Fuzzy Multicriteria Analysis for Performance Evaluation of Internet-of-Things-Based Supply Chains

Abstract

1. Introduction

2. Background

2.1. Existing Approaches for Evaluating the Performance of IoT-Based Supply Chains

2.2. Criteria for Evaluating the Performance of IoT-Based Supply Chains

3. The Fuzzy Multicriteria Group Decision Making Algorithm

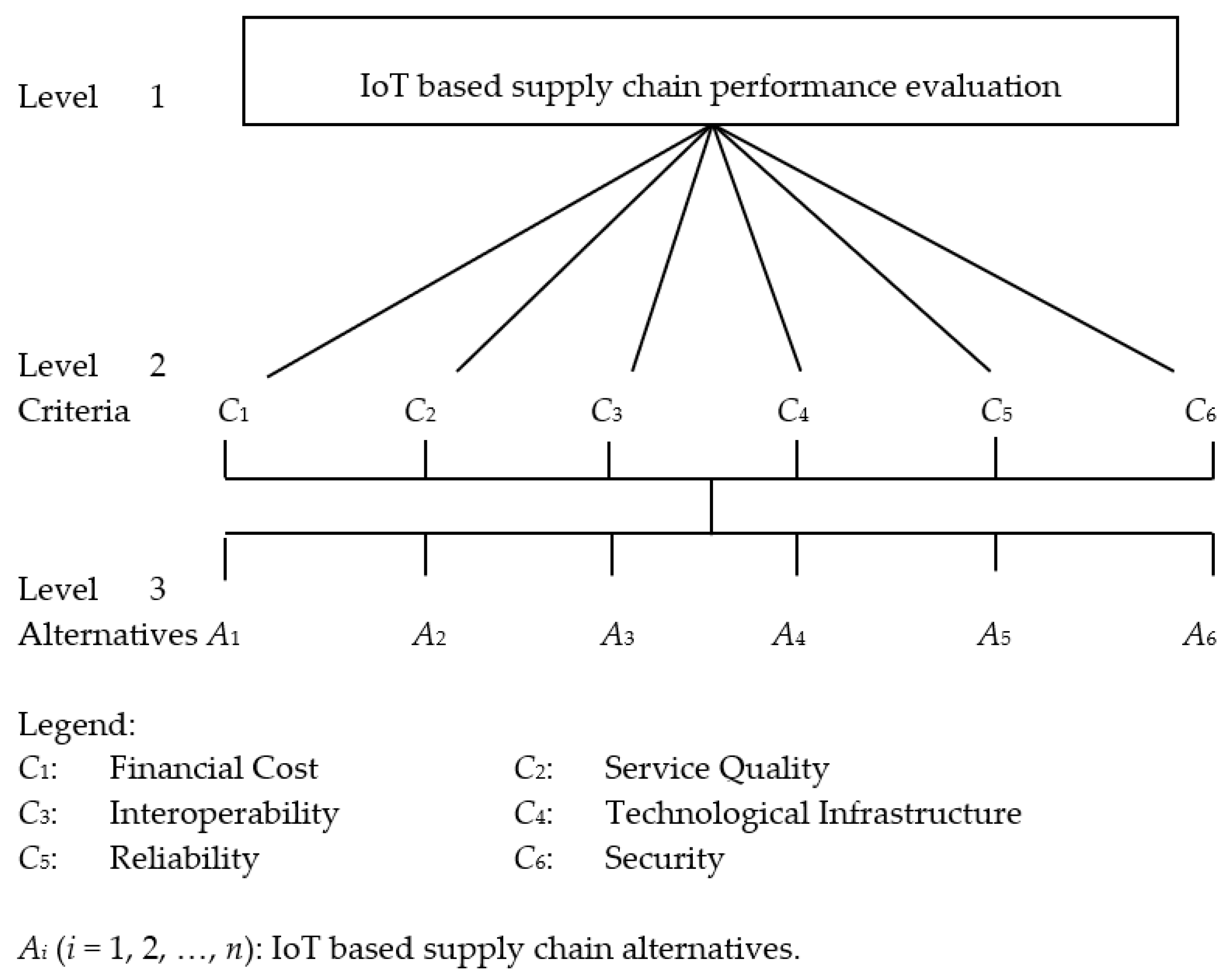

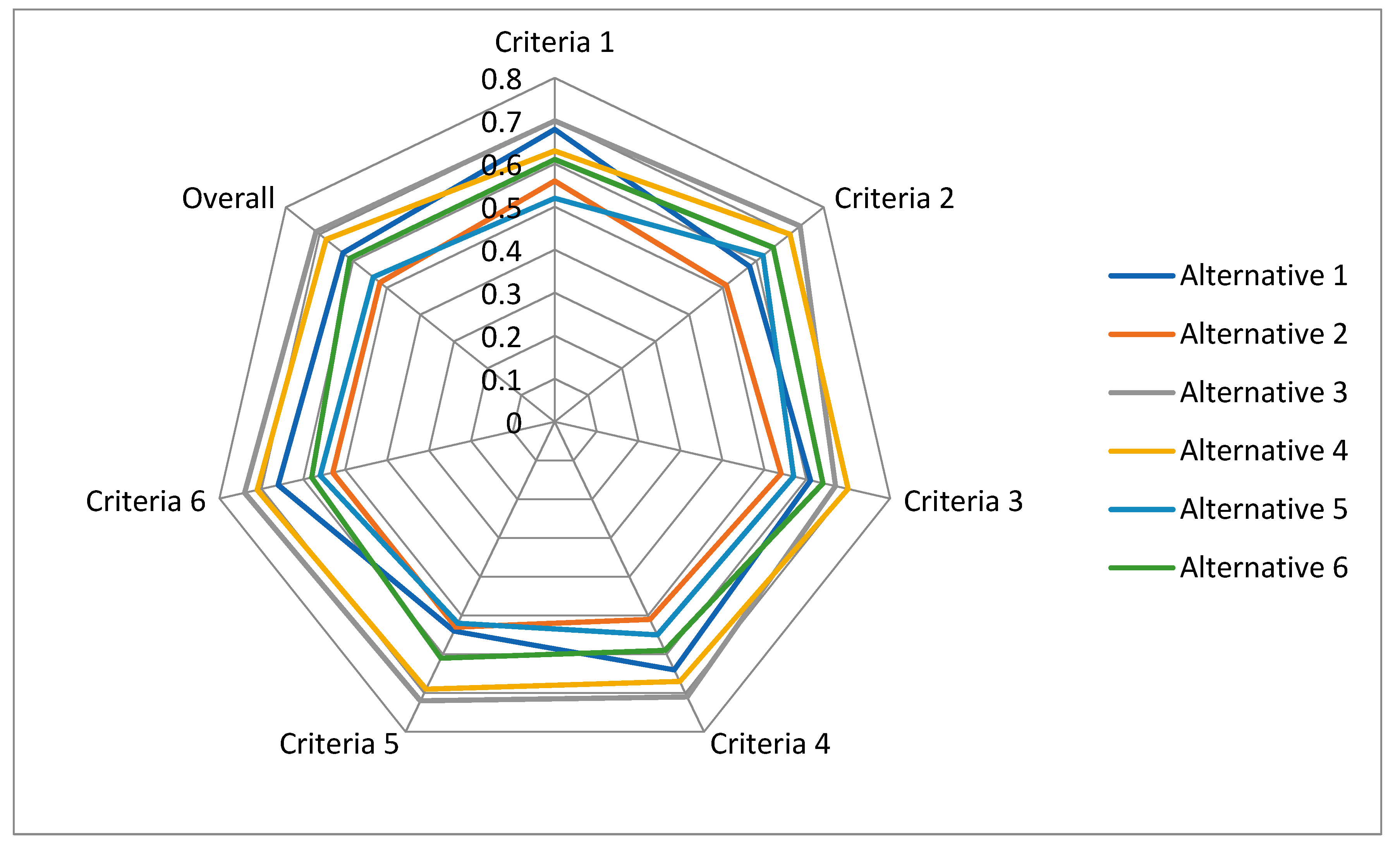

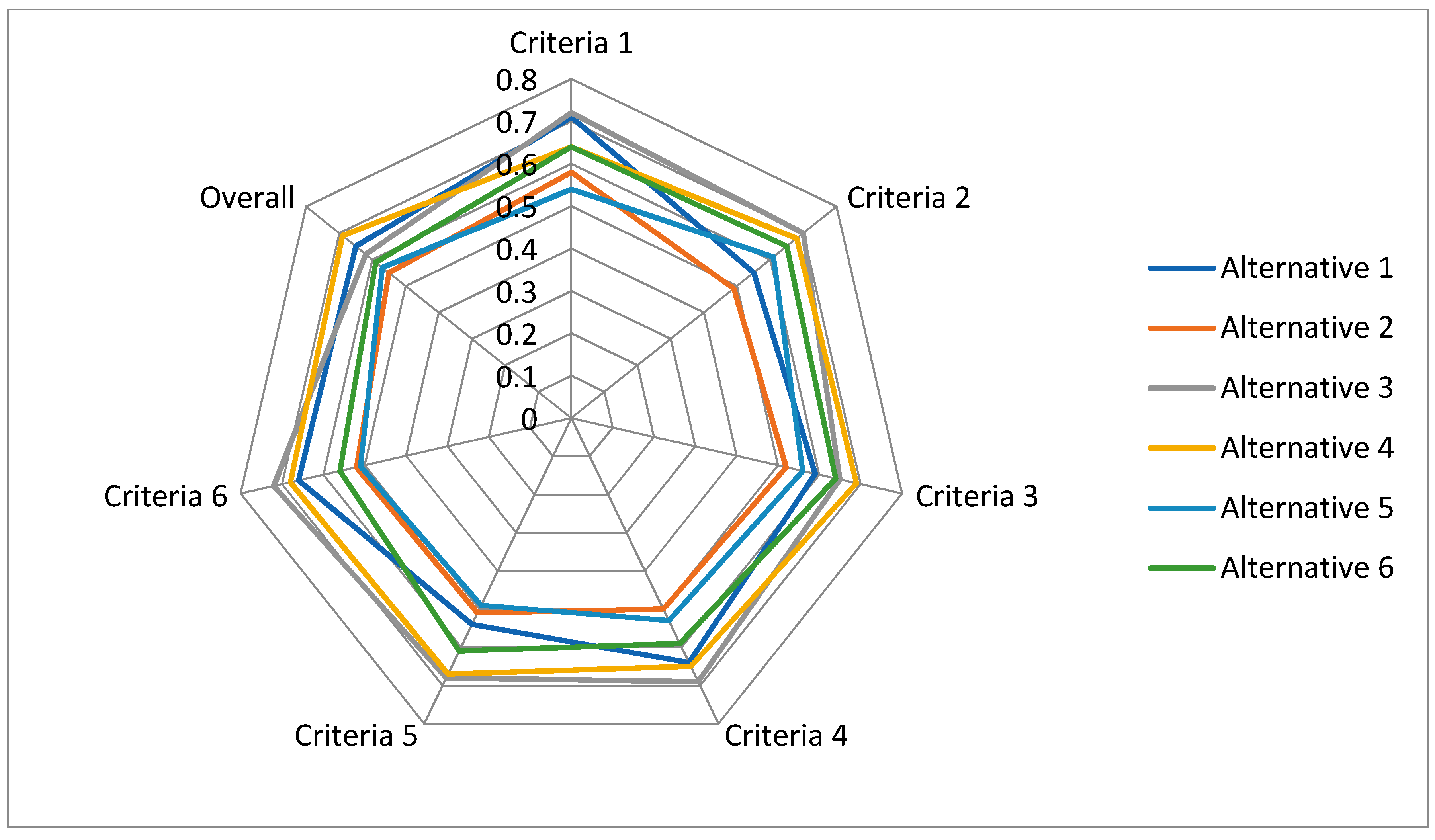

4. An Illustrative Example

5. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Liu, N. The application of Internet of Things in agricultural means of production supply chain management. J. Chem. Pharm. Res. 2014, 6, 2304–2310. [Google Scholar]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- García, C.G.; Núñez-Valdez, E.R.; García-Díaz, V.; Pelayo G-Bustelo, C.; Cueva-Lovelle, J.M. A review of artificial intelligence in the Internet of Things. Int. J. Interact. Multimed. Artif. Intell. 2018, in press. [Google Scholar] [CrossRef]

- Nallakaruppan, M.K.; Kumaran, U.S. Quick fix for obstacles emerging in management recruitment measure using IOT-based candidate selection. Serv. Oriented Comput. Appl. 2018, 1, 1–10. [Google Scholar] [CrossRef]

- Huang, Y.P.; Basanta, H.; Singh, A. Assessing health symptoms on intelligent IoT-based healthcare system. Adv. Sci. Technol. Lett. 2017, 144, 21–30. [Google Scholar]

- Dachyar, M.; Risky, S.A. Improving operational system performance of Internet of Things (IoT) in Indonesia telecomunication company. IOP Conf. Ser. Mater. Sci. Eng. 2014, 58, 1–5. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K.P. Multiple Attributes Decision Making Methods and Applications; Springer: Berlin, Germany, 1981. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Valacich, J.; Schneider, C. Information Systems Today: Managing in the Digital World; Pearson Education Limited: Hoboken, NJ, USA, 2014. [Google Scholar]

- Molano, J.I.R.; Lovelle, J.M.C.; Montenegro, C.E.; Granados, J.J.R.; Crespo, R.G. Metamodel for integration of internet of things, social networks, the cloud and industry 4.0. J. Ambient Intell. Humaniz. Comput. 2018, 9, 709–723. [Google Scholar] [CrossRef]

- Morente-Molinera, J.A.; Kou, G.; González-Crespo, R.; Corchado, J.M. Solving multi-criteria group decision making problems under environments with a high number of alternatives using fuzzy ontologies and multi-granular linguistic modelling methods. Knowl.-Based Syst. 2017, 137, 54–64. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Manogaran, G.; Mohamed, M. Internet of Things (IoT) and its impact on supply chain: A framework for building smart, secure and efficient systems. Future Gener. Comput. Syst. 2018, 86, 614–628. [Google Scholar] [CrossRef]

- Wibowo, S. A Fuzzy Approach for Evaluating the Performance of Supply Chain based on Internet of Things. In Proceedings of the IEEE International Conference on Cyber Technology in Automation, Control, and Intelligent Systems (IEEE-CYBER 2012), Bangkok, Thailand, 27–31 May 2012. [Google Scholar]

- Decker, C.; Berchtold, M.; Chaves, L.W.; Beigl, M.; Roehr, D.; Riedel, T.; Herzig, D. Cost-benefit model for smart items in the supply chain. Internet Things 2008, 1, 155–172. [Google Scholar]

- Huang, J.; Xu, L.; Xing, C.; Duan, Q. A novel bioinspired multiobjective optimization algorithm for designing wireless sensor networks in the Internet of Things. J. Sens. 2015, 1, 1–16. [Google Scholar] [CrossRef]

- Nunes, L.H.; Estrella, J.C.; Perera, C.; Reiff-Marganiec, S.; Delbem, A.C. Multi-criteria IoT resource discovery: A comparative analysis. Softw. Pract. Exper. 2017, 47, 1325–1341. [Google Scholar] [CrossRef]

- Fan, S.; Shi, W.; Wang, N.; Liu, Y. MODM-based evaluation model of service quality in the Internet of Things. Pocedia Environ. Sci. 2011, 11, 63–69. [Google Scholar]

- Du, J.; Zhao, L.; Feng, J.; Chu, X. Computation offloading and resource allocation in mixed fog/cloud computing systems with min-max fairness guarantee. IEEE Trans. Commun. 2018, 66, 1594–1608. [Google Scholar] [CrossRef]

- Habib, M.S.; Sarkar, B. An integrated location-allocation model for temporary disaster debris management under an uncertain environment. Sustainability 2017, 9, 716. [Google Scholar] [CrossRef]

- Welbourne, E.; Battle, L.; Cole, G.; Gould, K.; Rector, K.; Raymer, S.; Balazinska, M.; Borriello, G. Building the Internet of Things using RFID: The RFID ecosystem experience. IEEE Internet Comput. 2009, 13, 48–55. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Chui, M.; Loffler, M.; Roberts, R. The internet of things. McKinsey Q. 2010, 2, 70–79. [Google Scholar]

- Zanella, A.; Bui, N.; Castellani, A.; Vangelista, L.; Zorzi, M. Internet of Things for smart cities. IEEE J. Internet Things 2014, 1, 22–32. [Google Scholar] [CrossRef]

- Brody, P.; Pureswaran, V. The next digital gold rush: How the Internet of Things will create liquid, transparent markets. Strategy Leadersh. 2015, 43, 36–41. [Google Scholar] [CrossRef]

- Martinho, R.; Domingos, D. Quality of information and access cost of IoT resources in BPMN processes. Procedia Technol. 2014, 16, 737–744. [Google Scholar] [CrossRef]

- Kouicem, D.E.; Bouabdallah, A.; Lakhlef, H. Internet of things security: A top-down survey. Comput. Netw. 2018, 141, 199–221. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Benedetto, C.A. Designing service quality to survive: Empirical evidence from Chinese new ventures. J. Bus. Res. 2013, 66, 1098–1107. [Google Scholar] [CrossRef]

- Thaichon, P.; Lobo, A.; Prentice, C.; Quach, T.N. The development of service quality dimensions for Internet service providers: Retaining customers of different usage patterns. J. Retail. Consum. Serv. 2014, 21, 1047–1058. [Google Scholar] [CrossRef]

- Macaulay, T. Interoperability, flexibility, and industrial design requirements in the IoT. RIoT Control 2017, 1, 197–219. [Google Scholar]

- Kryvinska, N.; Strauss, C. Conceptual model of business services availability vs. interoperability on collaborative IoT-enabled eBusiness platforms. Stud. Comput. Intell. 2013, 1, 167–187. [Google Scholar]

- Dehury, C.K.; Sahoo, P.K. Design and implementation of a novel service management framework for IoT devices in cloud. J. Syst. Softw. 2016, 119, 149–161. [Google Scholar] [CrossRef]

- Chin, W.S.; Kim, H.S.; Heo, Y.J. A context-based future network infrastructure for IoT services. Procedia Comput. Sci. 2015, 56, 266–270. [Google Scholar] [CrossRef]

- Olivier, F.; Carlos, G.; Florent, N. New security architecture for IoT network. Procedia Comput. Sci. 2015, 52, 1028–1033. [Google Scholar] [CrossRef]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Sarkar, S. Internet of Things—Robustness and reliability. Internet Things 2016, 1, 201–218. [Google Scholar]

- Hersent, O.; Elloumi, O.; Boswarthick, D. The Internet of Things: Key Applications and Protocols; John Wiley and Sons: Milton, Queensland, Australia, 2011. [Google Scholar]

- Farooq, M.U.; Waseem, M.; Khairi, A.; Mazhar, S. A critical analysis on the security concerns of Internet of Things (IoT). Int. J. Comput. Appl. 2015, 111, 1–8. [Google Scholar]

- Weber, R.H. Internet of Things—New security and privacy challenges. Comput. Law Secur. Rev. 2010, 26, 23–30. [Google Scholar] [CrossRef]

- Gaona-García, P.; Montenegro-Marin, C.; Prieto, J.D.; Nieto, Y.V. Analysis of security mechanisms based on clusters IoT environments. Int. J. Interact. Multimed. Artif. Intell. 2017, 4, 55–60. [Google Scholar] [CrossRef]

- Atanassov, K. Intuitionistic fuzzy sets. Fuzzy Sets Syst. 1996, 20, 87–96. [Google Scholar] [CrossRef]

- Wibowo, S.; Deng, H. Consensus-based decision support for multicriteria group decision making. Comput. Ind. Eng. 2013, 66, 625–633. [Google Scholar] [CrossRef]

- Yeh, C.H.; Deng, H.; Wibowo, S.; Xu, Y. Multicriteria group decision for information systems project selection under uncertainty. Int. J. Fuzzy Syst. 2010, 12, 170–179. [Google Scholar]

- Chen, S.M.; Cheng, S.H.; Lan, T.C. A novel similarity measure between intuitionistic fuzzy sets based on the centroid points of transformed fuzzy numbers with applications to pattern recognition. Inf. Sci. 2016, 343, 15–40. [Google Scholar] [CrossRef]

- Lin, L.; Yuan, X.H.; Xia, Z.Q. Multicriteria fuzzy decision-making methods based on intuitionistic fuzzy sets. J. Comput. Syst. Sci. 2007, 73, 84–88. [Google Scholar] [CrossRef]

- Xia, M.; Xu, Z. Hesitant fuzzy information aggregation in decision making. Int. J. Approx. Reason. 2011, 52, 395–407. [Google Scholar] [CrossRef]

- Hashemi, S.S.; Hajiagha, S.H.; Zavadskas, E.K.; Mahdiraji, H.A. Multicriteria group decision making with ELECTRE III method based on interval-valued intuitionistic fuzzy information. Appl. Math. Modell. 2016, 40, 1554–1564. [Google Scholar] [CrossRef]

| Authors | Multicriteria Based | Multiobjective Optimization | ||

|---|---|---|---|---|

| Multicriteria Based | Cost Based | Model Objective | Model Formulation | |

| Nallakaruppan and Kumaran [4] | TOPSIS approach | |||

| Huang et al. [5] | Fuzzy AHP approach | |||

| Dachyar and Risky [6] | AHP approach | |||

| Lee and Lee [12] | Net present value method and real option approach | |||

| Abdel-Basset et al. [13] | DEMATEL and AHP | |||

| Wibowo [14] | Fuzzy approach | |||

| Decker et al. [15] | Quantification cost approach | |||

| Huang et al. [16] | Minimize design problem | Chaotic ant swarm approach | ||

| Nunes et al. [17] | Minimize resources | VIKOR approach | ||

| Fan et al. [18] | Minimize quality of service problem | Scale-extending, entropy weight, and least squares approaches | ||

| Du et al. [19] | Minimize resources | Mixed integer linear programming approach | ||

| Habib and Sarkar [20] | ANP and TOPSIS | Debris allocation | Fuzzy possibilistic programming | |

| Ai | Dk | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|---|

| A1 | D1 | (0.6, 0.7) | (0.3, 0.6) | (0.4, 0.6) | (0.3, 0.6) | (0.5, 0.6) | (0.5, 0.6) |

| D2 | (0.5, 0.8) | (0.5, 0.7) | (0.4, 0.7) | (0.4, 0.5) | (0.5, 0.7) | (0.5, 0.8) | |

| D3 | (0.5, 0.6) | (0.3, 0.4) | (0.7, 0.8) | (0.5, 0.7) | (0.4, 0.6) | (0.7, 0.8) | |

| A2 | D1 | (0.3, 0.6) | (0.5, 0.6) | (0.3, 0.5) | (0.5, 0.8) | (0.4, 0.8) | (0.1, 0.3) |

| D2 | (0.5, 0.7) | (0.5, 0.8) | (0.6, 0.8) | (0.6, 0.7) | (0.3, 0.7) | (0.7, 0.8) | |

| D3 | (0.2, 0.6) | (0.7, 0.8) | (0.5, 0.9) | (0.3, 0.6) | (0.5, 0.9) | (0.4, 0.6) | |

| A3 | D1 | (0.4, 0.5) | (0.3, 0.4) | (0.3, 0.6) | (0.4, 0.8) | (0.6, 0.8) | (0.5, 0.7) |

| D2 | (0.3, 0.7) | (0.7, 0.8) | (0.5, 0.8) | (0.6, 0.8) | (0.3, 0.6) | (0.5, 0.6) | |

| D3 | (0.5, 0.6) | (0.1, 0.3) | (0.7, 0.8) | (0.5, 0.6) | (0.3, 0.8) | (0.6, 0.8) | |

| A4 | D1 | (0.4, 0.8) | (0.6, 0.8) | (0.4, 0.7) | (0.3, 0.6) | (0.5, 0.6) | (0.5, 0.7) |

| D2 | (0.3, 0.4) | (0.4, 0.7) | (0.6, 0.9) | (0.3, 0.5) | (0.3, 0.6) | (0.7, 0.8) | |

| D3 | (0.7, 0.8) | (0.5, 0.6) | (0.5, 0.8) | (0.5, 0.7) | (0.5, 0.7) | (0.5, 0.6) | |

| A5 | D1 | (0.5, 0.7) | (0.3, 0.8) | (0.6, 0.8) | (0.5, 0.7) | (0.6, 0.9) | (0.6, 0.7) |

| D2 | (0.5, 0.6) | (0.4, 0.6) | (0.3, 0.6) | (0.5, 0.6) | (0.5, 0.8) | (0.6, 0.8) | |

| D3 | (0.7, 0.8) | (0.5, 0.8) | (0.5, 0.8) | (0.6, 0.8) | (0.4, 0.6) | (0.3, 0.6) | |

| A6 | D1 | (0.2, 0.6) | (0.6, 0.7) | (0.4, 0.6) | (0.4, 0.5) | (0.4, 0.7) | (0.4, 0.8) |

| D2 | (0.7, 0.8) | (0.5, 0.6) | (0.3, 0.7) | (0.7, 0.8) | (0.6, 0.8) | (0.5, 0.7) | |

| D3 | (0.5, 0.6) | (0.4, 0.7) | (0.5, 0.6) | (0.3, 0.4) | (0.4, 0.6) | (0.5, 0.6) |

| Criteria | Decision Makers | ||

|---|---|---|---|

| D1 | D2 | D3 | |

| C1 | (0.6, 0.3) | (0.5, 0.1) | (0.7, 0.3) |

| C2 | (0.5, 0.4) | (0.4, 0.3) | (0.5, 0.4) |

| C3 | (0.2, 0.5) | (0.3, 0.6) | (0.6, 0.4) |

| C4 | (0.6, 0.8) | (0.2, 0.5) | (0.8, 0.6) |

| C5 | (0.4, 0.2) | (0.7, 0.3) | (0.4, 0.3) |

| C6 | (0.7, 0.3) | (0.5, 0.4) | (0.5, 0.3) |

| Ai | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| A1 | (0.52, 0.64) | (0.58, 0.63) | (0.67, 0.75) | (0.51, 0.62) | (0.43, 0.48) | (0.42, 0.51) |

| A2 | (0.37, 0.46) | (0.46, 0.57) | (0.41, 0.49) | (0.35, 0.46) | (0.44, 0.52) | (0.52, 0.59) |

| A3 | (0.73, 0.87) | (0.56, 0.71) | (0.68, 0.76) | (0.63, 0.68) | (0.55, 0.64) | (0.37, 0.64) |

| A4 | (0.68, 0.73) | (0.52, 0.58) | (0.54, 0.61) | (0.55, 0.63) | (0.35, 0.46) | (0.56, 0.71) |

| A5 | (0.44, 0.58) | (0.36, 0.62) | (0.48, 0.54) | (0.52, 0.59) | (0.63, 0.68) | (0.47, 0.63) |

| A6 | (0.48, 0.53) | (0.48, 0.55) | (0.54, 0.62) | (0.43, 0.52) | (0.55, 0.63) | (0.38, 0.53) |

| Alternatives | Criteria | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Financial Cost (C1) | Service Quality (C2) | Functionality (C3) | Technological Infrastructure (C4) | Reliability (C5) | Security (C6) | Overall | ||||||||

| Index | Ranking | Index | Ranking | Index | Ranking | Index | Ranking | Index | Ranking | Index | Ranking | Index | Ranking | |

| A1 | 0.68 | 2 | 0.58 | 5 | 0.61 | 4 | 0.64 | 3 | 0.54 | 3 | 0.66 | 4 | 0.63 | 3 |

| A2 | 0.56 | 5 | 0.51 | 6 | 0.54 | 6 | 0.51 | 6 | 0.53 | 6 | 0.53 | 6 | 0.52 | 6 |

| A3 | 0.70 | 1 | 0.73 | 1 | 0.67 | 2 | 0.71 | 1 | 0.72 | 2 | 0.74 | 1 | 0.71 | 1 |

| A4 | 0.63 | 3 | 0.70 | 2 | 0.70 | 1 | 0.67 | 2 | 0.69 | 1 | 0.71 | 2 | 0.68 | 2 |

| A5 | 0.52 | 6 | 0.62 | 4 | 0.57 | 5 | 0.55 | 5 | 0.52 | 5 | 0.56 | 5 | 0.54 | 5 |

| A6 | 0.61 | 4 | 0.65 | 3 | 0.64 | 3 | 0.59 | 4 | 0.61 | 4 | 0.58 | 3 | 0.61 | 4 |

| Criteria | Decision Makers | ||

|---|---|---|---|

| D1 | D2 | D3 | |

| C1 | (0.8, 0.2) | (0.6, 0.1) | (0.8, 0.2) |

| C2 | (0.6, 0.3) | (0.5, 0.2) | (0.6, 0.5) |

| C3 | (0.2, 0.5) | (0.3, 0.2) | (0.6, 0.3) |

| C4 | (0.4, 0.8) | (0.2, 0.1) | (0.4, 0.2) |

| C5 | (0.3, 0.1) | (0.6, 0.4) | (0.5, 0.4) |

| C6 | (0.6, 0.2) | (0.4, 0.3) | (0.3, 0.2) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wibowo, S.; Grandhi, S. Fuzzy Multicriteria Analysis for Performance Evaluation of Internet-of-Things-Based Supply Chains. Symmetry 2018, 10, 603. https://doi.org/10.3390/sym10110603

Wibowo S, Grandhi S. Fuzzy Multicriteria Analysis for Performance Evaluation of Internet-of-Things-Based Supply Chains. Symmetry. 2018; 10(11):603. https://doi.org/10.3390/sym10110603

Chicago/Turabian StyleWibowo, Santoso, and Srimannarayana Grandhi. 2018. "Fuzzy Multicriteria Analysis for Performance Evaluation of Internet-of-Things-Based Supply Chains" Symmetry 10, no. 11: 603. https://doi.org/10.3390/sym10110603

APA StyleWibowo, S., & Grandhi, S. (2018). Fuzzy Multicriteria Analysis for Performance Evaluation of Internet-of-Things-Based Supply Chains. Symmetry, 10(11), 603. https://doi.org/10.3390/sym10110603