Debris Flow Risk Assessment for the Large-Scale Temporary Work Site of Railways—A Case Study of Jinjia Gully, Tianquan County

Abstract

1. Introduction

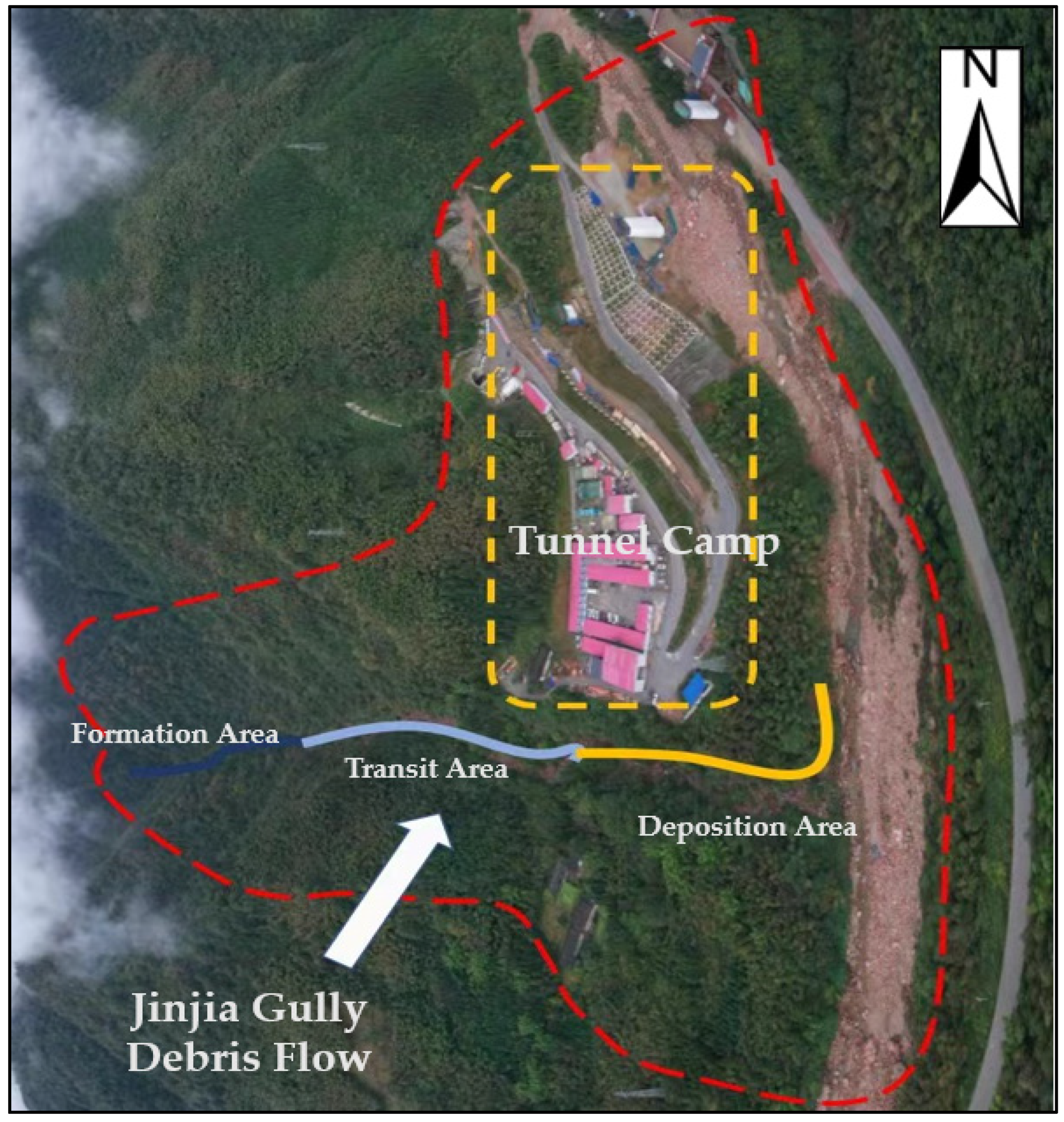

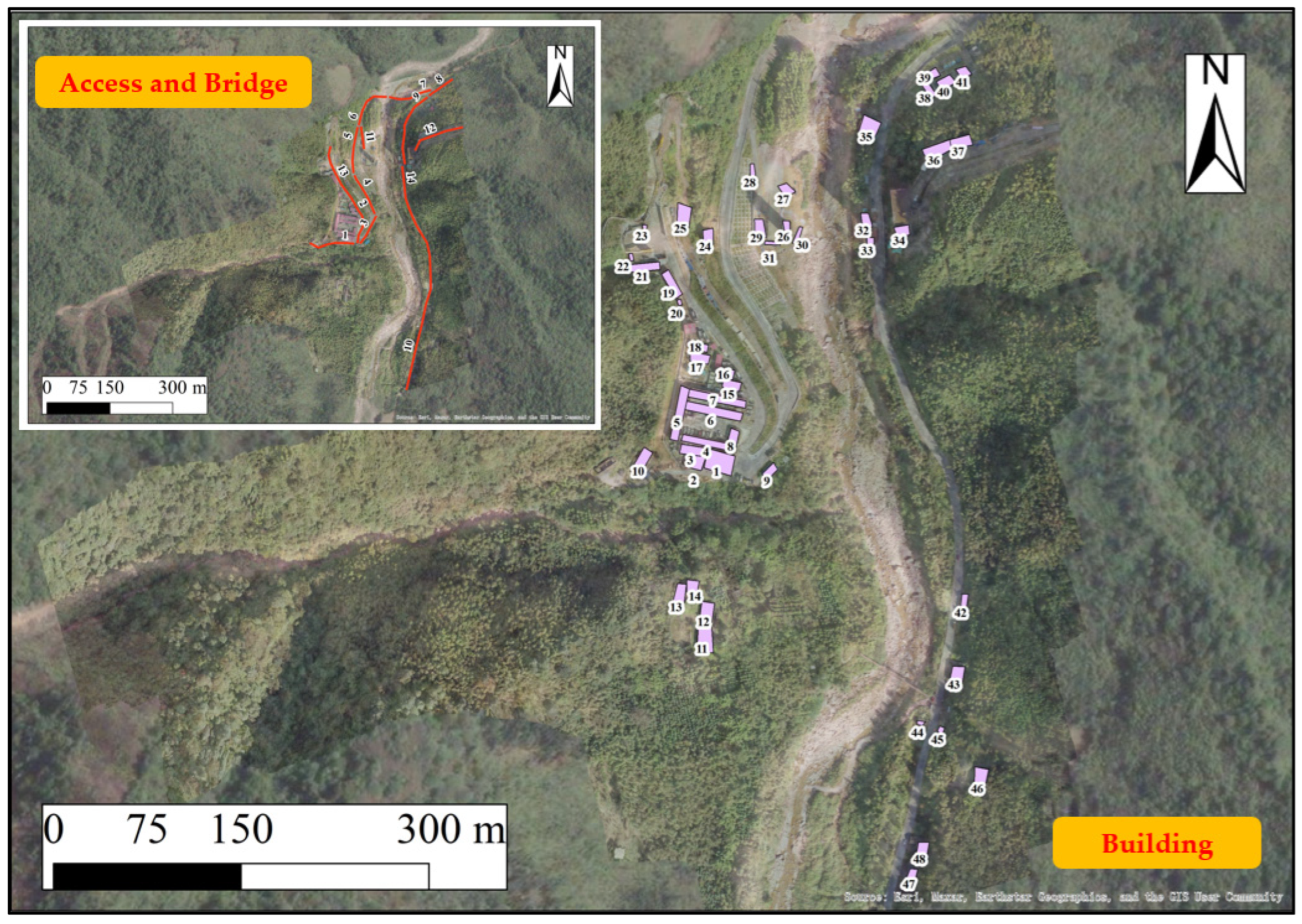

2. Study Area

3. Debris Flow Hazard Assessment

3.1. Processing Topographic Data

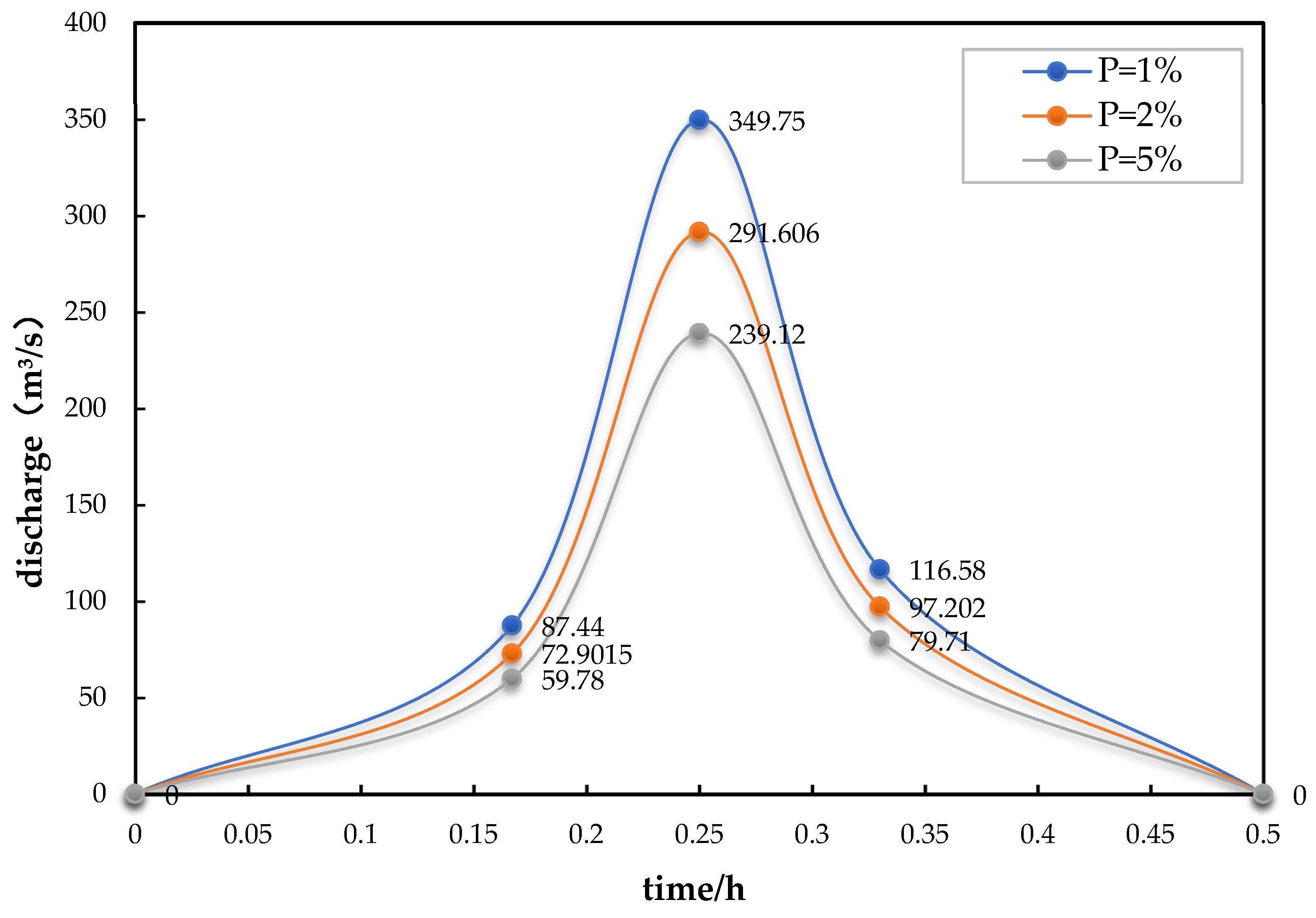

3.2. Establishing the Debris Flow Discharge Hydrograph

3.3. Selecting Relevant Parameters for Debris Flow Simulation

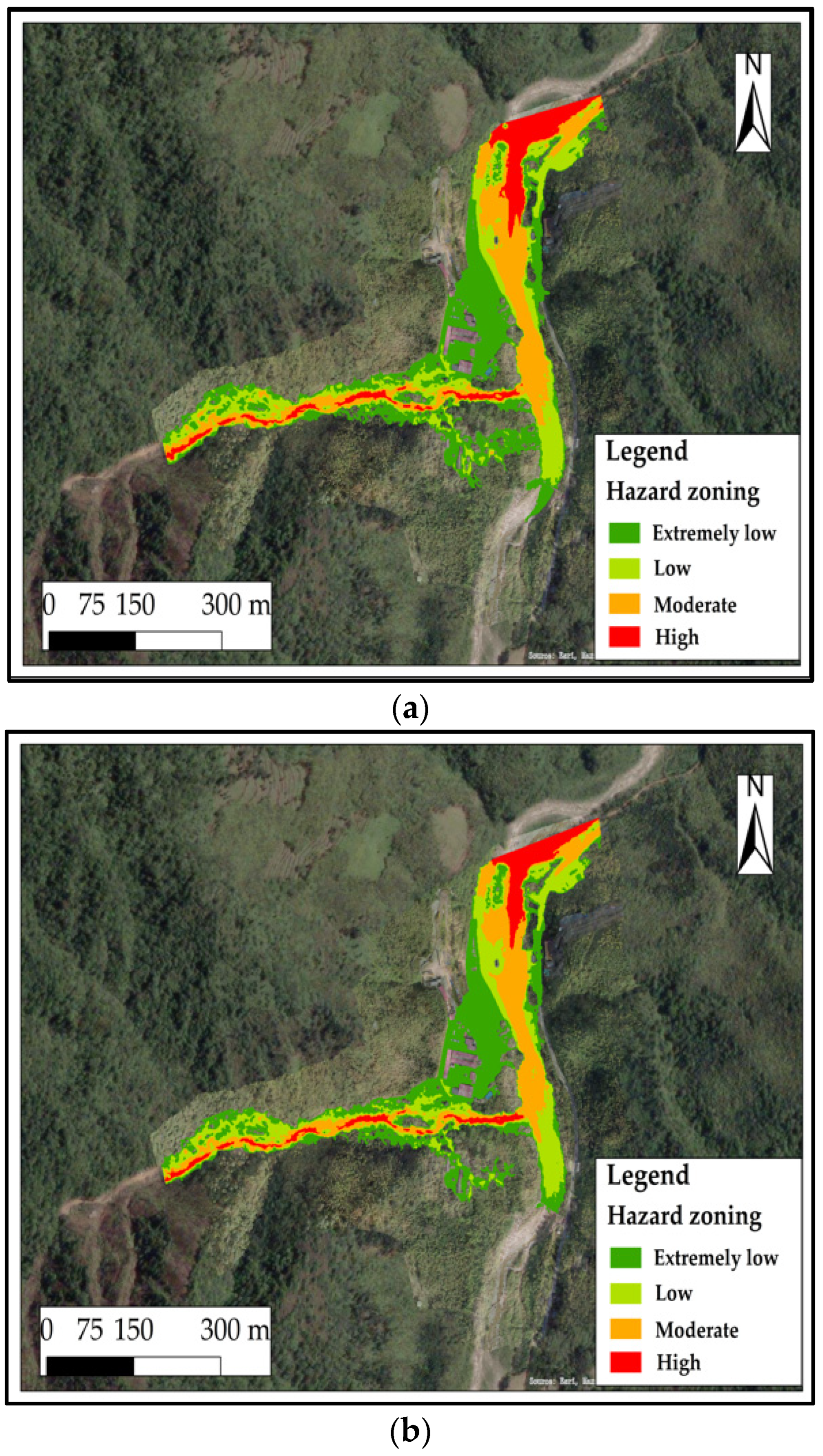

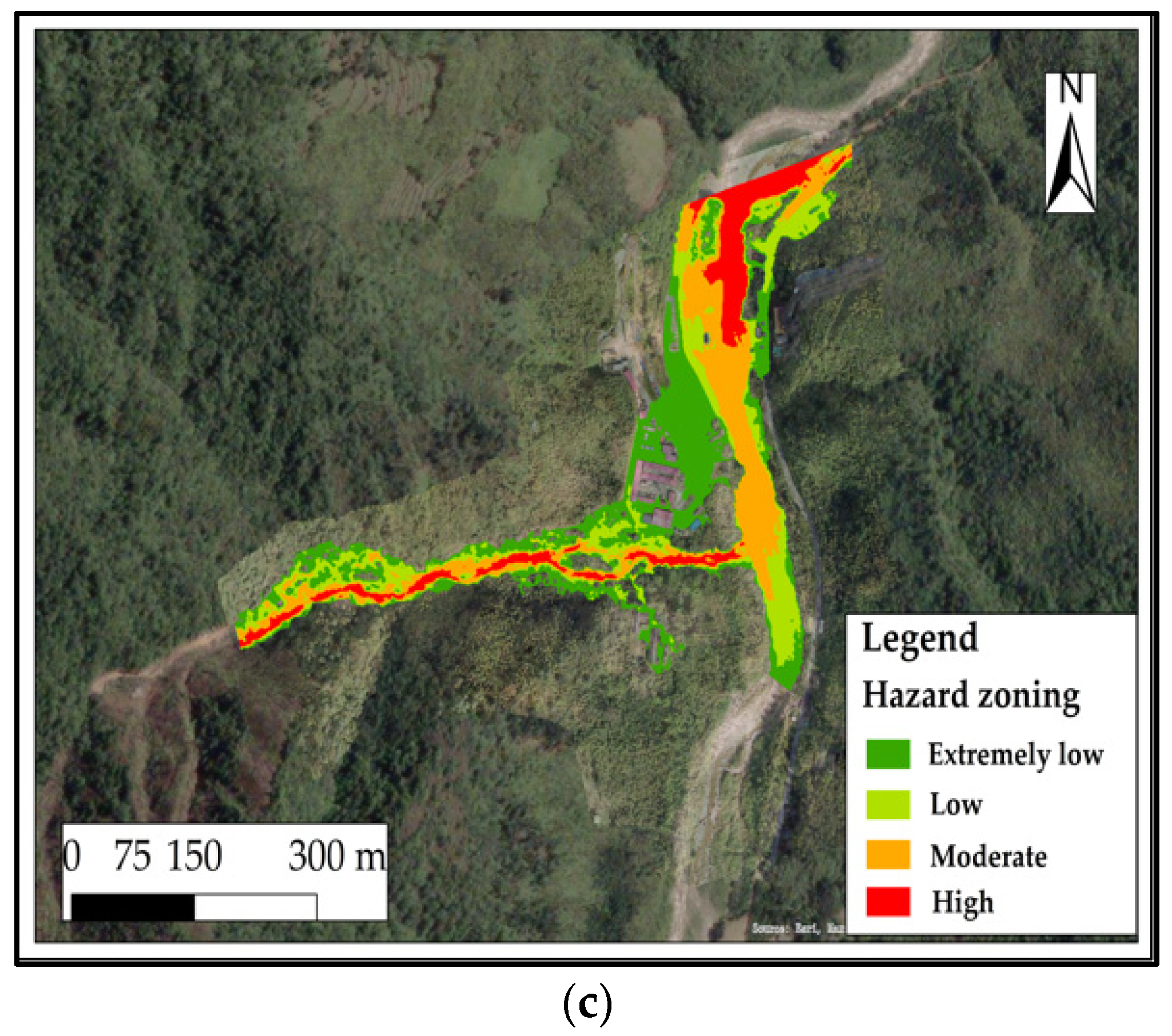

3.4. Simulating Debris Flow and Zoning for Hazard Assessment

3.5. Verifying the Simulation Results of Debris Flow

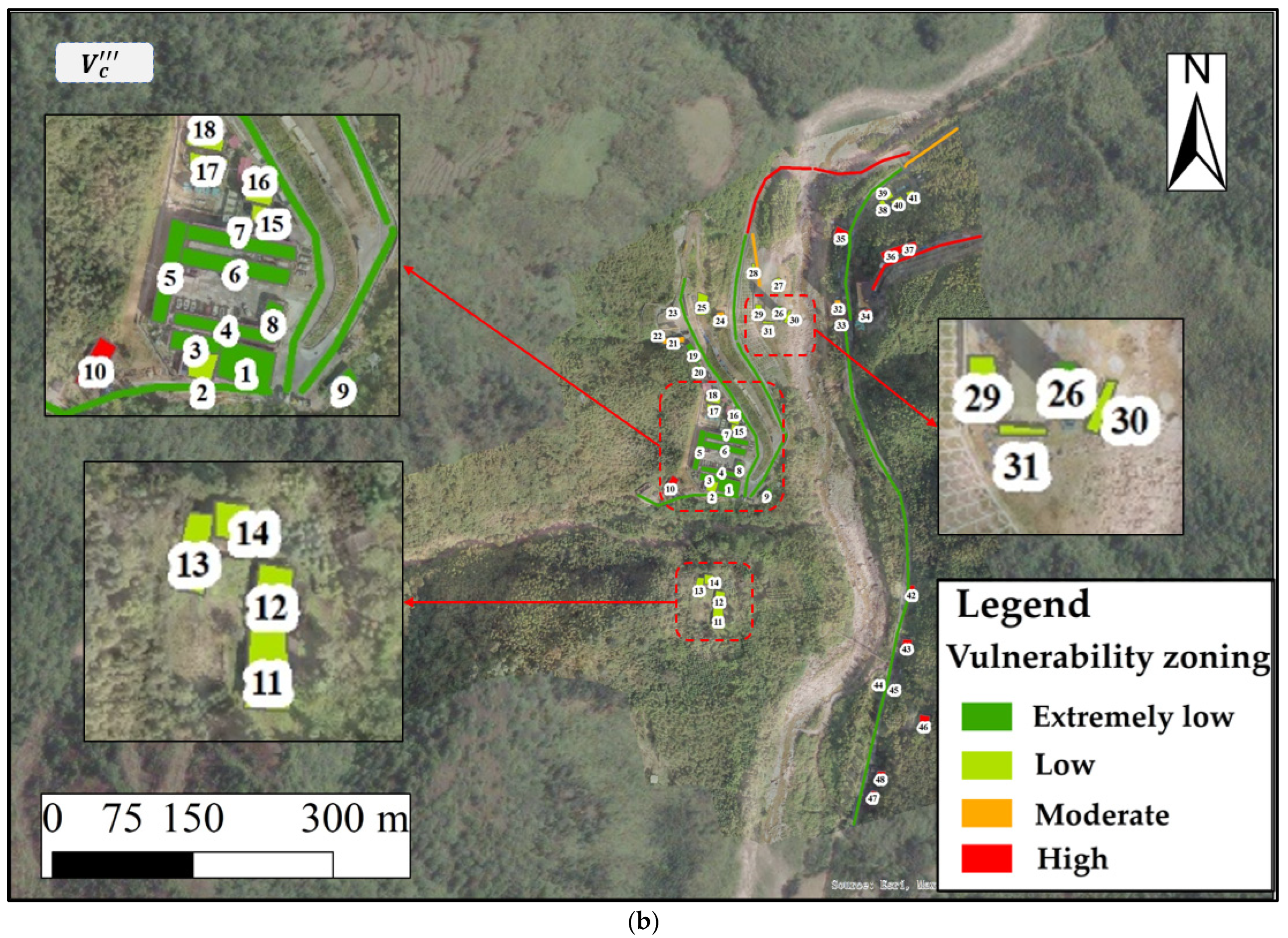

4. Vulnerability Assessment of Large-Scale Temporary Works—Indicator Factor

4.1. Selecting Evaluation Indicators

4.2. Determining Indicator Weights

4.3. Establishing Vulnerability Functions and Vulnerability Classification

5. Analysis of Shielding Effects—Modified Indicator Factor Assessment Method

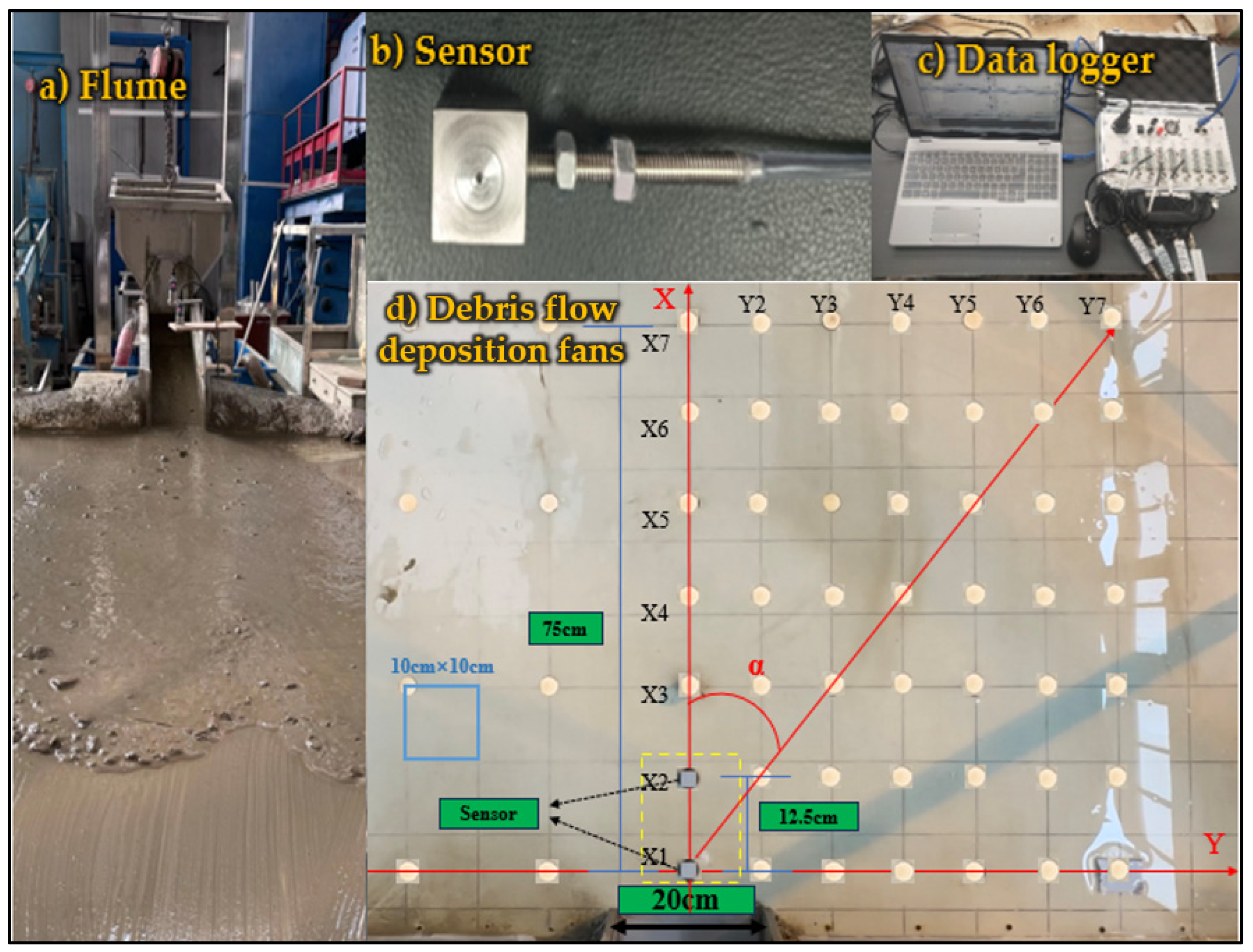

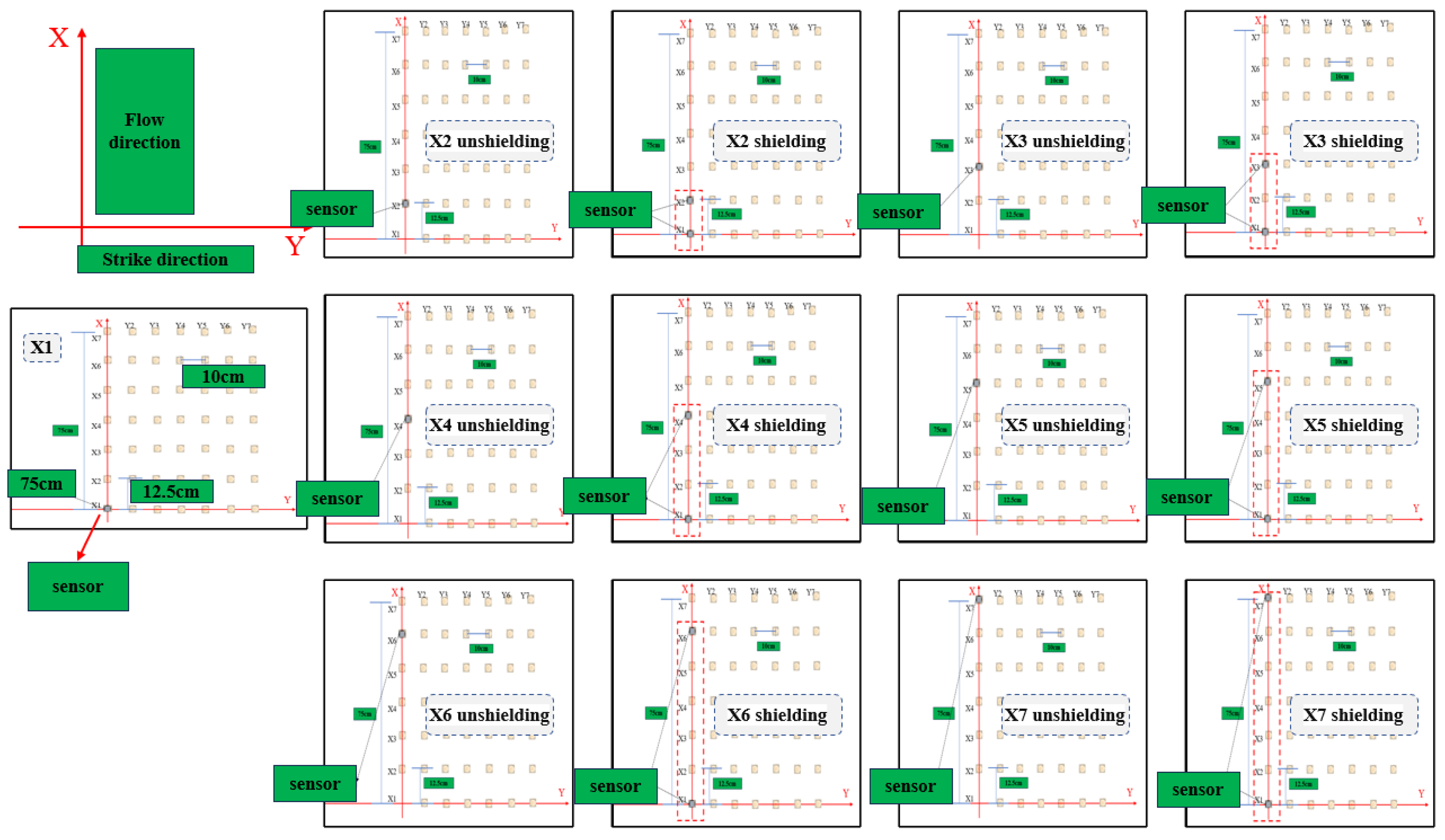

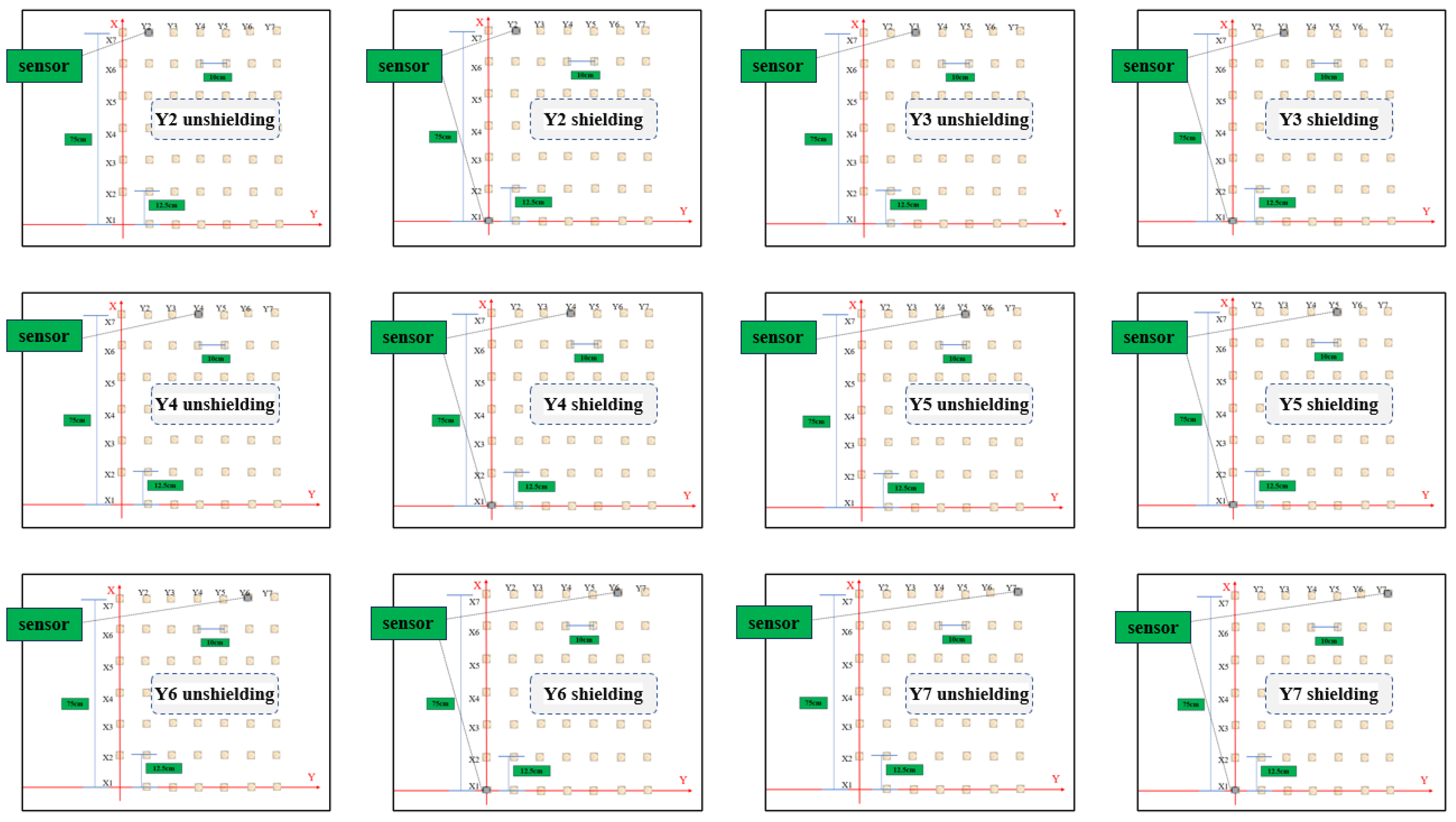

5.1. Experimental Design and Setup

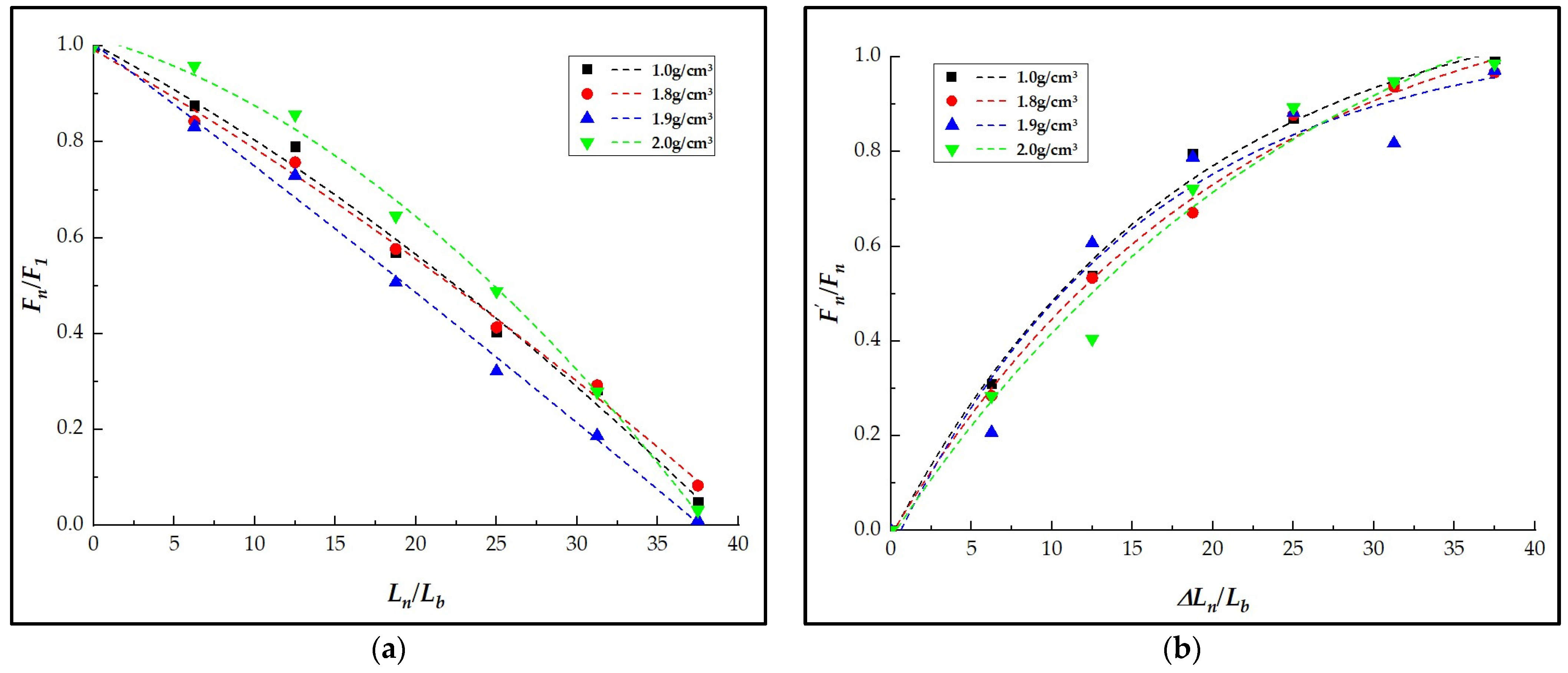

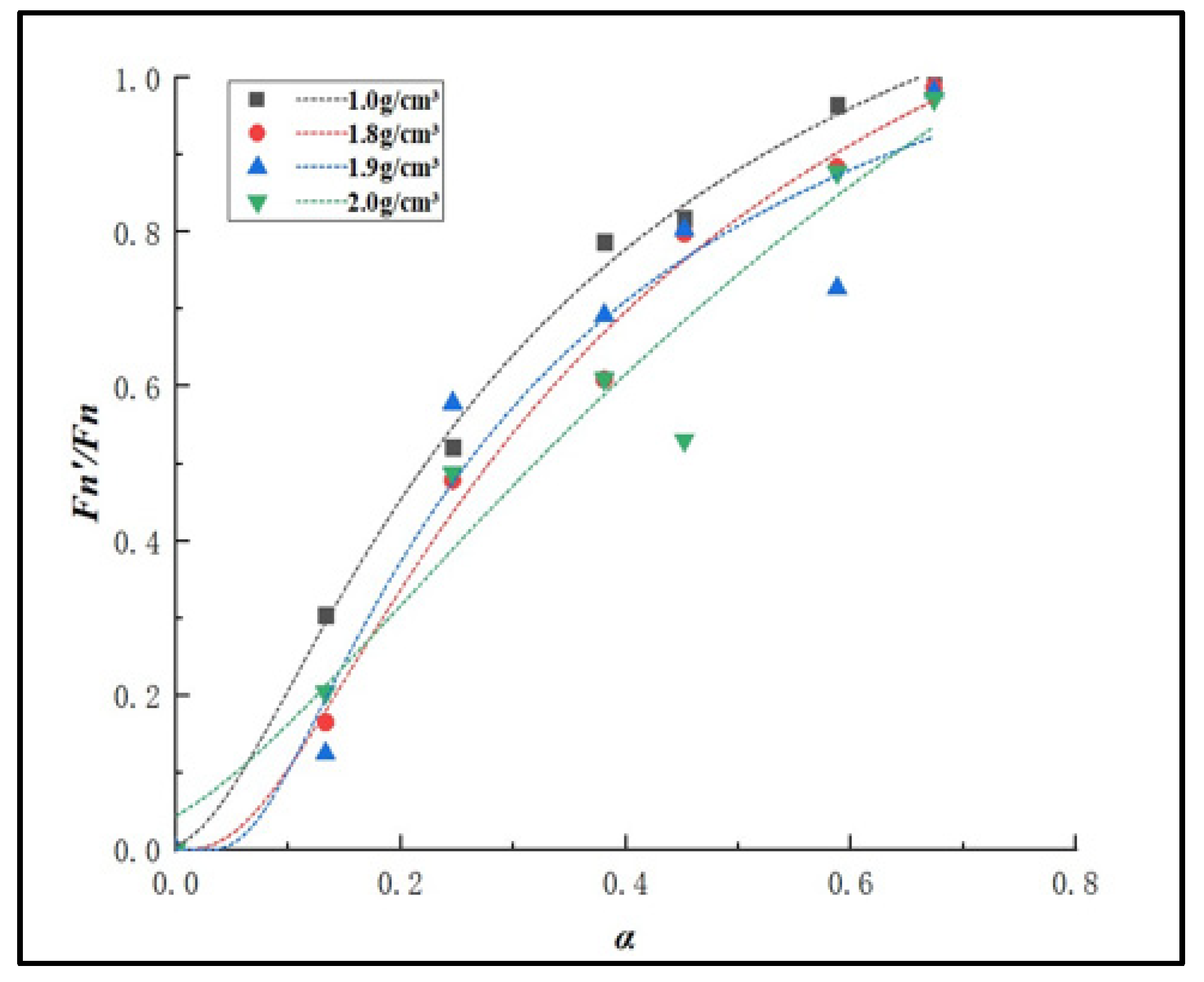

5.2. Data Processing and Results

5.3. Analysis of Shielding Effects

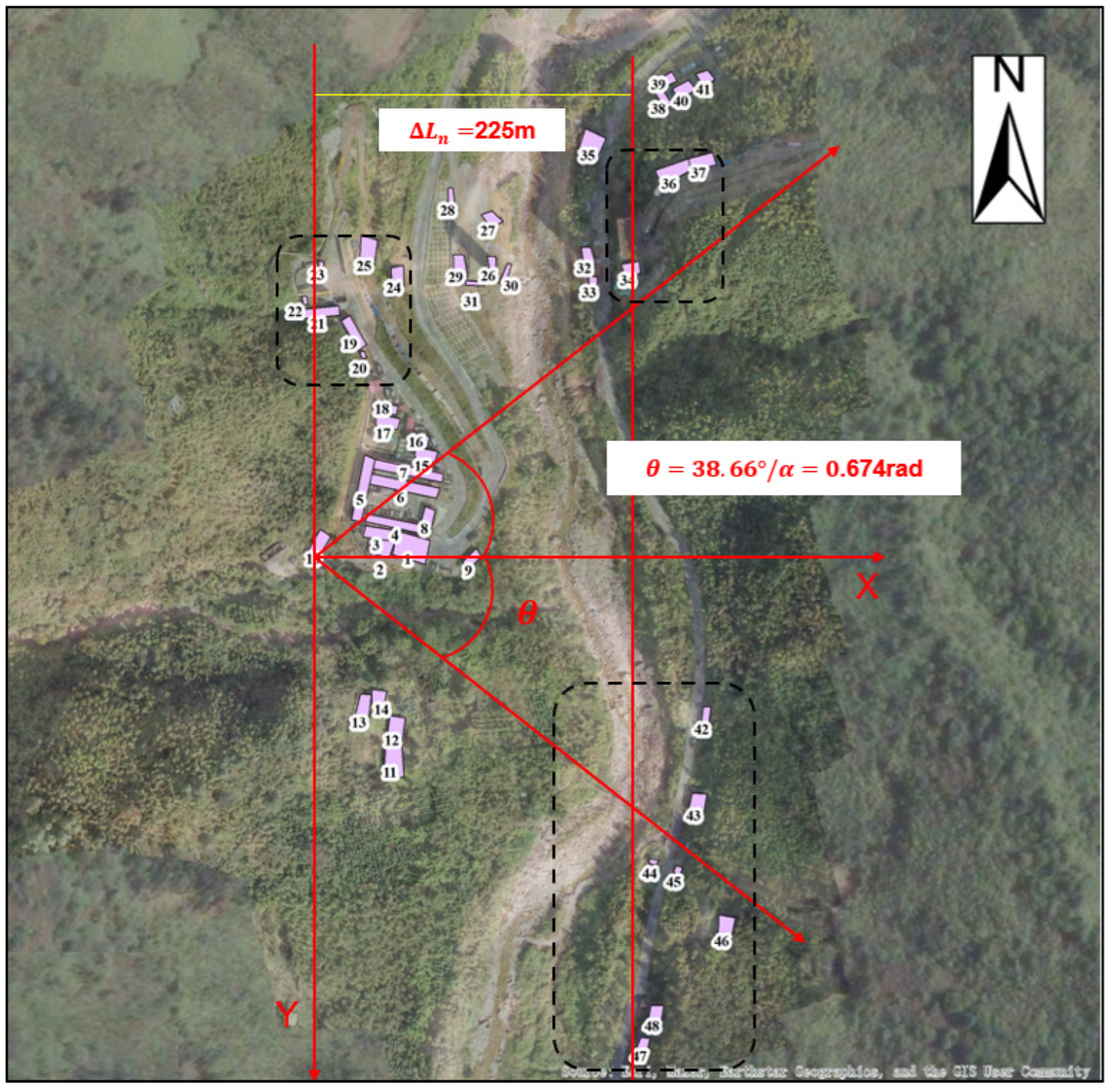

5.4. Case Study

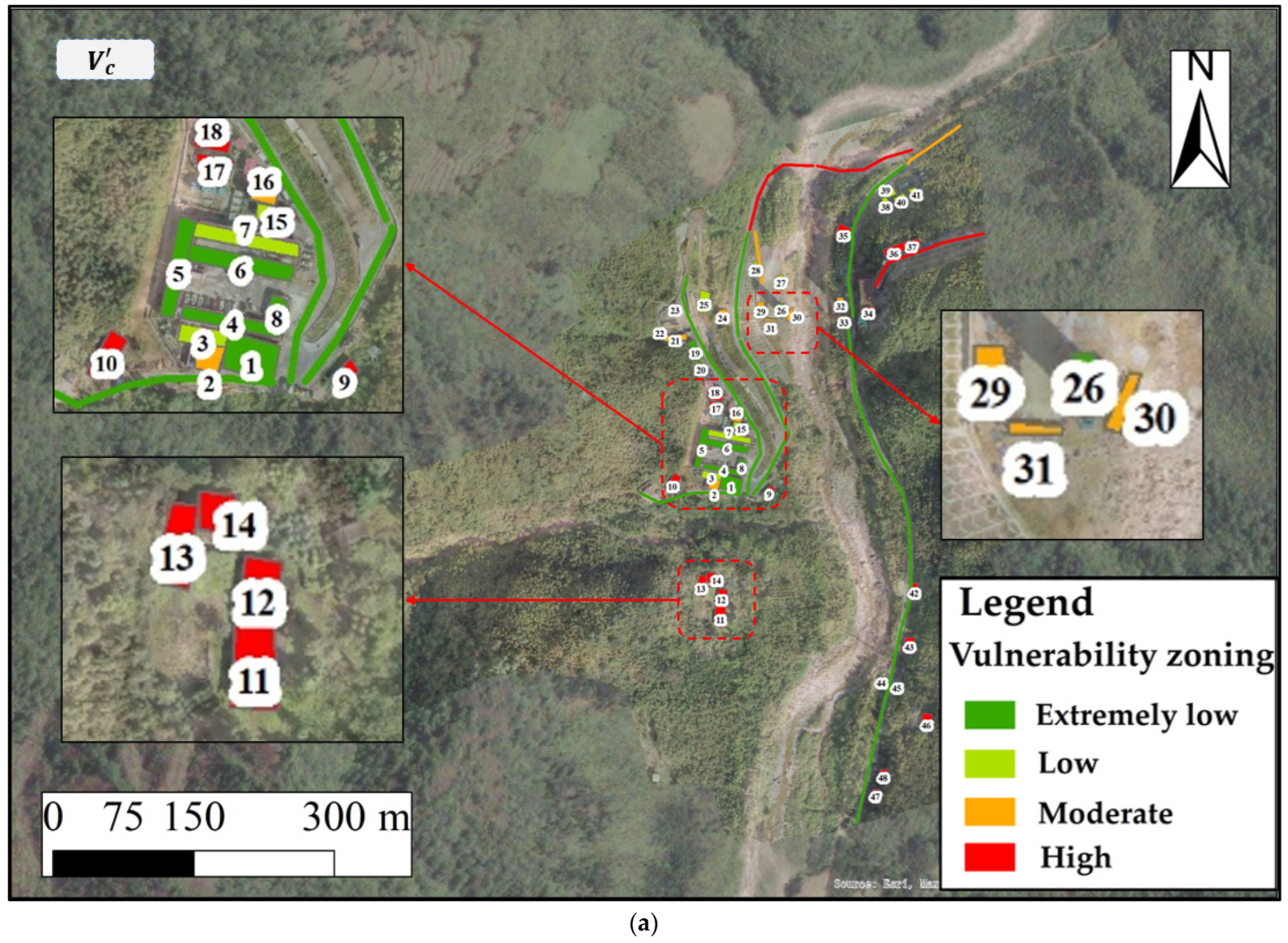

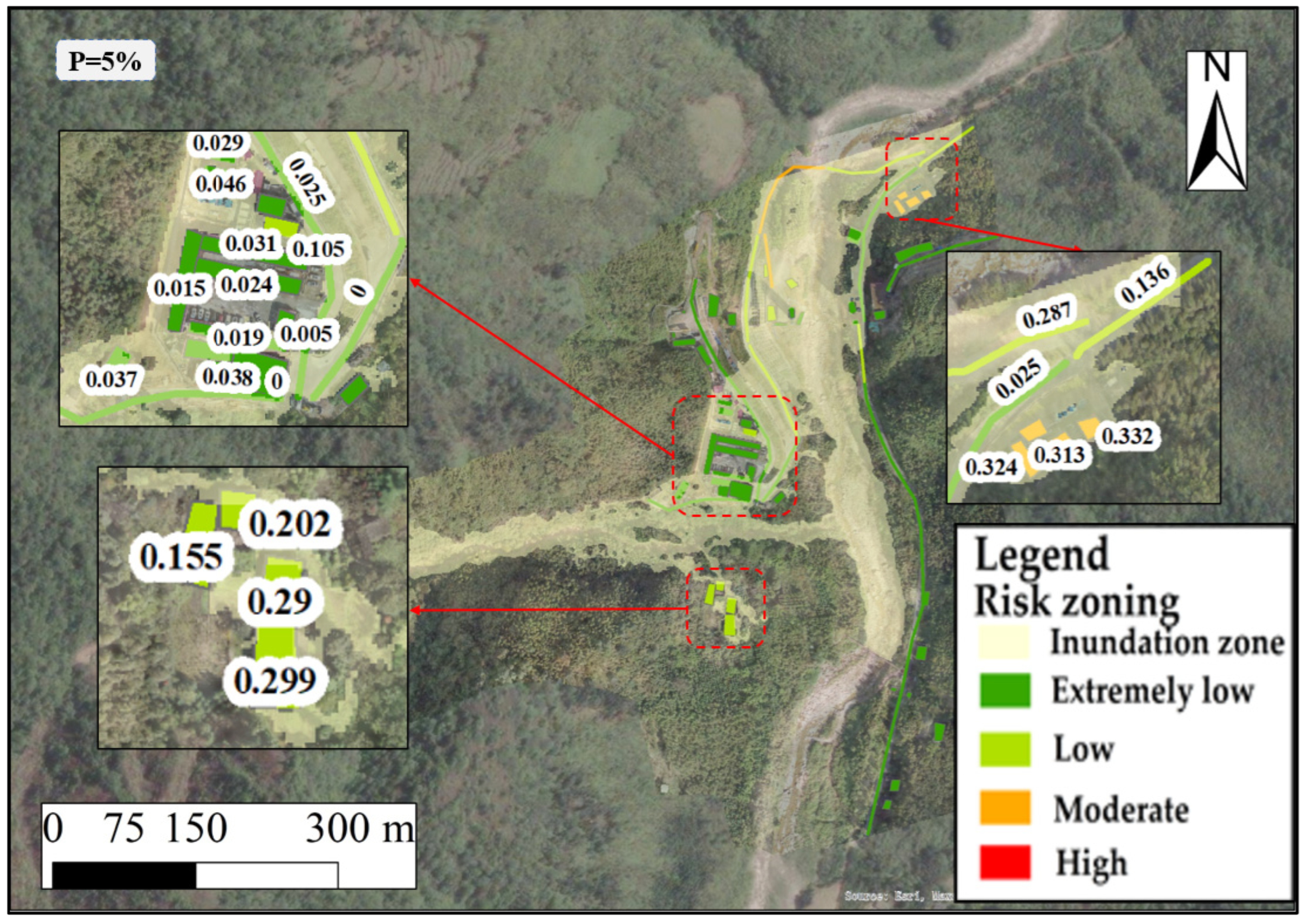

6. Risk Assessment of Large-Scale Temporary Works (p = 5%)

7. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| ID | Experimental Conditions | Measured Sensors | Impact Force Value (kPa) | |

|---|---|---|---|---|

| 1 | 1.0 | X1 | X1 | 5.94 |

| 2 | 1.0 | X2 unshielding | X2 | 5.21 |

| 3 | 1.0 | X2 shielding | X2 | 1.62 |

| 4 | 1.0 | X3 unshielding | X3 | 4.69 |

| 5 | 1.0 | X3 shielding | X3 | 2.52 |

| 6 | 1.0 | X4 unshielding | X4 | 3.39 |

| 7 | 1.0 | X4 shielding | X4 | 2.69 |

| 8 | 1.0 | X5 unshielding | X5 | 3.43 |

| 9 | 1.0 | X5 shielding | X5 | 2.99 |

| 10 | 1.0 | X6 unshielding | X6 | 1.69 |

| 11 | 1.0 | X6 shielding | X6 | 1.61 |

| 12 | 1.0 | X7 unshielding | X7 | 0.97 |

| 13 | 1.0 | X7 shielding | X7 | 0.96 |

| 14 | 1.8 | X1 | X1 | 7.74 |

| 15 | 1.8 | X2 unshielding | X2 | 6.53 |

| 16 | 1.8 | X2 shielding | X2 | 1.96 |

| 17 | 1.8 | X3 unshielding | X3 | 5.89 |

| 18 | 1.8 | X3 shielding | X3 | 3.24 |

| 19 | 1.8 | X4 unshielding | X4 | 4.49 |

| 20 | 1.8 | X4 shielding | X4 | 3.02 |

| 21 | 1.8 | X5 unshielding | X5 | 3.33 |

| 22 | 1.8 | X5 shielding | X5 | 2.94 |

| 23 | 1.8 | X6 unshielding | X6 | 2.32 |

| 24 | 1.8 | X6 shielding | X6 | 2.19 |

| 25 | 1.8 | X7 unshielding | X7 | 1.02 |

| 26 | 1.8 | X7 shielding | X7 | 0.99 |

| 27 | 1.9 | X1 | X1 | 9.96 |

| 28 | 1.9 | X2 unshielding | X2 | 8.29 |

| 29 | 1.9 | X2 shielding | X2 | 2.51 |

| 30 | 1.9 | X3 unshielding | X3 | 7.47 |

| 31 | 1.9 | X3 shielding | X3 | 5.08 |

| 32 | 1.9 | X4 unshielding | X4 | 5.78 |

| 33 | 1.9 | X4 shielding | X4 | 4.63 |

| 34 | 1.9 | X5 unshielding | X5 | 3.49 |

| 35 | 1.9 | X5 shielding | X5 | 3.12 |

| 36 | 1.9 | X6 unshielding | X6 | 2.99 |

| 37 | 1.9 | X6 shielding | X6 | 2.45 |

| 38 | 1.9 | X7 unshielding | X7 | 1.27 |

| 39 | 1.9 | X7 shielding | X7 | 1.25 |

| 40 | 2.0 | X1 | X1 | 11.52 |

| 41 | 2.0 | X2 unshielding | X2 | 11.06 |

| 42 | 2.0 | X2 shielding | X2 | 3.01 |

| 43 | 2.0 | X3 unshielding | X3 | 9.91 |

| 44 | 2.0 | X3 shielding | X3 | 4.16 |

| 45 | 2.0 | X4 unshielding | X4 | 7.49 |

| 46 | 2.0 | X4 shielding | X4 | 5.25 |

| 47 | 2.0 | X5 unshielding | X5 | 5.65 |

| 48 | 2.0 | X5 shielding | X5 | 5.01 |

| 49 | 2.0 | X6 unshielding | X6 | 3.46 |

| 50 | 2.0 | X6 shielding | X6 | 3.29 |

| 51 | 2.0 | X7 unshielding | X7 | 2.07 |

| 52 | 2.0 | X7 shielding | X7 | 2.05 |

| ID | Experimental Conditions | Measured Sensors | Impact Force Value (kPa) | |

|---|---|---|---|---|

| 53 | 1.0 | Y2 unshielding | Y2 | 1.14 |

| 54 | 1.0 | Y2 shielding | Y2 | 0.35 |

| 55 | 1.0 | Y3 unshielding | Y3 | 1.69 |

| 56 | 1.0 | Y3 shielding | Y3 | 0.93 |

| 57 | 1.0 | Y4 unshielding | Y4 | 0.92 |

| 58 | 1.0 | Y4 shielding | Y4 | 0.74 |

| 59 | 1.0 | Y5 unshielding | Y5 | 0.75 |

| 60 | 1.0 | Y5 shielding | Y5 | 0.62 |

| 61 | 1.0 | Y6 unshielding | Y6 | 0.24 |

| 62 | 1.0 | Y6 shielding | Y6 | 0.23 |

| 63 | 1.0 | Y7 unshielding | Y7 | 0.09 |

| 64 | 1.0 | Y7 shielding | Y7 | 0.09 |

| 65 | 1.8 | Y2 unshielding | Y2 | 2.03 |

| 66 | 1.8 | Y2 shielding | Y2 | 0.34 |

| 67 | 1.8 | Y3 unshielding | Y3 | 2.97 |

| 68 | 1.8 | Y3 shielding | Y3 | 1.43 |

| 69 | 1.8 | Y4 unshielding | Y4 | 1.59 |

| 70 | 1.8 | Y4 shielding | Y4 | 0.97 |

| 71 | 1.8 | Y5 unshielding | Y5 | 1.06 |

| 72 | 1.8 | Y5 shielding | Y5 | 0.85 |

| 73 | 1.8 | Y6 unshielding | Y6 | 0.62 |

| 74 | 1.8 | Y6 shielding | Y6 | 0.56 |

| 75 | 1.8 | Y7 unshielding | Y7 | 0.23 |

| 76 | 1.8 | Y7 shielding | Y7 | 0.21 |

| 77 | 1.9 | Y2 unshielding | Y2 | 2.29 |

| 78 | 1.9 | Y2 shielding | Y2 | 0.45 |

| 79 | 1.9 | Y3 unshielding | Y3 | 3.16 |

| 80 | 1.9 | Y3 shielding | Y3 | 1.83 |

| 81 | 1.9 | Y4 unshielding | Y4 | 1.77 |

| 82 | 1.9 | Y4 shielding | Y4 | 1.24 |

| 83 | 1.9 | Y5 unshielding | Y5 | 1.21 |

| 84 | 1.9 | Y5 shielding | Y5 | 0.98 |

| 85 | 1.9 | Y6 unshielding | Y6 | 0.69 |

| 86 | 1.9 | Y6 shielding | Y6 | 0.53 |

| 87 | 1.9 | Y7 unshielding | Y7 | 0.12 |

| 88 | 1.9 | Y7 shielding | Y7 | 0.11 |

| 89 | 2.0 | Y2 unshielding | Y2 | 2.91 |

| 90 | 2.0 | Y2 shielding | Y2 | 0.88 |

| 91 | 2.0 | Y3 unshielding | Y3 | 3.58 |

| 92 | 2.0 | Y3 shielding | Y3 | 1.79 |

| 93 | 2.0 | Y4 unshielding | Y4 | 2.09 |

| 94 | 2.0 | Y4 shielding | Y4 | 1.27 |

| 95 | 2.0 | Y5 unshielding | Y5 | 1.54 |

| 96 | 2.0 | Y5 shielding | Y5 | 0.82 |

| 97 | 2.0 | Y6 unshielding | Y6 | 1.07 |

| 98 | 2.0 | Y6 shielding | Y6 | 0.94 |

| 99 | 2.0 | Y7 unshielding | Y7 | 0.26 |

| 100 | 2.0 | Y7 shielding | Y7 | 0.25 |

References

- Lambe, T.W.; Whitman, R. Soil Mechanics; CHAPTER on Soil Stability with Flow; MIT: Cambridge, MA, USA; Wiley: New York, NY, USA, 1969. [Google Scholar]

- Cui, P.; Zou, Q. Theory and methods of risk assessment and risk management of mountain flood and debris flow. Geograph 2016, 2, 4. [Google Scholar]

- Peng, J.B.; Cui, P.; Zhuang, J.Q. Challenges to engineering geology of Sichuan-Tibet railway. Chin. J. Rock Mech. Eng. 2020, 39, 2377–2389. [Google Scholar]

- Lu, C.; Cai, C. Challenges and countermeasures for construction safety during the Sichuan–Tibet railway project. Engineering 2019, 5, 833–838. [Google Scholar] [CrossRef]

- Zou, Q.; Jiang, L.; You, Y.; Wang, D.; Jiang, H.; Zhang, G. Information Management System for Mountain Hazards along Sichuan-Tibet Railway. J. Yangtze River Sci. Res. Inst. 2020, 37, 177. [Google Scholar]

- Wei, R.; Zeng, Q.; Davies, T.; Yuan, G.; Wang, K.; Xue, X.; Yin, Q. Geohazard cascade and mechanism of large debris flows in Tianmo gully, SE Tibetan Plateau and implications to hazard monitoring. Eng. Geol. 2018, 233, 172–182. [Google Scholar] [CrossRef]

- Cui, P.; Ge, Y.; Li, S.; Li, Z.; Xu, X.; Zhou, G.G.; Chen, H.; Wang, H.; Lei, Y.; Zhou, L.; et al. Scientific challenges in disaster risk reduction for the Sichuan–Tibet Railway. Eng. Geology. 2022, 309, 106837. [Google Scholar] [CrossRef]

- Li, B.X.; Cai, Q.; Song, J.; Chen, L.; Liu, J.-K. Risk assessment of debris flow disasters based on FLO-2D: A case study of the Maiduogou debris flow. J. Nat. Disasters 2022, 31, 256. [Google Scholar]

- Jia, T.; Tang, C.; Wang, N. Zoning method and application of debris flow hazard based on FLO-2D and momentum model. Hydroelectr. Energy Sci. 2015, 33, 152–155. [Google Scholar]

- Zhang, P.; Ma, J.; Shu, H.; Wang, G. Numerical simulation of debris flow movement and erosion-sedimentation based on the FLO-2D model. J. Lanzhou Univ. Nat. Sci. 2014, 50, 363–368. [Google Scholar]

- Lin, J.-Y.; Yang, M.-D.; Lin, B.-R.; Lin, P.-S. Risk assessment of debris flows in Songhe Stream, Taiwan. Eng. Geol. 2011, 123, 100–112. [Google Scholar] [CrossRef]

- Eidsvig, U.; Papathoma-Köhle, M.; Du, J.; Glade, T.; Vangelsten, B. Quantification of model uncertainty in debris flow vulnerability assessment. Eng. Geol. 2014, 181, 15–26. [Google Scholar] [CrossRef]

- Papathoma-Köhle, M.; Keiler, M.; Totschnig, R.; Glade, T. Improvement of vulnerability curves using data from extreme events: Debris flow event in South Tyrol. Nat. Hazards 2012, 64, 2083–2105. [Google Scholar] [CrossRef]

- Birkmann, J.; Cardona, O.D.; Carreño, M.L.; Barbat, A.H.; Pelling, M.; Schneiderbauer, S.; Kienberger, S.; Keiler, M.; Alexander, D.; Zeil, P.; et al. Framing vulnerability, risk and societal responses: The MOVE framework. Nat. Hazards 2013, 67, 193–211. [Google Scholar] [CrossRef]

- Apel, H.; Aronica, G.T.; Kreibich, H.; Thieken, A.H. Flood risk analyses—How detailed do we need to be. Nat. Hazards 2009, 49, 79–98. [Google Scholar] [CrossRef]

- Totschnig, R.; Sedlacek, W.; Fuchs, S. A quantitative vulnerability function for fluvial sediment transport. Nat. Hazards 2011, 58, 681–703. [Google Scholar] [CrossRef]

- Papathoma-Köhle, M.; Gems, B.; Sturm, M.; Fuchs, S. Matrices, curves and indicators: A review of approaches to assess physical vulnerability to debris flows. Earth-Sci. Rev. 2017, 171, 272–288. [Google Scholar] [CrossRef]

- Du, Y. Construction of construction camps in permafrost areas of the Qinghai-Tibet Plateau. Railw. Constr. Technol. 2003, z1, 150–152. [Google Scholar]

- Guo, L.B.; Wang, J.G.; Guo, Y.X. Geological disaster hazards of temporary construction camps in high-altitude Tibetan areas. Yunnan Hydropower 2019, 35, 20–21. [Google Scholar]

- Zhao, J.; Li, Z.; Li, R.; Wei, Q.; Yin, H.; Hu, H. Research on key technical issues in the construction of railway construction camps in rugged mountainous areas. China Railw. 2021. [Google Scholar] [CrossRef]

- Xu, Z.X.; Yuan, D.; Liu, Z.J.; Liu, J.F.; You, Y. Development characteristics and risk analysis of debris flow in Songjiagou along the Sichuan-Tibet Railway. J. Yangtze River Sci. Res. Inst. 2020, 37, 165. [Google Scholar]

- Di, B.; Stamatopoulos, C.A.; Stamatopoulos, A.C.; Liu, E.; Balla, L. Proposal, application and partial validation of a simplified expression evaluating the stability of sandy slopes under rainfall conditions. Geomorphology 2021, 395, 107966. [Google Scholar] [CrossRef]

- Gong, K.; Yang, T.; Xia, C.H.; Yang, Y. Risk assessment of debris flow based on FLO-2D: A case study of Cutougou in Mianzili Township, Wenchuan County, Sichuan Province. J. Water Resour. Water Eng. 2017, 28, 134–138. [Google Scholar]

- Zhang, F.X.; Zhang, L.Q.; Zhou, J.; Wang, S. Risk analysis of debris flow in Ruoru Village, Tibet based on FLO-2D. J. Water Resour. Water Eng. 2019, 30, 95–102. [Google Scholar]

- Xu, H.L. Research on Prediction of Debris Flow Runoff Scale in Steep Gullies Based on FLO-2D; Chengdu University of Technology: Chengdu, China, 2018. [Google Scholar]

- Zou, Q.; Cui, P.; Jiang, H.; Wang, J.; Li, C.; Zhou, B. Analysis of regional river blocking by debris flows in response to climate change. Sci. Total Environ. 2020, 741, 140262. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.B. Analytical calculation of flood routing with pentagonal flood hydrograph. Jiangxi Hydraul. Sci. Technol. 1993, 19, 198–201. [Google Scholar]

- Take, W.A.; Bolton, M.D.; Wong, P.C.P.; Yeung, F.J. Evaluation of landslide triggering mechanisms in model fill slopes. Landslides 2004, 1, 173–184. [Google Scholar] [CrossRef]

- O’Brien, J.S.; Garcia, R. FLO-2D Reference Manual. 2009, p. 595. Available online: www.flo-2d.com (accessed on 10 March 2024).

- Fiebiger, G. The Estimation of the Hazard Potency of Debris Flows and The Step to Step Method. In Environmental Forest Science, Proceedings of the IUFRO Division 8 Conference Environmental Forest Science, Kyoto, Japan, 19–23 October 1998; Springer: Amsterdam, The Netherlands, 1998; pp. 529–540. [Google Scholar]

- Zhang, Z.Y.; Liu, Q.; Wang, G.; Xu, Z.W. Research on health assessment of Fenghe River based on AHP-fuzzy mathematical model and item-by-item evaluation method. Pearl River 2023, 44, 9. [Google Scholar]

- Hu, K.; Wei, F.; Li, Y. Real-time measurement and preliminary analysis of debris-flow impact force at Jiangjia Ravine, China. Earth Surf. Process. Landf. 2011, 36, 1268–1278. [Google Scholar] [CrossRef]

- Tang, J.; Hu, K.; Zhou, G.; Chen, H.; Zhu, X.; Ma, C. Signal processing of debris flow impact force based on wavelet analysis. J. Sichuan Univ. Eng. Sci. Ed. 2013, 45, 8–13. [Google Scholar]

- Qi, X.; Tang, C.; Chen, Z.F.; Shao, C.S. Research on Geological Disaster Risk Assessment. J. Nat. Disasters 2012, 21, 33–40. [Google Scholar]

- Yan, H. Risk Assessment of Debris Flow in Dry Gullies Based on FLO-2D; Southwest Jiaotong University: Chengdu, China, 2017. [Google Scholar]

- Woolhiser, D.A. Unsteady Free-Surface Flow Problems; Institute on Unsteady Flow in Open Channels, Colorado State University: Fort Collins, CO, USA, 1974; pp. 195–213. [Google Scholar]

- Lei, Y.; Gu, H.; Cui, P. Vulnerability assessment for buildings exposed to torrential hazards at Sichuan-Tibet transportation corridor. Eng. Geol. 2022, 308, 106803. [Google Scholar] [CrossRef]

| /% | /(kN·m−3) | /h | ||||

|---|---|---|---|---|---|---|

| 1 | 20.0 | 0.954 | 80.527 | 8.053 | 0.826 | 1.538 |

| 2 | 19.0 | 0.949 | 77.654 | 8.343 | 0.776 | 1.200 |

| 5 | 18.0 | 0.941 | 72.147 | 8.926 | 0.757 | 0.941 |

| /% | /(m3·s−1) | /(m3·s−1) |

|---|---|---|

| 1 | 68.902 | 349.750 |

| 2 | 66.274 | 291.606 |

| 5 | 61.598 | 239.120 |

| Parameter Items | Values | |

|---|---|---|

| Manning’s coefficient () | 0.3 | |

| Volume concentration () | 0.45 | |

| Laminar flow resistance coefficient () | 2280 | |

| Viscous coefficient () | 0.0248 | |

| 14.62 | ||

| Yield stress coefficient () | 0.00236 | |

| 11.24 |

| /% | Sim. Results/m3 | Calc. Results/m3 | Error/% |

|---|---|---|---|

| 1 | 71,011.72 | 77,077.19 | 8.54 |

| 2 | 51,601.28 | 57,827.64 | 12.07 |

| 5 | 38,770.41 | 42,150.47 | 8.72 |

| Primary Indicators | Weight | Secondary Indicators | Weight | Evaluation Score Y | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Engineering Type C1 | 0.2 | Material Storage Shed X1 | 0.05 | 0.4 | ||||||

| Ash Pond X2 | 0.05 | 0.5 | ||||||||

| Explosives Storage X3 | 0.15 | 0.7 | ||||||||

| Power Station X4 | 0.10 | 0.7 | ||||||||

| Air Supply Station X5 | 0.05 | 0.6 | ||||||||

| Water Supply Station X6 | 0.05 | 0.6 | ||||||||

| Concrete Mixing Station X7 | 0.06 | 0.5 | ||||||||

| Aggregate Mixing Station X8 | 0.06 | 0.5 | ||||||||

| Beam Storage Yard X9 | 0.05 | 0.3 | ||||||||

| Track Joint Assembly Yard X10 | 0.05 | 0.3 | ||||||||

| Long Rail Welding Yard X11 | 0.05 | 0.3 | ||||||||

| Steel Beam Assembly Yard X12 | 0.05 | 0.4 | ||||||||

| Ballast Storage Yard X13 | 0.05 | 0.4 | ||||||||

| Other Materials Warehouse X14 | 0.05 | 0.5 | ||||||||

| Residential Area X15 | 0.10 | 0.7 | ||||||||

| Office Area X16 | 0.02 | 0.5 | ||||||||

| Other Living Utility Area X17 | 0.01 | 0.3 | ||||||||

| Structural Characteristics C2 | 0.4 | Structural Type X18 | 0.4 | 0.2 (Steel) | 0.4 (RC) | 0.6 (BC) | 0.7 (Container) | 0.8 (MP House) | ||

| Number of Floors X19 | 0.3 | 0.8 (1–2 Floors) | 0.6 (2–4 Floors) | |||||||

| Construction Time X20 | 0.3 | 0.2 (2 yrs ago) | 0.4 (5 yrs ago) | 0.6 (10 yrs ago) | ||||||

| Construction Quality C3 | 0.4 | Degree of Deformation X21 | 0.6 | 0.1 (None) | 0.4 (Minor) | 0.7 (Significant) | ||||

| Crack Length X22 | 0.2 | 0.1 (<0.5 m) | 0.4 (0.5~1.0 m) | 0.7 (>1.0 m) | ||||||

| Crack Width X23 | 0.2 | 0.1 (<0.1 m) | 0.4 (0.1~0.3 m) | 0.7 (>0.3 m) | ||||||

| Primary Indicators | Weight | Secondary Indicators | Weight | Evaluation Score Y | |||||

|---|---|---|---|---|---|---|---|---|---|

| Engineering Type C1 | 0.2 | Construction Access X1 | 0.5 | 0.7 | |||||

| Construction Bridge X2 | 0.5 | 0.7 | |||||||

| Structural Characteristics C2 | 0.4 | Structural Type X3 | 0.6 | 0.7 (other) | 0.6 (concrete) | 0.6 (cement) | 0.7 (asphalt) | ||

| Construction Time X4 | 0.4 | 0.2 (2 yrs ago) | 0.4 (5 yrs ago) | 0.6 (10 yrs ago) | |||||

| Construction Quality C3 | 0.4 | Degree of Deformation X5 | 0.6 | 0.1 (None) | 0.4 (Minor) | 0.7 (Significant) | |||

| Crack Length X6 | 0.2 | 0.1 (<0.5 m) | 0.4 (0.5~1.0 m) | 0.7 (>1.0 m) | |||||

| Crack Width X7 | 0.2 | 0.1 (<0.1 m) | 0.4 (0.1~0.3 m) | 0.7 (>0.3 m) | |||||

| ID | (Floors) | (Yrs Ago) | (m) | (m) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | X12 | Steel | 1 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.34 | 0.005 |

| 2 | X14 | Container | 2 | 5 | Significant | 0.5~1 | 0.1~0.3 | 0.493 | 0.703 |

| 3 | X14 | Container | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.421 | 0.374 |

| 4 | X15 | RC | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.382 | 0.196 |

| 5 | X16 | RC | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.37 | 0.142 |

| 6 | X15 | RC | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.382 | 0.196 |

| 7 | X17 | MP House | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.433 | 0.427 |

| 8 | X16 | RC | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.37 | 0.142 |

| 9 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 10 | X14 | Container | 2 | 5 | Significant | >1 | >0.3 | 0.541 | 0.922 |

| 11 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 12 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 13 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 14 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 15 | X6 | MP House | 1 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.452 |

| 16 | X9 | RC | 2 | 5 | Significant | >1 | >0.3 | 0.491 | 0.694 |

| 17 | X8 | BC | 1 | 5 | Significant | >1 | >0.3 | 0.526 | 0.854 |

| 18 | X7 | BC | 1 | 5 | Significant | >1 | >0.3 | 0.526 | 0.854 |

| 19 | X10 | Steel | 1 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.339 | 0 |

| 20 | X4 | RC | 1 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.382 | 0.196 |

| 21 | X12 | Steel | 1 | 5 | Significant | >1 | >0.3 | 0.46 | 0.553 |

| 22 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 23 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 24 | X10 | Steel | 1 | 5 | Significant | >1 | >0.3 | 0.459 | 0.548 |

| 25 | X11 | Steel | 1 | 5 | Significant | 0.5~1 | >0.3 | 0.435 | 0.438 |

| 26 | X13 | RC | 1 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.372 | 0.151 |

| 27 | X14 | BC | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.405 | 0.301 |

| 28 | X6 | MP House | 1 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.452 |

| 29 | X12 | Steel | 1 | 5 | Significant | >1 | >0.3 | 0.46 | 0.553 |

| 30 | X11 | Steel | 1 | 5 | Significant | >1 | >0.3 | 0.459 | 0.548 |

| 31 | X7 | RC | 1 | 5 | Significant | >1 | >0.3 | 0.494 | 0.708 |

| 32 | X5 | BC | 1 | 5 | Significant | 0.5~1 | >0.3 | 0.502 | 0.744 |

| 33 | X4 | BC | 2 | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.414 | 0.342 |

| 34 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 35 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 36 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 37 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 38 | X14 | BC | 2 | 10 | Minor | 0.5~1 | 0.1~0.3 | 0.429 | 0.411 |

| 39 | X14 | BC | 2 | 10 | Minor | 0.5~1 | 0.1~0.3 | 0.429 | 0.411 |

| 40 | X14 | BC | 2 | 10 | Minor | 0.5~1 | 0.1~0.3 | 0.429 | 0.411 |

| 41 | X14 | BC | 2 | 10 | Minor | 0.5~1 | 0.1~0.3 | 0.429 | 0.411 |

| 42 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 43 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 44 | X15 | BC | 1 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 45 | X15 | BC | 2 | 10 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.452 |

| 46 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 47 | X15 | BC | 2 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| 48 | X15 | BC | 1 | 10 | Significant | >1 | >0.3 | 0.558 | 1 |

| ID | (Yrs Ago) | (m) | (m) | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | X1 | Cement | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.188 |

| 2 | X1 | Cement | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.188 |

| 3 | X1 | Cement | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.188 |

| 4 | X1 | Cement | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.188 |

| 5 | X1 | Cement | 5 | Minor | 0.5~1 | 0.1~0.3 | 0.438 | 0.188 |

| 6 | X1 | Asphalt | 5 | Significant | 0.5~1 | 0.1~0.3 | 0.534 | 0.938 |

| 7 | X1 | Asphalt | 10 | Significant | 0.5~1 | <0.1 | 0.542 | 1 |

| 8 | X1 | Other | 10 | Minor | 0.5~1 | 0.1~0.3 | 0.494 | 0.625 |

| 9 | X1 | Asphalt | 5 | Minor | 0.5~1 | <0.1 | 0.438 | 0.188 |

| 10 | X1 | Asphalt | 5 | Minor | 0.5~1 | <0.1 | 0.438 | 0.188 |

| 11 | X1 | Concrete | 5 | Significant | 0.5~1 | <0.1 | 0.486 | 0.563 |

| 12 | X1 | Other | 10 | Significant | 0.5~1 | <0.1 | 0.542 | 1 |

| 13 | X1 | Cement | 5 | Minor | 0.5~1 | <0.1 | 0.414 | 0 |

| 14 | X1 | Asphalt | 5 | Minor | 0.5~1 | <0.1 | 0.438 | 0.188 |

| 0.8~1.0 | 0.5~0.8 | 0.2~0.5 | 0~0.2 | |

|---|---|---|---|---|

| Level | High | Moderate | Low | Extremely low |

| a | b | c | R2 | |

|---|---|---|---|---|

| 1.0 | −1.9 × 10−4 ± 9.3 × 10−5 | −0.018 ± 0.004 | 1.005 ± 0.029 | 0.9906 |

| 1.8 | −1.2 × 10−4 ± 6.9 × 10−5 | −0.019 ± 0.003 | 0.992 ± 0.021 | 0.9942 |

| 1.9 | −3.9 × 10−5 ± 8.2 × 10−5 | −0.025 ± 0.003 | 1.005 ± 0.026 | 0.9934 |

| 2.0 | −4.5 × 10−4 ± 7.4 × 10−5 | −0.009 ± 0.003 | 1.018 ± 0.023 | 0.9947 |

| A | B | C | R2 | |

|---|---|---|---|---|

| 1.0 | −1.169 ± 0.068 | 18.041 ± 2.633 | 1.157 ± 0.073 | 0.9914 |

| 1.8 | −1.209 ± 0.087 | 21.133 ± 3.492 | 1.201 ± 0.094 | 0.9913 |

| 1.9 | −1.096 ± 0.143 | 15.506 ± 5.326 | 1.005 ± 0.144 | 0.9431 |

| 2.0 | −1.383 ± 0.263 | 26.691 ± 10.172 | 1.368 ± 0.284 | 0.9694 |

| D | F | H | R2 | |

|---|---|---|---|---|

| 1.0 | 1.555 ± 0.121 | −0.316 ± 0.062 | 0.056 ± 0.033 | 0.9957 |

| 1.8 | 1.642 ± 0.282 | −0.373 ± 0.135 | 0.035 ± 0.060 | 0.9862 |

| 1.9 | 1.352 ± 0.434 | −0.257 ± 0.216 | 1.3 × 10−11 ± 0.112 | 0.9203 |

| 2.0 | 2.349 ± 1.465 | −0.806 ± 0.699 | 0.202 ± 0.224 | 0.9196 |

| ID | (m) | (m) | ||||||

|---|---|---|---|---|---|---|---|---|

| 5 | 25.82 | 6 | 0.215 | 0.175 | 0.191 | 0.193 | 0.370 | 0.071 |

| 11 | 55.99 | 6 | 0.424 | 0.405 | 0.393 | 0.407 | 0.558 | 0.227 |

| 12 | 56.41 | 6 | 0.426 | 0.407 | 0.396 | 0.409 | 0.558 | 0.229 |

| 13 | 30.62 | 6 | 0.251 | 0.216 | 0.226 | 0.231 | 0.558 | 0.129 |

| 14 | 44.87 | 6 | 0.352 | 0.328 | 0.323 | 0.335 | 0.558 | 0.187 |

| 15 | 70.16 | 6 | 0.506 | 0.489 | 0.476 | 0.490 | 0.438 | 0.215 |

| 16 | 65.41 | 6 | 0.479 | 0.462 | 0.449 | 0.463 | 0.491 | 0.228 |

| 17 | 40.75 | 6 | 0.324 | 0.298 | 0.296 | 0.306 | 0.526 | 0.161 |

| 18 | 38.26 | 6 | 0.307 | 0.279 | 0.279 | 0.288 | 0.526 | 0.152 |

| 26 | 120.02 | 6 | 0.732 | 0.703 | 0.714 | 0.716 | 0.372 | 0.267 |

| 27 | 121.51 | 6 | 0.737 | 0.708 | 0.720 | 0.722 | 0.405 | 0.292 |

| 28 | 96.67 | 6 | 0.637 | 0.617 | 0.612 | 0.622 | 0.438 | 0.272 |

| 29 | 98.85 | 6 | 0.647 | 0.626 | 0.622 | 0.632 | 0.460 | 0.291 |

| 30 | 125.83 | 6 | 0.753 | 0.722 | 0.738 | 0.737 | 0.459 | 0.338 |

| 31 | 104.77 | 6 | 0.672 | 0.650 | 0.649 | 0.657 | 0.494 | 0.324 |

| 32 | 181.92 | 6 | 0.913 | 0.850 | 0.924 | 0.896 | 0.502 | 0.450 |

| 33 | 183.04 | 6 | 0.916 | 0.852 | 0.927 | 0.898 | 0.414 | 0.372 |

| 35 | 182.19 | 6 | 0.914 | 0.850 | 0.925 | 0.896 | 0.558 | 0.500 |

| ID | (m) | (m) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 62.02 | 6 | 0.460 | 0.442 | 0.429 | 0.444 | 0.340 | 0.151 |

| 2 | 43.61 | 6 | 0.344 | 0.319 | 0.315 | 0.326 | 0.493 | 0.161 |

| ID | 3 | 4 | 6 | 7 | 8 | 9 |

| (m) | 41.72 | 50.97 | 51.13 | 51.28 | 71.94 | 105.08 |

| (m) | 6 | 6 | 6 | 6 | 6 | 6 |

| (rad) | 0.204 | 0.296 | 0.573 | 0.631 | 0.263 | 0.172 |

| 0.331 | 0.392 | 0.393 | 0.394 | 0.515 | 0.673 | |

| 0.305 | 0.371 | 0.372 | 0.373 | 0.499 | 0.651 | |

| 0.302 | 0.362 | 0.363 | 0.364 | 0.485 | 0.650 | |

| 0.313 | 0.375 | 0.376 | 0.377 | 0.500 | 0.658 | |

| 0.345 | 0.532 | 0.889 | 0.938 | 0.470 | 0.271 | |

| 0.384 | 0.567 | 0.863 | 0.900 | 0.509 | 0.303 | |

| 0.323 | 0.466 | 0.830 | 0.893 | 0.415 | 0.272 | |

| 0.350 | 0.522 | 0.861 | 0.910 | 0.465 | 0.282 | |

| 0.110 | 0.196 | 0.324 | 0.343 | 0.232 | 0.186 | |

| 0.421 | 0.382 | 0.382 | 0.433 | 0.370 | 0.558 | |

| 0.046 | 0.075 | 0.124 | 0.149 | 0.086 | 0.104 |

| Risk Levels | Characteristic Descriptions |

|---|---|

| Extremely low | The hazard of debris flows and the vulnerability of the LT works are both low. There is minimal risk of damage to the LT works from debris flow hazards, which does not affect normal operations. |

| Low | The damage caused by debris flows is minor, with a low vulnerability of the LT works. The overall risk value of debris flow disasters is low, and they have minimal impact on normal operations. |

| Moderate | The hazard level of debris flow disasters is moderate, affecting the normal operation of the LT works. It is necessary to design and construct debris flow disaster prevention and control projects of different levels to ensure the normal operation of transportation. |

| High | The hazard of debris flows and the vulnerability of the LT works are both high, with debris flows causing significant damage to engineering structures and severely impacting their operation. Alongside strengthening debris flow prevention and control measures, it is necessary to enhance monitoring and early warning measures. In severe cases, measures such as rerouting or selecting new routes should be taken based on the specific conditions of the road sections. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Lei, Y.; Gu, H. Debris Flow Risk Assessment for the Large-Scale Temporary Work Site of Railways—A Case Study of Jinjia Gully, Tianquan County. Water 2024, 16, 1152. https://doi.org/10.3390/w16081152

Wu Y, Lei Y, Gu H. Debris Flow Risk Assessment for the Large-Scale Temporary Work Site of Railways—A Case Study of Jinjia Gully, Tianquan County. Water. 2024; 16(8):1152. https://doi.org/10.3390/w16081152

Chicago/Turabian StyleWu, Yunpu, Yu Lei, and Haihua Gu. 2024. "Debris Flow Risk Assessment for the Large-Scale Temporary Work Site of Railways—A Case Study of Jinjia Gully, Tianquan County" Water 16, no. 8: 1152. https://doi.org/10.3390/w16081152

APA StyleWu, Y., Lei, Y., & Gu, H. (2024). Debris Flow Risk Assessment for the Large-Scale Temporary Work Site of Railways—A Case Study of Jinjia Gully, Tianquan County. Water, 16(8), 1152. https://doi.org/10.3390/w16081152