Adaptive PID Control of Hydropower Units Based on Particle Swarm Optimization and Fuzzy Inference

Abstract

1. Introduction

1.1. Aims and Motivation

1.2. Literature Review

1.3. Research Gaps and Contributions

1.4. Paper Organization

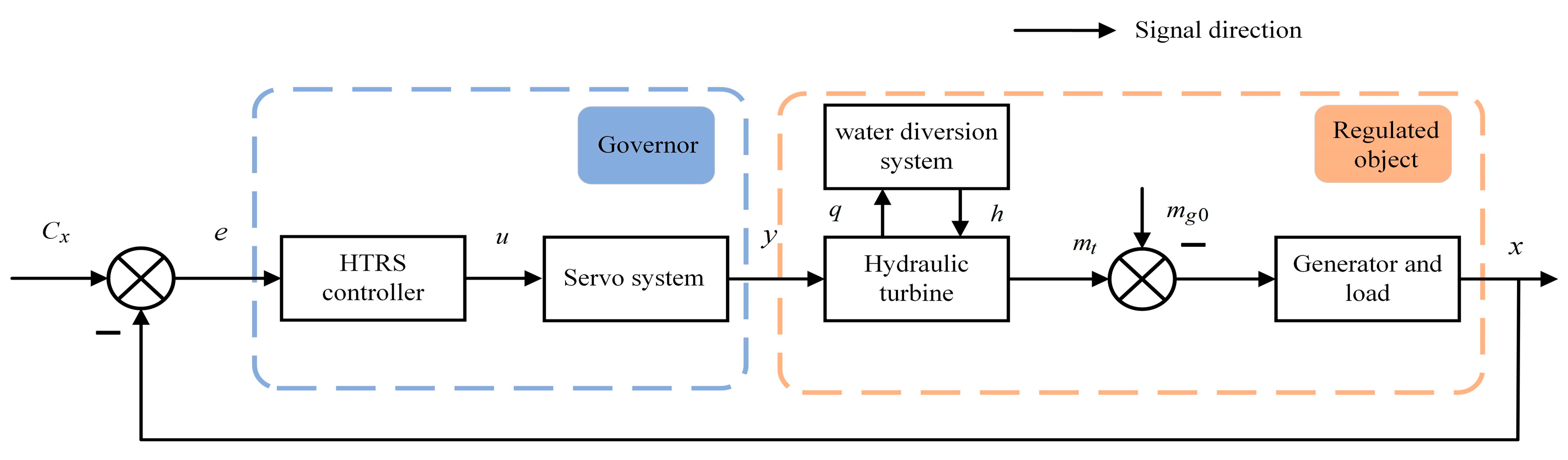

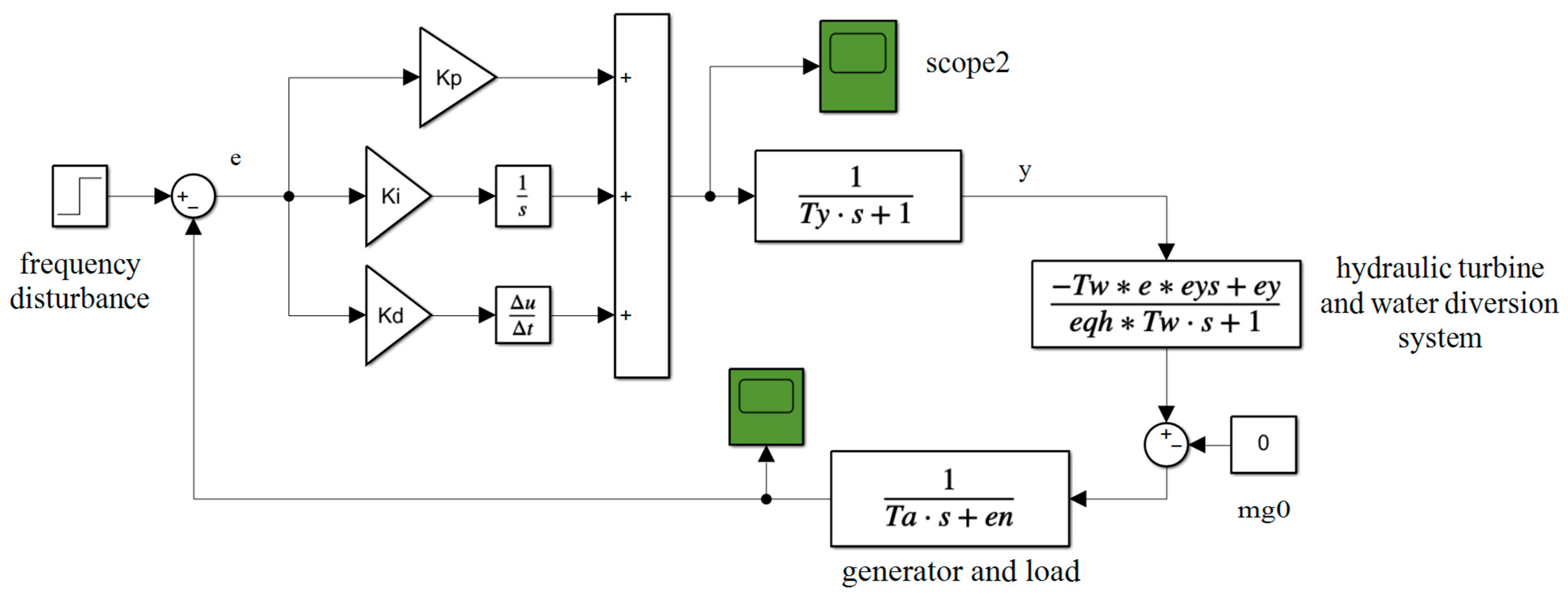

2. The HTRS Model

2.1. Controller

2.2. Servo System

2.3. Water Diversion System

2.4. Hydraulic Turbine

2.5. Hydraulic Turbine and Water Diversion System

2.6. Generator and Load

3. Adaptive Control of Operating Conditions for an HPU

3.1. PID Control

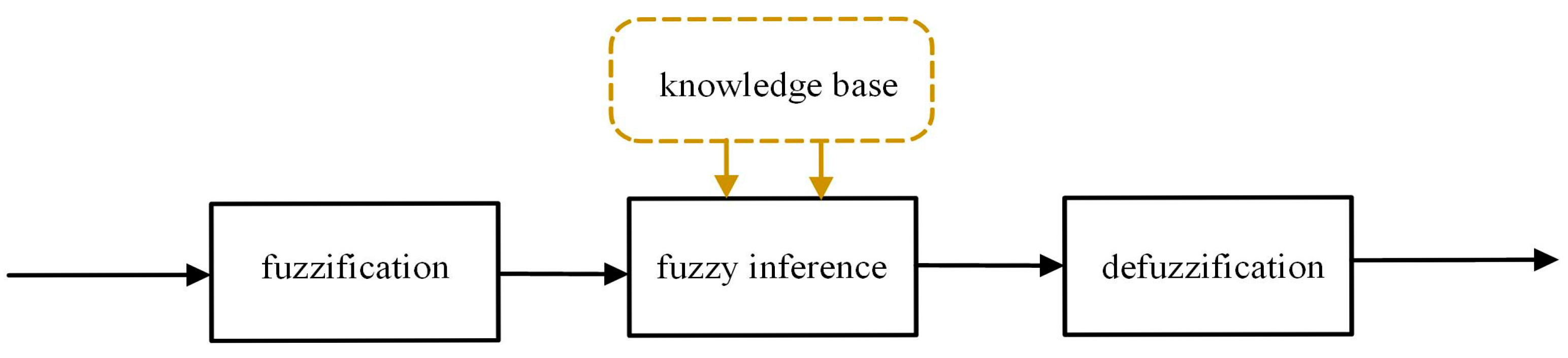

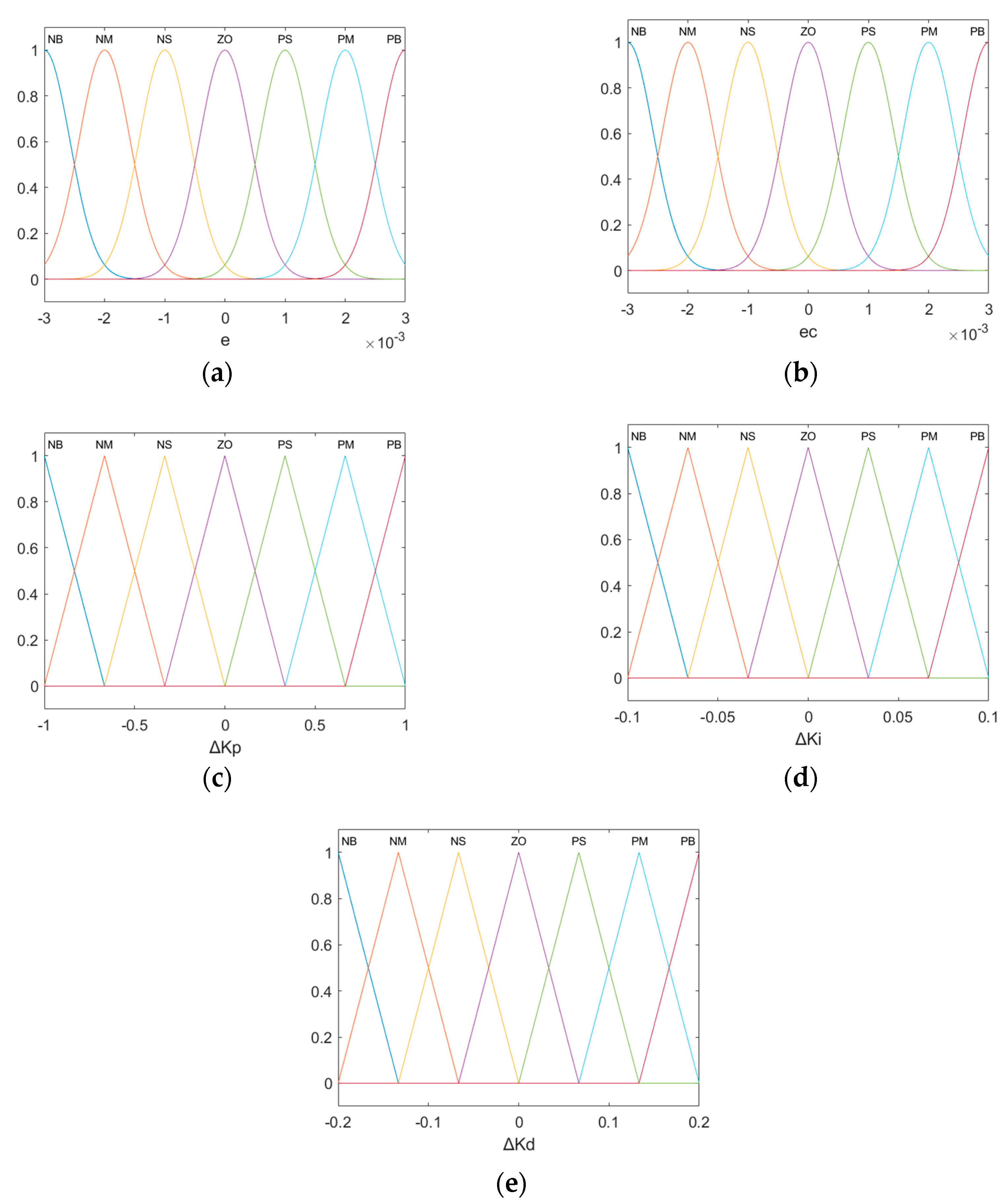

3.2. Fuzzy Control

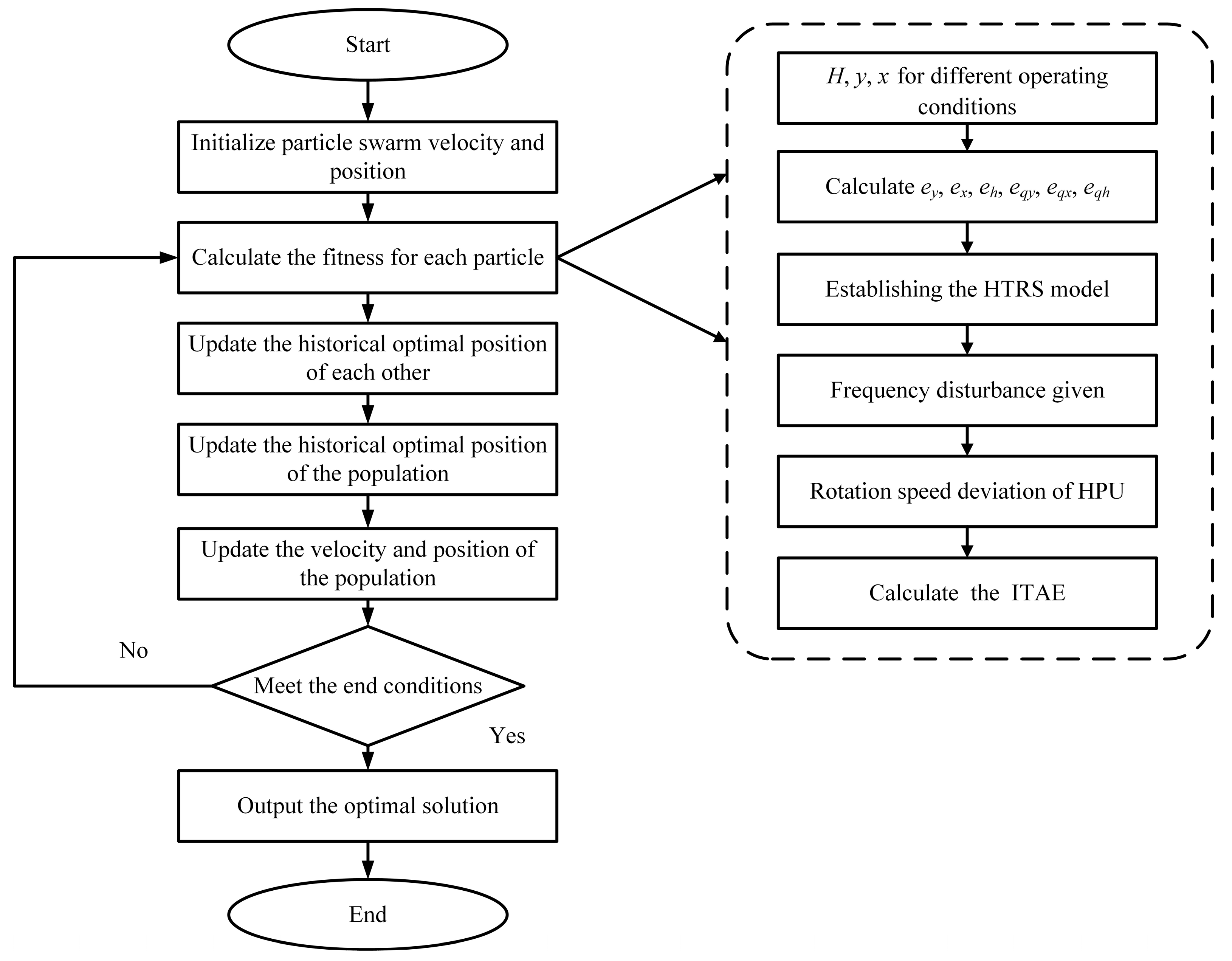

3.3. The Optimization of Control Parameters Based on the Particle Swarm Algorithm

- Initialize particle swarm velocity and position. In the initial phase of the algorithm, velocities and positions are randomly assigned to particles in the solution space.

- Calculate the fitness of each particle. First, the transfer coefficients (, , , , , ) of the hydraulic turbine are calculated based on the state parameters (, , ) for the specified operating conditions. Based on this, the overall model of the HTRS corresponding to this operating condition is obtained. Then, the system is simulated at a given perturbation in frequency to obtain the rotational speed deviation response curve of the HPU. Finally, the ITAE is calculated by substituting the speed deviation into Equation (9) and used as the fitness of each particle to provide the reference for updating the particle velocity and position subsequently.

- Update the historical optimal position of each particle. If the current fitness is better than the historical record, replace the historical optimal position with the current optimal position.

- Update the historical optimal position of the population. If the particle’s is better than the current , the latter is replaced by the former.

- Update the velocity and position of the population. The velocity and position of each particle are updated using Equation (8).

- Determine whether the end condition is met. If the number of iterations satisfies the maximum number of iterations, the algorithm will stop and output the optimal solution; otherwise, return to Step 2.

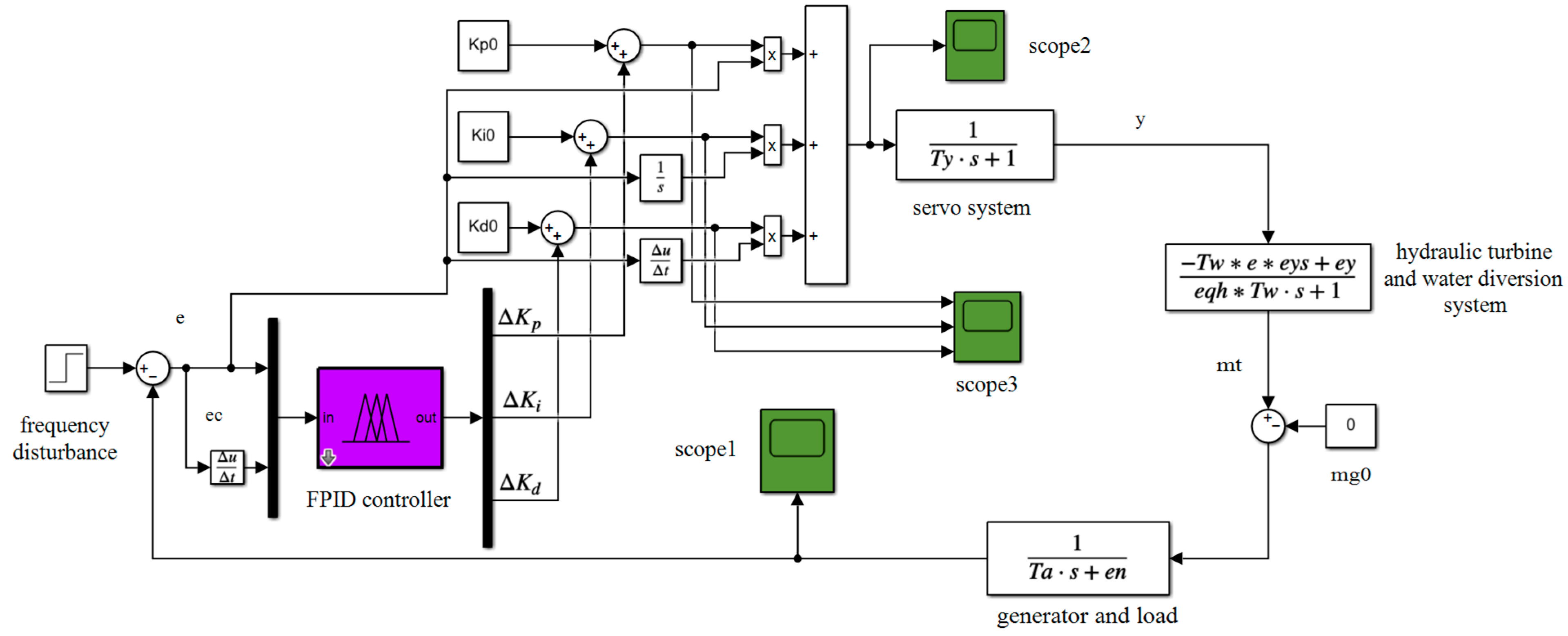

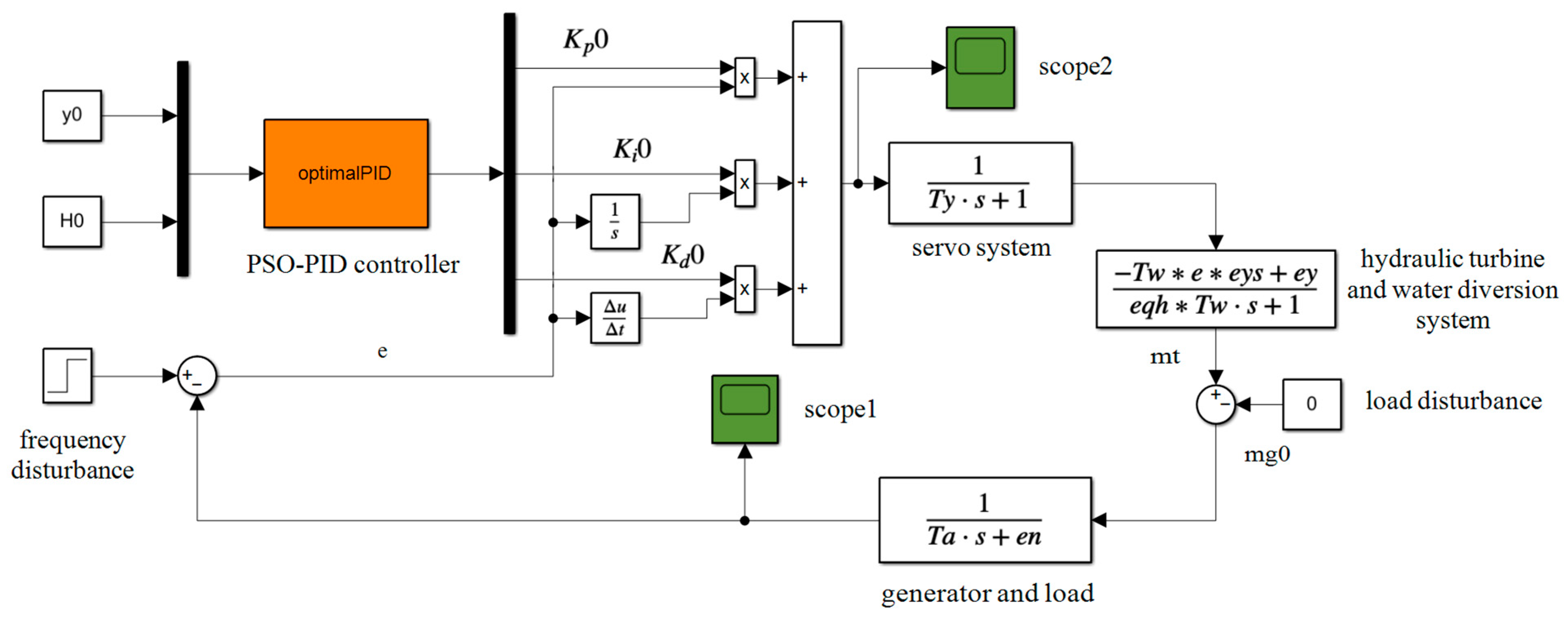

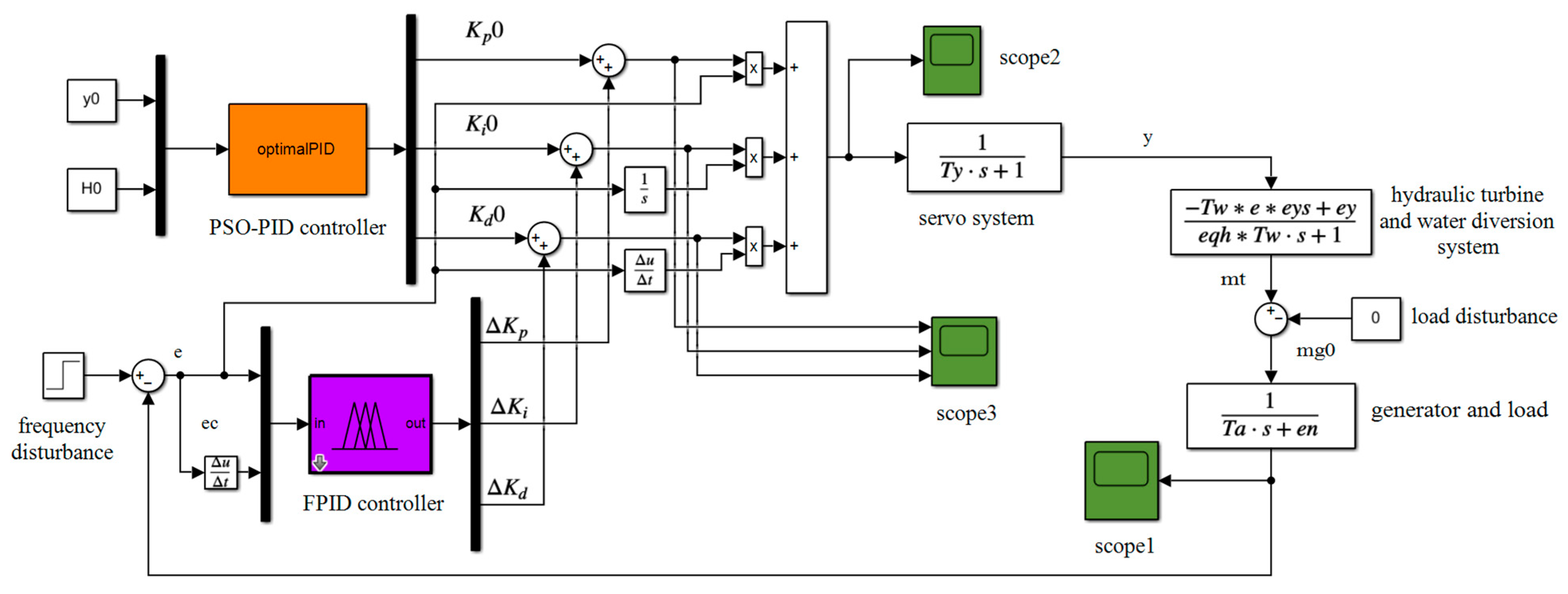

3.4. Adaptive Control of an HPU Based on the Particle Swarm Algorithm and Fuzzy PID

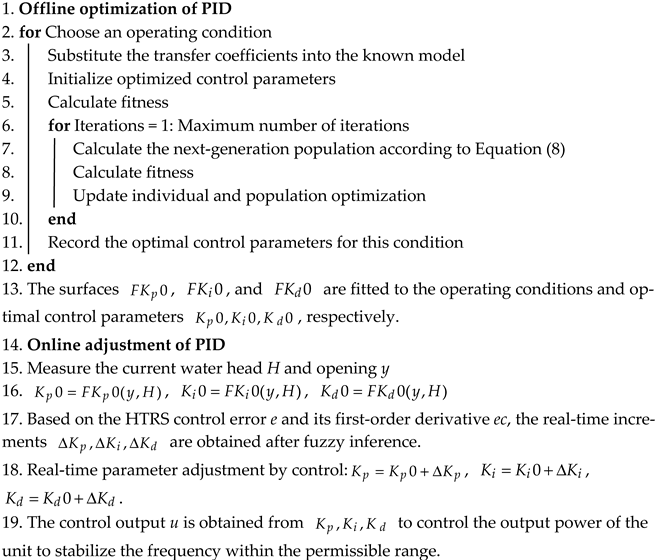

| Algorithm 1. PSO-FPID control of an HPU adapted to variable operating conditions |

|

4. Numerical Experiments and Analysis

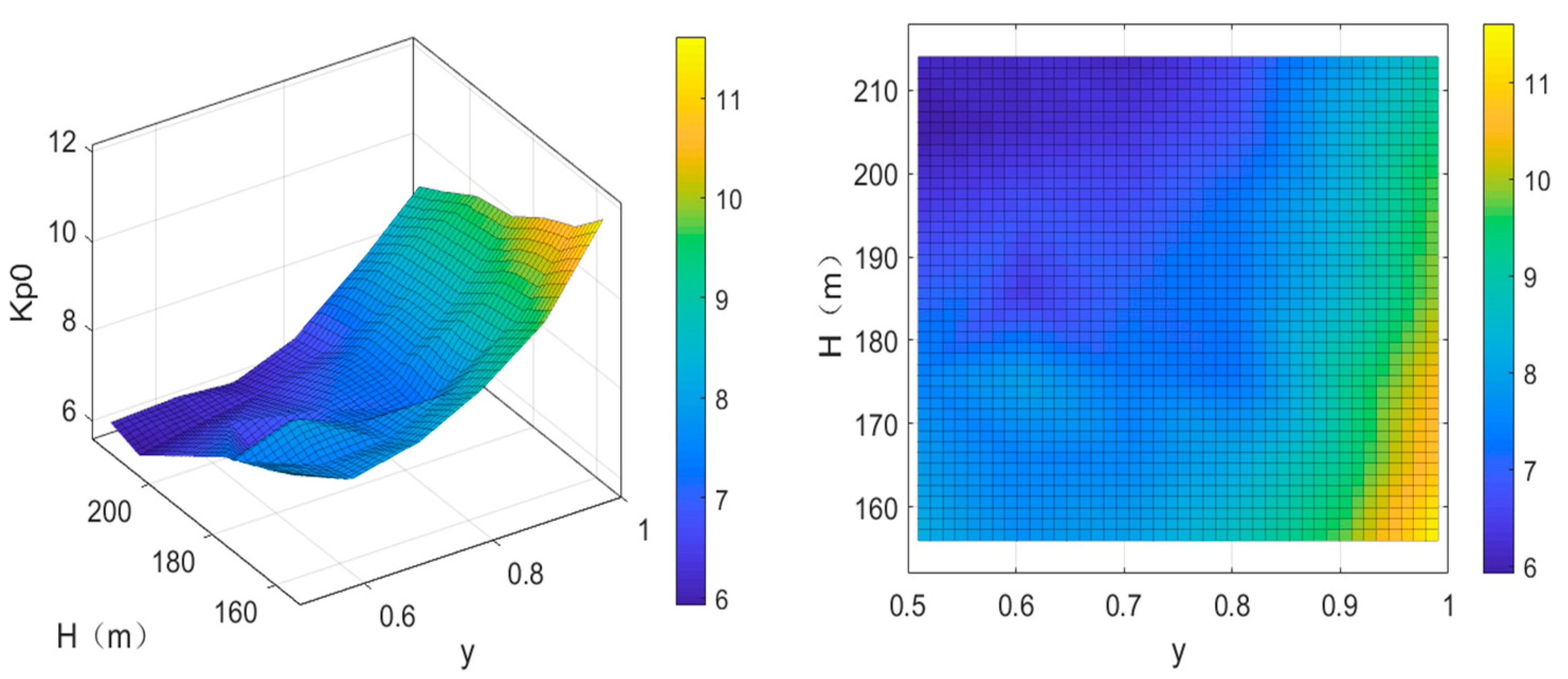

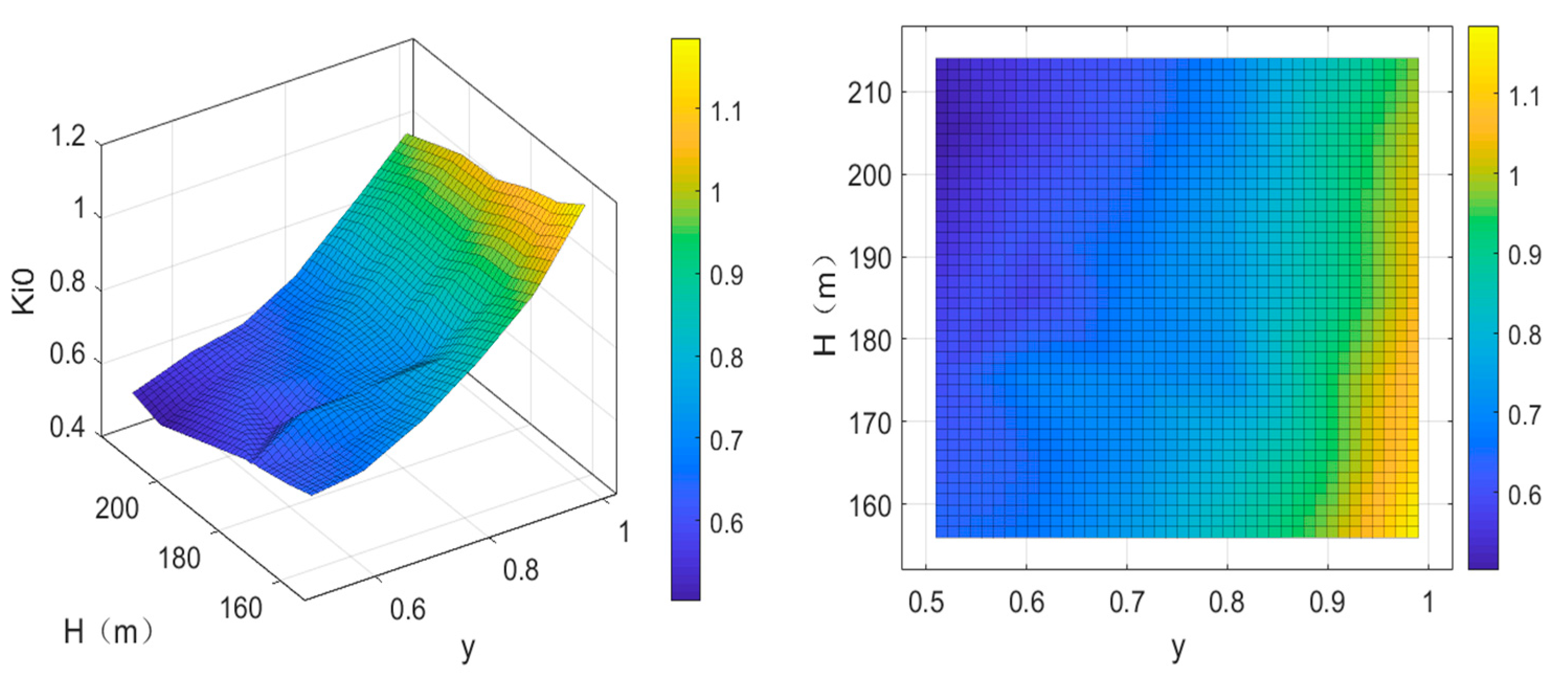

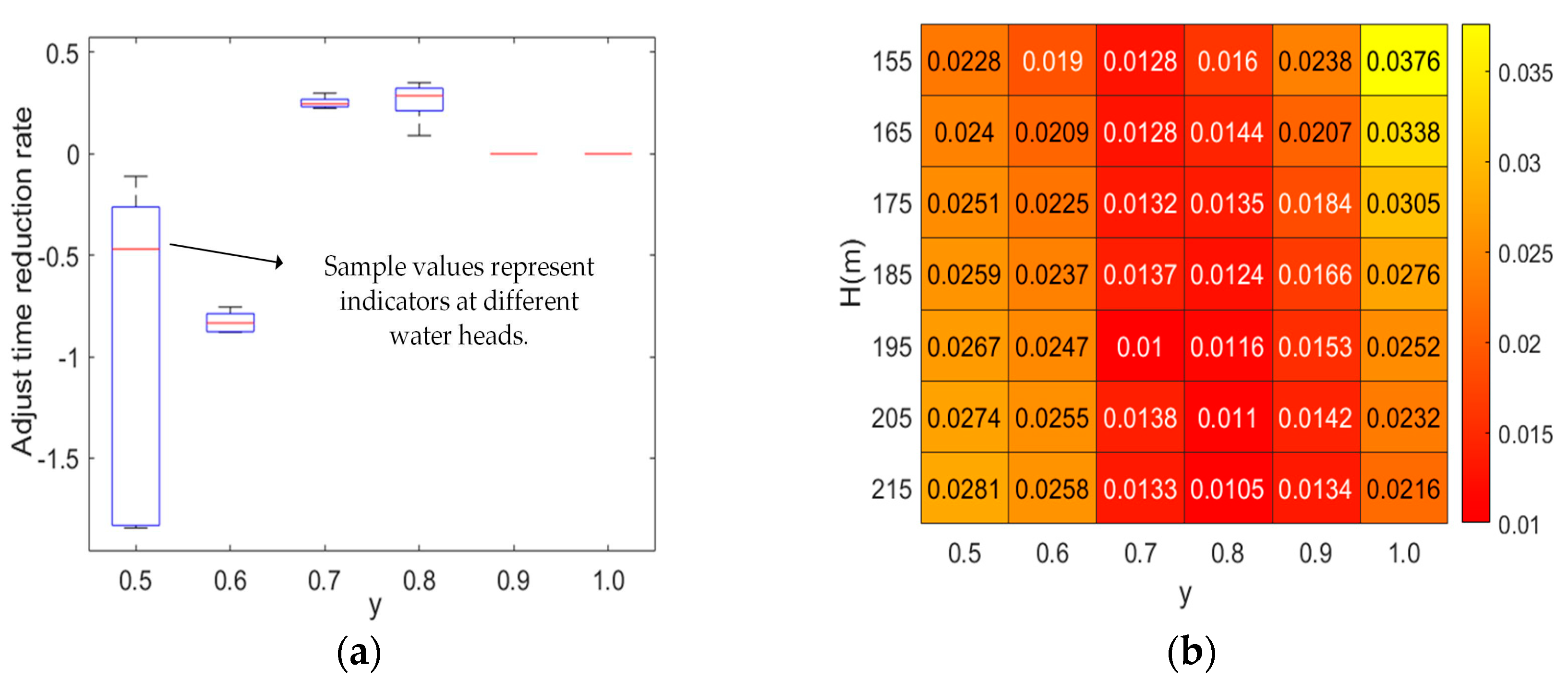

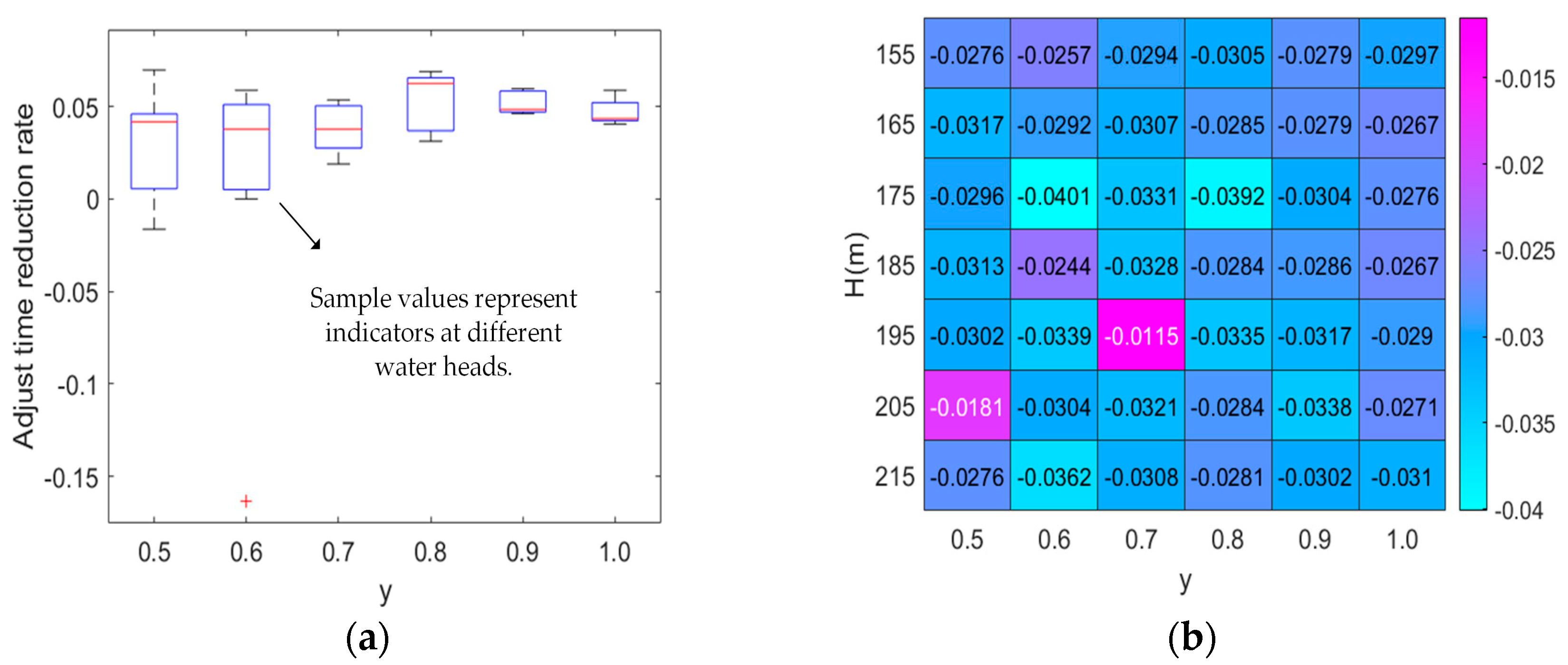

4.1. Results of PID Optimization Under Different Operating Conditions

4.2. Simulation Models of Different Control Strategies

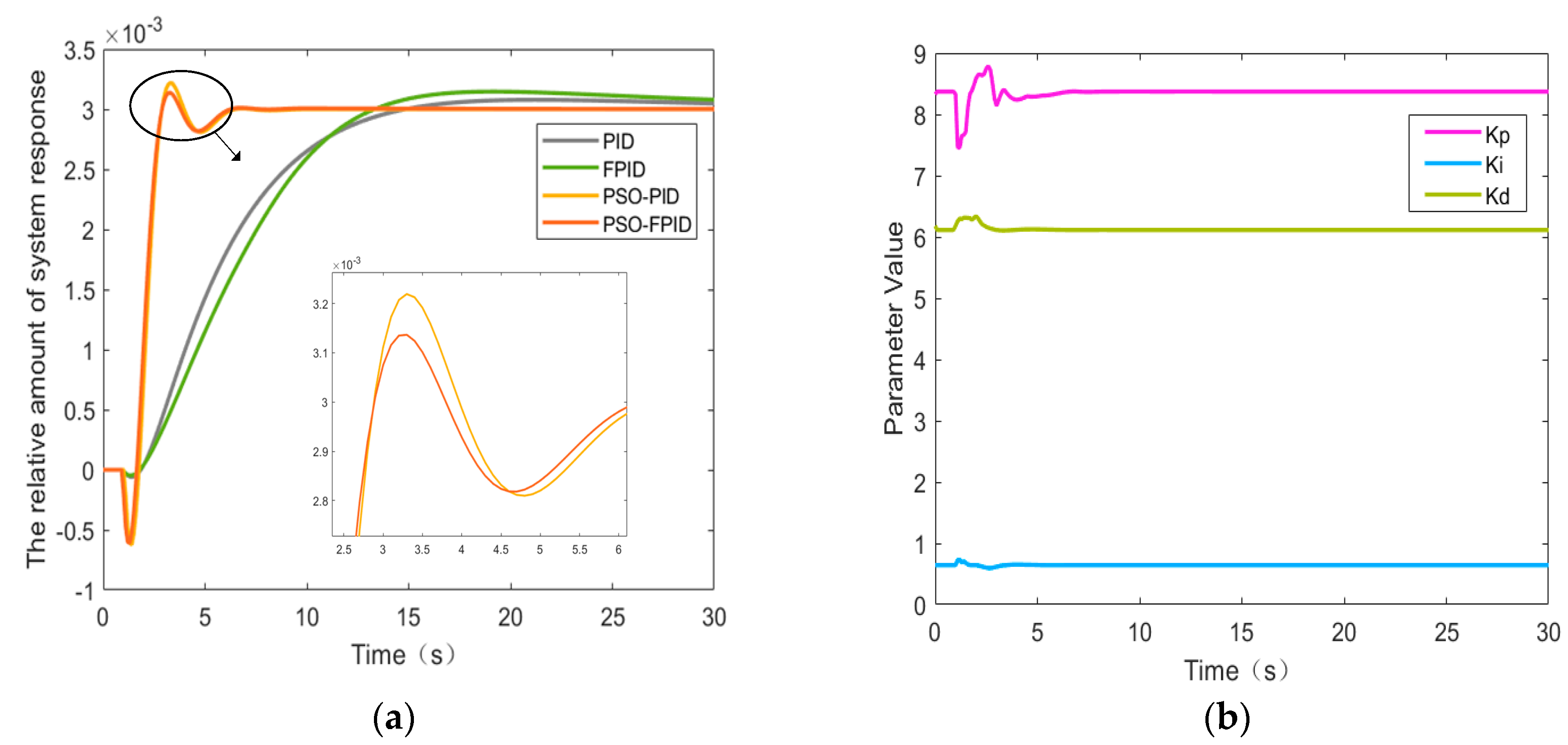

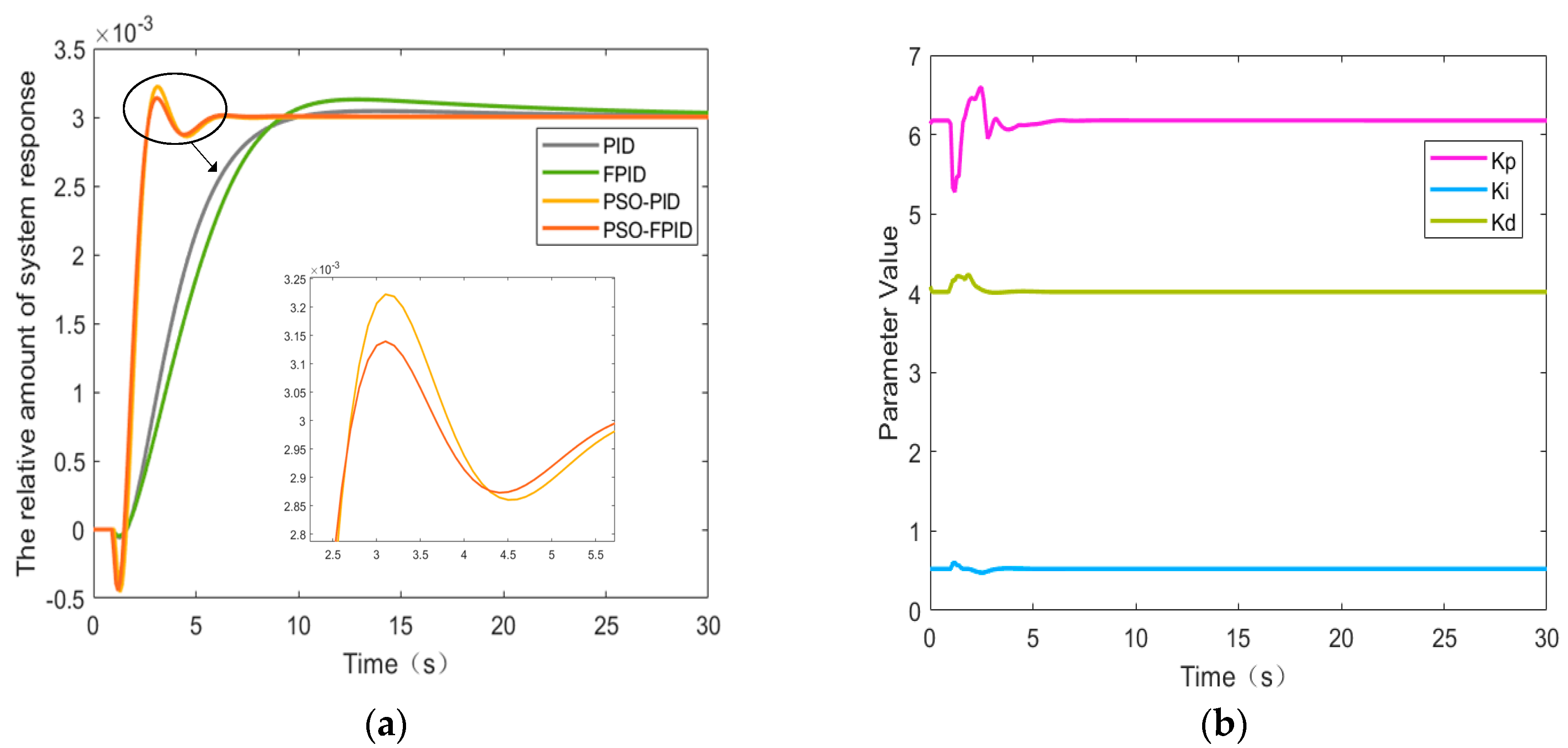

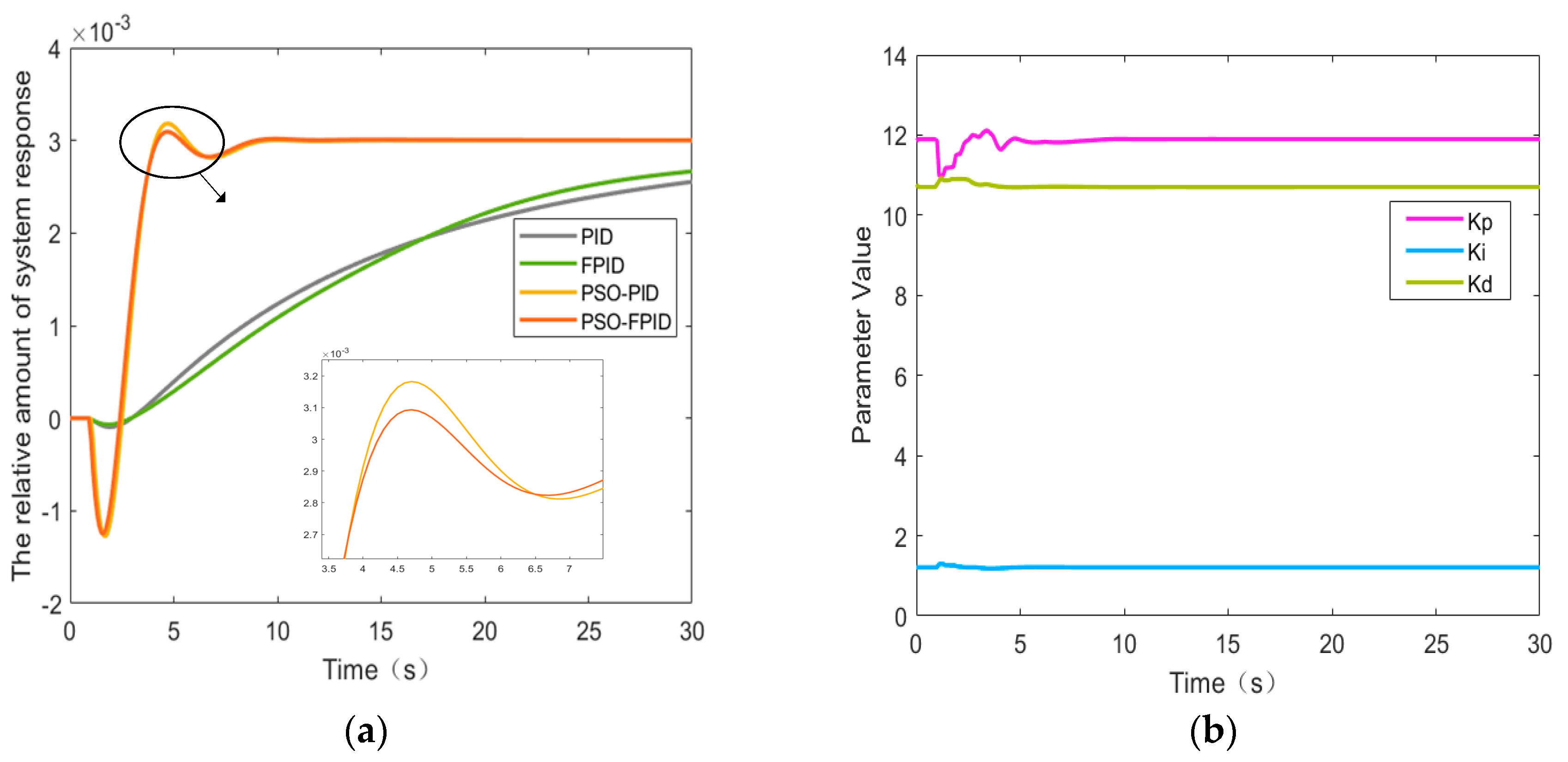

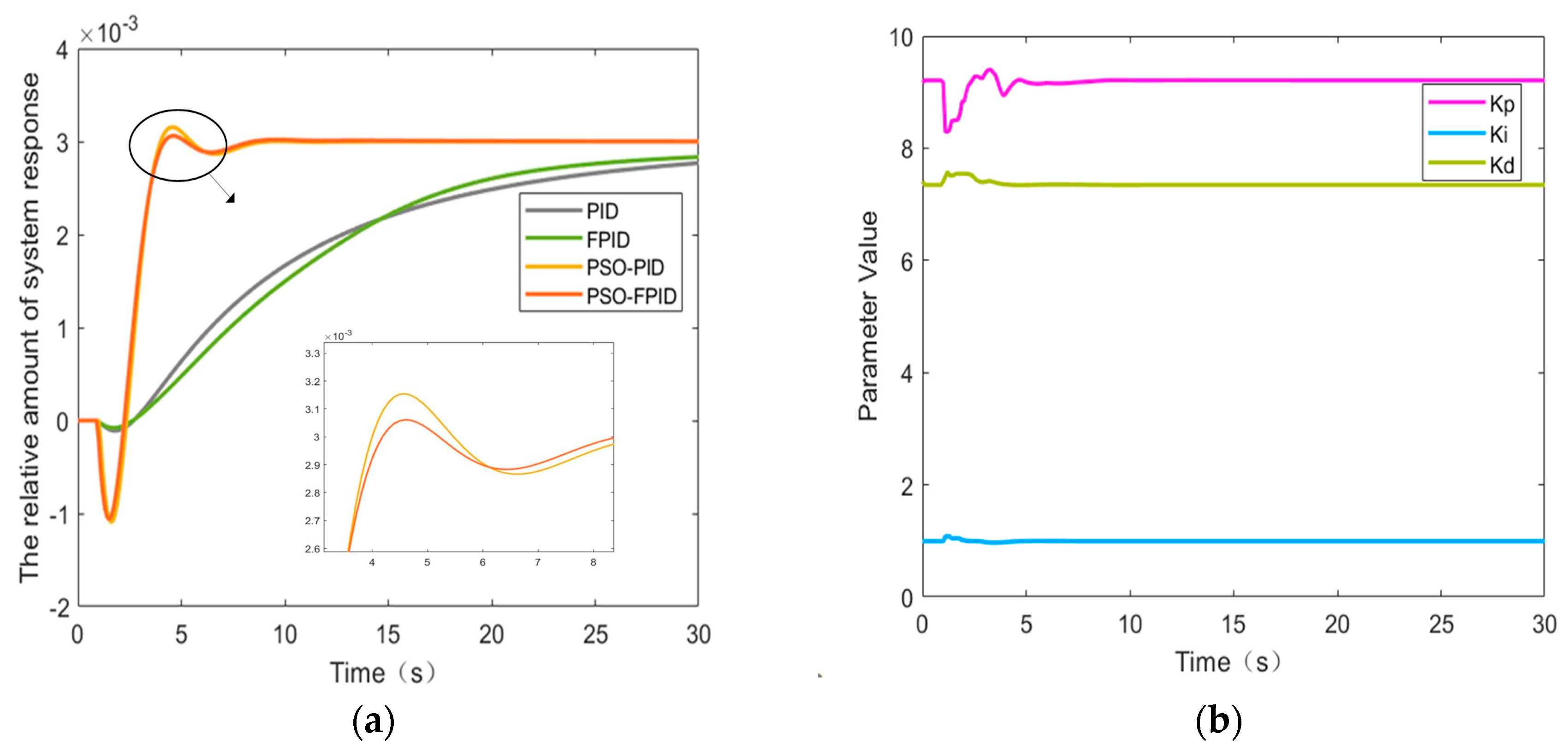

4.3. Performance Comparison and Analysis of Different Control Strategies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PID | Proportional–integral–derivative |

| PSO | Particle swarm optimization |

| HTRS | Hydraulic turbine regulation system |

| HPU | Hydropower unit |

| FPID | Fuzzy PID |

| PSO-PID | Particle swarm optimization-based PID |

| PSO-FPID | Particle swarm optimization-based fuzzy PID |

| GVO | Guide vane opening |

| ITAE | Integrated time and absolute error |

Appendix A

- (1)

- Specialized parameters. Firstly, the common parameter settings for PSO are selected: w = 0.4, 0.6, 0.8; = 1, 1.4, 1.8. Under different combinations of parameters, the population size is 20; the number of iterations is 30. The parameter sensitivity analysis is then performed. The ITAE index is used as the objective function, and five experiments are conducted for each of the nine specialized parameter combinations (optimizing the control parameters with PSO) to take the average value of the objective function. The results are shown in Table A1. When w is unchanged, the larger the , the better the ITAE. When are unchanged, the larger the w, the better the ITAE. The maximum value of ITAE is 0.00654684, and the minimum value is 0.00628372, with a difference of 0.00026312. The overall change in ITAE is not significant. Therefore, in this study, PSO is less sensitive to w and , and the optimization results corresponding to any of the above sets of parameters are similar to each other. In this paper, the middle values are chosen with w = 0.6 and = 1.4.

| w | The Population Size | The Number of Iterations | Average ITAE | |

|---|---|---|---|---|

| 0.4 | 1 | 20 | 30 | 0.00654684 |

| 0.4 | 1.4 | 20 | 30 | 0.00650220 |

| 0.4 | 1.8 | 20 | 30 | 0.00629074 |

| 0.6 | 1 | 20 | 30 | 0.00646532 |

| 0.6 | 1.4 | 20 | 30 | 0.00644622 |

| 0.6 | 1.8 | 20 | 30 | 0.00628660 |

| 0.8 | 1 | 20 | 30 | 0.00636662 |

| 0.8 | 1.4 | 20 | 30 | 0.00631812 |

| 0.8 | 1.8 | 20 | 30 | 0.00628372 |

- (2)

- Generic parameters. Population sizes of 20, 30, and 40 are chosen; the number of iterations is 30, 40, and 50. The specialized parameters are all set to w = 0.6 and = 1.4 for different combinations of parameters. Again, the ITAE indicator is used as the objective function, and five experiments are conducted for each of the nine generic parameter combinations to take the average of the objective function. The results are shown in Table A2. When the population sizes are unchanged, the larger the number of iterations, the smaller the ITAE. When the number of iterations is unchanged, the larger the population size, the smaller the ITAE. The maximum value of ITAE is 0.00644622, and the minimum value is 0.0062282, with a difference of 0.00021802. The overall change in ITAE is not significant. Therefore, in this study, PSO is less sensitive to population size and the number of iterations. The optimization results corresponding to any of the above sets of parameters are similar. However, since the larger the population size and the number of iterations, the longer the simulation time and the lower the efficiency, the population size of 20 and the number of iterations of 30 are selected in this paper.

| w | The Population Size | The Number of Iterations | Average ITAE | |

|---|---|---|---|---|

| 0.6 | 1.4 | 20 | 30 | 0.00644622 |

| 0.6 | 1.4 | 20 | 40 | 0.00641404 |

| 0.6 | 1.4 | 20 | 50 | 0.00638412 |

| 0.6 | 1.4 | 30 | 30 | 0.00629498 |

| 0.6 | 1.4 | 30 | 40 | 0.00623754 |

| 0.6 | 1.4 | 30 | 50 | 0.00623232 |

| 0.6 | 1.4 | 40 | 30 | 0.00625644 |

| 0.6 | 1.4 | 40 | 40 | 0.00623422 |

| 0.6 | 1.4 | 40 | 50 | 0.00622820 |

References

- Li, Y.; Tong, Z.; Zhang, J.; Liu, D.; Yue, X.; Mahmud, M.A. Operational Characteristics Assessment of a Wind–Solar–Hydro Hybrid Power System with Regulating Hydropower. Water 2023, 15, 4051. [Google Scholar] [CrossRef]

- Yang, W.; Norrlund, P.; Saarinen, L.; Witt, A.; Smith, B.; Yang, J.; Lundin, U. Burden on hydropower units for short-term balancing of renewable power systems. Nat. Commun. 2018, 9, 2633. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.-S.; Yue, L.; Chu, S.-C.; Hu, P.; Yan, B.; Yang, H. Binary bamboo forest growth optimization algorithm for feature selection problem. Entropy 2023, 25, 314. [Google Scholar] [CrossRef] [PubMed]

- Illias, H.; Nurjannah, N.; Mokhlis, H. Optimization of Automatic Generation Control Performance for Power System of Two-Area based on Genetic Algorithm-Particle Swarm Optimization. In Proceedings of the 2024 IEEE 4th International Conference in Power Engineering Applications (ICPEA), Pulau Pinang, Malaysia, 4–5 March 2024. [Google Scholar]

- Ding, T.; Chang, L.; Li, C.; Feng, C.; Zhang, N. A mixed-strategy-based whale optimization algorithm for parameter identification of hydraulic turbine governing systems with a delayed water hammer effect. Energies 2018, 11, 2367. [Google Scholar] [CrossRef]

- Lei, G.; Chang, X.; Tianhang, Y.; Tuerxun, W. An Improved Mayfly Optimization Algorithm Based on Median Position and Its Application in the Optimization of PID Parameters of Hydro-Turbine Governor. IEEE Access 2022, 10, 36335–36349. [Google Scholar] [CrossRef]

- Da Silva, C.S.; Da Silva, N.J.; Florindo, A.D.; De Medeiros, R.L.; Silva, L.E.; De Lucena, V.F. Experimental Implementation of Hydraulic Turbine Dynamics and a Fractional Order Speed Governor Controller on a Small-Scale Power System. IEEE Access 2024, 12, 40480–40495. [Google Scholar] [CrossRef]

- Köse, I.H.; Danayiyen, Y.; Çavdar, B. Fractional order PID controller design for hydroelectric power plant model with PSO, GWO and MA optimization algorithms. In Proceedings of the 2023 Innovations in Intelligent Systems and Applications Conference (ASYU), Sivas, Turkey, 11–13 October 2023. [Google Scholar]

- Rajagopal, K.; Jahanshahi, H.; Jafari, S.; Weldegiorgis, R.; Karthikeyan, A.; Duraisamy, P. Coexisting attractors in a fractional order hydro turbine governing system and fuzzy PID based chaos control. Asian J. Control 2021, 23, 894–907. [Google Scholar] [CrossRef]

- Piraisoodi, T.; Maria Siluvairaj, W.I.; Kappuva, M.A.K. Multi-objective robust fuzzy fractional order proportional–integral–derivative controller design for nonlinear hydraulic turbine governing system using evolutionary computation techniques. Expert Syst. 2019, 36, e12366. [Google Scholar] [CrossRef]

- Gheisarnejad, M. An effective hybrid harmony search and cuckoo optimization algorithm based fuzzy PID controller for load frequency control. Appl. Soft Comput. 2018, 65, 121–138. [Google Scholar] [CrossRef]

- Jovanović, R.Ž.; Božić, I.O. Feedforward neural network and ANFIS-based approaches to forecasting the off-cam energy characteristics of Kaplan turbine. Neural Comput. Appl. 2018, 30, 2569–2579. [Google Scholar] [CrossRef]

- Weldcherkos, T.; Salau, A.O.; Ashagrie, A. Modeling and design of an automatic generation control for hydropower plants using Neuro-Fuzzy controller. Energy Rep. 2021, 7, 6626–6637. [Google Scholar] [CrossRef]

- Jiang, X.; Chen, X.; Wang, Z. Research on modeling and control strategy of hydraulic turbine governing system based on improved genetic algorithm. IOP Conf. Ser. Earth Environ. Sci. 2018, 774, 012136. [Google Scholar] [CrossRef]

- Shi, K.; Wang, B.; Chen, H. Fuzzy generalised predictive control for a fractional-order nonlinear hydro-turbine regulating system. IET Renew. Power Gener. 2018, 12, 1708–1713. [Google Scholar] [CrossRef]

- Ma, T.; Wang, B.; Zhang, Z.; Yang, Y. A Takagi-Sugeno fuzzy-model-based finite-time H-infinity control for a hydraulic turbine governing system with time delay. Int. J. Electr. Power Energy Syst. 2021, 132, 107152. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, B.; Chen, P.; Yang, Y. Finite-time Takagi–Sugeno fuzzy controller design for hydraulic turbine governing systems with mechanical time delays. Renew. Energy 2021, 173, 614–624. [Google Scholar] [CrossRef]

- Jiang, X.P.; Wang, Z.T.; Zhu, H.; Wang, W.S. Hydraulic turbine system identification and predictive control based on GASA-BPNN. International. J. Miner. Metall. Mater. 2021, 28, 1240–1247. [Google Scholar]

- Yu, P.; Yu, Y.; Ren, Z.; Wu, C.; Xu, Y. Research on speed regulation system of water turbine generator unit based on PID neural network. IOP Conf. Ser. Earth Environ. Sci. 2020, 525, 012101. [Google Scholar] [CrossRef]

- Zeng, Y.; Hussein, Z.A.; Chyad, M.H.; Farhadi, A.; Yu, J.; Rahbarimagham, H. Integrating type-2 fuzzy logic controllers with digital twin and neural networks for advanced hydropower system management. Sci. Rep. 2025, 15, 5140. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, J.; Lu, X.; Li, C.; Malik, O.P. Model-free adaptive optimal control for fast and safe start-up of pumped storage hydropower units. J. Energy Storage 2024, 87, 111345. [Google Scholar] [CrossRef]

- Chen, J.; Liu, S.; Wang, Y.; Hu, W.; Zou, Y.; Zheng, Y.; Xiao, Z. Generalized predictive control application scheme for nonlinear hydro-turbine regulation system: Based on a precise novel control structure. Energy 2024, 296, 130916. [Google Scholar] [CrossRef]

- Dao, F.; Zou, Y.; Qian, J.; Zeng, Y. Design of a novel state-feedback robust sliding-mode controller for a hydraulic turbine governing system. Sci. Rep. 2024, 14, 29083. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zeng, Q.; Zou, Y.; Li, S.; Zheng, Y.; Liu, D.; Xiao, Z. Intelligent robust control for nonlinear complex hydro-turbine regulation system based on a novel state space equation and dynamic feedback linearization. Energy 2024, 302, 131798. [Google Scholar] [CrossRef]

- Wang, C.; Wang, D.-K.; Zhang, J.-M. Experimental study on the optimal strategy for power regulation of governing system of hydropower station. Water 2021, 13, 421. [Google Scholar] [CrossRef]

- Zeng, Y.; Yu, S.; Dao, F.; Li, X.; Xu, Y.; Qian, J. Hamiltonian Additional Damping Control for Suppressing Power Oscillation Induced by Draft Tube Pressure Fluctuation. Water 2023, 15, 1479. [Google Scholar] [CrossRef]

- Chen, J.; He, G.; Wang, Y.; Zheng, Y.; Xiao, Z. Adaptive PID Control for Hydraulic Turbine Regulation Systems Based on INGWO and BPNN. Prot. Control Mod. Power Syst. 2024, 9, 126–146. [Google Scholar] [CrossRef]

- Zhao, W.; Shi, T.; Wang, L.; Cao, Q.; Zhang, H. An adaptive hybrid atom search optimization with particle swarm optimization and its application to optimal no-load PID design of hydro-turbine governor. J. Comput. Des. Eng. 2021, 8, 1204–1233. [Google Scholar] [CrossRef]

- Lei, G. Application of improved PID control technology in hydraulic turbine governing systems. In Proceedings of the 2017 3rd International Conference on Control, Automation and Robotics (ICCAR), Nagoya, Japan, 22–24 April 2017. [Google Scholar]

- Jiang, X.P.; Zhu, H.; Wang, W.S.; Wang, Z.W.; Luo, Y.Y. Research on optimization of hydraulic turbine governor based on PSO algorithm. IOP Conf. Ser. Earth Environ. Sci. 2018, 163, 012098. [Google Scholar] [CrossRef]

- Liu, D.; Li, C.; Malik, O. Nonlinear modeling and multi-scale damping characteristics of hydro-turbine regulation systems under complex variable hydraulic and electrical network structures. Appl. Energy 2021, 293, 116949. [Google Scholar] [CrossRef]

- Liu, D.; Li, C.; Tan, X.; Lu, X.; Malik, O.P. Damping characteristics analysis of hydropower units under full operating conditions and control parameters: Accurate quantitative evaluation based on refined models. Appl. Energy 2021, 292, 116881. [Google Scholar] [CrossRef]

- Wang, C.; Li, D.H.; Zhang, H.L.; Ma, P.; Li, X.K.; Zhang, S.H.; Dong, Y.C. Prescribed performance sliding mode control for the bursting oscillation of a fractional-order hydro-turbine governing system based on time-varying tangent barrier Lyapunov function. Appl. Energy 2024, 356, 122414. [Google Scholar] [CrossRef]

- Wu, X.; Xu, Y.; Liu, J.; Lv, C.; Zhou, J.; Zhang, Q. Characteristics analysis and fuzzy fractional-order PID parameter optimization for primary frequency modulation of a pumped storage unit based on a multi-objective gravitational search algorithm. Energies 2019, 13, 137. [Google Scholar] [CrossRef]

- Barakat, M. Optimal design of fuzzy-PID controller for automatic generation control of multi-source interconnected power system. Neural Comput. Appl. 2022, 34, 18859–18880. [Google Scholar] [CrossRef]

- Liu, D.; Xiao, Z.; Li, H.; Liu, D.; Hu, X.; Malik, O.P. Accurate parameter estimation of a hydro-turbine regulation system using adaptive fuzzy particle swarm optimization. Energies 2019, 12, 3903. [Google Scholar] [CrossRef]

- Gong, X. Optimization of the power generation control process of hydraulic turbine set based on the improved BFO-PSO algorithm. J. Coast. Res. 2019, 94, 227–231. [Google Scholar] [CrossRef]

- Liu, D.; Wang, X.; Peng, Y.; Zhang, H.; Xiao, Z.; Han, X.; Malik, O.P. Stability analysis of hydropower units under full operating conditions considering turbine nonlinearity. Renew. Energy 2020, 154, 723–742. [Google Scholar] [CrossRef]

| Controller | H | y = 0.5 | y = 0.6 | y = 0.7 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ITAE | AT | OS | RR | NO | ITAE | AT | OS | RR | NO | ITAE | AT | OS | RR | NO | ||

| PID | 155 m | 0.0872 | 26.10 | 0.0261 | 0.0001 | 0.50 | 0.0961 | 15.90 | 0.0085 | 0.0001 | 0.00 | 0.1424 | 22.70 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1128 | 29.00 | 0.0489 | 0.0000 | 0.50 | 0.1172 | 28.20 | 0.0274 | 0.0001 | 0.50 | 0.1334 | 17.60 | 0.0070 | 0.0001 | 0.00 | |

| PSO-PID | 0.0088 | 4.80 | 0.0731 | 0.0006 | 0.50 | 0.0108 | 5.50 | 0.0531 | 0.0007 | 0.50 | 0.0130 | 6.10 | 0.0590 | 0.0008 | 0.50 | |

| PSO-FPID | 0.0091 | 4.60 | 0.0455 | 0.0006 | 0.50 | 0.0117 | 5.20 | 0.0274 | 0.0007 | 0.50 | 0.0140 | 5.80 | 0.0296 | 0.0008 | 0.50 | |

| PID | 165 m | 0.0750 | 23.60 | 0.0250 | 0.0001 | 0.50 | 0.0810 | 14.60 | 0.0077 | 0.0001 | 0.00 | 0.1198 | 20.80 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1026 | 29.00 | 0.0491 | 0.0000 | 0.50 | 0.1038 | 26.70 | 0.0286 | 0.0001 | 0.50 | 0.1172 | 16.00 | 0.0085 | 0.0001 | 0.00 | |

| PSO-PID | 0.0088 | 4.50 | 0.0919 | 0.0007 | 0.50 | 0.0104 | 5.30 | 0.0733 | 0.0007 | 0.50 | 0.0123 | 5.90 | 0.0531 | 0.0008 | 0.50 | |

| PSO-FPID | 0.0092 | 4.30 | 0.0602 | 0.0007 | 0.50 | 0.0110 | 5.10 | 0.0440 | 0.0007 | 0.50 | 0.0133 | 5.60 | 0.0224 | 0.0008 | 0.50 | |

| PID | 175 m | 0.0675 | 21.00 | 0.0235 | 0.0001 | 0.50 | 0.0715 | 13.30 | 0.0066 | 0.0001 | 0.00 | 0.1067 | 19.40 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.0934 | 28.60 | 0.0486 | 0.0000 | 0.50 | 0.0940 | 25.00 | 0.0290 | 0.0001 | 0.50 | 0.1045 | 14.80 | 0.0094 | 0.0001 | 0.00 | |

| PSO-PID | 0.0080 | 4.50 | 0.0867 | 0.0006 | 0.50 | 0.0117 | 4.90 | 0.1928 | 0.0008 | 0.50 | 0.0118 | 5.70 | 0.0750 | 0.0008 | 0.50 | |

| PSO-FPID | 0.0084 | 4.40 | 0.0571 | 0.0006 | 0.50 | 0.0116 | 5.70 | 0.1526 | 0.0008 | 1.00 | 0.0126 | 5.50 | 0.0419 | 0.0008 | 0.50 | |

| PID | 185 m | 0.0581 | 18.30 | 0.0217 | 0.0001 | 0.50 | 0.0606 | 12.40 | 0.0051 | 0.0001 | 0.00 | 0.0929 | 18.30 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.0851 | 26.90 | 0.0476 | 0.0001 | 0.50 | 0.0853 | 23.30 | 0.0288 | 0.0001 | 0.50 | 0.0940 | 13.80 | 0.0097 | 0.0001 | 0.00 | |

| PSO-PID | 0.0165 | 6.40 | 0.6008 | 0.0007 | 1.00 | 0.0094 | 5.10 | 0.0415 | 0.0006 | 0.50 | 0.0114 | 5.60 | 0.0821 | 0.0007 | 0.50 | |

| PSO-FPID | 0.0162 | 6.40 | 0.5695 | 0.0007 | 1.00 | 0.0105 | 4.80 | 0.0171 | 0.0006 | 0.50 | 0.0122 | 5.30 | 0.0493 | 0.0007 | 0.50 | |

| PID | 195 m | 0.0525 | 8.90 | 0.0194 | 0.0001 | 0.00 | 0.0544 | 11.50 | 0.0034 | 0.0001 | 0.00 | 0.0917 | 19.00 | 0.0000 | 0.0000 | 0.00 |

| FPID | 0.0775 | 25.20 | 0.0461 | 0.0001 | 0.50 | 0.0776 | 21.50 | 0.0281 | 0.0001 | 0.50 | 0.0837 | 14.20 | 0.0049 | 0.0000 | 0.00 | |

| PSO-PID | 0.0145 | 6.10 | 0.5878 | 0.0007 | 1.00 | 0.0094 | 4.90 | 0.1058 | 0.0006 | 0.50 | 0.0067 | 4.00 | 0.1278 | 0.0003 | 0.50 | |

| PSO-FPID | 0.0150 | 6.20 | 0.5577 | 0.0007 | 1.00 | 0.0100 | 4.80 | 0.0719 | 0.0006 | 0.50 | 0.0064 | 3.90 | 0.1163 | 0.0003 | 0.50 | |

| PID | 205 m | 0.0450 | 8.30 | 0.0173 | 0.0001 | 0.00 | 0.0462 | 10.80 | 0.0015 | 0.0001 | 0.00 | 0.0771 | 16.80 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.0708 | 23.50 | 0.0447 | 0.0001 | 0.50 | 0.0706 | 19.80 | 0.0270 | 0.0001 | 0.50 | 0.0770 | 12.20 | 0.0090 | 0.0001 | 0.00 | |

| PSO-PID | 0.0071 | 4.30 | 0.0278 | 0.0004 | 0.50 | 0.0088 | 4.90 | 0.0640 | 0.0006 | 0.50 | 0.0104 | 5.30 | 0.0549 | 0.0007 | 0.50 | |

| PSO-FPID | 0.0080 | 4.00 | 0.0097 | 0.0004 | 0.50 | 0.0096 | 4.70 | 0.0335 | 0.0006 | 0.50 | 0.0114 | 5.20 | 0.0228 | 0.0007 | 0.50 | |

| PID | 215 m | 0.0409 | 7.70 | 0.0149 | 0.0001 | 0.00 | 0.0426 | 10.20 | 0.0000 | 0.0001 | 0.00 | 0.0733 | 16.40 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.0647 | 21.90 | 0.0430 | 0.0000 | 0.50 | 0.0643 | 17.90 | 0.0257 | 0.0001 | 0.50 | 0.0700 | 11.50 | 0.0081 | 0.0001 | 0.00 | |

| PSO-PID | 0.0069 | 4.30 | 0.0742 | 0.0005 | 0.50 | 0.0087 | 4.60 | 0.0993 | 0.0006 | 0.50 | 0.0100 | 5.30 | 0.0463 | 0.0006 | 0.50 | |

| PSO-FPID | 0.0076 | 4.10 | 0.0466 | 0.0004 | 0.50 | 0.0093 | 4.60 | 0.0631 | 0.0006 | 0.50 | 0.0111 | 5.10 | 0.0155 | 0.0006 | 0.50 | |

| Controller | H | y = 0.8 | y = 0.9 | y = 1.0 | ||||||||||||

| ITAE | AT | OS | RR | NO | ITAE | AT | OS | RR | NO | ITAE | AT | OS | RR | NO | ||

| PID | 155 m | 0.2193 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3214 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.4523 | 29.00 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.2015 | 26.40 | 0.0000 | 0.0001 | 0.00 | 0.3009 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.4311 | 29.00 | 0.0000 | 0.0001 | 0.00 | |

| PSO-PID | 0.0152 | 6.40 | 0.0605 | 0.0010 | 0.50 | 0.0173 | 7.00 | 0.0471 | 0.0010 | 0.50 | 0.0200 | 7.40 | 0.0608 | 0.0013 | 0.50 | |

| PSO-FPID | 0.0161 | 6.20 | 0.0300 | 0.0009 | 0.50 | 0.0182 | 6.60 | 0.0192 | 0.0010 | 0.50 | 0.0202 | 7.10 | 0.0311 | 0.0012 | 0.50 | |

| PID | 165 m | 0.1896 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.2863 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.4155 | 29.00 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1749 | 23.50 | 0.0000 | 0.0001 | 0.00 | 0.2692 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3968 | 29.00 | 0.0000 | 0.0001 | 0.00 | |

| PSO-PID | 0.0143 | 6.40 | 0.0464 | 0.0009 | 0.50 | 0.0164 | 6.80 | 0.0380 | 0.0010 | 0.50 | 0.0188 | 7.30 | 0.0433 | 0.0012 | 0.50 | |

| PSO-FPID | 0.0155 | 6.00 | 0.0178 | 0.0009 | 0.50 | 0.0175 | 6.40 | 0.0101 | 0.0010 | 0.50 | 0.0196 | 6.90 | 0.0166 | 0.0011 | 0.50 | |

| PID | 175 m | 0.1683 | 28.50 | 0.0000 | 0.0001 | 0.00 | 0.2624 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3894 | 29.00 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1512 | 20.50 | 0.0000 | 0.0001 | 0.00 | 0.2429 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3675 | 29.00 | 0.0000 | 0.0001 | 0.00 | |

| PSO-PID | 0.0155 | 6.50 | 0.0669 | 0.0011 | 0.50 | 0.0158 | 6.70 | 0.0634 | 0.0010 | 0.50 | 0.0181 | 7.10 | 0.0486 | 0.0011 | 0.50 | |

| PSO-FPID | 0.0169 | 6.20 | 0.0278 | 0.0010 | 0.50 | 0.0166 | 6.30 | 0.0330 | 0.0010 | 0.50 | 0.0188 | 6.80 | 0.0209 | 0.0011 | 0.50 | |

| PID | 185 m | 0.1513 | 27.60 | 0.0000 | 0.0001 | 0.00 | 0.2374 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3613 | 29.00 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1368 | 19.70 | 0.0000 | 0.0001 | 0.00 | 0.2211 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3424 | 29.00 | 0.0000 | 0.0001 | 0.00 | |

| PSO-PID | 0.0130 | 6.10 | 0.0346 | 0.0008 | 0.50 | 0.0151 | 6.50 | 0.0385 | 0.0009 | 0.50 | 0.0177 | 7.00 | 0.0316 | 0.0011 | 0.50 | |

| PSO-FPID | 0.0143 | 5.70 | 0.0062 | 0.0008 | 0.50 | 0.0162 | 6.20 | 0.0099 | 0.0009 | 0.50 | 0.0187 | 6.70 | 0.0048 | 0.0011 | 0.50 | |

| PID | 195 m | 0.1399 | 26.60 | 0.0000 | 0.0001 | 0.00 | 0.2215 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3425 | 29.00 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1233 | 18.40 | 0.0000 | 0.0001 | 0.00 | 0.2029 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3209 | 29.00 | 0.0000 | 0.0001 | 0.00 | |

| PSO-PID | 0.0126 | 5.90 | 0.0635 | 0.0008 | 0.50 | 0.0146 | 6.40 | 0.0628 | 0.0009 | 0.50 | 0.0170 | 6.90 | 0.0527 | 0.0011 | 0.50 | |

| PSO-FPID | 0.0135 | 5.70 | 0.0300 | 0.0008 | 0.50 | 0.0154 | 6.10 | 0.0310 | 0.0009 | 0.50 | 0.0177 | 6.60 | 0.0236 | 0.0011 | 0.50 | |

| PID | 205 m | 0.1267 | 25.90 | 0.0000 | 0.0001 | 0.00 | 0.2034 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3209 | 29.00 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1123 | 17.40 | 0.0000 | 0.0001 | 0.00 | 0.1876 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3023 | 29.00 | 0.0000 | 0.0001 | 0.00 | |

| PSO-PID | 0.0130 | 6.10 | 0.0346 | 0.0008 | 0.50 | 0.0143 | 6.30 | 0.0813 | 0.0009 | 0.50 | 0.0165 | 6.80 | 0.0413 | 0.0010 | 0.50 | |

| PSO-FPID | 0.0143 | 5.70 | 0.0062 | 0.0008 | 0.50 | 0.0150 | 6.00 | 0.0475 | 0.0009 | 0.50 | 0.0175 | 6.40 | 0.0142 | 0.0010 | 0.50 | |

| PID | 215 m | 0.1198 | 25.40 | 0.0000 | 0.0001 | 0.00 | 0.1929 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.3069 | 29.00 | 0.0000 | 0.0001 | 0.00 |

| FPID | 0.1034 | 16.50 | 0.0000 | 0.0001 | 0.00 | 0.1748 | 29.00 | 0.0000 | 0.0001 | 0.00 | 0.2857 | 29.00 | 0.0000 | 0.0001 | 0.00 | |

| PSO-PID | 0.0117 | 5.80 | 0.0408 | 0.0007 | 0.50 | 0.0136 | 6.20 | 0.0503 | 0.0009 | 0.50 | 0.0167 | 6.80 | 0.0513 | 0.0011 | 0.50 | |

| PSO-FPID | 0.0130 | 5.40 | 0.0127 | 0.0007 | 0.50 | 0.0146 | 5.90 | 0.0202 | 0.0008 | 0.50 | 0.0176 | 6.50 | 0.0203 | 0.0011 | 0.50 | |

| Operating Condition | Controller | Adjust Time (s) | Overshoot (%) | Reverse Regulation (%) | Number of Oscillations |

|---|---|---|---|---|---|

| H = 155 m y = 0.5 | PID | 26.100 | 2.610 | 0.006 | 0.500 |

| FPID | 29.000 | 4.885 | 0.005 | 0.500 | |

| PSO-PID | 4.800 | 7.310 | 0.062 | 0.500 | |

| PSO-FPID | 4.600 | 4.550 | 0.061 | 0.500 | |

| H = 215 m y = 0.5 | PID | 7.700 | 1.489 | 0.006 | 0 |

| FPID | 21.900 | 4.295 | 0.005 | 0.500 | |

| PSO-PID | 4.300 | 7.417 | 0.045 | 0.500 | |

| PSO-FPID | 4.100 | 4.656 | 0.044 | 0.500 | |

| H = 195 m y = 0.7 | PID | 19.000 | 0 | 0.001 | 0 |

| FPID | 14.200 | 0.495 | 0.001 | 0 | |

| PSO-PID | 4.000 | 12.777 | 0.026 | 0.500 | |

| PSO-FPID | 3.900 | 11.632 | 0.026 | 0.500 | |

| H = 155 m y = 1.0 | PID | 29.000 | 0 | 0.009 | 0 |

| FPID | 29.000 | 0 | 0.007 | 0 | |

| PSO-PID | 7.400 | 6.075 | 0.128 | 0.500 | |

| PSO-FPID | 7.100 | 3.108 | 0.125 | 0.500 | |

| H = 215 m y = 1.0 | PID | 29.000 | 0 | 0.011 | 0 |

| FPID | 29.000 | 0 | 0.008 | 0 | |

| PSO-PID | 6.800 | 5.131 | 0.109 | 0.500 | |

| PSO-FPID | 6.500 | 2.031 | 0.106 | 0.500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Zhao, S.; Zhang, J. Adaptive PID Control of Hydropower Units Based on Particle Swarm Optimization and Fuzzy Inference. Water 2025, 17, 1512. https://doi.org/10.3390/w17101512

Liu D, Zhao S, Zhang J. Adaptive PID Control of Hydropower Units Based on Particle Swarm Optimization and Fuzzy Inference. Water. 2025; 17(10):1512. https://doi.org/10.3390/w17101512

Chicago/Turabian StyleLiu, Dong, Shichao Zhao, and Jingjing Zhang. 2025. "Adaptive PID Control of Hydropower Units Based on Particle Swarm Optimization and Fuzzy Inference" Water 17, no. 10: 1512. https://doi.org/10.3390/w17101512

APA StyleLiu, D., Zhao, S., & Zhang, J. (2025). Adaptive PID Control of Hydropower Units Based on Particle Swarm Optimization and Fuzzy Inference. Water, 17(10), 1512. https://doi.org/10.3390/w17101512