New Design of Composite Structures Used in Automotive Engineering

Abstract

1. Introduction

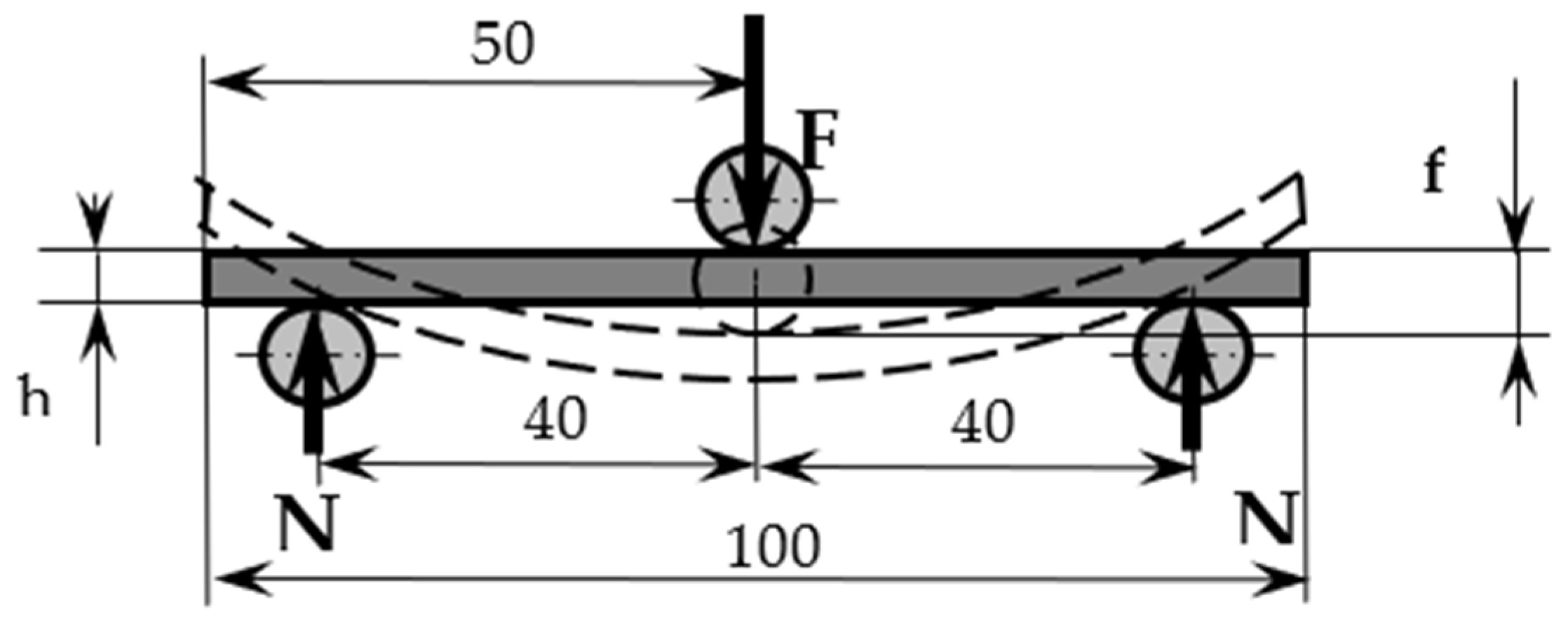

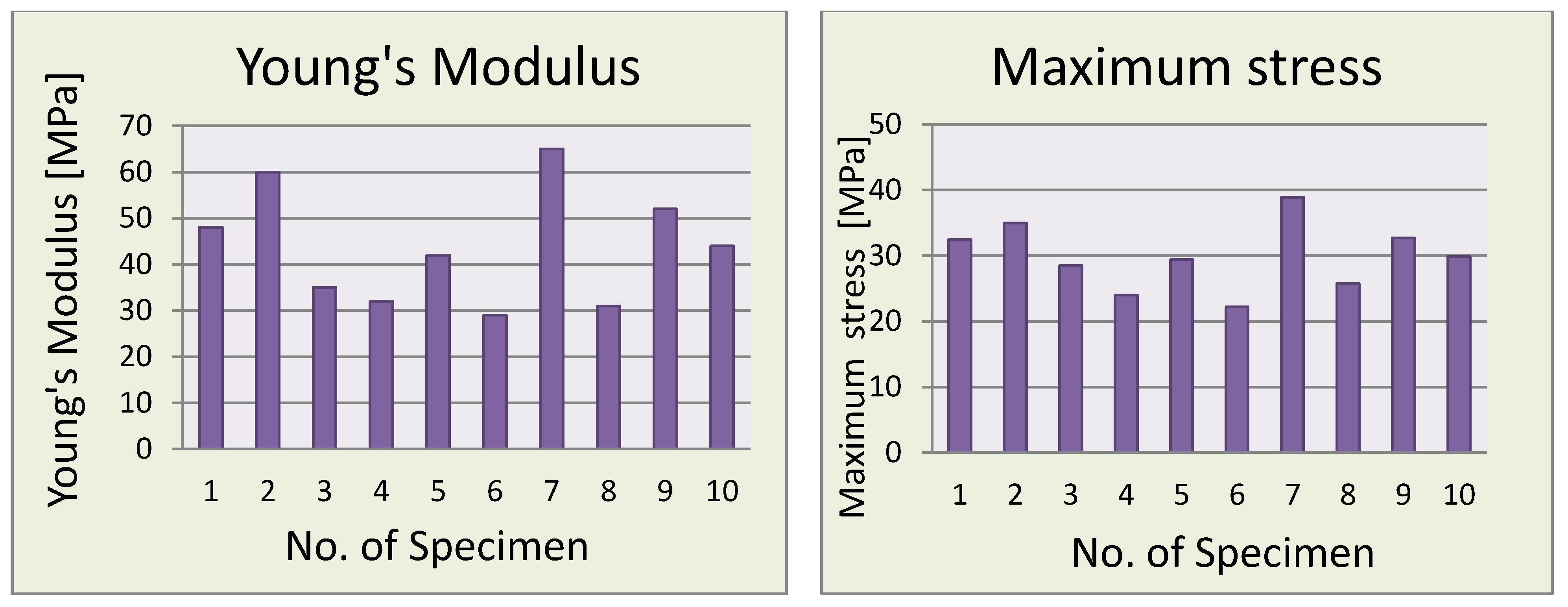

2. Materials and Methods

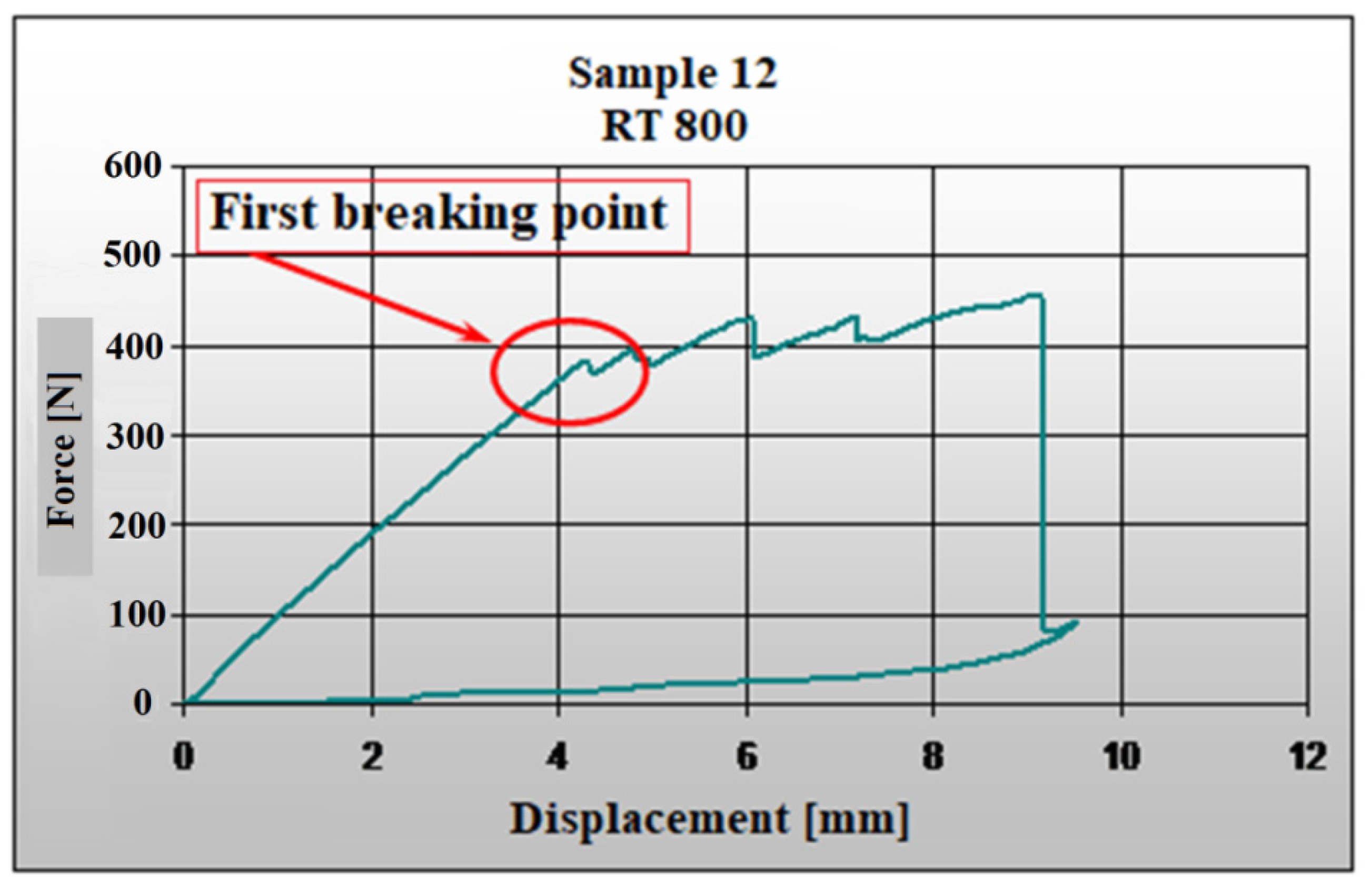

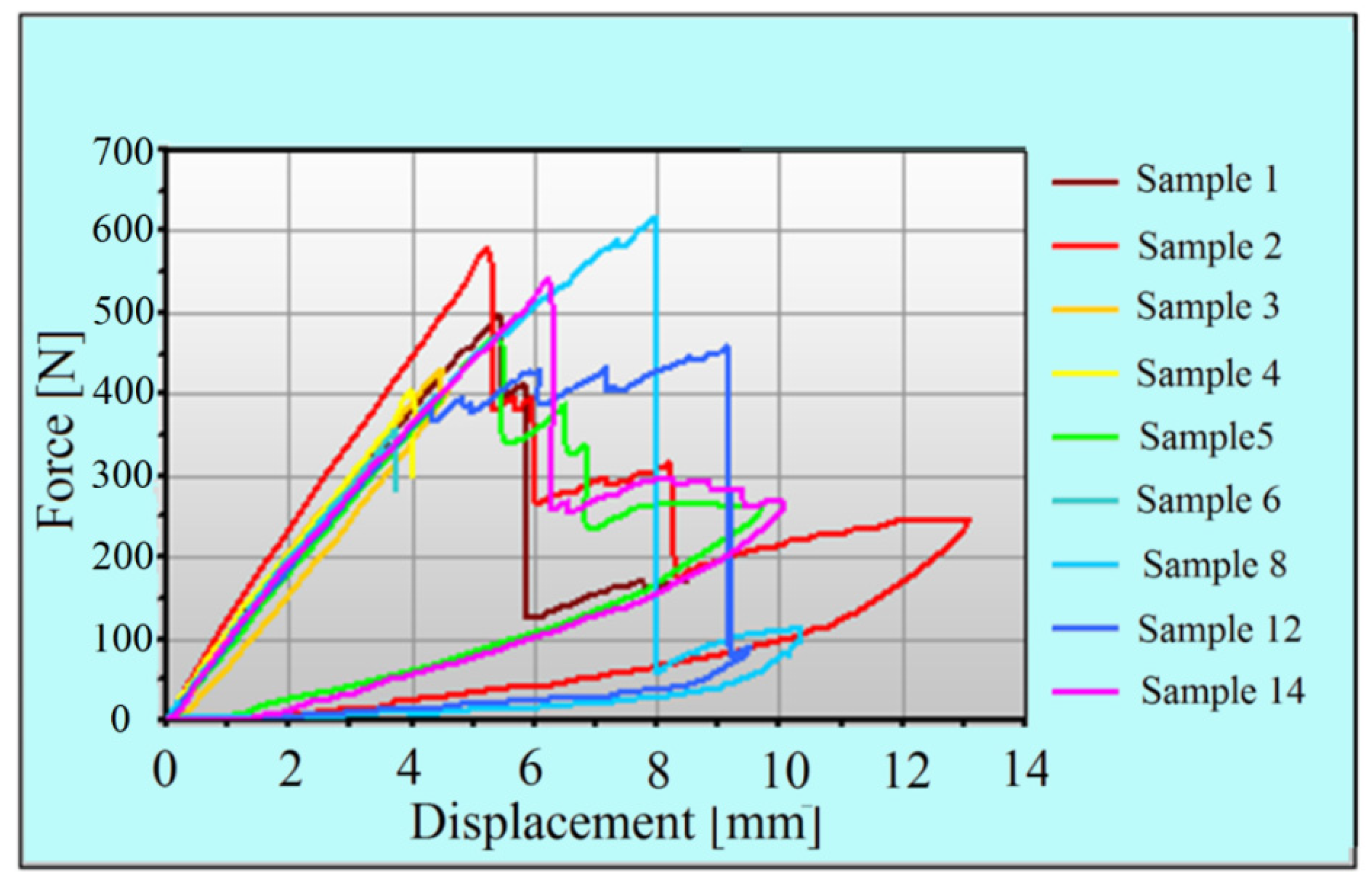

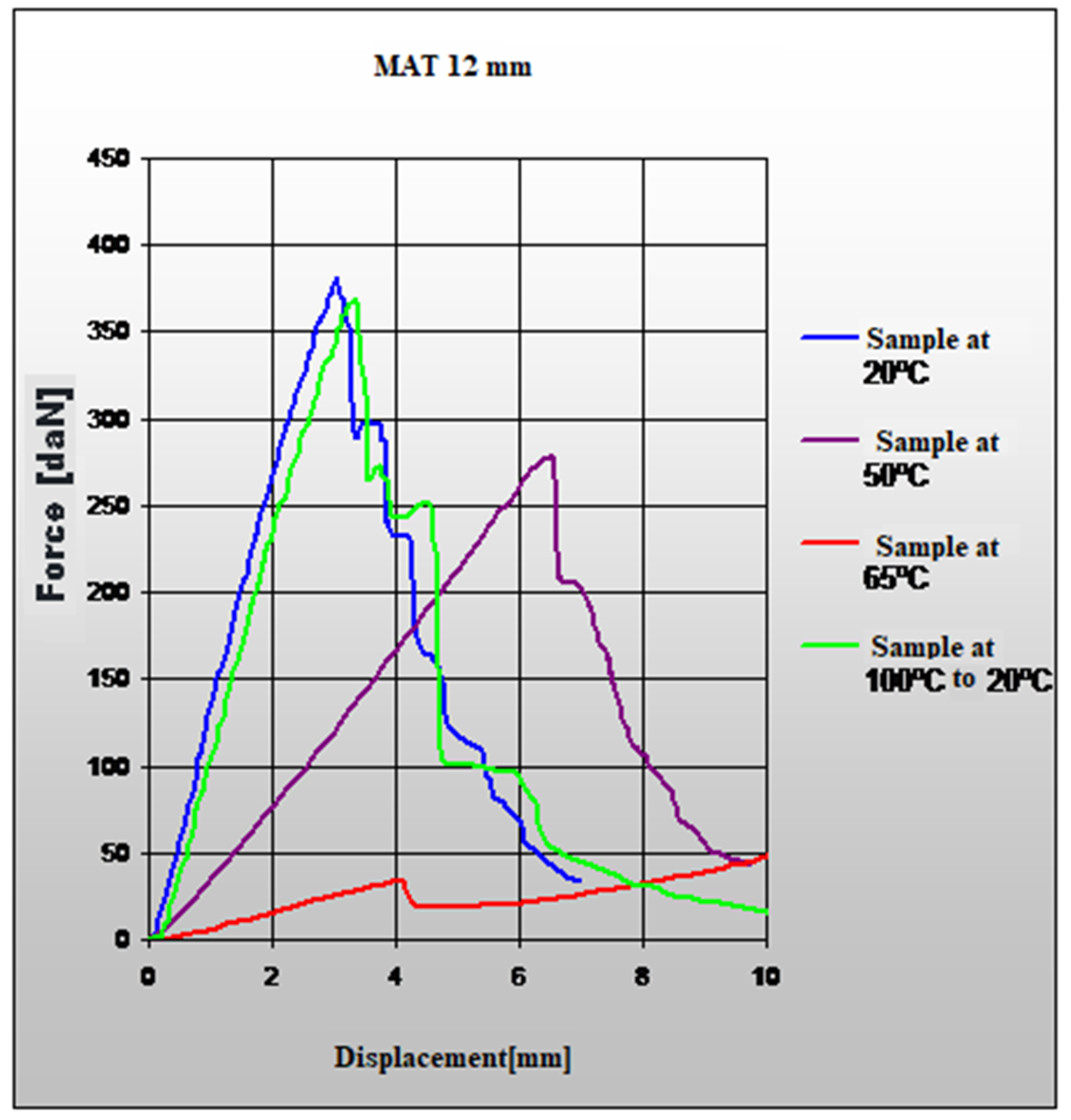

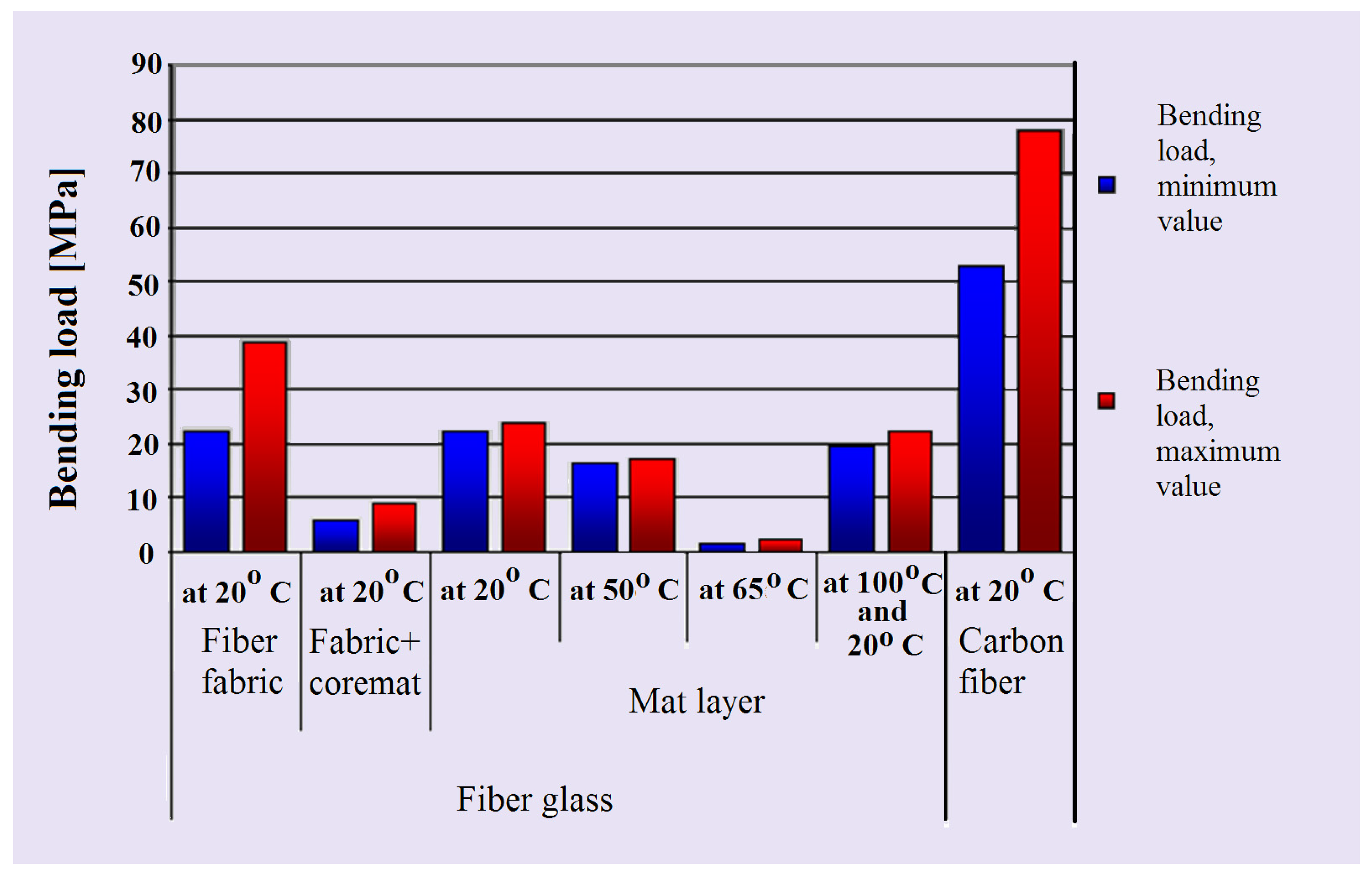

- The first class of composite test specimens are made of polyester resin, reinforced with 5 layers of fiberglass fabric, which we call RT-800, with a specific mass of 845g/m2. After deposition of the five layers, the material was allowed to polymerize at ambient temperature. From the first material, specimens with a thickness of 4.5 mm were made.

- The second material tested was also made of polyester resin, reinforced with 7 layers of fiberglass fabric with a specific mass of 845g/m2. These two types of materials were made of the same constituents, differing only in the number of layers of fiberglass fabric used. The specimens made of the second material had a thickness of 6 mm.

- The third material subjected to bending tests was a material made of polyester resin, of the “sandwich” type, made of layers of fiberglass fabric, but also composed of coremat. The specimens obtained from this material have a thickness of 8 mm.

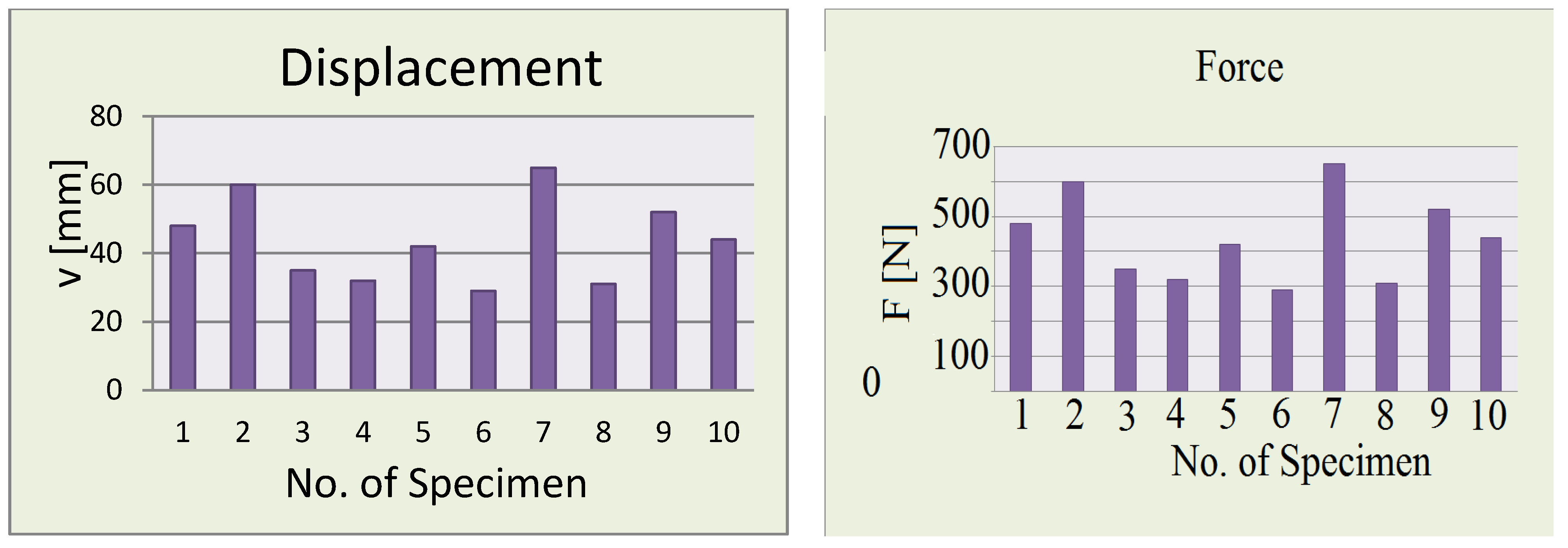

- The fourth material is fiberglass in the form of mat was used to reinforce a plate of polyester resin. Fifteen layers of mat were used to make this composite.

- The fifth material tested was made of epoxy resin, reinforced with five layers of carbon fiber fabrics and one layer of polyester. These specimens suffered total ruptures, only one showing detachments between the layers. It could rather be said that these specimens were broken during the bending tests.

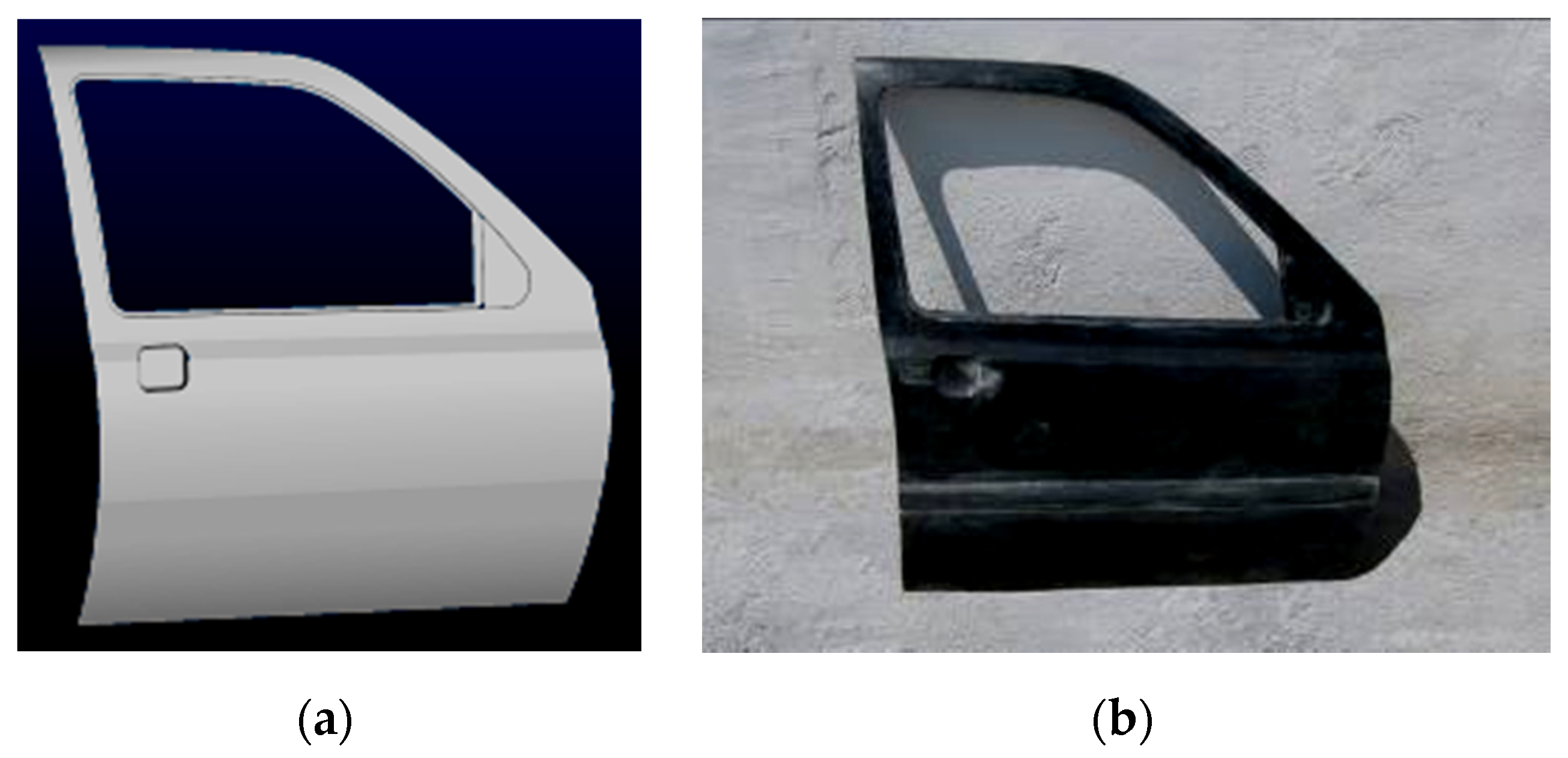

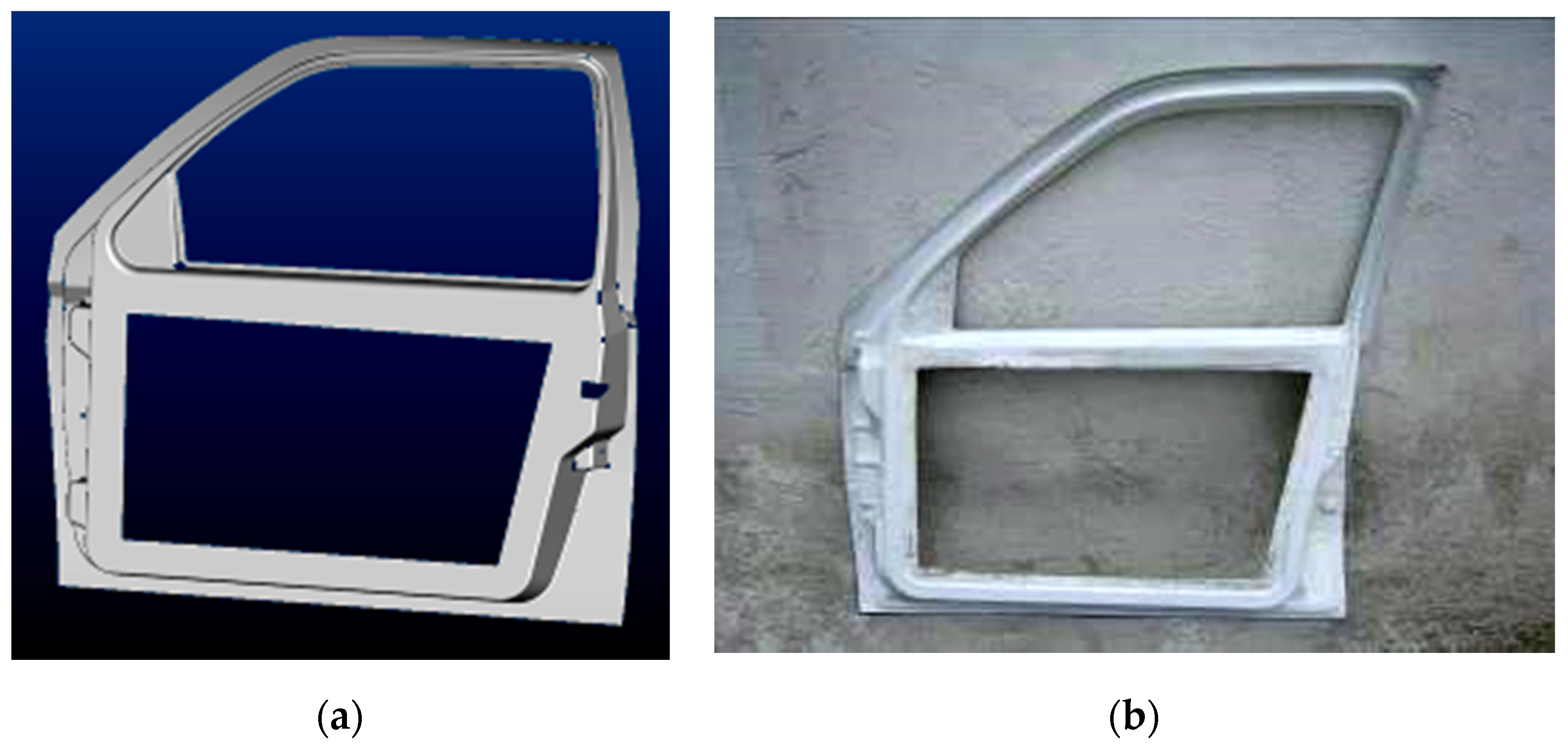

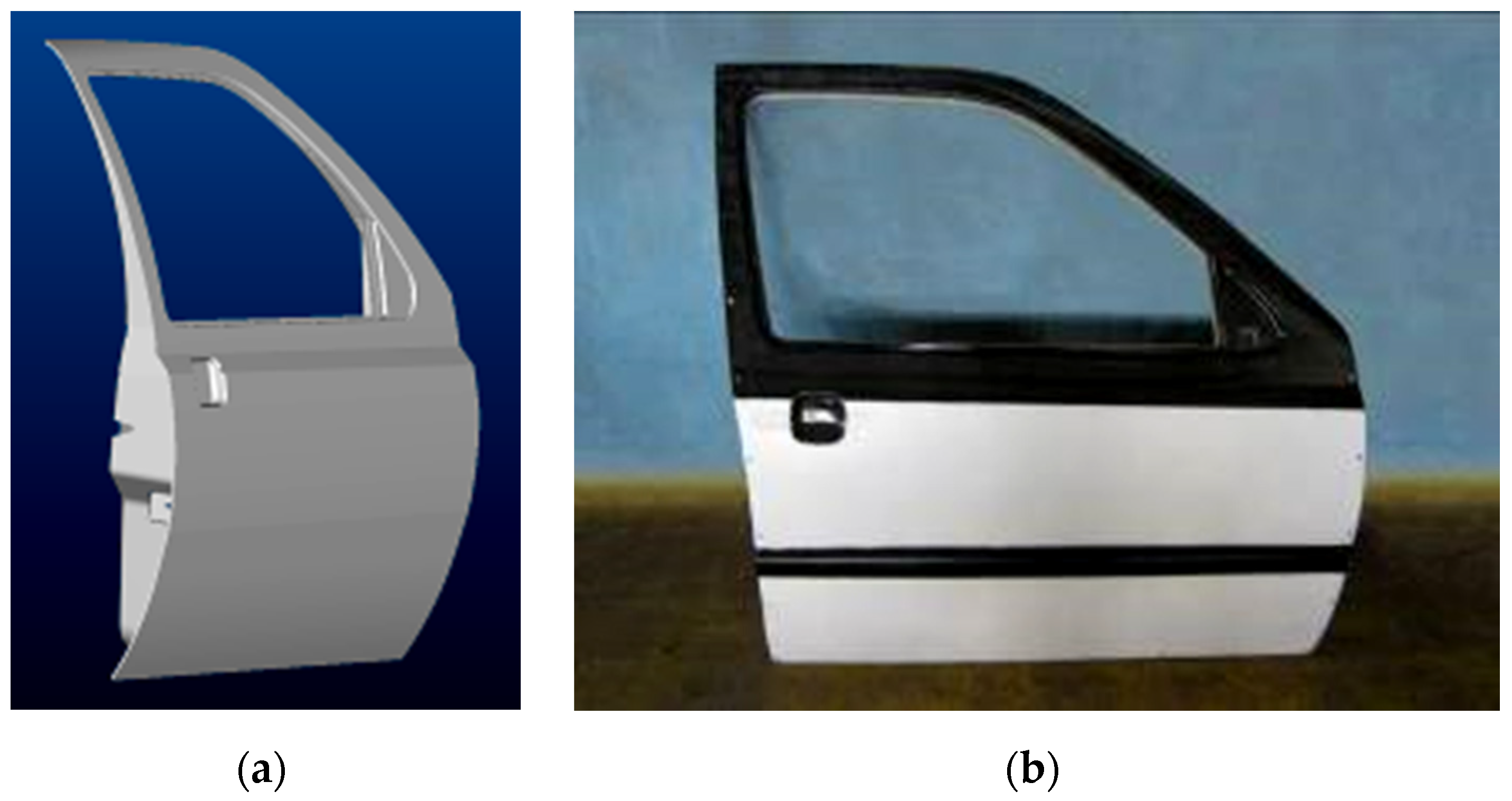

Design of the Door

3. Modeling and Experimental Research of the Car Door

- -

- each sheet is shaped in the form of a continuous, linear elastic medium. The theory does not include cracks, air gaps, etc;

- -

- the laminates are orthotropic, parallel, and perfectly glued to each other;

- -

- the fibers are not examined in isolation from the matrix or the adhesive layer (interface effects are neglected);

- -

- the individual layers are ideally glued to each other. In case of application of loads, no relative slips appear;

- -

- the materials behave linearly, ideally elastic, i.e., for each individual layer the laws of linear elasticity are valid;

- -

- the connections between the components of a mechanical assembly are relatively difficult to make;

- -

- the damping of the mechanical system is generally ignored.

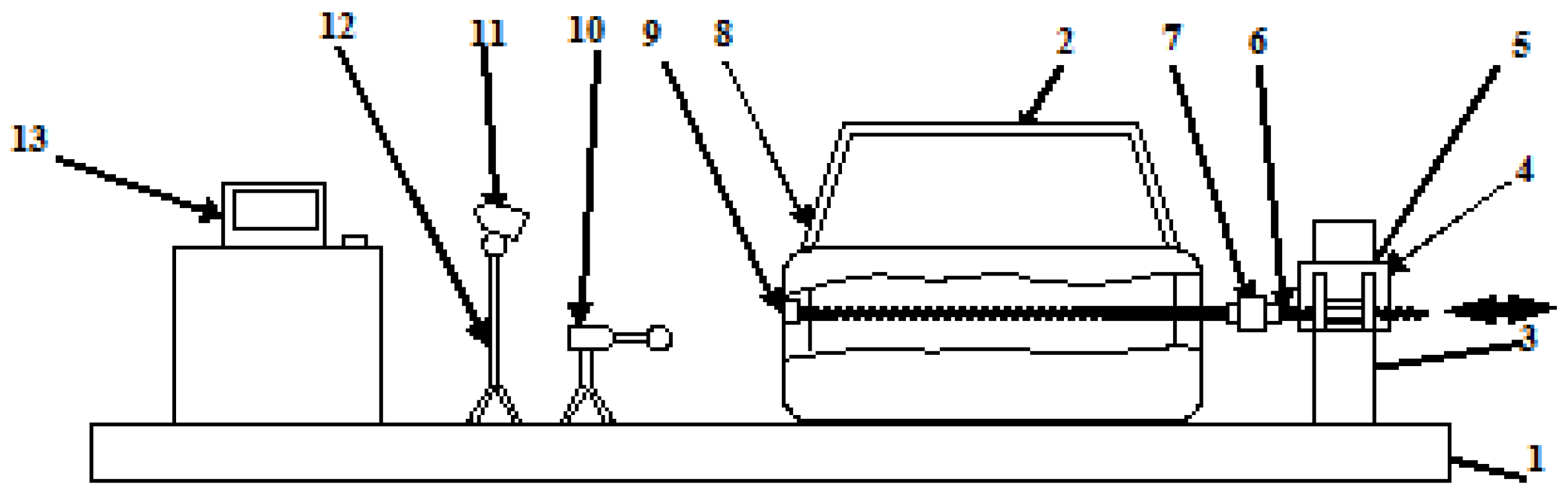

3.1. Test Stand for Car Structure

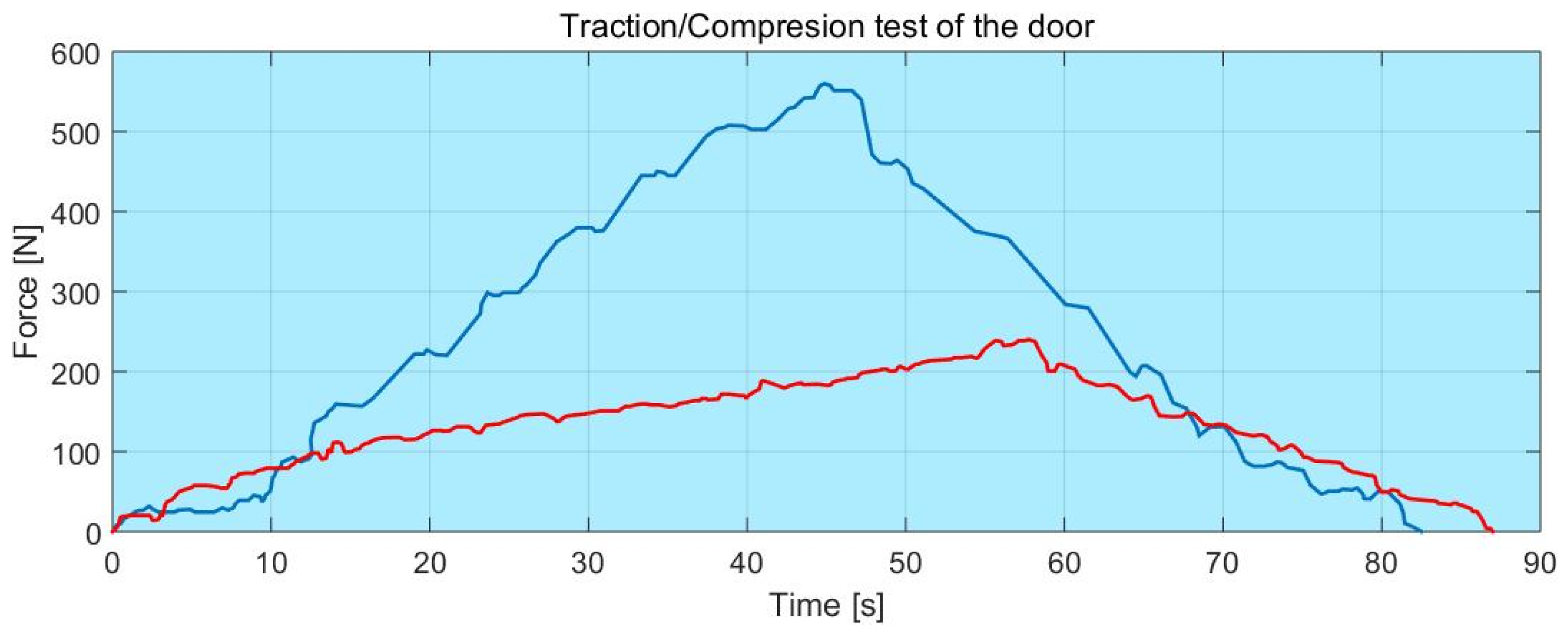

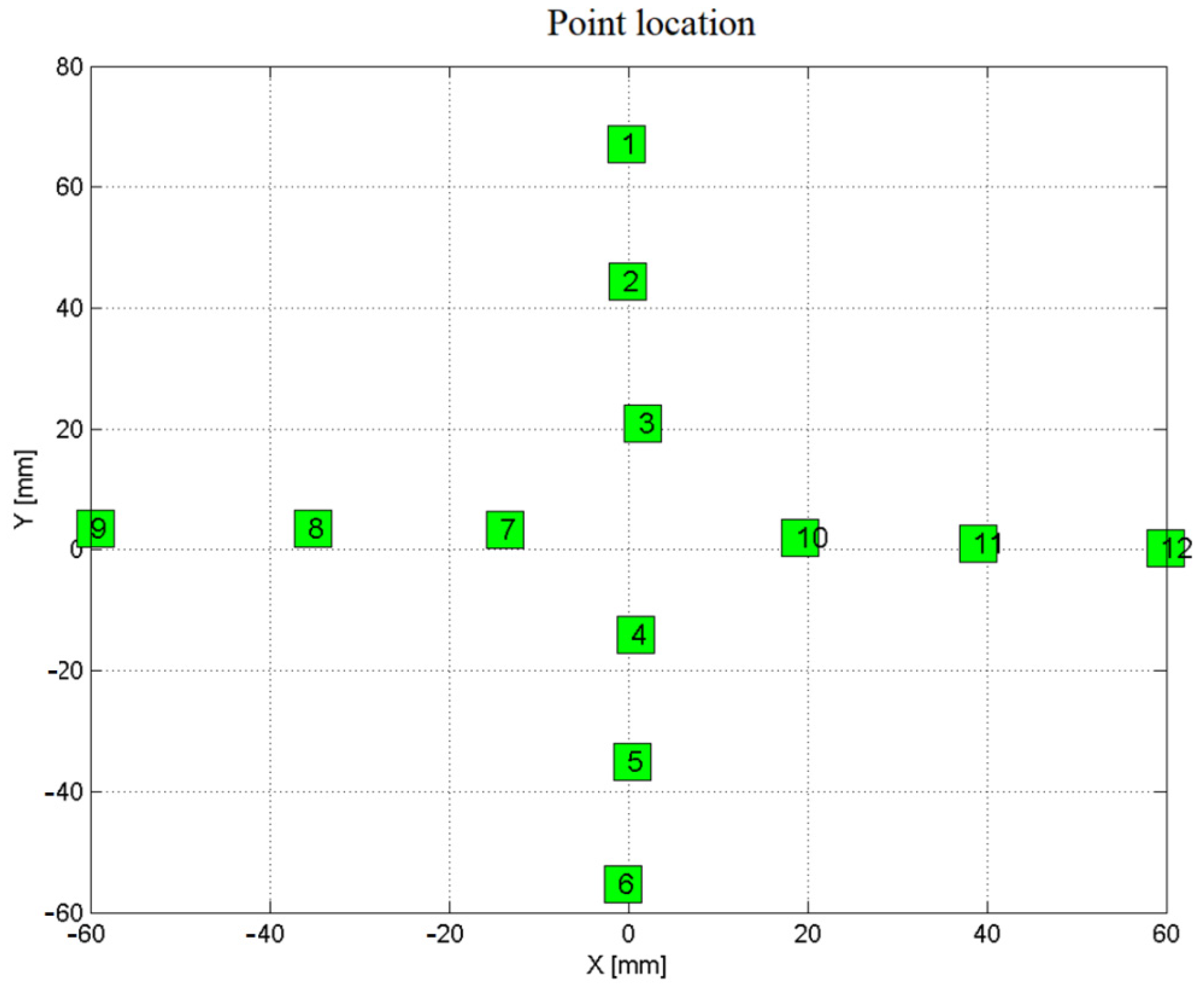

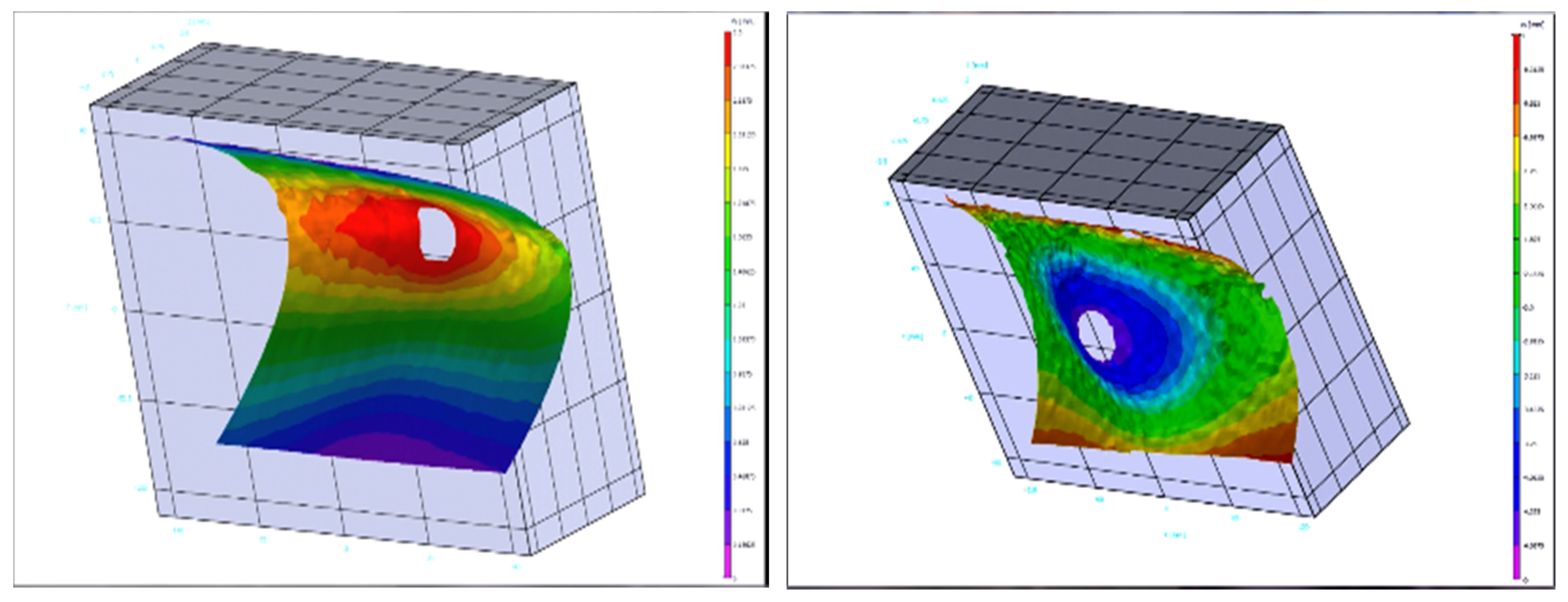

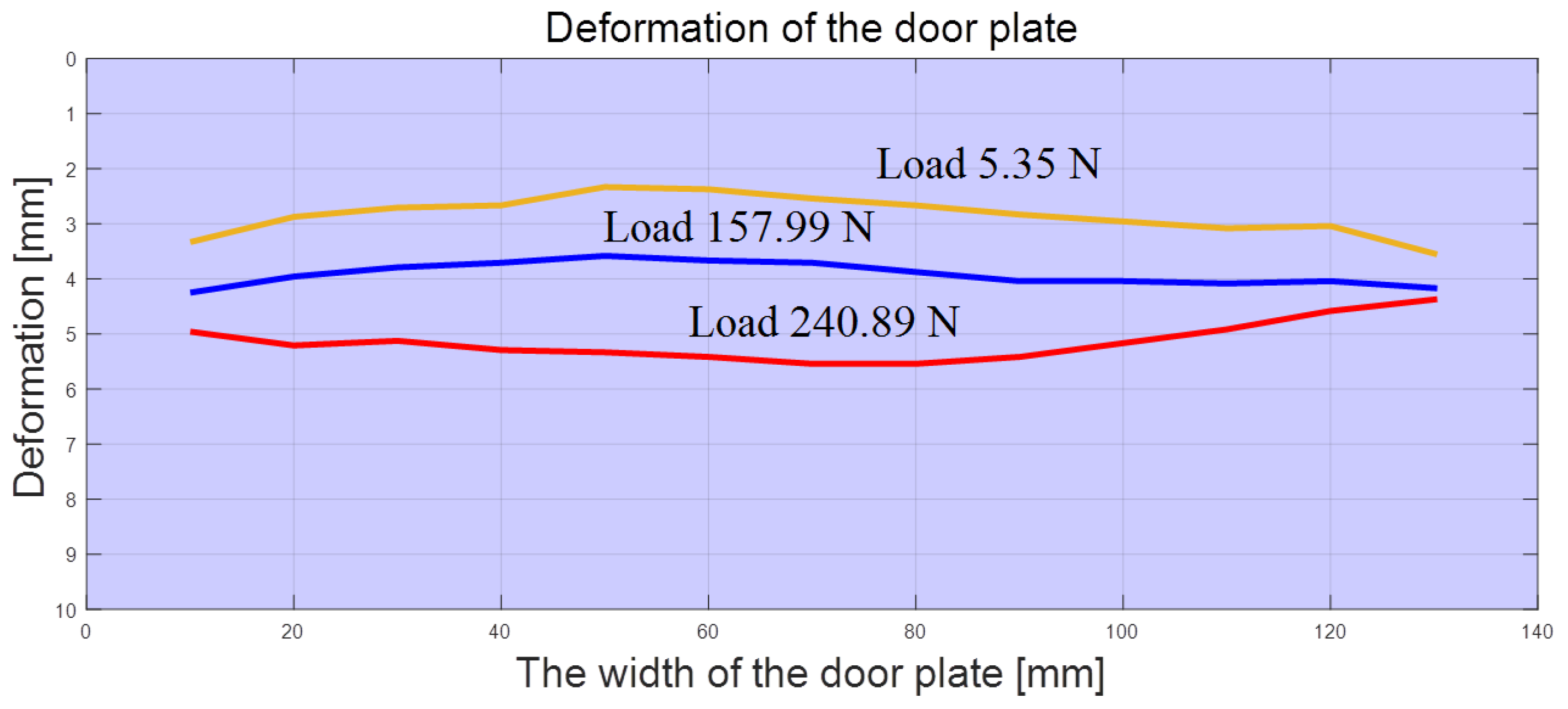

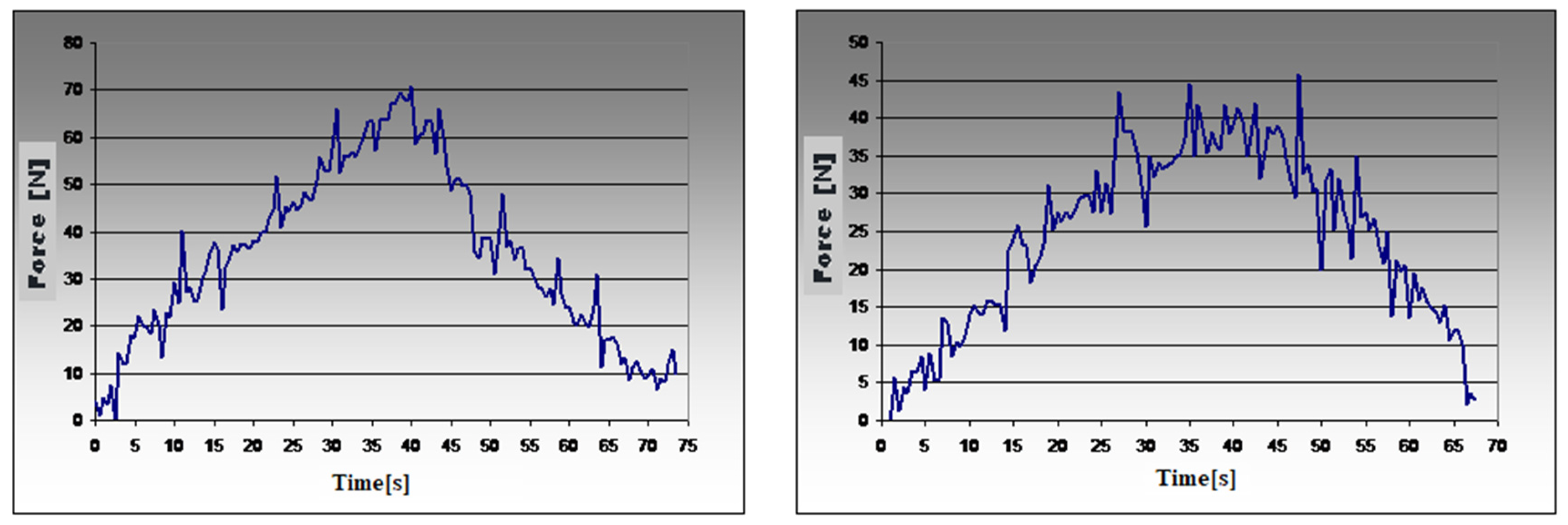

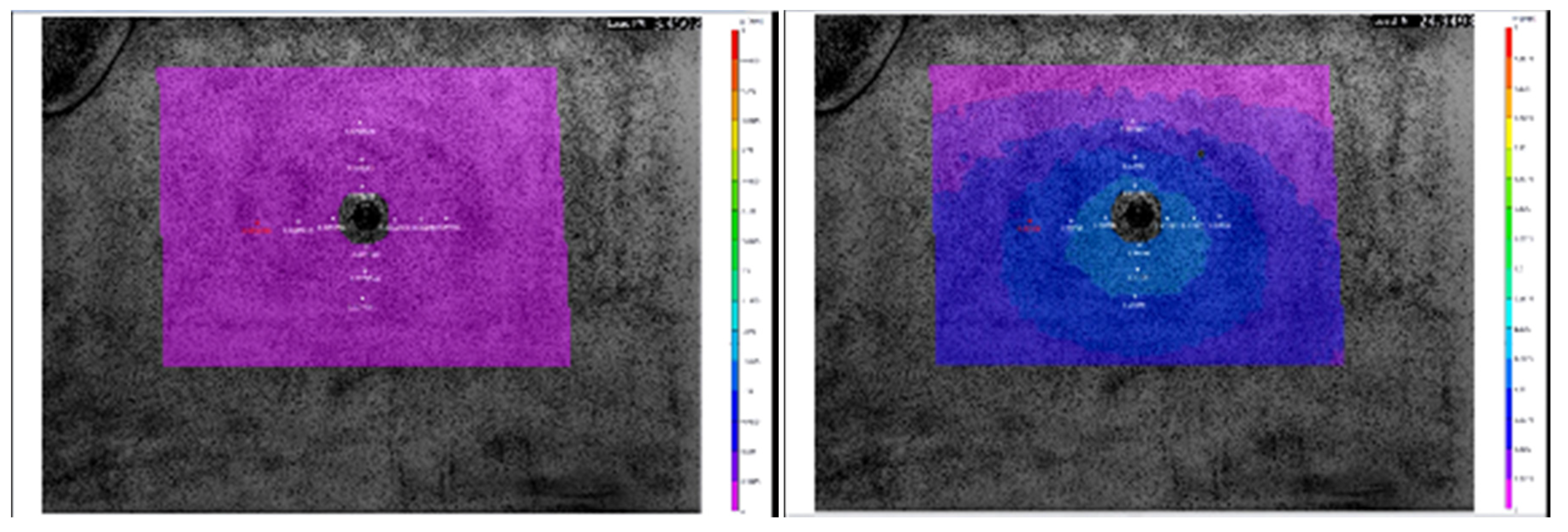

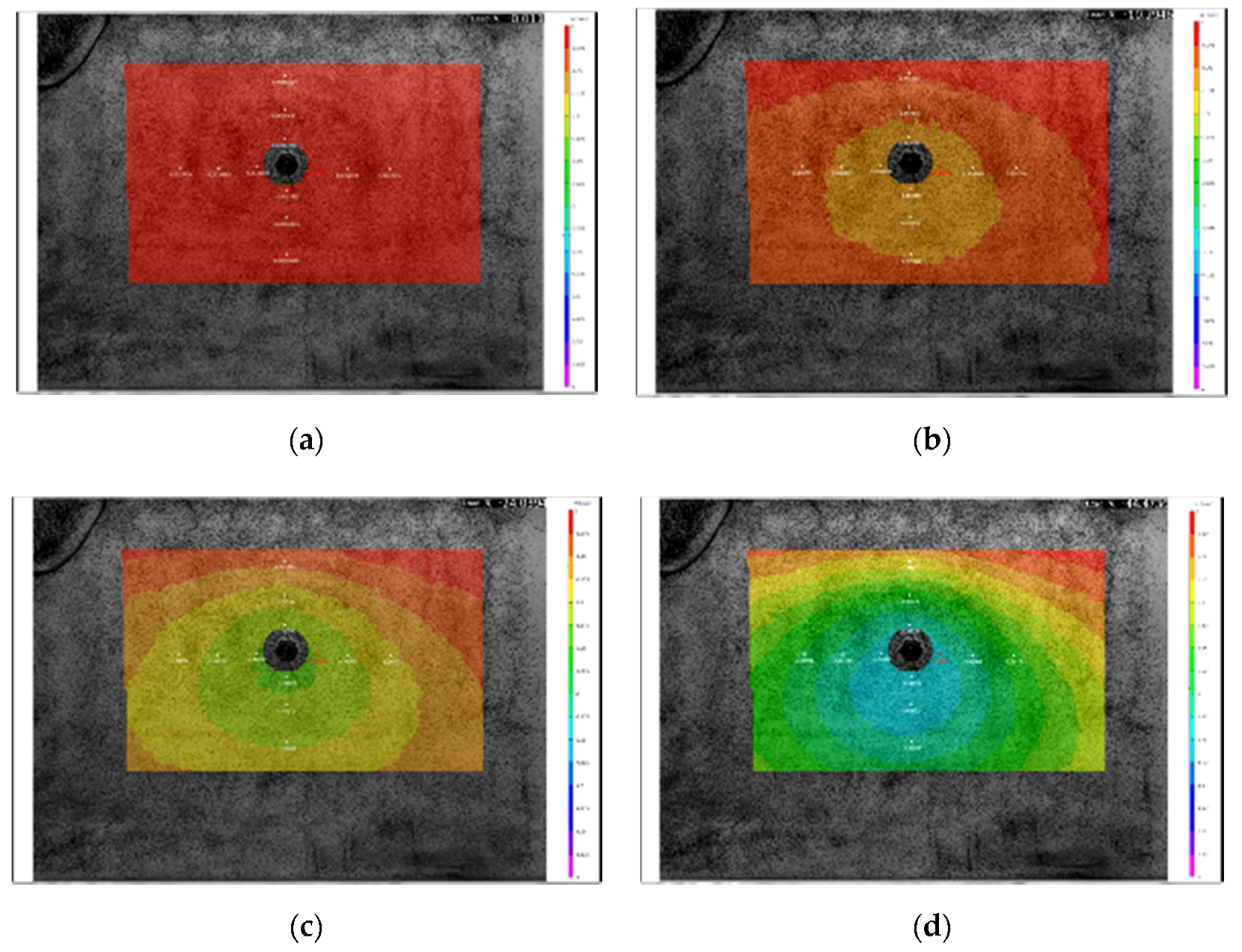

3.2. Experimental Research of a Classical Metal Structure

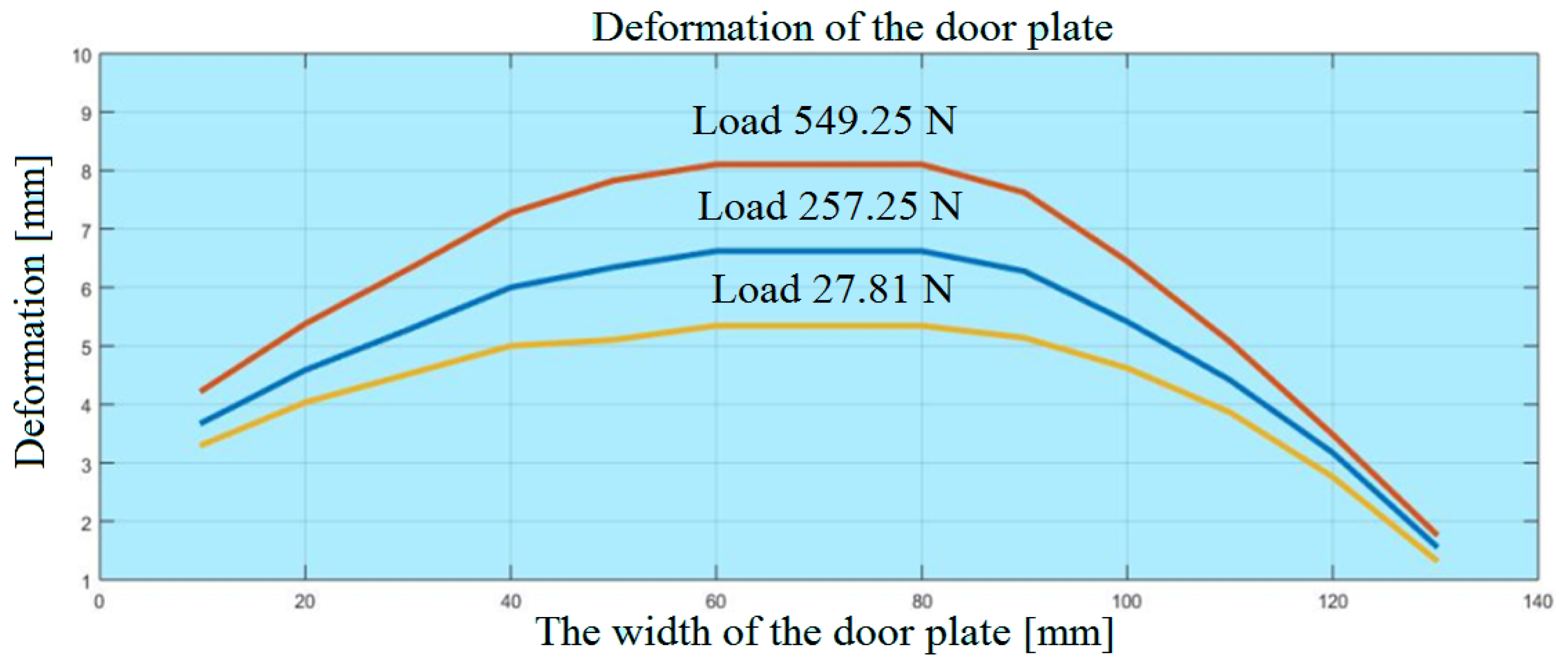

3.3. Experimental Research of a Structure Made of Composite Materials

4. Discussions Comparative Evaluation of Solution

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hagnell, M.; Kumaraswamy, S.; Nyman, T.; Åkermo, M. From aviation to automotive—A study on material selection and its implication on cost and weight efficient structural composite and sandwich designs. Heliyon 2020, 6, e03716. [Google Scholar] [CrossRef] [PubMed]

- Stylios, G.K. Novel Smart Textiles. Materials 2020, 13, 950. [Google Scholar] [CrossRef] [PubMed]

- Irez, A.B.; Bayraktar, E.; Miskioglu, I. Fracture Toughness Analysis of Epoxy-Recycled Rubber-Based Composite Reinforced with Graphene Nanoplatelets for Structural Applications in Automotive and Aeronautics. Polymers 2020, 12, 448. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Sudhakara, P.; Misra, S.; Singh, J. A comprehensive review of current developments on the waste-reinforced polymer-matrix composites for automotive, sports goods and construction applications: Materials, processes and properties. Mater. Today Proc. 2020, 33, 1671–1679. [Google Scholar] [CrossRef]

- Alhijazi, M.; Zeeshan, Q.; Qin, Z.; Safaei, B.; Asmael, M. Finite element analysis of natural fibers composites: A review. Nanotechnol. Rev. 2020, 9, 853–875. [Google Scholar] [CrossRef]

- Müller, U.; Jost, T.; Kurzböck, C.; Stadlmann, A.; Wagner, W.; Kirschbichler, S.; Baumann, G.; Pramreiter, M.; Feist, F. Crash simulation of wood and composite wood for future automotive engineering. Wood Mater. Sci. Eng. 2019, 15, 312–324. [Google Scholar] [CrossRef]

- Lixandrão, K.C.D.L.; Ferreira, F.F. Polypropylene and tire powder composite for use in automotive industry. Heliyon 2019, 5, e02405. [Google Scholar] [CrossRef]

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Duan, S.Y.; Han, X.; Liu, G.R. Structural Optimization and Reliability Analysis of Automotive Composite Bumper Against Low-Velocity Longitudinal and Corner Pendulum Impacts. Int. J. Comput. Methods 2019, 16. [Google Scholar] [CrossRef]

- Nunna, S.; Blanchard, P.; Buckmaster, D.; Davis, S.; Naebe, M. Development of a cost model for the production of carbon fibres. Heliyon 2019, 5, e02698. [Google Scholar] [CrossRef] [PubMed]

- Khodadadian, A.; Parvizi, M.; Abbaszadeh, M.; Dehghan, M.; Heitzinger, C. A multilevel Monte Carlo finite element method for the stochastic Cahn–Hilliard–Cook equation. Comput. Mech. 2019, 64, 937–949. [Google Scholar] [CrossRef] [PubMed]

- Katouzian, M.; Vlase, S.; Calin, R. Experimental procedures to determine the viscoelastic parameters of laminated composites. J. Optoelectron. Adv. Mater. 2011, 13, 1185–1188. [Google Scholar]

- Sadeghpour, E.; Guo, Y.; Chua, D.; Shim, V.P. A modified Mori–Tanaka approach incorporating filler-matrix interface failure to model graphene/polymer nanocomposites. Int. J. Mech. Sci. 2020, 180, 105699. [Google Scholar] [CrossRef]

- Song, Z.; Peng, X.; Tang, S.; Fu, T. A homogenization scheme for elastoplastic composites using concept of Mori-Tanaka method and average deformation power rate density. Int. J. Plast. 2020, 128, 102652. [Google Scholar] [CrossRef]

- Marin, M.; Vlase, S.; Paun, M. Considerations on double porosity structure for micropolar bodies. AIP Adv. 2015, 5, 037113. [Google Scholar] [CrossRef]

- Teodorescu-Draghicescu, H.; Stanciu, A.; Vlase, S.; Scutaru, L.; Calin, M.R.; Serbina, L. Finite Element Method Analysis of Some Fibre-Reinforced Composite Laminates. Optoelectron. Adv. Mater. Rapid Commun. 2011, 5, 782–785. [Google Scholar]

- Teodorescu-Draghicescu, H.; Vlase, S.; Stanciu, M.D.; Curtu, I.; Mihalcica, M. Advanced Pultruded Glass Fibers-Reinforced Isophtalic Polyester Resin. Mater. Plast. 2015, 52, 62–64. [Google Scholar]

- Vlase, S.; Scutaru, L.; Serbina, L.; Calin, M.R. Hysteresis effect in a three-phase polymer matrix composite subjected to static cyclic loadings. Optoelectron. Adv. Mater Rapid Commun. 2011, 5, 273–277. [Google Scholar]

- ISO 178: Plastics—Determination of Flexural Properties. Available online: www.iso.org/standard/70513 (accessed on 26 December 2020).

- ASTM D790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. Available online: www.astm.org/Standards/D790 (accessed on 26 December 2020).

- ASTM D7264: Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. Available online: www.astm.org/Standards/D7264 (accessed on 26 December 2020).

- ASTM C1161: Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature. Available online: www.astm.org/Standards/C1161 (accessed on 26 December 2020).

- ASTM D6272: Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending. Available online: www.astm.org/Standards/D6272 (accessed on 26 December 2020).

- ASTM C393: Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure. Available online: www.astm.org/Standards/C393 (accessed on 26 December 2020).

- ASTM D7249: Standard Test Method for Facing Properties of Sandwich Constructions by Long Beam Flexure. Available online: www.astm.org/Standards/D7249 (accessed on 26 December 2020).

- ASTM D7250: Standard Practice for Determining Sandwich Beam Flexural and Shear Stiffness. Available online: www.astm.org/Standards/D7250 (accessed on 26 December 2020).

| Material | Type of Structure | Test Temperature | Bending Load at Break | |

|---|---|---|---|---|

| °C | σ [MPa] | |||

| Min | Max | |||

| Fiberglass | Fiber fabric | at 20 °C | 22.23 | 38.90 |

| Fabric + coremat | at 20 °C | 5.85 | 8.81 | |

| Mat layer | at 20 °C | 22.15 | 23.69 | |

| at 50 °C | 16.41 | 17.15 | ||

| at 65 °C | 1.49 | 2.31 | ||

| at 20 °C after heating to 100 °C | 19.51 | 22.25 | ||

| Carbon fiber | at 20 °C | 52.95 | 77.87 | |

| Compression | Traction | |||

|---|---|---|---|---|

| Force [N] | Deformation [mm] | Force [N] | Deformation [mm] | |

| Metal door | 549.24 | 3.13 | 240.89 | 5.93 |

| Composite door | 70.71 | 3.24 | 3.24 | 4.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gheorghe, V.; Scutaru, M.L.; Ungureanu, V.B.; Chircan, E.; Ulea, M. New Design of Composite Structures Used in Automotive Engineering. Symmetry 2021, 13, 383. https://doi.org/10.3390/sym13030383

Gheorghe V, Scutaru ML, Ungureanu VB, Chircan E, Ulea M. New Design of Composite Structures Used in Automotive Engineering. Symmetry. 2021; 13(3):383. https://doi.org/10.3390/sym13030383

Chicago/Turabian StyleGheorghe, Vasile, Maria Luminita Scutaru, Virgil Barbu Ungureanu, Eliza Chircan, and Mihai Ulea. 2021. "New Design of Composite Structures Used in Automotive Engineering" Symmetry 13, no. 3: 383. https://doi.org/10.3390/sym13030383

APA StyleGheorghe, V., Scutaru, M. L., Ungureanu, V. B., Chircan, E., & Ulea, M. (2021). New Design of Composite Structures Used in Automotive Engineering. Symmetry, 13(3), 383. https://doi.org/10.3390/sym13030383