Experimental Study on Heating Performances of Integrated Battery and HVAC System with Serial and Parallel Circuits for Electric Vehicle

Abstract

1. Introduction

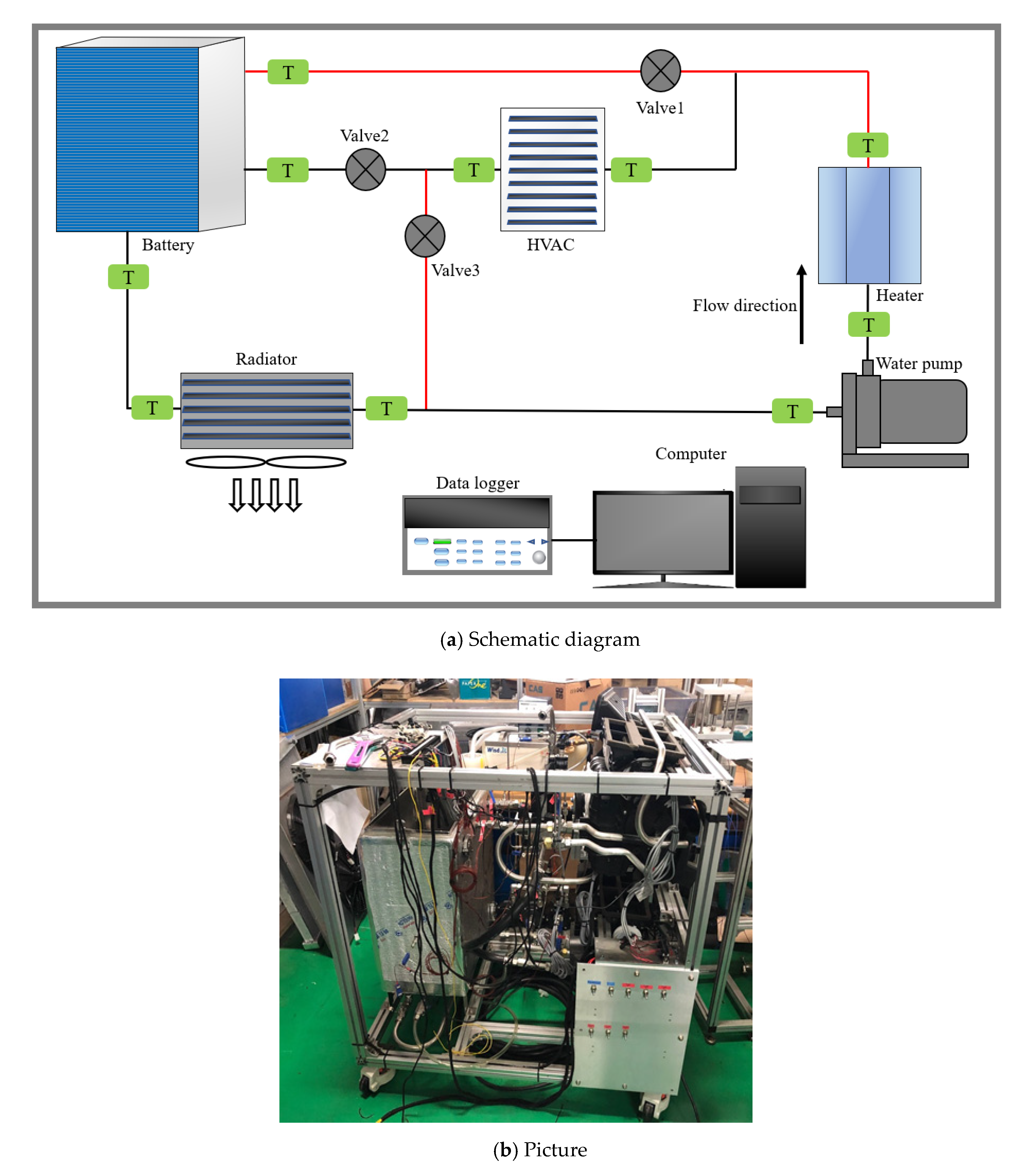

2. Experimental Method

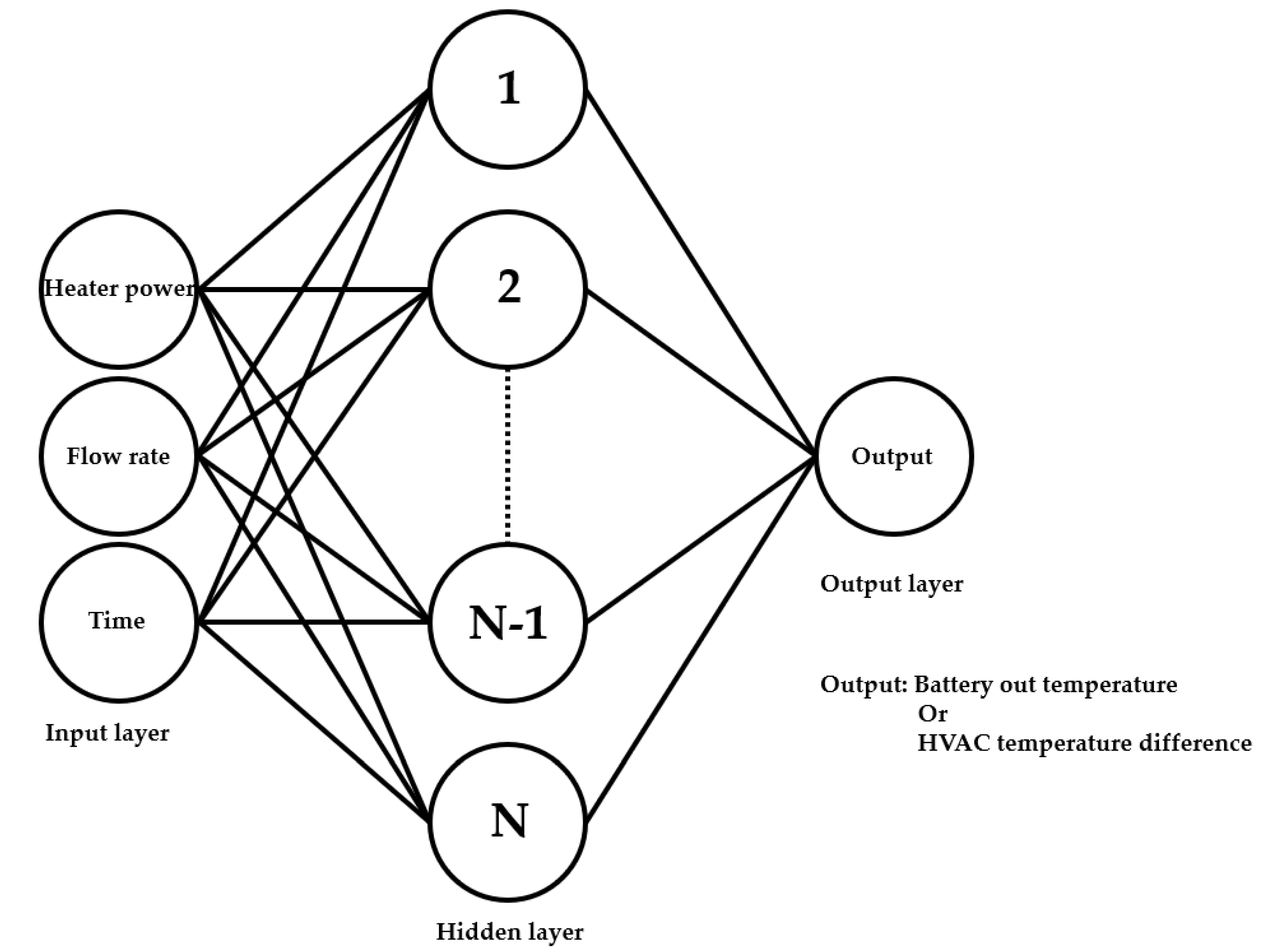

3. Artificial Neural Network (ANN)

4. Data Reduction

5. Results and Discussion

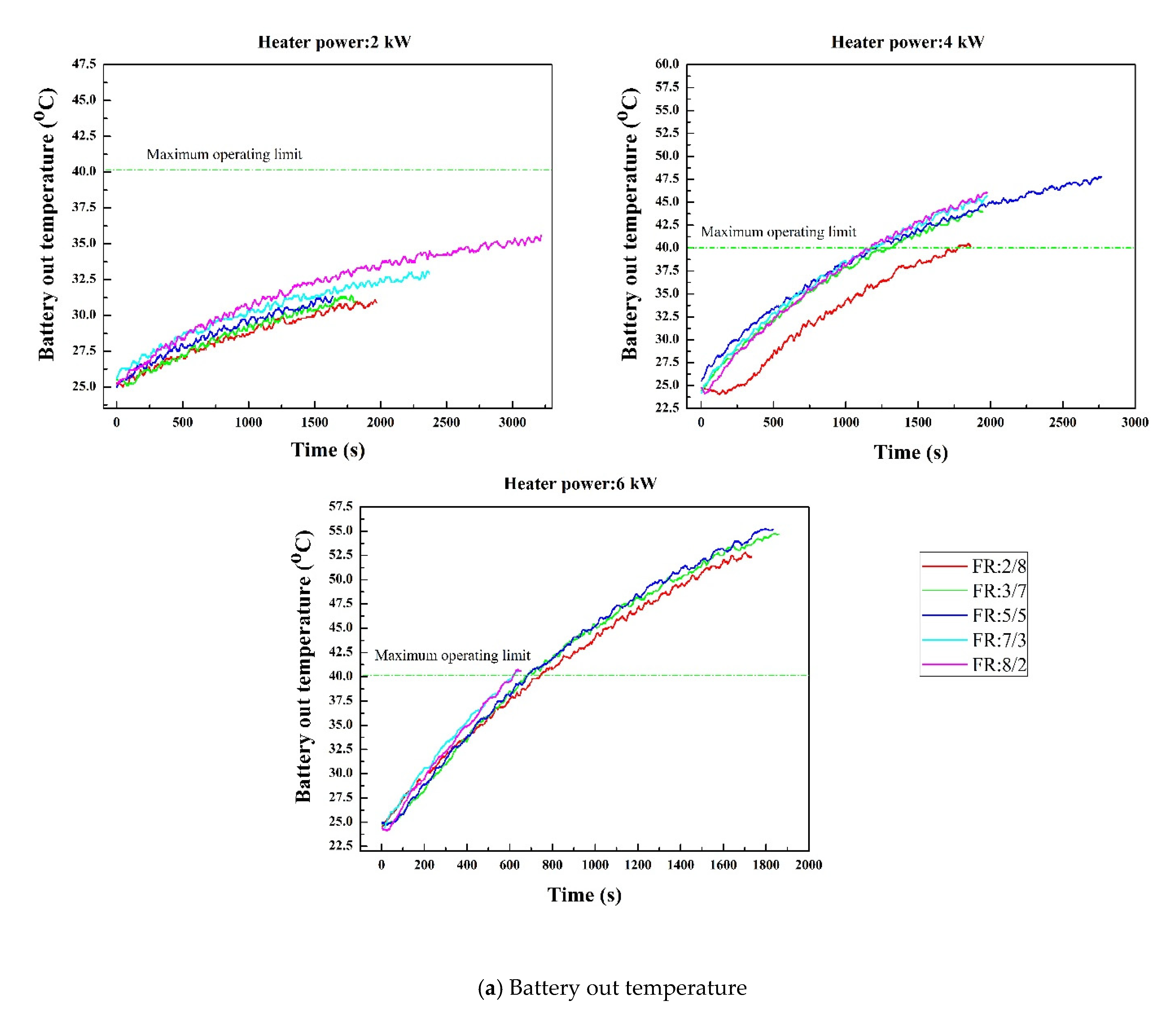

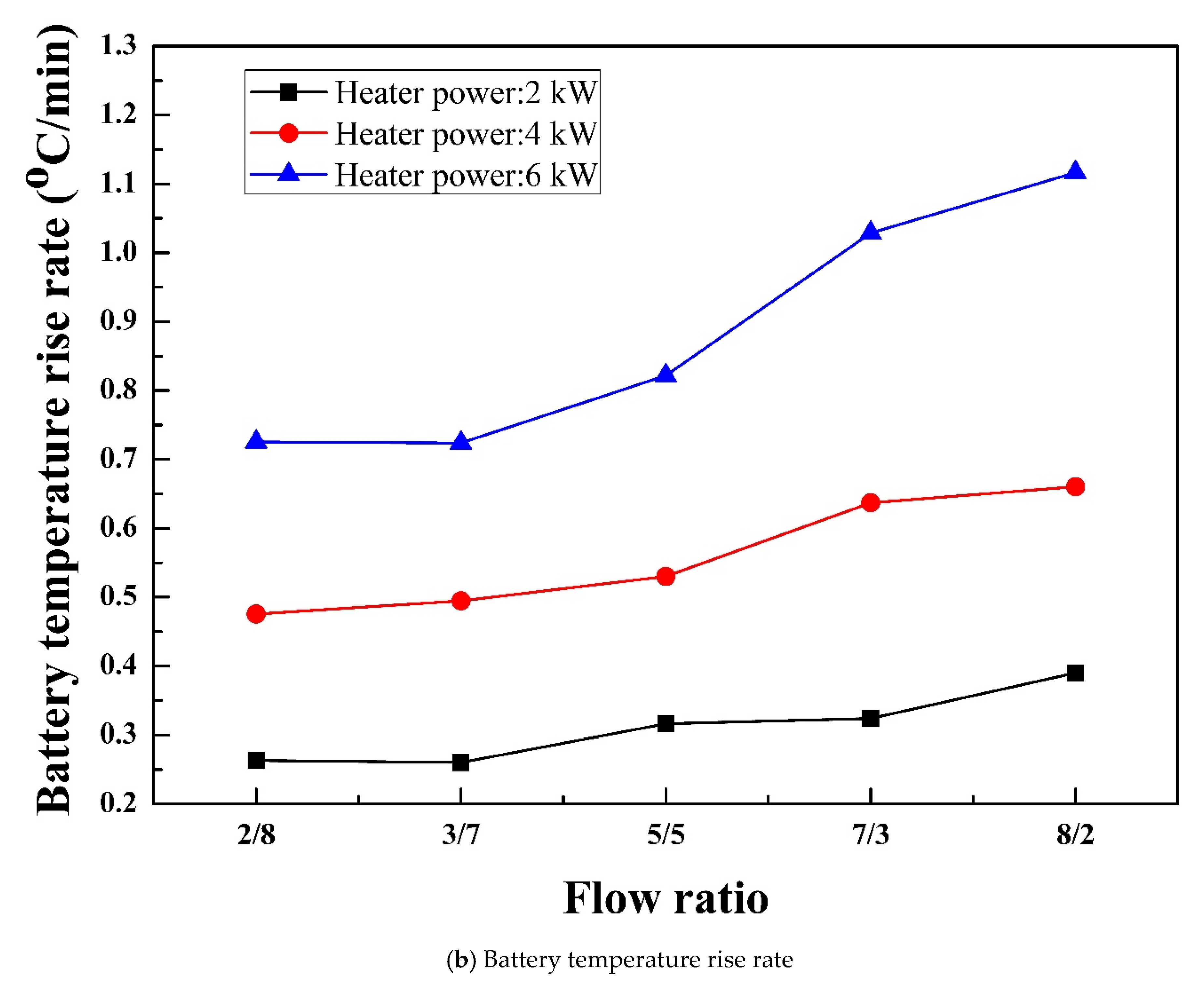

5.1. Heating Performances of Battery and HVAC for Integrated System with Parallel Circuit

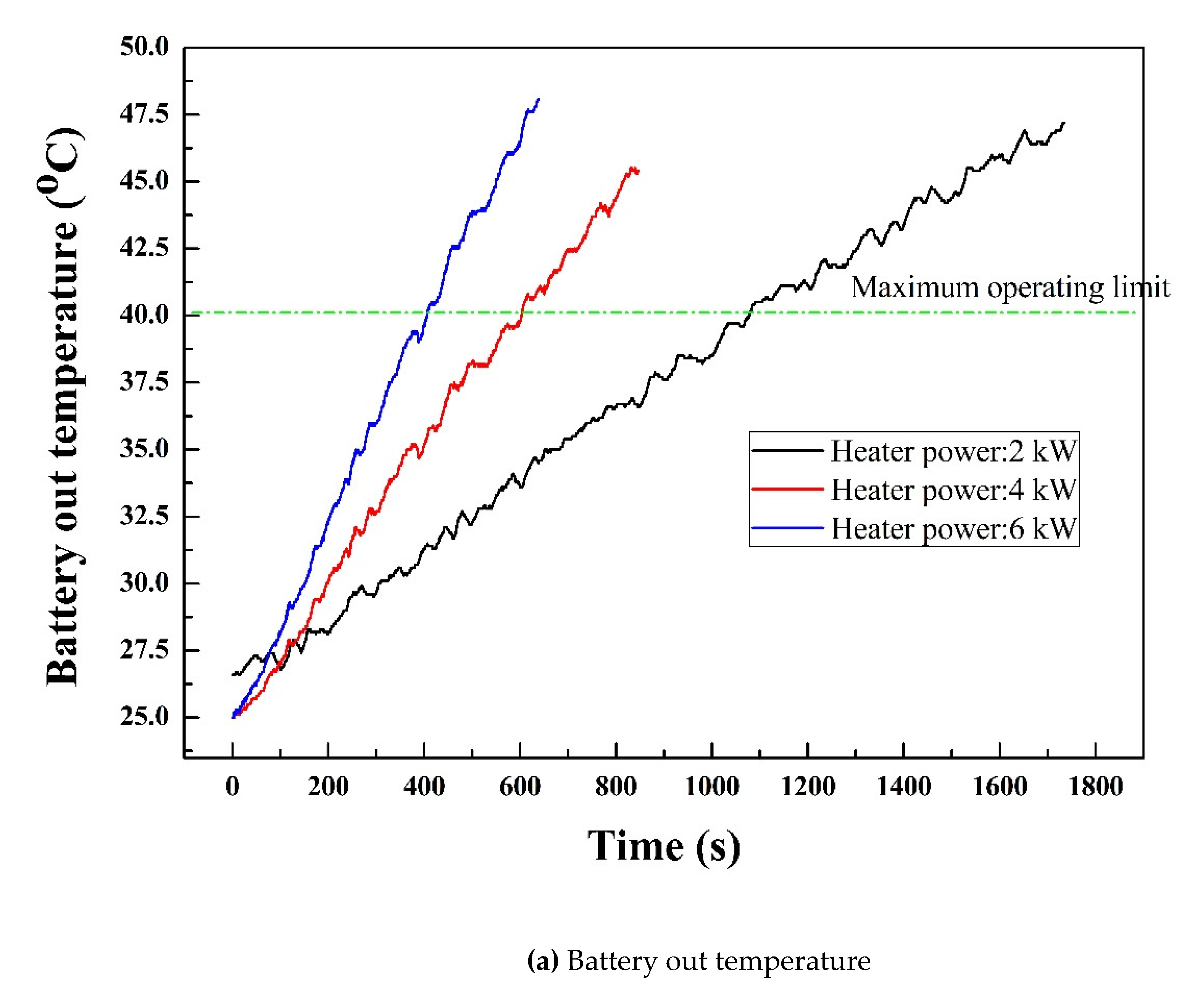

5.1.1. Battery out Temperature and Battery Temperature Rise Rate

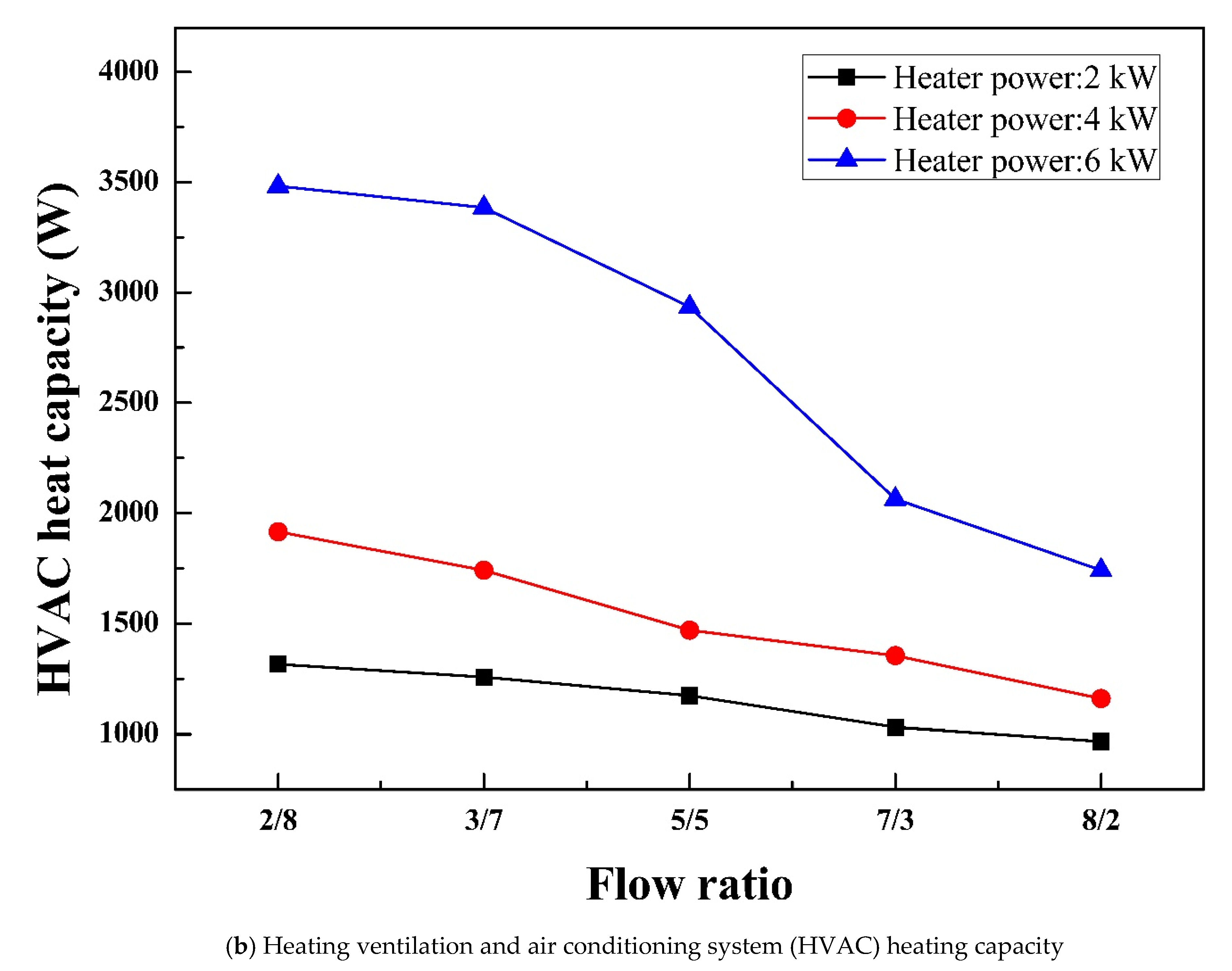

5.1.2. Battery and HVAC Heating Capacities

5.2. Heating Performances of Battery and HVAC for Integrated System with Serial Circuit

5.2.1. Battery out Temperature and Battery Temperature Rise Rate

5.2.2. Battery and HVAC Heating Capacities

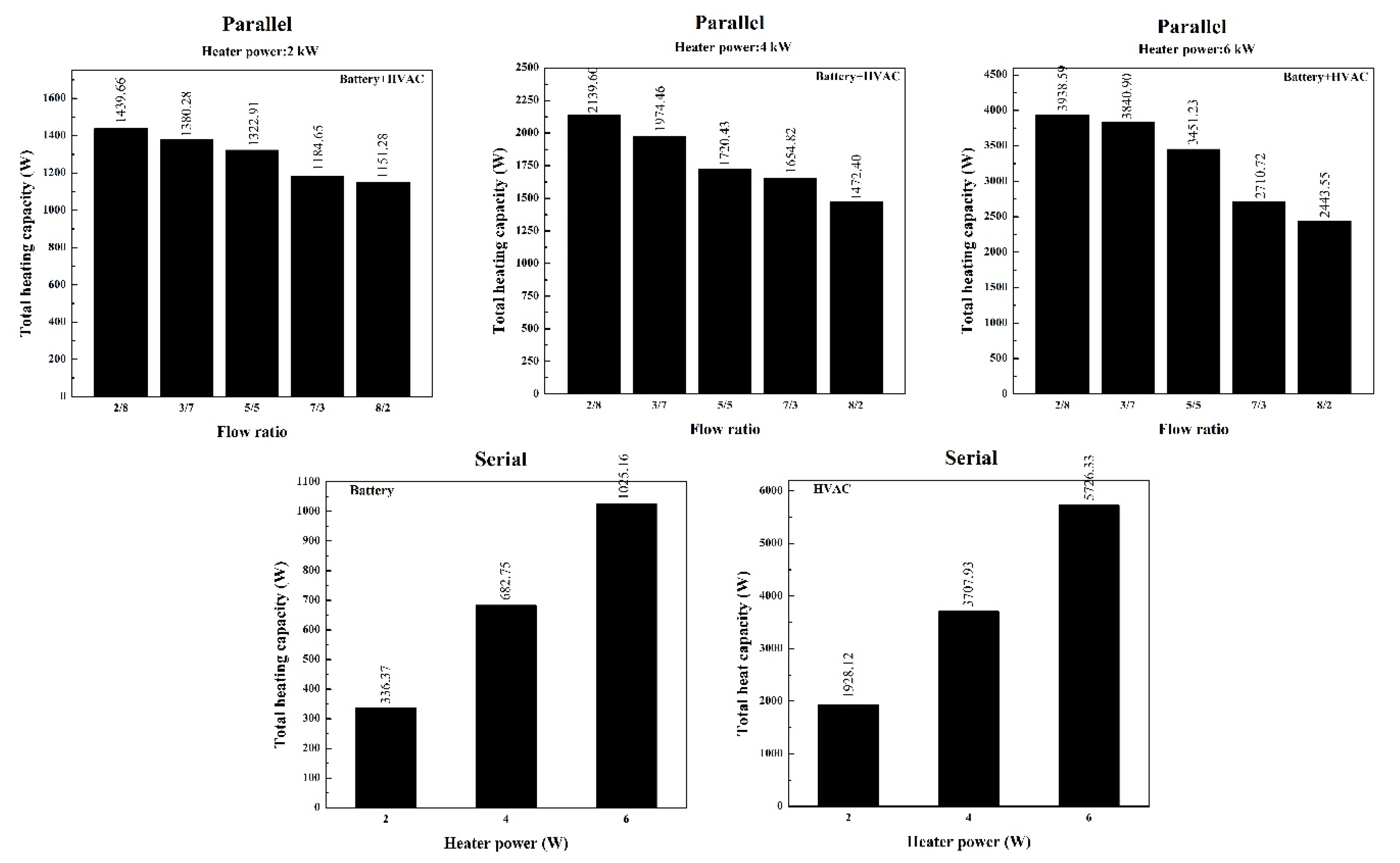

5.3. Total Heating Capacity of Integrated System with Serial and Parallel Circuits

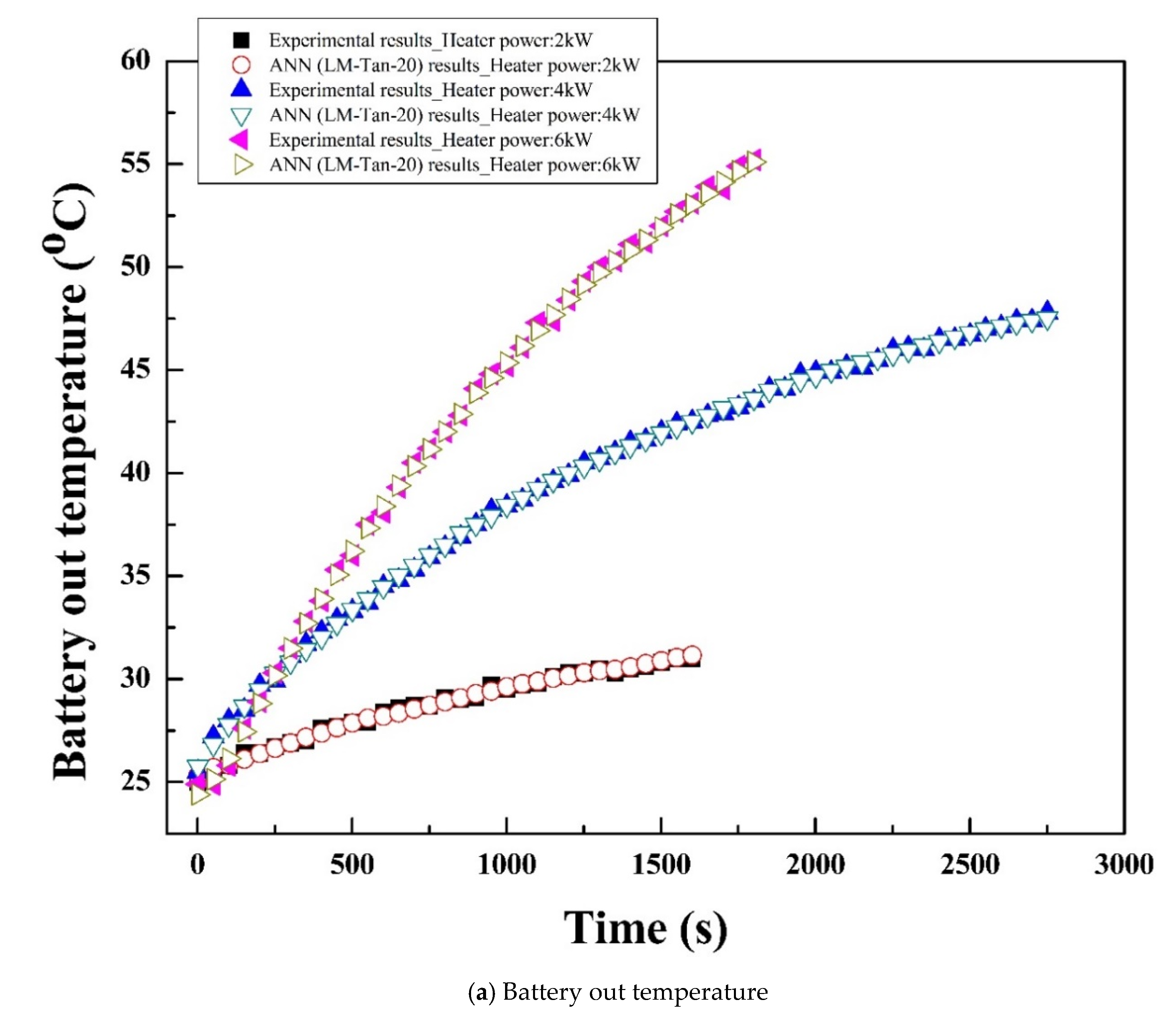

5.4. ANN Model for Battery and HVAC Heating Performances

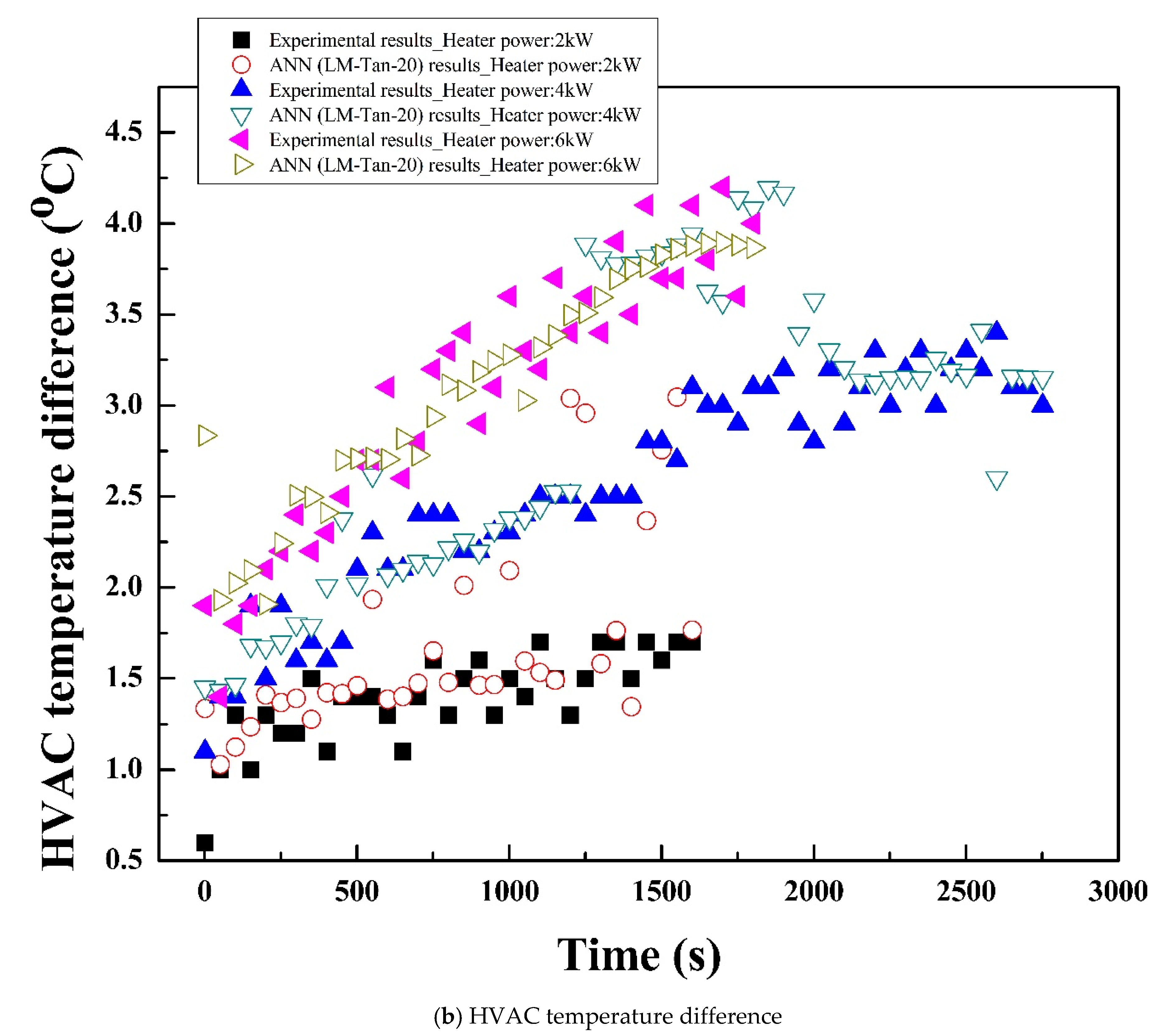

5.4.1. Integrated System with Parallel Circuit

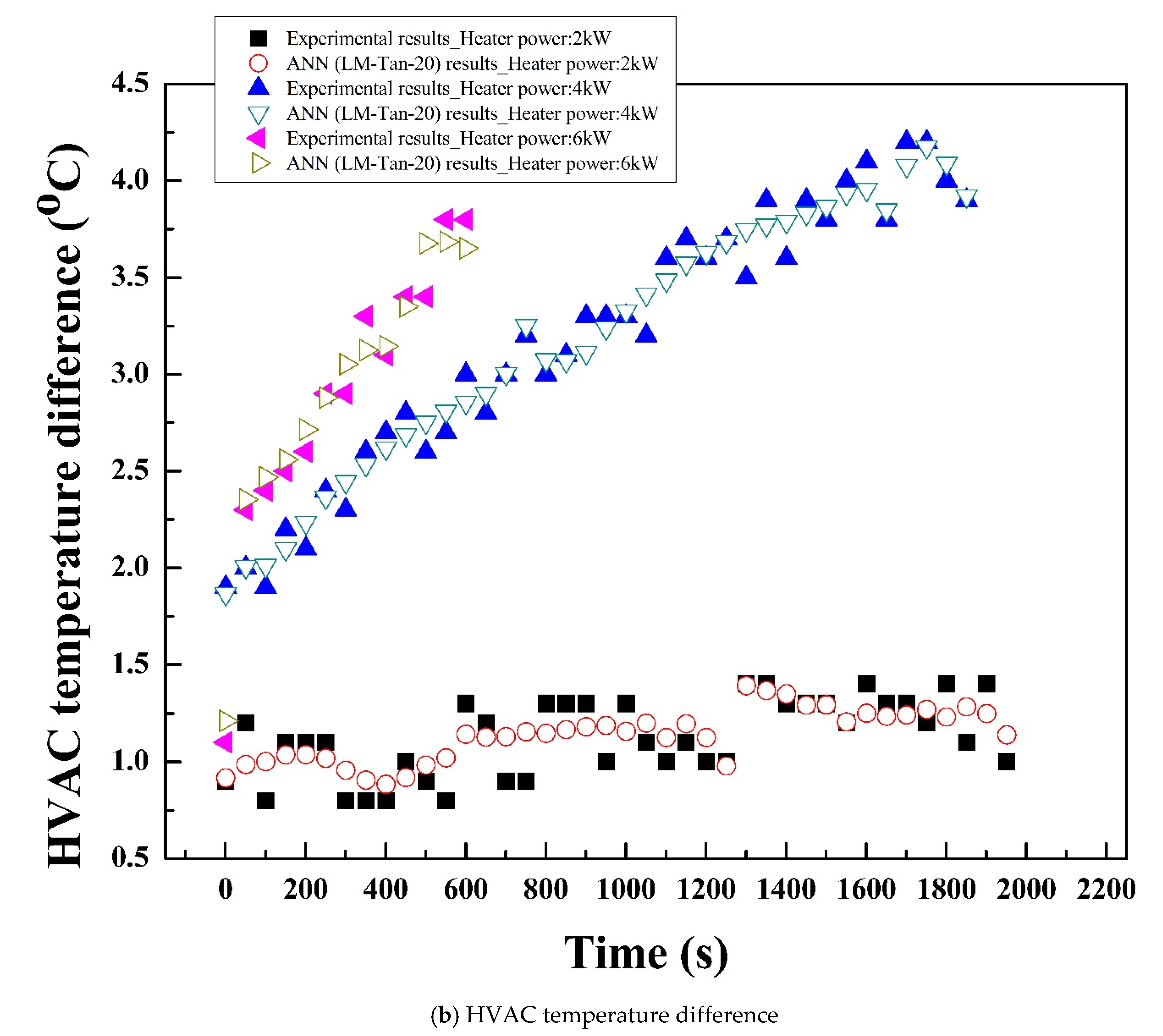

5.4.2. Integrated System with Serial Circuit

6. Conclusions

- (a)

- The effect of heater power on heating performances of the integrated system with serial and parallel circuits and effect of flow ratio on heating performances of the integrated system with parallel circuit are analyzed. As the heater power increases, the heating performances increases for the integrated system with serial and parallel circuits. With an increase in the flow ratio to the battery, battery heating performance enhances, whereas HVAC heating performance decreases.

- (b)

- In the case of integrated system with parallel circuit, battery out temperature reaches 40 °C within 20 min at the rate of 1.22 °C/min. Battery heating capacity is evaluated as 764.99 W and HVAC heating capacity is evaluated as 3869.15 W.

- (c)

- The battery out temperature reaches to 40 °C within 10 min at the rate of 2.17 °C/min for the integrated system with serial circuit. The battery and HVAC heating capacities for the integrated system with serial circuit are evaluated as 1025.16 W and 5726.33 W, respectively.

- (d)

- The integrated system with serial circuit enables faster heating performance than the integrated system with parallel circuit for both battery and HVAC. However, the integrated system with parallel circuit enables the tradeoff heating between battery and HVAC at the desired level with the slower rate.

- (e)

- The battery and HVAC heating performances of the integrated system with serial and parallel circuits are accurately predicted using the developed ANN models with back-propagation training algorithm, Levenberg-Marquardt training variant, Tan-sigmoidal transfer function and 20 hidden neurons.

- (f)

- The effects of various operating conditions on the heating performances of battery and HVAC using the proposed integrated system with serial and parallel circuits could be investigated and optimized, to find the optimum point for tradeoff heating of battery and HVAC under various conditions. The extracted results could be used in practical applications such as under cold weather conditions, the extracted optimum point for tradeoff heating of battery and HVAC could successfully achieve the efficient battery and HVAC heating performances of full size commercial electric vehicles with increased driving range and improved battery performance and life. The integrated system with serial circuit could be used for applications where rapid heating of battery or HVAC is needed, whereas the integrated system with parallel circuit could be used for applications where tradeoff simultaneous heating of battery and HVAC is needed. Thus, the proposed integrated system with serial and parallel circuits has the practical applicability to enable rapid, as well as tradeoff heating for both battery and HVAC in electric vehicles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, S.; Xiong, R.; Li, H.; Nian, V.; Ma, S. The state of the art on preheating lithium-ion batteries in cold weather. J. Energy Storage 2020, 27, 101059. [Google Scholar]

- Kang, B.H.; Lee, H.J. A review of recent research on automotive HVAC systems for EVs. Int. J. Air-Cond. Refrig. 2017, 25, 1730003. [Google Scholar]

- Lei, Z.; Zhang, Y.; Lei, X. Temperature uniformity of a heated lithium-ion battery cell in cold climate. Appl. Therm. Eng. 2018, 129, 148–154. [Google Scholar]

- Guo, S.; Xiong, R.; Wang, K.; Sun, F. A novel echelon internal heating strategy of cold batteries for all-climate electric vehicles application. Appl. Energy 2018, 219, 256–263. [Google Scholar]

- Ruan, H.; Jiang, J.; Sun, B.; Su, X.; He, X.; Zhao, K. An optimal internal-heating strategy for lithium-ion batteries at low temperature considering both heating time and lifetime reduction. Appl. Energy 2019, 256, 113797. [Google Scholar]

- Lei, Z.; Zhang, Y.; Lei, X. Improving temperature uniformity of a lithium-ion battery by intermittent heating method in cold climate. Int. J. Heat Mass Transf. 2018, 121, 275–281. [Google Scholar]

- Shang, Y.; Zhu, C.; Lu, G.; Zhang, Q.; Cui, N.; Zhang, C. Modeling and analysis of high-frequency alternating-current heating for lithium-ion batteries under low-temperature operations. J. Power Sources 2020, 450, 227435. [Google Scholar]

- Fan, R.; Zhang, C.; Wang, Y.; Ji, C.; Meng, Z.; Xu, L.; Chin, C.S. Numerical study on the effects of battery heating in cold climate. J. Energy Storage 2019, 26, 100969. [Google Scholar]

- Reyes, J.R.M.D.; Parsons, R.V.; Hoemsen, R. Winter happens: The effect of ambient temperature on the travel range of electric vehicles. IEEE Trans. Veh. Technol. 2016, 65, 4016–4022. [Google Scholar]

- Qi, Z. Advances on air conditioning and heat pump system in electric vehicles–A review. Renew. Sust. Energ. Rev. 2014, 38, 754–764. [Google Scholar]

- Zhang, Z.; Li, W.; Shi, J.; Chen, J. A study on electric vehicle heat pump systems in cold climates. Energies 2016, 9, 881. [Google Scholar]

- Cho, C.W.; Lee, H.S.; Won, J.P.; Lee, M.Y. Measurement and evaluation of heating performance of heat pump systems using wasted heat from electric devices for an electric bus. Energies 2012, 5, 658–669. [Google Scholar]

- Qin, F.; Zhang, G.; Xue, Q.; Zou, H.; Tian, C. Experimental investigation and theoretical analysis of heat pump systems with two different injection portholes compressors for electric vehicles. Appl. Energy 2017, 185, 2085–2093. [Google Scholar]

- Qin, F.; Xue, Q.; Zhang, G.; Zou, H.; Tian, C. Experimental investigation on heat pump for electric vehicles with different refrigerant injection compressors. Energy Procedia 2015, 75, 1490–1495. [Google Scholar]

- Qin, F.; Xue, Q.; Velez, G.M.A.; Zhang, G.; Zou, H.; Tian, C. Experimental investigation on heating performance of heat pump for electric vehicles at− 20 C ambient temperature. Energy Convers. Manag. 2015, 102, 39–49. [Google Scholar]

- Ahn, J.H.; Kang, H.; Lee, H.S.; Jung, H.W.; Baek, C.; Kim, Y. Heating performance characteristics of a dual source heat pump using air and waste heat in electric vehicles. Appl. Energy 2014, 119, 1–9. [Google Scholar]

- Lee, H.S.; Won, J.P.; Cho, C.W.; Kim, Y.C.; Lee, M.Y. Heating performance characteristics of stack coolant source heat pump using R744 for fuel cell electric vehicles. J. Mech. Sci. Technol. 2012, 26, 2065–2071. [Google Scholar]

- Shi, Y.; Guo, X.; Zhang, X. Study on economized vapor injection heat pump system using refrigerant R32. Int. J. Air-Cond. Refrig. 2016, 24, 1650006. [Google Scholar]

- Jung, J.; Jeon, Y.; Lee, H.; Kim, Y. Numerical study of the effects of injection-port design on the heating performance of an R134a heat pump with vapor injection used in electric vehicles. Appl. Therm. Eng. 2017, 127, 800–811. [Google Scholar]

- Patil, M.S.; Cho, C.P.; Lee, M.Y. Numerical study on thermal performances of 2.0 kW burner for the cabin heater of an electric passenger vehicle. Appl. Therm. Eng. 2018, 138, 819–831. [Google Scholar]

- Zhang, L.; Hashimoto, K.; Hasegawa, H.; Saikawa, M. Performance analysis of a heat pump system with integrated desiccant for electric vehicles. Int. J. Refrig. 2018, 86, 154–162. [Google Scholar] [CrossRef]

- Choi, Y.U.; Kim, M.S.; Kim, G.T.; Kim, M.; Kim, M.S. Performance analysis of vapor injection heat pump system for electric vehicle in cold startup condition. Int. J. Refrig. 2017, 80, 24–36. [Google Scholar] [CrossRef]

- Kwon, C.; Kim, M.S.; Choi, Y.; Kim, M.S. Performance evaluation of a vapor injection heat pump system for electric vehicles. Int. J. Refrig. 2017, 74, 138–150. [Google Scholar] [CrossRef]

- Ahn, J.H.; Kang, H.; Lee, H.S.; Kim, Y. Performance characteristics of a dual-evaporator heat pump system for effective dehumidifying and heating of a cabin in electric vehicles. Appl. Energy 2015, 146, 29–37. [Google Scholar] [CrossRef]

- Lee, D.Y.; Cho, C.W.; Won, J.P.; Park, Y.C.; Lee, M.Y. Performance characteristics of mobile heat pump for a large passenger electric vehicle. Appl. Therm. Eng. 2013, 50, 660–669. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Gao, T.; Shi, J.; Chen, J.; Wang, T.; Pan, L. Performance evaluation of propane heat pump system for electric vehicle in cold climate. Int. J. Refrig. 2018, 95, 51–60. [Google Scholar] [CrossRef]

- Li, W.; Liu, R.; Liu, Y.; Wang, D.; Shi, J.; Chen, J. Performance evaluation of R1234yf heat pump system for an electric vehicle in cold climate. Int. J. Refrig. 2020, 115, 117–125. [Google Scholar] [CrossRef]

- Bellocchi, S.; Guizzi, G.L.; Manno, M.; Salvatori, M.; Zaccagnini, A. Reversible heat pump HVAC system with regenerative heat exchanger for electric vehicles: Analysis of its impact on driving range. Appl. Therm. Eng. 2018, 129, 290–305. [Google Scholar] [CrossRef]

- Lee, H.S.; Lee, M.Y. Steady state and start-up performance characteristics of air source heat pump for cabin heating in an electric passenger vehicle. Int. J. Refrig. 2016, 69, 232–242. [Google Scholar] [CrossRef]

- Lee, M.Y.; Garud, K.S.; Jeon, H.B.; Lee, H.S. A Study on Performance Characteristics of a Heat Pump System with High-Pressure Side Chiller for Light-Duty Commercial Electric Vehicles. Symmetry 2020, 12, 1237. [Google Scholar] [CrossRef]

- Jeffs, J.; McGordon, A.; Picarelli, A.; Robinson, S.; Tripathy, Y.; Widanage, W.D. Complex heat pump operational mode identification and comparison for use in electric vehicles. Energies 2018, 11, 2000. [Google Scholar] [CrossRef]

- Jeffs, J.; Dinh, T.Q.; Widanage, W.D.; McGordon, A.; Picarelli, A. Optimisation of Direct Battery Thermal Management for EVs Operating in Low-Temperature Climates. Energies 2020, 13, 5980. [Google Scholar] [CrossRef]

- Arun, K.R.; Kunal, G.; Srinivas, M.; Kumar, C.S.; Mohanraj, M.; Jayaraj, S. Drying of untreated Musa nendra and Momordica charantia in a forced convection solar cabinet dryer with thermal storage. Energy 2020, 192, 116697. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.H.; Patil, M.S.; Bang, Y.M.; Pyo, Y.D.; Cho, C.P.; Lee, M.Y. Thermal–electrical–structural performances of hot heat exchanger with different internal fins of thermoelectric generator for low power generation application. J. Therm. Anal. Calorim. 2020, 1–33. [Google Scholar] [CrossRef]

- Seo, J.H.; Garud, K.S.; Lee, M.Y. Grey Relational Based Taguchi Analysis on Thermal and Electrical Performances of Thermoelectric Generator System with Inclined Fins Hot Heat Exchanger. Appl. Therm. Eng. 2020, 116279. [Google Scholar] [CrossRef]

- Raj, A.K.; Kunal, G.; Srinivas, M.; Jayaraj, S. Performance analysis of a double-pass solar air heater system with asymmetric channel flow passages. J. Therm. Anal. Calorim. 2019, 136, 21–38. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A.; Zavadskas, E.K.; Antucheviciene, J.; Bausys, R. A model for shovel capital cost estimation, using a hybrid model of multivariate regression and neural networks. Symmetry 2017, 9, 298. [Google Scholar] [CrossRef]

- Garud, K.S.; Jayaraj, S.; Lee, M.Y. A review on modeling of solar photovoltaic systems using artificial neural networks, fuzzy logic, genetic algorithm and hybrid models. Int. J. Energy Res. 2020, 45, 6–35. [Google Scholar] [CrossRef]

- Mohanraj, M.; Jayaraj, S.; Muraleedharan, C. Performance prediction of a direct expansion solar assisted heat pump using artificial neural networks. Appl. Energy 2009, 86, 1442–1449. [Google Scholar] [CrossRef]

- Islam, K.T.; Raj, R.G.; Mujtaba, G. Recognition of traffic sign based on bag-of-words and artificial neural network. Symmetry 2017, 9, 138. [Google Scholar] [CrossRef]

- Moya-Rico, J.D.; Molina, A.E.; Belmonte, J.F.; Tendero, J.C.; Almendros-Ibanez, J.A. Characterization of a triple concentric-tube heat exchanger with corrugated tubes using Artificial Neural Networks (ANN). Appl. Therm. Eng. 2019, 147, 1036–1046. [Google Scholar] [CrossRef]

- Şahin, A.Ş. Performance analysis of single-stage refrigeration system with internal heat exchanger using neural network and neuro-fuzzy. Renew. Energy 2011, 36, 2747–2752. [Google Scholar] [CrossRef]

- Garud, K.S.; Seo, J.H.; Cho, C.P.; Lee, M.Y. Artificial Neural Network and Adaptive Neuro-Fuzzy Interface System Modelling to Predict Thermal Performances of Thermoelectric Generator for Waste Heat Recovery. Symmetry 2020, 12, 259. [Google Scholar] [CrossRef]

- Min, H.; Zhang, Z.; Sun, W.; Min, Z.; Yu, Y.; Wang, B. A thermal management system control strategy for electric vehicles under low-temperature driving conditions considering battery lifetime. Appl. Therm. Eng. 2020, 181, 115944. [Google Scholar] [CrossRef]

- Seo, J.H.; Patil, M.S.; Cho, C.P.; Lee, M.Y. Heat transfer characteristics of the integrated heating system for cabin and battery of an electric vehicle under cold weather conditions. Int. J. Heat Mass Transf. 2018, 117, 80–94. [Google Scholar] [CrossRef]

| Component | Specification |

|---|---|

| Pipe | Material: stainless |

| Heater | Type: sheath |

| Water pump | Max flow: 25 L/min Max head: 25 m Power voltage: 24 VCD |

| Radiator | Applied vehicle: GM Volt Core size: 147 206 28 mm |

| HVAC | Applied vehicle: Kona Core size: 152 222 26 mm |

| Heater | 510 V, 11.8 A |

| Device/Instrument | Accuracy |

|---|---|

| T-type thermocouple | 0.75% |

| DAQ | −200 °C ≤ TS ≤ −100 °C, ± (0.10% of reading) −100 °C ≤ TS ≤ 400 °C, ± (0.10% of reading) |

| Flow rate sensor | ±1.50% |

| Heater Power | Algorithm | Number of Hidden Neurons | R2 | RMSE | COV | |

|---|---|---|---|---|---|---|

| Battery heating performance | 2 kW | LM-Tan | 10 | 0.999964 | 0.172015 | 0.598317 |

| 15 | 0.999965 | 0.170036 | 0.591433 | |||

| 20 | 0.999971 | 0.154166 | 0.536230 | |||

| LM-Log | 10 | 0.999962 | 0.176631 | 0.614369 | ||

| 15 | 0.999965 | 0.170120 | 0.591725 | |||

| 20 | 0.999968 | 0.163048 | 0.567126 | |||

| 4 kW | LM-Tan | 10 | 0.999976 | 0.197036 | 0.494352 | |

| 15 | 0.999978 | 0.189969 | 0.476623 | |||

| 20 | 0.999979 | 0.183539 | 0.460489 | |||

| LM-Log | 10 | 0.999976 | 0.198585 | 0.498239 | ||

| 15 | 0.999976 | 0.196935 | 0.494101 | |||

| 20 | 0.999978 | 0.187425 | 0.470238 | |||

| 6 kW | LM-Tan | 10 | 0.999975 | 0.218650 | 0.514204 | |

| 15 | 0.999976 | 0.211399 | 0.497152 | |||

| 20 | 0.999979 | 0.201043 | 0.472796 | |||

| LM-Log | 10 | 0.999931 | 0.360343 | 0.847426 | ||

| 15 | 0.999976 | 0.212566 | 0.499896 | |||

| 20 | 0.999977 | 0.208056 | 0.489290 | |||

| HVAC heating performance | 2 kW | LM-Tan | 10 | 0.786929 | 0.657742 | 46.61972 |

| 15 | 0.798038 | 0.640366 | 45.38813 | |||

| 20 | 0.803624 | 0.631449 | 44.75612 | |||

| LM-Log | 10 | 0.785127 | 0.660519 | 46.81651 | ||

| 15 | 0.794651 | 0.645714 | 45.76716 | |||

| 20 | 0.799947 | 0.637332 | 45.17311 | |||

| 4 kW | LM-Tan | 10 | 0.955619 | 0.556058 | 21.54665 | |

| 15 | 0.956040 | 0.553408 | 21.44398 | |||

| 20 | 0.956737 | 0.549005 | 21.27336 | |||

| LM-Log | 10 | 0.954056 | 0.565763 | 21.92271 | ||

| 15 | 0.955687 | 0.555626 | 21.52991 | |||

| 20 | 0.956573 | 0.550047 | 21.31374 | |||

| 6 kW | LM-Tan | 10 | 0.993304 | 0.261362 | 8.409131 | |

| 15 | 0.993737 | 0.252775 | 8.132854 | |||

| 20 | 0.994077 | 0.245819 | 7.909049 | |||

| LM-Log | 10 | 0.991877 | 0.287864 | 9.291802 | ||

| 15 | 0.993562 | 0.256273 | 8.245384 | |||

| 20 | 0.993748 | 0.252538 | 8.125237 |

| Heater Power | Algorithm | Number of Hidden Neurons | R2 | RMSE | COV | |

|---|---|---|---|---|---|---|

| Battery heating performance | 2 kW | LM-Tan | 10 | 0.999963 | 0.227245 | 0.612664 |

| 15 | 0.999966 | 0.220835 | 0.595383 | |||

| 20 | 0.999970 | 0.205704 | 0.554591 | |||

| LM-Log | 10 | 0.999961 | 0.234787 | 0.632999 | ||

| 15 | 0.999964 | 0.226566 | 0.610835 | |||

| 20 | 0.999967 | 0.216158 | 0.582773 | |||

| 4 kW | LM-Tan | 10 | 0.999979 | 0.164997 | 0.463474 | |

| 15 | 0.999978 | 0.197546 | 0.470634 | |||

| 20 | 0.999980 | 0.170831 | 0.479862 | |||

| LM-Log | 10 | 0.999969 | 0.201567 | 0.566196 | ||

| 15 | 0.999978 | 0.170591 | 0.479186 | |||

| 20 | 0.999980 | 0.161314 | 0.453130 | |||

| 6 kW | LM-Tan | 10 | 0.999972 | 0.198939 | 0.542413 | |

| 15 | 0.999981 | 0.164124 | 0.447487 | |||

| 20 | 0.999982 | 0.158077 | 0.431001 | |||

| LM-Log | 10 | 0.999967 | 0.214850 | 0.585792 | ||

| 15 | 0.999975 | 0.188060 | 0.512750 | |||

| 20 | 0.999981 | 0.161996 | 0.441684 | |||

| HVAC heating performance | 2 kW | LM-Tan | 10 | 0.986886 | 0.132118 | 11.59836 |

| 15 | 0.987196 | 0.130549 | 11.46062 | |||

| 20 | 0.987539 | 0.128786 | 11.30589 | |||

| LM-Log | 10 | 0.986881 | 0.132142 | 11.60054 | ||

| 15 | 0.987086 | 0.131105 | 11.50950 | |||

| 20 | 0.987226 | 0.130393 | 11.44697 | |||

| 4 kW | LM-Tan | 10 | 0.998091 | 0.142413 | 4.463665 | |

| 15 | 0.998137 | 0.140689 | 4.409637 | |||

| 20 | 0.998338 | 0.132884 | 4.164997 | |||

| LM-Log | 10 | 0.998029 | 0.144687 | 4.534949 | ||

| 15 | 0.998106 | 0.141871 | 4.446673 | |||

| 20 | 0.998229 | 0.137182 | 4.299688 | |||

| 6 kW | LM-Tan | 10 | 0.997789 | 0.144090 | 4.769143 | |

| 15 | 0.997864 | 0.141669 | 4.688989 | |||

| 20 | 0.998081 | 0.134271 | 4.444122 | |||

| LM-Log | 10 | 0.997779 | 0.144445 | 4.780861 | ||

| 15 | 0.997815 | 0.143260 | 4.741652 | |||

| 20 | 0.997894 | 0.140671 | 4.655938 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, T.-K.; Garud, K.S.; Seo, J.-H.; Lee, M.-Y.; Lee, D.-Y. Experimental Study on Heating Performances of Integrated Battery and HVAC System with Serial and Parallel Circuits for Electric Vehicle. Symmetry 2021, 13, 93. https://doi.org/10.3390/sym13010093

Lim T-K, Garud KS, Seo J-H, Lee M-Y, Lee D-Y. Experimental Study on Heating Performances of Integrated Battery and HVAC System with Serial and Parallel Circuits for Electric Vehicle. Symmetry. 2021; 13(1):93. https://doi.org/10.3390/sym13010093

Chicago/Turabian StyleLim, Taek-Kyu, Kunal Sandip Garud, Jae-Hyeong Seo, Moo-Yeon Lee, and Dong-Yeon Lee. 2021. "Experimental Study on Heating Performances of Integrated Battery and HVAC System with Serial and Parallel Circuits for Electric Vehicle" Symmetry 13, no. 1: 93. https://doi.org/10.3390/sym13010093

APA StyleLim, T.-K., Garud, K. S., Seo, J.-H., Lee, M.-Y., & Lee, D.-Y. (2021). Experimental Study on Heating Performances of Integrated Battery and HVAC System with Serial and Parallel Circuits for Electric Vehicle. Symmetry, 13(1), 93. https://doi.org/10.3390/sym13010093