Abstract

Processing of meat waste into meat and bone meal generates wastewater that must be properly treated to minimize its environmental impact. In addition to its high organic load, it contains microorganisms, including pathogens, that pose a threat to human health. In this study, wastewater from meat and bone meal production was treated using the Fenton process with a variable Fe2⁺/H2O2 mass ratio ranging from 1:2 to 1:10, followed by neutralization with lime milk. A microbiological analysis was performed on both the raw wastewater and the liquid fractions obtained after treatment, along with additional analyses of selected physicochemical parameters. The identification of isolated microorganisms was carried out using the MALDI-TOF MS technique. Qualitative analysis of the treated wastewater samples showed the presence of microorganisms belonging to the genera Staphylococcus, Enterococcus, Alcaligenes, and Pseudomonas. Staphylococcus aureus and Alcaligenes faecalis were present in each of the treated samples. The Fenton process effectively reduced the total number of microorganisms, with the lowest counts of 1.3 × 102 CFU/mL and 3.2 × 102 CFU/mL found in wastewater samples treated with Fe2⁺/H2O2 mass ratios of 1:8 and 1:10, which correlated with higher doses of hydrogen peroxide.

1. Introduction

The growth of industrial production, an increasing global population, and rising consumer demands result in the generation of billions of tons of wastewater annually [1], which contains large amounts of organic and inorganic chemicals, heavy metals, microorganisms, and microplastics. Wastewater provides a favorable environment for the growth of both pathogenic and non-pathogenic microorganisms. Dangerous pathogens that pose a threat to human health include intestinal bacteria, viruses, protozoa, parasitic worms, and their eggs [2], which can enter wastewater from various sources. Livestock and poultry can be infected with zoonotic enteric pathogens that are discharged into wastewater during processing and represent a potential health risk [3], alongside solid industrial waste generated during animal processing [4]. The degree of contamination in industrial wastewater can vary significantly depending on the nature of the production process and the raw materials used. Therefore, an individual approach tailored to each specific wastewater type is essential for effective treatment and, in some cases, even recovery of certain components.

The composition of wastewater from meat and bone meal production can be highly variable in terms of its physicochemical and microbiological properties and depends on the type and amount of processed meat waste. The primary raw material is animal carcasses or animal by-products rejected during meat inspection, as well as animals that died naturally or were euthanized. The most common method of processing animal by-products is their conversion into meat and bone meal (MBM) using the hydrothermal method [5]. In the European Union, about 20 million t/year of meat waste is generated, which is mainly processed into meat and bone meal [6], while in Poland, the amount is estimated at approximately 1 million t/year [7]. In the MBM production process, animal waste is crushed into particles of up to 50 mm in diameter and mixed to ensure homogenization and uniform heating. The mixture is then transferred into a jacketed tank, where it is stirred and preheated with steam to 101–104 °C. The next stage is sterilization, carried out in accordance with EU regulations, at a temperature of 133 °C for 20 min and under a pressure of 3 bar. The drying process follows, conducted at atmospheric pressure at temperatures ranging from 100 °C to 120 °C. The fat fraction is separated using a screw press and further purified via centrifugation. The defatted pomace is then cooled and ground into meat and bone meal [5,8,9]. The MBM production process generates wastewater with a high content of organic compounds, with chemical oxygen demand (COD) reaching up to 25 g/m3, and a high level of microbiological diversity, which poses a potential threat to the environment. In Poland, approximately 1 million m3/year of this type of wastewater is produced, which presents considerable challenges and requires a multi-stage purification and neutralization process. Chemical treatment methods, often in combination with biological approaches, are used to manage wastewater from MBM production. The effectiveness of wastewater treatment depends on the policy of the disposal plant, the technologies implemented, and the final management of the treated effluent [10,11].

To reduce the level of pollutants in wastewater from MBM production, it is necessary to combine multiple purification methods, whose synergistic action enables achieving the intended goal. In MBM production, the raw material is animal waste containing numerous microorganisms. Therefore, in accordance with regulations, these materials must undergo thermal treatment to eliminate microbial contamination. Despite the application of high temperatures in the technological process, reaching up to 133 °C, various biological pollutants persist in the wastewater, including pathogens responsible for numerous diseases. This type of wastewater contains a diverse bacterial microflora, including bacteria of the genera Escherichia, Staphylococcus, Enterococcus, Pseudomonas, Corynebacterium, Ralstonia, Proteus, Alcaligenes, Providencia, and Morganella. Due to the high microbial diversity in MBM wastewater, effective purification is essential to minimize risks to human health and the environment.

In recent years, advanced oxidation processes (AOPs) have gained significant importance in wastewater treatment. These processes are based on the generation of highly reactive oxygen species, such as hydroxyl radicals, which can destroy organic pollutants and pathogenic microorganisms. AOPs offer advantages over conventional oxidation methods: they do not generate disinfection by-products and present a viable alternative to chlorination [12,13,14]. AOPs refer to a group of processes that involve the generation of hydroxyl radicals, with ozone and H2O2 acting as oxidants, often in the presence of light, catalysts, ultrasound, and/or heat. Various configurations include Fenton, photo-Fenton, and peroxidation combined with ultraviolet light, etc. [15,16,17].

Advanced oxidation processes (AOPs), including the Fenton process, are widely used for the removal of recalcitrant organic pollutants from industrial and municipal wastewater. The Fenton process employs a reagent consisting of a mixture of hydrogen peroxide and ferrous iron. The oxidation mechanism is based on the generation of reactive hydroxyl radicals, which exhibit rapid and non-selective oxidation of various organic compounds, as well as some inorganic substances. Due to the strong oxidative properties of hydroxyl radicals, organic pollutants in wastewater are effectively degraded, often to the point of complete mineralization into carbon dioxide, water, and inorganic salts. Additionally, iron complexes formed during the reaction act as flocculants [18,19,20].

One of the advantages of the Fenton process is that it operates under ambient temperature and atmospheric pressure. However, process parameters such as temperature, pH, and the initial concentration of organic substances significantly affect the required amounts of hydrogen peroxide and iron, as well as the reaction time. The oxidation activity of hydroxyl radicals (•OH) is strongly influenced by the pH of the solution. The Fenton process is typically carried out at a pH of around 3. The activity of the Fenton reagent decreases with increasing pH due to the precipitation of inactive iron oxo-hydroxides and iron hydroxide, which limit the availability of active Fe2⁺. On the other hand, at very low pH values, the presence of iron complexes [Fe(H2O)6]2⁺ and the stable oxonium ion [H3O2]⁺ reduce the reactivity between iron and hydrogen peroxide. Therefore, both excessively low and high pH values reduce the efficiency of the Fenton process [19,21,22,23]. Hydrogen peroxide concentration also plays a critical role in the process’s effectiveness. Generally, as H2O2 concentration increases, the degradation of pollutants also increases. However, excessive dosages can lead to reduced efficiency due to scavenging of •OH radicals by excess H2O2 or their recombination into less reactive species [21,22,24]. The application of coagulation after the treatment process leads to the removal of iron hydroxy complexes, residual iron, as well as color [21,25,26].

The Fenton process is a promising alternative to conventional wastewater treatment methods, which, despite their widespread use, have certain limitations, especially when dealing with industrial effluents containing high concentrations of organic and microbiological pollutants. Traditional methods often struggle with persistent pollutants, lack flexibility in adapting to variable wastewater composition, and produce excess sludge that requires further treatment. In contrast, the Fenton process ensures high removal efficiency of pollutants and allows for flexible adjustment of operational parameters to the specific properties and variable composition of the wastewater.

The goal of this study was to treat wastewater generated during meat and bone meal production using the Fenton process, followed by neutralization, and to evaluate the impact of the applied methodology and treatment parameters, particularly the mass ratio of Fenton reagents (Fe2⁺/H2O2 = 1:2–1:10) and their dosages, on the microbiological quality of the treated wastewater. The research focused mainly on the microbiological quality of the treated wastewater samples, as the Fenton process, compared to other treatment methods, is one of the most effective methods for eliminating microorganisms and reducing the risk to humans and the environment. A fixed dose of iron, approximately 2.0 g/L, was used in the treatment process, while the hydrogen peroxide dose varied within the range of 4–20 g/L of treated wastewater. This wide range of hydrogen peroxide dosages was necessitated by the high turbidity and significant microbiological contamination of the wastewater. Additionally, to provide a more comprehensive assessment of the quality of the treated liquid fractions, selected physicochemical parameters were measured, including chemical oxygen demand, color, turbidity, and pH.

2. Materials and Methods

2.1. Wastewater from Meat and Bone Meal Production

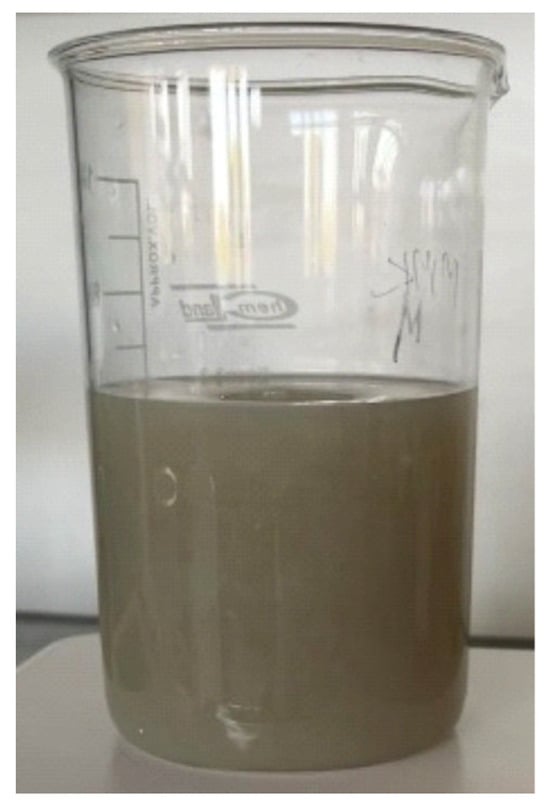

The analyzed wastewater was collected from an agricultural and industrial facility located in the Wielkopolska Province of Poland, engaged in the production of meat and bone meal (see Figure 1). The wastewater was characterized by an unpleasant odor, a strongly gray coloration, and high turbidity, resulting from the processing of large quantities of animal by-products such as horns, hooves, and feathers. The treated wastewater was subjected to microbiological analysis and selected physicochemical assessments, as described in Section 2.4.1 and Section 2.4.2, respectively.

Figure 1.

Wastewater from meat and bone meal production.

2.2. Reagents Used in the Wastewater Treatment Process

For the treatment of wastewater from MBM production using the Fenton process, a 30% solution of hydrogen peroxide (analytical grade), purchased from Avantor Performance Materials Poland S.A., Gliwice, Poland was used as an oxidant. The source of iron was iron(II) sulfate(VI) heptahydrate (FeSO4·7H2O), ACS reagent, 99% purity, from Sigma-Aldrich, St. Louis, MO, USA. In the neutralization reaction of the treated wastewater suspension, a 10% solution of lime milk was used; calcium oxide (pure grade) from Chempur, Piekary Śląskie, Poland (was used for its preparation. To adjust the pH of the wastewater, a 4 molar solution of sulfuric acid(VI), prepared from 98% H2SO4 (analytical grade, Chempur), was applied. For the determination of chemical oxygen demand (COD) by the titrimetric dichromate method, analytical grade potassium dichromate (K2Cr2O7) and ammonium iron(II) sulfate ((NH4)2Fe(SO4)2·6H2O) were obtained from Sigma-Aldrich. Analytical grade sulfuric acid (H2SO4), silver sulfate (Ag2SO4), and mercury(II) sulfate (HgSO4) were also sourced from Chempur. Analytical grade 1,10-phenanthroline monohydrate (C12H8N2·H2O), used in the preparation of ferroin as a titration indicator, was obtained from the former POCH S.A., Gliwice, Poland.

2.3. Media Used in Microbiological Analyses

In microbiological tests, microbiological media were used, purchased from BTL Sp. z o.o. Zakład Enzymów i Peptonów (Łódź, Poland). The TSA (tryptone soy agar) substrate was used to cultivate microorganisms; it is a universal substrate for culturing and multiplying microorganisms with increased nutritional requirements. The composition of the medium ensures optimal bacterial growth. This medium serves as a source of carbon, nitrogen, and minerals, and also contains casein and soy peptone, which support the growth of a wide range of microorganisms. MacConkey agar was also used, which is a selective medium that inhibits the growth of most Gram-positive bacteria due to the presence of bile salts and crystal violet. In addition, MacConkey agar serves as a differential medium, allowing for the assessment of microorganisms’ ability to utilize lactose. Selective Sabouraud agar with chloramphenicol was used for the cultivation and isolation of fungi [27].

To identify Enterococcus spp., the Slanetz–Bartley substrate was used. It is a selective medium for Gram-positive bacteria due to the presence of sodium azide, while the presence of 2,3,5-triphenyl tetrazolium chloride (TTC) inhibits the growth of most non-target bacteria. Enterococci reduce TTC to red formazan, resulting in colonies that range in color from pink to deep red [27].

For the isolation and differentiation of staphylococci, particularly Staphylococcus aureus, Baird-Parker agar was used. This is also a selective medium due to the presence of lithium chloride and potassium tellurite, which inhibit the growth of accompanying microflora. On Baird-Parker medium, typical Staphylococcus aureus colonies appear as black-gray to black, smooth, shiny, and convex, measuring 1.0–1.5 mm in diameter after 24 h of incubation, or 1.5–2.5 mm after 48 h. Due to their proteolytic and lipolytic activities, the colonies are typically surrounded by a clear halo [27].

For the detection and enumeration of Escherichia coli, TBX (Tryptone Bile X-glucuronide) selective medium was employed. The composition of this chromogenic medium includes the BCIG complex (5-bromo-4-chloro-3-indolyl-β-D-glucuronic acid), which undergoes enzymatic hydrolysis upon entering the bacterial cell. The chromogen accumulates within the cell, imparting a blue or blue-green coloration to E. coli colonies [27].

2.4. Wastewater Treatment Methodology

The treatment of wastewater from MBM production was carried out using the Fenton process, with variable mass ratios of Fe2⁺/H2O2 of 1:2, 1:4, 1:6, 1:8, and 1:10, respectively. After adjusting the pH to 3.0, 100 mL of wastewater was transferred into five beakers and placed on a magnetic stirrer. A constant, weighed amount (approximately 1.0 g) of iron(II) sulfate(VI) heptahydrate, the source of Fe2⁺ ions, was then added to each of the five wastewater samples, which were subsequently mixed for 15 min. Next, variable doses of H2O2 were added, with the amounts weighed to maintain the appropriate mass ratio of Fe2⁺/H2O2 in the range of 1:2–1:10. After adding hydrogen peroxide, the samples were stirred on the magnetic stirrer for 45 min. Then, a 10% solution of lime milk was introduced to adjust the pH of the wastewater suspension to a value between 8.0 and 8.5. The treatment process was conducted in duplicate. Table 1 shows the amounts of all reagents (the mean of two repetitions) used in the wastewater treatment process. In the final stage, the tested wastewater samples were filtered, resulting in the separation of liquid fractions (treated wastewater) and solid sediments. The subject of microbiological and physicochemical analyses was raw and treated wastewater.

Table 1.

Amounts of reagents used and parameters of wastewater treatment from meat and bone meal production in the Fenton process (reagent consumption per 100 mL of treated wastewater).

2.4.1. Methodology of Microbiological Analysis of Raw Wastewater and Samples Obtained After the Purification Process

The microbiological analysis of raw wastewater and treated wastewater samples began with a tenfold dilution series in a sterile physiological saline solution. Surface inoculation was used in the studies, which consisted of taking a 0.1 mL sample with a pipette and transferring it to the surface of the microbiological media in a Petri dish, followed by careful spreading with a spreader. The inoculations were performed in duplicate on the following microbiological media: TSA, Baird-Parker, Slanetz–Bartley, TBX, MacConkey, and Sabouraud agar with chloramphenicol. Dilutions and inoculations were carried out in an Alpina laminar flow cabinet. The inoculated medium was incubated under aerobic conditions in a Memmert incubator at 30–35 °C for 72 h for bacterial identification and at 20–25 °C for 7 days for fungal identification. After incubation, the grown microorganisms were counted using the Scan 100 Interscience bacterial colony counter, and calculations were performed. In the case of raw wastewater analysis, the total number of microorganisms per 1 mL of the sample was determined, and the number of Enterococcus and Staphylococcus aureus bacteria was calculated on selective microbiological media. No growth of characteristic blue-green colonies was observed on the TBX agar, which would confirm the presence of Escherichia coli bacteria, and no fungal growth was obtained on Sabouraud agar with chloramphenicol. In quantitative microbiological analyses of treated wastewater samples, the total number of microorganisms per 1 mL of the treated wastewater sample was calculated. All different colonies isolated from wastewater and treated wastewater samples in the Fenton process were subjected to qualitative identification using the MALDI-TOF MS technique, i.e., matrix-assisted laser desorption/ionization mass spectrometry with a time-of-flight analyzer. The MALDI-TOF MS method involves transferring a small amount of the tested material (a colony from the culture) onto a plate for analysis. Then, a solution of an appropriate matrix is applied to the tested material. After drying, the sample is placed in the analyzer chamber, where, under the influence of the laser, the matrix molecules and bacterial proteins undergo desorption and ionization. The matrix strongly absorbs the energy of laser light, contributing to the desorption of the analyte molecules. The measurement result of these molecules is recorded in the form of a mass spectrum, which is automatically analyzed and compared with a database containing spectra characteristic of specific microbial species. The probability of correct identification of a microorganism in the MALDI Biotyper system is expressed in the form of a numerical index, which determines the degree of similarity to the reference spectra [28]. In qualitative analyses, microbial identification based on MALDI-TOF MS technology was used: the Bruker MALDI Biotyper, Billerica, MA, USA, with the MBT IVD LIBRARY mass spectral library (version J, 2022). Microbial identification with an index of ≥ 2.00 was considered, allowing for high certainty.

2.4.2. Methodology of Physicochemical Characteristic Determinations of Raw Wastewater and Samples Obtained After the Purification Process

Selected physicochemical parameters were determined in raw wastewater from the MBM production and in treated wastewater samples: chemical oxygen demand (COD), color, turbidity, and pH. The COD was determined using the dichromate method according to the PN-ISO 6060:2006 standard [29]. This method consists of oxidizing organic and some inorganic compounds found in wastewater using an oxidizing mixture in which potassium dichromate (VI) is the oxidant. The mineralization process was carried out at 148 °C for 2 h in a WSL M9 mineralizer. A digital burette, Titrette, was used for titration. The color of the raw wastewater and its treated wastewater samples was determined according to the PN-EN ISO 7887:2012 standard [30] based on the platinum–cobalt scale. The actual color was determined after removing turbidity from the tested samples by filtering them through a filter with a pore diameter of 0.45 µm. Color measurements were performed at a wavelength of λ = 436 nm, using the calibration curve saved in the memory of the Nanocolor UV/VIS spectrophotometer from Macherey-Nagel, Düren, Germany. Turbidity was determined by the nephelometric method at a wavelength of λ = 860 nm [31]. A nephelometer built into the Nanocolor UV/VIS spectrophotometer from Macherey-Nagel was used for these determinations. pH measurements were performed potentiometrically using a glass electrode included in the Mettler Toledo Five Easy pH meter.

3. Results and Discussion

3.1. Characteristics of Wastewater from Meat and Bone Meal Production

Table 2 presents the results of the microbiological analysis of the raw wastewater, from MBM, which includes a qualitative analysis of isolated microorganisms conducted using the MALDI-TOF MS technique and a quantitative analysis of the total number of microorganisms per 1 mL of wastewater. Table 3 presents data on the number of specific types of bacteria isolated on the selective media used. Table 4 presents the results of the determination of selected physicochemical parameters of the wastewater.

Table 2.

Results of the qualitative analysis of microorganisms isolated from the wastewater and identified using the MALDI-TOF MS technique, and the general quantitative analysis. Total number of microorganisms.

Table 3.

Quantitative analysis of bacterial species isolated on selective media from meat and bone meal production wastewater.

Table 4.

Physicochemical characteristics of wastewater from meat and bone meal production.

The qualitative microbiological analysis of the wastewater performed by the MALDI-TOF MS method (Table 2) showed the presence of Gram-negative bacteria belonging to the genera Alcaligenes, Pseudomonas, and Ralstonia, and Gram-positive bacteria of the genera Corynebacterium, Enterococcus, Staphylococcus, and Lysinibacillus. The isolated Gram-negative bacteria were Alcaligenes faecalis, Pseudomonas oryzihabitans, Ralstonia pickettii, and Ralstonia sp., and the Gram-positive bacteria were Corynebacterium sp., Enterococcus faecalis, Staphylococcus aureus, and Lysinibacillus xylanilyticus. The total number of microorganisms in the raw wastewater was estimated at 2.4 × 1010 CFU/mL.

The bacterial species Alcaligenes faecalis belongs to the genus Alcaligenes, which was described by Castellani and Chalmer [32]. These bacteria are Gram-negative, strictly aerobic, motile, rod-shaped, or intermediate in shape between a coccus and a rod (coccobacilli), have catalase and oxidase activity, and are non-fermentative [33,34,35,36]. Alcaligenes faecalis commonly occurs in natural aquatic and terrestrial environments as well as in hospital environments, e.g., on respirators or hemodialysis systems [33,37]. It can cause opportunistic infections in humans, which are difficult to treat due to increased resistance to certain antibiotics. The most common sites of infection are the blood, urinary tract, skin and soft tissues, and the middle ear [38]. Literature data also report the positive effects of Alcaligenes faecalis bacterial strains and their use in active bioremediation for removing heavy metals, plastics, and xenobiotics [39].

The bacterial species Pseudomonas oryzihabitans, belonging to the genus Pseudomonas, was isolated from wastewater, which is one of the best-studied bacterial genera and the genus with the largest number of species among Gram-negative bacteria [40]. Pseudomonas oryzihabitans is an oxidase-negative, non-fermenting bacterium that does not form endospores and has a rod-like shape with dimensions of 0.8 by 2.0 µm, and rounded ends. The cells occur singly, rarely in pairs, and are motile using a polar monotrichous flagellum [41]. Pseudomonas oryzihabitans is a saprophytic microorganism that is considered a potential hospital pathogen responsible for infections in people with a weakened immune system or with catheters or prosthetic materials [42,43].

The genus Ralstonia was proposed in 1995, and the type species of the genus is Ralstonia pickettii [44]. Ralstonia pickettii (formerly Pseudomonas pickettii and Burkholderia pickettii) is a non-fermentative Gram-negative rod that occurs in soil, purified water, and sewage, and has human associations [45]. Ralstonia pickettii is the most common Ralstonia species in human medicine [46], and is an opportunistic pathogen in hospital infections, especially in immunocompromised patients [46,47,48].

The genus Corynebacterium has over 110 validated species [49] and is highly diverse, with bacteria described as Gram-positive, but the shape, oxygen requirement, and preferred environment are divergent among species [49,50,51]. Heterogeneity within the genus includes species that originate from the environment, as well as human, zoonotic, and strictly animal commensals or opportunistic pathogens [52]. Corynebacterium can cause opportunistic infections in both humans and immunocompromised domestic animals and can be multidrug resistant [52,53]. Non-pathogenic species have shown strong importance in human, veterinary, and biotechnological medicine [51].

Enterococcus faecalis has been found in wastewater as a Gram-positive commensal member of the gut microbiome of a wide range of organisms [54]. Enterococci are members of the gastrointestinal consortia of humans and other mammals, birds, and insects and are a major cause of multidrug-resistant hospital infections [55]. Enterococcus faecalis and Enterococcus faecium are primarily responsible for hospital infections [56,57], with Enterococcus faecalis having a greater inherent ability to cause infection regardless of resistance [58]. The habitats of enterococci include not only animal hosts but also plants, soil, water, and human-made products. In many of these habitats, antibiotic-resistant strains of enterococci have emerged, and strains with new resistance mechanisms are isolated with alarming regularity [55].

Staphylococcus aureus, a Gram-positive, coagulase-positive bacterium with a spherical shape, has been isolated from wastewater [59]. It is a commensal bacterium and a human pathogen, as it is estimated that about 30% of the human population is colonized by Staphylococcus aureus [60]. It causes a wide range of clinical infections, contributing to bacteremia, infective endocarditis, as well as osteoarticular, skin and soft tissue, pleural, and pulmonary infections, and device-related infections. Over the past two decades, an increasing number of healthcare-associated infections and an epidemic of skin and soft tissue infections caused by strains with specific virulence factors and resistance to β-lactam antibiotics have been observed [61].

The genus Lysinibacillus was proposed in 2007 by Ahmed et al. [62]. Lysinibacillus belongs to the family Bacillaceae and has been isolated from various environments, including soil [63], surface water [64], and plants [65]. These bacteria are motile, rod-shaped, and produce spherical or ellipsoidal endospores. Oxidase and catalase tests are positive, while indole and H2S production, nitrate reduction, and β-galactosidase (ONPG) tests are negative [62]. Lysinibacillus xylanilyticus isolated from wastewater from the MBM production is a Gram-positive, aerobic bacterium that, according to literature data, was isolated from forest humus and can degrade xylan [66].

The above-presented short description of selective characteristics of isolated types of bacteria and their species was aimed at showing the diversity of microflora occurring in wastewater from MBM production and the need to use appropriate methods of treating this wastewater type, which will enable the effective reduction of not only physicochemical but also microbiological parameters. It should also be mentioned that the microbiological parameters of wastewater from the production of meat and bone meal are very variable both in terms of quality and quantity, which are determined by the type, quality, and amount of processed raw materials (animal waste) in the production of meat and bone meal, as well as the parameters of the MBM production process.

The composition of the substrates and the ability of specific bacterial types to decompose the components of the substrates or accumulate them result in Staphylococci, and in this case, Staphylococcus aureus, confirmed by MALDI-TOF MS on Baird-Parker agar, growing as black colonies with a light border. Enterococcus bacteria on Slanetz–Bartley agar form round, convex colonies with a beetroot color.

Counting bacteria with a characteristic appearance on selective substrates (Baird-Parker and Slanetz–Bartley agar) allowed for determining the total number of bacteria from the genera Staphylococcus or Enterococcus (Table 3). From the genus Staphylococcus, only Staphylococcus aureus bacteria were confirmed by the MALDI-TOF MS technique, which occurred in very large numbers, reaching 2.8 × 10⁶ CFU/mL. The number of bacteria from the genus Enterococcus was 4.3 × 10⁴ CFU/mL, and the identified species was Enterococcus faecalis. No Escherichia coli bacteria were isolated from the wastewater, and they did not grow on any of the microbiological media used, including TBX.

The goal of this study was to examine the biological contamination of raw wastewater and purified wastewater samples; additionally, the basic physicochemical characteristics were determined (Table 4). Physicochemical parameters of raw wastewater from the MBM production have been examined many times by the authors [10,11] and are very variable depending on the type and amount of processed raw material. The COD of the raw wastewater was relatively low and amounted to 4940 mg O2/L, and in this type of wastewater, COD values can reach even several thousand mg O2/L. The wastewater contained a large amount of suspended solids, which caused a high turbidity of 968 NTU (Nephelometric Turbidity Unit). The actual color of the wastewater after the removal of suspensions by the filter was at the level of 1630 mg Pt/L, and the visual appearance of the wastewater was gray. The pH of the wastewater was alkaline, ranging from 8.50 to 8.72.

3.2. Results of the Analyses of Treated Wastewater Samples Obtained from the Purification of Wastewater from MBM Production Using the Fenton Process

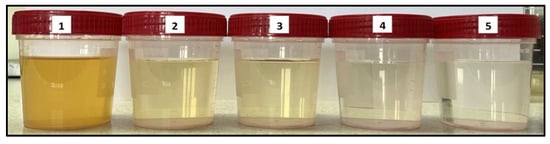

Figure 2 presents images of the appearance of wastewater samples purified using the Fenton process with a variable Fe2⁺/H2O2 mass ratio ranging from 1:2 to 1:10. Table 5 presents the results of microbiological analyses of the purified wastewater samples, while Table 6 presents the results of physicochemical analyses.

Figure 2.

Images of wastewater samples from the production of meat and bone meal purified in the Fenton process (mass ratio of Fe2⁺/H2O2 in the purification process: 1—1:2, 2—1:4, 3—1:6, 4—1:8, 5—1:10).

Table 5.

Results of qualitative and quantitative microbiological analysis of wastewater samples from meat and bone meal production purified in the Fenton process (qualitative analysis using MALDI-TOF MS, general quantitative analysis).

Table 6.

Physicochemical parameters of liquid samples after the purification of wastewater from meat and bone meal production using the Fenton process.

The results of the microbiological analysis presented in Table 5 show that the microbiological quality of the wastewater treatment samples changes as the doses of Fenton’s reagent increase. In the wastewater treatment, a constant dose of Fe2⁺ (2 g/L of wastewater) and variable doses of hydrogen peroxide (ranging from 4 to 20 g/L) were used, resulting in the Fenton process being carried out at mass ratios of Fe2⁺/H2O2 of 1:2, 1:4, 1:6, 1:8, and 1:10, respectively. In the final stage of treatment, the wastewater slurry was neutralized with a 10% solution of lime milk, primarily to remove iron from the liquid fraction and to achieve the appropriate pH of the wastewater treatment samples after treatment and filtration.

The applied wastewater treatment method and the selected process parameters significantly reduced the total number of microorganisms. Prior to the purification process, the degree of microbiological contamination in the wastewater was estimated at 2.4 × 101⁰ CFU/mL. After purification, the total number of microorganisms in the purified wastewater samples ranged from 3.3 × 10⁴ to 1.3 × 102 CFU/mL (Table 5). The highest degree of microbiological contamination, 3.3 × 10⁴ CFU/mL, was observed in the wastewater treated with the lowest dose of hydrogen peroxide (4 g/L) and a mass ratio of Fe2⁺/H2O2 of 1:2 (sample 1). Further purification of the wastewater using higher amounts of hydrogen peroxide (8 g/L and 12 g/L, with Fe2⁺:H2O2 mass ratios of 1:4 and 1:6, respectively) resulted in a fivefold (sample 2) and twofold (sample 3) reduction in the number of microorganisms in the purified filtrates, compared to the purification with the lowest reagent mass ratio (1:2). Using the Fenton process with the highest Fe2⁺/H2O2 mass ratios of 1:8 and 1:10 led to the greatest reduction in microorganism numbers in the treated wastewater, with counts of 1.3 × 102 CFU/mL (sample 4) and 3.2 × 102 CFU/mL (sample 5), respectively.

Identification of microorganisms by the MALDI-TOF MS method revealed the types of bacteria or specific species present in the treated wastewater samples and indicated which of them showed the greatest resistance to the applied treatment method and its parameters. In the first three samples, obtained as a result of wastewater treatment with Fe2⁺/H2O2 mass ratios in the range of 1:2 to 1:6, nearly identical microbiological compositions were found, as Staphylococcus aureus, Alcaligenes faecalis, Pseudomonas oryzihabitans, and Enterococcus faecalis were isolated and identified on the media (Table 5). In sample 2, obtained with a Fe2⁺/H2O2 mass ratio of 1:4 (8 g H2O2/L of wastewater), no fecal streptococci were detected, although they were present in sample 3, which had a higher hydrogen peroxide dose (12 g H2O2/L of wastewater). This suggests that, with these purification parameters, fecal streptococci were still resistant to the prevailing environmental conditions. Increasing the amount of hydrogen peroxide, and consequently the Fe2⁺/H2O2 mass ratio, to 1:8 and 1:10 resulted in the isolation of only Staphylococcus aureus and Alcaligenes faecalis from the purified liquid samples. None of the purified liquid samples contained bacteria from the genera Ralstonia, Corynebacterium, or Lysinibacillus, which had been isolated from the wastewater before the purification process.

In summary, the MALDI-TOF MS analysis results clearly indicate that the most resistant microorganisms to the purification parameters were Staphylococcus aureus and Alcaligenes faecalis, both of which were present in each sample after wastewater purification. Throughout the entire purification process, highly variable conditions were applied, which influenced the survival of microorganisms in the wastewater sample. The purified wastewater also exhibited high turbidity (968 NTU), caused by suspended solid particles, which may have diminished the effectiveness of the reagents in the Fenton process.

Particles present in wastewater can interfere with treatment processes and significantly increase treatment costs, thereby raising operational expenses (chemical demand, energy consumption) or infrastructure costs by requiring additional treatment steps to achieve the required levels of pathogen inactivation. Many microorganisms (viruses, bacteria, protozoa) bind to particles in wastewater, allowing them to survive disinfection processes and pose a health risk [67]. Particles contained in wastewater can either be physically associated with microorganisms in the form of clumps or be unassociated, but still protect the microorganisms from UV light or contribute to increased demand for disinfectants [68]. The binding of microorganisms to particles can occur through electrostatic attraction, hydrophobic interactions, or physical entrapment [67,69]. In wastewater treatment plant effluents after various treatment steps, turbidity can serve as a measure of treatment efficiency [70].

Hydrogen peroxide is used in wastewater treatment; however, according to the literature, extracellular hydrogen peroxide weakens cell walls, making bacteria more sensitive to oxidative stress, which may explain the inactivity. Despite the high disinfection efficiency of hydrogen peroxide, little is known about its biocidal mechanism. In hydrogen peroxide disinfection, the cytotoxic effect has not been attributed to the oxidative properties of the molecular form, but to the oxidative stress caused by hydroxyl radicals (HO•), singlet oxygen (O2*), and superoxide species (•O2−) derived from its natural decomposition. The decomposition products of H2O2 are active oxygen molecules, which are toxic to cells and can attack organic compounds, including lipids, membrane proteins, and nucleic acids of cells [71,72,73]. In the Fenton process, reactive oxygen species are generated by the decomposition of hydrogen peroxide mainly to hydroxyl and hydroperoxyl radicals, thanks to the catalyzed homolytic cleavage of the peroxide bond by dissolved metal ions (most often Fe2+) in the homogeneous phase [72,73,74]. The disinfection efficiency in the Fenton process will depend on the reaction rate between the catalyzing metal ion and hydrogen peroxide and on the formation rate of reactive oxygen species. However, the efficiency of the Fenton process is influenced by many factors, such as the reaction medium, pH, the presence of suspended solids, and chemical and physical interactions between reagents and microorganisms; therefore, each wastewater treatment system should be approached individually.

Literature data show that structural differences between Gram-negative and Gram-positive bacteria may be the main reason for differences in sensitivity to the applied disinfection treatments. For example, Escherichia coli (Gram-negative) is more sensitive than Enterococcus sp. (Gram-positive), which has a thicker cell wall. However, other factors, such as the internal defense mechanisms of these bacteria, must also be considered [12]. Osmotic stress causes a greater weakening of the E. coli cell wall, increasing permeability, making its cells more sensitive than those of Enterococcus sp. [12,75]. In our study, Staphylococcus aureus (Gram-positive bacterium) and Alcaligenes faecalis (Gram-negative bacterium) were present in each sample of treated wastewater. Therefore, the structural differences between these bacteria did not affect their survival, but rather the internal defense mechanisms of these bacteria. Staphylococcus aureus can survive in many different environments, including stressful ones, and adapt to them because it has regulatory systems to cope with stress. Staphylococcus aureus can form biofilm in response to environmental stressors such as desiccation and oxidative damage [76]. Alcaligenes faecalis, commonly found in the natural environment, can survive there thanks to effective adaptation to the environment. Additionally, it has an excellent ability to decompose various pollutants, from heavy metals to plastic and other hydrocarbons [77]. Some strains of Alcaligenes faecalis can cause diseases in humans, birds, and other vertebrates. Most of these strains are resistant to almost all existing antibiotics, and this resistance is conferred by antibiotic resistance genes (ARGs) [78]. Antibiotic resistance genes in A. faecalis strains are activated by a wide range of antibiotics currently used to treat infections, and strains living in the open environment are less resistant to antibiotics than clinical strains. The release of large amounts of antimicrobials into natural ecosystems can alter microbial population dynamics, including the selection for resistance, which may have uncertain consequences for human health [79].

The present study focused on comparing the effectiveness of microorganism elimination depending on the concentration of H2O2 in a system with a constant amount of Fe2⁺ ions. Although the observed increase in pathogen removal efficiency with higher H2O2 concentrations suggests the involvement of radical reactions, the direct effect of hydrogen peroxide on microorganisms cannot be definitively excluded. Therefore, future research will expand the experimental setup to include controls without the iron catalyst, which will allow for a more precise assessment of the contribution of individual oxidation mechanisms to the observed effect.

Table 6 presents the physicochemical parameters of the liquid samples obtained as a result of wastewater treatment using the Fenton process and neutralization with a 10% solution of lime milk. Analyzing the determined parameters, it can be clearly stated that increasing the mass ratio of Fe2+/H2O2 in the range from 1:2 to 1:10 resulted in a significant effect on the efficiency of the treatment process. The least effective wastewater treatment was achieved with the lowest Fe2⁺/H2O2 mass ratio of 1:2 (sample 1), while the most effective treatment was achieved with a 1:10 mass ratio (sample 5). Comparing the turbidity results, sample 1 of the treatment, with the lowest mass ratio of reagents, had a value of 106 NTU (turbidity reduction degree of about 89%). However, the remaining samples, 2–4, showed the value of this parameter below 1 NTU. This showed that using a Fe2⁺/H2O2 mass ratio in the range of 1:4 to 1:10 had an equal effect on the removal of pollutants causing turbidity in the wastewater. The color of the purified samples ranged from 2092 to 56 mg Pt/L, with an increased color value in sample 1 compared to the raw wastewater color after filtration. This was due to the addition of too small an amount of oxidant (H2O2) relative to the catalyst (Fe2⁺), resulting in the yellow color of the filtrate caused by iron. In subsequent samples, i.e., 2–5, the mass ratio of the reagents was systematically increased by increasing the doses of hydrogen peroxide. As a result, the color systematically decreased, and in sample 5, purified at the highest mass ratio of the reagents, the highest color reduction degree was obtained, amounting to about 97%.

The content of organic compounds, determined by the COD parameter, systematically decreased with increasing doses of oxidant, varying within the range of 2407–1091 mg O2/L. This corresponds to a reduction in COD values of approximately 51% to 78%. After the neutralization and filtration stages, the pH of the treated wastewater ranged from 7.62 to 8.15.

The Fenton process can be applied as a supplementary or supporting method for wastewater treatment prior to biological treatment, or as a primary treatment method, depending on the type and concentration of pollutants present in the wastewater, the required treatment efficiency, and the potential for further reuse. The COD values of wastewater generated from meat and bone meal production may range from 4000 mg O2/L to as high as 25,000 mg O2/L; therefore, various treatment strategies must be developed. Wastewater from MBM production, after undergoing mechanical treatment followed by chemical processes (coagulation and flocculation), often supported by pressure flotation in a DAF (Dissolved Air Flotation) system [11], must be adjusted to contain a level of organic pollutants compatible with the capacity of the on-site biological treatment facility (typically, COD values should not exceed 5000 mg O2/L) before being discharged into it. However, achieving such levels is not always straightforward. As such, the Fenton process may serve as an effective solution, provided that process parameters are appropriately tailored to the degree of pollution. Additionally, monitoring of microbiological and physicochemical parameters after treatment (including residual hydrogen peroxide levels) is essential, as these influence the feasibility of subsequent treatment stages or the reuse of the treated wastewater within the facility.

A wide range of hydrogen peroxide concentrations (4–20 g/L) was used in this study; therefore, the concentration of residual hydrogen peroxide in the treated wastewater should be monitored, depending on its intended further application. This is particularly important when the next stage involves biological wastewater treatment. Neutralization with lime milk (calcium hydroxide suspension) may support the decomposition of hydrogen peroxide, primarily through pH elevation and potential catalytic effects, but it does not function as a typical neutralizing reagent for H2O2. Hydrogen peroxide decomposes spontaneously into water and oxygen, particularly under alkaline conditions (elevated pH), in the presence of trace metals (Fe, Cu, Ni, Mn, Cr) acting as catalysts [80,81], under UV radiation, and in the presence of certain enzymes (catalase) [80]. In the case of storing treated wastewater in tanks (prior to potential reuse for technical purposes within the plant), hydrogen peroxide will gradually decompose over time, with its half-life decreasing as the pH increases [82].

There are no publications in the available scientific literature regarding the study of the impact of the Fenton reagent on the microbiological quality of treated wastewater from meat and bone meal production. Oxidation processes can be applied as an alternative to conventional technologies for removing hazardous pollutants and pathogens from wastewater, as well as for increasing their reuse and reducing risks to human health and the environment. The inactivation of wastewater samples is a complex issue, which requires consideration of the composition of the effluent, including the number and presence of both organic and inorganic substances, as well as the microbial population. The matrix composition plays a crucial role in the effectiveness of removing different types of pollutants, which is why the efficiency of the treatment process, including disinfection, will vary for samples with different levels of contamination.

4. Conclusions

The application of the Fenton process using varying doses of hydrogen peroxide (4–20 g/L) and a constant concentration of ferrous ions (Fe2⁺, 2 g/L) significantly improved both the microbiological and physicochemical quality of wastewater generated during meat and bone meal production. An increase in the Fe2⁺/H2O2 mass ratio from 1:2 to 1:10 resulted in a gradual decrease in the total microbial count, which was reduced to a range of 3.3 ×∙10⁴–1.3∙× 102 CFU/mL. Despite the considerable reduction in microbial populations, two species—Staphylococcus aureus and Alcaligenes faecalis—were present in all samples, regardless of treatment intensity, indicating their resistance to oxidative stress and variable environmental conditions. Their persistence is most likely due to intracellular defense mechanisms rather than differences in cell wall structure.

The process was also effective in removing turbidity and color; turbidity values dropped below 1 NTU, and color removal reached up to 97% with higher oxidant doses, demonstrating efficient removal of suspended solids and residual iron. The concentration of organic compounds, expressed as COD, was reduced by up to 78%, confirming the effectiveness of the Fenton process in removing organic pollutants from a complex wastewater matrix. The presence of suspended particles in the wastewater significantly affected treatment efficiency by shielding microorganisms from oxidative agents and increasing chemical demand, underscoring the importance of their effective removal for process optimization.

Future research should include systems without the iron catalyst to better assess the individual role of hydrogen peroxide and radical-based mechanisms in microbial deactivation. The obtained results highlight the need for further targeted studies, particularly concerning pathogen resistance and the integration of the Fenton process with existing treatment technologies.

Author Contributions

Conceptualization, A.M. and Z.K.; methodology, A.M.; software, A.M.; validation, W.S., A.G. and I.W.; formal analysis, A.M., Z.K., A.G. and I.W.; investigation, A.M. and W.S.; resources, A.M.; data curation, A.M.; writing—original draft preparation, A.M. and Z.K.; writing—review and editing, A.M. and Z.K.; visualization, A.M.; supervision, Z.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, R.P.; Yadav, P.; Gupta, R.K.; Singh, S.K.; Verma, H.; Singh, P.K.; Kaushalendra; Pandey, K.D.; Kumar, A. Chapter Fourteen—Pathogenic microbes in wastewater: Identification and characterization. In Advances in Chemical Pollution, Environmental Management and Protection, 1st ed.; Ferreira, L.F.R., Kumar, A., Bilal, M., Eds.; Academic Press: Cambridge, MA, USA, 2023; Volume 9, pp. 247–262. [Google Scholar] [CrossRef]

- Abdel-Raouf, N.; Al-Homaidan, A.A.; Ibraheem, I.B.M. Microalgae and wastewater treatment. Saudi J. Biol. Sci. 2012, 19, 257–275. [Google Scholar] [CrossRef] [PubMed]

- Gerardi, M.H.; Zimmerman, M.C. Wastewater Pathogens, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Symonds, E.M.; Verbyla, M.E.; Lukasik, J.O.; Kafle, R.C.; Breitbart, M.; Mihelcic, J.R. A case study of enteric virus removal and insights into the associated risk of water reuse for two wastewater treatment pond systems in Bolivia. Water Res. 2014, 65, 257–270. [Google Scholar] [CrossRef]

- Skovgaard, N. Chapter 23—Bovine spongiform encephalitis: The case of an unexpected and rapidly spreading epidemic in cattle with serious consequences. In Case Studies in Food Safety and Authenticity: Lessons from Real-Life Situations, 1st ed.; Hoorfar, J., Ed.; Woodhead Publishing: Cornwall, UK, 2012; pp. 204–214. [Google Scholar] [CrossRef]

- European Food Safety Authority. Animal By-Products. Available online: https://www.efsa.europa.eu/en/topics/animal-by-products (accessed on 15 February 2025).

- Kowalski, Z.; Makara, A. The circular economy model used in the polish agro-food consortium: A case study. J. Clean. Prod. 2021, 284, 124751. [Google Scholar] [CrossRef]

- Kowalski, Z.; Krupa-Żuczek, K. A model of the meat waste management. Pol. J. Chem. Technol. 2007, 9, 91–97. [Google Scholar] [CrossRef]

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef]

- Makara, A.; Kowalski, Z.; Saeid, A. Treatment of wastewater from production of meat-bone meal. Open Chem. 2015, 13, 1275–1285. [Google Scholar] [CrossRef]

- Makara, A.; Kowalski, Z.; Radomski, P.; Olczak, P. Treatment of wastewater from the production of meat and bone meal by the Fenton process and coagulation. Pol. J. Chem. Technol. 2022, 24, 51–60. [Google Scholar] [CrossRef]

- Rodríguez-Chueca, J.; Mediano, A.; Ormad, M.P.; Mosteo, R.; Ovelleiro, J.L. Disinfection of wastewater effluents with the Fenton-like process induced by electromagnetic fields. Water Res. 2014, 60, 250–258. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhu, R.; Xi, Y.; Zhu, J.; Zhu, G.; He, H. Strategies for enhancing the heterogeneous Fenton catalytic reactivity: A review. Appl. Catal. B 2019, 255, 117739. [Google Scholar] [CrossRef]

- Rahim Pouran, S.; Raman, A.A.A.; Wan Daud, W.M.A. Review on the application of modified iron oxides as heterogeneous catalysts in Fenton reactions. J. Clean. Prod. 2014, 64, 24–45. [Google Scholar] [CrossRef]

- Soon, A.N.; Hameed, B.H. Heterogeneous catalytic treatment of synthetic dyes in aqueous media using Fenton and photo-assisted Fenton process. Desalination 2011, 269, 1–16. [Google Scholar] [CrossRef]

- Patel, S.K.; Patel, S.G.; Patel, G.V. Degradation of Reactive Dye in Aqueous Solution by Fenton, Photo-Fenton Process and Combination Process with Activated Charcoal and TiO2. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2020, 90, 579–591. [Google Scholar] [CrossRef]

- Akinyemi, A.; Agboola, O.; Alagbe, E.; Igbokwe, E. The role of catalyst in the adsorption of dye: Homogeneous catalyst, heterogeneous catalyst, and advanced catalytic activated carbon, critical review. Desalin. Water. Treat. 2024, 320, 100780. [Google Scholar] [CrossRef]

- Stasinakis, A.S. Use of selected advanced oxidation processes (AOPs) for wastewater treatment—A mini review. Glob. Nest J. 2008, 10, 376–385. [Google Scholar] [CrossRef]

- Xu, M.; Wu, C.; Zhou, Y. Advancements in the Fenton Process for Wastewater Treatment. In Advanced Oxidation Processes—Application, Trends, and Prospects; Bustillo-Lecompte, C., Ed.; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Zhang, M.; Dong, H.; Zhao, L.; Wang, D.; Meng, D. A review on Fenton process for organic wastewater treatment based on optimization perspective. Sci. Total Environ. 2019, 670, 110–121. [Google Scholar] [CrossRef]

- Babuponnusami, A.; Muthukumar, K. A review on Fenton and improvements to the Fenton process for wastewater treatment. J. Environ. Chem. Eng. 2014, 2, 557–572. [Google Scholar] [CrossRef]

- Rivas, F.R.; Beltrán, F.J.; Frades, J.; Buxeda, P. Oxidation of p-hydroxybenzoic acid by Fenton’s reagent. Water Res. 2001, 35, 387–396. [Google Scholar] [CrossRef]

- Kavitha, V.; Palanivelu, K. Destruction of cresols by Fenton oxidation process. Water. Res. 2005, 39, 3062–3072. [Google Scholar] [CrossRef]

- Xu, X.R.; Li, X.Y.; Li, X.Z.; Bin Li, H. Degradation of melatonin by UV, UV/H2O2, Fe2+/H2O2 and UV/Fe2+/H2O2 processes. Sep. Purif. Technol. 2009, 68, 261–266. [Google Scholar] [CrossRef]

- Lin, S.H.; Lin, C.M.; Leu, H.G. Operating characteristics and kinetic studies of surfactant wastewater treatment by fenton oxidation. Water Res. 1999, 33, 1735–1741. [Google Scholar] [CrossRef]

- Lin, S.H.; Lo, C.C. Fenton process for treatment of desizing wastewater. Water Res. 1997, 31, 2050–2056. [Google Scholar] [CrossRef]

- Zakład Enzymów i Peptonów. BTL Product Register. Materials Related to Microbiological Media Obtained by BTL Sp. z o.o.; Zakład Enzymów i Peptonów: Łódź, Poland, 2022. [Google Scholar]

- Cieślik, J.; Wróblewska, M. MALDI TOF MS—New possibilities in routine microbiological diagnostics. J. Lab. Diagn. 2018, 54, 99–104. [Google Scholar] [CrossRef]

- PN-ISO 6060:2006; Water Quality—Determination of Chemical Oxygen Demand. Polish Committee for Standardization: Warsaw, Poland, 2006.

- PN-EN ISO 7887:2012; Water Quality—Color Testing and Marking. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN ISO 7027-1:2016-09; Water Quality—Determination of Turbidity—Part 1: Quantitative Methods. ISO: Geneva, Switzerland, 2016.

- Castellani, A.; Chalmers, A.J. Manual of Tropical Medicine, 3rd ed.; Williams Wood and Company: New York, NY, USA, 1919. [Google Scholar]

- Bizet, J.; Bizet, C. Strains of Alcaligenes faecalis from clinical material. J. Infect. 1997, 35, 167–169. [Google Scholar] [CrossRef]

- Foss, S.; Heyen, U.; Harder, J. Alcaligenes defragans sp. nov., description of four strains isolated on alkenoic monoterpenes ((+)-menthene, α-pinene, 2-carene, and α-phellandrene) and nitrate. Syst. Appl. Microbiol. 1998, 21, 237–244. [Google Scholar] [CrossRef]

- Schroll, G.; Busse, H.J.; Parrer, G.; Rölleke, S.; Lubitz, W.; Denner, E.B.M. Alcaligenes faecalis subsp. parafaecalis subsp. nov., a bacterium accumulating poly-β-hydroxybutyrate from acetone-butanol bioprocess residues. Syst. Appl. Microbiol. 2001, 24, 37–43. [Google Scholar] [CrossRef]

- Coenye, T.; Vancanneyt, M.; Cnockaert, M.C.; Falsen, E.; Swings, J.; Vandamme, P. Kerstersia gyiorum gen. nov., sp. nov., a novel Alcaligenes faecalis-like organism isolated from human clinical samples and reclassification of Alcaligenes denitrificans Rüger and Tan 1983 as Achromobacter denitrificans comb. nov. Int. J. Syst. Evol. Microbiol. 2003, 53, 1825–1831. [Google Scholar] [CrossRef][Green Version]

- Pereira, M.; Perilli, M.; Mantengoli, E.; Luzzaro, F.; Toniolo, A.; Rossolini, G.M.; Amicosante, G. PER-1 extended-spectrum beta-lactamase production in an Alcaligenes faecalis clinical isolate resistant to expanded-spectrum cephalosporins and monobactams from a hospital in northern Italy. Microb. Drug. Resist. 2000, 6, 85–90. [Google Scholar] [CrossRef]

- Huang, C. Extensively drug-resistant Alcaligenes faecalis infection. BMC Infect. Dis. 2020, 20, 833. [Google Scholar] [CrossRef]

- Ray, R.R.; Pattnaik, S. Alcaligenes faecalis: A bacterium for sustainable management of environment. Environ. Qual. Manag. 2024, 34, e22189. [Google Scholar] [CrossRef]

- Jorge Lalucat, J.; Gomila, M.; Mulet, M.; Zaruma, A.; García-Valdés, E. Past, present and future of the boundaries of the Pseudomonas genus: Proposal of Stutzerimonas gen. Nov. Syst. Appl. Microbiol. 2022, 45, 126289. [Google Scholar] [CrossRef]

- Kodama, K.; Kimura, N.; Komagata, K. Two New Species of Pseudomonas: P. oryzihabitans Isolated from Rice Paddy and Clinical Specimens and P. luteola Isolated from Clinical Specimens. Int. J. Syst. Evol. Microbiol. 1985, 35, 467–474. [Google Scholar] [CrossRef]

- Dussart-Baptista, L.; Bodilis, J.; Barray, S.; Frébourg, N.; Fournier, M.; Dupont, J.P.; Jouenne, T. Recurrent recovery of Pseudomonas oryzihabitans strains in a karstified chalk aquifer. Water Res. 2007, 41, 111–117. [Google Scholar] [CrossRef]

- Panagopoulos, G.N.; Megaloikonomos, P.D.; Liontos, M.; Giannitsioti, E.; Drogari-Apiranthitou, M.; Mavrogenis, A.F.; Kontogeorgakos, V. Pseudomonas oryzihabitans Infected Total Hip Arthroplasty. J. Bone Jt. Infect. 2016, 1, 54–58. [Google Scholar] [CrossRef]

- Yabuuchi, E.; Kosako, Y.; Yano, I.; Hotta, H.; Nishiuchi, Y. Transfer of two Burkholderia and an Alcaligenes species to Ralstonia gen. nov.: Proposal of Ralstonia pickettii (Ralston, Palleroni and Doudoroff 1973) comb. nov., Ralstonia solanacearum (Smith 1896) comb. nov. and Ralstonia eutropha (Davis 1969) comb. nov. Microbiol. Immunol. 1995, 39, 897–904. [Google Scholar] [CrossRef]

- Gilligan, P.H.; Lum, G.; Vandamme, P.; Whittier, S. Burkholderia, Stenotrophomonas, Ralstonia, Brevundimonas, Comamonas, Delftia, Pandoraea and Acidovorax. In Manual of Clinical Microbiology, 8th ed.; Murray, P.R., Baron, E.J., Pfaller, M.A., Jorgenson, J.H., Yolken, R.H., Eds.; ASM Press: Washington, DC, USA, 2003; pp. 729–748. [Google Scholar]

- Ryan, M.P.; Pembroke, J.T.; Adley, C.C. Ralstonia pickettii: A persistent gram-negative nosocomial infectious organism. J. Hosp. Infect. 2006, 62, 278–284. [Google Scholar] [CrossRef]

- Labarca, J.A.; Trick, W.E.; Peterson, C.L.; Carson, L.A.; Holt, S.C.; Arduino, M.J.; Meylan, M.; Mascola, L.; Jarvis, W.R. A multistate nosocomial outbreak of Ralstonia pickettii colonization associated with an intrinsically contaminated respiratory care solution. Clin. Infect. Dis. 1999, 29, 1281–1286. [Google Scholar] [CrossRef]

- Ryan, M.P.; Pembroke, J.T.; Adley, C.C. Differentiating the growing nosocomial infectious threats Ralstonia pickettii and Ralstonia insidiosa. Eur. J. Clin. Microbiol. Infect. Dis. 2011, 30, 1245–1247. [Google Scholar] [CrossRef]

- Eikmanns, B.J.; Blombach, B. The pyruvate dehydrogenase complex of Corynebacterium glutamicum: An attractive target for metabolic engineering. J. Biotechnol. 2014, 192, 339–345. [Google Scholar] [CrossRef]

- Funke, G.; von Graevenitz, A.; Clarridge, J.E., 3rd; Bernard, K.A. Clinical microbiology of coryneform bacteria. Clin. Microbiol. Rev. 1997, 10, 125–159. [Google Scholar] [CrossRef]

- Oliveira, A.; Oliveira, L.C.; Aburjaile, F.; Benevides, L.; Tiwari, S.; Jamal, S.B.; Silva, A.; Figueiredo, H.C.P.; Ghosh, P.; Portela, R.W.; et al. Insight of Genus Corynebacterium: Ascertaining the Role of Pathogenic and Non-pathogenic Species. Front. Microbiol. 2017, 8, 1937. [Google Scholar] [CrossRef]

- Bernard, K. The genus corynebacterium and other medically relevant coryneform-like bacteria. J. Clin. Microbiol. 2012, 50, 3152–3158. [Google Scholar] [CrossRef]

- Venezia, J.; Cassiday, P.K.; Marini, R.P.; Shen, Z.; Buckley, E.M.; Peters, Y.; Taylor, N.; Dewhirst, F.E.; Tondella, M.L.; Fox, J.G. Characterization of Corynebacterium species in macaques. J. Med. Microbiol. 2012, 61, 1401–1408. [Google Scholar] [CrossRef]

- Van Tyne, D.; Martin, M.J.; Gilmore, M.S. Structure, Function, and Biology of the Enterococcus faecalis Cytolysin. Toxins 2013, 5, 895–911. [Google Scholar] [CrossRef]

- Lebreton, F.; Willems, R.J.L.; Gilmore, M.S. Enterococcus Diversity, Origins in Nature, and Gut Colonization. In Enterococci: From Commensals to Leading Causes of Drug Resistant Infection; Gilmore, M.S., Clewell, D.B., Ike, Y., Shankar, N., Eds.; Massachusetts Eye and Ear Infirmary: Boston, MA, USA, 2014. [Google Scholar]

- De Kraker, M.E.A.; Jarlier, V.; Monen, J.C.M.; Heuer, O.E.; van de Sande, N.; Grundmann, H. The changing epidemiology of bacteraemias in Europe: Trends from the European Antimicrobial Resistance Surveillance System. Clin. Microbiol. Infect. 2013, 19, 860–868. [Google Scholar] [CrossRef]

- Werner, G.; Coque, T.M.; Hammerum, A.M.; Hope, R.; Hryniewicz, W.; Johnson, A.; Klare, I.; Kristinsson, K.G.; Leclercq, R.; Lester, C.H.; et al. Emergence and spread of vancomycin resistance among enterococci in Europe. Euro Surveill. 2008, 13, 19046. [Google Scholar]

- Mundy, L.M.; Sahm, D.F.; Gilmore, M.S. Relationships between enterococcal virulence and antimicrobial resistance. Clin. Microbiol. Rev. 2000, 13, 513–522. [Google Scholar] [CrossRef]

- Gherardi, G. Staphylococcus aureus Infection: Pathogenesis and Antimicrobial Resistance. Int. J. Mol. Sci. 2023, 24, 8182. [Google Scholar] [CrossRef]

- Wertheim, H.F.L.; Melles, D.C.; Vos, M.C.; van Leeuwen, W.; van Belkum, A.; Verbrugh, H.A.; Nouwen, J.L. The role of nasal carriage in Staphylococcus aureus infections. Lancet Infect. Dis. 2005, 5, 751–762. [Google Scholar] [CrossRef]

- Tong, S.Y.C.; Davis, J.S.; Eichenberger, E.; Holland, T.L.; Fowler, V.G., Jr. Staphylococcus aureus infections: Epidemiology, pathophysiology, clinical manifestations, and management. Clin. Microbiol. Rev. 2015, 28, 603–661. [Google Scholar] [CrossRef]

- Ahmed, I.; Yokota, A.; Yamazoe, A.; Fujiwara, T. Proposal of Lysinibacillus boronitolerans gen. nov. sp. nov., and transfer of Bacillus fusiformis to Lysinibacillus fusiformis comb. nov. and Bacillus sphaericus to Lysinibacillus sphaericus comb. nov. Int. J. Syst. Evol. Microbiol. 2007, 57, 1117–1125. [Google Scholar] [CrossRef]

- Kan, Y.; Niu, X.K.; Rao, M.P.N.; Dong, Z.Y.; Xie, Y.G.; Kang, Y.Q.; Li, W.J. Lysinibacillus cavernae sp. nov., isolated from cave soil. Arch. Microbiol. 2020, 202, 1529–1534. [Google Scholar] [CrossRef] [PubMed]

- Kämpfer, P.; Martin, K.; Glaeser, S.P. Lysinibacillus contaminans sp. nov., isolated from surface water. Int. J. Syst. Evol. Microbiol. 2013, 63, 3148–3153. [Google Scholar] [CrossRef]

- Shabanamol, S.; Divya, K.; George, T.K.; Rishad, K.S.; Sreekumar, T.S.; Jisha, M.S. Characterization and in planta nitrogen fixation of plant growth promoting endophytic diazotrophic Lysinibacillus sphaericus isolated from rice (Oryza sativa). Physiol. Mol. Plant Pathol. 2017, 102, 46–54. [Google Scholar] [CrossRef]

- Lee, C.S.; Jung, Y.T.; Park, S.; Oh, T.K.; Yoon, J.H. Lysinibacillus xylanilyticus sp. nov., a xylan-degrading bacterium isolated from forest humus. Int. J. Syst. Evol. Microbiol. 2010, 60, 281–286. [Google Scholar] [CrossRef]

- Chahal, C.; van den Akker, B.; Young, F.; Franco, C.; Blackbeard, J.; Monis, P. Pathogen and Particle Associations in Wastewater: Significance and Implications for Treatment and Disinfection Processes. Adv. Appl. Microbiol. 2016, 97, 63–119. [Google Scholar] [CrossRef]

- Sophonsiri, C.; Morgenroth, E. Chemical composition associated with different particle size fractions in municipal, industrial, and agricultural wastewaters. Chemosphere 2004, 55, 691–703. [Google Scholar] [CrossRef]

- Templeton, M.R.; Andrews, R.C.; Hofmann, R. Inactivation of particle-associated viral surrogates by ultraviolet light. Water Res. 2005, 39, 3487–3500. [Google Scholar] [CrossRef]

- Mccoy, W.F.; Olson, B.H. Relationship among turbidity, particle counts and bacteriological quality within water distribution lines. Water Res. 1986, 20, 1023–1029. [Google Scholar] [CrossRef]

- Malik, D.J.; Shaw, C.M.; Rielly, C.D.; Shama, G. The inactivation of Bacillus subtilis spores at low concentrations of hydrogen peroxide vapour. J. Food Eng. 2013, 114, 391–396. [Google Scholar] [CrossRef][Green Version]

- Sciacca, F.; Rengifo-Herrera, J.A.; Wéthé, J.; Pulgarin, C. Dramatic enhancement of solar disinfection (SODIS) of wild Salmonella sp. in PET bottles by H2O2 addition on natural water of Burkina Faso containing dissolved iron. Chemosphere 2010, 78, 1186–1191. [Google Scholar] [CrossRef]

- Brienza, M.; Özkal, C.B.; Li Puma, G. Photo(Catalytic) Oxidation Processes for the Removal of Natural Organic Matter and Contaminants of Emerging Concern from Water. In Applications of Advanced Oxidation Processes (AOPs) in Drinking Water Treatment; Gil, A., Galeano, L.A., Vicente, M.Á., Eds.; Springer: Cham, Switzerland, 2018; Volume 67, pp. 133–154. [Google Scholar]

- Flores, M.J.; Brandi, R.J.; Cassano, A.E.; Labas, M.D. Chemical disinfection with H2O2 the proposal of a reaction kinetic model. Chem. Eng. J. 2012, 198–199, 388–396. [Google Scholar] [CrossRef]

- Drakopoulou, S.; Terzakis, S.; Fountoulakis, M.S.; Mantzavinos, D.; Manios, T. Ultrasound-induced inactivation of gram-negative and gram-positive bacteria in secondary treated municipal wastewater. Ultrason. Sonochem. 2009, 16, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.J.; Yang, S.; Lim, Y. Antibiotic susceptibility of Staphylococcus aureus with different degrees of biofilm formation. J. Anal. Sci. Technol. 2021, 12, 41. [Google Scholar] [CrossRef]

- Ju, S.; Lin, J.; Zheng, J.; Wang, S.; Zhou, H.; Sun, M. Alcaligenes faecalis ZD02, a novel nematicidal bacterium with an extracellular serine protease virulence factor. Appl. Environ. Microbiol. 2016, 82, 2112–2120. [Google Scholar] [CrossRef]

- Ray, R.R.; Pattnaik, S. Alcaligenes Faecalis, An Opportunistic Pathogen of Multidrug Resistance. Scope 2023, 13, 592–604. [Google Scholar]

- Martinez, J.L. Environmental pollution by antibiotics and by antibiotic resistance determinants. Environ. Pollut. 2009, 157, 2893–2902. [Google Scholar] [CrossRef]

- Evonik. Leading Beyond Chemistry. Hydrogen Peroxide Stability and Decomposition. Available online: https://active-oxygens.evonik.com/en/products-and-services/hydrogen-peroxide/general-information/stability-and-decomposition (accessed on 10 May 2025).

- Wilms, K.G.; Waldmann, H. Hydrogen Peroxide Treatment of Effluent. U.S. Patent 4,294,703, 13 October 1981. [Google Scholar]

- Galbács, Z.M.; Csányi, L.J. Alkali-induced decomposition of hydrogen peroxide. J. Chem. Soc. Dalton Trans. 1983, 11, 2353–2357. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).