A New DEA Model for Evaluation of Supply Chains: A Case of Selection and Evaluation of Environmental Efficiency of Suppliers

Abstract

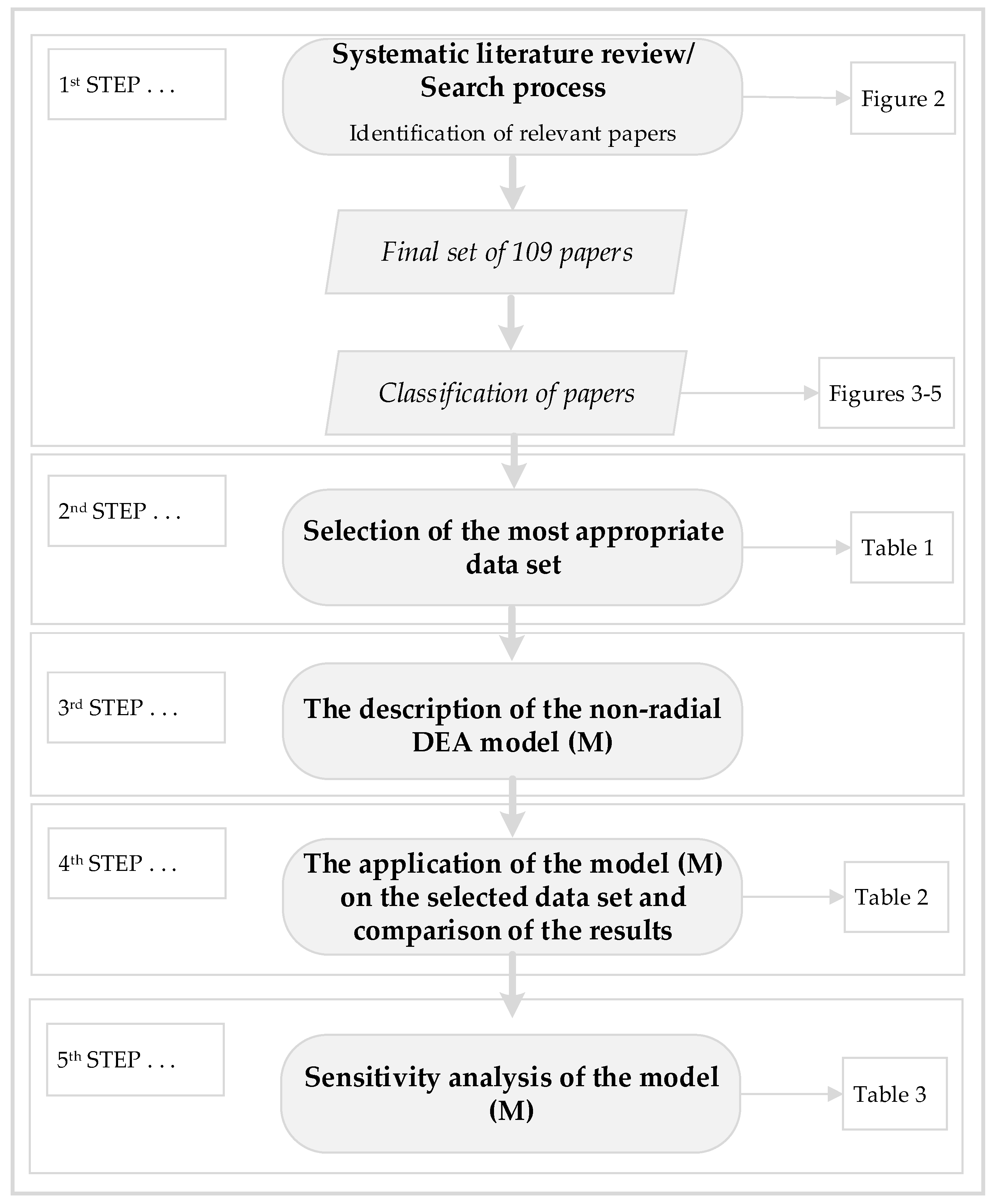

1. Introduction

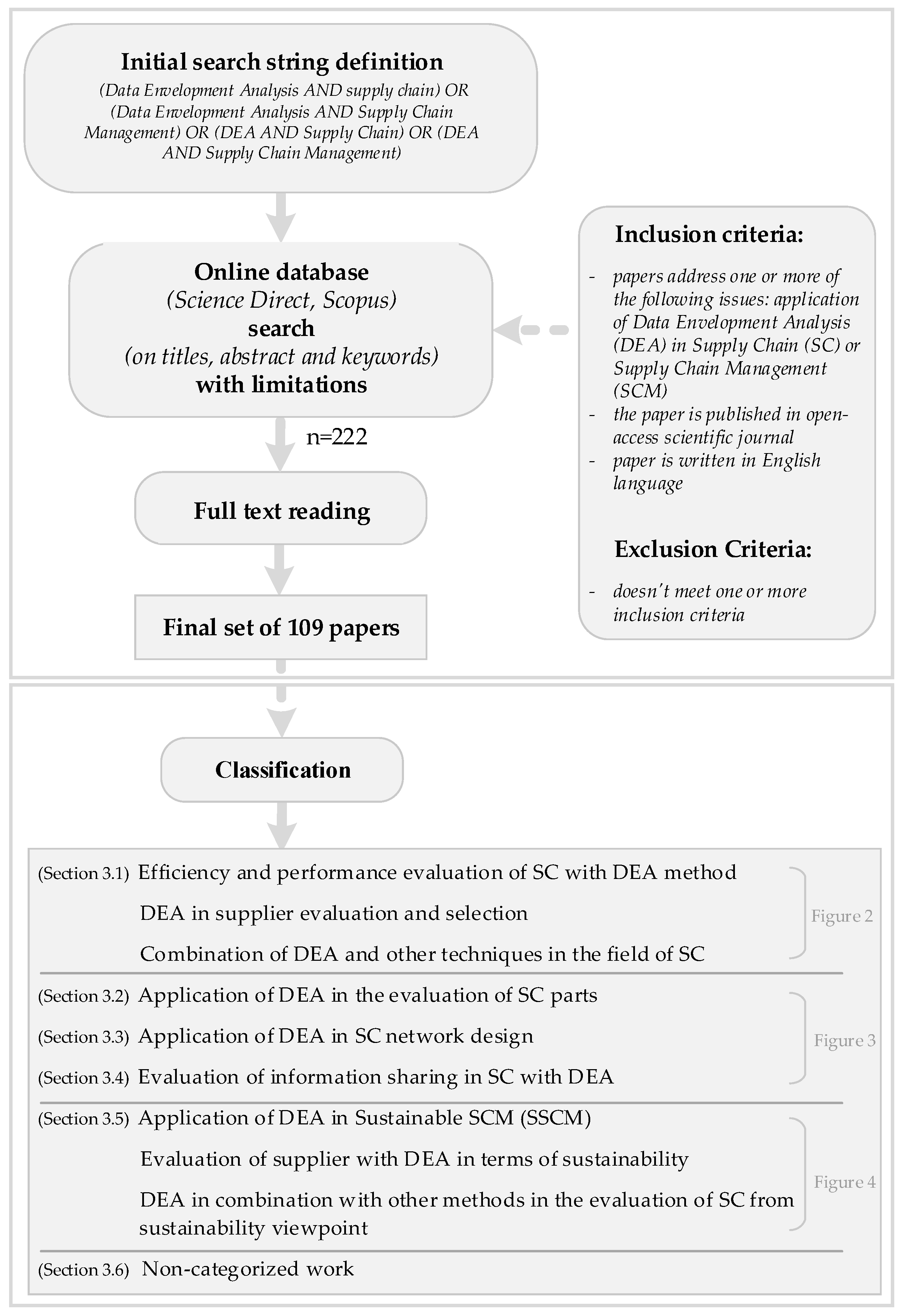

2. Previous Research

Methodology of Literature Review

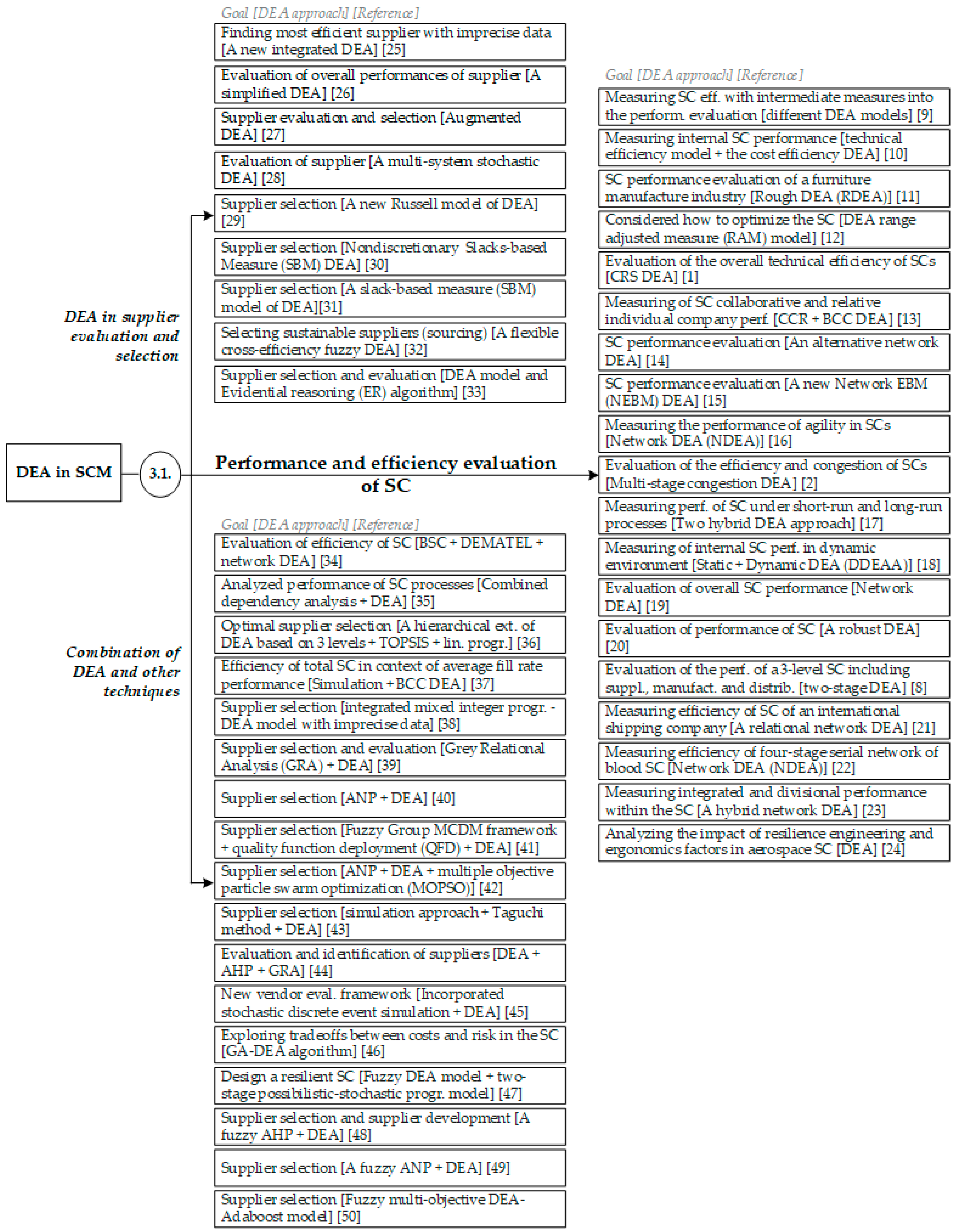

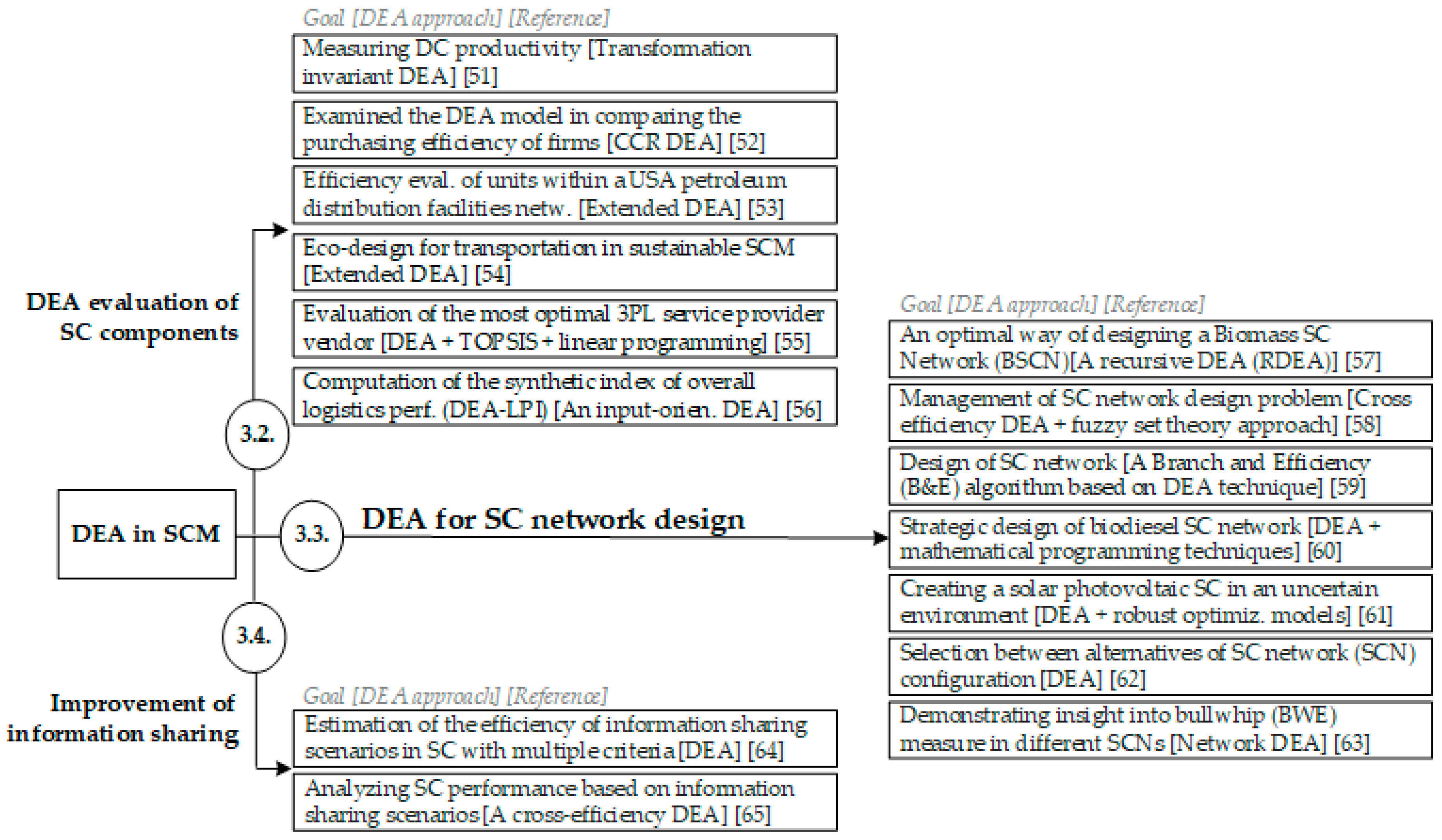

3. Results of the Literature Review and Classification

3.1. Efficiency and Performance Evaluation of SC with the DEA Method

3.2. Application of DEA in the Evaluation of SC Parts

3.3. Application of DEA in SC Network Design

3.4. Evaluation of Information Sharing in SC with DEA

3.5. Application of DEA in Sustainable SCM

3.6. Non-Categorized Works

4. The Proposal of a Non-Radial DEA Model in SC

A Brief Description of the Non-Radial DEA Model

5. Illustration of Application of the Non-Radial Model M—Numerical Example

Validation of Non-Radial DEA Model M

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yang, F.; Wu, D.; Liang, L.; Bi, G.; Wu, D.D. Supply chain DEA: Production possibility set and performance evaluation model. Ann. Oper. Res. 2011, 185, 195–211. [Google Scholar] [CrossRef]

- Sharma, M.J.; Yu, S.J. Multi-Stage data envelopment analysis congestion model. Oper. Res. Int. J. 2013, 13, 399–413. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Soheilirad, S.; Govindan, K.; Mardani, A.; Zavadskas, K.E.; Nilashi, M.; Zakuan, N. Application of data envelopment analysis models in supply chain management: A systematic review and meta-analysis. Ann. Oper. Res. 2018, 271, 915–969. [Google Scholar] [CrossRef]

- Mahdiloo, M.; Saen, F.R.; Lee, K.-H. Technical, environmental and eco-efficiency measurement for supplier selection: An extension and application of data envelopment analysis. Int. J. Prod. Econ. 2015, 168, 279–289. [Google Scholar] [CrossRef]

- Krmac, E.; Djordjević, B. An evaluation of train control information systems for sustainable railway using the analytic hierarchy process (AHP) model. Eur. Transp. Res. Rev. 2017, 9, 35. [Google Scholar] [CrossRef]

- Djordjević, B.; Krmac, E.; Mlinarić, T.J. Non-radial DEA model: A new approach to evaluation of safety at railway level crossings. Saf. Sci. 2018, 103, 234–246. [Google Scholar]

- Tavana, M.; Kaviani, M.A.; Caprio, D.D.; Rahpeyma, B. A two-stage data envelopment analysis model for measuring performance in three-level supply chains. Measurement 2016, 78, 322–333. [Google Scholar] [CrossRef]

- Liang, L.; Yang, F.; Cook, W.D.; Zhu, J. DEA models for supply chain efficiency evaluation. Ann. Oper. Res. 2006, 145, 35–49. [Google Scholar] [CrossRef]

- Wong, W.P.; Wong, K.Y. Supply chain performance measurement system using DEA modeling. Ind. Manag. Data Syst. 2007, 107, 361–381. [Google Scholar] [CrossRef]

- Xu, J.; Li, B.; Wu, D. Rough data envelopment analysis and its application to supply chain performance evaluation. Int. J. Prod. Econ. 2009, 122, 628–638. [Google Scholar] [CrossRef]

- Aoki, S.; Naito, A.; Gejima, R.; Inoue, K.; Tsuji, H. Data envelopment analysis for a supply chain. Artif. Life Robot. 2010, 15, 171–175. [Google Scholar] [CrossRef]

- Li, D.-C.; Dai, W.-L. Determining the optimal collaborative benchmarks in a supply chain. Int. J. Prod. Res. 2009, 47, 4457–4471. [Google Scholar] [CrossRef]

- Chen, C.; Yan, H. Network DEA model for supply chain performance evaluation. Eur. J. Oper. Res. 2011, 213, 147–155. [Google Scholar] [CrossRef]

- Tavana, M.; Mirzagoltabar, H.; Mirhedayatian, S.M.; Saen, R.F.; Azadi, M. A new network epsilon-based DEA model for supply chain performance evaluation. Comput. Ind. Eng. 2013, 66, 501–513. [Google Scholar] [CrossRef]

- Khalili-Damghani, K.; Tavana, M. A new fuzzy network data envelopment analysis model for measuring the performance of agility in supply chains. Int. J. Adv. Manuf. Technol. 2013, 69, 291–318. [Google Scholar] [CrossRef]

- Nikfarjam, H.; Rostamy-Malkhalifeh, M.; Mamizadeh-Chatghayeh, S. Measuring supply chain efficiency based on a hybrid approach. Transp. Res. Part D 2015, 39, 141–150. [Google Scholar] [CrossRef]

- Kumar, A.; Mukherjee, K.; Adlakha, A. Dynamic performance assessment of a supply chain process: A case from pharmaceutical supply chain in India. Bus. Process Manag. J. 2015, 21, 743–770. [Google Scholar] [CrossRef]

- Tavassoli, M.; Saen, R.F.; Faramarzi, G.R. Developing network data envelopment analysis model for supply chain performance measurement in the presence of zero data. Expert Syst. 2015, 32, 381–391. [Google Scholar] [CrossRef]

- Khamseh, A.A.; Zahmatkesh, D. Supply chain performance evaluation using robust data envelopment analysis. Uncertain Supply Chain Manag. 2015, 3, 311–320. [Google Scholar] [CrossRef]

- Omrani, H.; Keshavarz, M. A performance evaluation model for supply chain of shipping company in Iran: An application of the relational network DEA. Marit. Policy Manag. 2016, 43, 121–135. [Google Scholar] [CrossRef]

- Moslemi, S.; Mirzazadeh, A. Performance Evaluation of Four-Stage Blood Supply Chain with Feedback Variables Using NDEA Cross-Efficiency and Entropy Measures Under IER Uncertainty. Numer. Algebra Control Optim. 2017, 7, 379–401. [Google Scholar] [CrossRef]

- Huang, C.-W. Assessing the performance of tourism supply chains by using the hybrid network data envelopment analysis model. Tour. Manag. 2018, 65, 303–316. [Google Scholar] [CrossRef]

- Amalnick, M.S.; Saffar, M.M. An integrated approach for supply chain assessment from resilience engineering and ergonomics perspectives. Uncertain Supply Chain Manag. 2017, 5, 159–168. [Google Scholar] [CrossRef]

- Toloo, M.; Nalchigar, S. A new DEA method for supplier selection in presence of both cardinal and ordinal data. Expert Syst. Appl. 2011, 38, 14726–14731. [Google Scholar] [CrossRef]

- Liu, J.; Ding, F.-Y.; Lall, V. Using data envelopment analysis to compare suppliers for supplier selection and performance improvement. Supply Chain Manag. Int. J. 2000, 5, 143–150. [Google Scholar] [CrossRef]

- Wu, T.; Blackhurst, J. Supplier evaluation and selection: An augmented DEA approach. Int. J. Prod. Res. 2009, 47, 4593–4608. [Google Scholar] [CrossRef]

- Wu, D.D. A systematic stochastic efficiency analysis model and application to international supplier performance evaluation. Expert Syst. Appl. 2010, 37, 6257–6264. [Google Scholar] [CrossRef]

- Azadi, M.; Saen, R.F. Supplier Selection using a New Russell Model in the Presence of Undesirable Outputs and Stochastic Data. J. Appl. Sci. 2012, 12, 336–344. [Google Scholar]

- Azadi, M.; Saen, R.F. Developing a Nondisretionary Slacks-based Measure Model for Supplier Selection in the Presence of Stochastic Data. Res. J. Bus. Manag. 2012, 6, 103–120. [Google Scholar]

- Mahdiloo, M.; Noorizadeh, A.; Saen, R.F. Benchmarking suppliers’ performance when some factors play the role of both inputs and outputs: A new development to the slacks-based measure of efficiency. Benchmark. Int. J. 2014, 5, 792–813. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Agrell, P.J.; Tavana, M.; Khoshnevis, P. A flexible cross-efficiency fuzzy data envelopment analysis model for sustainable sourcing. J. Clean. Prod. 2017, 142, 2761–2779. [Google Scholar] [CrossRef]

- Momeni, M.; Vandchali, R.H. Providing a structured methodology for supplier selection and evaluation for strategic outsourcing. Int. J. Bus. Perform. Supply Chain Model. 2017, 9, 66–85. [Google Scholar] [CrossRef]

- Shafiee, M.; Lotfi, F.H.; Saleh, H. Supply chain performance evaluation with data envelopment analysis and balanced scorecard approach. Appl. Math. Model. 2014, 38, 5092–5112. [Google Scholar] [CrossRef]

- Reiner, G.; Hofmann, P. Efficiency analysis of supply chain processes. Int. J. Prod. Res. 2006, 44, 5065–5087. [Google Scholar] [CrossRef]

- Dotoli, M.; Falagario, M. A hierarchical model for optimal supplier selection in multiple sourcing contexts. Int. J. Prod. Res. 2012, 50, 2953–2967. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Debnath, R.M. Supply chain efficiency: A simulation cum DEA approach. Int. J. Adv. Manuf. Technol. 2014, 72, 1537–1549. [Google Scholar] [CrossRef]

- Toloo, M. Selecting and full ranking suppliers with imprecise data: A new DEA method. Int. J. Adv. Manuf. Technol. 2014, 74, 1141–1148. [Google Scholar] [CrossRef]

- Markabi, M.S.; Sabbagh, M. A Hybrid Method of GRA and DEA for Evaluating and Selecting Efficient Suppliers plus a Novel Ranking Method for Grey Numbers. J. Ind. Eng. Manag. 2014, 7, 1197–1221. [Google Scholar]

- Abdollahi, M.; Arvan, M.; Razmi, J. An integrated approach for supplier portfolio selection: Lean or agile? Expert Syst. Appl. 2015, 42, 679–690. [Google Scholar] [CrossRef]

- Karsak, E.E.; Dursun, M. An integrated supplier selection methodology incorporating QFD and DEA with imprecise data. Expert Syst. Appl. 2014, 41, 6995–7004. [Google Scholar] [CrossRef]

- Che, Z.H.; Chang, Y.F. Integrated methodology for supplier selection: The case of a sphygmomanometer manufacturer in Taiwan. J. Bus. Econ. Manag. 2016, 17, 17–34. [Google Scholar] [CrossRef][Green Version]

- Azadeh, A.; Zarrin, M.; Salehi, N. Supplier selection in closed loop supply chain by an integrated simulation-Taguchi-DEA approach. J. Enterp. Inf. Manag. 2016, 29, 302–326. [Google Scholar] [CrossRef]

- Prasad, D.G.K.; Subbaiah, V.K.; Prasad, V.M. Supplier evaluation and selection through DEA-AHP-GRA integrated approach—A case study. Uncertain Supply Chain Manag. 2017, 5, 369–382. [Google Scholar] [CrossRef]

- Park, S.; Ok, C.; Ha, C. A stochastic simulation-based holistic evaluation approach with DEA for vendor selection. Comput. Oper. Res. 2017, 100, 368–378. [Google Scholar] [CrossRef]

- Paraizar, M.; Sir, Y.M. A multi-objective approach for supply chain design considering disruptions impacting supply availability and quality. Comput. Ind. Eng. 2018, 121, 113–130. [Google Scholar] [CrossRef]

- Sabouhi, F.; Pishvaee, S.M.; Jabalameli, S.M. Resilient supply chain design under operational and disruption risks considering quantity discount: A case study of pharmaceutical supply chain. Comput. Ind. Eng. 2018, 126, 657–672. [Google Scholar] [CrossRef]

- Diouf, M.; Kwak, C. Fuzzy AHP, DEA, and Managerial Analysis for Supplier Selection and Development; From the Perspective of Open Innovation. Sustainability 2018, 10, 3779. [Google Scholar] [CrossRef]

- Wang, C.-N.; Nguyen, T.V.; Duong, H.D.; Do, T.H. A Hybrid Fuzzy Analytic Network Process (FANP) and Data Envelopment Analysis (DEA) Approach for Supplier Evaluation and Selection in the Rice Supply Chain. Symmetry 2018, 10, 221. [Google Scholar] [CrossRef]

- Cheng, Y.; Peng, J.; Zhou, Z.; Gu, X.; Liu, W. A Hybrid DEA-Adaboost Model in Supplier Selection for Fuzzy Variable and Multiple Objectives. IFAC PapersOnLine 2017, 50, 12255–12260. [Google Scholar] [CrossRef]

- Ross, A.; Droge, C. An integrated benchmarking approach to distribution center performance using DEA modeling. J. Oper. Manag. 2002, 20, 19–32. [Google Scholar] [CrossRef]

- Easton, L.; Murphy, D.J.; Pearson, J.N. Purchasing performance evaluation: With data envelopment analysis. Eur. J. Purch. Supply Manag. 2002, 8, 123–134. [Google Scholar] [CrossRef]

- Ross, A.D.; Droge, C. An analysis of operations efficiency in large-scale distribution systems. J. Oper. Manag. 2004, 15, 673–688. [Google Scholar] [CrossRef]

- Ji, X.; Wu, J.; Zhu, Q. Eco-design of transportation in sustainable supply chain management: A DEA-like method. Transp. Res. Part D 2016, 48, 451–459. [Google Scholar] [CrossRef]

- Haldar, A.; Qamaruddin, U.; Raut, R.; Kamble, S.; Kharat, M.G.; Kamble, S.J. 3PL evaluation and selection using integrated analytical modeling. J. Model. Manag. 2017, 12, 224–242. [Google Scholar] [CrossRef]

- Marti, L.; Martin, J.C.; Puertas, R. A DEA-Logistics Performance Index. J. Appl. Econ. 2017, 20, 169–192. [Google Scholar] [CrossRef]

- Grigoroudis, E.; Petridis, K.; Arabatzis, G. RDEA: A recursive DEA based algorithm for the optimal design of biomass supply chain networks. Renew. Energy 2014, 71, 113–122. [Google Scholar] [CrossRef]

- Dotoli, M.; Epicoco, N.; Falagario, M. A Technique for Supply Chain Network Design under Uncertainty using Cross-Efficiency Fuzzy Data Envelopment Analysis. IFAC-PapersOnLine 2015, 48, 634–639. [Google Scholar] [CrossRef]

- Petridis, K.; Dey, P.K.; Emrouznejad, A. A branch and efficiency algorithm for the optimal design of supply chain networks. Ann. Oper. Res. 2017, 253, 545–571. [Google Scholar] [CrossRef]

- Babazadeh, R.; Razmi, J.; Rabbani, M.; Pishvaee, M.S. An integrated data envelopment analysise mathematical programming approach to strategic biodiesel supply chain network design problem. J. Clean. Prod. 2017, 147, 694–707. [Google Scholar] [CrossRef]

- Dehghani, E.; Jabalameli, M.S.; Jabbarzadeh, A. Robust design and optimization of solar photovoltaic supply chain in an uncertain environment. Energy Econ. 2017, 142, 139–156. [Google Scholar] [CrossRef]

- Pourhejazy, P.; Kwon, O.K.; Chang, Y.-T.; Park, H. Evaluating Resiliency of Supply Chain Network: A Data Envelopment Analysis Approach. Sustainability 2017, 9, 255. [Google Scholar] [CrossRef]

- Goodarzi, M.; Saen, F.R. How to measure bullwhip effect by network data envelopment analysis? Comput. Ind. Eng. 2018, in press. [Google Scholar] [CrossRef]

- Chen, M.-C.; Yang, T.; Yen, C.-T. Investigating the value of information sharing in multi-echelon supply chains. Qual. Quant. 2007, 41, 497–511. [Google Scholar] [CrossRef]

- Yu, M.-M.; Ting, S.-C.; Chen, M.-C. Evaluating the cross-efficiency of information sharing in supply chains. Expert Syst. Appl. 2010, 37, 2891–2897. [Google Scholar] [CrossRef]

- Khodakarami, M.; Shabani, A.; Saen, R.F.; Azadi, M. Developing distinctive two-stage data envelopment analysis models: An application in evaluating the sustainability of supply chain management. Measurement 2015, 70, 62–74. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Wang, D. Sustainability development for supply chain management in U.S. petroleum industry by DEA environmental assessment. Energy Econ. 2014, 46, 360–374. [Google Scholar] [CrossRef]

- Mirhedayatian, S.M.; Azadi, M.; Saen, R.F. A novel network data envelopment analysis model for evaluating green supply chain management. Int. J. Prod. Econ. 2014, 147, 544–554. [Google Scholar] [CrossRef]

- Tajbakhsh, A.; Hassini, E. A data envelopment analysis approach to evaluate sustainability in supply chain networks. J. Clean. Prod. 2015, 105, 74–85. [Google Scholar] [CrossRef]

- Izadikhah, M.; Saen, R.F. Evaluating sustainability of supply chains by two-stage range directional measure in the presence of negative data. Transp. Res. Part D 2016, 49, 110–126. [Google Scholar] [CrossRef]

- Kahi, V.S.; Yousefi, S.; Shabanpour, H.; Saen, R.F. How to evaluate sustainability of supply chains? A dynamic network DEA approach. Ind. Manag. Data Syst. 2017, 117, 1866–1889. [Google Scholar] [CrossRef]

- Badiezadeh, T.; Saen, R.F.; Samavati, T. Assessing sustainability of supply chains by double frontier network DEA: A big data approach. Comput. Oper. Res. 2017, 98, 284–290. [Google Scholar] [CrossRef]

- Izadikhah, M.; Saen, R.F. Assessing sustainability of supply chains by chance-constrained two-stage DEA model in the presence of undesirable factors. Comput. Oper. Res. 2017, 100, 343–367. [Google Scholar] [CrossRef]

- Kalantary, M.; Saen, F.R. Assessing sustainability of supply chains: An inverse network dynamic DEA model. Comput. Ind. Eng. 2018, in press. [Google Scholar] [CrossRef]

- Zhai, D.; Shang, J.; Yang, F.; Ang, S. Measuring energy supply chains’ efficiency with emission trading: A two-stage frontier-shift data envelopment analysis. J. Clean. Prod. 2019, 210, 1462–1474. [Google Scholar] [CrossRef]

- De, D.; Chowdhury, S.; Dey, K.P.; Ghosh, K.S. Impact of Lean and Sustainability oriented innovation on Sustainability performance of Small and Medium Sized Enterprises: A Data Envelopment Analysis-based Framework. Int. J. Prod. Econ. 2018. accepted. [Google Scholar] [CrossRef]

- Omrani, H.; Keshavarza, M.; Ghaderib, F.S. Evaluation of supply chain of a shipping company in Iran by a fuzzy relational network data envelopment analysis model. Sci. Iran. E 2018, 25, 868–890. [Google Scholar] [CrossRef]

- Chen, Y.-J. Structured methodology for supplier selection and evaluation in a supply chain. Inf. Sci. 2011, 181, 1651–1670. [Google Scholar] [CrossRef]

- Jain, V.; Kumar, S.; Kumar, A.; Chandra, C. An integrated buyer initiated decision-making process for green greensupplier selection. J. Manuf. Syst. 2016, 41, 256–265. [Google Scholar] [CrossRef]

- Kumar, A.; Jain, V.; Kumar, S. A comprehensive environment friendly approach for supplier selection. Omega 2014, 42, 109–123. [Google Scholar] [CrossRef]

- Azadi, M.; Jafarian, M.; Saen, R.F.; Mirhedayatian, S.M. A new fuzzy DEA model for evaluation of efficiency and effectiveness of supplier sinsustainable supply chain management context. Comput. Oper. Res. 2015, 54, 274–285. [Google Scholar] [CrossRef]

- Shi, P.; Yan, B.; Shi, S.; Ke, C. A decision support system to select suppliers for a sustainable supply chain based on a systematic DEA approach. Inf. Technol. Manag. 2015, 16, 39–49. [Google Scholar] [CrossRef]

- Zhou, X.; Pedrycz, W.; Kuang, Y.; Zhang, Z. Type-2 fuzzy multi-objective DEA model: An application to sustainable supplier evaluation. Appl. Soft Comput. 2016, 46, 424–440. [Google Scholar] [CrossRef]

- Izadikhah, M.; Saen, R.F.; Ahmadi, K. How to assess sustainability of suppliers in volume discount context? A new data envelopment analysis approach. Transp. Res. Part D 2017, 51, 102–121. [Google Scholar] [CrossRef]

- Yu, M.-C.; Su, M.-H. Using Fuzzy DEA for Green Suppliers Selection Considering Carbon Footprints. Sustainability 2017, 9, 495. [Google Scholar] [CrossRef]

- Tavassoli, M.; Saen, F.R. Predicting group membership of sustainable suppliers via data envelopment analysis and discriminant analysis. Sustain. Prod. Consum. 2018, in press. [Google Scholar] [CrossRef]

- Ghoushchi, J.S.; Milan, D.M.; Rezaee, J.M. Evaluation and selection of sustainable suppliers in supply chain using new GP-DEA model with imprecise data. J. Ind. Eng. Int. 2018, 14, 613–625. [Google Scholar] [CrossRef]

- Kuo, R.J.; Wang, Y.C.; Tien, F.C. Integration of artificial neural network and MADA methods for green supplier selection. J. Clean. Prod. 2010, 18, 1161–1170. [Google Scholar] [CrossRef]

- Egilmez, G.; Kucukvar, M.; Tatari, O.; Bhutta, M.S. Supply chain sustainability assessment of the U.S. food manufacturing manufacturingsectors: A life cycle-based frontier approach. Resour. Conserv. Recycl. 2014, 82, 8–20. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Determining and applying sustainable supplier key performance indicators. Supply Chain Manag. Int. J. 2014, 19, 275–291. [Google Scholar] [CrossRef]

- Haghighi, M.S.; Torabi, S.A.; Ghasemi, R. An integrated approach for performance evaluation in sustainable supply chain networks (with a case study). J. Clean. Prod. 2016, 137, 579–597. [Google Scholar] [CrossRef]

- Fallahpour, A.; Olugu, E.U.; Musa, S.N.; Khezrimotlagh, D.; Wong, Y.K. An integrated model for green supplier selection under fuzzy environment: Application of data envelopment analysis and genetic programming approach. Neural Comput. Appl. 2016, 27, 707–725. [Google Scholar] [CrossRef]

- Tavana, M.; Shabanpour, H.; Yousefi, S.; Saen, R.F. A hybrid goal programming and dynamic data envelopment analysis framework for sustainable supplier evaluation. Neural Comput. Appl. 2017, 28, 3683–3696. [Google Scholar] [CrossRef]

- Yousefi, S.; Soltani, R.; Saen, R.F.; Pishvaee, M.S. A robust fuzzy possibilistic programming for a new network GP-DEA model to evaluate sustainable supply chains. J. Clean. Prod. 2017, 166, 537–549. [Google Scholar] [CrossRef]

- Ramezankhani, M.J.; Vahidi, F. Supply chain performance measurement and evaluation: A mixed sustainability and resilience approach. Comput. Ind. Eng. 2018, 126, 531–548. [Google Scholar] [CrossRef]

- He, X.; Zhang, J. Supplier Selection Study under the Respective of Low-Carbon Supply Chain: A Hybrid Evaluation Model Based on FA-DEA-AHP. Sustainability 2018, 10, 564. [Google Scholar] [CrossRef]

- Sevkli, M.; Koh, S.L.; Zaim, S.; Demirbag, M.; Tatoglu, E. An application of data envelopment analytic hierarchy process for supplier selection: A case study of BEKO in Turkey. Int. J. Prod. Res. 2007, 45, 1973–2003. [Google Scholar] [CrossRef]

- Wu, D.; Olson, D.L. Supply chain risk, simulation, and vendor selection. Int. J. Prod. Econ. 2008, 114, 646–655. [Google Scholar] [CrossRef]

- Azadeh, A.; Alem, S.M. A flexible deterministic, stochastic and fuzzy Data Envelopment Analysis approach for supply chain risk and vendor selection problem: Simulation analysis. Expert Syst. Appl. 2010, 37, 7438–7448. [Google Scholar] [CrossRef]

- Wu, D.D.; Olson, D. Enterprise risk management: A DEA VaR approach in vendor selection. Int. J. Prod. Res. 2010, 48, 4919–4932. [Google Scholar] [CrossRef]

- Visani, F.; Barbieri, P.; di Lascio, F.M.; Raffoni, A.; Vigo, D. Supplier’s total cost of ownership evaluation: A data envelopment analysis approach. Omega 2016, 61, 141–154. [Google Scholar] [CrossRef]

- Boudaghi, E.; Saen, R.F. Developing a novel model of data envelopment analysis–discriminant analysis for predicting group membership of suppliers in sustainable supply chain. Comput. Oper. Res. 2018, 89, 348–359. [Google Scholar] [CrossRef]

- Pournader, M.; Rotaru, K.; Kach, A.P.; Hajiagha, S.H. An analytical model for system-wide and tier-specific assessment of resilience to supply chain risks. Supply Chain Manag. Int. J. 2016, 21, 589–609. [Google Scholar] [CrossRef]

- Azadeh, A.; Gaeini, Z.; Shabanpour, N. Optimization of healthcare supply chain in context of macro-ergonomics factors by a unique mathematical programming approach. Appl. Ergon. 2016, 55, 46–55. [Google Scholar] [CrossRef]

- Saranga, H.; Moser, R. Performance evaluation of purchasing and supply management using value chain DEA approach. Eur. J. Oper. Res. 2010, 207, 197–205. [Google Scholar] [CrossRef]

- Amirteimoori, A.; Khoshandam, L. A Data Envelopment Analysis Approach to Supply Chain Efficiency. Adv. Decis. Sci. 2011, 2011, 608324. [Google Scholar] [CrossRef]

- Pournader, M.; Kach, A.; Fahimnia, B.; Sarkis, J. Outsourcing performance quality assessment using data envelopment analytics. Int. J. Prod. Econ. 2019, 207, 173–182. [Google Scholar] [CrossRef]

- Azadeh, A.; Atrchin, N.; Salehi, V.; Shojaei, H. Modelling and improvement of supply chain with imprecise transportation delays and resilience factors. Int. J. Logist. Res. Appl. 2014, 17, 269–282. [Google Scholar] [CrossRef]

- Bayraktar, E.; Gunasekaran, A.; Koh, S.L.; Tatoglu, E.; Demirbag, M.; Zaim, S. An efficiency comparison of supply chain management and information systems practices: A study of Turkish and Bulgarian small- and medium-sized enterprises in food products and beverages. Int. J. Prod. Res. 2010, 48, 425–451. [Google Scholar] [CrossRef]

- Jalalvand, F.; Teimoury, E.; Makui, A.; Aryanezhad, M.B.; Jolai, F. A method to compare supply chains of an industry. Supply Chain Manag. Int. J. 2011, 16, 82–97. [Google Scholar] [CrossRef]

- Cooper, W.W.; Seiford, L.M.; Tone, K. Introduction to Data Envelopment Analysis and Its Use: With DEA-Solver Softwer and References; Springer: New York, NY, USA, 2006. [Google Scholar]

- Djordjević, B.; Krmac, E. Application of Multicriteria Decision-Making Methods in Railway Engineering: A Case Study of Train Control Information Systems (TCIS), Modern Railway Engineering; Hessami, A., Ed.; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar]

- Wu, J.; Zhu, Q.; Yin, P.; Song, M. Measuring energy and environmental performance for regions in China by using DEA-based Malmquist indices. Oper. Res. Int. J. 2015, 17, 715–735. [Google Scholar] [CrossRef]

| Suppliers | Number of Employees (N1) | Energy Consumption (kWh/year) (L1) | Sales (1000 Korean Won) (M1) | ROA (M2) | Environmental R&D Investment (100,000 Korean Won) (M3) | CO2 (kg) (J1) |

|---|---|---|---|---|---|---|

| 1 | 1112 | 1267 | 119,477 | 0.04046 | 67 | 43,562 |

| 2 | 118 | 968 | 125,762 | 0.04499 | 65 | 45,000 |

| 3 | 458 | 1001 | 58,770 | 0.02221 | 57 | 42,400 |

| 4 | 416 | 1393 | 62,989 | 0.02920 | 62 | 43,734 |

| 5 | 413 | 1586 | 67,088 | 0.03269 | 50 | 44,890 |

| 6 | 430 | 1802 | 72,318 | 0.03116 | 36 | 42,913 |

| 7 | 426 | 1998 | 74,626 | 0.02184 | 47 | 39,438 |

| 8 | 452 | 1824 | 74,476 | 0.0348 | 44 | 40,078 |

| 9 | 503 | 1479 | 79,710 | 0.03976 | 47 | 39,500 |

| 10 | 498 | 1623 | 79,384 | 0.03723 | 89 | 45,023 |

| 11 | 192 | 1322 | 73,124 | 0.01269 | 256 | 41,324 |

| 12 | 171 | 831 | 62,529 | 0.00385 | 423 | 45,000 |

| 13 | 163 | 913 | 65,424 | 0.02776 | 508 | 42,400 |

| 14 | 161 | 893 | 71,027 | 0.04847 | 536 | 43,734 |

| 15 | 161 | 903 | 74,093 | 0.0514 | 570 | 44,890 |

| 16 | 162 | 778 | 72,830 | 0.04356 | 472 | 42,913 |

| 17 | 159 | 710 | 71,940 | 0.03932 | 426 | 39,438 |

| 18 | 157 | 695 | 82,203 | 0.02599 | 386 | 40,078 |

| 19 | 151 | 637 | 55,681 | 0.00001 | 376 | 39,500 |

| 20 | 151 | 781 | 64,839 | 0.02742 | 369 | 38,570 |

| Suppliers | Technical Efficiency (Model 2) | Environmental Efficiency (Model 4) | Eco-Efficiency (Model 5) | Model M |

|---|---|---|---|---|

| 1 | 0.73 | 0.99 | 0.99 | 0.60 |

| 2 | 1.00 | 1.00 | 1.00 | 1.00 |

| 3 | 0.47 | 0.52 | 0.52 | 0.37 |

| 4 | 0.40 | 0.63 | 0.63 | 0.41 |

| 5 | 0.39 | 0.68 | 0.68 | 0.44 |

| 6 | 0.34 | 0.69 | 0.69 | 0.42 |

| 7 | 0.29 | 0.68 | 0.68 | 0.38 |

| 8 | 0.37 | 0.82 | 0.82 | 0.47 |

| 9 | 0.50 | 0.93 | 0.93 | 0.56 |

| 10 | 0.44 | 0.78 | 0.78 | 0.48 |

| 11 | 0.55 | 0.80 | 0.80 | 0.62 |

| 12 | 0.83 | 0.79 | 0.83 | 0.80 |

| 13 | 0.88 | 0.94 | 0.94 | 0.90 |

| 14 | 0.96 | 0.98 | 0.98 | 0.96 |

| 15 | 1.00 | 1.00 | 1.00 | 1.00 |

| 16 | 1.00 | 0.95 | 1.00 | 0.97 |

| 17 | 1.00 | 0.99 | 1.00 | 0.98 |

| 18 | 1.00 | 1.00 | 1.00 | 1.00 |

| 19 | 0.96 | 0.80 | 0.96 | 0.85 |

| 20 | 0.84 | 0.89 | 0.89 | 0.89 |

| Suppliers | Case 1 (C1) | Case 2 (C2) | Case 3 (C3) | Remarks 1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2% | 5% | 10% | 2% | 5% | 10% | 2% | 5% | 10% | 2% | 5% | 10% | |

| 1 | 0.63 | 0.67 | 0.74 | 0.63 | 0.66 | 0.73 | 0.63 | 0.67 | 0.75 | C1=C2=C3 | C1>C2<C3 | C3>C1<C2 |

| 2 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | C1=C2=C3 | C1=C2=C3 | C1=C2=C3 |

| 3 | 0.39 | 0.41 | 0.45 | 0.39 | 0.40 | 0.44 | 0.39 | 0.41 | 0.46 | C1=C2=C3 | C1>C2<C3 | C3>C1>C2 |

| 4 | 0.43 | 0.45 | 0.47 | 0.43 | 0.44 | 0.46 | 0.43 | 0.45 | 0.48 | C1=C2=C3 | C1>C2<C3 | C3>C1>C2 |

| 5 | 0.45 | 0.47 | 0.49 | 0.45 | 0.46 | 0.48 | 0.45 | 0.47 | 0.50 | C1=C2=C3 | C1>C2<C3 | C3>C1>C2 |

| 6 | 0.43 | 0.45 | 0.48 | 0.43 | 0.45 | 0.47 | 0.43 | 0.45 | 0.49 | C1=C2=C3 | C1=C2=C3 | C3>C1>C2 |

| 7 | 0.40 | 0.42 | 0.46 | 0.39 | 0.41 | 0.45 | 0.40 | 0.43 | 0.48 | C1>C2<C3 | C3>C1>C2 | C3>C1>C2 |

| 8 | 0.49 | 0.51 | 0.53 | 0.49 | 0.50 | 0.53 | 0.49 | 0.51 | 0.54 | C1=C2=C3 | C1>C2<C3 | C1<C3>C2 |

| 9 | 0.58 | 0.60 | 0.63 | 0.58 | 0.60 | 0.62 | 0.58 | 0.60 | 0.63 | C1=C2=C3 | C1=C2=C3 | C1>C2<C3 |

| 10 | 0.50 | 0.52 | 0.55 | 0.50 | 0.51 | 0.54 | 0.50 | 0.52 | 0.55 | C1=C2=C3 | C1>C2<C3 | C1>C2<C3 |

| 11 | 0.65 | 0.67 | 0.69 | 0.64 | 0.66 | 0.68 | 0.66 | 0.67 | 0.71 | C3>C1>C2 | C1>C2<C3 | C3>C1>C2 |

| 12 | 0.83 | 0.83 | 0.83 | 0.82 | 0.83 | 0.83 | 0.83 | 0.83 | 0.83 | C1>C2<C3 | C1=C2=C3 | C1=C2=C3 |

| 13 | 0.94 | 0.95 | 0.95 | 0.93 | 0.95 | 0.95 | 0.95 | 0.95 | 0.95 | C3>C1<C2 | C1=C2=C3 | C1=C2=C3 |

| 14 | 1.00 | 1.00 | 1.00 | 0.99 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | C1>C2<C3 | C1=C2=C3 | C1=C2=C3 |

| 15 | 1.00 | 0.95 | 0.86 | 1.00 | 0.98 | 0.92 | 1.00 | 0.92 | 0.81 | C1=C2=C3 | C2>C1>C3 | C2>C1>C3 |

| 16 | 1.00 | 1.00 | 1.00 | 0.99 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | C1=C2=C3 | C1=C2=C3 | C1=C2=C3 |

| 17 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | C1=C2=C3 | C1=C2=C3 | C1=C2=C3 |

| 18 | 1.00 | 0.97 | 0.89 | 1.00 | 0.99 | 0.94 | 1.00 | 0.94 | 0.84 | C1=C2=C3 | C2>C1>C3 | C2>C1>C3 |

| 19 | 0.88 | 0.88 | 0.88 | 0.87 | 0.88 | 0.88 | 0.88 | 0.88 | 0.88 | C1>C2<C3 | C1=C2=C3 | C1=C2=C3 |

| 20 | 0.88 | 0.88 | 0.89 | 0.87 | 0.88 | 0.89 | 0.88 | 0.88 | 0.89 | C1>C2<C3 | C1=C2=C3 | C1=C2=C3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krmac, E.; Djordjević, B. A New DEA Model for Evaluation of Supply Chains: A Case of Selection and Evaluation of Environmental Efficiency of Suppliers. Symmetry 2019, 11, 565. https://doi.org/10.3390/sym11040565

Krmac E, Djordjević B. A New DEA Model for Evaluation of Supply Chains: A Case of Selection and Evaluation of Environmental Efficiency of Suppliers. Symmetry. 2019; 11(4):565. https://doi.org/10.3390/sym11040565

Chicago/Turabian StyleKrmac, Evelin, and Boban Djordjević. 2019. "A New DEA Model for Evaluation of Supply Chains: A Case of Selection and Evaluation of Environmental Efficiency of Suppliers" Symmetry 11, no. 4: 565. https://doi.org/10.3390/sym11040565

APA StyleKrmac, E., & Djordjević, B. (2019). A New DEA Model for Evaluation of Supply Chains: A Case of Selection and Evaluation of Environmental Efficiency of Suppliers. Symmetry, 11(4), 565. https://doi.org/10.3390/sym11040565