Abstract

A robust assessment of water used in agriculture, including livestock production systems and supply chains, is critical to inform diversification and the development of productivity and sustainable food production systems. This paper presents a detailed analysis of water used and consumed in nine dairy milk processing plants spread across Punjab, India’s leading dairy milk-producing state. Over the five years (2015–2019), the direct water use (DWU) was quantified at 3.31 L of groundwater per kg of milk processed. Only about 26% of the direct water used was consumed, including evaporative losses in various milk processing operations, while the remaining 74% was returned as effluent discharges. The average total water footprint (TWF), accounting for both direct and indirect water consumption, was quantified at 9.0 L of water per kg of milk processed. The majority share (~89%) of the total water footprint was contributed by the indirect water footprint associated with the consumption of electricity (energy) in dairy milk processing activities. The plant’s milk processing capacity and processing products mix also affected significant seasonal and annual variations in the direct and indirect water footprints of dairy milk processing. The analysis also found an inverse relationship between the average total water footprint and the average monthly amount of milk processed in the study plants. Therefore, efforts to reduce the indirect water footprint (associated with energy consumption), the treatment and recycling of effluent discharges, and the optimization of milk processing capacity, the dairy processing product mix, and the locations of dairy processing plants are expected to help reduce the water footprint of dairy processing in the state.

1. Introduction

Agriculture is facing an unprecedented challenge of limited land and water resources available for the production and supply of healthy nutritious food products, especially in countries like India. Available land and water resources are impacted by the potentially adverse effects of changing climate conditions in many parts of the world, including the semi-arid north-western region of India [1]. A significant share (~86%) of the world’s freshwater is consumed in food production globally [2]. Policies and practices prompting efficient and sustainable use of the available water for agriculture are required for achieving water, food, and nutrition security globally and protecting freshwater ecosystems for their benefits for humans and nature. Various food production systems worldwide require a robust assessment of water use and its productivity.

Water is one of the most critical factors affecting agricultural production. At the global level, the livestock sector is one of the primary users of natural resources such as land and water, with estimated current uses of about 35% of total cropland and about 20% of blue (surface water and groundwater) for feed production [3]. Among the livestock sector, dairy is the fastest-growing sector, with a projected increase of 22% in global milk production by 2030 [4]. Deutsch et al. [5] estimated that the livestock sector uses an equivalent of 11,900 km3 of fresh water annually, approximately 10% of the global water flow. The Food and Agriculture Organization (FAO) has established a Livestock Environmental Assessment and Performance (LEAP) partnership to develop and implement comprehensive guidance and methodologies for understanding environmental performance, including the water use of livestock production systems and supply chains. Recently, the FAO LEAP Water Technical Advisory Group recommended a consistent application of water productivity and water scarcity footprints as metrics for assessing water use in livestock production and supply chains [6].

In recent years, water footprint assessments in the dairy milk processing sector have received much attention, particularly in countries such as Germany [7], Australia [8], New Zealand [9], Argentina [10], China [11], Ireland [12] South Africa [13], and Brazil [14]. With only 2.40% of the world’s land mass and 4% of global freshwater resources, India supports about 18% of the world’s bovine population and contributes 23% to global milk production [15]. However, many regions of India are already facing moderate-to-severe water stress conditions, especially the north-western states of Haryana and Punjab. Punjab, India’s leading food-producing state, contributes 12.8% of grains (wheat and rice), 2.5% of horticulture, and 6.4% of milk to the national pool. However, due to the intensification of agriculture with water-intensive cropping systems, particularly the very high area under rice cultivation, Punjab is experiencing severe water stress due to limited surface water supplies and the over-drafting of groundwater [16].

In the Indian context, only limited studies have been conducted on the assessment of water use in dairy milk production in India in general [17,18,19] and Punjab in particular [20]. The scope of a previous study conducted in Punjab by Amarasinghe et al. [20] was limited to only one district, i.e., Moga district. Their study mainly focused on the analysis of Consumptive Water Usage (CWU) in dairy milk production (940 m3/tons) as compared to rice (1870 m3/tons) cultivation. Furthermore, no study has been conducted so far to analyze the direct and indirect water footprints associated with dairy milk processing in Punjab and other Indian states.

India has a typical milk production system dominated by millions of small and medium household dairy farms spread across the length and breadth of the country, with 6.11 to 12.97 L of milk production per day [21]. The milk collection handling system involves organized sector players consisting of dairy cooperatives and private milk plants, and unorganized sector players like milkmen and halwais. Of the total milk produced in India, only 40% is handled by the organized sector players and processed and packed before reaching consumers, while the remaining 60% is still handled by unorganized sector players and directly sold to consumers as fresh milk without any processing and packaging. In dairy-developed countries, more than 90% of milk reaches dairy milk processing plants for processing and packing before being delivered to consumers. With the formalization of the dairy sector in India, the share of the organized sector in milk processing is expected to increase further in the coming years. Although there are published studies on the water footprint of processed Liquid Milk, as well as various dairy products, from advanced dairy countries like Australia [22], France [23], and Poland [24], no similar report on the water footprint of Liquid Milk processing or dairy product making is available from any of the South Asian countries. Moreover, most existing studies accounted for only direct water use [25] and covered limited spatial and temporal variations in water consumption in the dairy processing sector [24].

The present study was, therefore, conducted to quantify and assess the spatial and temporal variations of the water footprint of the dairy milk processing plants in Punjab (India). We aimed to quantify and assess both the direct and indirect (associated with the energy use) water footprints of dairy milk processing in nine milk plants under an organized sector spread across the length and breadth of Punjab. The relevant datasets of all nine commercial dairy milk processing plants were collected and analyzed over a period of five years (2015–19). The study aimed to gain insights into the direct and indirect water used and consumed in the processing of dairy milk. Moreover, analyzing spatial and temporal variations, direct and indirect water footprints, and the potential effects of different processing technologies and dairy milk product compositions on the water footprints of dairy milk processing in the Indian context is another important aspect of this study. Further, this is the first elaborate study of its kind where time series data of five years’ duration (2015–19) have been used for water footprint analysis of milk processing plants. Previously, most studies have been conducted using single-point data on water consumption for water footprint analysis, which may not be able to depict the seasonal variation in milk production in the Indian context. Therefore, the findings of this study are expected to inform the development of productive and sustainable livestock production systems and supply chains in India and globally.

2. Methods and Materials

2.1. The Study Area

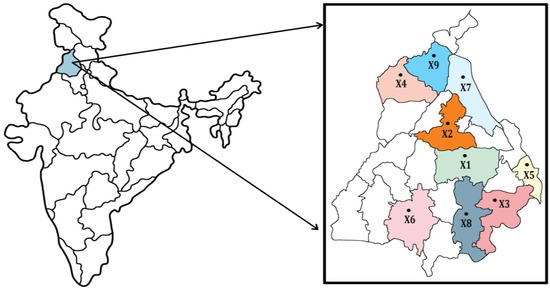

The study area, Punjab, is located in the north-western part of India and covers an area of 50,362 sq. km, which is 1.53% of the total geographical area of the country (Figure 1). Punjab is mainly spread over a flat alluvial plain, except for a thin belt along the north-eastern border, where it is mountainous, and in the south-western parts, where stable sand dunes are seen dotting the landscape.

Figure 1.

Map showing districts of the dairy milk processing plants selected in the study area of Punjab state, located in north-western part of India.

The climate of Punjab state is semi-humid to semi-arid in the north, arid in the south and southwest, and semi-arid in the remaining part of the state. It has a well-defined rainy period from July to September, when almost 80% of annual rainfall occurs due to the southwest monsoon, while the remaining 20% occurs during winter from December to March. The annual rainfall in Punjab state varies from about 1000 mm in the northeast to less than 300 mm in the southwest [26]. Wheat and rice are dominant crops grown in Punjab, contributing a significant share of grain stocks in India. However, cultivating water-intensive crops such as rice has increased water stress conditions, particularly declining groundwater levels in agricultural areas. Due to limited surface water supplies, groundwater is used mainly for the irrigation of crops. Groundwater levels in Punjab vary from almost near the surface to about 60 m below ground level [26]. The groundwater levels are recorded deep (>20 m) in the Kandi belt, while waterlogging conditions exist in some parts of south-western districts.

In the last decade, milk production in Punjab has increased at an impressive growth rate of around six percent [16], while during the corresponding period at the global level, it grew at 1.85% [15]. With 13.39 million tons (MT) of milk production (2020–21), Punjab contributes about 6.4% to Indian milk production. The nature of dairy farming in Punjab differs from the farming practices in other developed dairy nations, e.g., Northern Europe, Australia, and New Zealand. In terms of the livestock in Punjab, dairy buffalo contribute 56% of the total milk production, while the remainder comes from dairy cows (43%) and goats (1%) [27]. In Punjab, agricultural land is mainly under very high cropping intensity (180%), leaving limited land available for pasture growing. Therefore, all dairy animals are stall-fed under an intensive dairy husbandry system.

On the dairy milk processing front, a significant share (74%) of milk produced in Punjab is handled by the unorganized sector consisting of local milkman supplying raw (unprocessed and unpacked) milk to urban households, confectionery/sweetmeat makers (halwais), and creameries. Only about 26% of total milk produced in the state is processed in dairy processing plants, producing mainly pasteurized Liquid Milk and milk products (like Dahi, Paneer, Milk Powder, Paneer, and Ice Cream). Within the organized dairy processing sector, the share of cooperative dairy plants is about 30%; the remaining 70% is with private dairy milk processing plants. There are about 94 dairy milk processing plants across Punjab state [16]. Out of these, 35 dairy milk processing plants are large plants with an installed milk processing capacity of >0.05 million liters of milk per day, while the remaining are smaller milk plants.

2.2. The Study Variables

In this study, we collated and analyzed the direct and indirect water uses associated with the processing of dairy milk in the nine (9) selected commercial dairy milk processing plants spread across the length and breadth of Punjab (Figure 1). The selected plants were noted as X1 to X9 for protection of their identity and data privacy. The installed milk processing capacity of the selected plants ranged from 0.1 to 0.75 million liters per day (Table 1). The actual milk processing of the selected plants ranged from 100% to 133% of their installed milk processing capacity (Table 1).

Table 1.

Dairy milk processing capacity of the selected dairy milk processing plants in Punjab (India) from 2015 to 2019.

The recorded data of daily milk procurement, product mix, total groundwater drafted, water used in different milk processing activities, quantity of effluent generated, and energy consumption were collated from each of the selected nine plants on a monthly basis for a period of over five years (2015–2019). The monthly water and energy consumption were determined based on the audit measurements and questionnaires returned by the selected plants based on their water and energy used. The monthly information on the dairy products mix included the total quantity of milk products like Ghee (an Indian counterpart of butter oil), Dahi (an Indian counterpart of set yoghurt), Paneer (an Indian counterpart of cottage cheese), Liquid Milk, Ice cream, Butter, Milk Cake (a traditional Indian sweet), and Milk Powder produced; it was also collated for each of the selected plants (Table 2). The collated comprehensive datasets were then used to quantify the direct and indirect water footprints of dairy milk processing in the selected study plants.

Table 2.

List of dairy products produced in the nine (9) selected dairy milk processing plants in Punjab (India) from 2015 to 2019.

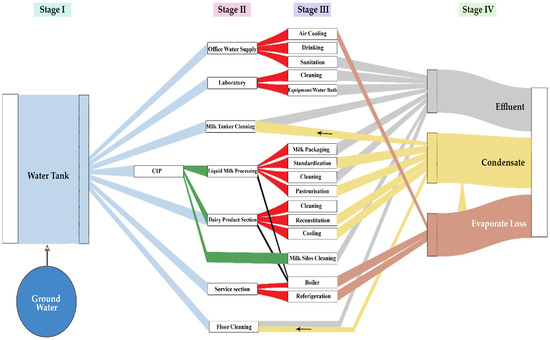

2.3. Quantification of Water Footprint of Dairy Milk Processing

A schematic of water flow in a typical dairy milk processing plant was first developed to map and quantify sources and uses of water in different operations of dairy milk processing plants (Figure 2). In all of the study milk plants, groundwater water was the sole source of water supply, which was pumped out and stored in water tanks for a continuous and uninterrupted water supply to various operations in the plant. A water flow schematic (Figure 2) has been categorized into four stages with distinct color codes for the better accountability and traceability of water used and consumed in various processes in the study plants. Stage 1 explains the amount of groundwater pumped and stored in the water tank. Stage 2 depicts the general distribution of water to different sections of the milk processing plant, while Stage 3 depicts elaborative water flow and uses in various activities. Stage 4 explains the quantity of water effluent discharges, evaporative losses, and condensate generated and its reuse, if any, for the cleaning of floors and milk tankers (Figure 2).

Figure 2.

A schematic of water flow and uses in different processes in a dairy milk processing plant in Punjab state.

As Hoekstra et al. [28] explained, standard terminologies and empirical procedures were adopted to quantify the water footprint of a kg of processed milk. Conceptually, the groundwater utilized in the selected milk processing plants (Figure 2) is quantified as the blue water used for dairy milk processing. We calculated the following three water use indicators to analyze different forms of water used and consumed in the dairy processing plants, as follows:

The direct water usage accounted for the total direct water used for milk processing activities in the dairy milk processing plant, expressed as follows:

Direct water usage (DWU) (liters of water per kg of milk processed) = water usage (liters)/kg of milk processed.

The direct water footprint accounted for the direct water consumed (i.e., the water used minus effluent discharged) in the milk processing plant, expressed as follows:

Direct water footprint (DWF) (liters of water per kg of milk processed) = direct water consumed (i.e., water used − effluent returned) (liters)/kg of milk processed.

The indirect water footprint accounted for the indirect water consumed in the milk processing plant. The indirect water in dairy milk processing plants could be associated with other inputs required in various milk processing activities. Dairy milk processing requires both heating (to variable temperatures depending on the types of milk products to be made), cooling, and storage at refrigeration temperature (except for milk powder); therefore, the indirect water footprint could be proportional to the energy involved in the particular processing and storage activity in the milk processing plant.

In this study, the indirect water footprint was quantified as associated with energy consumption as the primary source of indirect water in the selected dairy milk processing plants. In Punjab, 74% of the electricity is obtained from thermal energy, while the rest comes from hydropower energy [16]. As per the Central Electricity Authority (CEA) [29], about 18,000 L of water is consumed per giga joules of electricity produced from coal, while in hydro energy, the water footprint was quantified to be 9222 L/GJ. In this study, the water footprint of hydropower was quantified based on the surface area, potential evaporation, and electricity generated by the local major hydro reservoirs, including the Bhakhra Dam, Ranjit Sagar Dam, Pong Dam, UBDC, Mukerian, and Anandpur Sahib Hydel Projects, located in lower Punjab and Himachal Pradesh [16]. The hydropower water footprint (WFhydro) (m3/GJ) was calculated as the evaporative water loss from the surface of the reservoir divided by the energy produced by the hydropower plant [30,31], as follows:

where E0 is the annual open water evaporative loss from the reservoir (m3) and P is the annual energy production of the power plant (GJ). For Punjab, the water footprint of the Hydel Projects was estimated at an average of 9.22 m3/GJ, the weighted average at 9.00 m3/GJ, which is significantly lower than the average water footprint for hydroelectricity (68.00 m3/GJ) as reported by Mekonnen and Hoekstra [32].

WFhydro = E0/P

The water footprint of thermal electricity (18.00 m3/GJ) [29] and hydropower (9.22 m3/GJ) (quantified in this study) were averaged using a ratio of 0.74 and 0.26, respectively, to quantify the average water footprint of energy (electricity) in Punjab state. The calculated average water footprint of Punjab electricity (energy) was further multiplied by the energy (electricity) consumed in each dairy milk processing plant to quantify the indirect water footprint as follows:

Indirect water footprint (IWF) (liters of water per kg of milk processed) = energy (electricity) consumed (GJ)* average water footprint of Punjab electricity (energy (liters/GJ)/kg of milk processed

It is worth mentioning that furnace oil (FO) was used as an energy source for steam generation using boilers in the study plants. However, electricity was the main source of energy, accounting for more than 80% of the total energy consumed in the study plants. Due to the lack of data available, the accounting of FO was omitted in the calculation of the IWF of the study plants.

Finally, the total water footprint (TWF) was calculated as the sum of the direct (Equation (2)) and indirect (Equation (4)) water footprints for the selected dairy milk processing plants.

2.4. Data Analysis

The quantified DWU, DWF, IWF, and TWF were analyzed for their spatial and temporal (annual and seasonal) variability across the selected dairy milk processing plants. A multiple regression analysis was conducted to predict changes in the water usage in dairy milk processing (dependent variable) in response to the milk processing parameters (independent variables), such as the total milk processed in the milk plants. The explained variability in dairy processing water usage was measured via the adjusted R2 and the accuracy of the forecast of the statistical variable was ascertained via linear regression analysis. Principal component analysis (PCA) was performed to identify the products which were major contributors to the water footprint of the milk processing plants. A two-dimensional analysis of the principal components (PC) was applied, utilizing the component data matrix [33]. PCA analysis separated the most significant variables among the different attributes, using the Kaiser’s criterion (eigen value > 1). To clarify the results, the variables were orthogonally rotated using the Varimax technique to produce the correlation between different products associated with the water footprint of dairy milk processing in the selected dairy plants.

3. Results and Discussion

3.1. Water Used and Consumed in the Dairy Milk Processing Plants

The groundwater was used as a source of direct water supply in the selected dairy processing plants (Figure 1). The direct water supply was used and consumed in various milk processing activities in the study plants, as follows:

- (a)

- Direct Water Usage (DWU)

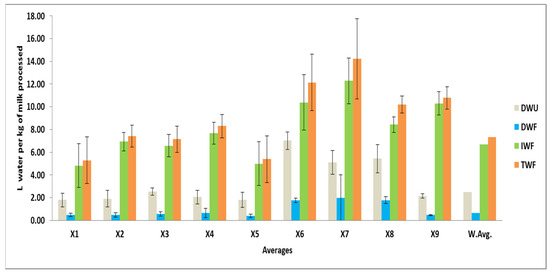

The average DWU of the study plants over the five years (2015–19) was quantified at 3.31 L of water per kg of milk processed (Figure 3). As compared to the average DWU (3.31 L/kg), the study plants X6 (7.02 L/kg), X8 (5.43 L/kg), and X7 (5.10 L/kg) had a relatively higher DWU, while plants X1 (1.79 L/kg) and X5 (1.82 L/kg) had a relatively lower DWU (Figure 3). This variation in DWU across the study plants may be attributed to differences in their milk product-making profile (i.e., product mix) (Table 2) and other technology and management practices (e.g., floor and tanker cleaning practices) [24]. Cleaning operations, including the cleaning in place (CIP), are directly responsible for 70% of the water usage requirements [34]. Plants like X1 and X5 were technologically upgraded milk plants with installed water-saving equipment, as compared to the X6, X8, and X7 plants. Further, operational capacity appears not to significantly affect DWU in some milk processing plants, as Plant X5 was operating at 107% of the installed capacity compared to Plant X7 (100% of the installed capacity).

Figure 3.

Average direct water used and direct and indirect water footprints (based on water consumption) for nine (09) study dairy milk processing plants in Punjab state (India), from 2015 to 2019. The abbreviation DWU stands for the direct water usage; DWF stands for the direct water (consumed) footprint; IWF stands for the indirect water (consumed) footprint; and TWF stands for the total water footprint.

- (b)

- Direct Water Footprint (DWF)

The average DWF, which is a measure of the quantity of water consumed (evaporative losses) per kg of milk processed (Equation (2)), was calculated at 0.95 L/kg of milk processed in the study milk plants during the study period of five years (2015–19) (Figure 3). The plant-wise analysis indicated that the average DWF was relatively higher (1.76 to 1.96 L/kg) in plants X7, X8, and X6, while being relatively lower (0.40 to 0.47 L/kg) in plants X5 and X2 (Figure 3), which could be attributed to the higher reception of Liquid Milk in the X2 and X5 plants and, therefore, less reconstitution of Milk Powder into Liquid Milk during the lean seasons. Vourch et al. [23] reported water consumption during milk processing in the range of 1.2 to 3.4 L of water per liter of milk processed in France. Olmstead et al. [35] reported a water consumption of milk processing in the range of 0.98 to 2.98 L of water per liter of white and flavored milk processed in an Australian study. In similar studies in Poland, Wojdalski et al. [24] and Boguniewicz-Zablocka et al. [36] reported water consumption in the range of 4.29–7.65 and 3.2–4.0 L of water per kg of milk processed. In this study, the average direct water consumption (DWF) (0.95 L/kg) was quantified as relatively lower as compared to, e.g., in France [23], Australia [35], and Poland [24,36].

However, on average, the average DWF (0.95 L/kg) was quantified as relatively much lower than the average DWU (3.31 L/kg) of the study plants (Figure 3). This suggests that >70% of the direct water used in dairy milk processing is not consumed but discharged as effluent in the study plants.

- (c)

- Indirect Water Footprint (IWF)

The average IWF associated with energy (electricity) consumption was quantified at 8.04 L per kg of milk processed in the study plants during the study period of five years (2015–19) (Figure 3). The average IWF was quantified as relatively higher in plants X7 (12.28 L/kg), X6 (10.39 L/kg), X9 (10.30 L/kg), and X8 (8.42 L/kg), while a relatively lower IWF was quantified in plants X1 (4.81 L/kg), X5 (4.99 L/kg), and X3 (6.58 L/kg) (Figure 3). This variation in IWF across the study milk processing plants may be attributed to the quantity of milk handled by individual plants, their milk product-making profile, and technology-related factors affecting variability in their energy consumption. All other study plants except for X3 and X5 had milk-drying (powder-making) facilities besides milk processing into other milk products (Table 2). Milk drying is the most energy-intensive process, where milk with around 87% moisture is dried into Milk Powder with less than 3.0 percent moisture. Therefore, the milk processing plants with a higher proportion of Milk Powder (MP) drying facilities (such as X6, X8, and X9) (Table 4) resulted in a relatively higher IWF as compared to the milk processing plants without drying facilities (such as X3 and X5) (Table 4). Besides milk drying (Milk Powder making), Ice Cream making involves the ageing of Ice Cream mix at 5 °C for 8 to 12 h, followed by Ice Cream freezing at subzero temperature (−5 to −7 °C), and its hardening and storage at (−30 to −18 °C) is another energy-intensive process in dairy milk processing plants. Energy consumption in various operations of Ice Cream making was calculated by Singh et al. [37], and they reported that 72% of electricity was consumed in the refrigeration section. In the present study, plant X6 had both Milk Powder and Ice Cream in their product profile, which led to a higher IWF. See Section 3.3 for further potential influences of the dairy milk processing product mix on the water footprint of the studied dairy milk processing plants.

- (d)

- Total Water Footprint (TWF)

The average TWF, the sum of the averages of DWF and IWF, was quantified at 9.0 L/kg of milk processed for the study plants during the study period of 2015–19 (Figure 3). Interestingly, a large share of the average TWF was contributed by the IWF (89%), while the DWF accounted for only 11%. This highlights the potential scope of reducing dairy milk processing water footprints by improving the sources and consumption of energy in dairy milk processing plants.

3.2. Seasonal Variability in Water Used and Consumed in the Dairy Milk Processing Plants

India is a tropical country with well-defined seasons. From the dairy husbandry and milk production points of view, it has been classified into two seasons, i.e., a lean season from April to October (summer months) and a flush season from November to March (winter months). There is plenty of dairy milk production in the flush (winter) season. After meeting the daily demands of their households, farmers generally sell surplus milk to dairy milk processing plants. However, due to a significant reduction in milk production during the lean season (summer), the quantity of surplus milk to be sold to the dairy milk processing plants by the dairy farmers gets significantly reduced. Therefore, to meet the daily demand for Liquid Milk and milk products, dairy processing plants generally augment their milk production by the reconstitution of dried Milk Powder into pasteurized Liquid Milk and other dairy products in the lean (summer season). This seasonal variation in the supply and production of dairy milk and its products could affect a seasonal variation in the water footprint associated with dairy milk processing.

In this study, a significant variation (p < 0.05) was observed in both direct and indirect water footprints on a seasonal (summer and winter) and annual basis (Table 3). The average water used (DWU) and consumed both directly (DWF) and indirectly (IWF) were quantified as relatively higher during the lean (summer) season as compared to the flush (winter) season. On average, the study plants processed about 23% less milk but consumed about 37% more water (both directly and indirectly) during the lean (summer season), as compared to the flush (winter season). Study plant X1 consumed 0.20 L of water per kg of milk processed in 2017, while plant X7 consumed 5.01 L of water per kg of milk processed in 2016. These seasonal and annual variations in water consumption for processing a unit quantity of milk may be attributed to changes in the quantity of milk handled by each milk plant, besides changes in their product profile vis-à-vis the amount of milk.

Table 3.

Average (mean) dairy milk processed and its associated average (mean) water used or consumed (in liters per kg of milk processed) of the study (09) dairy milk processing plants in Punjab (India) from 2015 to 2019. * Means (n = 9) in the same row with superscripts are significantly different (p < 0.05).

The average TWF was quantified to be highest (10.08 L of water per kg of milk processed, L/kg) during the year 2016, while the lowest TWF (7.17 L/kg) was quantified during the year 2017 (Table 3). During the corresponding period, the total milk handled by all study plants was recorded at 27.48 million kg in 2016 and 72.85 million kg in 2017. This suggests that the quantity of milk processed had an inverse correlation with the TWF of dairy milk processing in the study plants.

The average TWF was quantified to be higher (10.38 L/kg) in the lean (summer) season, as compared to the flush (winter) season, when it decreased to 7.56 L/kg only (Table 3). The main reason for the higher TWF in the lean (summer) season may be attributed to the reconstitution of Milk Powder, which leads to increased direct water consumption in milk processing. The average DWF was quantified as about 42% higher in the lean (summer) season (1.19 L/kg), as compared to 0.84 L/kg in the flush (winter) season (Table 3). Also, a higher ambient temperature, which increases the temperature difference (∆t) and, therefore, the refrigeration load, could result in a higher IWF associated with energy consumption during the summer season. The average IWF was quantified as about 37% higher in the lean (summer) season (9.19 L/kg), as compared to 6.72 L/kg in the flush (winter) season (Table 3). Wojdalski et al. [24] also reported a relatively higher TWF of 5.36 L/kg in summer compared to 4.88 L/kg during the winter season for a composite dairy plant with different types of products in Poland.

3.3. Relationship between Dairy Processing Product Mix and Its Water Footprint

Dairy milk processing into different dairy product mixes could affect the water footprint associated with dairy milk processing. In this study, all nine study milk plants were composite dairy plants engaged in the processing and packaging of pasteurized Liquid Milk, besides making various dairy products (Table 4). In India, because of people’s Liquid Milk drinking habits, there is more demand for fresh Liquid Milk, mainly supplied as pasteurized Liquid Milk by organized sector milk processing plants. This trend is reflected in Table 4, reporting the majority (>84%) of the milk processing towards Liquid Milk products in the study milk plants over five years, from 2015 to 2019.

Table 4.

A composition of dairy milk product mix produced, milk processed, and total water consumed in the (09) study dairy milk processing plants in Punjab state (India), from 2015 to 2019. TWF stands for the total water footprint, accounting both the direct and indirect (associated with energy) water consumed in the milk processing.

In average terms, the milk share used for making different products was mainly for pasteurized Liquid Milk (83.77%), Dahi (6.29%), Milk Powder (3.42%), Paneer (2.23%), Ghee (2.21%), Butter (2.04%), Ice Cream (0.38%), and Milk Cake (0.01%) (Table 4). Processing milk products like Dahi involves heating milk to 85–90 °C and holding it at this temperature for 5–10 min, then cooling it to 37–42 °C for starter culture addition before incubation. Similarly, Paneer processing involves heating milk to 85–90 °C and then cooling it to 70 °C [38,39] before adding a coagulant. In the dairy industry, water is used both as a heating and cooling medium in the form of steam/hot water and chilled water, respectively. The lowering of milk temperature from 90 °C to 70 °C during Paneer processing and 90 °C to 37–42 °C for Dahi processing is mainly achieved by circulating chilled water or regular tap water at an ambient temperature [40]. Also, variability in energy consumption is required for processing dairy milk into a variable product mix. Alli et al. [41] reported the highest electricity consumption in the refrigeration section (53.72%), followed by the pasteurization and milk packaging section (22.42%), effluent treatment (6.13%), and miscellaneous (5.74%) in a commercial dairy milk processing plant with a 0.05 million liters per day milk processing capacity. As per ETSU [42], the energy consumption in Liquid Milk processing plants takes place in the refrigeration of milk (19%), followed by milk processing treatments (14%) and cleaning (cleaning in place—CIP) of equipment (14%), while in dairy milk processing plants with cheese- or Milk Powder-making sections, the highest energy is consumed in milk drying by spray dryers (22%) and evaporators (22%). Therefore, a milk plant with a combination of dairy products such as Milk Powder, Dahi, and Panner could have a higher water footprint associated with direct water consumed in heating and cooling and indirect water footprinting in the form of energy consumed.

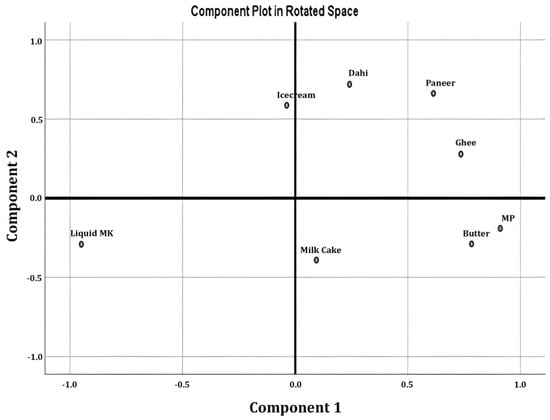

In this study, the plant-wise data of the product mix vis-à-vis TWF (including direct and indirect water consumed) have been analyzed using a principal component analysis (PCA) (Figure 4). The first two PCs (PC1 and PC2) accounted for 63% of the variation in the TWF of the study plants. Under PC1, Milk Powder, Butter, and Ghee showed a higher positive correlation, while Liquid Milk showed a negative correlation. Under PC2, a higher positive correlation was observed for Dahi and Paneer, while a negative correlation was observed for Liquid Milk, Butter, and Milk Powder. In PC1 and PC2, a correlation between the products and the TWF suggests that if the production of the negatively correlated products is minimized, there would be a significant reduction in the total water footprint of daily milk processing in the study plants. It is evident from Figure 4, presenting Varimax rotated PC factor loadings, that a strong correlation was observed in the loadings (>0.5 value) of the PCs for Liquid Milk, Milk Powder (MP), Butter, Ghee, and Dahi as the significant contributors to the TWF of the dairy processing plants. This further confirmed that the type of process operations involved in dairy milk processing and the choice of product mix are important components concerning water consumption in dairy milk processing.

Figure 4.

A principal component analysis of the milk products in the (09) study dairy milk processing plants in Punjab (India), over the period of 5 years (2015–19).

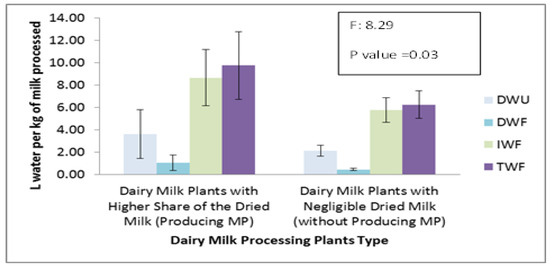

Based on the types of milk products produced, the study milk plants were categorized into two broader categories, viz., (i) milk plants with a higher share of dried milk (producing Milk Powder), noted as X8 and X9, and (ii) milk plants with negligible dried milk (without producing Milk Powder), noted as X3 and X5 (Table 4). Figure 5 presents the significant (p < 0.05) variation in water use and footprints in both categories of the milk plants. The plants with a higher share of dried Milk Powder (X8 and X9) had a higher water usage and water footprint than those without dried Milk Powder processing (X3 and X5).

Figure 5.

A comparison of water usage and water footprints in the dairy milk processing plants producing a higher share of milk as dried Milk Powder and no dried Milk Powder in their product mix in Punjab state, over a period of 5 years (2015–19).

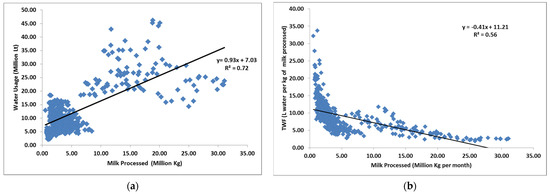

A linear regression analysis further reveals a strong relation between the milk processed and water usage in the study plants (Figure 6a). The higher value of R2 0.72–0.77 further confirmed the strong relationship between milk processing activities and water used in the study dairy processing plants. The monthly water usage is modeled as a factor of 0.93 of the monthly milk processed in the study plants. A further linear regression analysis revealed a strong inverse relationship between the average monthly milk processed and the TWF of the study plants (Figure 6b). Wojdalski et al. [24] also found, in their analysis of milk processing plants in Poland, a strong relationship (R2 of 0.64–0.83) between milk processing and water utilization in dairy processing. The formulas produced in Figure 6a,b (where R2 was obtained > 0.50) could be used for modeling water consumption demands in dairy milk processing plants.

Figure 6.

A correlation between monthly dairy milk processed and water used in milk processing activities(a) and total water consumed (TWF) in milk processing activities (b), in the (9) study dairy milk processing plants in Punjab, India, from 2015 to 2019.

3.4. Assessment of Dairy Processing Water Footprint Impact on Water Resources in Punjab State

Punjab is India’s leading agrarian state, contributing significantly to the country’s food security. However, in recent years, because of the over-drafting of groundwater for the irrigation of water-intensive crops such as rice, the state has witnessed a severe decline in its groundwater levels. Annually, 35.78 billion cubic meters (BCM) of groundwater is drafted against the available groundwater of 21.58 BCM, which is estimated to be around a 166% over-drafting of groundwater in the state (Table 5). This is rendering contemporary groundwater use highly unsustainable in Punjab [26]. Further, out of the total groundwater drafted, nearly 96% is utilized for agricultural irrigation purposes, and only 4% is used for industrial and domestic usage (Table 5).

Table 5.

Assessment of groundwater resources of Punjab [26].

Over five years (2015–19), the direct water usage in dairy milk processing varied, on average, from 0.13 million cubic meters (MCM) per year (in X9) to 1.46 MCM per year (in X1), with a total of 5.85 MCM per year in all study plants (Table 5). An extrapolation of the quantified direct water usage suggested that dairy milk processing plants in Punjab are approximately utilizing around 27.64 MCM of groundwater per year (Table 5), i.e., about 2.27% of the total groundwater usage in the industrial and domestic sectors, and only 0.08% of total groundwater usage in agricultural activities in the state.

The predominant rice–wheat system in Punjab is significantly affecting water consumption, particularly in terms of the unsustainable withdrawal of groundwater and the drying of aquifers. The average DWF of dairy milk processing is quantified, on average, at 0.95 L of groundwater per kg of milk processed in the study milk plants. The corresponding water used to produce one kilogram of rice in Punjab state is estimated to be 2053 L of groundwater [43].

As summarized in Table 5, the direct water footprint of milk processing varied, on average, from 0.03 MCM per year (in X9) to 0.39 MCM per year (in X1), with a total of 1.54 MCM per year in all nine study dairy processing plants (Table 5). In percentage terms, the study plants consumed only 26% of the direct water used (DWU) (5.85 MCM per year) in various milk processing activities. The remaining 74% of the total water used was discharged as effluent generated (4.31 MCM per year).

Although the current DWF of dairy milk processing is estimated to be much lower compared to the share of groundwater used for crop production activities in Punjab (Table 5), by the recycling of treated effluent for different dairy operations, the DWF of milk processing can be further reduced and contribute towards the long-term sustainability of water use in dairy milk processing plants in the state. Currently, all effluent discharges thus generated by the study milk processing plants are mainly used for plantation purposes after their treatment at an effluent treatment plant (ETP).

4. Conclusions

Punjab is a leading milk-producing state in India and contributes around 6.4 per cent to the total national milk pool. With the formalization of the dairy sector, the share of commercially organized dairy milk processing plants is continuously increasing, processing increasing amounts of raw milk into various dairy processing product mixes. Milk processing is considered as a water-intensive activity. However, a limited study has been conducted on the quantification and assessment of the water footprint of dairy milk processing in Punjab and other parts of India. We conducted a comprehensive analysis of water used and consumed over five years (2015–2019) in nine dairy processing plants spread over Punjab.

Groundwater is the main source of direct water supply in the study dairy processing plants. The current direct use of groundwater in dairy milk processing is estimated to be relatively much lower, at only about 0.08%, compared to the estimated usage of groundwater in agricultural activities in Punjab. Considering the implications of depleting groundwater levels, it is essential to adopt suitable measures to reduce the water footprint of current and future dairy milk processing and dairy products to reduce the environmental impact of growing dairy processing in Punjab.

Over the five years (2015–2019), the direct water use (DWU) was quantified at 3.31 L of water per kg of milk processed, while the direct water consumed (DWF) was quantified at 0.95 L of water per kg of milk processed. More than 70% of the direct water used in dairy milk processing is not consumed but discharged as effluent in the study plants. The effluent discharges generated by the study plants are mainly used for plantation purposes after their primary and secondary treatments at the effluent treatment plant. By adopting further advanced technical interventions like membrane processing treatments [44] like ultrafiltration (UF), reverse osmosis (RO), and bulk nanobubble technology [45,46], the treated effluent water can be potentially recycled for various operations like milk tanker cleaning and floor cleaning in dairy plants, as well as for general sanitary services in dairy processing plants.

The average total water footprint (TWF), accounting for both direct and indirect water consumed, was quantified at 9.0 L of water per kg of milk processed for the study plants during the study period of 2015–19. Interestingly, a large share (89%) of the average TWF was contributed by the indirect water footprint associated with the electricity (energy) consumed in various dairy milk processing activities. This highlights the potential of reducing dairy milk processing water footprints by focusing on improving the sources and consumption of energy in dairy milk processing. Further research is required in the reduction of energy consumed and the potential use of alternative energy sources, with lower water and carbon footprints, in processing of dairy milk activities in the state. Punjab has high average sunshine hours in a year, making it a suitable location for the adoption of renewable energy, such as solar power, for augmented energy supply to the milk processing plants.

The plant-wise analysis highlighted a significant variation in both the direct and indirect water footprints of dairy milk processing in the study plants. On average, a significant variation was observed in the seasonal and annual water footprint of dairy milk processing in the study plants. This variation could be partly attributed to the milk processing capacity and product mix produced in the study pants. The average monthly TWF showed an inverse relationship with the average monthly milk processed in the study plants. Also, the production of dry Milk Powder and its subsequent use in the reconstitution of Liquid Milk (during the lean summer season) affected the TWF of dairy milk processing in the study plants. This suggests the potential for a further optimization of dairy processing product mixes and the locations of dairy processing plants. A dairy processing product mix requiring a relatively higher TWF could potentially be located in areas with relatively lower groundwater stress. However, this requires further research into various processes and a product-wise quantification of water consumption by accurately measuring water flows and consumption in different production lines in dairy processing plants.

Author Contributions

Conceptualization, H.S., P.K.S., I.K. and R.S.; methodology, H.S., P.K.S., I.K. and R.S; data curation, H.S.; formal analysis, H.S.; writing—original draft preparation, H.S.; supervision, data analysis guidance, writing—review and editing, H.S., P.K.S., I.K. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the funding from TIF-AWaDH (Technology Innovation Hub- Agriculture and Water Technology Development Hub), Indian Institute of Technology, Ropar (Punjab) under National Mission on Interdisciplinary Cyber-Physical Systems (NM-ICPS) and APC was funded by OECD Co-operative Research Program: Sustainable Agricultural and Food Systems.

Data Availability Statement

Data Sources are contained within the article.

Acknowledgments

The authors would like to acknowledge TIF-AWaDH (Technology Innovation Hub–Agriculture and Water Technology Development Hub) at the Indian Institute of Technology, Ropar, Punjab, in the framework of the National Mission on Interdisciplinary Cyber-Physical Systems (NM—ICPS) for providing research funding. The Workshop was sponsored by the OECD Co-operative Research Program: Sustainable Agricultural and Food Systems, whose financial support made it possible for some of the invited speakers to participate in the Workshop.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mall, R.K.; Gupta, A.; Singh, R.; Singh, R.S.; Rathore, L.S. Water Resources and Climate Change. Curr. Sci. 2006, 90, 1610–1626. [Google Scholar] [CrossRef]

- Molden, D. Water for Food Water for Life: A Comprehensive Assessment of Water Management in Agriculture; Earthscan: London, UK, 2013. [Google Scholar] [CrossRef]

- Opio, C.; Gerber, P.; Steinfeld, H. Livestock and the Environment: Addressing the Consequences of Livestock Sector Growth. Adv. Anim. Biosci. 2011, 2, 601–607. [Google Scholar] [CrossRef]

- OECD/FAO. OECD-FAO Agricultural Outlook 2021–2030; OECD: Paris, France, 2021. [Google Scholar]

- Deutsch, L.; Falkenmark, M.; Gordon, L.; Rockström, J.; Folke, C. Water-Mediated Ecological Consequences of Intensification and Expansion of Livestock Production. In Livestock in a Changing Landscape; Island Press: Washington, DC, USA, 2010; Volume 1, pp. 97–110. [Google Scholar]

- FAO. Water Use in Livestock Production Systems and Supply Chains; FAO: Rome, Italy, 2019. [Google Scholar]

- Drastig, K.; Prochnow, A.; Kraatz, S.; Klauss, H.; Plöchl, M. Water Footprint Analysis for the Assessment of Milk Production in Brandenburg (Germany). Adv. Geosci. 2010, 27, 65–70. [Google Scholar] [CrossRef]

- Ridoutt, B.G.; Williams, S.R.O.; Baud, S.; Fraval, S.; Marks, N. Short Communication: The Water Footprint of Dairy Products: Case Study Involving Skim Milk Powder. J. Dairy Sci. 2010, 93, 5114–5117. [Google Scholar] [CrossRef]

- Zonderland-Thomassen, M.A.; Ledgard, S.F. Water Footprinting—A Comparison of Methods Using New Zealand Dairy Farming as a Case Study. Agric. Syst. 2012, 110, 30–40. [Google Scholar] [CrossRef]

- Manazza, J.F.; Iglesias, D.H. Water Footprint in Milk Agrifood Chain in the Subhumid and Semiarid Central Region of Argentina. In Proceedings of the International Association of Agricultural Economists (IAAE) Triennial Conference, Foz do Iguaçu, Brazil, 18–24 August 2012; pp. 1–24. [Google Scholar]

- Huang, J.; Xu, C.C.; Ridoutt, B.G.; Liu, J.J.; Zhang, H.L.; Chen, F.; Li, Y. Water Availability Footprint of Milk and Milk Products from Large-Scale Dairy Production Systems in Northeast China. J. Clean. Prod. 2014, 79, 91–97. [Google Scholar] [CrossRef]

- Murphy, E.; de Boer, I.J.M.; van Middelaar, C.E.; Holden, N.M.; Shalloo, L.; Curran, T.P.; Upton, J. Water Footprinting of Dairy Farming in Ireland. J. Clean. Prod. 2017, 140, 547–555. [Google Scholar] [CrossRef]

- Owusu-Sekyere, E.; Jordaan, H.; Chouchane, H. Evaluation of Water Footprint and Economic Water Productivities of Dairy Products of South Africa. Ecol. Indic. 2017, 83, 32–40. [Google Scholar] [CrossRef]

- Espíndola, J.C.; Mierzwa, J.C.; Amaral, M.C.S.; De Andrade, L.H. Water Reuse through Membrane Technologies for a Dairy Plant Using Water Pinch Simulation Software. Sustainability 2023, 15, 2540. [Google Scholar] [CrossRef]

- FAO. World Food and Agriculture—Statistical Yearbook 2022; FAO: Rome, Italy, 2022. [Google Scholar] [CrossRef]

- Economic and Statistical Organisation, Department of Planning, G. o. P. Statistical Abstract of Punjab 2021; Economic and Statistical Organisation, Department of Planning, G. o. P.: Mohali, India, 2021.

- Singh, O.P.; Kumar, M.D. Impact of Dairy Farming on Agricultural Water Productivity and Irrigation Water Use; 2007; pp. 85–98. Available online: https://cgspace.cgiar.org/items/e402efbf-c81b-4077-bfe5-45e642fa8a25 (accessed on 10 December 2023).

- Singh, O.P.; Singh, P.K.; Singh, R.; Singh, H.P.; Badal, P.S. Water Intensity of Milk Production: A Comparative Analysis from Waterscarce and Water Rich Regions of India. Econ. Aff. 2014, 59, 299–309. [Google Scholar] [CrossRef]

- Harika, R.; Pandey, D.; Sharma, A.; Sirohi, S. Water Footprint of Milk Production in Andhra Pradesh. Indian J. Dairy Sci. 2015, 68, 384–389. [Google Scholar]

- Amarasinghe, U.A.; Smakhtin, V.; Sharma, B.R.; Eriyagama, N. Bailout with White Revolution or Sink Deeper? Groundwater Depletion and Impacts in the Moga District of Punjab, India; IWMI: Colombo, Sri Lanka, 2010. [Google Scholar]

- Rao, G.V.L.N.; Srivastava, A.K.; Das, M.; John, A.J.; Prasad, S.N.; Gujarathi, P.; Srivastava, D.; Kumar, R. External Monitoring and Evaluation of the National Dairy Plan Phase I (National Dairy Support Project)—Baseline Study; Development and Research Services (P) Ltd.: New Delhi, India, 2013; p. 129. [Google Scholar]

- Prasad, P.; Pagan, R.; Kauter, M.; Price, N.; Crittenden, P. Eco-Efficiency for the Dairy Processing Industry. In The UNEP Working Group for Cleaner Production in the Food Industry; Environmental Management Centre, The University of Queensland: St. Lucia, Australia, 2004; p. 153. [Google Scholar]

- Vourch, M.; Balannec, B.; Chaufer, B.; Dorange, G. Treatment of Dairy Industry Wastewater by Reverse Osmosis for Water Reuse. Desalination 2008, 219, 190–202. [Google Scholar] [CrossRef]

- Wojdalski, J.; Drózdz, B.; Piechocki, J.; Gaworski, M.; Zander, Z.; Marjanowski, J. Determinants of Water Consumption in the Dairy Industry. Polish J. Chem. Technol. 2013, 15, 61–72. [Google Scholar] [CrossRef]

- Irfan, Z.B.; Mondal, M. Water Footprint Analysis in Dairy Industry in India. Int. J. Environ. Sci. Dev. 2016, 7, 591–594. [Google Scholar] [CrossRef]

- Anonymous. Ground Water Year Book Punjab and Chandigarh (UT) 2017-18; Central Ground Water Board, North Western Region Chandigarh, Department of Water Resources, River Development & Ganga Rejuvenation Ministry of Jal Shakti, Government of India: New Delhi, India, 2018; pp. 1–205.

- Department of Animal Husbandry, Ministry of Agriculture. Basic Animal Husbandry Statistics 2021; Government of India: New Delhi, India, 2021.

- Hoekstra, A.; Chapagain, A.; Aldaya, M.; Mekonnen, M. Water Footprint Manual: State of the Art; Water Footprint Network: Hengelo/Enschede, The Netherlands, 2009. [Google Scholar]

- CEA. Report on Minimisation of Water Requirement in Coal Based Thermal Power Stations; Central Electricity Authority: New Delhi, India, 2012; pp. 1–52.

- Herath, I.; Deurer, M.; Horne, D.; Singh, R.; Clothier, B. The Water Footprint of Hydroelectricity: A Methodological Comparison from a Case Study in New Zealand. J. Clean. Prod. 2011, 19, 1582–1589. [Google Scholar] [CrossRef]

- Gerbens-Leenes, P.W.; Hoekstra, A.Y.; van der Meer, T. The Water Footprint of Energy from Biomass: A Quantitative Assessment and Consequences of an Increasing Share of Bio-Energy in Energy Supply. Ecol. Econ. 2009, 68, 1052–1060. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. The Blue Water Footprint of Electricity from Hydropower. Hydrol. Earth Syst. Sci. 2012, 16, 179–187. [Google Scholar] [CrossRef]

- Jackson, J.E. A User’s Guide to Principal Components; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Vasilaki, V.; Katsou, E.; Ponsá, S.; Colón, J. Water and Carbon Footprint of Selected Dairy Products: A Case Study in Catalonia. J. Clean. Prod. 2016, 139, 504–516. [Google Scholar] [CrossRef]

- Olmstead, I.; Prasad, P.; Pagan, R.; Kauter, M.; Price, N.; Crittenden, P. Eco-Efficiency for the Dairy Processing Industry, 2019th ed.; Dairy Australia: Victoria, Australia, 2019. [Google Scholar]

- Boguniewicz-Zablocka, J.; Klosok-Bazan, I.; Naddeo, V. Water Quality and Resource Management in the Dairy Industry. Environ. Sci. Pollut. Res. 2019, 26, 1208–1216. [Google Scholar] [CrossRef]

- Singh, R.; Singh, P.K.; Kaur, I.; Kaur, R. Decomposition of Cost Structure and Evaluating Operational Feasibility of Low Fat Yoghurt Ice Cream. Indian J. Econ. Dev. 2016, 12, 483. [Google Scholar] [CrossRef]

- Kumar, S.; Rai, D.C.; Niranjan, K.; Bhat, Z.F. Paneer—An Indian Soft Cheese Variant: A Review. J. Food Sci. Technol. 2014, 51, 821–831. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Chandel, B.; Chauhan, A.; Das, J.; KM, R. Economics of Milk Processing in Cooperative Sector of Haryana. Indian J. Dairy Sci. 2021, 74, 255–261. [Google Scholar] [CrossRef]

- Mudgal, S.P.; Prajapati, J.B. Dahi-An Indian Naturally Fermented Yogurt; Elsevier Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Alli, M.M.; Chauhan, A.K.; Franco, D.; Singh, S.P. Economics of Resource Utilization for Manufacturing of Dairy Products in a Cooperative Dairy Plant in Coastal Odisha. Indian J. Econ. Dev. 2020, 16, 631–635. [Google Scholar] [CrossRef]

- ETSU. Reducing Energy Costs in Dairies—A Guide to Improved Profitability, Good Practice Guide 209, UK Energy Efficiency Best Practice Programme; ETSU: Oxford, UK, 1998. [Google Scholar]

- Srivastava, S.K.; Chand, R.; Raju, S.S.; Jain, R.; Kingsly, I.; Sachdeva, J.; Singh, J.; Kaur, A.P. Unsustainable Groundwater Use in Punjab Agriculture: Insights from Cost of Cultivation Survey. Indian J. Agric. Econ. 2015, 70, 365–378. [Google Scholar] [CrossRef]

- Kumar, R.V.; Goswami, L.; Pakshirajan, K.; Pugazhenthi, G. Dairy Wastewater Treatment Using a Novel Low Cost Tubular Ceramic Membrane and Membrane Fouling Mechanism Using Pore Blocking Models. J. Water Process Eng. 2016, 13, 168–175. [Google Scholar] [CrossRef]

- Jia, M.; Farid, M.U.; Kharraz, J.A.; Kumar, N.M.; Chopra, S.S.; Jang, A.; Chew, J.; Khanal, S.K.; Chen, G.; An, A.K. Nanobubbles in Water and Wastewater Treatment Systems: Small Bubbles Making Big Difference. Water Res. 2023, 245, 120613. [Google Scholar] [CrossRef]

- Levitsky, I.; Tavor, D.; Gitis, V. Micro and Nanobubbles in Water and Wastewater Treatment: A State-of-The-Art Review. J. Water Process Eng. 2022, 47, 102688. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).