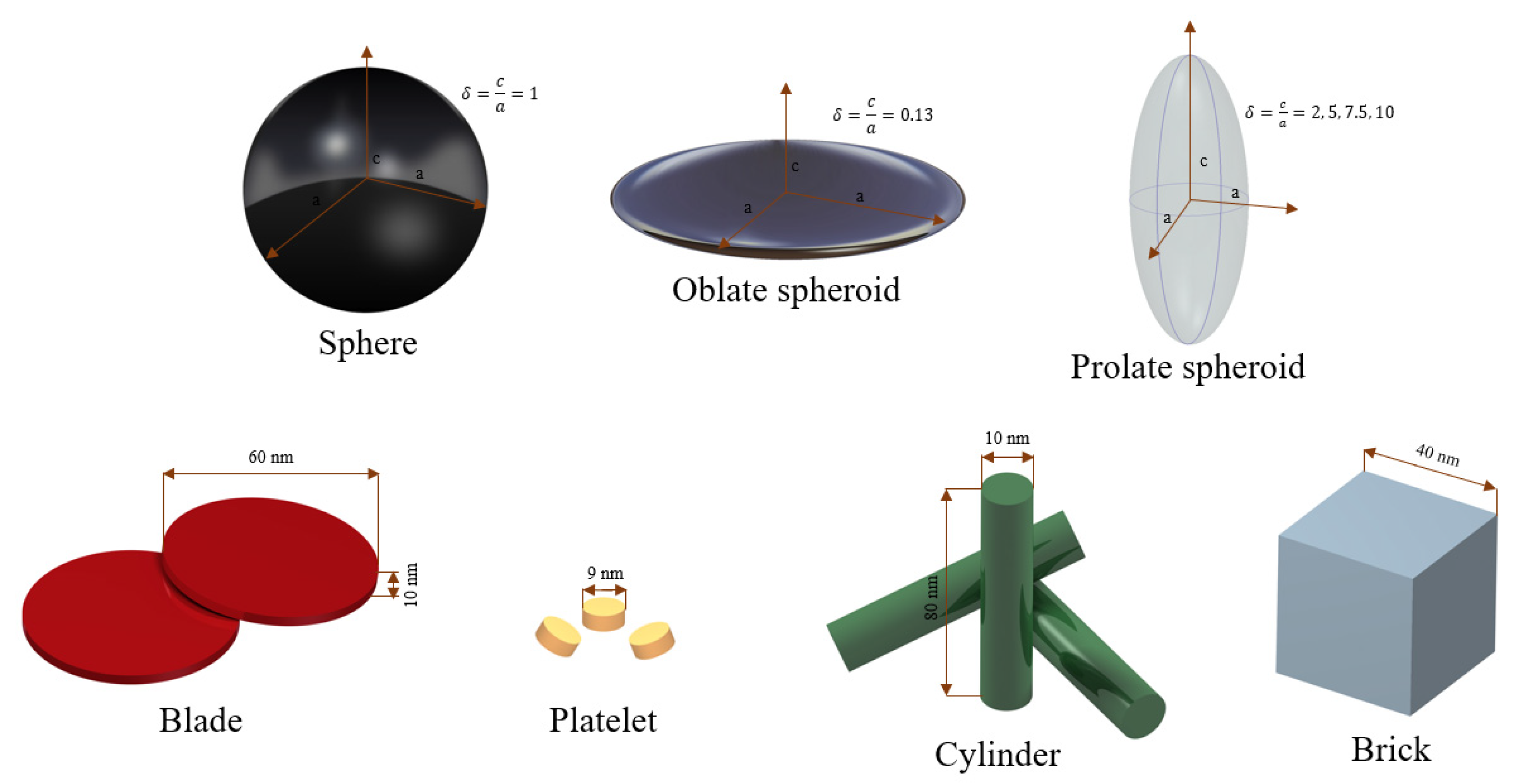

3. Thermophysical Properties of Nanofluids with Nanoparticle Shapes

3.1. Single-Particle Nanofluid Properties

3.2. Hybrid Nanofluid Properties

4. Data Reduction

5. Results and Discussion

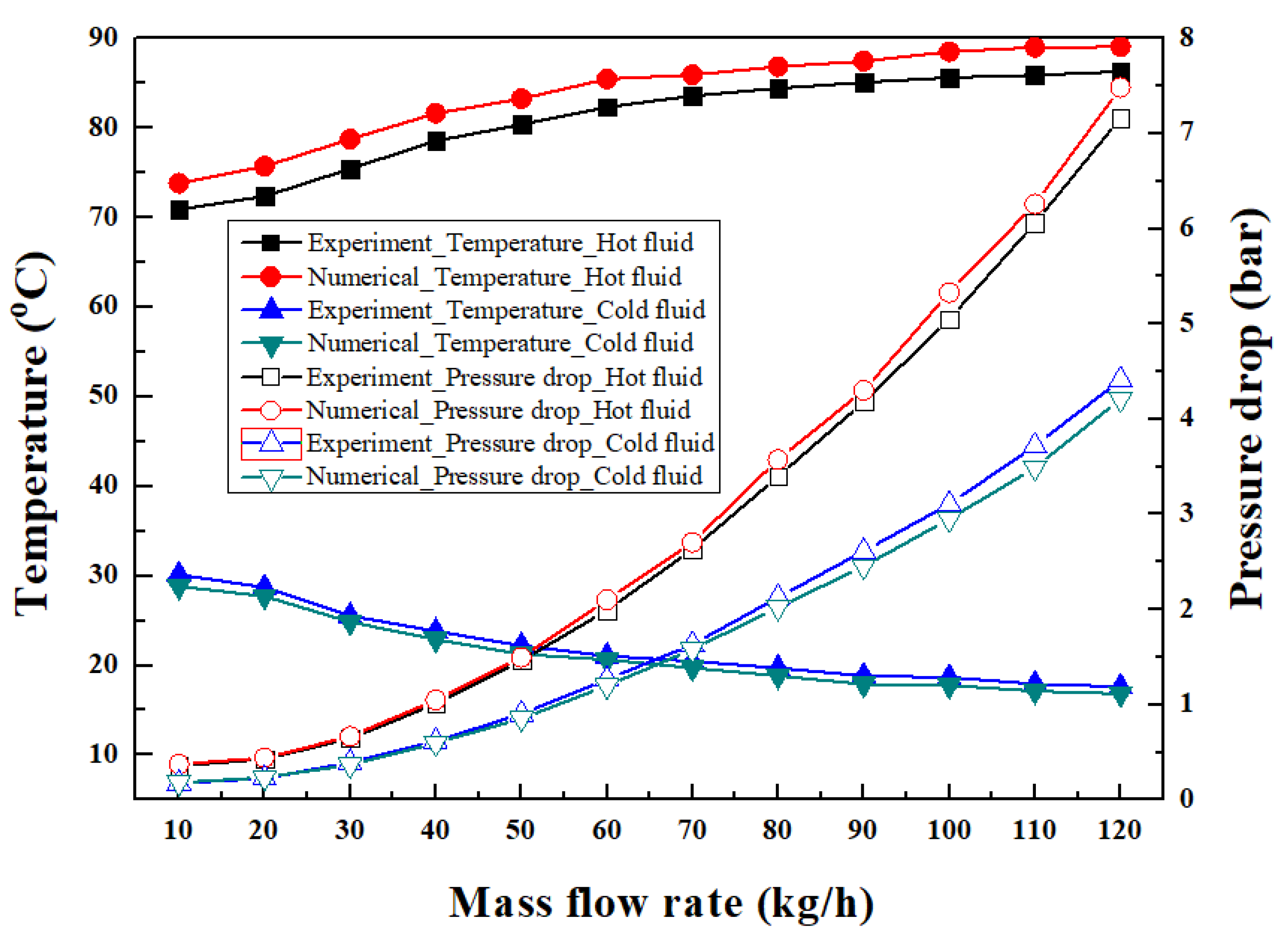

5.1. Validation

5.2. Evaluation of Nanofluid Thermophysical Properties for Different Nanoparticle Shapes

5.3. Evaluation of First Law Characteristics for Different Nanoparticle Shapes

5.4. Evaluation of Second Law Characteristics for Different Nanoparticle Shapes

5.5. Effect of Hot Fluid Temperature on First and Second Law Characteristics

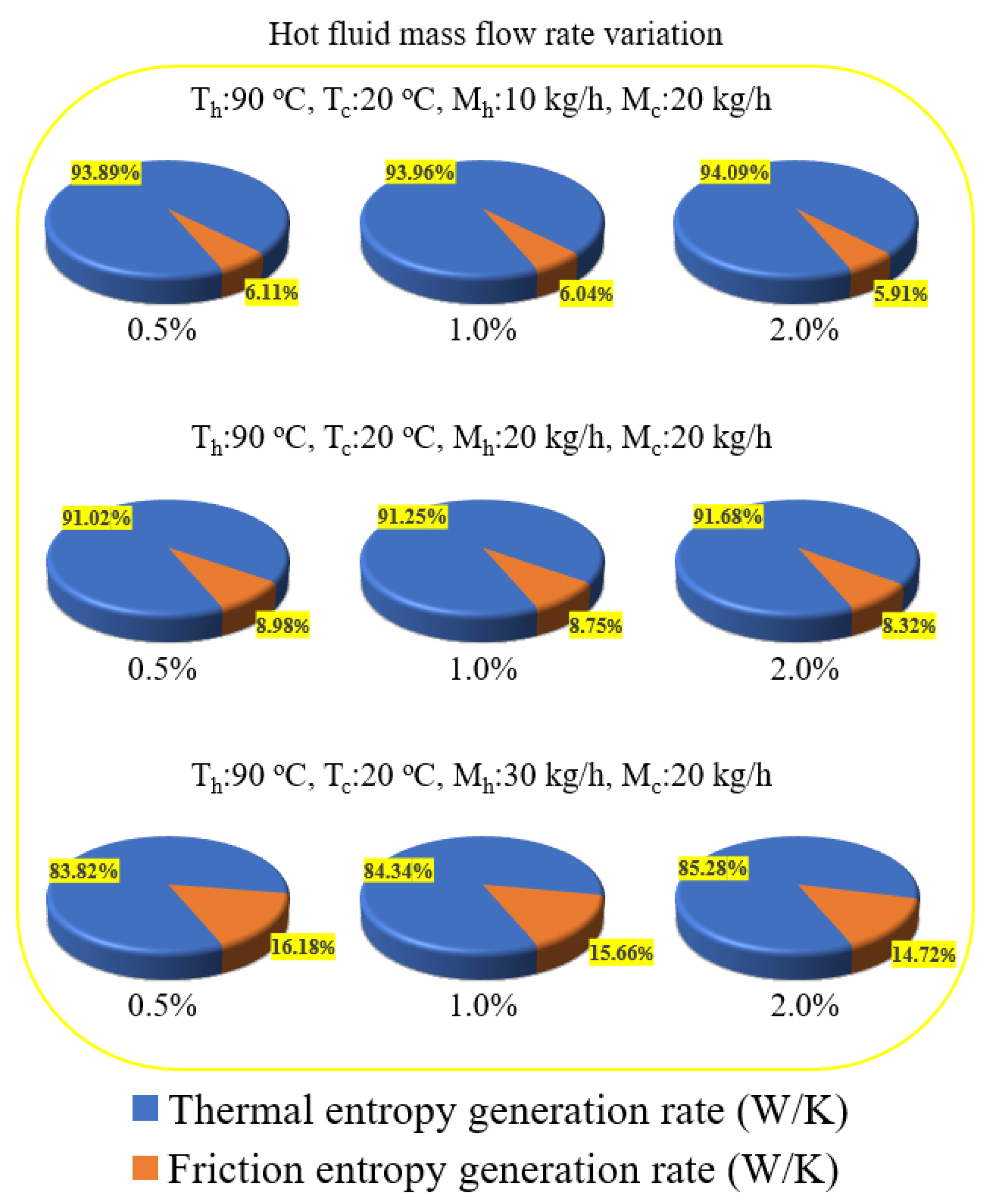

5.6. Effect of Hot Fluid Mass Flow Rate on First and Second Law Characteristics

5.7. Effect of Cold Fluid Temperature on First and Second Law Characteristics

5.8. Effect of Cold Fluid Mass Flow Rate on First and Second Law Characteristics

6. Conclusions

- (a)

- The decreasing order of first law characteristics is evaluated as hybrid nanofluid, single-particle nanofluid and water, respectively, for all nanoparticle shapes. The Al2O3/Cu nanofluid with OS-shaped nanoparticles shows maximum values of NTU, effectiveness and performance index, which are higher by 6.38%, 6.10% and 6.58%, respectively, compared to water. The Al2O3 nanofluid with PL-shaped nanoparticles shows minimum values of NTU, effectiveness and performance index, which are lower by 3.99%, 3.65% and 8.78%, respectively, compared to water. The Al2O3/Cu nanofluid with OS-shaped nanoparticles shows the optimum values of first law characteristics.

- (b)

- The thermal entropy generation rates of OS-shaped nanoparticles are at a maximum, which are 0.14% and 0.70% higher for Al2O3 and Al2O3/Cu nanofluids, respectively, compared to water. The friction entropy generation rates are maximum for PL-shaped nanoparticles which are 2.73% higher and 0.74% lower for Al2O3 and Al2O3/Cu nanofluids, respectively, compared to water. The increasing order of Bejan numbers are water, single-particle nanofluid and hybrid nanofluid, respectively, for all nanoparticle shapes. The Bejan number of the Al2O3/Cu nanofluid with OS-shaped nanoparticles is the maximum, and that of the Al2O3 nanofluid with PL-shaped nanoparticles is the minimum, which are 0.54% higher and 0.86% lower compared to water. The Al2O3/Cu nanofluid with OS-shaped nanoparticles shows the optimum values of second law characteristics.

- (c)

- The first law characteristic performance index of the Al2O3/Cu nanofluid with OS-shaped nanoparticles has increased with an increase in volume fraction for various temperature and mass flow rate conditions of hot and cold fluids. The performance index increases with the increase in the hot fluid temperature and decrease in the cold fluid temperature for all volume fractions. The performance index has decreased with the increase in the hot and cold fluid mass flow rates.

- (d)

- The second law characteristic Bejan number of the Al2O3/Cu nanofluid with OS-shaped nanoparticles has increased with the increase in the volume fraction for all temperature and mass flow rate conditions of hot and cold fluids. The Bejan number has increased with the increase in hot fluid temperature, whereas with the increase in the cold fluid temperature, the Bejan number has decreased for all volume fractions. The Bejan number has decreased with the increase in hot and cold fluid mass flow rates for all volume fractions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| total heat transfer area (m2) | |

| cold fluid heat capacity (W/K) | |

| hot fluid heat capacity (W/K) | |

| minimum heat capacity (W/K) | |

| specific heat of base fluid (J/kg·K) | |

| cold fluid specific heat (J/kg·K) | |

| hot fluid specific heat (J/kg·K) | |

| specific heat of hybrid nanofluid (J/kg·K) | |

| specific heat of nanofluid (J/kg·K) | |

| specific heat of nanoparticles (J/kg·K) | |

| specific heat of nanoparticle1 (J/kg·K) | |

| specific heat of nanoparticle2 (J/kg·K) | |

| enthalpy (J/kg) | |

| turbulent kinetic energy (J/kg) | |

| thermal conductivity of base fluid (W/m·K) | |

| thermal conductivity of hybrid nanofluid (W/m·K) | |

| thermal conductivity of nanofluid (W/m·K) | |

| thermal conductivity of nanoparticle (W/m·K) | |

| thermal conductivity of nanoparticle1 (W/m·K) | |

| thermal conductivity of nanoparticle2 (W/m·K) | |

| cold fluid mass flow rate (kg/s) | |

| hot fluid mass flow rate (kg/s) | |

| mass of nanoparticles (kg) | |

| static pressure (Pa) | |

| maximum possible heat transfer rate (W) | |

| Volumetric friction entropy generation rate (W/m3 K) | |

| Volumetric thermal entropy generation rate (W/m3 K) | |

| Volumetric total entropy generation rate (W/m3 K) | |

| cold fluid inlet temperature (K) | |

| cold fluid outlet temperature (K) | |

| hot fluid inlet temperature (K) | |

| hot fluid output temperature (K) | |

| average temperature (K) | |

| temperature fluctuation (K) | |

| average velocity (m/s) | |

| volume of base fluid (L) | |

| volume of nanoparticles = (L) | |

| average velocity (m/s) | |

| fluctuating velocity (m/s) | |

| density (kg/m3) | |

| density of base fluid (kg/m3) | |

| density of hybrid nanofluid (kg/m3) | |

| density of nanofluid (kg/m3) | |

| density of nanoparticles (kg/m3) | |

| density of nanoparticle1 (kg/m3) | |

| density of nanoparticle2 (kg/m3) | |

| dynamic viscosity (Pa·s) | |

| viscosity of base fluid (Pa·s) | |

| viscosity of nanofluid (Pa·s) | |

| volume fraction of hybrid nanofluid (%) | |

| volume fraction of nanoparticle1 (%) | |

| volume fraction of nanoparticle2 (%) | |

| thermal conductivity (W/m·K) | |

| effective thermal conductivity (W/m·K) | |

| turbulent thermal conductivity (W/m·K) | |

| gradient operator | |

| specific dissipation rate (s−1) |

References

- Kim, H.J.; Lee, S.H.; Lee, J.H.; Jang, S.P. Effect of particle shape on suspension stability and thermal conductivities of water-based bohemite alumina nanofluids. Energy 2015, 90, 1290–1297. [Google Scholar] [CrossRef]

- Xie, H.Q.; Wang, J.C.; Xi, T.G.; Liu, Y. Thermal conductivity of suspensions containing nanosized SiC particles. Int. J. Thermophys. 2002, 23, 571–580. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Enhanced thermal conductivity of TiO2–Water based nanofluids. Int. J. Therm. Sci. 2005, 44, 367–373. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Routbort, J.L.; Singh, D. Particle shape effects on thermophysical properties of alumina nanofluids. J. Appl. Phys. 2009, 106, 014304. [Google Scholar] [CrossRef]

- Maheshwary, P.B.; Handa, C.C.; Nemade, K.R. A comprehensive study of effect of concentration, particle size and particle shape on thermal conductivity of titania/water based nanofluid. Appl. Therm. Eng. 2017, 119, 79–88. [Google Scholar] [CrossRef]

- Singh, D.; Timofeeva, E.; Yu, W.; Routbort, J.; France, D.; Smith, D.; Lopez-Cepero, J.M. An investigation of silicon carbide-water nanofluid for heat transfer applications. J. Appl. Phys. 2009, 105, 064306. [Google Scholar] [CrossRef]

- Jeong, J.; Li, C.; Kwon, Y.; Lee, J.; Kim, S.H.; Yun, R. Particle shape effect on the viscosity and thermal conductivity of ZnO nanofluids. Int. J. Refrig. 2013, 36, 2233–2241. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, W.; Zhu, D.; Xie, H.; Huang, G. Enhanced thermal conductivity for nanofluids containing silver nanowires with different shapes. J. Nanomater. 2017, 2017, 5802016. [Google Scholar] [CrossRef] [Green Version]

- Nithiyanantham, U.; González-Fernández, L.; Grosu, Y.; Zaki, A.; Igartua, J.M.; Faik, A. Shape effect of Al2O3 nanoparticles on the thermophysical properties and viscosity of molten salt nanofluids for TES application at CSP plants. Appl. Therm. Eng. 2020, 169, 114942. [Google Scholar] [CrossRef]

- Vanaki, S.M.; Mohammed, H.A.; Abdollahi, A.; Wahid, M.A. Effect of nanoparticle shapes on the heat transfer enhancement in a wavy channel with different phase shifts. J. Mol. Liq. 2014, 196, 32–42. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Heris, S.Z.; Wongwises, S. First and second laws analysis of a minichannel-based solar collector using boehmite alumina nanofluids: Effects of nanoparticle shape and tube materials. Int. J. Heat Mass Transf. 2014, 78, 1166–1176. [Google Scholar] [CrossRef]

- Akbar, N.S.; Butt, A.W.; Tripathi, D. Nanoparticle shapes effects on unsteady physiological transport of nanofluids through a finite length non-uniform channel. Results Phys. 2017, 7, 2477–2484. [Google Scholar] [CrossRef]

- Bahiraei, M.; Monavari, A.; Naseri, M.; Moayedi, H. Irreversibility characteristics of a modified microchannel heat sink operated with nanofluid considering different shapes of nanoparticles. Int. J. Heat Mass Transf. 2020, 151, 119359. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Shamlooei, M.; Moradi, R.J.C.E. Numerical simulation for heat transfer intensification of nanofluid in a porous curved enclosure considering shape effect of Fe3O4 nanoparticles. Chem. Eng. Process. 2018, 124, 71–82. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Shehzad, S.A. Numerical analysis of Fe3O4–H2O nanofluid flow in permeable media under the effect of external magnetic source. Int. J. Heat Mass Transf. 2018, 118, 182–192. [Google Scholar] [CrossRef]

- Nguyen, T.K.; Saidizad, A.; Jafaryar, M.; Sheikholeslami, M.; Gerdroodbary, M.B.; Moradi, R.; Li, Z. Influence of various shapes of CuO nanomaterial on nanofluid forced convection within a sinusoidal channel with obstacles. Chem. Eng. Res. Des. 2019, 146, 478–485. [Google Scholar] [CrossRef]

- Hatami, M.; Jafaryar, M.; Zhou, J.; Jing, D. Investigation of engines radiator heat recovery using different shapes of nanoparticles in H2O/(CH2OH)2 based nanofluids. Int. J. Hydrogen Energy 2017, 42, 10891–10900. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, S.H.; Kim, S.B.; Jang, S.P. The effect of nanoparticle shape on the thermal resistance of a flat-plate heat pipe using acetone-based Al2O3 nanofluids. Int. J. Heat Mass Transf. 2016, 92, 572–577. [Google Scholar] [CrossRef]

- Bahiraei, M.; Monavari, A. Thermohydraulic characteristics of a micro plate heat exchanger operated with nanofluid considering different nanoparticle shapes. Appl. Therm. Eng. 2020, 179, 115621. [Google Scholar] [CrossRef]

- Vo, D.D.; Alsarraf, J.; Moradikazerouni, A.; Afrand, M.; Salehipour, H.; Qi, C. Numerical investigation of γ-AlOOH nano-fluid convection performance in a wavy channel considering various shapes of nanoadditives. Powder Technol. 2019, 345, 649–657. [Google Scholar] [CrossRef]

- Khan, U.; Ahmed, N.; Mohyud-Din, S.T. Analysis of magnetohydrodynamic flow and heat transfer of Cu–water nanofluid between parallel plates for different shapes of nanoparticles. Neural Comput. Appl. 2018, 29, 695–703. [Google Scholar] [CrossRef]

- Raza, J.; Mebarek-Oudina, F.; Chamkha, A.J. Magnetohydrodynamic flow of molybdenum disulfide nanofluid in a channel with shape effects. Multidiscip. Model. Mater. Struct. 2019, 15, 737–757. [Google Scholar] [CrossRef]

- Gireesha, B.J.; Sindhu, S. Entropy generation analysis of nanoliquid flow through microchannel considering heat source and different shapes of nanoparticle. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 1457–1477. [Google Scholar] [CrossRef]

- Elias, M.M.; Miqdad, M.; Mahbubul, I.M.; Saidur, R.; Kamalisarvestani, M.; Sohel, M.R.; Amalina, M.A. Effect of nanoparticle shape on the heat transfer and thermodynamic performance of a shell and tube heat exchanger. Int. Commun. Heat Mass Transf. 2013, 44, 93–99. [Google Scholar] [CrossRef]

- Elias, M.M.; Shahrul, I.M.; Mahbubul, I.M.; Saidur, R.; Rahim, N.A. Effect of different nanoparticle shapes on shell and tube heat exchanger using different baffle angles and operated with nanofluid. Int. J. Heat Mass Transf. 2014, 70, 289–297. [Google Scholar] [CrossRef]

- Shahsavar, A.; Rahimi, Z.; Salehipour, H. Nanoparticle shape effects on thermal-hydraulic performance of boehmite alumina nanofluid in a horizontal double-pipe minichannel heat exchanger. Heat Mass Transf. 2019, 55, 1741–1751. [Google Scholar] [CrossRef]

- Alsarraf, J.; Moradikazerouni, A.; Shahsavar, A.; Afrand, M.; Salehipour, H.; Tran, M.D. Hydrothermal analysis of turbulent boehmite alumina nanofluid flow with different nanoparticle shapes in a minichannel heat exchanger using two-phase mixture model. Phys. A Stat. Mech. Appl. 2019, 520, 275–288. [Google Scholar] [CrossRef]

- Al-Rashed, A.A.; Ranjbarzadeh, R.; Aghakhani, S.; Soltanimehr, M.; Afrand, M.; Nguyen, T.K. Entropy generation of boehmite alumina nanofluid flow through a minichannel heat exchanger considering nanoparticle shape effect. Phys. A Stat. Mech. Appl. 2019, 521, 724–736. [Google Scholar] [CrossRef]

- Monfared, M.; Shahsavar, A.; Bahrebar, M.R. Second law analysis of turbulent convection flow of boehmite alumina nanofluid inside a double-pipe heat exchanger considering various shapes for nanoparticle. J. Therm. Anal. Calorim. 2019, 135, 1521–1532. [Google Scholar] [CrossRef]

- Sadripour, S.; Chamkha, A.J. The effect of nanoparticle morphology on heat transfer and entropy generation of supported nanofluids in a heat sink solar collector. Therm. Sci. Eng. Prog. 2019, 9, 266–280. [Google Scholar] [CrossRef]

- Liu, J.B.; Bayati, M.; Abbas, M.; Rahimi, A.; Naderi, M. Mesoscopic approach for simulating nanofluid flow and heat transfer in a finned multi-pipe heat exchanger. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 2822–2839. [Google Scholar] [CrossRef]

- Ghadikolaei, S.S.; Yassari, M.; Sadeghi, H.; Hosseinzadeh, K.; Ganji, D.D. Investigation on thermophysical properties of TiO2–Cu/H2O hybrid nanofluid transport dependent on shape factor in MHD stagnation point flow. Powder Technol. 2017, 322, 428–438. [Google Scholar] [CrossRef]

- Ghadikolaei, S.S.; Hosseinzadeh, K.; Ganji, D.D. Investigation on three dimensional squeezing flow of mixture base fluid (ethylene glycol-water) suspended by hybrid nanoparticle (Fe3O4-Ag) dependent on shape factor. J. Mol. Liq. 2018, 262, 376–388. [Google Scholar] [CrossRef]

- Dinarvand, S.; Rostami, M.N.; Pop, I. A novel hybridity model for TiO2-CuO/water hybrid nanofluid flow over a static/moving wedge or corner. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J. Effects of nanoparticle shape and size on the thermohydraulic performance of plate evaporator using hybrid nanofluids. J. Therm. Anal. Calorim. 2019, 143, 767–779. [Google Scholar] [CrossRef]

- Benkhedda, M.; Boufendi, T.; Tayebi, T.; Chamkha, A.J. Convective heat transfer performance of hybrid nanofluid in a horizontal pipe considering nanoparticles shapes effect. J. Therm. Anal. Calorim. 2020, 140, 411–425. [Google Scholar] [CrossRef]

- Ghobadi, A.H.; Hassankolaei, M.G. A numerical approach for MHD Al2O3–TiO2/H2O hybrid nanofluids over a stretching cylinder under the impact of shape factor. Heat Transf. Asian Res. 2019, 48, 4262–4282. [Google Scholar] [CrossRef]

- Aziz, A.; Jamshed, W.; Ali, Y.; Shams, M. Heat transfer and entropy analysis of Maxwell hybrid nanofluid including effects of inclined magnetic field, Joule heating and thermal radiation. Discret. Contin. Dyn. Syst. S 2020, 13, 2667. [Google Scholar] [CrossRef] [Green Version]

- Ghadikolaei, S.S.; Hosseinzadeh, K.; Ganji, D.D. Investigation on ethylene glycol-water mixture fluid suspend by hybrid nanoparticles (TiO2-CuO) over rotating cone with considering nanoparticles shape factor. J. Mol. Liq. 2018, 272, 226–236. [Google Scholar] [CrossRef]

- Ghadikolaei, S.S.; Gholinia, M.; Hoseini, M.E.; Ganji, D.D. Natural convection MHD flow due to MoS2–Ag nanoparticles suspended in C2H6O2H2O hybrid base fluid with thermal radiation. J. Taiwan Inst. Chem. Eng. 2019, 97, 12–23. [Google Scholar] [CrossRef]

- Ghadikolaei, S.S.; Gholinia, M. 3D mixed convection MHD flow of GO-MoS2 hybrid nanoparticles in H2O–(CH2OH)2 hybrid base fluid under the effect of H2 bond. Int. Commun. Heat Mass Transf. 2020, 110, 104371. [Google Scholar] [CrossRef]

- Maraj, E.N.; Iqbal, Z.; Azhar, E.; Mehmood, Z. A comprehensive shape factor analysis using transportation of MoS2-SiO2/H2O inside an isothermal semi vertical inverted cone with porous boundary. Results Phys. 2018, 8, 633–641. [Google Scholar] [CrossRef]

- Sahu, M.; Sarkar, J. Steady-state energetic and exergetic performances of single-phase natural circulation loop with hybrid nanofluids. J. Heat Transf. 2019, 141, 082401. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.H.; Patil, M.S.; Bang, Y.M.; Pyo, Y.D.; Cho, C.P.; Lee, M.Y. Thermal–electrical–structural performances of hot heat exchanger with different internal fins of thermoelectric generator for low power generation application. J. Therm. Anal. Calorim. 2021, 143, 387–419. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.H.; Cho, C.P.; Lee, M.Y. Artificial neural network and adaptive neuro-fuzzy interface system modelling to predict thermal performances of thermoelectric generator for waste heat recovery. Symmetry 2020, 12, 259. [Google Scholar] [CrossRef] [Green Version]

- Dadsetani, R.; Sheikhzadeh, G.A.; Safaei, M.R.; Leon, A.S.; Goodarzi, M. Cooling enhancement and stress reduction opti-mization of disk-shaped electronic components using nanofluids. Symmetry 2020, 12, 931. [Google Scholar] [CrossRef]

- Seo, J.H.; Garud, K.S.; Lee, M.Y. Grey relational based Taguchi analysis on thermal and electrical performances of thermoelectric generator system with inclined fins hot heat exchanger. Appl. Therm. Eng. 2021, 184, 116279. [Google Scholar] [CrossRef]

- Bahiraei, M.; Monavari, A.; Moayedi, H. Second law assessment of nanofluid flow in a channel fitted with conical ribs for utilization in solar thermal applications: Effect of nanoparticle shape. Int. J. Heat Mass Transf. 2020, 151, 119387. [Google Scholar] [CrossRef]

- Lee, M.Y.; Seo, J.H.; Lee, H.S.; Garud, K.S. Power generation, efficiency and thermal stress of thermoelectric module with leg geometry, material, segmentation and two-stage arrangement. Symmetry 2020, 12, 786. [Google Scholar] [CrossRef]

- Ooi, E.H.; Popov, V. Numerical study of influence of nanoparticle shape on the natural convection in Cu-water nanofluid. Int. J. Therm. Sci. 2013, 65, 178–188. [Google Scholar] [CrossRef]

- Garud, K.S.; Lee, M.Y. Numerical Investigations on Heat Transfer Characteristics of Single Particle and Hybrid Nanofluids in Uniformly Heated Tube. Symmetry 2021, 13, 876. [Google Scholar] [CrossRef]

- Sanches, M.; Marseglia, G.; Ribeiro, A.P.; Moreira, A.L.; Moita, A.S. Nanofluids Characterization for Spray Cooling Applications. Symmetry 2021, 13, 788. [Google Scholar] [CrossRef]

- Arani, A.A.A.; Sadripour, S.; Kermani, S. Nanoparticle shape effects on thermal-hydraulic performance of boehmite alumina nanofluids in a sinusoidal–wavy mini-channel with phase shift and variable wavelength. Int. J. Mech. Sci. 2017, 128, 550–563. [Google Scholar] [CrossRef]

- Ghachem, K.; Aich, W.; Kolsi, L. Computational analysis of hybrid nanofluid enhanced heat transfer in cross flow micro heat exchanger with rectangular wavy channels. Case Stud. Therm. Eng. 2021, 24, 100822. [Google Scholar] [CrossRef]

- Bhattad, A.; Sarkar, J.; Ghosh, P. Energy-economic analysis of plate evaporator using brine-based hybrid nanofluids as secondary refrigerant. Int. J. Air-Cond. Refrig. 2018, 26, 1850003. [Google Scholar] [CrossRef]

- Arun, K.R.; Kunal, G.; Srinivas, M.; Kumar, C.S.; Mohanraj, M.; Jayaraj, S. Drying of untreated Musa nendra and Momordica charantia in a forced convection solar cabinet dryer with thermal storage. Energy 2020, 192, 116697. [Google Scholar] [CrossRef]

- Kwon, J.T.; Nahm, T.H.; Kim, T.W.; Kwon, Y.C. An Experimental study on pressure drop and heat transfer coefficient of laminar Ag nanofluid flow in mini-tubes. J. Korea Acad. Ind. Coop. Soc. 2009, 10, 3525–3532. [Google Scholar]

- Zheng, D.; Wang, J.; Chen, Z.; Baleta, J.; Sundén, B. Performance analysis of a plate heat exchanger using various nanofluids. Int. J. Heat Mass Transf. 2020, 158, 119993. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Ghosh, P.; Sarkar, J. Heat transfer and pressure drop characteristics of CeO2/water nanofluid in plate heat exchanger. Appl. Therm. Eng. 2013, 57, 24–32. [Google Scholar] [CrossRef]

- Kim, N.H. An experimental investigation on the air-side performance of fin-and-tube heat exchangers having radial slit fins. Int. J. Air-Cond. Refrig. 2015, 23, 1550021. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Ghosh, P.; Sarkar, J. Performance comparison of the plate heat exchanger using different nanofluids. Exp. Therm. Fluid Sci. 2013, 49, 141–151. [Google Scholar] [CrossRef]

- Singh, S.K.; Sarkar, J. Improving hydrothermal performance of hybrid nanofluid in double tube heat exchanger using tapered wire coil turbulator. Adv. Powder Technol. 2020, 31, 2092–2100. [Google Scholar] [CrossRef]

- Raj, A.K.; Kunal, G.; Srinivas, M.; Jayaraj, S. Performance analysis of a double-pass solar air heater system with asymmetric channel flow passages. J. Therm. Anal. Calorim. 2019, 136, 21–38. [Google Scholar] [CrossRef]

- Alm, B.; Imke, U.; Knitter, R.; Schygulla, U.; Zimmermann, S. Testing and simulation of ceramic micro heat exchangers. Chem. Eng. J. 2008, 135, S179–S184. [Google Scholar] [CrossRef]

- Ghosh, M.M.; Ghosh, S.; Pabi, S.K. Effects of particle shape and fluid temperature on heat-transfer characteristics of nanofluids. J. Mater. Eng. Perform. 2013, 22, 1525–1529. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.H.; Lee, M.Y. Effect of Guide Fin Structures and Boundary Parameters on Thermal Performances of Heat Exchanger for Waste Heat Recovery Thermoelectric Generator. J. Korea Acad. Ind. Coop. Soc. 2021, 22, 30–35. [Google Scholar]

| Mesh Elements | Hot Fluid-Temperature (°C) | Cold Fluid-Temperature (°C) | Hot Fluid-Pressure Drop(bar) | Cold Fluid-Pressure Drop (bar) |

|---|---|---|---|---|

| 157,649 | 88.669 | 29.841 | 2.413 | 1.321 |

| 489,478 | 86.295 | 26.877 | 2.637 | 1.444 |

| 732,993 | 85.180 | 24.888 | 2.738 | 1.502 |

| 1,142,485 | 85.182 | 24.086 | 2.742 | 1.505 |

| 1,588,899 | 85.181 | 23.865 | 2.751 | 1.507 |

| Particle Shape | |||

|---|---|---|---|

| Sphere | 1 | 1 | 0.599 |

| Oblate spheroid | 0.13 | 0.4904 | 0.575 |

| Prolate spheroid 1 | 2 | 0.9287 | 0.546 |

| Prolate spheroid 2 | 5 | 0.7321 | 0.432 |

| Prolate spheroid 3 | 7.5 | 0.6453 | 0.368 |

| Prolate spheroid 4 | 10 | 0.5883 | 0.321 |

| Particle Shape | Aspect Ratio | |||

|---|---|---|---|---|

| Blade | 1:6:1/12 | 2.74 | 8.26 | −5.52 |

| Platelet | 1:1/8 | 2.61 | 5.72 | −3.11 |

| Cylinder | 1:8 | 3.95 | 4.82 | −0.87 |

| Brick | 1:1:1 | 3.37 | 3.72 | −0.35 |

| Particle Shape | Coefficients | |

|---|---|---|

| Blade | 14.6 | 123.3 |

| Platelet | 37.1 | 612.6 |

| Cylinder | 13.5 | 904.4 |

| Brick | 1.90 | 471.4 |

| Property | Water | Alumina | Copper |

|---|---|---|---|

| Density (kg/m3) | 997.1 | 3050 | 8933 |

| Specific heat (J/kg∙K) | 4179 | 618.3 | 385 |

| Thermal conductivity (W/m∙K) | 0.613 | 30 | 400 |

| Viscosity (Pa∙s) | 0.001003 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garud, K.S.; Hwang, S.-G.; Lim, T.-K.; Kim, N.; Lee, M.-Y. First and Second Law Thermodynamic Analyses of Hybrid Nanofluid with Different Particle Shapes in a Microplate Heat Exchanger. Symmetry 2021, 13, 1466. https://doi.org/10.3390/sym13081466

Garud KS, Hwang S-G, Lim T-K, Kim N, Lee M-Y. First and Second Law Thermodynamic Analyses of Hybrid Nanofluid with Different Particle Shapes in a Microplate Heat Exchanger. Symmetry. 2021; 13(8):1466. https://doi.org/10.3390/sym13081466

Chicago/Turabian StyleGarud, Kunal Sandip, Seong-Guk Hwang, Taek-Kyu Lim, Namwon Kim, and Moo-Yeon Lee. 2021. "First and Second Law Thermodynamic Analyses of Hybrid Nanofluid with Different Particle Shapes in a Microplate Heat Exchanger" Symmetry 13, no. 8: 1466. https://doi.org/10.3390/sym13081466

APA StyleGarud, K. S., Hwang, S.-G., Lim, T.-K., Kim, N., & Lee, M.-Y. (2021). First and Second Law Thermodynamic Analyses of Hybrid Nanofluid with Different Particle Shapes in a Microplate Heat Exchanger. Symmetry, 13(8), 1466. https://doi.org/10.3390/sym13081466