A Review of Biochar-Industrial Waste Composites for Sustainable Soil Amendment: Mechanisms and Perspectives

Abstract

1. Introduction

2. Properties, Impacts, and Limitations of Biochar in Agricultural Soils

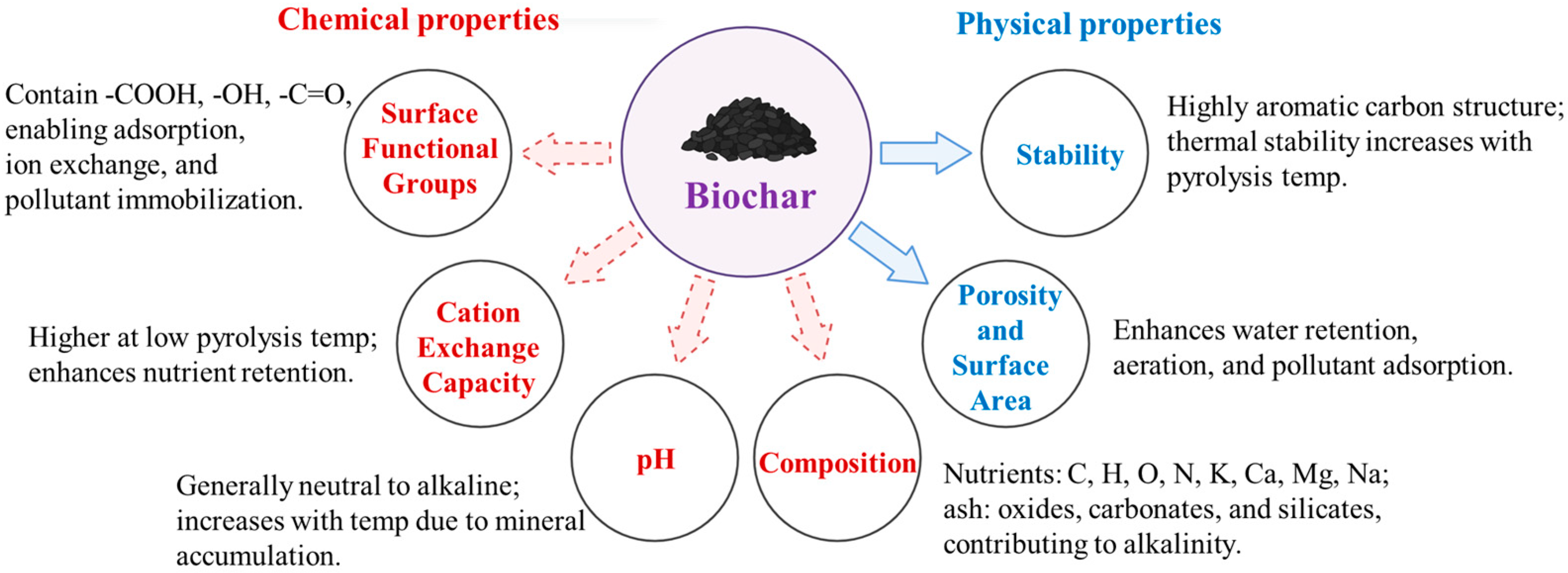

2.1. Properties of Biochar

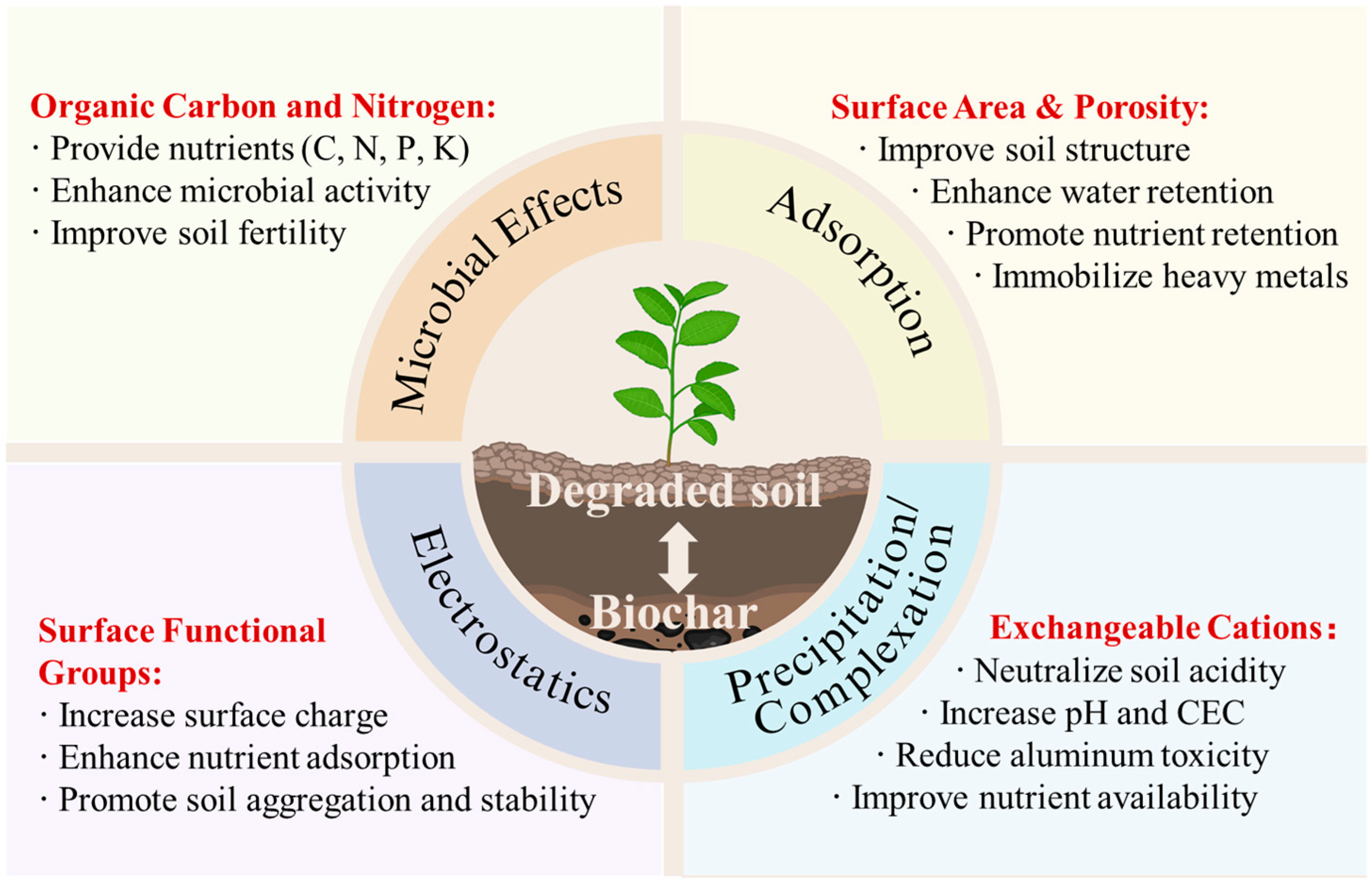

2.2. Effects of Biochar on Soil Properties and Plant Growth

2.3. Potential Risks and Limitations of Biochar

3. Utilization of Industrial Wastes in Agricultural Soils

3.1. Fly Ash

3.1.1. Composition and Properties

3.1.2. Effects on Soil Properties and Plant Growth

3.1.3. Potential Environmental Risks

3.2. Steel Slag

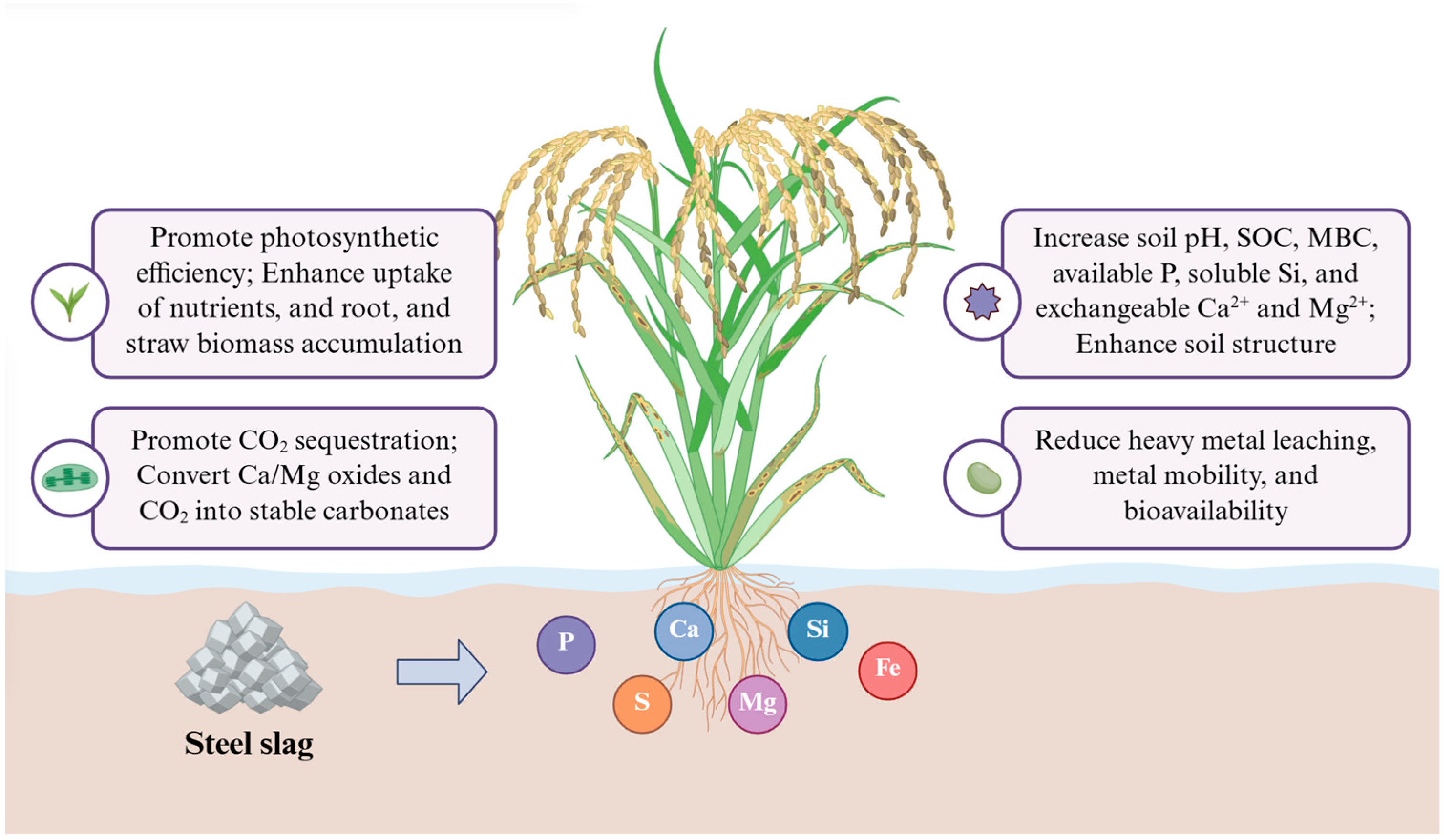

3.2.1. Composition and Properties

3.2.2. Effects on Soil Properties and Plant Growth

3.2.3. Potential Environmental Risks

3.3. Red Mud

3.3.1. Composition and Properties

3.3.2. Effects on Soil Properties and Plant Growth

3.3.3. Potential Environmental Risks

3.4. Phosphogypsum

3.4.1. Composition and Properties

3.4.2. Effects on Soil Properties and Plant Growth

3.4.3. Potential Environmental Risks

4. Advantages of Biochar-Industrial Waste Composites for Soil Improvement

4.1. Interaction Mechanisms Between Biochar and Industrial Wastes

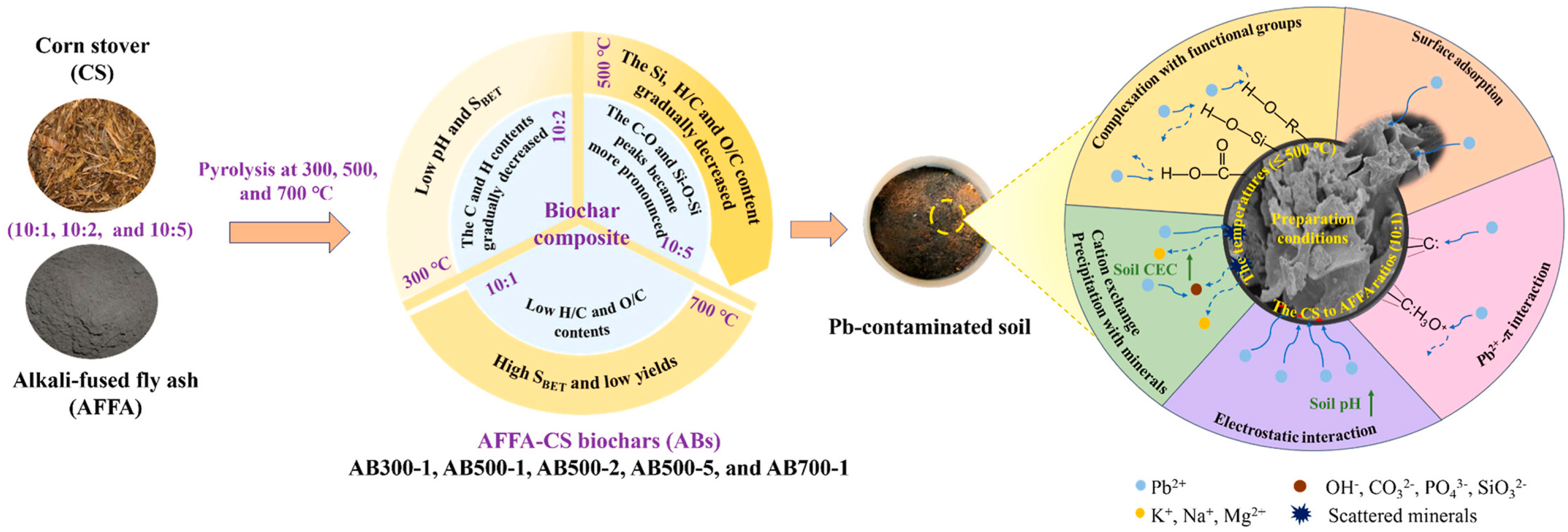

4.1.1. Biochar and Fly Ash

4.1.2. Biochar and Steel Slag

4.1.3. Biochar and Red Mud

4.1.4. Biochar and Phosphogypsum

4.2. Effects of Biochar-Industrial Waste Composites on Agricultural Soils

4.2.1. Amendment of Acidic and Saline/Alkaline Soils

4.2.2. Remediation of Heavy Metal Contaminated Soils

4.2.3. Improvement of Low Fertility Soils

4.2.4. Impact on Soil Carbon Sequestration

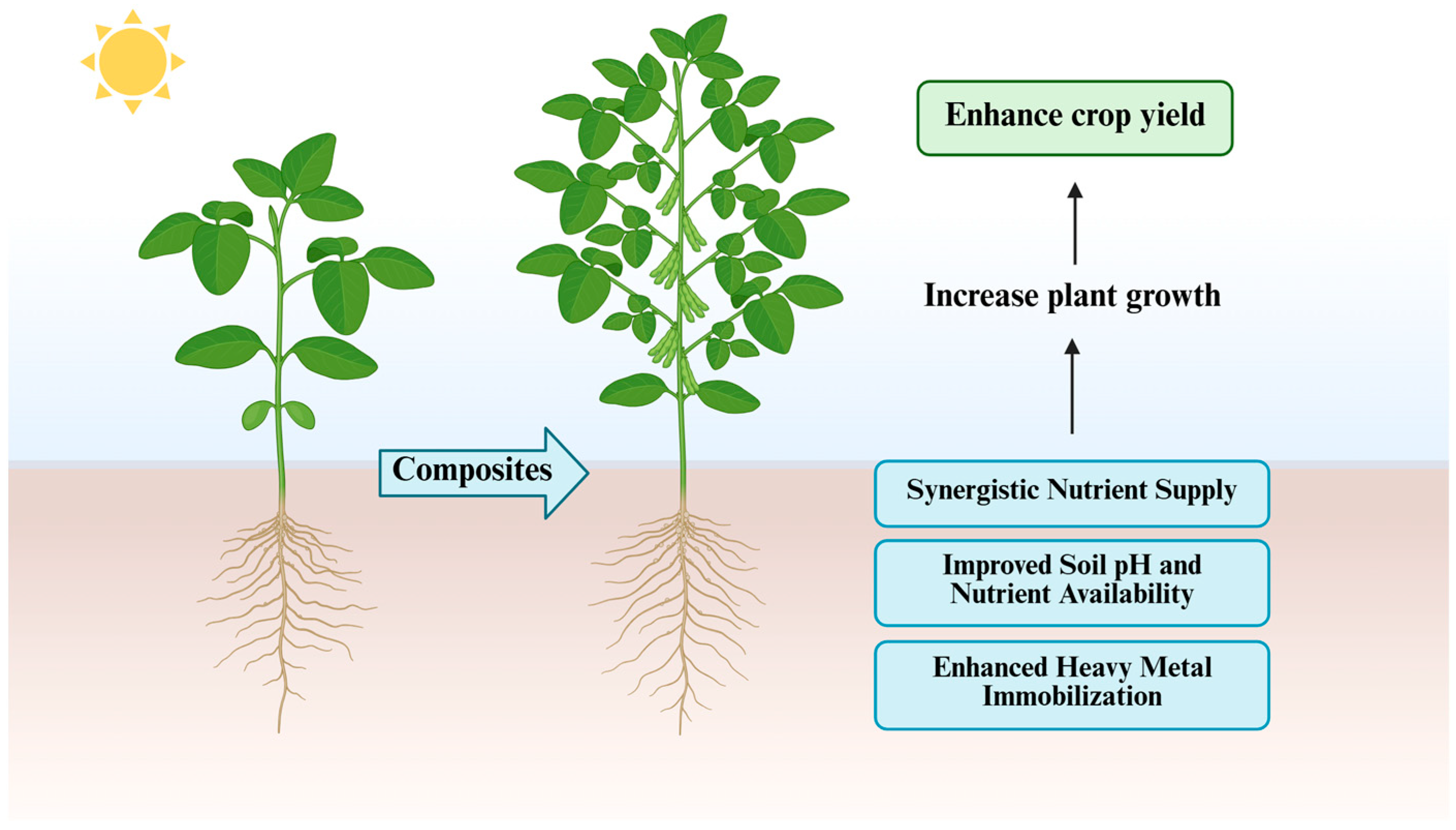

4.3. Role of Biochar-Industrial Waste Composites on Crop Growth and Yield

5. Challenges and Prospects of Co-Application in Agricultural Soils

5.1. Challenges of Biochar and Industrial Waste Co-Application

5.1.1. Environmental Risks

5.1.2. Technical and Application Constraints

5.1.3. Adoption and Policy Barriers

5.2. Future Perspectives

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BC | Biochar |

| FL | Fly ash |

| SS | Steel slag |

| RM | Red mud |

| PG | Phosphogypsum |

References

- Wall, D.H.; Nielsen, U.N.; Six, J. Soil Biodiversity and Human Health. Nature 2015, 528, 69–76. [Google Scholar] [CrossRef]

- Yu, H.; Zou, W.; Chen, J.; Chen, H.; Yu, Z.; Huang, J.; Tang, H.; Wei, X.; Gao, B. Biochar Amendment Improves Crop Production in Problem Soils: A Review. J. Environ. Manag. 2019, 232, 8–21. [Google Scholar] [CrossRef] [PubMed]

- Reynolds, T.W.; Waddington, S.R.; Anderson, C.L.; Chew, A.; True, Z.; Cullen, A. Environmental Impacts and Constraints Associated with the Production of Major Food Crops in Sub-Saharan Africa and South Asia. Food Sec. 2015, 7, 795–822. [Google Scholar] [CrossRef]

- Garbowski, T.; Bar-Michalczyk, D.; Charazińska, S.; Grabowska-Polanowska, B.; Kowalczyk, A.; Lochyński, P. An Overview of Natural Soil Amendments in Agriculture. Soil Tillage Res. 2023, 225, 105462. [Google Scholar] [CrossRef]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a Sorbent for Contaminant Management in Soil and Water: A Review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef]

- Blanco-Canqui, H. Does Biochar Application Alleviate Soil Compaction? Review and Data Synthesis. Geoderma 2021, 404, 115317. [Google Scholar] [CrossRef]

- Hafiz, H.; Jun, Z.; Yu-Shuang, G.; Mei-Xu, G.; Wei, G. Proteomic analysis of pathogen-responsive proteins from maize stem apoplast triggered by Fusarium verticillioides. J. Integr. Agric. 2022, 21, 446–459. [Google Scholar] [CrossRef]

- Huang, Z.; Lu, Q.; Wang, J.; Chen, X.; Mao, X.; He, Z. Inhibition of the Bioavailability of Heavy Metals in Sewage Sludge Biochar by Adding Two Stabilizers. PLoS ONE 2017, 12, e0183617. [Google Scholar] [CrossRef]

- El-Mahrouky, M.; Al-Barakah, F.N.; Schoenau, J.J.; Ahmed, I.; Alotaibi, K.D.; Fahad, S. Use of Poultry Litter-Based Fertilizers in Calcareous Soil: Effects on Corn Growth and Selected Properties. Appl. Environ. Soil Sci. 2025, 1590143. [Google Scholar]

- Xu, X.; Zhao, Y.; Sima, J.; Zhao, L.; Mašek, O.; Cao, X. Indispensable Role of Biochar-Inherent Mineral Constituents in Its Environmental Applications: A Review. Bioresour. Technol. 2017, 241, 887–899. [Google Scholar] [CrossRef]

- Munir, M.A.M.; Liu, G.; Yousaf, B.; Ali, M.U.; Abbas, Q.; Ullah, H. Synergistic Effects of Biochar and Processed Fly Ash on Bioavailability, Transformation and Accumulation of Heavy Metals by Maize (Zea mays L.) in Coal-Mining Contaminated Soil. Chemosphere 2020, 240, 124845. [Google Scholar] [CrossRef]

- Zou, Q.; An, W.; Wu, C.; Li, W.; Fu, A.; Xiao, R.; Chen, H.; Xue, S. Red Mud-Modified Biochar Reduces Soil Arsenic Availability and Changes Bacterial Composition. Environ. Chem. Lett. 2018, 16, 615–622. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.; Lan, X.; Abid, A.A.; Xu, X.; Singla, A.; Sardans, J.; Llusia, J.; Penuelas, J.; Wang, W. Coupled Steel Slag and Biochar Amendment Correlated with Higher Methanotrophic Abundance and Lower CH4 Emission in Subtropical Paddies. Environ. Geochem. Health 2020, 42, 483–497. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Deng, Y.; Liu, L.; Tian, X.; Gang, S.; Wei, Z.; Zhang, X.; Yue, K. The Addition of Biochar as a Fertilizer Supplement for the Attenuation of Potentially Toxic Elements in Phosphogypsum-Amended Soil. J. Clean. Prod. 2020, 277, 124052. [Google Scholar] [CrossRef]

- Akfas, F.; Elghali, A.; Aboulaich, A.; Munoz, M.; Benzaazoua, M.; Bodinier, J.-L. Exploring the Potential Reuse of Phosphogypsum: A Waste or a Resource? Sci. Total Environ. 2024, 908, 168196. [Google Scholar] [CrossRef]

- Ram, L.C.; Masto, R.E. Fly Ash for Soil Amelioration: A Review on the Influence of Ash Blending with Inorganic and Organic Amendments. Earth-Sci. Rev. 2014, 128, 52–74. [Google Scholar] [CrossRef]

- Buss, W.; Wurzer, C.; Manning, D.A.C.; Rohling, E.J.; Borevitz, J.; Mašek, O. Mineral-Enriched Biochar Delivers Enhanced Nutrient Recovery and Carbon Dioxide Removal. Commun. Earth Environ. 2022, 3, 67. [Google Scholar] [CrossRef]

- Hassan, M.; Liu, Y.; Naidu, R.; Parikh, S.J.; Du, J.; Qi, F.; Willett, I.R. Influences of Feedstock Sources and Pyrolysis Temperature on the Properties of Biochar and Functionality as Adsorbents: A Meta-Analysis. Sci. Total Environ. 2020, 744, 140714. [Google Scholar] [CrossRef]

- Karim, A.A.; Kumar, M.; Mohapatra, S.; Singh, S.K.; Panda, C.R. Co-Plasma Processing of Banana Peduncle with Phosphogypsum Waste for Production of Lesser Toxic Potassium–Sulfur Rich Biochar. J. Mater. Cycles Waste Manag. 2019, 21, 107–115. [Google Scholar] [CrossRef]

- Rizwan, M.; Ali, S.; Qayyum, M.F.; Ibrahim, M.; Zia-ur-Rehman, M.; Abbas, T.; Ok, Y.S. Mechanisms of Biochar-Mediated Alleviation of Toxicity of Trace Elements in Plants: A Critical Review. Environ. Sci. Pollut. Res. 2016, 23, 2230–2248. [Google Scholar] [CrossRef]

- El-Naggar, A.; Lee, S.S.; Rinklebe, J.; Farooq, M.; Song, H.; Sarmah, A.K.; Zimmerman, A.R.; Ahmad, M.; Shaheen, S.M.; Ok, Y.S. Biochar Application to Low Fertility Soils: A Review of Current Status, and Future Prospects. Geoderma 2019, 337, 536–554. [Google Scholar] [CrossRef]

- Zhao, Q.; Xu, T.; Song, X.; Nie, S.; Choi, S.-E.; Si, C. Preparation and Application in Water Treatment of Magnetic Biochar. Front. Bioeng. Biotechnol. 2021, 9, 769667. [Google Scholar] [CrossRef]

- Melo, T.M.; Bottlinger, M.; Schulz, E.; Leandro, W.M.; de Oliveira, S.B.; de Aguiar Filho, A.M.; El-Naggarg, A.; Bolan, N.; Wang, H.; Ok, Y.S.; et al. Management of Biosolids-Derived Hydrochar (Sewchar): Effect on Plant Germination, and Farmers’ Acceptance. J. Environ. Manag. 2019, 237, 200–214. [Google Scholar] [CrossRef]

- Qin, P.; Wang, H.; Yang, X.; He, L.; Muller, K.; Shaheen, S.M.; Xu, S.; Rinklebe, J.; Tsang, D.C.W.; Ok, Y.S.; et al. Bamboo- and Pig-Derived Biochars Reduce Leaching Losses of Dibutyl Phthalate, Cadmium, and Lead from Co-Contaminated Soils. Chemosphere 2018, 198, 450–459. [Google Scholar] [CrossRef] [PubMed]

- Palansooriya, K.N.; Wong, J.T.F.; Hashimoto, Y.; Huang, L.; Rinklebe, J.; Chang, S.X.; Bolan, N.; Wang, H.; Ok, Y.S. Response of Microbial Communities to Biochar-Amended Soils: A Critical Review. Biochar 2019, 1, 3–22. [Google Scholar] [CrossRef]

- Yuan, J.-H.; Xu, R.-K.; Zhang, H. The Forms of Alkalis in the Biochar Produced from Crop Residues at Different Temperatures. Bioresour. Technol. 2011, 102, 3488–3497. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Li, Y.; Cao, Y.; Han, L. Characteristics of Tetracycline Adsorption by Cow Manure Biochar Prepared at Different Pyrolysis Temperatures. Bioresour. Technol. 2019, 285, 121348. [Google Scholar] [CrossRef] [PubMed]

- Tag, A.T.; Duman, G.; Ucar, S.; Yanik, J. Effects of Feedstock Type and Pyrolysis Temperature on Potential Applications of Biochar. J. Anal. Appl. Pyrolysis 2016, 120, 200–206. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Ryu, C.; Gang, K.S.; Yang, W.; Park, Y.-K.; Jung, J.; Hyun, S. Comparison of Biochar Properties from Biomass Residues Produced by Slow Pyrolysis at 500 Degrees C. Bioresour. Technol. 2013, 148, 196–201. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.G.; Kleber, M. Dynamic Molecular Structure of Plant Biomass-Derived Black Carbon (Biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef]

- Ding, W.; Dong, X.; Ime, I.M.; Gao, B.; Ma, L.Q. Pyrolytic Temperatures Impact Lead Sorption Mechanisms by Bagasse Biochars. Chemosphere 2014, 105, 68–74. [Google Scholar] [CrossRef]

- Lataf, A.; Jozefczak, M.; Vandecasteele, B.; Viaene, J.; Schreurs, S.; Carleer, R.; Yperman, J.; Marchal, W.; Cuypers, A.; Vandamme, D. The Effect of Pyrolysis Temperature and Feedstock on Biochar Agronomic Properties. J. Anal. Appl. Pyrolysis 2022, 168, 105728. [Google Scholar] [CrossRef]

- Glaser, B.; Lehmann, J.; Zech, W. Ameliorating Physical and Chemical Properties of Highly Weathered Soils in the Tropics with Charcoal—A Review. Biol. Fertil. Soils 2002, 35, 219–230. [Google Scholar] [CrossRef]

- Huang, H.; Reddy, N.G.; Huang, X.; Chen, P.; Wang, P.; Zhang, Y.; Huang, Y.; Lin, P.; Garg, A. Effects of Pyrolysis Temperature, Feedstock Type and Compaction on Water Retention of Biochar Amended Soil. Sci Rep 2021, 11, 7419. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Pu, S.; Adhikari, S.; Ma, H.; Kim, D.-H.; Bai, Y.; Hou, D. Progress and Future Prospects in Biochar Composites: Application and Reflection in the Soil Environment. Crit. Rev. Environ. Sci. Technol. 2021, 51, 219–271. [Google Scholar] [CrossRef]

- Kim, W.-K.; Shim, T.; Kim, Y.-S.; Hyun, S.; Ryu, C.; Park, Y.-K.; Jung, J. Characterization of Cadmium Removal from Aqueous Solution by Biochar Produced from a Giant Miscanthus at Different Pyrolytic Temperatures. Bioresour. Technol. 2013, 138, 266–270. [Google Scholar] [CrossRef]

- Singh Yadav, S.P.; Bhandari, S.; Bhatta, D.; Poudel, A.; Bhattarai, S.; Yadav, P.; Ghimire, N.; Paudel, P.; Paudel, P.; Shrestha, J.; et al. Biochar Application: A Sustainable Approach to Improve Soil Health. J. Agric. Food Res. 2023, 11, 100498. [Google Scholar] [CrossRef]

- Liu, Q.; Yuan, Y.; Liu, Y.; Shi, M.; Wang, X.; Luo, X.; Li, X.; Zheng, H.; Li, F. Research Progress: The Application of Biochar in the Remediation of Salt-affected Soils. Adv. Earth Scie. 2022, 37, 1005–1024. [Google Scholar]

- Omondi, M.O.; Xia, X.; Nahayo, A.; Liu, X.; Korai, P.K.; Pan, G. Quantification of Biochar Effects on Soil Hydrological Properties Using Meta-Analysis of Literature Data. Geoderma 2016, 274, 28–34. [Google Scholar] [CrossRef]

- Suliman, W.; Harsh, J.B.; Abu-Lail, N.I.; Fortuna, A.-M.; Dallmeyer, I.; Garcia-Pérez, M. The Role of Biochar Porosity and Surface Functionality in Augmenting Hydrologic Properties of a Sandy Soil. Sci. Total Environ. 2017, 574, 139–147. [Google Scholar] [CrossRef]

- Borchard, N.; Ladd, B.; Eschemann, S.; Hegenberg, D.; Moeseler, B.M.; Amelung, W. Black Carbon and Soil Properties at Historical Charcoal Production Sites in Germany. Geoderma 2014, 232, 236–242. [Google Scholar] [CrossRef]

- Kinney, T.J.; Masiello, C.A.; Dugan, B.; Hockaday, W.C.; Dean, M.R.; Zygourakis, K.; Barnes, R.T. Hydrologic Properties of Biochars Produced at Different Temperatures. Biomass Bioenergy 2012, 41, 34–43. [Google Scholar] [CrossRef]

- Gamage, D.N.V.; Mapa, R.B.; Dharmakeerthi, R.S.; Biswas, A. Effect of Rice-Husk Biochar on Selected Soil Properties in Tropical Alfisols. Soil Res. 2016, 54, 302–310. [Google Scholar] [CrossRef]

- Hossain, M.Z.; Bahar, M.M.; Sarkar, B.; Donne, S.W.; Ok, Y.S.; Palansooriya, K.N.; Kirkham, M.B.; Chowdhury, S.; Bolan, N. Biochar and Its Importance on Nutrient Dynamics in Soil and Plant. Biochar 2020, 2, 379–420. [Google Scholar] [CrossRef]

- Sun, X.; Feng, T.; Yin, X.; Deng, X.; Lv, D.; Xu, W.; Zhang, M.; Wu, X. The impact of biochar on soil physicochemical properties and corn yield. Shaanxi Agric. Sci. 2022, 68, 5–9. [Google Scholar]

- Pandit, N.R.; Mulder, J.; Hale, S.E.; Martinsen, V.; Schmidt, H.P.; Cornelissen, G. Biochar Improves Maize Growth by Alleviation of Nutrient Stress in a Moderately Acidic Low-Input Nepalese Soil. Sci. Total Environ. 2018, 625, 1380–1389. [Google Scholar] [CrossRef]

- Steiner, C.; Teixeira, W.G.; Lehmann, J.; Nehls, T.; de Macedo, J.L.V.; Blum, W.E.H.; Zech, W. Long Term Effects of Manure, Charcoal and Mineral Fertilization on Crop Production and Fertility on a Highly Weathered Central Amazonian Upland Soil. Plant Soil 2007, 291, 275–290. [Google Scholar] [CrossRef]

- Van Zwieten, L.; Kimber, S.; Morris, S.; Chan, K.Y.; Downie, A.; Rust, J.; Joseph, S.; Cowie, A. Effects of Biochar from Slow Pyrolysis of Papermill Waste on Agronomic Performance and Soil Fertility. Plant Soil 2010, 327, 235–246. [Google Scholar] [CrossRef]

- Premalatha, R.P.; Poorna Bindu, J.; Nivetha, E.; Malarvizhi, P.; Manorama, K.; Parameswari, E.; Davamani, V. A Review on Biochar’s Effect on Soil Properties and Crop Growth. Front. Energy Res. 2023, 11, 1092637. [Google Scholar] [CrossRef]

- Lehmann, J.; Rillig, M.C.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar Effects on Soil Biota—A Review. Soil Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Purakayastha, T.J.; Kumari, S.; Pathak, H. Characterisation, Stability, and Microbial Effects of Four Biochars Produced from Crop Residues. Geoderma 2015, 239–240, 293–303. [Google Scholar] [CrossRef]

- Yamato, M.; Okimori, Y.; Wibowo, I.F.; Anshori, S.; Ogawa, M. Effects of the Application of Charred Bark of Acacia Mangium on the Yield of Maize, Cowpea and Peanut, and Soil Chemical Properties in South Sumatra, Indonesia. Soil Sci. Plant Nutr. 2006, 52, 489–495. [Google Scholar] [CrossRef]

- Pradhan, S.; Lahlou, F.Z.; Ghiat, I.; Bilal, H.; McKay, G.; Al-Ansari, T. A Comprehensive Decision-Making Approach for the Application of Biochar in Agriculture to Enhance Water Security: A GIS-AHP Based Approach. Environ. Technol. Innov. 2024, 36, 103801. [Google Scholar] [CrossRef]

- Liew, Y.W.; Arumugasamy, S.K.; Selvarajoo, A. Potential of Biochar as Soil Amendment: Prediction of Elemental Ratios from Pyrolysis of Agriculture Biomass Using Artificial Neural Network. Water Air Soil Pollut 2022, 233, 54. [Google Scholar] [CrossRef]

- Cho, Y.; Lim, J.Y.; Igalavithana, A.D.; Hwang, G.; Sang, M.K.; Mašek, O.; Ok, Y.S. AI-Guided Investigation of Biochar’s Efficacy in Pb Immobilization for Remediation of Pb Contaminated Agricultural Land. Appl Biol Chem 2024, 67, 82. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar Physicochemical Properties: Pyrolysis Temperature and Feedstock Kind Effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Wang, L.; Ok, Y.S.; Tsang, D.C.W.; Alessi, D.S.; Rinklebe, J.; Wang, H.; Mašek, O.; Hou, R.; O’Connor, D.; Hou, D. New Trends in Biochar Pyrolysis and Modification Strategies: Feedstock, Pyrolysis Conditions, Sustainability Concerns and Implications for Soil Amendment. Soil Use Manag. 2020, 36, 358–386. [Google Scholar] [CrossRef]

- Goldan, E.; Nedeff, V.; Barsan, N.; Culea, M.; Tomozei, C.; Panainte-Lehadus, M.; Mosnegutu, E. Evaluation of the Use of Sewage Sludge Biochar as a Soil Amendment—A Review. Sustainability 2022, 14, 5309. [Google Scholar] [CrossRef]

- Rathnayake, D.; Schmidt, H.-P.; Leifeld, J.; Mayer, J.; Epper, C.A.; Bucheli, T.D.; Hagemann, N. Biochar from Animal Manure: A Critical Assessment on Technical Feasibility, Economic Viability, and Ecological Impact. GCB Bioenergy 2023, 15, 1078–1104. [Google Scholar] [CrossRef]

- Barry, D.; Barbiero, C.; Briens, C.; Berruti, F. Pyrolysis as an Economical and Ecological Treatment Option for Municipal Sewage Sludge. Biomass Bioenergy 2019, 122, 472–480. [Google Scholar] [CrossRef]

- Marcińczyk, M.; Oleszczuk, P. Biochar and Engineered Biochar as Slow- and Controlled-Release Fertilizers. J. Clean. Prod. 2022, 339, 130685. [Google Scholar] [CrossRef]

- Gul, S.; Whalen, J.K. Biochemical Cycling of Nitrogen and Phosphorus in Biochar-Amended Soils. Soil Biol. Biochem. 2016, 103, 1–15. [Google Scholar] [CrossRef]

- Mia, S.; Dijkstra, F.A.; Singh, B. Chapter One—Long-Term Aging of Biochar: A Molecular Understanding with Agricultural and Environmental Implications. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2017; Volume 141, pp. 1–51. [Google Scholar]

- Hardy, B.; Sleutel, S.; Dufey, J.E.; Cornelis, J.-T. The Long-Term Effect of Biochar on Soil Microbial Abundance, Activity and Community Structure Is Overwritten by Land Management. Front. Environ. Sci. 2019, 7, 110. [Google Scholar] [CrossRef]

- Novak, J.M.; Cantrell, K.B.; Watts, D.W.; Busscher, W.J.; Johnson, M.G. Designing Relevant Biochars as Soil Amendments Using Lignocellulosic-Based and Manure-Based Feedstocks. J Soils Sediments 2014, 14, 330–343. [Google Scholar] [CrossRef]

- Kwon, G.; Bhatnagar, A.; Wang, H.; Kwon, E.E.; Song, H. A Review of Recent Advancements in Utilization of Biomass and Industrial Wastes into Engineered Biochar. J. Hazard. Mater. 2020, 400, 123242. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Xu, X.; Wang, Q.; Park, J.; Han, Y.; Guo, L.; Song, B. Stabilization/solidification of composite heavy metal contaminated soil using a novel red mud-slag based geopolymer (RM-SGP): Performance and mechanisms. Constr. Build. Mater. 2025, 486, 141996. [Google Scholar] [CrossRef]

- Qi, J.; Zhu, H.; Zhou, P.; Wang, X.; Wang, Z.; Yang, S.; Yang, D.; Li, B. Application of Phosphogypsum in Soilization: A Review. Int. J. Environ. Sci. Technol. 2023, 20, 10449–10464. [Google Scholar] [CrossRef]

- Belyaeva, O.N.; Haynes, R.J. Comparison of the Effects of Conventional Organic Amendments and Biochar on the Chemical, Physical and Microbial Properties of Coal Fly Ash as a Plant Growth Medium. Environ. Earth Sci. 2012, 66, 1987–1997. [Google Scholar] [CrossRef]

- Xing, L.; Li, G.; Luo, J.; Jiang, H. From Waste to Wealth: Separation of Alumina from Coal Fly Ash and Synergistic Preparation of Soil Amendments. J. Environ. Manag. 2025, 385, 125675. [Google Scholar] [CrossRef]

- Fu, J.; Pu, Y.; Shi, S.; Zhang, J.; Cao, S.; Xu, X.; Jiao, W.; Zhan, M. Analysis of the Effect and Mechanism of Heavy Metals in Stabilized Landfill Humus Soil Using Fly Ash-Based Materials. Appl. Soil Ecol. 2025, 210, 106090. [Google Scholar] [CrossRef]

- Li, T.; Wang, B.; Zhang, X.; Han, X.; Xing, Y.; Fan, C.; Liu, Z. A Novel Method for Solidification/Stabilization of MSWI Fly Ash by Graphene Nanoplatelets Synergistic Alkali-Activated Technology. J. Environ. Chem. Eng. 2023, 11, 110589. [Google Scholar] [CrossRef]

- Katiyar, D.; Singh, A.; Malaviya, P.; Pant, D.; Singh, P.; Abraham, G.; Singh, S.K. Impact of Fly-Ash-Amended Soil on Growth and Yield of Crop Plants. Int. J. Environ. Waste Manag. 2012, 10, 150–162. [Google Scholar] [CrossRef]

- Lee, H.; Ha, H.S.; Lee, C.H.; Lee, Y.B.; Kim, P.J. Fly Ash Effect on Improving Soil Properties and Rice Productivity in Korean Paddy Soils. Bioresour. Technol. 2006, 97, 1490–1497. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Singh, B. The Use of Coal Fly Ash in Sodic Soil Reclamation. Land Degrad. Dev. 2003, 14, 285–299. [Google Scholar] [CrossRef]

- Hu, X.; Huang, X.; Zhao, H.; Liu, F.; Wang, L.; Zhao, X.; Gao, P.; Li, X.; Ji, P. Possibility of Using Modified Fly Ash and Organic Fertilizers for Remediation of Heavy-Metal-Contaminated Soils. J. Clean. Prod. 2021, 284, 124713. [Google Scholar] [CrossRef]

- GB/T 14848-2017; Groundwater Quality Standards. Standardization Administration of China: Beijing, China, 2017.

- Xu, R.; Liu, Y.; Li, X.; Yao, G.; Xu, Y.; She, K. Research on Leakage Environmental Risk Assessment and Risk Prevention and Control Measures in the Long-Term Landfill Process of Ultra-Alkaline Fly Ash. Waste Manag. 2023, 172, 320–325. [Google Scholar] [CrossRef]

- Rehman, A.; Ma, H.; Ozturk, I.; Ulucak, R. Sustainable development and pollution: The effects of CO2 emission on population growth, food production, economic development, and energy consumption in Pakistan. Environ. Sci. Pollut. Res. 2022, 29, 17319–17330. [Google Scholar] [CrossRef]

- Gao, W.; Zhou, W.; Lyu, X.; Liu, X.; Su, H.; Li, C.; Wang, H. Comprehensive Utilization of Steel Slag: A Review. Powder Technol. 2023, 422, 118449. [Google Scholar] [CrossRef]

- Tangadagi, B.; Ravichandran, T.; Manjunath, R. Experimental Investigation on Stabilization of Soil Using Steel Slag: A Step Towards Sustainability. AIP Conf. Proc. 2024, 3187, 040012. [Google Scholar] [CrossRef]

- Das, S.; Gwon, H.S.; Khan, M.I.; Jeong, S.T.; Kim, P.J. Steel Slag Amendment Impacts on Soil Microbial Communities and Activities of Rice (Oryza sativa L.). Sci Rep 2020, 10, 6746. [Google Scholar] [CrossRef]

- Xu, B.; Tan, X.Y.; Yi, Y. Synergistic Approach for CO2 Capture and Remediation of Lead-Contaminated Soils Utilizing Steel Slag. J. Environ. Chem. Eng. 2025, 13, 117543. [Google Scholar] [CrossRef]

- O’Connor, J.; Nguyen, T.B.T.; Honeyands, T.; Monaghan, B.; O’Dea, D.; Rinklebe, J.; Vinu, A.; Hoang, S.A.; Singh, G.; Kirkham, M.B.; et al. Production, Characterisation, Utilisation, and Beneficial Soil Application of Steel Slag: A Review. J. Hazard. Mater. 2021, 419, 126478. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, X.; Yan, X.; Tu, C.; Yu, Z. Environmental Risks for Application of Iron and Steel Slags in Soils in China: A Review. Pedosphere 2021, 31, 28–42. [Google Scholar] [CrossRef]

- Zhou, Y.; Cui, Y.; Yang, J.; Chen, L.; Qi, J.; Zhang, L.; Zhang, J.; Huang, Q.; Zhou, T.; Zhao, Y.; et al. Roles of Red Mud in Remediation of Contaminated Soil in Mining Areas: Mechanisms, Advances and Perspectives. J. Environ. Manag. 2024, 356, 120608. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.V.; Thorat, B.N. Mechanical Dewatering of Red Mud. Sep. Purif. Technol. 2022, 294, 121157. [Google Scholar] [CrossRef]

- Winkler, D.; Bidlo, A.; Bolodar-Varga, B.; Erdo, A.; Horvath, A. Long-Term Ecological Effects of the Red Mud Disaster in Hungary: Regeneration of Red Mud Flooded Areas in a Contaminated Industrial Region. Sci. Total Environ. 2018, 644, 1292–1303. [Google Scholar] [CrossRef]

- Lombi, E.; Zhao, F.J.; Zhang, G.Y.; Sun, B.; Fitz, W.; Zhang, H.; McGrath, S.P. In Situ Fixation of Metals in Soils Using Bauxite Residue: Chemical Assessment. Environ. Pollut. 2002, 118, 435–443. [Google Scholar] [CrossRef]

- Friesl, W.; Lombi, E.; Horak, O.; Wenzel, W.W. Immobilization of Heavy Metals in Soils Using Inorganic Amendments in a Greenhouse Study. J. Plant Nutr. Soil Sci. 2003, 166, 191–196. [Google Scholar] [CrossRef]

- Li, P.; Peng, X.; Luan, Z.; Zhao, T.; Zhang, C.; Liu, B. Effects of Red Mud Addition on Cadmium Accumulation in Cole (Brassica campestris L.) under High Fertilization Conditions. J. Soils Sediments 2016, 16, 2097–2104. [Google Scholar] [CrossRef]

- Hua, Y.; Heal, K.V.; Friesl-Hanl, W. The Use of Red Mud as an Immobiliser for Metal/Metalloid-Contaminated Soil: A Review. J. Hazard. Mater. 2017, 325, 17–30. [Google Scholar] [CrossRef]

- Cooper, M.B.; Clarke, P.C.; Robertson, W.; McPharlin, I.R.; Jeffrey, R.C. An Investigation of Radionuclide Uptake into Food Crops Grown in Soils Treated with Bauxite Mining Residues. J. Radioanal. Nucl. Chem. Artic. 1995, 194, 379–387. [Google Scholar] [CrossRef]

- Mohammed, F.; Biswas, W.K.; Yao, H.; Tade, M. Sustainability Assessment of Symbiotic Processes for the Reuse of Phosphogypsum. J. Clean Prod. 2018, 188, 497–507. [Google Scholar] [CrossRef]

- Duart, V.M.; Garbuio, F.J.; Caires, E.F. Does Direct-Seeded Rice Performance Improve upon Lime and Phosphogypsum Use? Soil Tillage Res. 2021, 212, 105055. [Google Scholar] [CrossRef]

- Silva, L.F.O.; Oliveira, M.L.S.; Crissien, T.J.; Santosh, M.; Bolivar, J.; Shao, L.; Dotto, G.L.; Gasparotto, J.; Schindler, M. A Review on the Environmental Impact of Phosphogypsum and Potential Health Impacts through the Release of Nanoparticles. Chemosphere 2022, 286, 131513. [Google Scholar] [CrossRef] [PubMed]

- Saadaoui, E.; Ghazel, N.; Ben Romdhane, C.; Massoudi, N. Phosphogypsum: Potential Uses and Problems—A Review. Int. J. Environ. Stud. 2017, 74, 558–567. [Google Scholar] [CrossRef]

- Hong, S.; Chen, X.; Zhou, X.; Yang, X.; Shi, Y.; Man, J.; Wu, H. Effects of Phosphogypsum on Coastal Saline-sodic Soil and the Growth of Winter Wheat. Acta Pedol. Sin. 2012, 49, 1262–1266. [Google Scholar]

- Da Costa, C.H.M.; Carmeis Filho, A.C.A.; Crusciol, C.A.C.; Soratto, R.P.; Guimaraes, T.M. Intensive Annual Crop Production and Root Development in a Tropical Acid Soil under Long-Term No-till and Soil-Amendment Management. Crop Pasture Sci. 2018, 69, 488–505. [Google Scholar] [CrossRef]

- Al-Enazy, A.-A.; Al-Barakah, F.; Al-Oud, S.; Usman, A. Effect of Phosphogypsum Application and Bacteria Co-Inoculation on Biochemical Properties and Nutrient Availability to Maize Plants in a Saline Soil. Arch. Agron. Soil Sci. 2018, 64, 1394–1406. [Google Scholar] [CrossRef]

- Smaoui-Jardak, M.; Kriaa, W.; Maalej, M.; Zouari, M.; Kamoun, L.; Trabelsi, W.; Ben Abdallah, F.; Elloumi, N. Effect of the Phosphogypsum Amendment of Saline and Agricultural Soils on Growth, Productivity and Antioxidant Enzyme Activities of Tomato (Solanum lycopersicum L.). Ecotoxicology 2017, 26, 1089–1104. [Google Scholar] [CrossRef]

- Jiang, N.; Cai, D.; He, L.; Zhong, N.; Wen, H.; Zhang, X.; Wu, Z. A Facile Approach To Remediate the Microenvironment of Saline–Alkali Soil. ACS Sustain. Chem. Eng. 2015, 3, 374–380. [Google Scholar] [CrossRef]

- Lütke, S.F.; Oliveira, M.L.S.; Silva, L.F.O.; Cadaval, T.R.S.; Dotto, G.L. Nanominerals Assemblages and Hazardous Elements Assessment in Phosphogypsum from an Abandoned Phosphate Fertilizer Industry. Chemosphere 2020, 256, 127138. [Google Scholar] [CrossRef]

- Enamorado, S.; Abril, J.M.; Delgado, A.; Más, J.L.; Polvillo, O.; Quintero, J.M. Implications for Food Safety of the Uptake by Tomato of 25 Trace-Elements from a Phosphogypsum Amended Soil from SW Spain. J. Hazard. Mater. 2014, 266, 122–131. [Google Scholar] [CrossRef]

- Lu, Y.; Gu, K.; Shen, Z.; Tang, C.-S.; Shi, B.; Zhou, Q. Biochar Implications for the Engineering Properties of Soils: A Review. Sci. Total Environ. 2023, 888, 164185. [Google Scholar] [CrossRef]

- Jiang, Q.; He, Y.; Wu, Y.; Dian, B.; Zhang, J.; Li, T.; Jiang, M. Solidification/Stabilization of Soil Heavy Metals by Alkaline Industrial Wastes: A Critical Review. Environ. Pollut. 2022, 312, 120094. [Google Scholar] [CrossRef] [PubMed]

- Hanafi, M.M.; Azizi, P.; Vijayanathan, J. Phosphogypsum Organic, a Byproduct from Rare-Earth Metals Processing, Improves Plant and Soil. Agronomy 2021, 11, 2561. [Google Scholar] [CrossRef]

- Yousaf, B.; Liu, G.; Abbas, Q.; Wang, R.; Ali, M.U.; Ullah, H.; Liu, R.; Zhou, C. Systematic Investigation on Combustion Characteristics and Emission-Reduction Mechanism of Potentially Toxic Elements in Biomass- and Biochar-Coal Co-Combustion Systems. Appl. Energy 2017, 208, 142–157. [Google Scholar] [CrossRef]

- Yang, P.; Xu, H.; Yu, M.; Yamsomphong, K.; Setyawan, M.I.B.; Takahashi, F. Enhancing Water Retention Performance of Biochar Modified by Alkali-Treated Coal Fly Ash: Pyrolysis Behavior, Field Simulation, and Metal Leaching Assessment. Environ. Technol. Innov. 2025, 39, 104306. [Google Scholar] [CrossRef]

- Wang, A.; Wu, M.; Li, Z.; Zhou, Y.; Zhu, F.; Huang, Z. Utilizing Different Types of Biomass Materials to Modify Steel Slag for the Preparation of Composite Materials Used in the Adsorption and Solidification of Pb in Solutions and Soil. Sci. Total Environ. 2024, 914, 170023. [Google Scholar] [CrossRef]

- Kazak, O.; Tor, A. In Situ Preparation of Magnetic Hydrochar by Co-Hydrothermal Treatment of Waste Vinasse with Red Mud and Its Adsorption Property for Pb(II) in Aqueous Solution. J. Hazard. Mater. 2020, 393, 122391. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, C.; Jiang, H.; Li, L.; Li, Z.; Zhao, L.; Chen, H. Phosphogypsum/Titanium Gypsum Coupling for Enhanced Biochar Immobilization of Lead: Mineralization Reaction Behavior and Electron Transfer Effect. J. Environ. Manag. 2023, 345, 118781. [Google Scholar] [CrossRef]

- Lian, G.; Wang, B.; Lee, X.; Li, L.; Liu, T.; Lyu, W. Enhanced Removal of Hexavalent Chromium by Engineered Biochar Composite Fabricated from Phosphogypsum and Distillers Grains. Sci. Total Environ. 2019, 697, 134119. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, W.; Li, Y.; Wu, Y.; Chen, Y.; Xiao, W.; Zhao, L.; Zhang, J.; Li, H. Modification, Application and Reaction Mechanisms of Nano-Sized Iron Sulfide Particles for Pollutant Removal from Soil and Water: A Review. Chem. Eng. J. 2019, 362, 144–159. [Google Scholar] [CrossRef]

- Li, X.; Li, L.; Huang, Z.; Chang, Z.; Tu, Z.; Tian, L.; Du, W.; Li, H.; Zhang, P.; Pan, B. Enhancing the Stability and Heavy Metal Immobilization of Co-Pyrolysis Biochar through Biomass and Red Mud Co-Pyrolysis: A Synergistic Mechanism. J. Environ. Manag. 2025, 376, 124422. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Li, J.; Xu, R. The ameliorative effect of combined application of steel slag and biochar on the acidity of red soil. Soil 2013, 45, 722–726. [Google Scholar] [CrossRef]

- Masto, R.E.; Ansari, M.A.; George, J.; Selvi, V.A.; Ram, L.C. Co-Application of Biochar and Lignite Fly Ash on Soil Nutrients and Biological Parameters at Different Crop Growth Stages of Zea mays. Ecol. Eng. 2013, 58, 314–322. [Google Scholar] [CrossRef]

- Mao, S.; Gao, J.; Zhang, X. An experimental study on the improvement effect of combined additive on soda saline-alkali soil in western Jilin Province. Water Sav. Irrig. 2022, 85–90. [Google Scholar]

- Panda, L.; Kumar, M.; Pradhan, A. Leaching of Sulphate From Biochar and Phosphogypsum- Biochar for the Treatment of Acidic Red Soil. Asian J. Water Environ. Pollut. 2022, 19, 23–29. [Google Scholar] [CrossRef]

- Cao, J.; Chen, Z.; Wu, Q.; Wu, Z.; Dong, H.; Yao, A.; Chou, R.; Wang, S.; He, E.; Tang, Y. Mitigation of cadmium and arsenic in rice plant by soil application of steel slag and/or biochar with water management. J. Argo-Environ. Sci. 2018, 37, 1475–1483. [Google Scholar]

- Wang, A.; Liu, Y.; Zhang, Y.; Ren, J.; Zeng, Y.; Huang, Z. Synthesis of Biochar Modified Steel Slag Composites for Passivation of Multiple Heavy Metals in Soil. J. Environ. Chem. Eng. 2024, 12, 114026. [Google Scholar] [CrossRef]

- Li, D.; Yang, W.; Li, Q.; Wang, Y.; Chen, J.; Xu, D.; Chen, Q.; Jiang, B. Research on the application of silkworm excrement and red mud in the remediation of lead and cadmium contaminated soil. Chin. J. Soil Sci. 2015, 46, 977–984. [Google Scholar] [CrossRef]

- Weng, X.; Long, H.; Yang, X.; Luo, Z.; Su, J.; Wang, W. Effects of combined amendments on the absorption of heavy metals by Eucalyptus—Taking Cd, Zn and Cu of mine soils as example. China Environ. Sci. 2020, 40, 3911–3918. [Google Scholar] [CrossRef]

- Moon, D.H.; Wazne, M.; Cheong, K.H.; Chang, Y.-Y.; Baek, K.; Ok, Y.S.; Park, J.-H. Stabilization of As-, Pb-, and Cu-Contaminated Soil Using Calcined Oyster Shells and Steel Slag. Environ. Sci. Pollut. Res. 2015, 22, 11162–11169. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Shang, X.; Zhang, Y.; Chen, W.; Gao, Y.; Guo, J.; Zheng, H.; Xing, B. Co-Pyrolysis of Alkali-Fused Fly Ash and Corn Stover to Synthesize Biochar Composites for Remediating Lead-Contaminated Soil. Environ. Res. 2024, 252, 118938. [Google Scholar] [CrossRef] [PubMed]

- Munda, S.; Nayak, A.K.; Mishra, P.N.; Bhattacharyya, P.; Mohanty, S.; Kumar, A.; Kumar, U.; Baig, M.J.; Tripathi, R.; Shahid, M.; et al. Combined Application of Rice Husk Biochar and Fly Ash Improved the Yield of Lowland Rice. Soil Res. 2016, 54, 451–459. [Google Scholar] [CrossRef]

- Vimal, V.; Karim, A.A.; Kumar, M.; Ray, A.; Biswas, K.; Maurya, S.; Subudhi, D.; Dhal, N.K. Nutrients Enriched Biochar Production through Co-Pyrolysis of Poultry Litter with Banana Peduncle and Phosphogypsum Waste. Chemosphere 2022, 300, 134512. [Google Scholar] [CrossRef]

- Wang, M.; Lan, X.; Xu, X.; Fang, Y.; Singh, B.P.; Sardans, J.; Romero, E.; Penuelas, J.; Wang, W. Steel Slag and Biochar Amendments Decreased CO2 Emissions by Altering Soil Chemical Properties and Bacterial Community Structure over Two-Year in a Subtropical Paddy Field. Sci. Total Environ. 2020, 740, 140403. [Google Scholar] [CrossRef]

- Lin, S.; Wang, W.; Sardans, J.; Lan, X.; Fang, Y.; Singh, B.P.; Xu, X.; Wiesmeier, M.; Tariq, A.; Zeng, F.; et al. Effects of Slag and Biochar Amendments on Microorganisms and Fractions of Soil Organic Carbon during Flooding in a Paddy Field after Two Years in Southeastern China. Sci. Total Environ. 2022, 824, 153783. [Google Scholar] [CrossRef]

- Fang, Y.; Singh, B.; Singh, B.P.; Krull, E. Biochar Carbon Stability in Four Contrasting Soils. Eur. J. Soil Sci. 2014, 65, 60–71. [Google Scholar] [CrossRef]

- Wang, W.; Lai, D.Y.F.; Abid, A.A.; Neogi, S.; Xu, X.; Wang, C. Effects of Steel Slag and Biochar Incorporation on Active Soil Organic Carbon Pools in a Subtropical Paddy Field. Agronomy 2018, 8, 135. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Yang, B.; Zhong, Q.; Wang, L.; Niu, Z.; Xin, H.; Zhang, W. Performance of Red Mud/Biochar Composite Material (RMBC) as Heavy Metal Passivator in Pb-Contaminated Soil. Bull. Environ. Contam. Toxicol. 2022, 109, 30–43. [Google Scholar] [CrossRef]

- Yu, H.-Y.; Ding, X.; Li, F.; Wang, X.; Zhang, S.; Yi, J.; Liu, C.; Xu, X.; Wang, Q. The Availabilities of Arsenic and Cadmium in Rice Paddy Fields from a Mining Area: The Role of Soil Extractable and Plant Silicon. Environ. Pollut. 2016, 215, 258–265. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Guo, Q.; Huang, B.; Chen, H.; Pan, X.; Fan, R.; Du, J. Effects of biochar-based soil conditioners on ameliorating acid soil in vegetable field. J. Agric. Res. Environ. 2023, 40, 15–24. [Google Scholar] [CrossRef]

- Cárdenas- Aguiar, E.; Gascó, G.; Paz-Ferreiro, J.; Méndez, A. The Effect of Biochar and Compost from Urban Organic Waste on Plant Biomass and Properties of an Artificially Copper Polluted Soil. Int. Biodeterior. Biodegrad. 2017, 124, 223–232. [Google Scholar] [CrossRef]

- Kammann, C.I.; Schmidt, H.-P.; Messerschmidt, N.; Linsel, S.; Steffens, D.; Müller, C.; Koyro, H.-W.; Conte, P.; Joseph, S. Plant Growth Improvement Mediated by Nitrate Capture in Co-Composted Biochar. Sci. Rep. 2015, 5, 11080. [Google Scholar] [CrossRef] [PubMed]

- Schulz, H.; Dunst, G.; Glaser, B. Positive Effects of Composted Biochar on Plant Growth and Soil Fertility. Agron. Sustain. Dev. 2013, 33, 817–827. [Google Scholar] [CrossRef]

- Agegnehu, G.; Bird, M.I.; Nelson, P.N.; Bass, A.M. The Ameliorating Effects of Biochar and Compost on Soil Quality and Plant Growth on a Ferralsol. Soil Res. 2015, 53, 1–12. [Google Scholar] [CrossRef]

- Freddo, A.; Cai, C.; Reid, B.J. Environmental Contextualisation of Potential Toxic Elements and Polycyclic Aromatic Hydrocarbons in Biochar. Environ. Pollut. 2012, 171, 18–24. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, B.; Liu, G.; Cai, Z.; Zhang, C. Chapter 19—Potential Toxic Compounds in Biochar: Knowledge Gaps Between Biochar Research and Safety. In Biochar from Biomass and Waste; Ok, Y.S., Tsang, D.C.W., Bolan, N., Novak, J.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 349–384. ISBN 978-0-12-811729-3. [Google Scholar]

- Michalovicz, L.; Tormena, C.A.; Lopes Muller, M.M.; Dick, W.A.; Cervi, E.C. Residual Effects of Phosphogypsum Rates and Machinery Traffic on Soil Attributes and Common-Bean (Phaseolus vulgaris) Yield in a No-Tillage System. Soil Tillage Res. 2021, 213, 105152. [Google Scholar] [CrossRef]

- Morillon, A.; Mudersbach, D.; Rex, M.; Spiegel, H.; Mauhart, M.; Tuomikoski, S.; Branca, T.A.; Ragaglini, G.; Colla, V.; Romaniello, L. Impact of Long-Term Application of Blast Furnace and Steel Slags as Liming Materials on Soil Fertility and Crop Yields. In; AUT, 2015. In Proceedings of the 8th European Slag Conference EUROSLAG 2015, Linz, Austria, 21–23 October 2015. [Google Scholar]

- Bossolani, J.W.; Crusciol, C.A.C.; Garcia, A.; Moretti, L.G.; Portugal, J.R.; Rodrigues, V.A.; Fonseca, M.d.C.d.; Calonego, J.C.; Caires, E.F.; Amado, T.J.C.; et al. Long-Term Lime and Phosphogypsum Amended-Soils Alleviates the Field Drought Effects on Carbon and Antioxidative Metabolism of Maize by Improving Soil Fertility and Root Growth. Front. Plant Sci. 2021, 12, 650296. [Google Scholar] [CrossRef]

- Lahori, A.H.; Guo, Z.; Zhang, Z.; Li, R.; Mahar, A.; Awasthi, M.K.; Shen, F.; Sial, T.A.; Kumbhar, F.; Wang, P.; et al. Use of Biochar as an Amendment for Remediation of Heavy Metal-Contaminated Soils: Prospects and Challenges. Pedosphere 2017, 27, 991–1014. [Google Scholar] [CrossRef]

| Type of Wastes | Advantages | Risks | References |

|---|---|---|---|

| Sewage sludge biochar (SSB) | Enriches soil with N and P; Reduces availability of certain heavy metals; Provides functional groups for pollutant sorption | Introduces heavy metals (e.g., Zn, Cd, Cu), PAHs, antibiotics, or pathogens into soil | [60,61] |

| Animal manure biochar (AMB) | Supplies bioavailable nutrients; Enhances soil structure and fertility | Raises soil pH excessively; Reduces nutrient availability in fertile soils | [61,65] |

| Fly ash (FA) | Improves soil pH, fertility, porosity, and crop yield; Increases availability of P, K, Mg, Zn, and Mn | Leaches heavy metals (e.g., Zn, Cd, Pb) under carbonation or landfill conditions | [73,74,78] |

| Steel slag (SS) | Supplies nutrients (P, Fe, Ca, Mg, Si); Increases soil pH and organic carbon; Enhances CO2 sequestration and crop productivity | Accumulates toxic metals (e.g., Cr, Ni, Pb, Zn, Cd); Compact soil and reduce aeration | [82,83,84] |

| Red mud (RM) | Reduces heavy metal bioavailability (e.g., Cd, Zn, Ni); Improves microbial activity and crop quality | Releases radionuclides (e.g., 228Th) and toxic metals (e.g., As, Cr) into soils and crops | [89,90,92,93] |

| Phosphogypsum (PG) | Remediates saline-alkali soils; Provides Ca, S, and P; Lowers pH and improves crop biomass | Leaches radioactive elements and fluoride into groundwater; Transfers toxic metals into edible plant tissues | [98,100,103,104] |

| Composite Type | Preparation Method | Soil Type | Main Effects | Potential Risks | References |

|---|---|---|---|---|---|

| Peanut straw + Steel slag | Pyrolysis | Acidic red soil | Neutralizes soil acidity; Increases exchangeable K, Ca, Mg and salt-based ions; Reduces exchangeable Al3+ | - | [116] |

| Lantana camara + Lignite fly ash | Mix | Acidic red soil with sandy loam texture | Improves plant-available P and K levels; Enhances soil enzyme activity; Promotes soil pH and decreases bioavailable heavy metals (Zn, Ni, Co, Cu, Mn, Cd, Pb) | - | [117] |

| Corn stalk + Earthworm dung + Phosphogypsum | Mix | Saline-alkali Soil | Lowers soil pH and exchangeable Na+; Increases soil CEC | - | [118] |

| Banana peduncle + Phosphogypsum | Co-pyrolysis at 700 °C | Acidic red soil | Increases soil pH and plant bioavailability of nutrients; Alleviates Al toxicity; Immobilizes soil heavy metals | - | [119] |

| Corn stalk + Steel slag | Pyrolysis at 500 °C | Topsoil of farmland with Pd and Cd | Passivates Pb and Cd in soil; Enhances plant height, biomass, chlorophyll, and nitrogen content; Reduces heavy metal accumulation in crops | Heavy metal leaching risks | [121] |

| Biochar + Steel slag | Mix | Pb- and As-contaminated paddy soil | Increases soil pH; Decreases Eh; Reduces Cd concentration in soil solution; Inhibits rice uptake of Cd and As | Increases As concentration in soil solution | [120] |

| Silkworm sand + Red mud | Mix | Pb-, and Cd-contaminated soil | Improve soil organic matter and pH; Promote transformation of Pb and Cd from exchangeable to residual forms; Enhance height and dry biomass of pak choi | - | [122] |

| Sugarcane bagasse + Red mud | Mix | Cd-, Zn-, and Cu-contaminated soil | Reduces bioavailability of Cd, Zn, and Cu in soil; Increases biomass | - | [123] |

| Oyster shells + Steel slag | Calcine | As-, Pb-, and Cu-contaminated soil | Reduces leachability of As, Pb, and Cu; Forms Ca-As and Fe-As precipitates for As immobilization; Promotes pozzolanic reactions for Pb and Cu stabilization | - | [124] |

| Corn stover + Alkali-fused fly ash | Co-pyrolysis | Pb-contaminated soil | Reduces soil Pb concentration; Increases soil pH and CEC | - | [125] |

| Rice husk + Fly ash | Mix | Low-fertility soil | Improves soil pH, OC, CEC, EC and available N, P, K; Increases lowland rice yield | Fe, Mn, Zn, Cu, and Pb release risks | [126] |

| poultry litter + Banana peduncle + Phosphogypsum | Co-Pyrolysis | Low-fertility acidic red soil | Improves soil P, S, K, and Mg; Reduces the release rate of P; Increases nutrient utilization efficiency | - | [127] |

| Biochar + Steel slag | Mix | Agronomy paddy field | Increases soil pH, salinity, and SOC contents; Decreases active organic C and cumulative CO2 emissions; Increases abundance of microbial genera related to carbon assimilation | - | [128] |

| Biochar + Steel slag | Mix | Agronomy paddy field | Increases soil pH and salinity; Decreases active SOC pools; Enhances soil C sequestration | - | [131] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, F.; Wang, Y.; Zhao, Y.; Sun, R.; Qi, M.; Wu, S.; Wang, L. A Review of Biochar-Industrial Waste Composites for Sustainable Soil Amendment: Mechanisms and Perspectives. Water 2025, 17, 2184. https://doi.org/10.3390/w17152184

Tian F, Wang Y, Zhao Y, Sun R, Qi M, Wu S, Wang L. A Review of Biochar-Industrial Waste Composites for Sustainable Soil Amendment: Mechanisms and Perspectives. Water. 2025; 17(15):2184. https://doi.org/10.3390/w17152184

Chicago/Turabian StyleTian, Feng, Yiwen Wang, Yawen Zhao, Ruyu Sun, Man Qi, Suqing Wu, and Li Wang. 2025. "A Review of Biochar-Industrial Waste Composites for Sustainable Soil Amendment: Mechanisms and Perspectives" Water 17, no. 15: 2184. https://doi.org/10.3390/w17152184

APA StyleTian, F., Wang, Y., Zhao, Y., Sun, R., Qi, M., Wu, S., & Wang, L. (2025). A Review of Biochar-Industrial Waste Composites for Sustainable Soil Amendment: Mechanisms and Perspectives. Water, 17(15), 2184. https://doi.org/10.3390/w17152184