Modeling and Trajectory Planning Optimization for the Symmetrical Multiwheeled Omnidirectional Mobile Robot

Abstract

1. Introduction

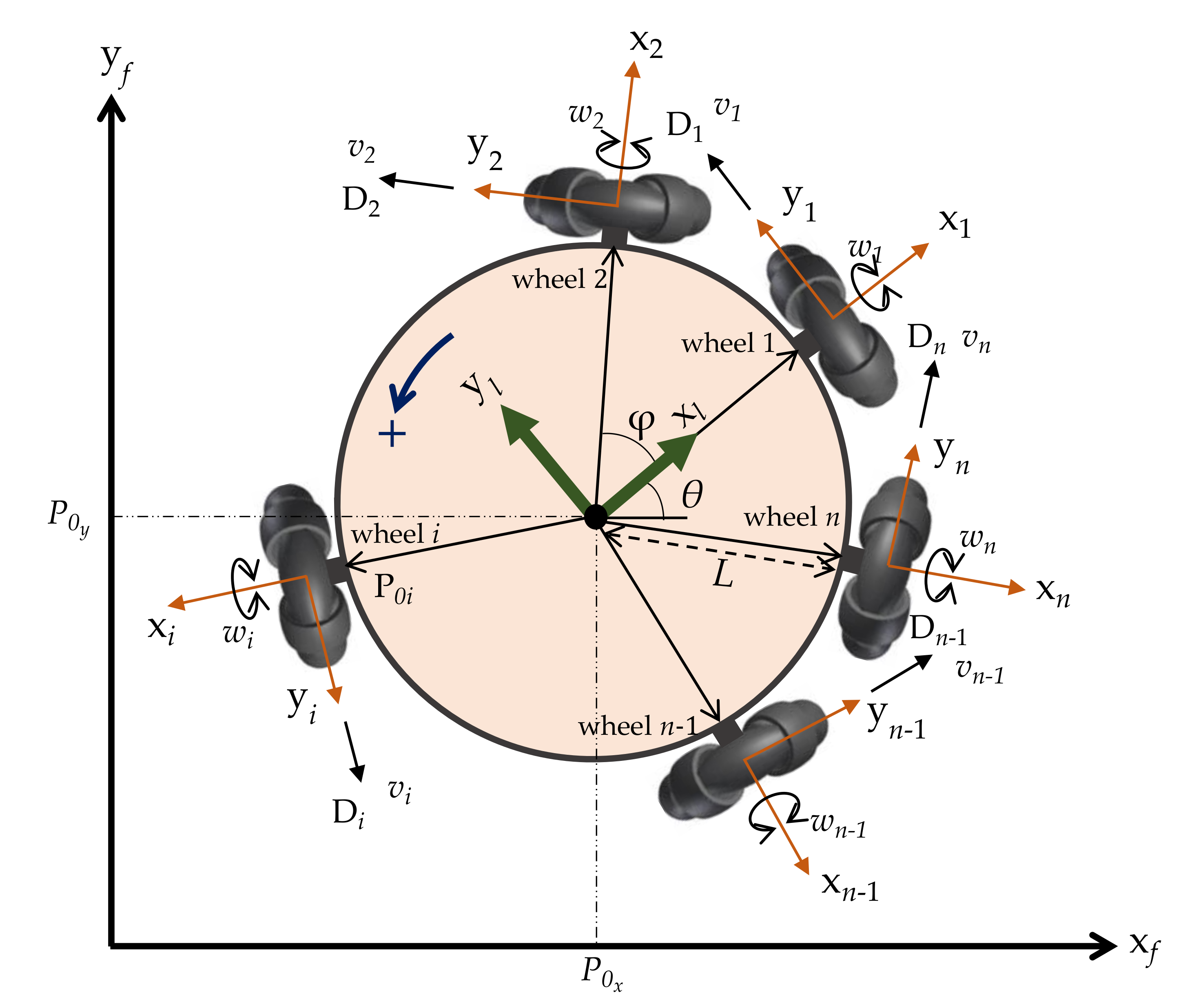

2. Mathematical Modeling of a SAOWMR with n-Omnidirectional Wheels

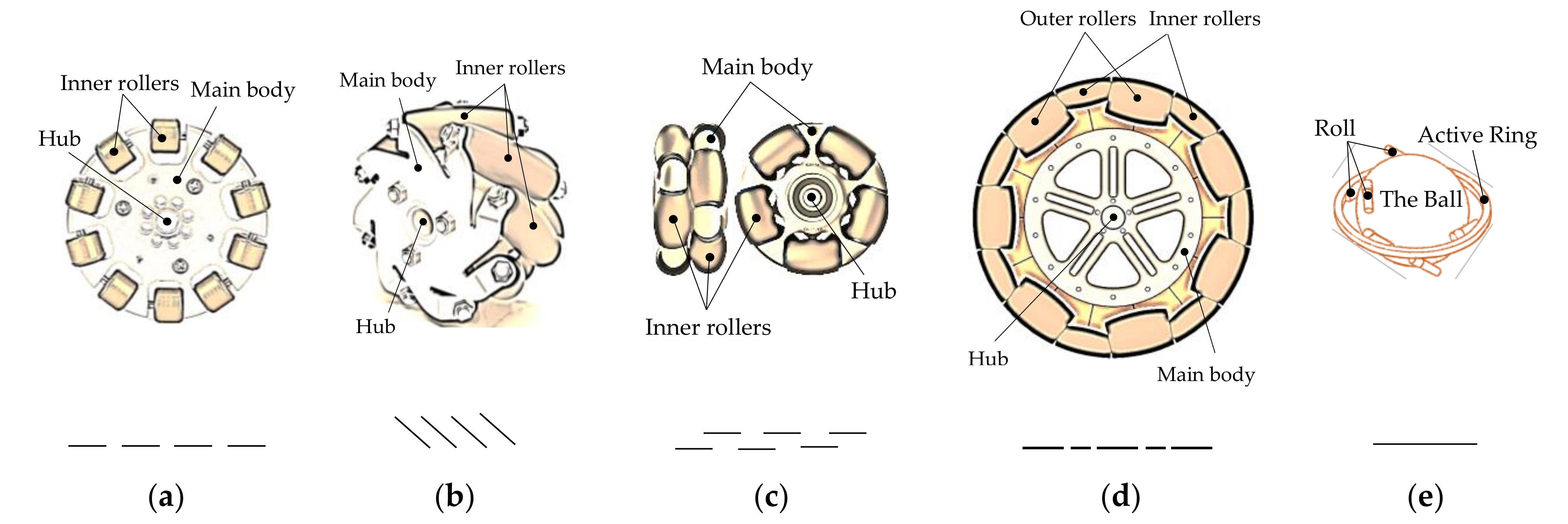

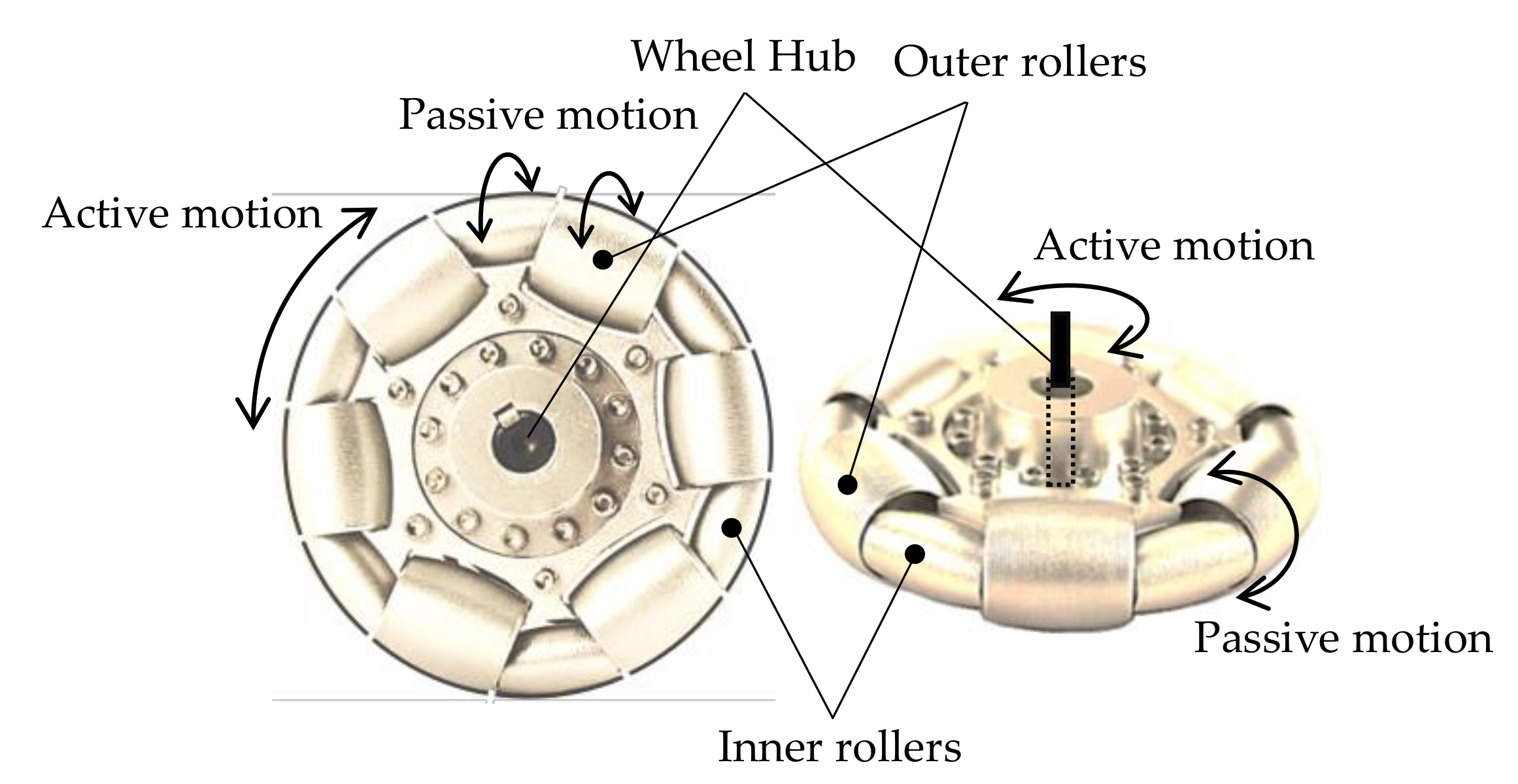

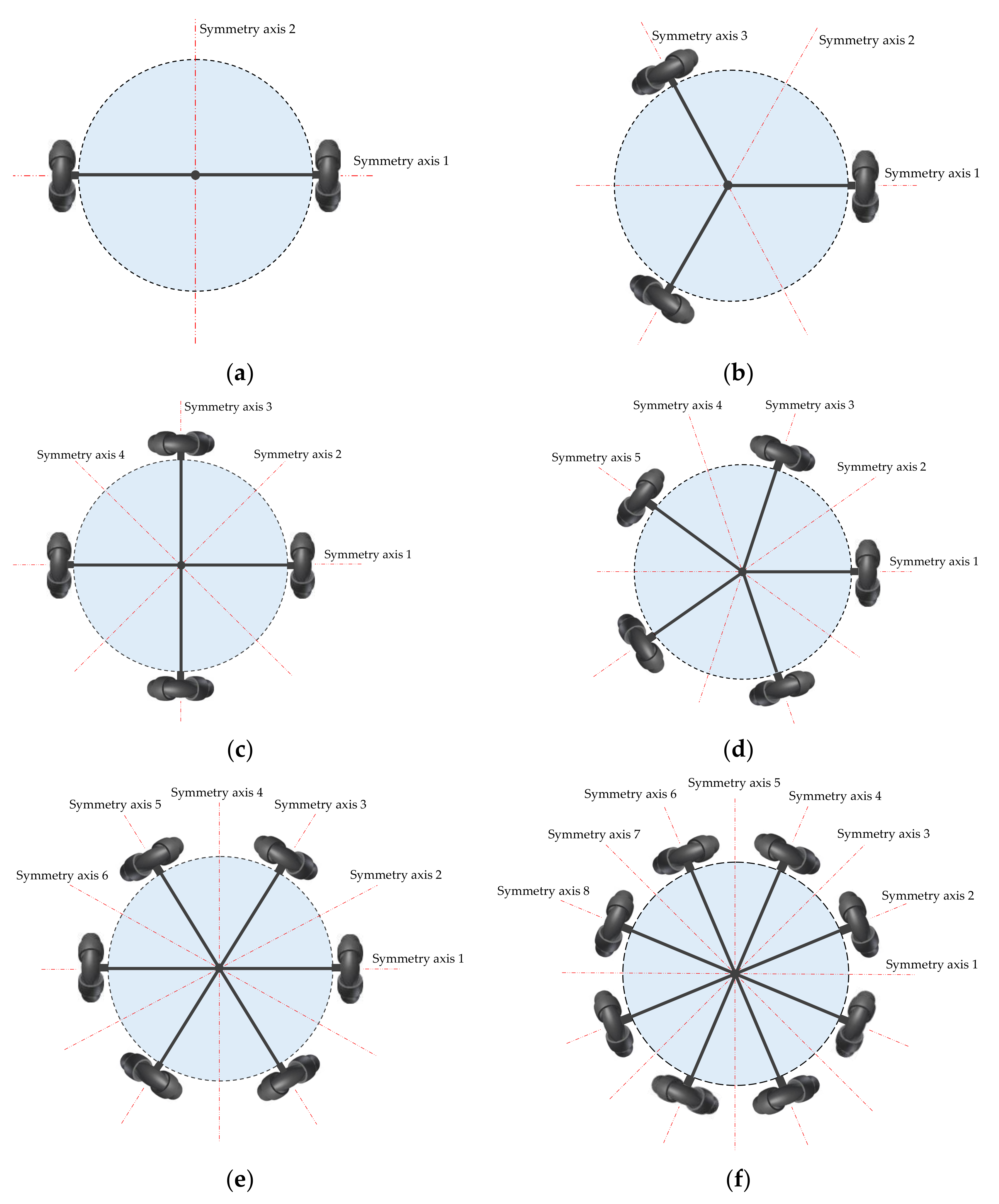

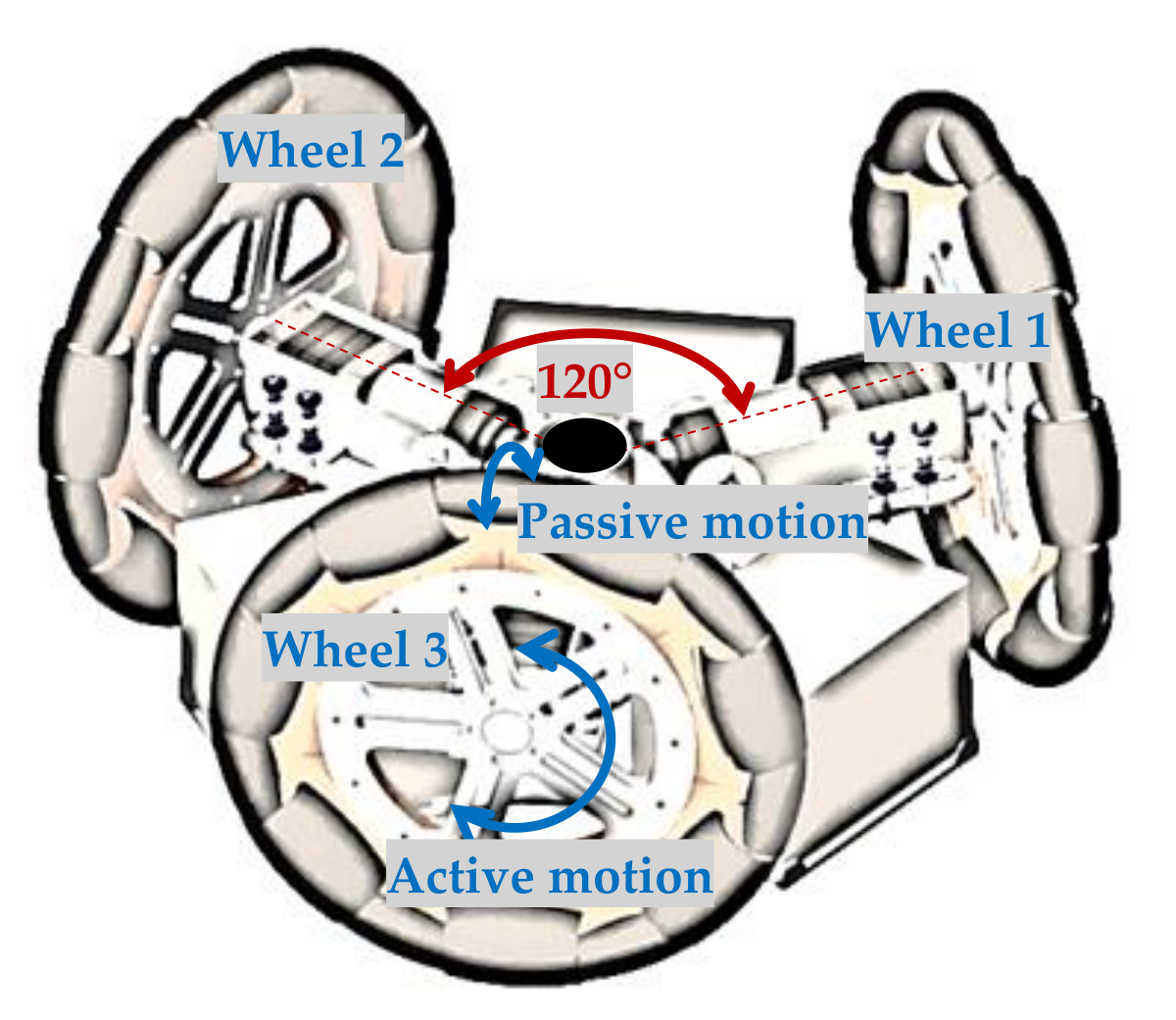

2.1. SAOWMR Description and Topology

2.2. Geometry of the SAOWMR

2.3. Kinematic Model of the SAOWMR

2.4. Dynamic Study of the SAOWMR

3. Optimal Trajectory Generation for a SAOWMR

3.1. Control Problem Formulation

3.2. Trajectory Generation

3.3. Optimization Process

3.4. Kinematic Saturation

3.5. Special Case (SAOWMR with Two Orthogonal Wheels)

3.5.1. Pure Rotational Motion

3.5.2. Pure Translational Motion

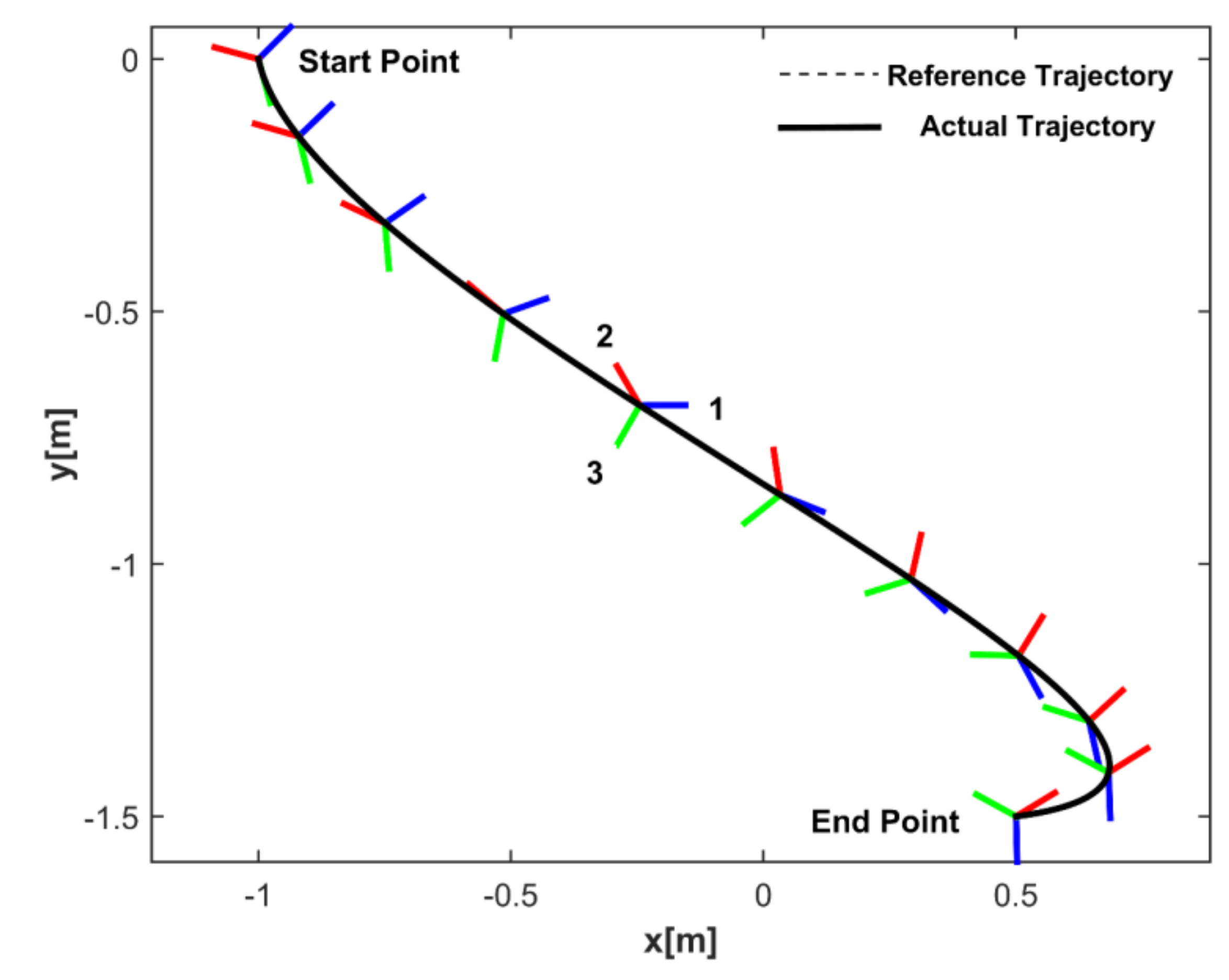

4. Validation and Experiment Process of the Representative Trajectories

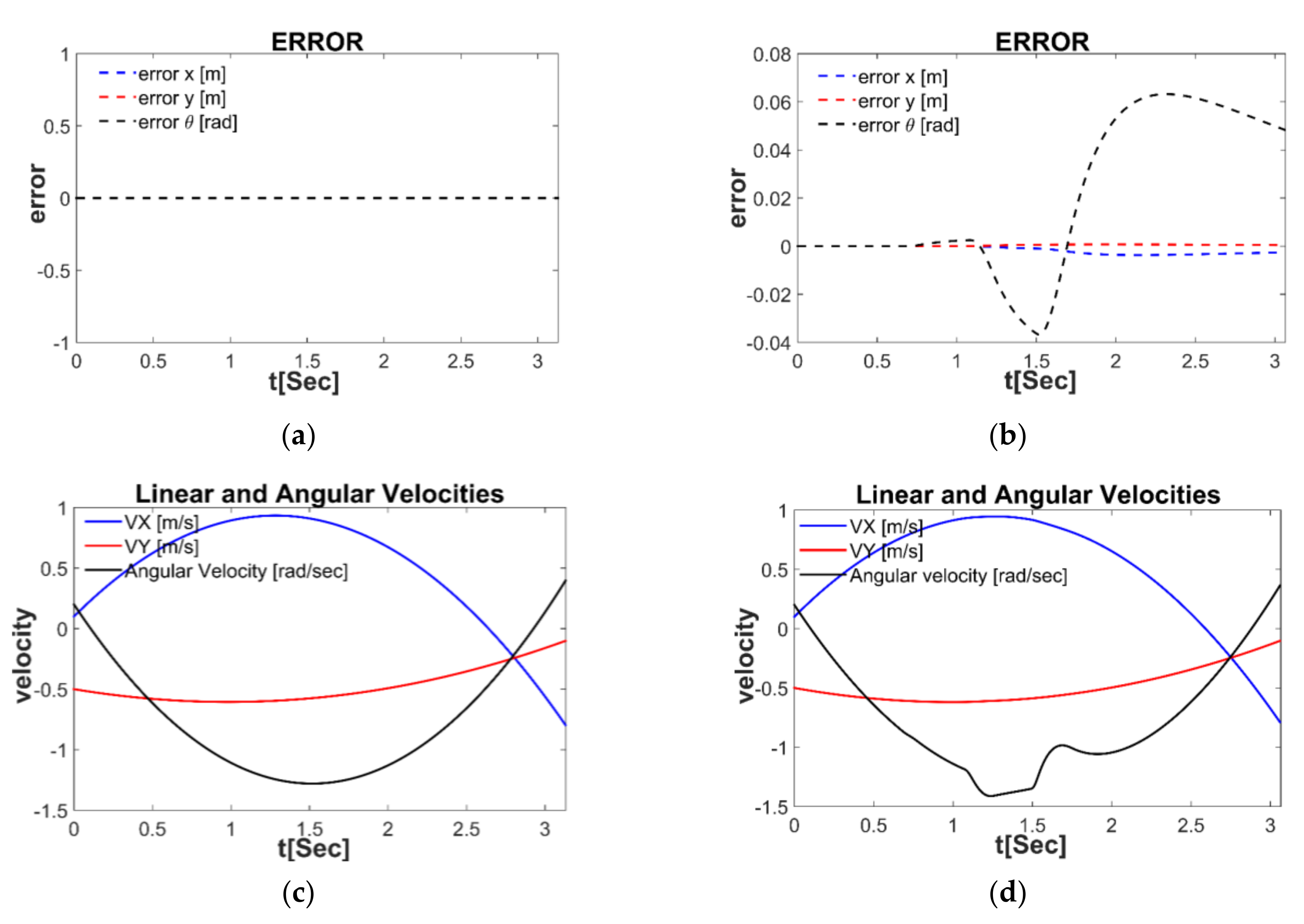

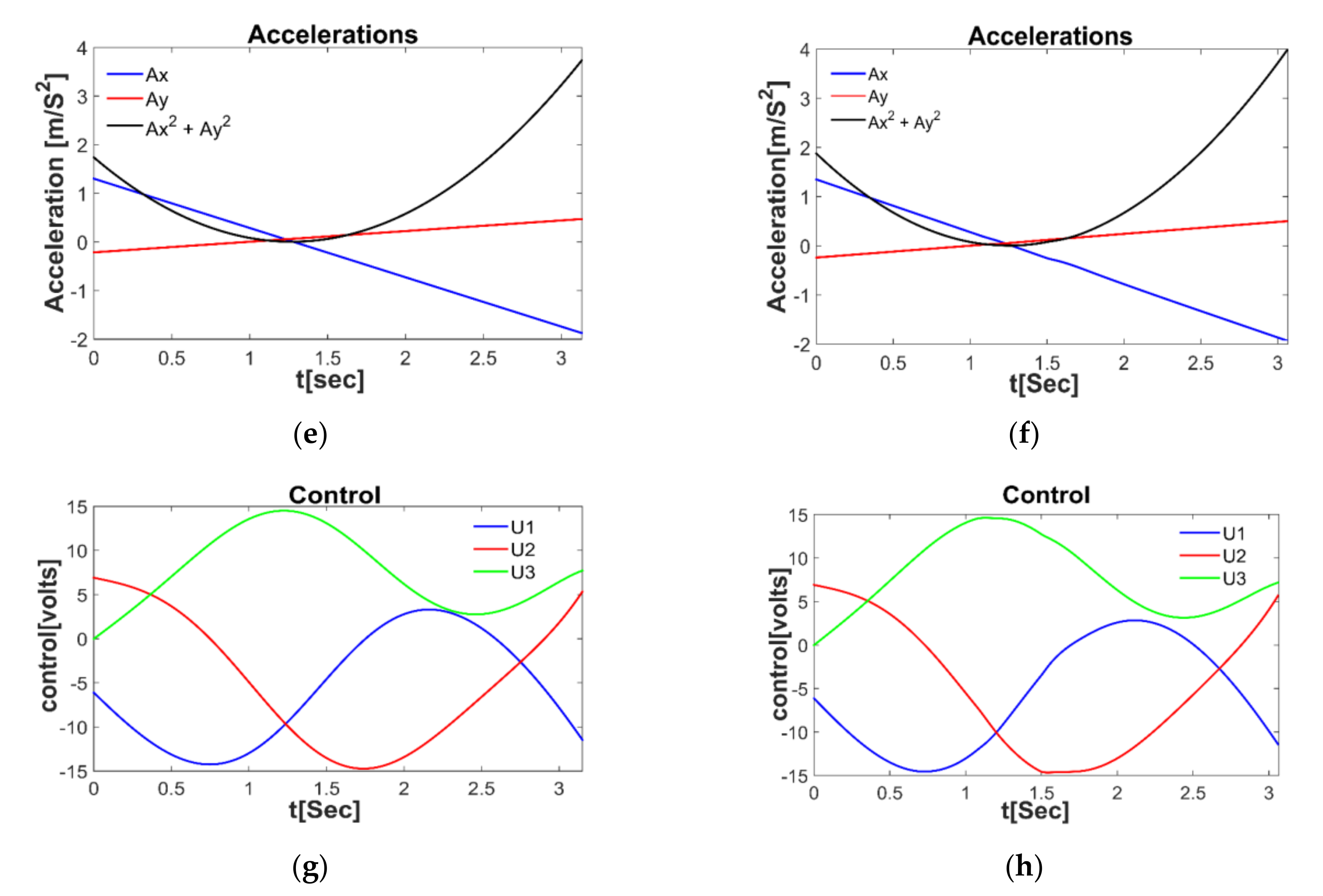

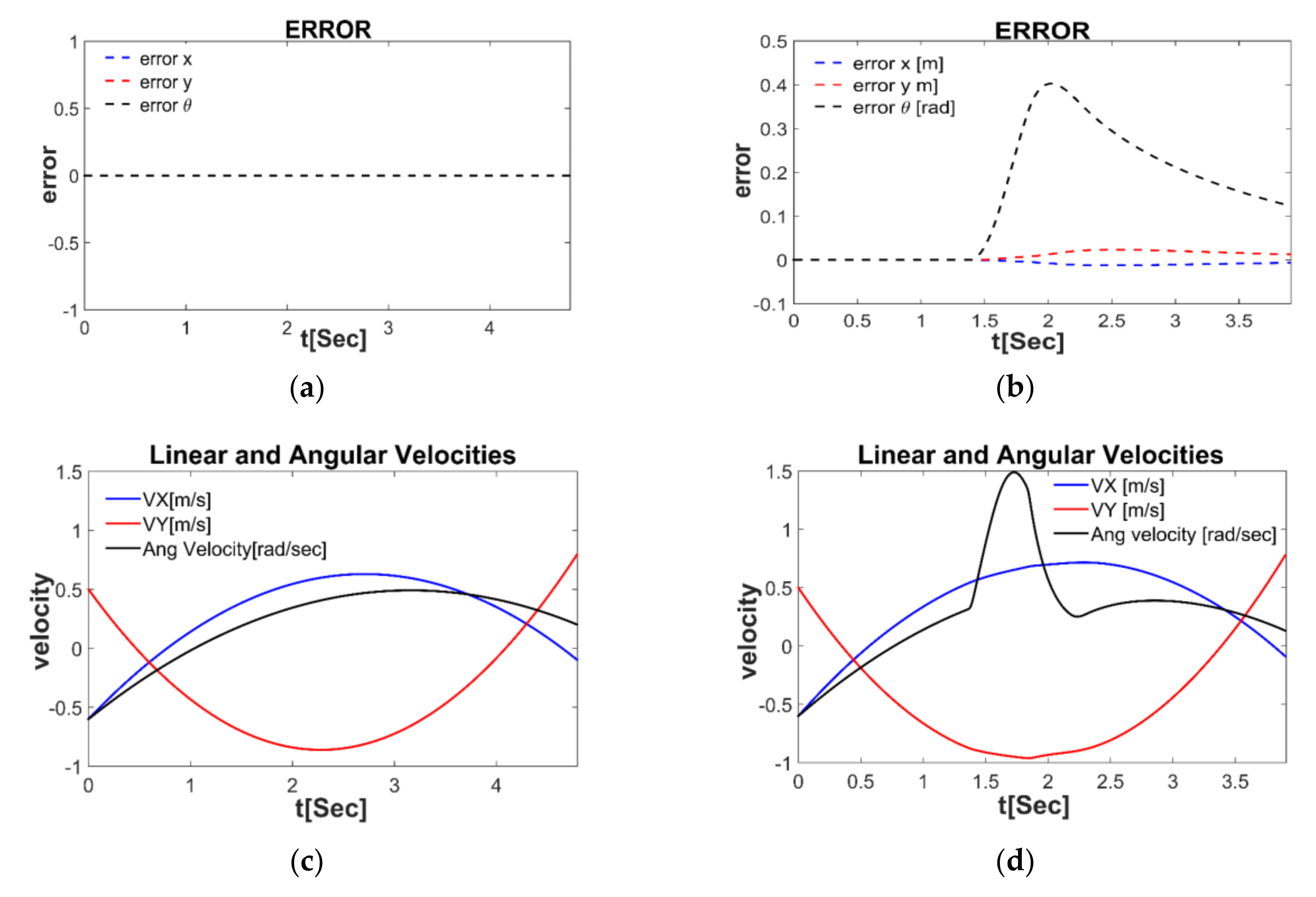

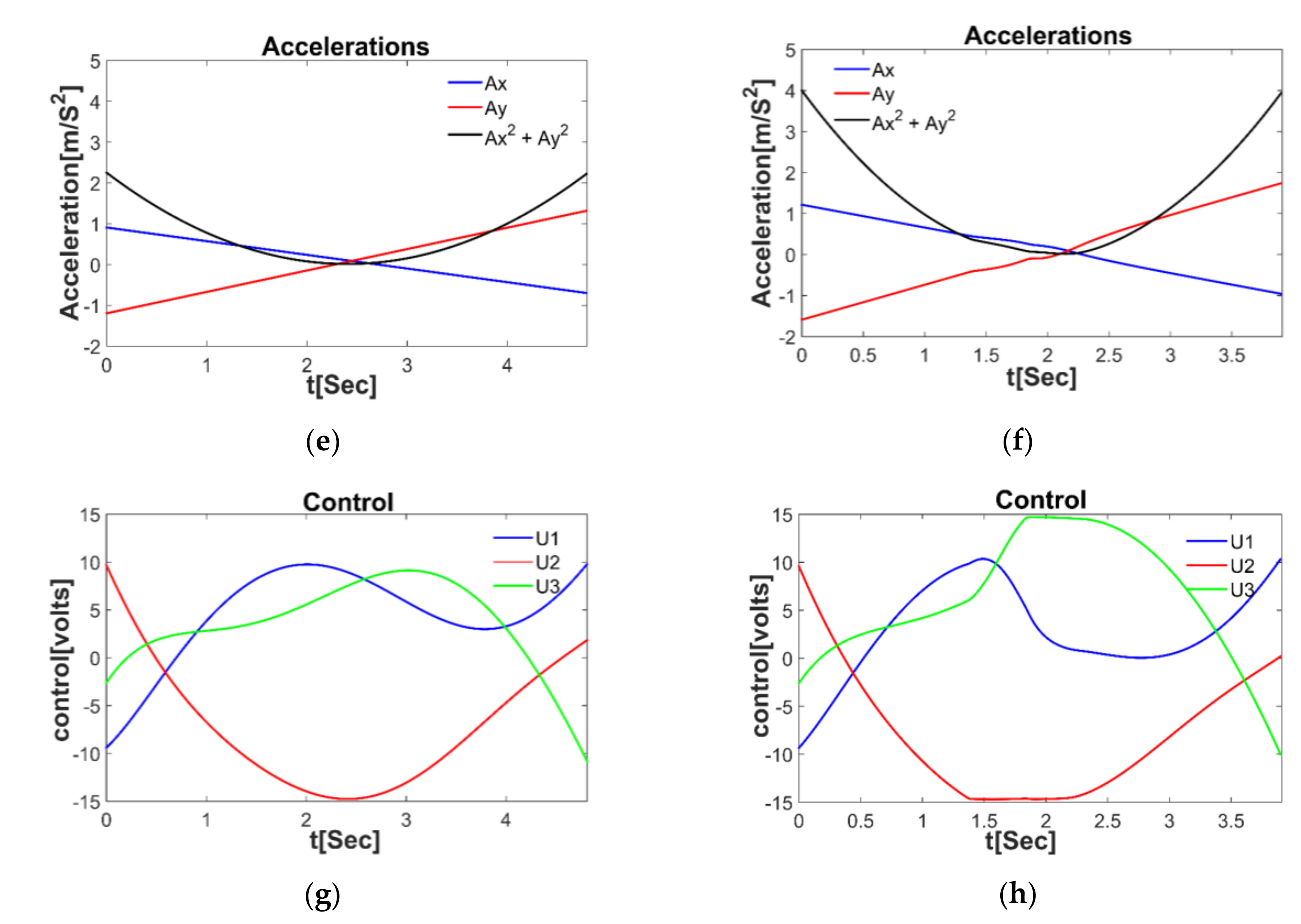

4.1. Simulation and Comparison Analysis

4.2. Study Discussion

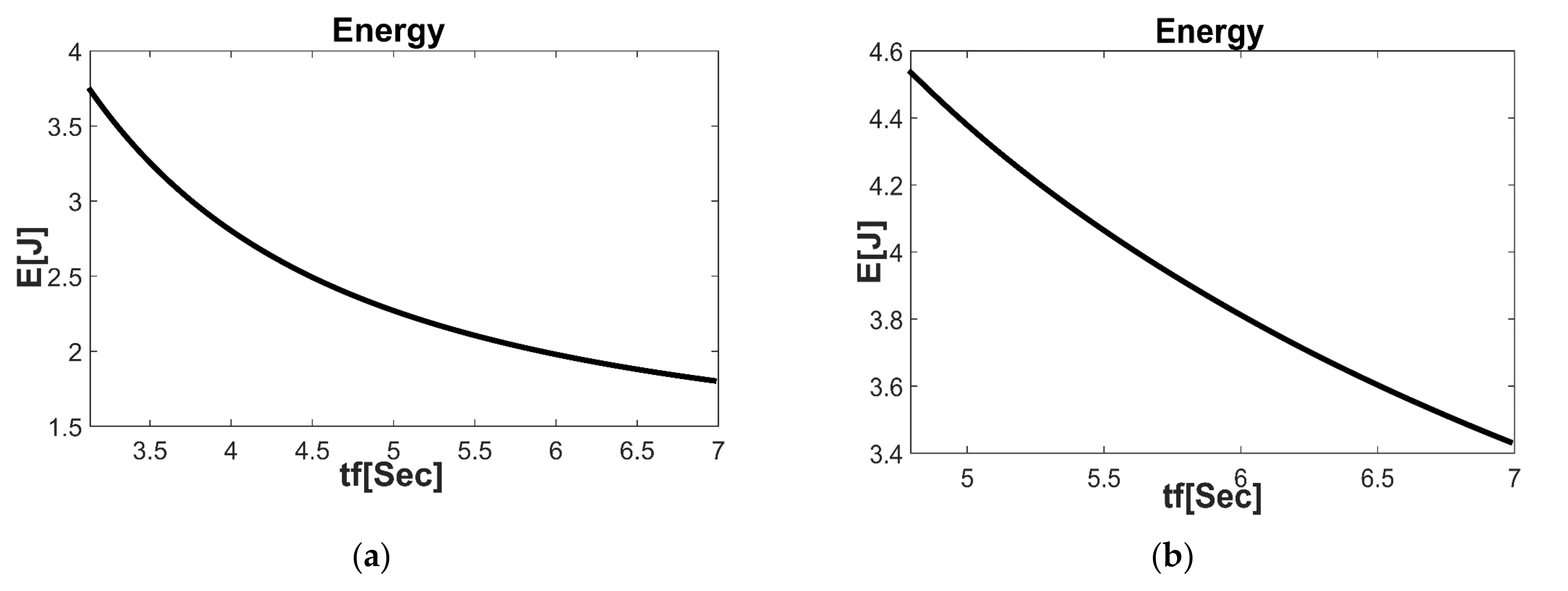

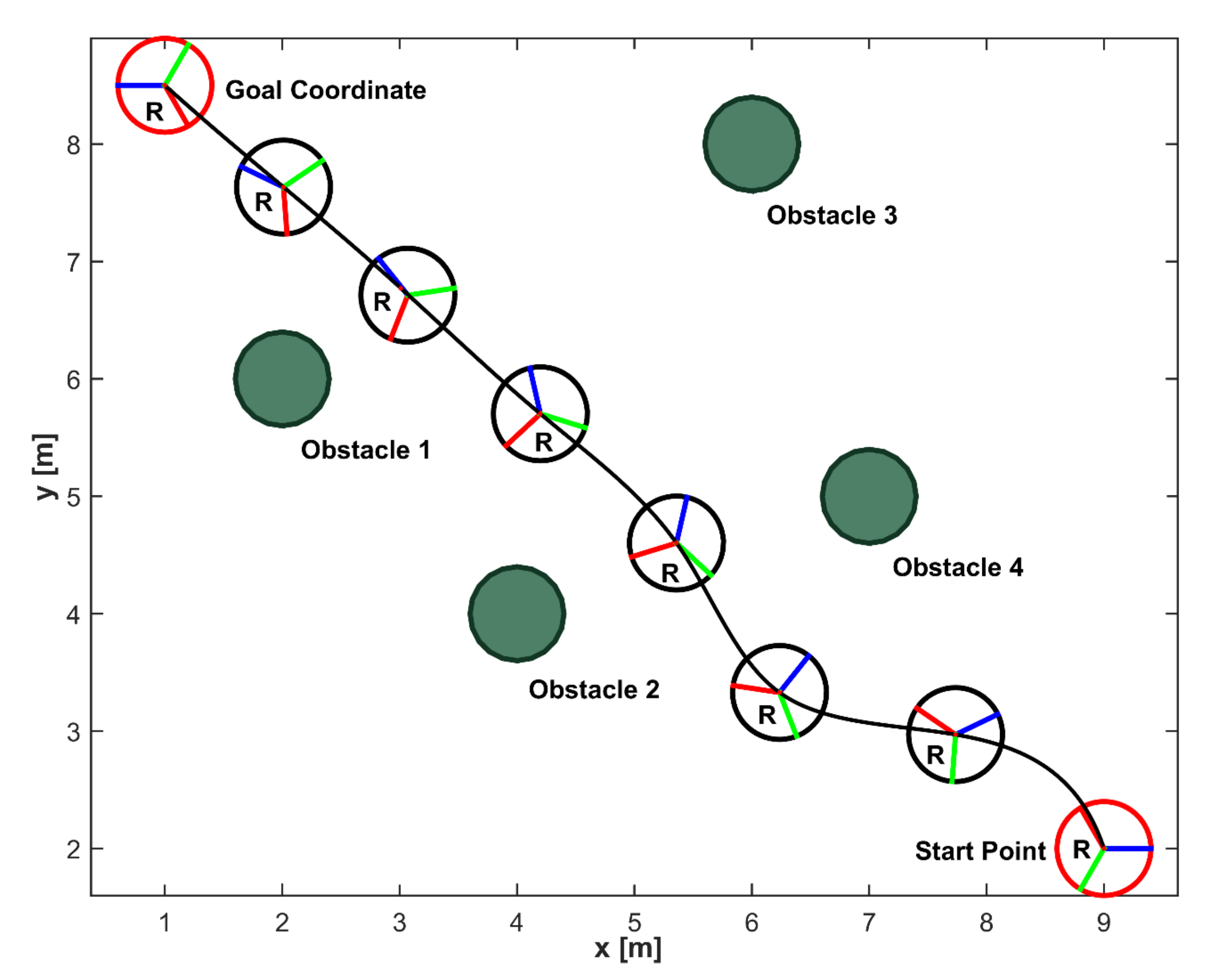

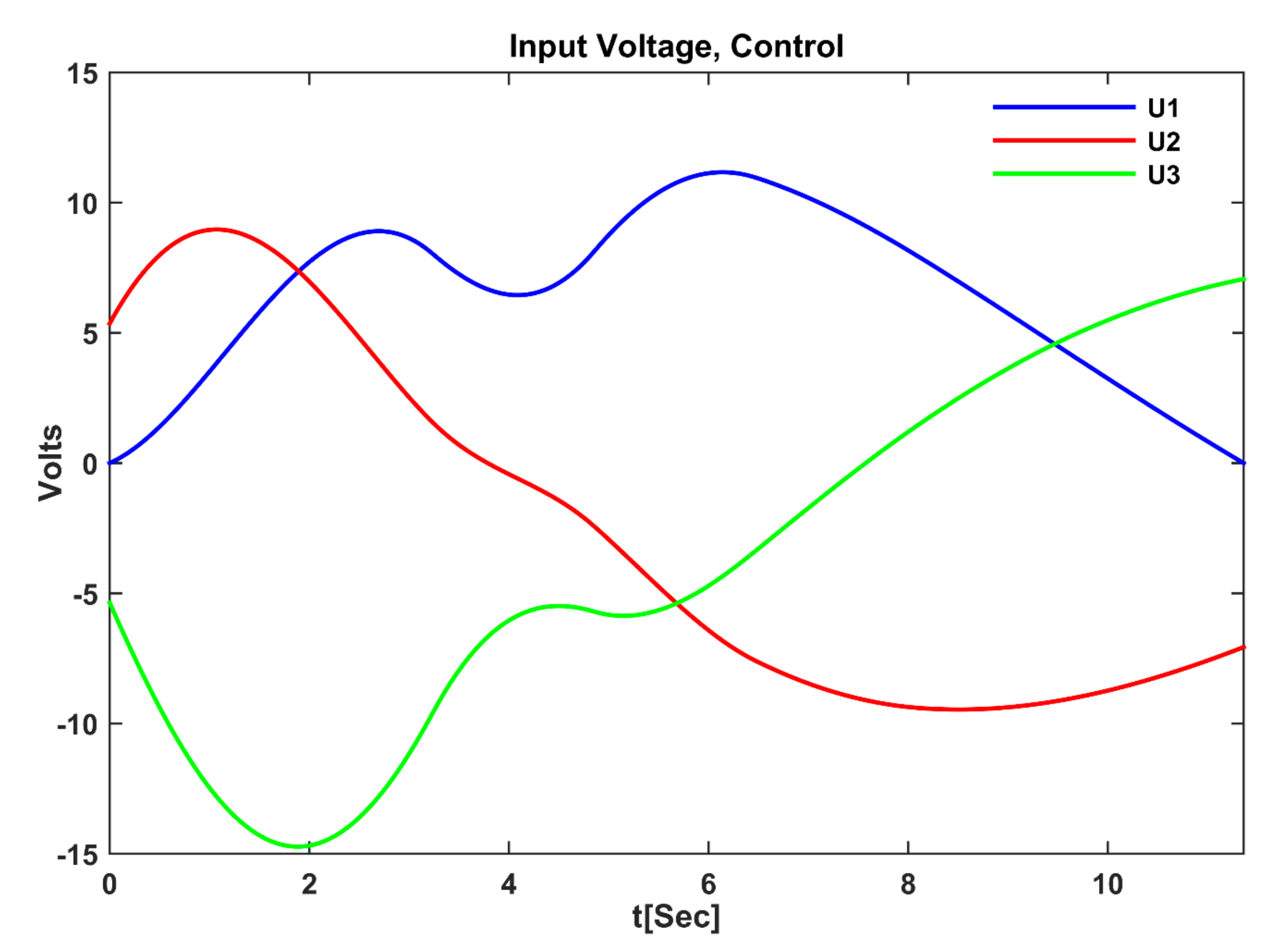

5. Obstacle Avoidance

5.1. Problem Statement and Approach

5.2. Numerical Experiment and Simulations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Mariappan, M.; Sing, J.C.; Wee, C.C.; Khoo, B.; Wong, W.K. Simultaneous Rotation and Translation Movement for Four Omnidirectional Wheels Holonomic Mobile Robot. In Proceedings of the 2014 IEEE International Symposium on Robotics and Manufacturing Automation (ROMA), Kuala Lumpur, Malaysia, 15–16 December 2014; pp. 69–73. [Google Scholar]

- Kale, S.; Shriramwar, S.S. FPGA-Based Controller for a Mobile Robot. arXiv 2009, arXiv:0908.221. [Google Scholar]

- Endo, G.; Hirose, S. Study on roller-walker (system integration and basic experiments). In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No.99CH36288C), Detroit, MI, USA, 10–15 May 1999; Volume 3, pp. 2032–2037. [Google Scholar]

- Yu, H.; Spenko, M.; Dubowsky, S. Omni-Directional Mobility Using Active Split Offset Castors. J. Mech. Des. 2004, 126, 822–829. [Google Scholar] [CrossRef]

- Grabowiecki, J. Vehicle Wheel. U.S. Patent No. 1,303,535, 3 June 1919. [Google Scholar]

- Ilon, B.E. Wheels for a Course Stable Selfpropelling Vehicle Movable in Any Desired Direction on the Ground or Some Other Base. U.S. Patent No. 3,876,255, 8 April 1975. [Google Scholar]

- Podnar, G.W. The Uranus Mobile Robot. In Autonomous Mobile Robots: Annual Report; Carnagie Melon University: Pittsburgh, PA, USA, 1985. [Google Scholar]

- Muir, P.F.; Neuman, C.P. Kinematic Modeling of Wheeled Mobile Robots. J. Robot. Syst. 1987, 4, 281–340. [Google Scholar] [CrossRef]

- Koestler, A.; Braunl, T. Mobile Robot Simulation with Realistic Error Models. In Proceedings of the Second International Conference on Autonomous Robots and Agents, Massey University, Palmerston North, New Zealand, 13–15 December 2004; pp. 46–51. [Google Scholar]

- Song, J.-B.; Byun, K.-S. Design and Control of a Four-Wheeled Omnidirectional Mobile Robot with Steerable Omnidirectional Wheels. J. Robot. Syst. 2004, 21, 193–208. [Google Scholar] [CrossRef]

- Salih, J.E.M.; Rizon, M.; Yaacob, S.; Adom, A.H.; Mamat, M.R. Designing Omni-Directional Mobile Robot with Mecanum Wheel. Am. J. Appl. Sci. 2006, 3, 1831–1835. [Google Scholar] [CrossRef]

- Qian, J.; Zi, B.; Wang, D.; Ma, Y.; Zhang, D. The Design and Development of an Omni-Directional Mobile Robot Oriented to an Intelligent Manufacturing System. Sensors 2017, 17, 2073. [Google Scholar] [CrossRef]

- Doroftei, I.; Grosu, V.; Spinu, V. Omnidirectional Mobile Robot-Design and Implementation; IntechOpen: London, UK, 2007; ISBN 978-3-902613-15-8. [Google Scholar]

- Dickerson, S.L.; Lapin, B.D. Control of an Omni-Directional Robotic Vehicle with Mecanum Wheels. In Proceedings of the NTC ’91-National Telesystems Conference Proceedings, Atlanta, GA, USA, 26–27 March 1991; pp. 323–328. [Google Scholar]

- Nagatani, K.; Tachibana, S.; Sofue, M.; Tanaka, Y. Improvement of Odometry for Omnidirectional Vehicle Using Optical Flow Information. In Proceedings of the 2000 IEEE/RSJ International Conference on Intelligent Robots and Systems, Takamatsu, Japan, 31 October–5 November 2000. [Google Scholar]

- Pin, F.G.; Killough, S.M. A New Family of Omnidirectional and Holonomic Wheeled Platforms for Mobile Robots. IEEE Trans. Robot. Autom. 1994, 10, 480–489. [Google Scholar] [CrossRef]

- Byun, K.-S.; Song, J.-B. Design and Construction of Continuous Alternate Wheels for an Omnidirectional Mobile Robot. J. Robot. Syst. 2003, 20, 569–579. [Google Scholar] [CrossRef]

- West, M.; Asada, H. Design and Control of Ball Wheel Omnidirectional Vehicles. In Proceedings of the 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; Volume 2, pp. 1931–1938. [Google Scholar]

- Li, Y.; Dai, S.; Zhao, L.; Yan, X.; Shi, Y. Topological Design Methods for Mecanum Wheel Configurations of an Omnidirectional Mobile Robot. Symmetry 2019, 11, 1268. [Google Scholar] [CrossRef]

- Gfrerrer, A. Geometry and Kinematics of the Mecanum Wheel. Comput. Aided Geom. Des. 2008, 25, 784–791. [Google Scholar] [CrossRef]

- Gao, P.; Peng, J.; Yu, W.; Li, S.; Qin, X. Design and Motion Analysis of a Mecanum Three-Round Omni-Directional Mobile Platform. J. Northwestern Polytech. Univ. 2017, 35, 857–862. [Google Scholar]

- Lafaye, J.; Gouaillier, D.; Wieber, P.-B. Linear Model Predictive Control of the Locomotion of Pepper, a Humanoid Robot with Omnidirectional Wheels. In Proceedings of the 2014 IEEE-RAS International Conference on Humanoid Robots, Madrid, Spain, 18–20 November 2014; pp. 336–341. [Google Scholar]

- Song, J.B.; Byun, K.S. Steering Control Algorithm for Efficient Drive of a Mobile Robot with Steerable Omni-Directional Wheels. J. Mech. Sci. Technol. 2009, 23, 2747–2756. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, S.; Liu, J.; Chen, F.; Li, L.; Xia, B. Research on a New Omnidirectional Mobile Platform with Heavy Loading and Flexible Motion. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Muir, P.F.; Neuman, C.P. Kinematic Modeling for Feedback Control of an Omnidirectional Wheeled Mobile Robot. In Autonomous Robot Vehicles; Springer: New York, NY, USA, 1990; pp. 25–31. [Google Scholar]

- Wieczorek, B. Methods of Determining Trajectory for Wheelchair with Manual Pushrims Drive. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1016, 012004. [Google Scholar] [CrossRef]

- Wieczorek, B.; Kukla, M. Biomechanical Relationships Between Manual Wheelchair Steering and the Position of the Human Body’s Center of Gravity. J. Biomech. Eng. 2020, 142. [Google Scholar] [CrossRef]

- Leow, Y.P.; Low, K.H.; Loh, W.K. Kinematic Modelling and Analysis of Mobile Robots with Omni-Directional Wheels. In Proceedings of the 7th International Conference on Control, Automation, Robotics and Vision, Singapore, 2–5 December 2002; Volume 2, pp. 820–825. [Google Scholar]

- Loh, W.K.; Low, K.H.; Leow, Y.P. Mechatronics Design and Kinematic Modelling of a Singularityless Omni-Directional Wheeled Mobile Robot. In Proceedings of the 2003 IEEE International Conference on Robotics and Automation (Cat. No.03CH37422), Taipei, Taiwan, 14–19 September 2003; Volume 3, pp. 3237–3242. [Google Scholar]

- Watanabe, K. Control of an Omnidirectional Mobile Robot. In Proceedings of the 1998 Second International Conference, Knowledge-Based Intelligent Electronic Systems, Adelaide, South Australia, 21–23 April 1998; Volume 1, pp. 51–60. [Google Scholar]

- Li, X.; Zell, A. Motion Control of an Omnidirectional Mobile Robot. In Informatics in Control, Automation and Robotics: Selected Papers from the International Conference on Informatics in Control, Automation and Robotics; Springer: Berlin/Heidelberg, Germany, 2009; pp. 181–193. ISBN 978-3-540-85640-5. [Google Scholar]

- Kalmár-Nagy, T.; D’Andrea, R.; Ganguly, P. Near-Optimal Dynamic Trajectory Generation and Control of an Omnidirectional Vehicle. Robot. Auton. Syst. 2004, 46, 47–64. [Google Scholar] [CrossRef]

- Purwin, O.; D’Andrea, R. Trajectory Generation and Control for Four Wheeled Omnidirectional Vehicles. Robot. Auton. Syst. 2006, 54, 13–22. [Google Scholar] [CrossRef]

- Kalmar-Nagy, T.; Ganguly, P.; D’Andrea, R. Real-Time Trajectory Generation for Omnidirectional Vehicles. In Proceedings of the 2002 American Control Conference (IEEE Cat. No.CH37301), Anchorage, AK, USA, 8–10 May 2002; Volume 1, pp. 286–291. [Google Scholar]

- Alwan, H.M. Dynamic Analysis Modeling of a Holonomic Wheeled Mobile Robot with Mecanum Wheels Using Virtual Work Method. J. Mech. Eng. Res. Dev. 2020, 43, 373–380. [Google Scholar]

- Hou, L.; Zhang, L.; Kim, J. Energy Modeling and Power Measurement for Mobile Robots. Energies 2019, 12, 27. [Google Scholar] [CrossRef]

- Alwan, H.M.; Volkov, A.N.; Shbani, A. Solution of Inverse and Forward Kinematics Problems for Mobile Robot with Six Mecanum Wheels. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012071. [Google Scholar] [CrossRef]

- Rijalusalam, D.U.; Iswanto, I. Implementation Kinematics Modeling and Odometry of Four Omni Wheel Mobile Robot on The Trajectory Planning and Motion Control Based Microcontroller. J. Robot. Control 2021, 2, 448–455. [Google Scholar] [CrossRef]

- Karras, G.C.; Fourlas, G.K. Model Predictive Fault Tolerant Control for Omni-Directional Mobile Robots. J. Intell. Robot. Syst. 2020, 97, 635–655. [Google Scholar] [CrossRef]

- Cuevas, F.; Castillo, O.; Cortés-Antonio, P. Omnidirectional Four Wheel Mobile Robot Control with a Type-2 Fuzzy Logic Behavior-Based Strategy. In Intuitionistic and Type-2 Fuzzy Logic Enhancements in Neural and Optimization Algorithms: Theory and Applications; Studies in Computational Intelligence; Springer International Publishing: Cham, Switzerland, 2020; pp. 49–62. ISBN 978-3-030-35445-9. [Google Scholar]

- Yang, H.; Wang, S.; Zuo, Z.; Li, P. Trajectory Tracking for a Wheeled Mobile Robot with an Omnidirectional Wheel on Uneven Ground. IET Control Theory Appl. 2020, 14, 921–929. [Google Scholar] [CrossRef]

- Serrano-Pérez, O.; Villarreal-Cervantes, M.G.; González-Robles, J.C.; Rodríguez-Molina, A. Meta-Heuristic Algorithms for the Control Tuning of Omnidirectional Mobile Robots. Eng. Optim. 2020, 52, 325–342. [Google Scholar] [CrossRef]

- Abiyev, R.H.; Günsel, I.S.; Akkaya, N.; Aytac, E.; Çağman, A.; Abizada, S. Fuzzy Control of Omnidirectional Robot. Procedia Comput. Sci. 2017, 120, 608–616. [Google Scholar] [CrossRef]

- Abiyev, R.H.; Akkaya, N.; Gunsel, I. Control of Omnidirectional Robot Using Z-Number-Based Fuzzy System. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 238–252. [Google Scholar] [CrossRef]

- Hacene, N.; Mendil, B. Motion Analysis and Control of Three-Wheeled Omnidirectional Mobile Robot. J. Control. Autom. Electr. Syst. 2019, 30, 194–213. [Google Scholar] [CrossRef]

- Alshorman, A.M.; Alshorman, O.; Irfan, M.; Glowacz, A.; Muhammad, F.; Caesarendra, W. Fuzzy-Based Fault-Tolerant Control for Omnidirectional Mobile Robot. Machines 2020, 8, 55. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Yang, X.; Hu, F.; Jiang, A.; Yang, C. Trajectory Tracking of an Omni-Directional Wheeled Mobile Robot Using a Model Predictive Control Strategy. Appl. Sci. 2018, 8, 231. [Google Scholar] [CrossRef]

- Thi, K.D.H.; Nguyen, M.C.; Vo, H.T.; Tran, V.M.; Nguyen, D.D.; Bui, A.D. Trajectory Tracking Control for Four-Wheeled Omnidirectional Mobile Robot Using Backstepping Technique Aggregated with Sliding Mode Control. In Proceedings of the 2019 First International Symposium on Instrumentation, Control, Artificial Intelligence, and Robotics (ICA-SYMP), Bangkok, Thailand, 16–18 January 2019; pp. 131–134. [Google Scholar]

- Xie, Y.; Zhang, X.; Meng, W.; Xie, S.; Jiang, L.; Meng, J.; Wang, S. Coupled Sliding Mode Control of an Omnidirectional Mobile Robot with Variable Modes. In Proceedings of the 2020 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 6–9 July 2020; pp. 1792–1797. [Google Scholar]

- Dong, F.; Jin, D.; Zhao, X.; Han, J. Adaptive Robust Constraint Following Control for Omnidirectional Mobile Robot: An Indirect Approach. IEEE Access 2021, 9, 8877–8887. [Google Scholar] [CrossRef]

- Sahoo, S.R.; Chiddarwar, S.S. Flatness-Based Control Scheme for Hardware-in-the-Loop Simulations of Omnidirectional Mobile Robot. SIMULATION 2020, 96, 169–183. [Google Scholar] [CrossRef]

- Amudhan, A.N.; Sakthivel, P.; Sudheer, A.P.; Kumar, T.K.S. Design of Controllers for Omnidirectional Robot Based on the Ystem Identification Technique for Trajectory Tracking. J. Phys. Conf. Ser. 2019, 1240, 012146. [Google Scholar] [CrossRef]

- Kalmár-Nagy, T. Real-Time Trajectory Generation for Omni-Directional Vehicles by Constrained Dynamic Inversion. Mechatronics 2016, 35, 44–53. [Google Scholar] [CrossRef]

- Wu, M.; Dai, S.-L.; Yang, C. Mixed Reality Enhanced User Interactive Path Planning for Omnidirectional Mobile Robot. Appl. Sci. 2020, 10, 1135. [Google Scholar] [CrossRef]

- Saenz, A.; Santibañez, V.; Bugarin, E.; Dzul, A.; Ríos, H.; Villalobos-Chin, J. Velocity Control of an Omnidirectional Wheeled Mobile Robot Using Computed Voltage Control with Visual Feedback: Experimental Results. Int. J. Control. Autom. Syst. 2021, 19, 1089–1102. [Google Scholar] [CrossRef]

- Ou, J.; Wang, M. Path Planning for Omnidirectional Wheeled Mobile Robot by Improved Ant Colony Optimization. In Proceedings of the 2019 Chinese Control Conference (CCC), Guangzhou, China, 27–30 July 2019; pp. 2668–2673. [Google Scholar]

- Choi, J.; Curry, R.E.; Elkaim, G.H. Obstacle Avoiding Real-Time Trajectory Generation and Control of Omnidirectional Vehicles. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 5510–5515. [Google Scholar]

- Azim Mohseni, N.; Fakharian, A. Direct Optimal Motion Planning for Omni-Directional Mobile Robots under Limitation on Velocity and Acceleration. J. Optim. Ind. Eng. 2017, 10, 93–101. [Google Scholar] [CrossRef]

- Williams, R.L.; Wu, J. Dynamic Obstacle Avoidance for an Omnidirectional Mobile Robot. J. Robot. 2010, 2010. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Wang, C.; Hu, F.; Yang, X. MPC Control and Path Planning of Omni-Directional Mobile Robot with Potential Field Method. In Proceedings of the Intelligent Robotics and Applications, Newcastle, NSW, Australia, 9–11 August 2018; Springer International Publishing: Cham, Switzerland, 2018; pp. 170–181. [Google Scholar]

- Guo, S.; Diao, Q.; Xi, F. Vision Based Navigation for Omni-Directional Mobile Industrial Robot. Procedia Comput. Sci. 2017, 105, 20–26. [Google Scholar] [CrossRef]

- Kim, C.; Suh, J.; Han, J.-H. Development of a Hybrid Path Planning Algorithm and a Bio-Inspired Control for an Omni-Wheel Mobile Robot. Sensors 2020, 20, 4258. [Google Scholar] [CrossRef]

- Azizi, M.R.; Rastegarpanah, A.; Stolkin, R. Motion Planning and Control of an Omnidirectional Mobile Robot in Dynamic Environments. Robotics 2021, 10, 48. [Google Scholar] [CrossRef]

- Cuevas, F.; Castillo, O.; Cortes-Antonio, P. Towards an Adaptive Control Strategy Based on Type-2 Fuzzy Logic for Autonomous Mobile Robots. In Proceedings of the 2019 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), New Orleans, LA, USA, 23–26 June 2019; pp. 1–6. [Google Scholar]

- Hacene, N.; Mendil, B. Fuzzy Behavior-Based Control of Three Wheeled Omnidirectional Mobile Robot. Int. J. Autom. Comput. 2019, 16, 163–185. [Google Scholar] [CrossRef]

- Ajeil, F.H.; Ibraheem, I.K.; Azar, A.T.; Humaidi, A.J. Autonomous Navigation and Obstacle Avoidance of an Omnidirectional Mobile Robot Using Swarm Optimization and Sensors Deployment. Int. J. Adv. Robot. Syst. 2020, 17. [Google Scholar] [CrossRef]

- Thakur, N.; Han, C.Y. Multimodal Approaches for Indoor Localization for Ambient Assisted Living in Smart Homes. Information 2021, 12, 114. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.-H.; Shao, X. User Preference-Aware Navigation for Mobile Robot in Domestic via Defined Virtual Area. J. Netw. Comput. Appl. 2021, 173, 102885. [Google Scholar] [CrossRef]

- Ran, T.; Yuan, L.; Zhang, J.B. Scene Perception Based Visual Navigation of Mobile Robot in Indoor Environment. ISA Trans. 2021, 109, 389–400. [Google Scholar] [CrossRef]

- Gamal, O.; Cai, X.; Roth, H. Learning from Fuzzy System Demonstration: Autonomous Navigation of Mobile Robot in Static Indoor Environment Using Multimodal Deep Learning. In Proceedings of the 2020 24th International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 8–10 October 2020; pp. 218–225. [Google Scholar]

- Al Khatib, E.I.; Jaradat, M.A.K.; Abdel-Hafez, M.F. Low-Cost Reduced Navigation System for Mobile Robot in Indoor/Outdoor Environments. IEEE Access 2020, 8, 25014–25026. [Google Scholar] [CrossRef]

- Iqbal, J.; Xu, R.; Sun, S.; Li, C. Simulation of an Autonomous Mobile Robot for LiDAR-Based In-Field Phenotyping and Navigation. Robotics 2020, 9, 46. [Google Scholar] [CrossRef]

- Bai, X.; Dong, L.; Ge, L.; Xu, H.; Zhang, J.; Yan, J. Robust Localization of Mobile Robot in Industrial Environments With Non-Line-of-Sight Situation. IEEE Access 2020, 8, 22537–22545. [Google Scholar] [CrossRef]

- Kim, E.-K.; Kim, S.-S. Generation of Feature Map for Improving Localization of Mobile Robot Based on Stereo Camera. J. Korea Inst. Inf. Electron. Commun. Technol. 2020, 13, 58–63. [Google Scholar] [CrossRef]

- Li, H.; Mao, Y.; You, W.; Ye, B.; Zhou, X. A Neural Network Approach to Indoor Mobile Robot Localization. In Proceedings of the 2020 19th International Symposium on Distributed Computing and Applications for Business Engineering and Science (DCABES), Xuzhou, China, 16–19 October 2020; pp. 66–69. [Google Scholar]

- Greenberg, J.N.; Tan, X. Dynamic Optical Localization of a Mobile Robot Using Kalman Filtering-Based Position Prediction. IEEE/ASME Trans. Mechatron. 2020, 25, 2483–2492. [Google Scholar] [CrossRef]

| Parameter | Description | Value | Unit |

|---|---|---|---|

| Desired accuracy in distance | m | ||

| Desired accuracy in orientation | 0.12 | rad | |

| Desired accuracy in velocity | m/s | ||

| Desired accuracy in angular velocity | 0.12 | Rad/s | |

| Positive weight illustrating the trade-off between the maneuver time and the error | 2 |

| Parameter | Description | Value | Unit |

|---|---|---|---|

| The torque constant of the robot | 0.293 | Nm/A | |

| R | The armature resistance | 1.465 | Ω |

| Limitation on the DC motor power source | 14.8 | V | |

| Characteristic constant | 10 | NV−1 | |

| Characteristic constant | 146 | Nsm−1 |

| Parameter | Description | Value | Unit |

|---|---|---|---|

| m | Mass of the vehicle | 2.45 | kg |

| J | Mass moment of inertia of the vehicle | 0.00625 | Kgm2 |

| L | The radius of the SAOWMR | 0.09 | m |

| r | The radius of the robot wheels | 0.02 | m |

| Limitations on the acceleration amplitude | 2 | ms−2 |

| Parameter | Value |

|---|---|

| Temperature reduction rule | Slow-decrease |

| Temperature update function | Exponential |

| Number of iterations per temperature | 50 |

| Maximum function evaluation | 2500 |

| Tolerance | 10−3 |

| Maneuvers | Starting Configurations | Termination Configurations |

|---|---|---|

| Maneuver 1 | ||

| Maneuver 2 |

| Maneuvers | Method | Optimal Final Time | Terminal Error | Fitness Function | Code Execution Time (MATLAB) | Code Execution Time (C) |

|---|---|---|---|---|---|---|

| Maneuver 1 | Proposed Method | 3.1320 s | 0.0000 | 3.1320 | 2.1265 s | 0.06947 s |

| CDIB [53] | 3.0656 s | 0.0044 | 3.0744 | 14.6981 s | 1.68790 s | |

| Maneuver 2 | Proposed Method | 4.7938 s | 0.0000 | 4.7938 | 1.9827 s | 0.06891 s |

| CDIB [53] | 3.9087 s | 0.0206 | 3.9499 | 15.0198 s | 1.49827 s |

| Maneuvers | Method | Trade-Off Value | E (J) | |

|---|---|---|---|---|

| Maneuver 1 | Proposed Method | 3.1320 | 3.7029 | |

| 4.5103 | 2.4688 | |||

| CDIB [53] | - | 3.0656 | 3.8327 | |

| Maneuver 2 | Proposed Method | 4.7938 | 4.4805 | |

| 5.7563 | 3.8798 | |||

| CDIB [53] | - | 3.9087 | 5.4504 |

| Starting Point Configurations | Ending Point Configurations |

|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almasri, E.; Uyguroğlu, M.K. Modeling and Trajectory Planning Optimization for the Symmetrical Multiwheeled Omnidirectional Mobile Robot. Symmetry 2021, 13, 1033. https://doi.org/10.3390/sym13061033

Almasri E, Uyguroğlu MK. Modeling and Trajectory Planning Optimization for the Symmetrical Multiwheeled Omnidirectional Mobile Robot. Symmetry. 2021; 13(6):1033. https://doi.org/10.3390/sym13061033

Chicago/Turabian StyleAlmasri, Eyad, and Mustafa Kemal Uyguroğlu. 2021. "Modeling and Trajectory Planning Optimization for the Symmetrical Multiwheeled Omnidirectional Mobile Robot" Symmetry 13, no. 6: 1033. https://doi.org/10.3390/sym13061033

APA StyleAlmasri, E., & Uyguroğlu, M. K. (2021). Modeling and Trajectory Planning Optimization for the Symmetrical Multiwheeled Omnidirectional Mobile Robot. Symmetry, 13(6), 1033. https://doi.org/10.3390/sym13061033