A Kinematic Calibration Method of a 3T1R 4-Degree-of-Freedom Symmetrical Parallel Manipulator

Abstract

1. Introduction

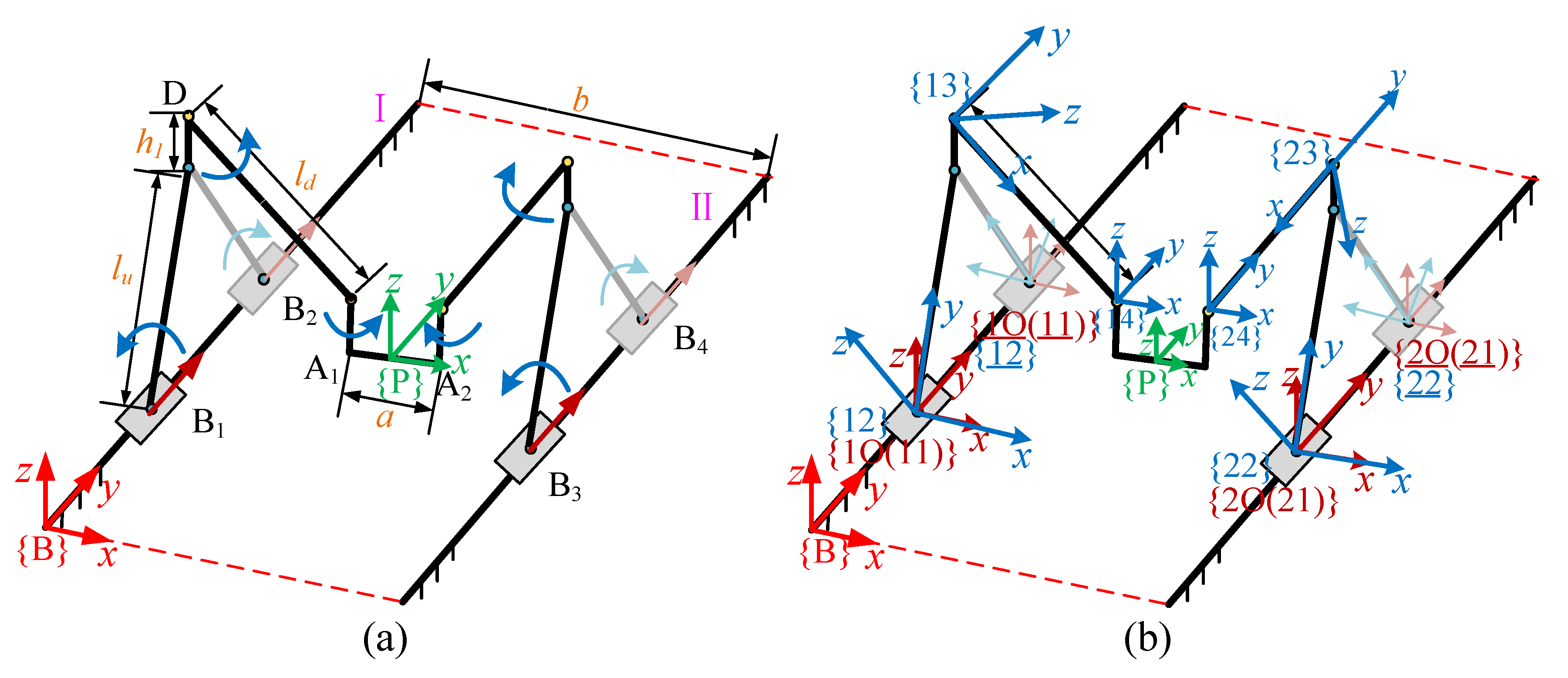

2. Kinematics of a Symmetrical 3T1R Parallel Manipulator

2.1. Structure of the 3T1R Parallel Manipulator

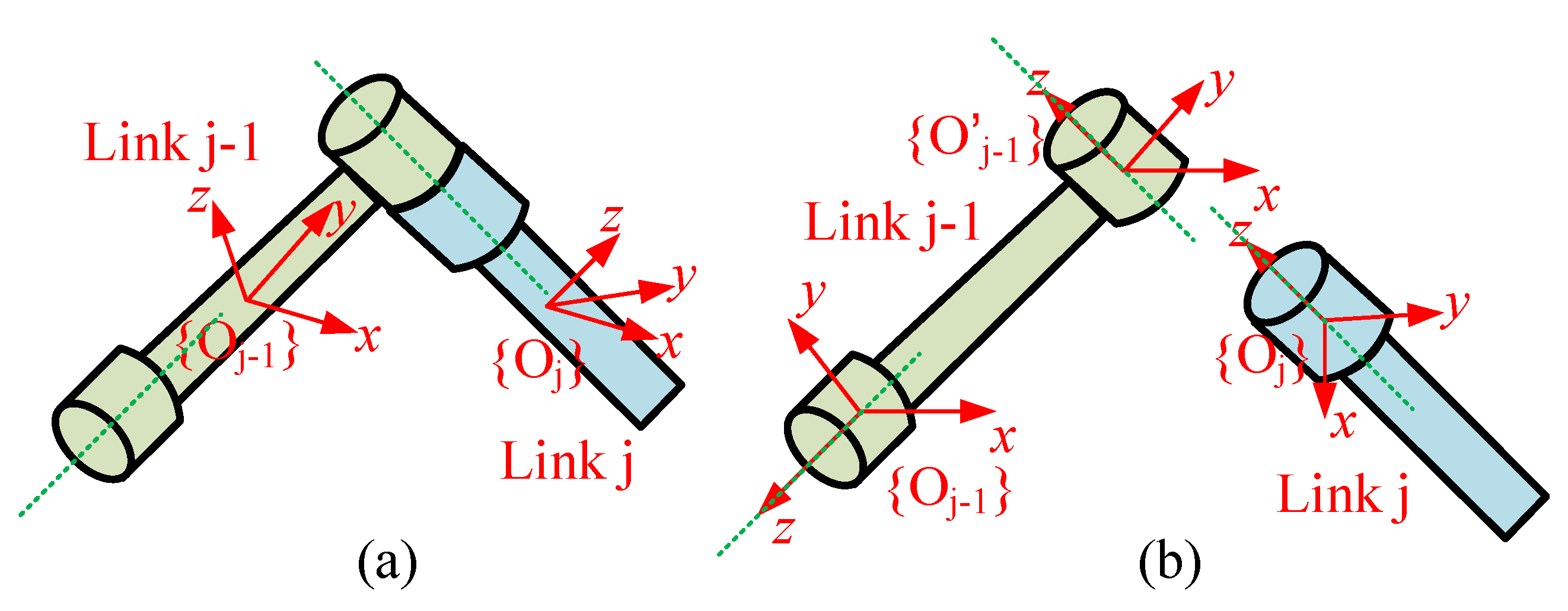

2.2. kinematics Based on local POE formula

2.3. Branched Chain Kinematics Based on the Local POE Formula

2.4. Kinematics of the Parallel Manipulator Branched Chain i Based on the Local POE Formula

3. Establishing the Kinematic Error Model for this 3T1R Parallel Manipulator

3.1. Establishment of the Kinematic Error Model from a Single Branched Chain

3.2. Establishment of the Overall Kinematic Error Model

4. Method to Reduce the Number of Sensors Used in Passive Joints

5. A Recursive Least Squares Method to Identify the Parameters in the Kinematic Error Model

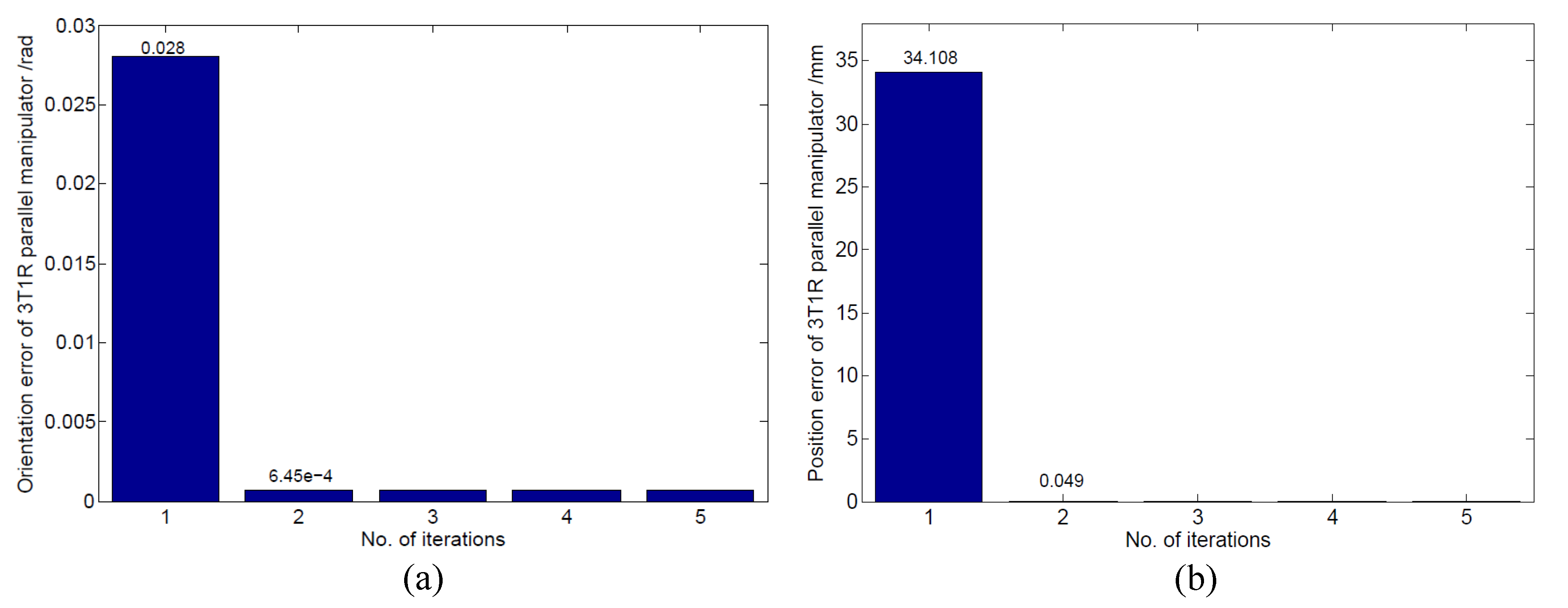

6. Simulation Results

- 1.

- Use the numerical forward kinematics algorithm to obtain the joint displacements and joint angles of 20 different parallel manipulator poses;

- 2.

- Assign errors to kinematic parameters, such as , , and , as shown in Table 1.

- 3.

- Simulate the actual initial pose using ;

- 4.

- The actual joint twist is computed as ;

- 5.

- The actual joint variable is computed as ;

- 6.

- The recursive calibration algorithm is used to identify the kinematic errors of the parallel manipulator.

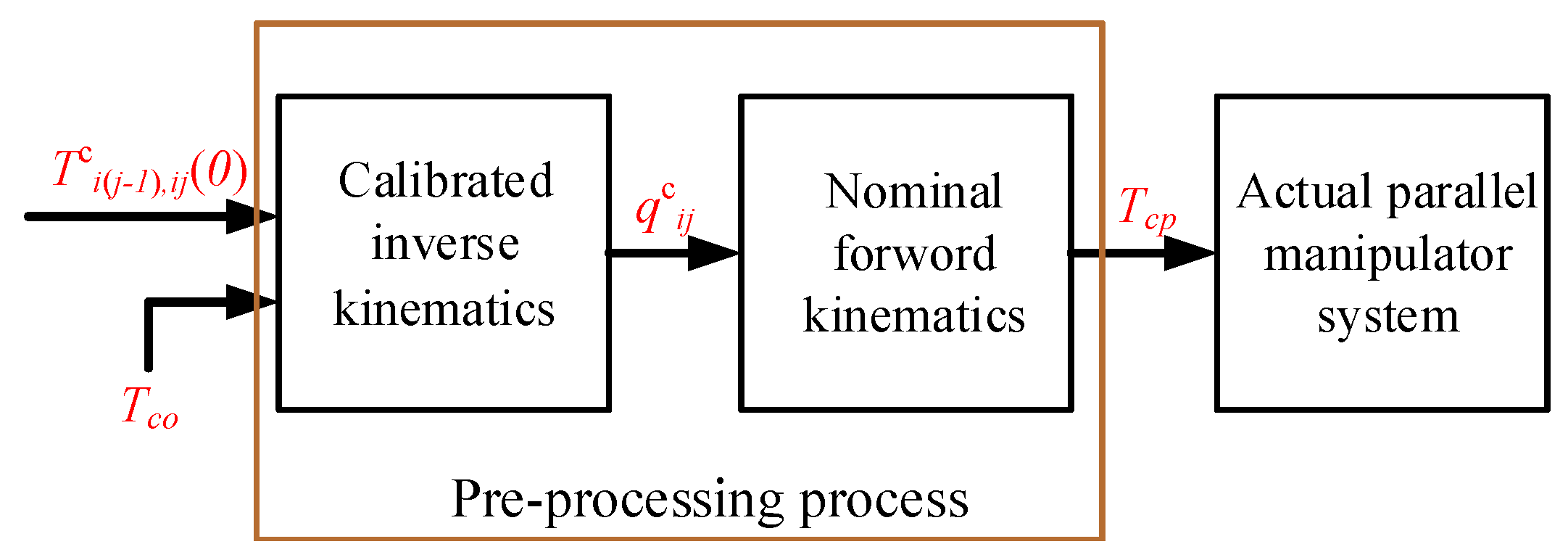

7. Pre-Processing Compensation

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 3T1R parallel manipulator | The parallel manipulator can achieve three degrees of freedom of translation along the X, Y, and Z axes and one degree of freedom of rotation around the Z axis |

| POE formula | The product of exponentials formula |

| D-H convention | The Denavit-Hartenberg convention |

Nomenclature

| n | The number of passive joints |

| i | Represents the parallel manipulator , branched chains |

| Represents the parallel manipulator , branched chains | |

| j | The number of joints on each branched chain |

| Forward kinematics of these parallel manipulator branched chains i | |

| The initial pose of the coordinate system relative to the coordinate system | |

| After calibration, the initial pose of the coordinate system relative to the coordinate system | |

| The actual initial pose of the coordinate system relative to the coordinate system | |

| Standard representation of joint variable; it represent the joint angle or joint displacement | |

| Standard representation of the nominal joint variable | |

| Standard representation of the joint variable after calibration | |

| Base coordinate system of the parallel manipulator | |

| , | Base coordinate system of these parallel manipulator branched chains i and |

| , | The translational motion coordinate system of these parallel manipulator branched chains i and |

| , | The rotational motion coordinate system where it is connected to the modules of these parallel manipulator branched chains i and |

| The coordinate system of link rotates around the D point of these parallel manipulator branched chains i and | |

| The parallel manipulator moving platform rotational motion coordinate system around the point | |

| Midpoint coordinate system of the end effector | |

| Forward kinematics after calibration of the parallel manipulator | |

| The nominal pose of the end effector | |

| The actual pose of the end effector | |

| The command pose of the end effector during error compensation | |

| The end pose after compensation | |

| The adjoint transformation of , also written as , | |

| The representation of the end error on these parallel manipulator branched chains i in the base coordinate system | |

| The error of t in coordinate system | |

| Error Jacobian matrix of these parallel manipulator branched chains i | |

| J | Error Jacobian matrix of the entire parallel manipulator |

References

- Stewart, D. A platform with six degrees of freedom. Proc. Inst. Mech. Eng. 1965, 180, 371–386. [Google Scholar] [CrossRef]

- Wu, C.; Yang, G.; Chen, C.; Liu, S.; Zheng, T. Kinematic design of a novel 4-dof parallel manipulator. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 6099–6104. [Google Scholar]

- Wu, J.-F.; Zhang, R.; Wang, R.-H.; Yao, Y.-X. A systematic optimization approach for the calibration of parallel kinematics machine tools by a laser tracker. Int. J. Mach. Tools Manuf. 2014, 86, 1–11. [Google Scholar] [CrossRef]

- Chanal, H.; Duc, E.; Ray, P.; Hascoet, J.Y. A new approach for the geometrical calibration of parallel kinematics machines tools based on the machining of a dedicated part. Int. J. Mach. Tools Manuf. 2007, 47, 1151–1163. [Google Scholar] [CrossRef]

- Fu, J.; Gao, F.; Chen, W.; Pan, Y.; Lin, R. Kinematic accuracy research of a novel six-degree-of-freedom parallel robot with three legs. Mech. Mach. Theory 2016, 102, 86–102. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, J.; Lian, B.; Sun, T. Kinematic calibration of a 5-dof parallel kinematic machine. Precis. Eng. 2016, 45, 242–261. [Google Scholar] [CrossRef]

- Sun, T.; Zhai, Y.; Song, Y.; Zhang, J. Kinematic calibration of a 3-dof rotational parallel manipulator using laser tracker. Robot. -Comput.-Integr. Manuf. 2016, 41, 78–91. [Google Scholar] [CrossRef]

- Liu, H.; Gong, M.; O, M.Z.H.A. Error analysis and calibration of a 4-dof parallel mechanism. Robot 2005, 27, 6–9. [Google Scholar]

- Hartenberg, R.S.; Denavit, J. A kinematic notation for lower pair mechanisms based on matrices. J. Appl. Mech. 1955, 77, 215–221. [Google Scholar]

- Mooring, B.W. An improved method for identifying the kinematic parameters in a six axes robots. In Computers in Engineering, Proceedings of the International Computers in Engineering Conference and Exhibit; American Soc of Mechanical Engineers (ASME): New York, NY, USA, 1984; Volume 1, pp. 79–84. [Google Scholar]

- Yang, G.; Chen, I.-M.; Lee, W.K.; Yeo, S.H. Self-calibration of three-legged modular reconfigurable parallel robots based on leg-end distance errors. Robotica 2001, 19, 187–198. [Google Scholar] [CrossRef]

- Chen, G.; Kong, L.; Li, Q.; Wang, H.; Lin, Z. Complete, minimal and continuous error models for the kinematic calibration of parallel manipulators based on poe formula. Mech. Mach. Theory 2018, 121, 844–856. [Google Scholar] [CrossRef]

- Okamura, K.; Park, F.C. Kinematic calibration using the product of exponentials formula. Robotica 1996, 14, 415–421. [Google Scholar] [CrossRef]

- He, R.; Zhao, Y.; Yang, S.; Yang, S. Kinematic-parameter identification for serial-robot calibration based on poe formula. IEEE Trans. Robot. 2010, 26, 411–423. [Google Scholar]

- Wang, H.; Shen, S.; Lu, X. A screw axis identification method for serial robot calibration based on the poe model. Ind. Robot. Int. J. 2012, 39, 146–153. [Google Scholar] [CrossRef]

- Chen, I.-M.; Yang, G.; Tan, C.T.; Yeo, S.H. Local poe model for robot kinematic calibration. Mech. Mach. Theory 2001, 36, 1215–1239. [Google Scholar] [CrossRef]

- Nubiola, A.; Bonev, I.A. Absolute robot calibration with a single telescoping ballbar. PRecision Eng. 2014, 38, 472–480. [Google Scholar] [CrossRef]

- Joubair, A.; Slamani, M.; Bonev, I.A. Kinematic calibration of a five-bar planar parallel robot using all working modes. Robot. -Comput.-Integr. Manuf. 2013, 29, 15–25. [Google Scholar] [CrossRef]

- Du, G.; Zhang, P. Online robot calibration based on vision measurement. Robot. Comput.-Integr. Manuf. 2013, 29, 484–492. [Google Scholar] [CrossRef]

- HuangFu, Y.; Hang, L.; Cheng, W.; Yu, L.; Shen, C.; Wang, J.; Qin, W.; Wang, Y. Research on robot calibration based on laser tracker. In Mechanism and Machine Science; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1475–1488. [Google Scholar]

- Elatta, A.Y.; Gen, L.P.; Zhi, F.L.; Daoyuan, Y.; Fei, L. An overview of robot calibration. Inf. Technol. J. 2004, 3, 74–78. [Google Scholar]

- Wu, L.; Yang, X.; Chen, K.; Ren, H. A minimal poe-based model for robotic kinematic calibration with only position measurements. IEEE Trans. Autom. Sci. Eng. 2014, 12, 758–763. [Google Scholar] [CrossRef]

- Sareh, P. The least symmetric crystallographic derivative of the developable double corrugation surface: Computational design using underlying conic and cubic curves. Mater. Des. 2019, 183, 108128. [Google Scholar] [CrossRef]

- Chen, J.; San, H.; Wu, X.; Chen, M.; He, W. Structural design and characteristic analysis for a 4-degree-of-freedom parallel manipulator. Adv. Mech. Eng. 2019, 11, 1687814019850995. [Google Scholar] [CrossRef]

- Yang, L.; Tian, X.; Li, Z.; Chai, F.; Dong, D. Numerical simulation of calibration algorithm based on inverse kinematics of the parallel mechanism. Optik 2019, 182, 555–564. [Google Scholar] [CrossRef]

- Huang, K.; Liu, R.G.; Wu, J.S.; Lao, X.R.; Mo, J.H. Parameter calibration method based on screw theory for articulated coordinate measuring arm. In Advanced Materials Research; Trans Tech Publ: Zurich, Switzerland, 2011; Volume 189, pp. 4049–4052. [Google Scholar]

- Gu, L.; Yang, G.; Fang, Z.; Shen, W.; Zheng, T.; Chen, C.; Zhang, C. A two-step self-calibration method with portable measurement devices for industrial robots based on poe formula. In International Conference on Intelligent Robotics and Applications; Springer: Berlin/Heidelberg, Germany, 2019; pp. 715–727. [Google Scholar]

| B-11 | 0.02 | ||

| 11-12 | 0.02 | ||

| 12-13 | 0.02 | ||

| 13-14 | 0.02 | ||

| 14-P | \ | \ | |

| B-21 | 0.02 | ||

| 21-22 | 0.02 | ||

| 22-23 | 0.02 | ||

| 23-24 | 0.02 | ||

| 24-P | \ | \ |

| Kinematic Errors | ||

|---|---|---|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Chen, S.; He, Y.; Ye, G.; Zhang, C.; Yang, G. A Kinematic Calibration Method of a 3T1R 4-Degree-of-Freedom Symmetrical Parallel Manipulator. Symmetry 2020, 12, 357. https://doi.org/10.3390/sym12030357

Zhang F, Chen S, He Y, Ye G, Zhang C, Yang G. A Kinematic Calibration Method of a 3T1R 4-Degree-of-Freedom Symmetrical Parallel Manipulator. Symmetry. 2020; 12(3):357. https://doi.org/10.3390/sym12030357

Chicago/Turabian StyleZhang, Fengxuan, Silu Chen, Yongyi He, Guoyun Ye, Chi Zhang, and Guilin Yang. 2020. "A Kinematic Calibration Method of a 3T1R 4-Degree-of-Freedom Symmetrical Parallel Manipulator" Symmetry 12, no. 3: 357. https://doi.org/10.3390/sym12030357

APA StyleZhang, F., Chen, S., He, Y., Ye, G., Zhang, C., & Yang, G. (2020). A Kinematic Calibration Method of a 3T1R 4-Degree-of-Freedom Symmetrical Parallel Manipulator. Symmetry, 12(3), 357. https://doi.org/10.3390/sym12030357