Investigation into the Working Behavior of Geotextile Pipe-Bag Systems on Soft Soil Foundations in the Ningde Port Industrial Zone, China

Abstract

1. Introduction

2. Mechanical Properties of Soft Soil and Geotextiles

2.1. Project Overview

2.2. Test Preparation

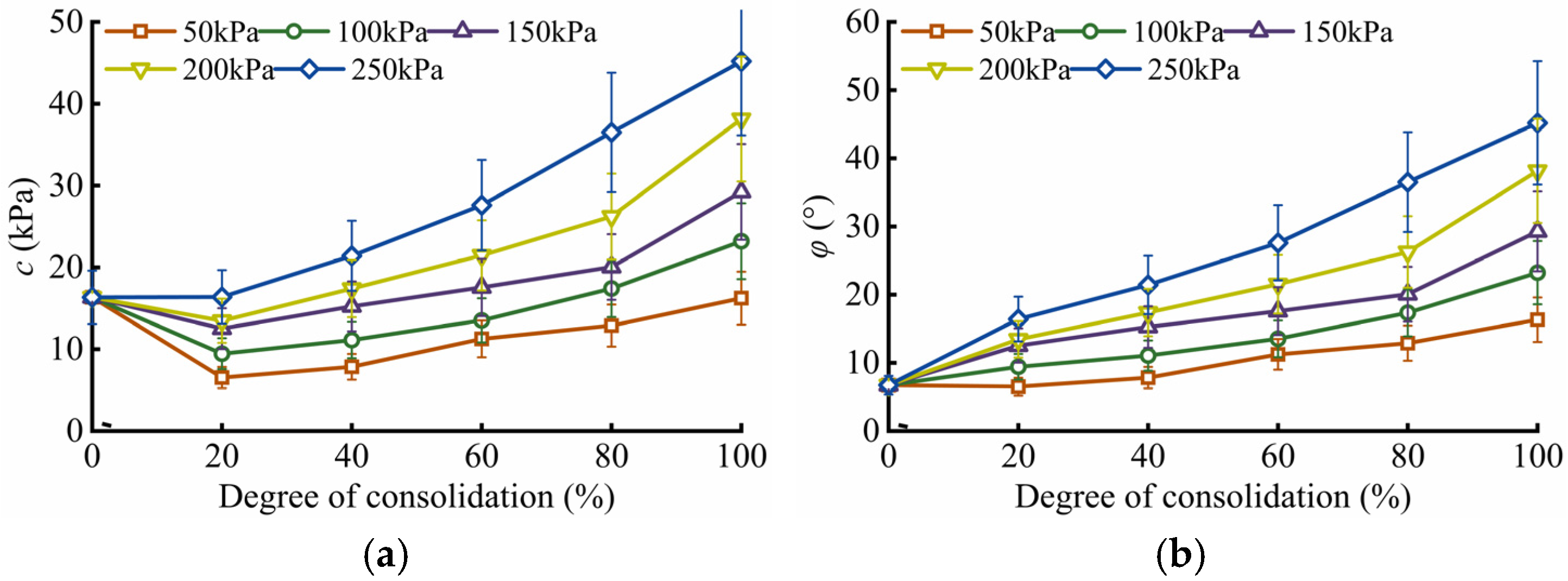

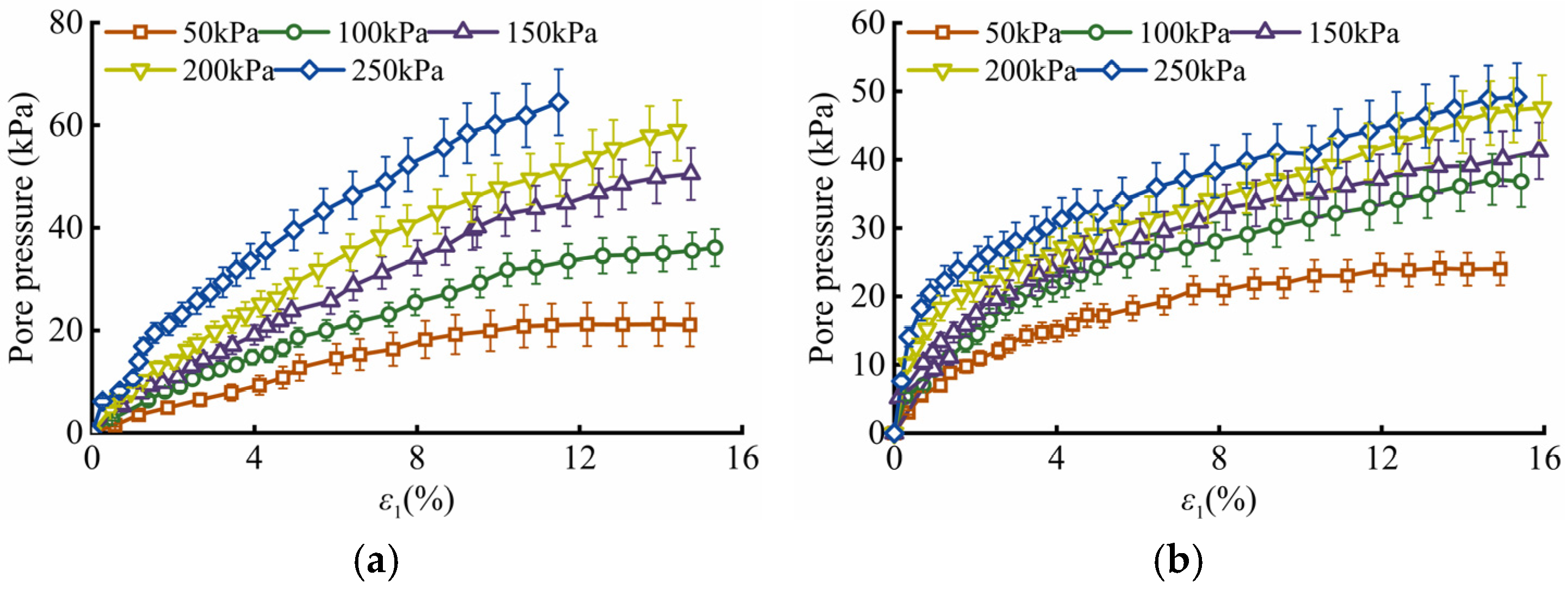

2.3. Mechanical Properties of Soft Soil

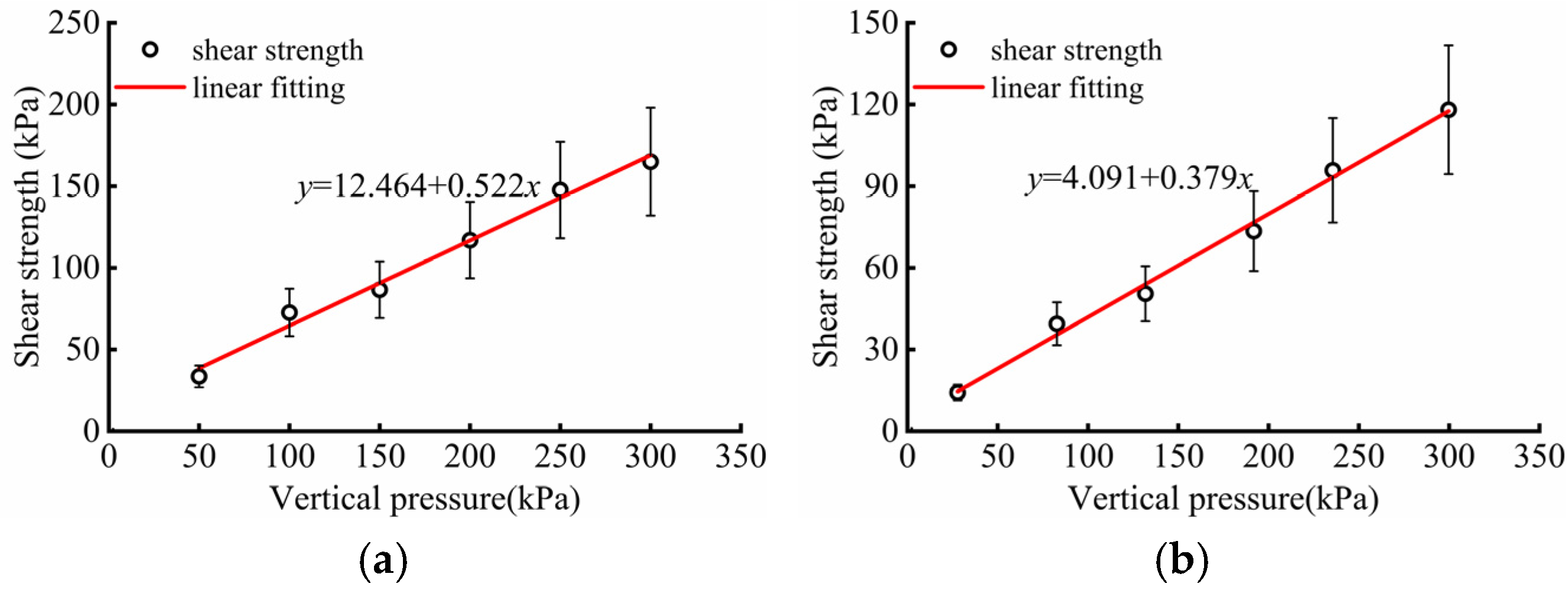

2.4. The Mechanical Properties of Geotextiles

3. Finite Element Modeling of Geotextile Pipe-Bag Structures

3.1. Constitutive Models

3.2. Parameters of Constitutive Models

3.3. FEM Model

4. Working Behavior of Geotextile Pipe-Bag Structures

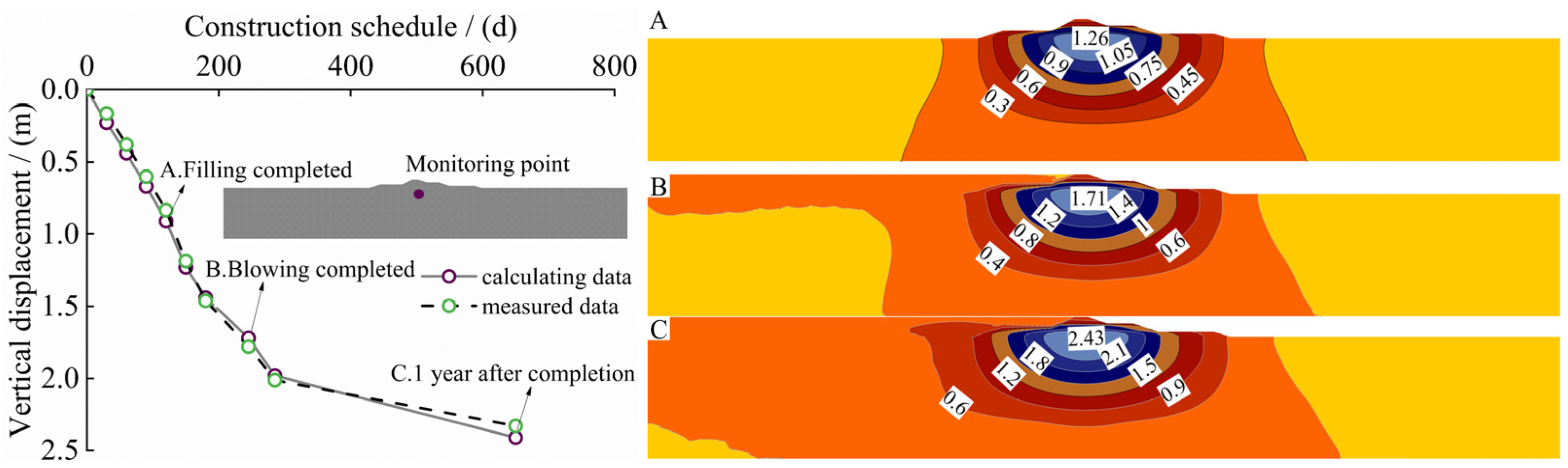

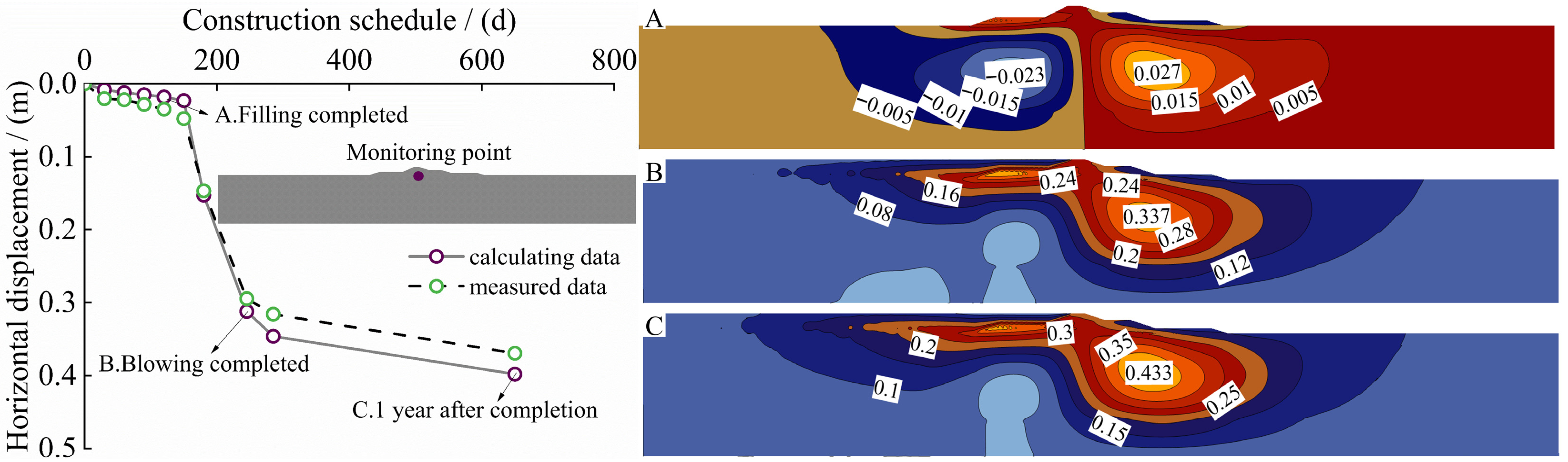

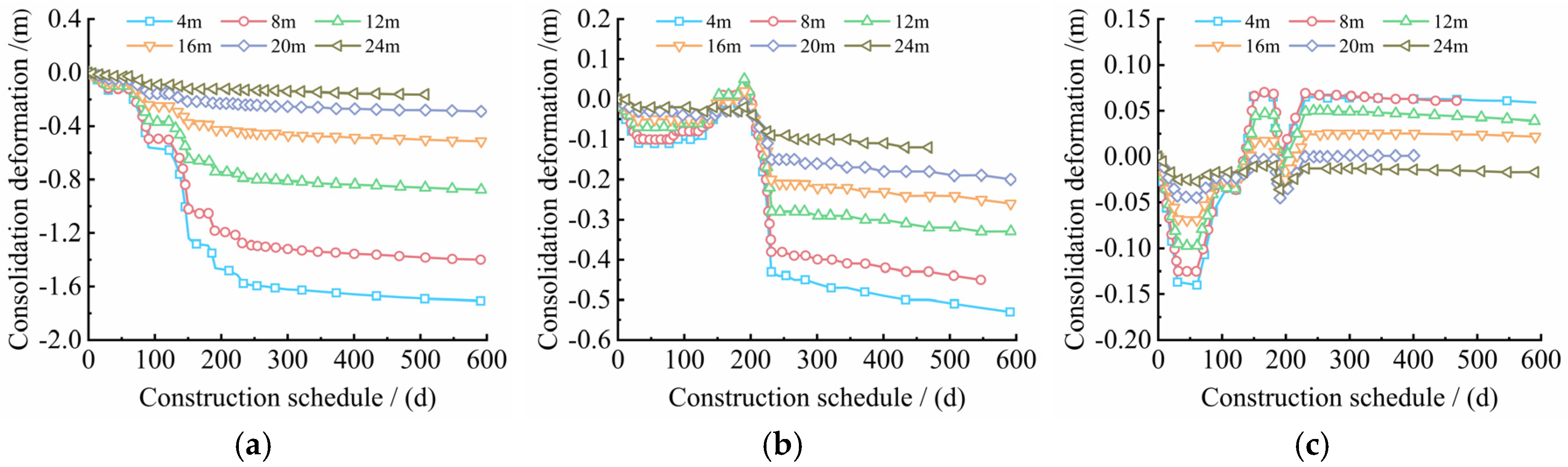

4.1. Displacement Deformation Characteristics

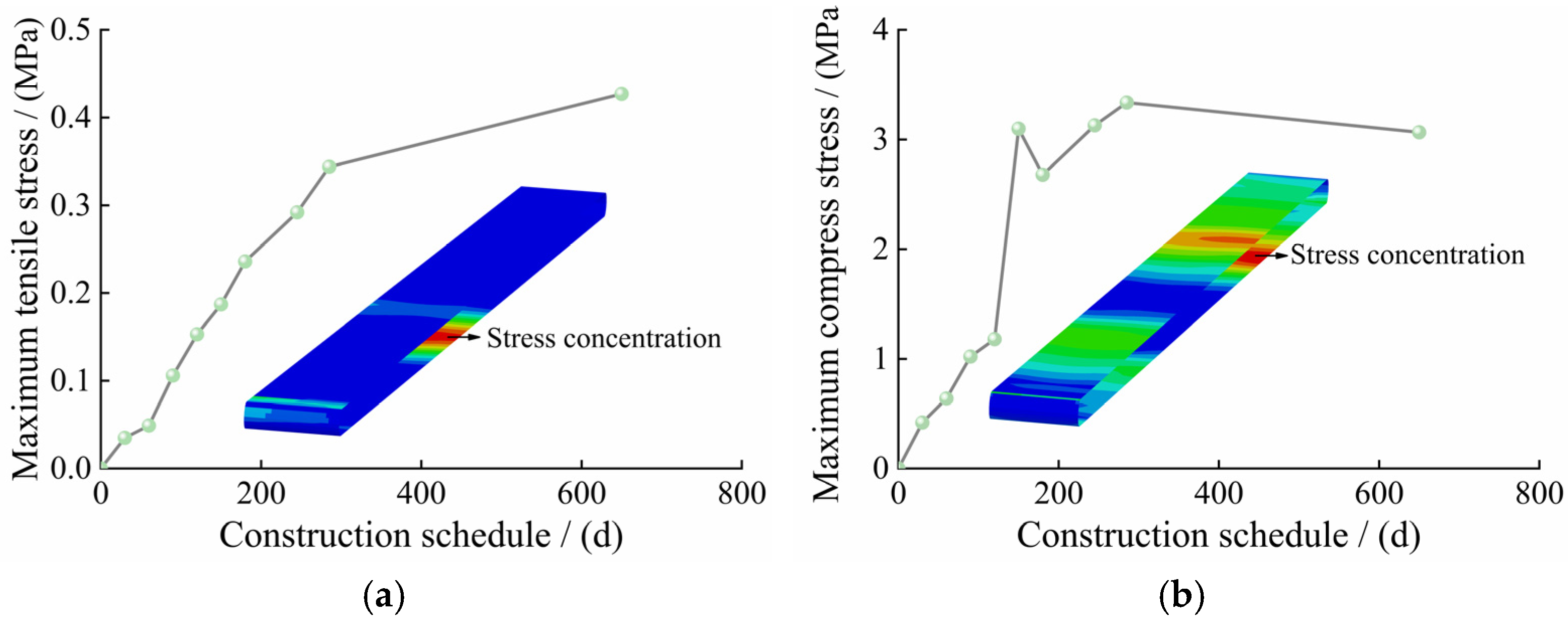

4.2. Stress Characteristics

5. Conclusions

- (1)

- The compression curve of soft soil exhibits significant nonlinear characteristics, with the apparent compressibility of silt being higher than that of silty clay. The compression and rebound coefficients of soft soil were determined from experimental data. As consolidation pressure increases, the deviatoric stress of soft soil rises significantly, demonstrating typical strain-hardening behavior. Based on these results, the effective stress ratio M for both types of soft soil was derived. A quantitative relationship between shear strength parameters c and φ and the degree of consolidation was established, and the evolution pattern of pore pressure was summarized. Interface characteristic tests were conducted to obtain the c and φ at the interfaces between bags and sand, as well as between adjacent bags.

- (2)

- A three-dimensional refined numerical model of the GPB structure was developed. Simulation results indicate that foundation settlement progressively increases with construction advancement. During construction breaks, the drainage boards facilitate drainage, effectively reducing the settlement rate. Horizontal displacement is highly influenced by the hydraulic filling process; when the upper fill is asymmetrically placed, uneven horizontal displacements occur across the foundation.

- (3)

- As hydraulic filling proceeds, the overall structure gradually transitions into a more pronounced tensile state, with stress concentration at the slope toe becoming increasingly evident. One year after completion of filling, tensile stress slightly decreases. The GPB structure remains under tension throughout, with the maximum tensile stress occurring in the central region. However, all peak tensile stresses remain below the material’s allowable stress limit. Drainage boards effectively accelerate pore pressure dissipation, which is nearly complete within one year after construction ends.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiong, W.; Luo, Y.; Shangguan, W.G.; Deng, Y.; Xiao, R. Co-hydrothermal carbonization of lignocellulosic biomass and swine manure: Optimal parameters for enhanced nutrient reclamation, carbon sequestration, and heavy metals passivation. Waste Manag. 2024, 190, 174–185. [Google Scholar] [CrossRef]

- Hagger, V.; Stewart-Sinclair, P.; Rossini, R.A.; Adame, M.F.; Lovelock, C.E. Lessons learned on the feasibility of coastal wetland restoration for blue carbon and co-benefits in Australia. J. Environ. Manag. 2024, 369, 122287. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.S.; Li, W.; Kwok, C.Y. Seawater effects on ground granulated blast furnace slag (GGBS)-stabilized marine deposits in land reclamation. Acta. Geotech. 2025, 37, 397–412. [Google Scholar] [CrossRef]

- Bradford, T.E.; Lo, C.C.; Astudillo, J.C.; Leung, R.W.; Lai, C.; Minuti, J.J.; Wong, C.K. Turning riprap into reefs: Integrating oyster shells into shoreline armouring. Mar. Pollut. Bull. 2025, 216, 117933. [Google Scholar] [CrossRef] [PubMed]

- Wei, G.; Chu, J.; Yan, S.W.; He, Z.B. Analytical solutions for geosynthetic tube resting on rigid foundation. Geotext. Geomembr. 2014, 6, 65–77. [Google Scholar]

- Wei, G.; Chu, J.; Nie, W. Analysis of geosynthetic tubes inflated by liquid and consolidated soil. Geotext. Geomembr. 2014, 42, 277–283. [Google Scholar]

- Wei, G.; Chu, J.; Yan, S.W. Simplified analytical solution for geosynthetic tube resting on deformable foundation soil. Geotext. Geomembr. 2015, 43, 432–439. [Google Scholar]

- Carneiro, J.R.; Almeida, F.; Carvalho, F.; Lopes, M. Tensile and tearing properties of a geocomposite mechanically damaged by repeated loading and abrasion. Materials 2023, 16, 7047. [Google Scholar] [CrossRef]

- Chmura, D.; Salachna, A.; Broda, J.; Katarzyna, K.M.; Gawłowski, A.; Rom, M. Multifunctional geotextiles produced from reclaimed fibres and their role in ecological engineering. Materials 2022, 15, 7957. [Google Scholar] [CrossRef]

- Thompsona, A.; Oberhagemannb, K. Yuntong She Geobag stability for riverbank erosion protection structures: Physical model study. Geotext. Geomembr. 2020, 48, 110–119. [Google Scholar] [CrossRef]

- Guin, S.; Bhattacherjee, D. Applicability of Geobags as a Sustainable Riverbank Protection Measure. Indian. Geotech. J. 2024, 54, 800–813. [Google Scholar] [CrossRef]

- Ying, Z.; Cui, Y.J.; Benahmed, N.; Duc, M. Changes in microstructure and water retention property of a lime-treated saline soil during curing. Acta Geotech. 2022, 17, 319–326. [Google Scholar] [CrossRef]

- Lei, H.Y.; Li, C.Y.; Liu, J.J. Experimental study and numerical simulation of an alternating vacuum preloading method for strengthening hydraulic fill super soft soils. Chin. J. Rock Mech. Eng. 2019, 38, 2112–2125. (In Chinese) [Google Scholar]

- Cai, Y.Q.; Chen, Y.; Cao, Z.G.; Ren, C. A combined method to predict the long-term settlements of roads on soft soil under cyclic traffic loadings. Acta. Geotech. 2018, 5, 1215–1226. [Google Scholar] [CrossRef]

- Jiang, X.; Huang, Z.; Ma, F.; Luo, X. Analysis of strength development and soil-water characteristics of rice husk ash-lime stabilized soft soil. Materials 2019, 12, 3873. [Google Scholar] [CrossRef]

- Chen, L.; Lin, D.F. Stabilization treatment of soft subgrade soil by sewage sludge ash and cement. J. Hazard. Mater. 2009, 162, 321–327. [Google Scholar] [CrossRef]

- Nanda, R.P.; Priya, N.; Kumar, A. Enhancement of strength of soft soil utilizing construction and demolition wastes reinforced with Recron-3s fibres. J. Clean. Prod. 2025, 505, 145442. [Google Scholar] [CrossRef]

- Liu, R.; Yan, H.; Liang, C. A unified lateral soil reaction model for monopiles in soft clay. Ocean Eng. 2025, 319, 120268. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, X.; Zhou, M.; Zhang, X. The behavior of ball penetrometer in soft-over-stiff soil deposits. Ocean Eng. 2023, 273, 114011. [Google Scholar] [CrossRef]

- Ye, R.R.; Huang, Z.Y.; Yang, Z.X.; Guo, N.; Jardine, R.; Fu, S. Large deformation analysis of intermittent pile penetration into dense sand incorporating a state-dependent Mohr–Coulomb model. Can. Geotech. J. 2025, 62, 463–472. [Google Scholar] [CrossRef]

- Wang, X.; Han, Y.H.; Chen, S.L.; Abousleiman, Y. An analytical drained solution based on graphical method for wellbore drilling problem in dilatant Mohr-Coulomb rock formations. Int. J. Rock Mech. Min. 2025, 193, 106170. [Google Scholar] [CrossRef]

- Moeineddin, A.; Platen, J.; Kaliske, M. Constitutive description of snow at finite strains by the modified cam-clay model and an implicit gradient damage formulation. Int. J. Numer. Meth. Eng. 2024, 125, e7595. [Google Scholar] [CrossRef]

- Wang, X.; Silbermann, C.B.; Nagel, T.; Nackenhorst, T. Modelling of the elastoplastic behaviour of the bio-cemented soils using an extended Modified Cam Clay model. J. Rock Mech. Geotech. 2024, 16, 2184–2197. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, P.; Shi, L.; Cai, Y.Q.; Wang, J. Analytical solution on vacuum consolidation of dredged slurry considering clogging effect. Geotext. Geomembr. 2021, 49, 842–851. [Google Scholar] [CrossRef]

- Zeng, L.L.; Cai, Y.Q.; Cui, Y.J.; Hong, Z.S. Hydraulic conductivity of reconstituted clays based on intrinsic compression. Géotechnique 2020, 70, 268–275. [Google Scholar] [CrossRef]

- Lan, P.; Su, J.J.; Ma, X.Y.; Zhang, S. Application of improved physics-informed neural networks for nonlinear consolidation problems with continuous drainage boundary conditions. Acta. Geotech. 2024, 19, 495–508. [Google Scholar] [CrossRef]

- Singh, A.; Chakraborty, M. Combined effect of non-darcian flow and semipermeable drainage boundaries on one-dimensional consolidation of unsaturated soil. Int. J. Geomech. 2024, 24, 04024157. [Google Scholar] [CrossRef]

- Cai, Y.Q. Consolidation mechanism of vacuum preloading for dredged slurry and anti-clogging method for drains. Chin. J. Geo. Eng. 2021, 43, 201–225. (In Chinese) [Google Scholar]

- Ye, G.B.; Xu, Y.; Zhang, Z. Performance Evaluation of PVD-Reinforced Soft Soil with Surcharge and Vacuum Preloading. Int. J. Civ. Eng. 2018, 16, 421–433. [Google Scholar] [CrossRef]

- Lim, B.S.; Tumay, M.T.; Lee, J.W.; Chun, B.S.; Jung, J.W. A case study in evaluating the status of consolidation of a soft soil deposit by incomplete piezocone dissipation tests using laboratory and field data. Soils Found. 2014, 54, 648–656. [Google Scholar] [CrossRef]

- Yang, S.P.; Yang, A.W.; Xu, A.J. Vacuum preloading reinforcement of soft dredger soil by modified fiber drainage plate. Rock Soil Mech. 2025, 46, 789–797. (In Chinese) [Google Scholar]

- Zhou, Y.; Chai, J.C. Equivalent ‘smear’ effect due to nonuniform consolidation surrounding a PVD. Géotechnique 2017, 67, 410–419. [Google Scholar] [CrossRef]

| Soft Soil | Moisture Content w (%) | Unit Weight γ (kN·m−3) | Void Ratio e | Liquid Limit WL (%) | Plastic Limit Wp (%) |

|---|---|---|---|---|---|

| Silt | 49.3 | 17.4 | 0.941 | 41.9 | 23.6 |

| Silty clay | 41.9 | 18.3 | 0.787 | 40.0 | 22.7 |

| γ/(kN/m) | c/(kPa) | φ/(°) | E/(MPa) | υ | Permeability Coefficient k/(m/s) | |

|---|---|---|---|---|---|---|

| Silt | 19 | 0 | 32 | 30 | 0.3 | 6.0 × 10−5 |

| Silty clay | 18 | 500 | 0.3 | 2.0 × 10−4 |

| Soil | υ | λ | κ | M | e0 | Permeability Coefficient k/(m/s) |

|---|---|---|---|---|---|---|

| dredger fill | 0.43 | 0.0593 | 0.0214 | 0.543 | 1.125 | 2.6 × 10−5 |

| Silt | 0.41 | 0.0646 | 0.0117 | 0.962 | 0.941 | 1.9 × 10−9 |

| Silty clay | 0.33 | 0.0775 | 0.0105 | 0.499 | 0.787 | 5.0 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, P.; Ren, H.; Zhang, X.; Li, W.; Guo, W. Investigation into the Working Behavior of Geotextile Pipe-Bag Systems on Soft Soil Foundations in the Ningde Port Industrial Zone, China. Water 2025, 17, 3063. https://doi.org/10.3390/w17213063

Fan P, Ren H, Zhang X, Li W, Guo W. Investigation into the Working Behavior of Geotextile Pipe-Bag Systems on Soft Soil Foundations in the Ningde Port Industrial Zone, China. Water. 2025; 17(21):3063. https://doi.org/10.3390/w17213063

Chicago/Turabian StyleFan, Peijun, Honglei Ren, Xiatao Zhang, Wei Li, and Wanli Guo. 2025. "Investigation into the Working Behavior of Geotextile Pipe-Bag Systems on Soft Soil Foundations in the Ningde Port Industrial Zone, China" Water 17, no. 21: 3063. https://doi.org/10.3390/w17213063

APA StyleFan, P., Ren, H., Zhang, X., Li, W., & Guo, W. (2025). Investigation into the Working Behavior of Geotextile Pipe-Bag Systems on Soft Soil Foundations in the Ningde Port Industrial Zone, China. Water, 17(21), 3063. https://doi.org/10.3390/w17213063