Flocculants for the High-Concentration Activated Sludge Method and the Effectiveness of Urban Wastewater Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Test Equipment and Instruments

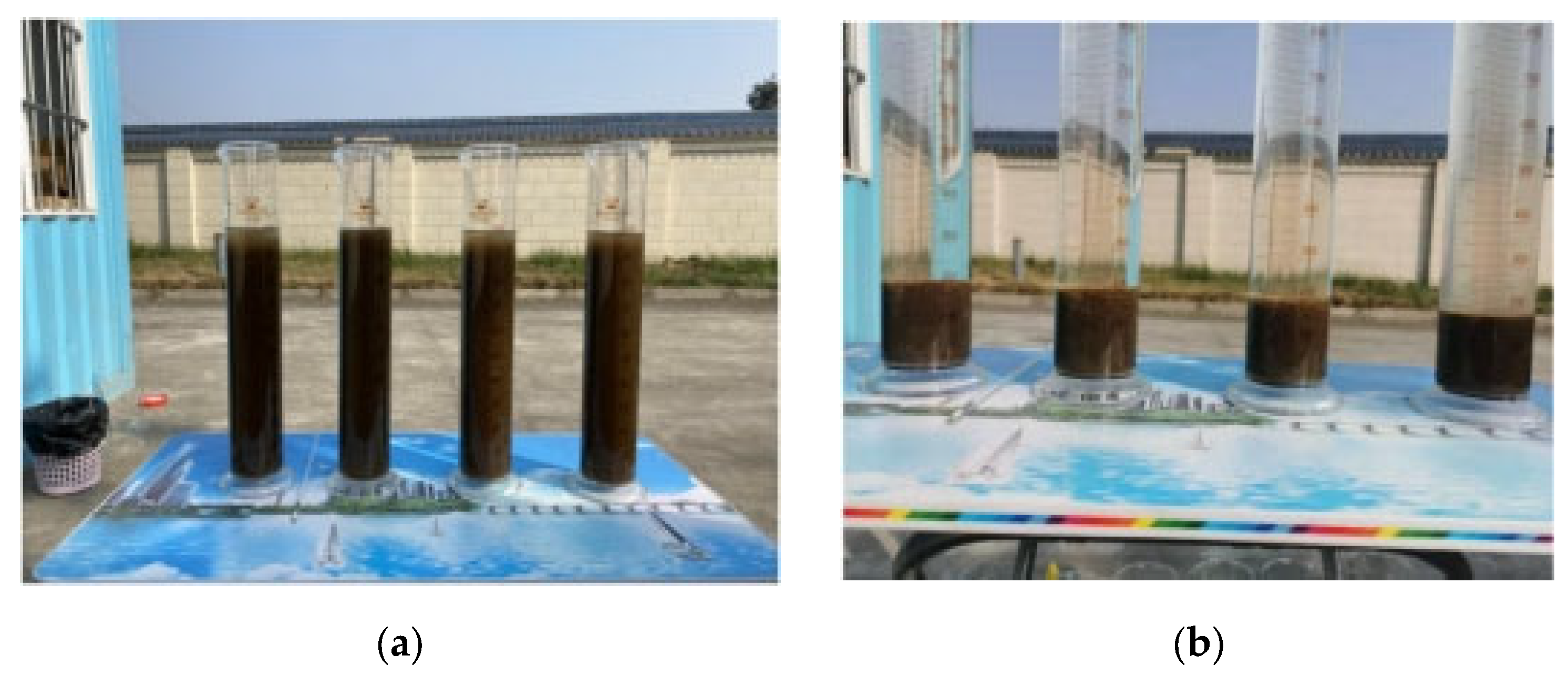

2.3. Test Methods

2.4. Test Equipment and Devices

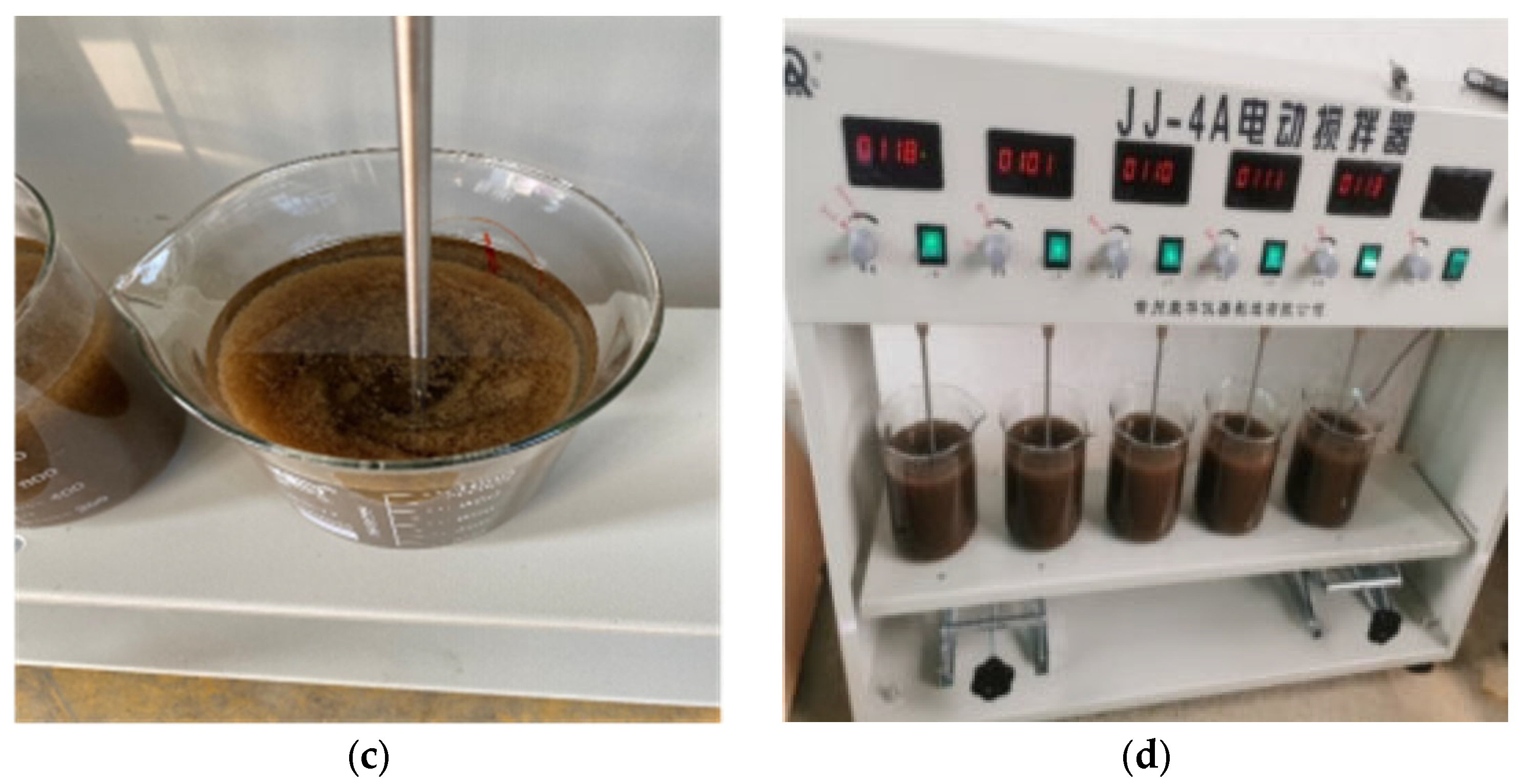

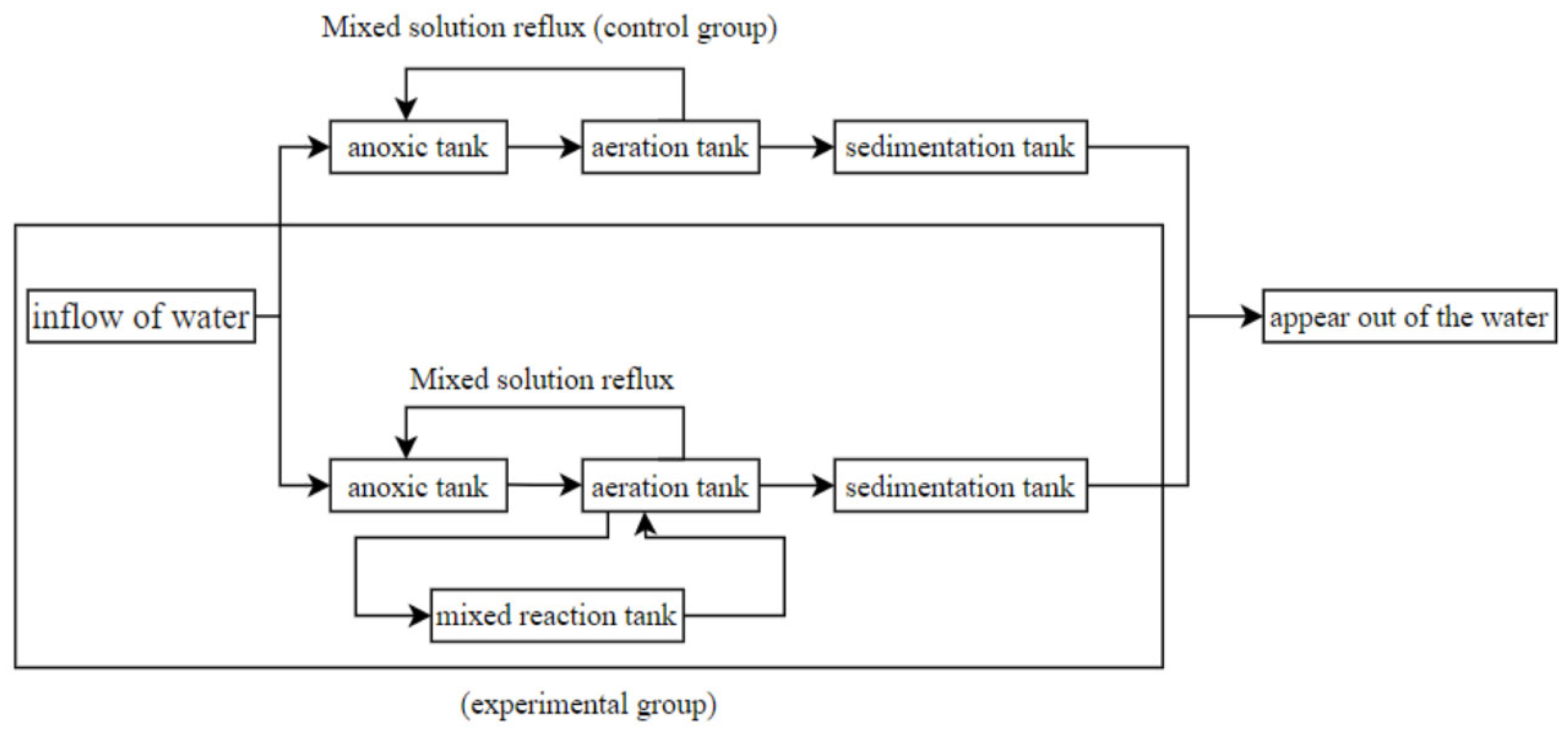

2.4.1. Pilot Test Equipment

2.4.2. Medium-Type Test Set

3. Results and Discussion

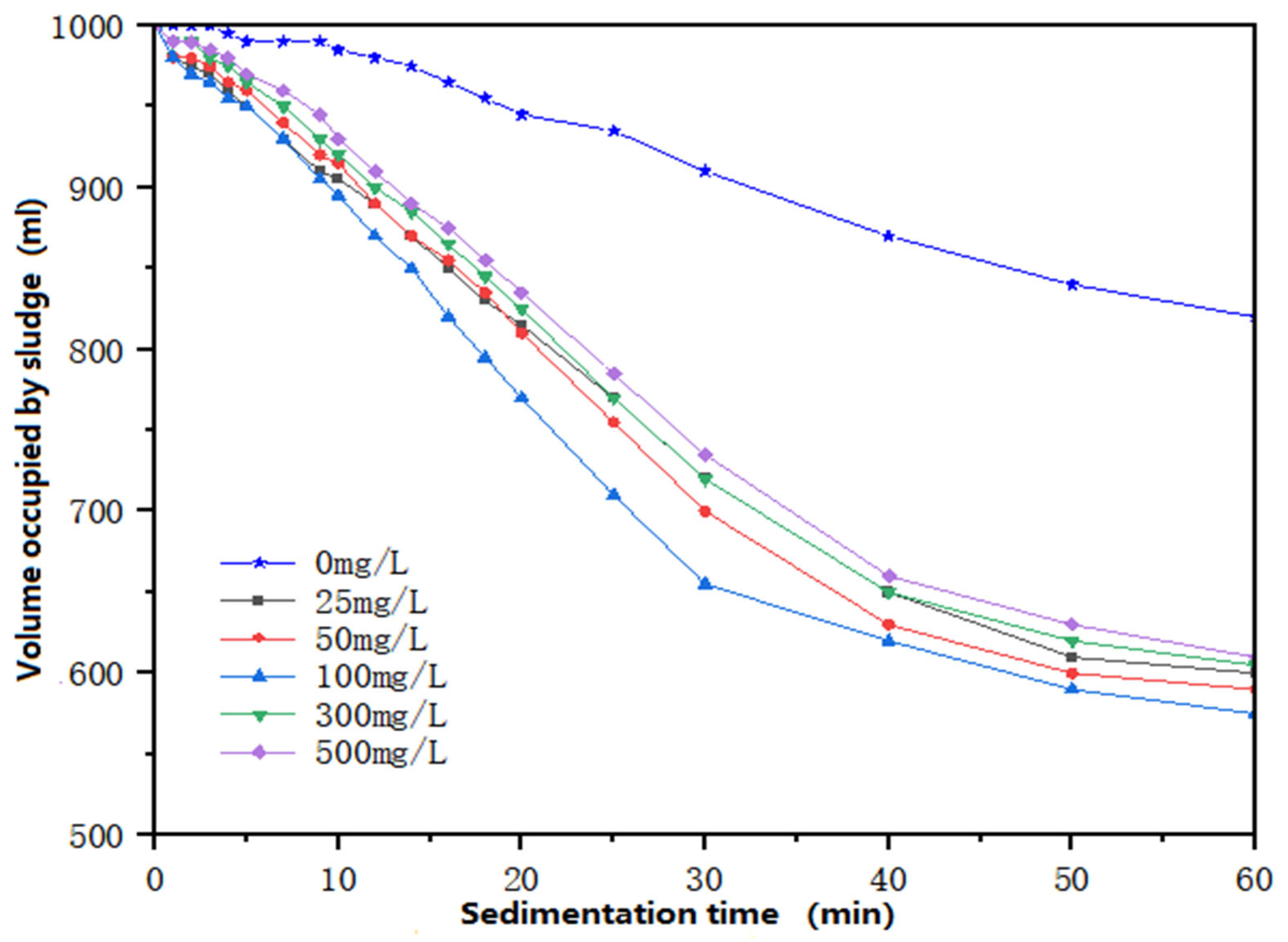

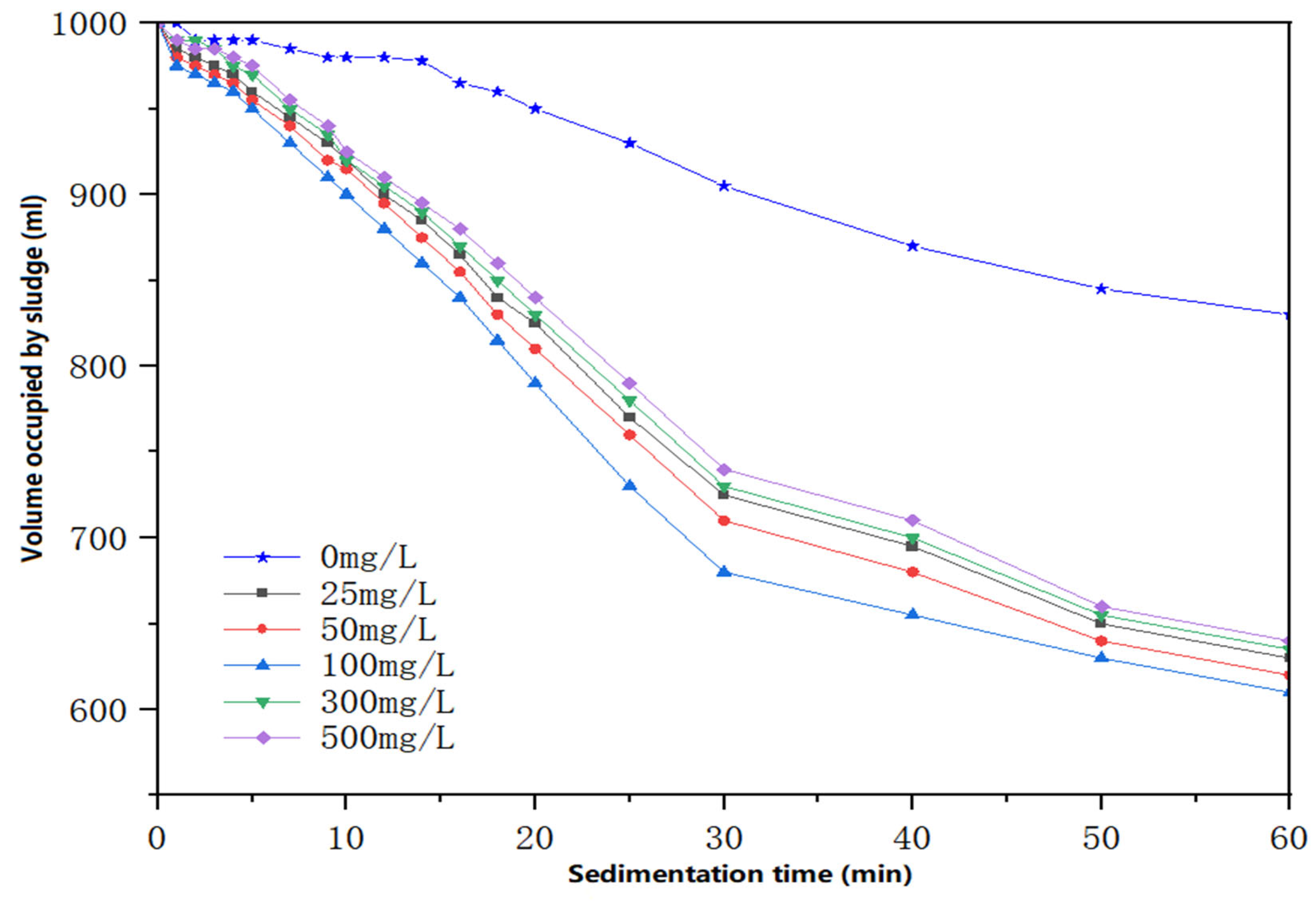

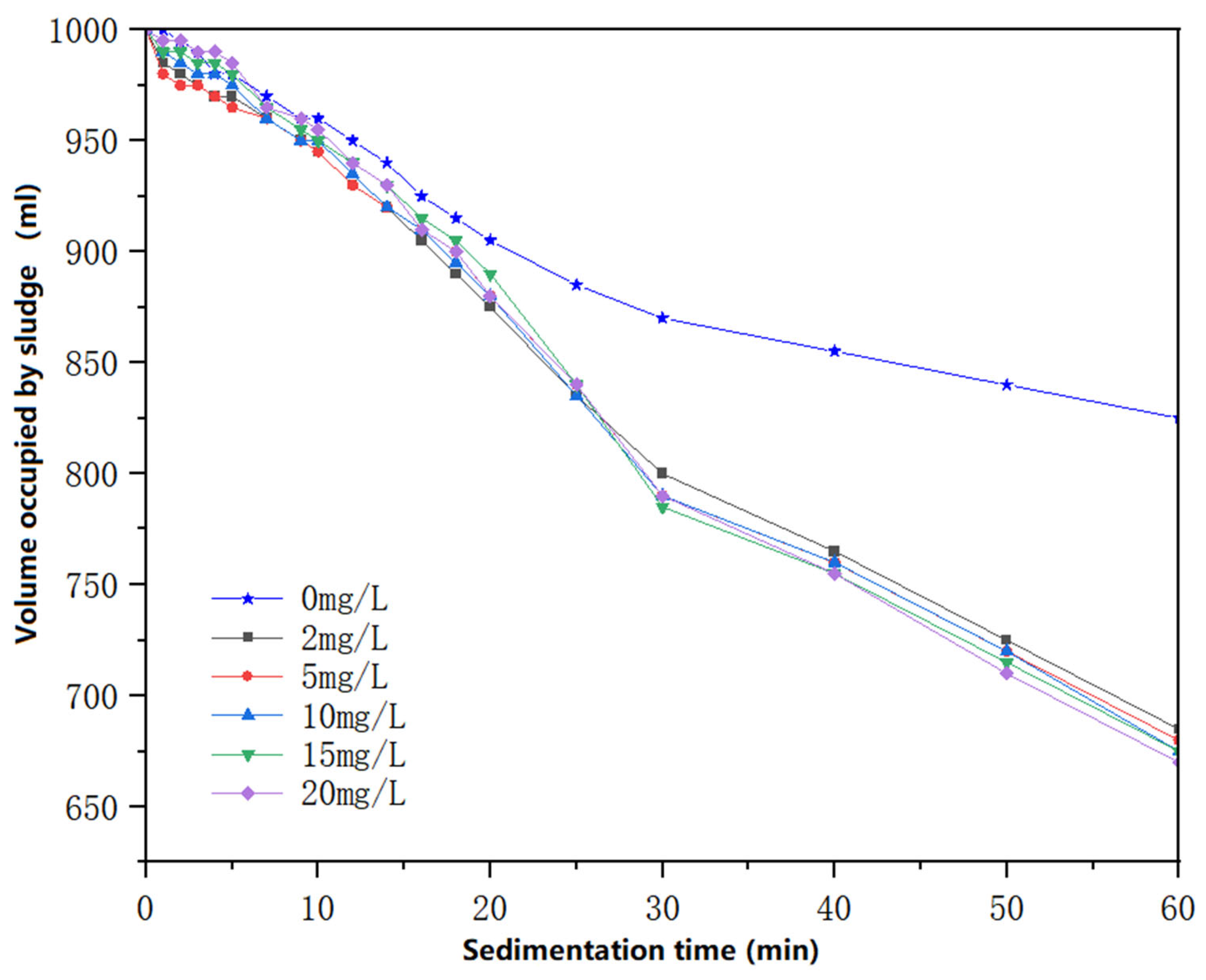

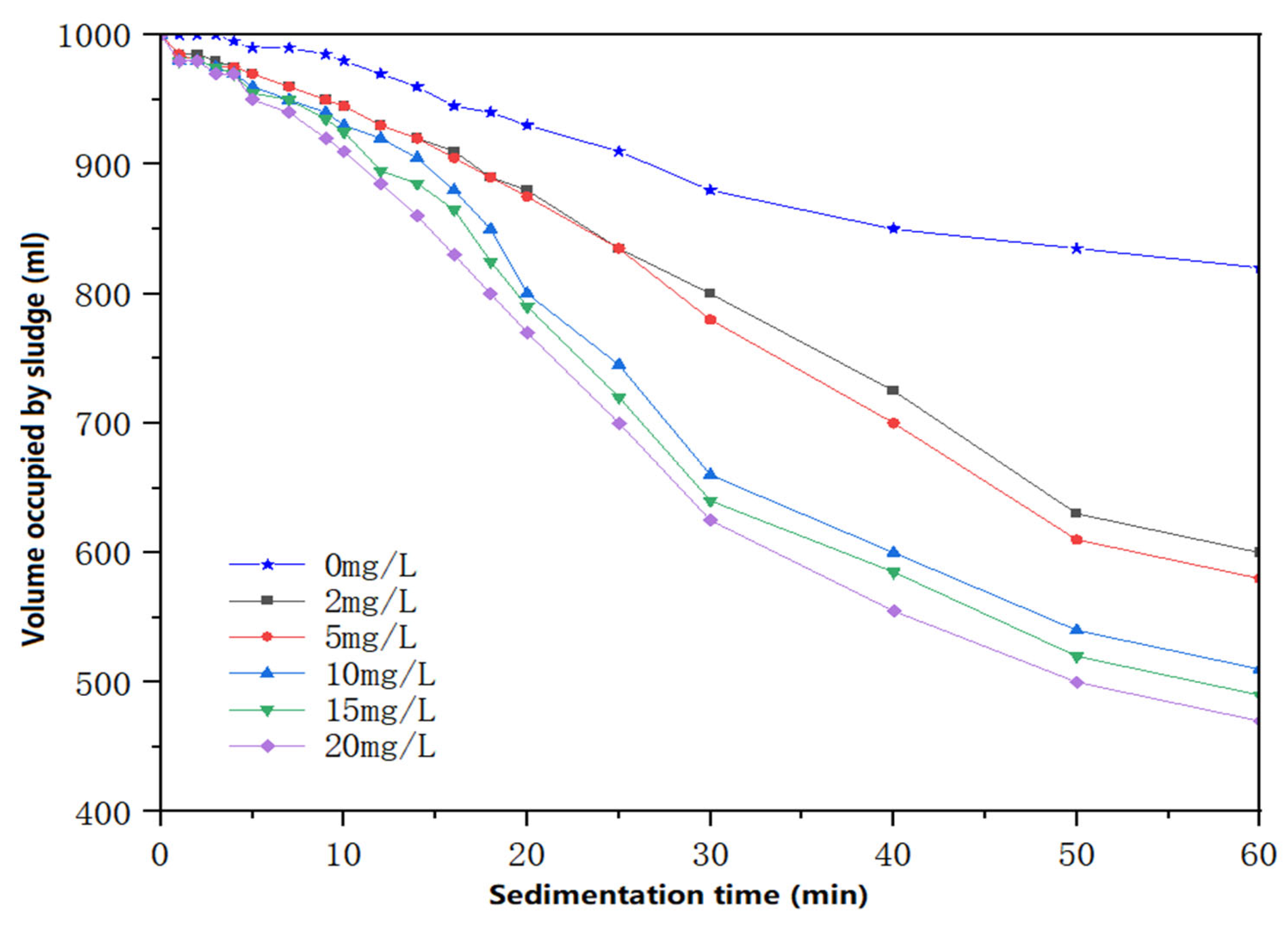

3.1. One-Way Flocculation Test

3.2. Orthogonal Test

3.3. Comparative Study of Lateral Flow High-Concentration Method and Conventional Activated Sludge Method

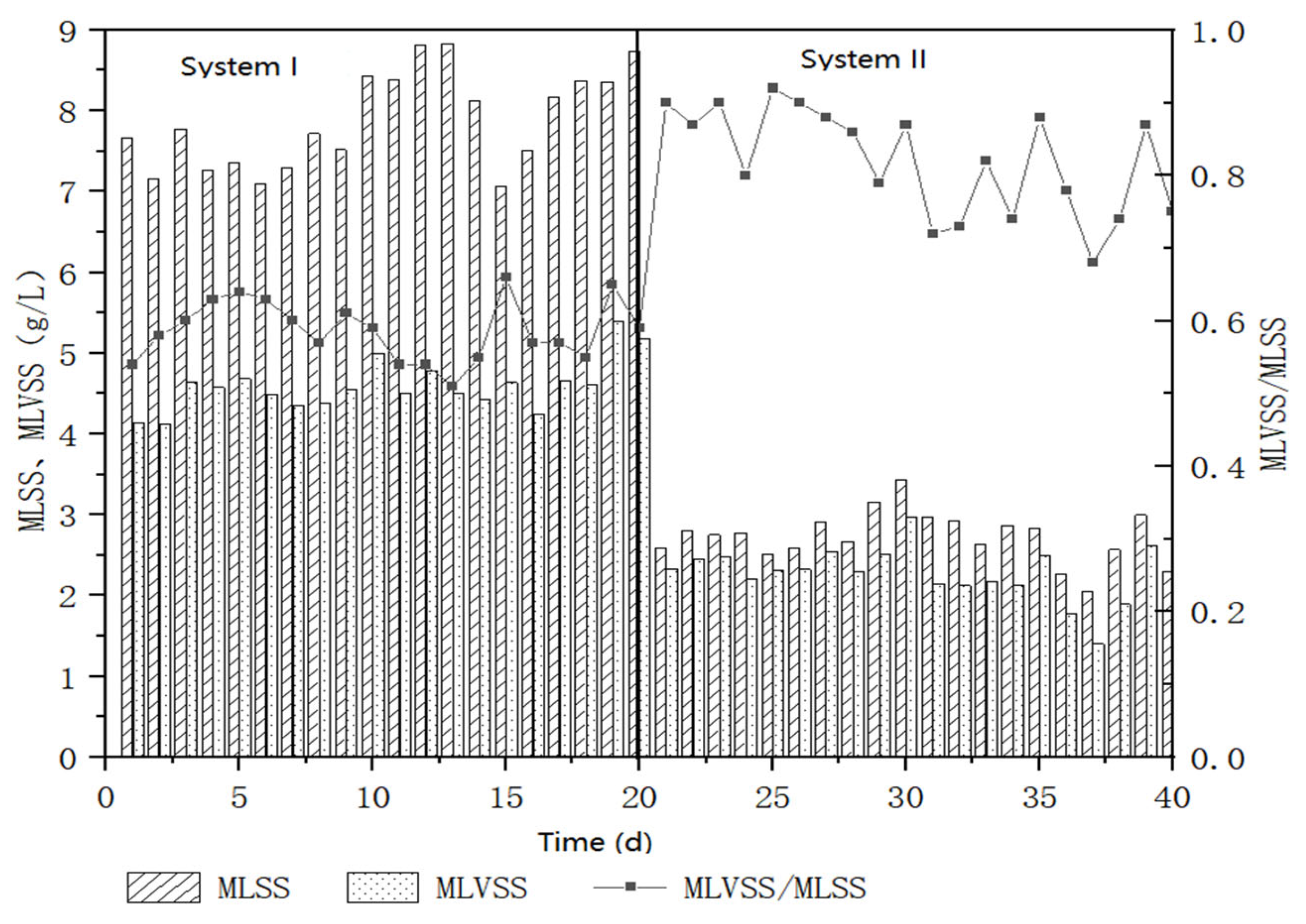

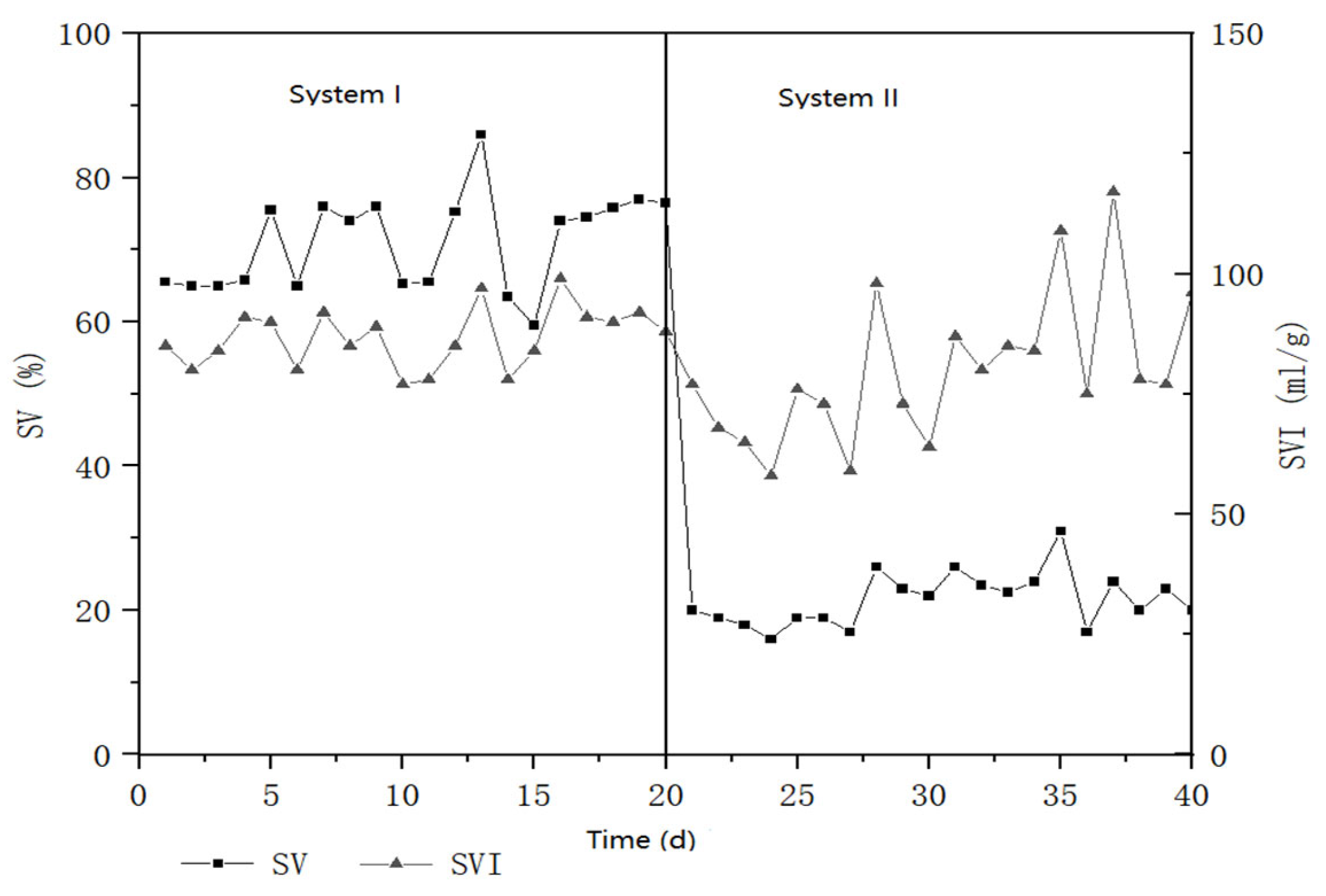

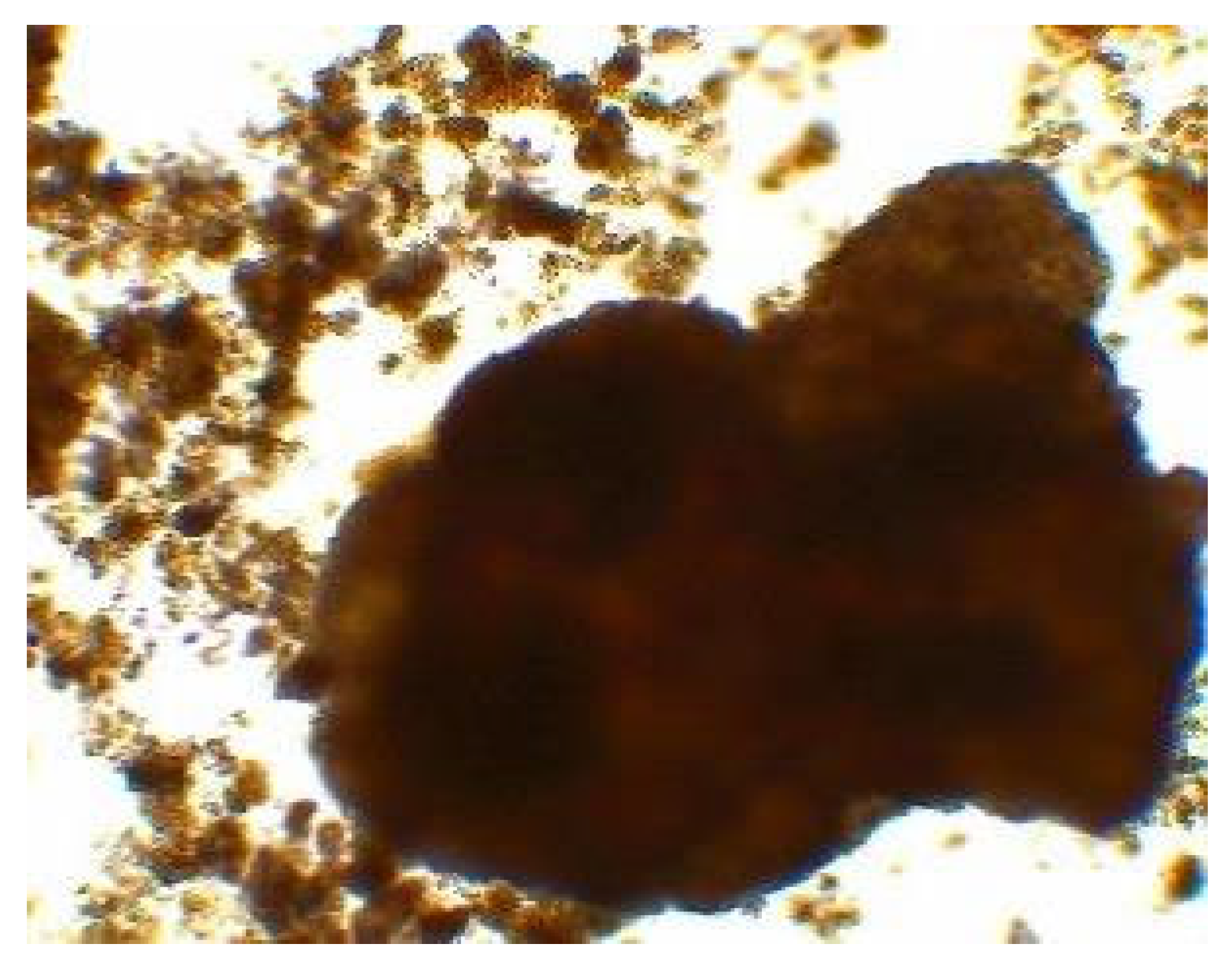

3.3.1. Comparison of Sludge Concentration and Settling Performance

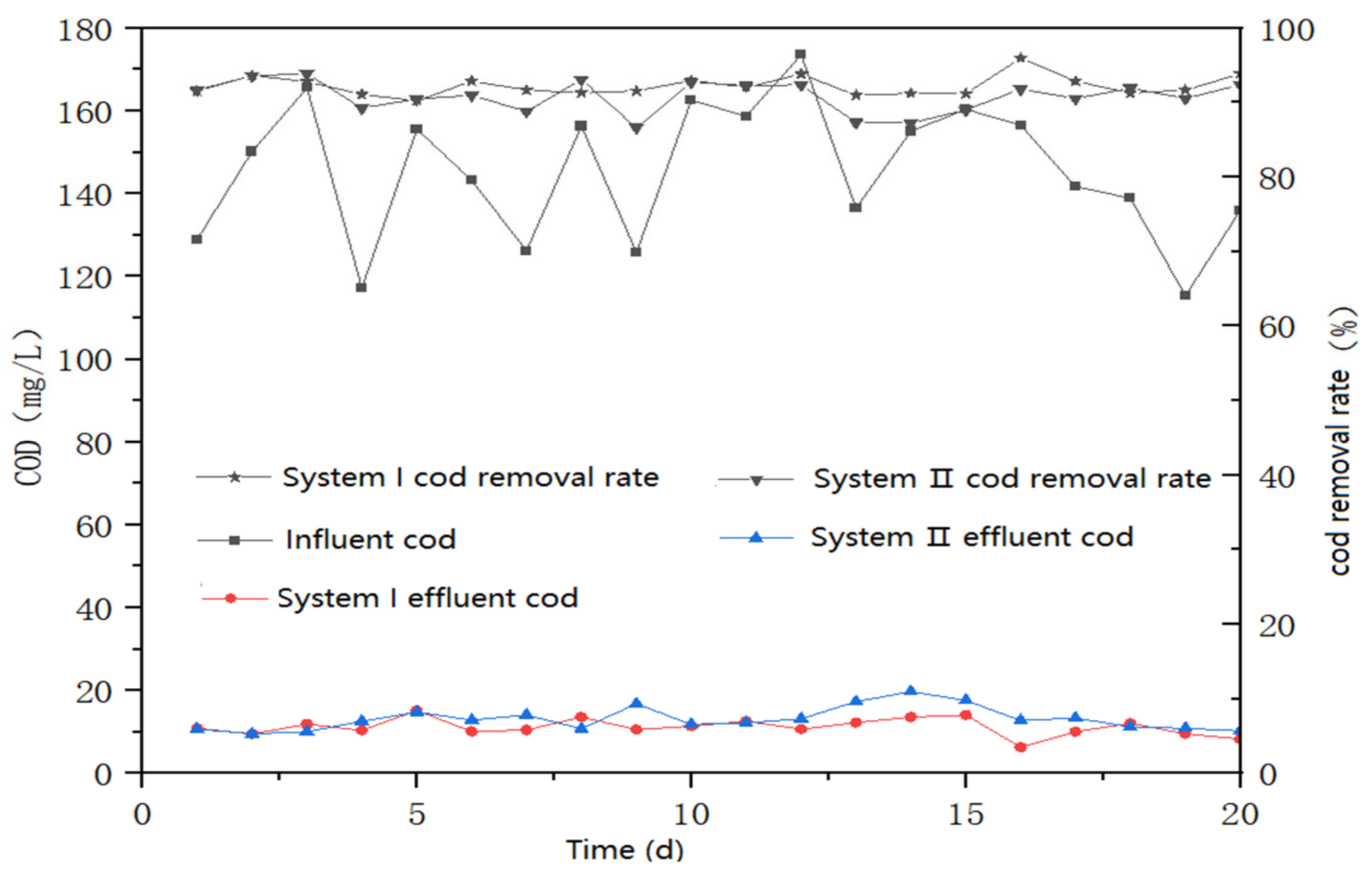

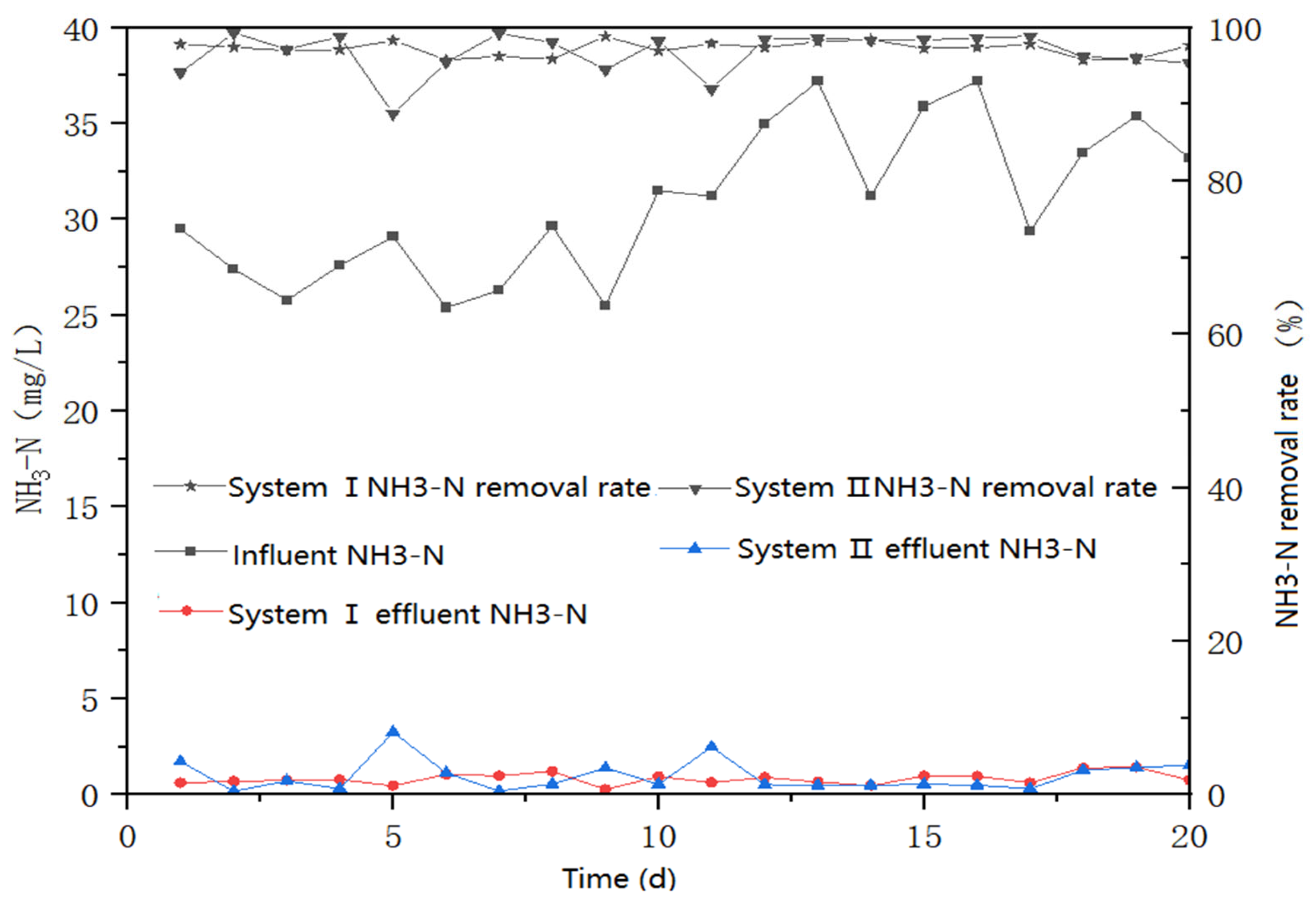

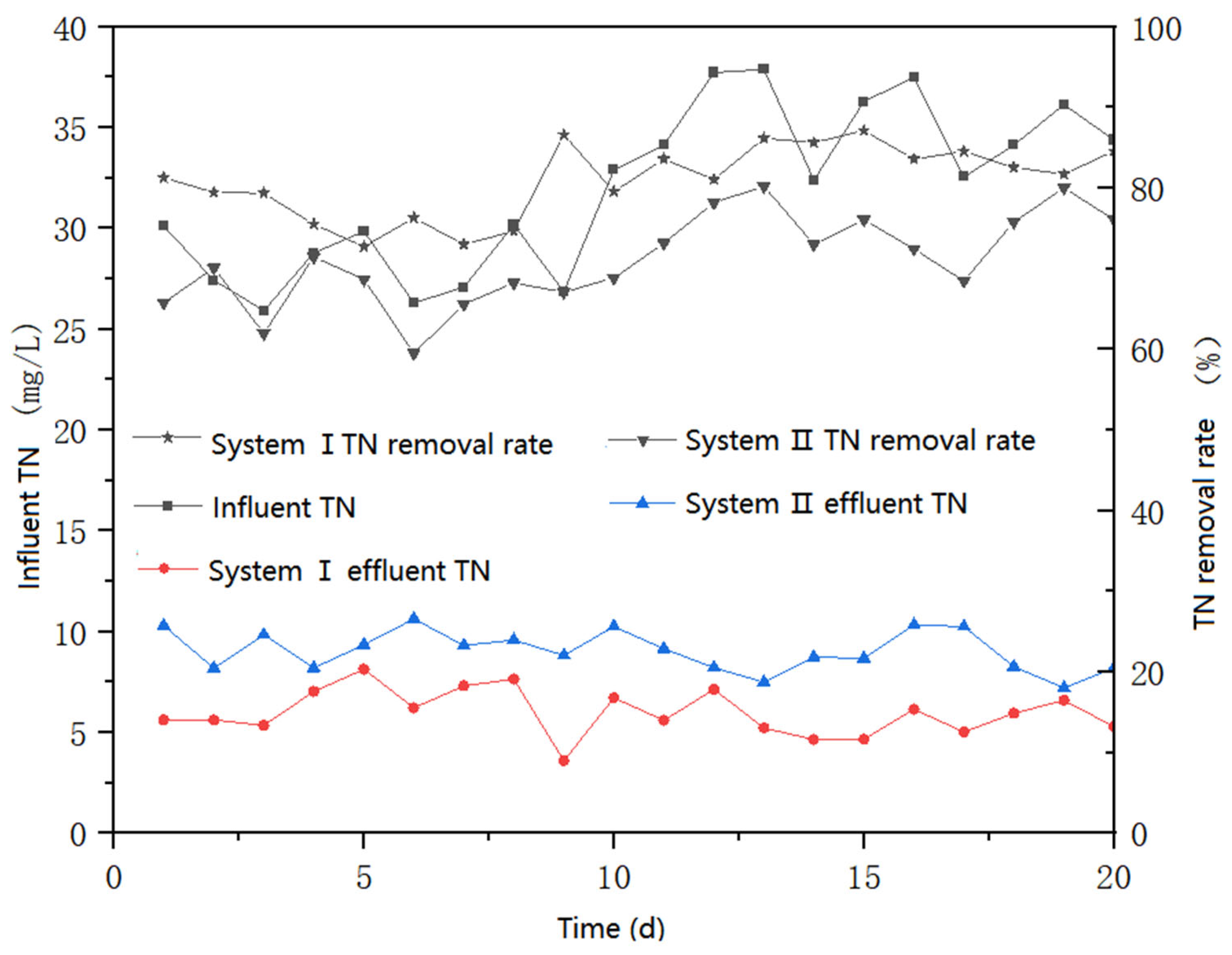

3.3.2. Comparison of Pollutant Removal Effect

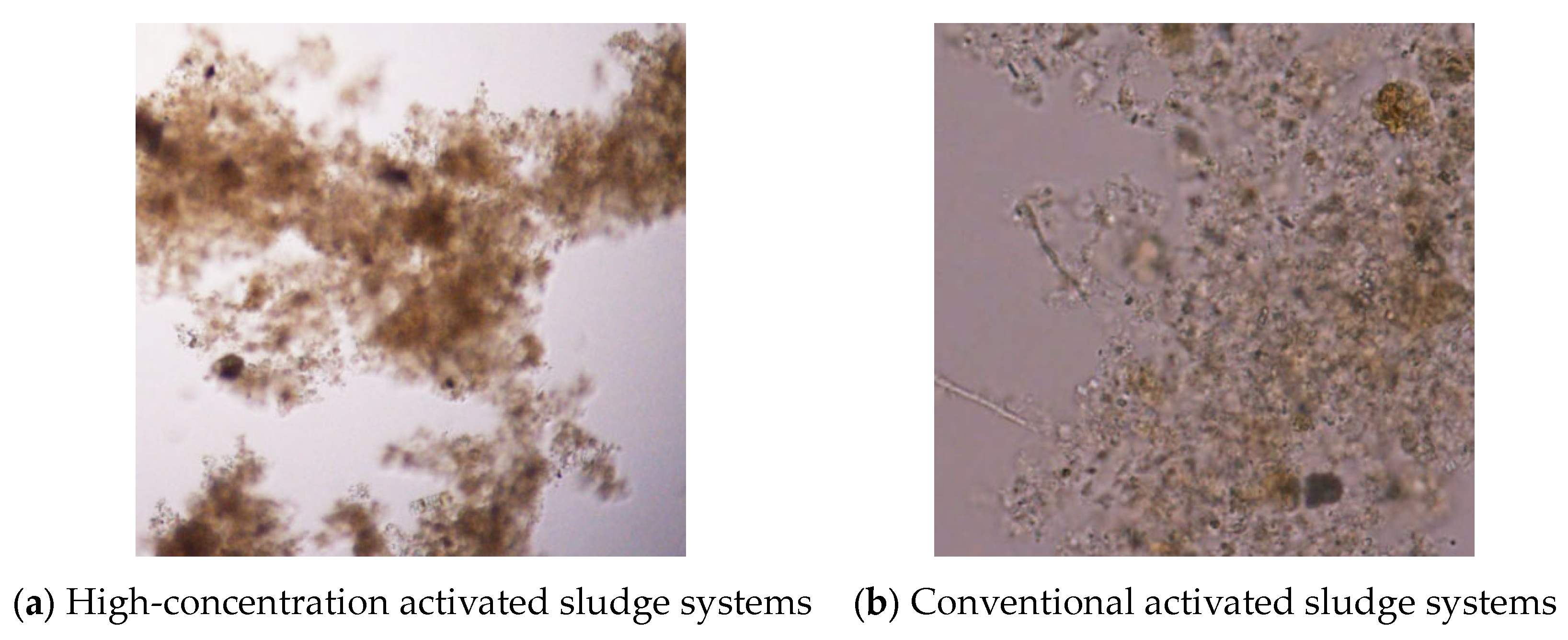

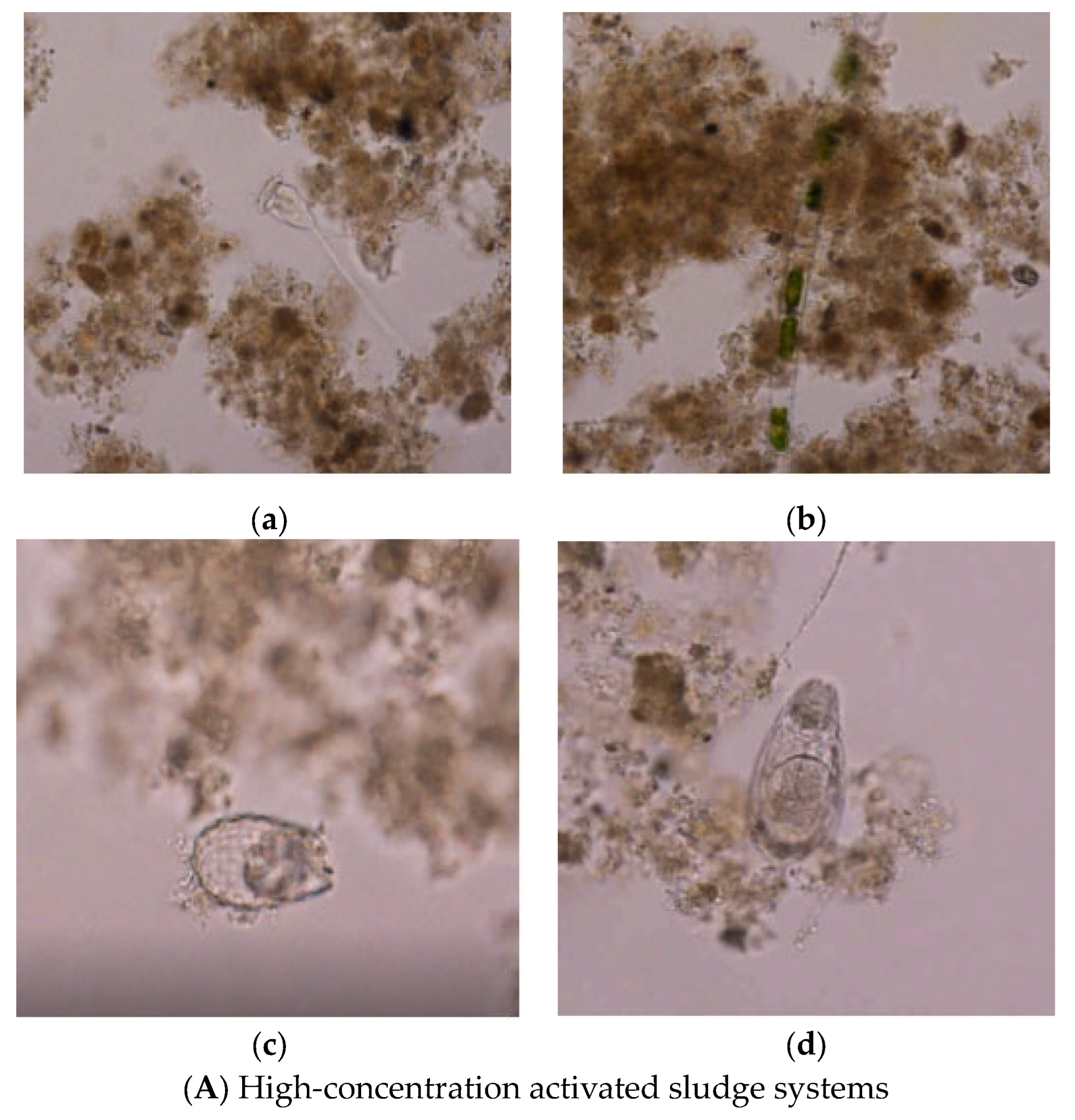

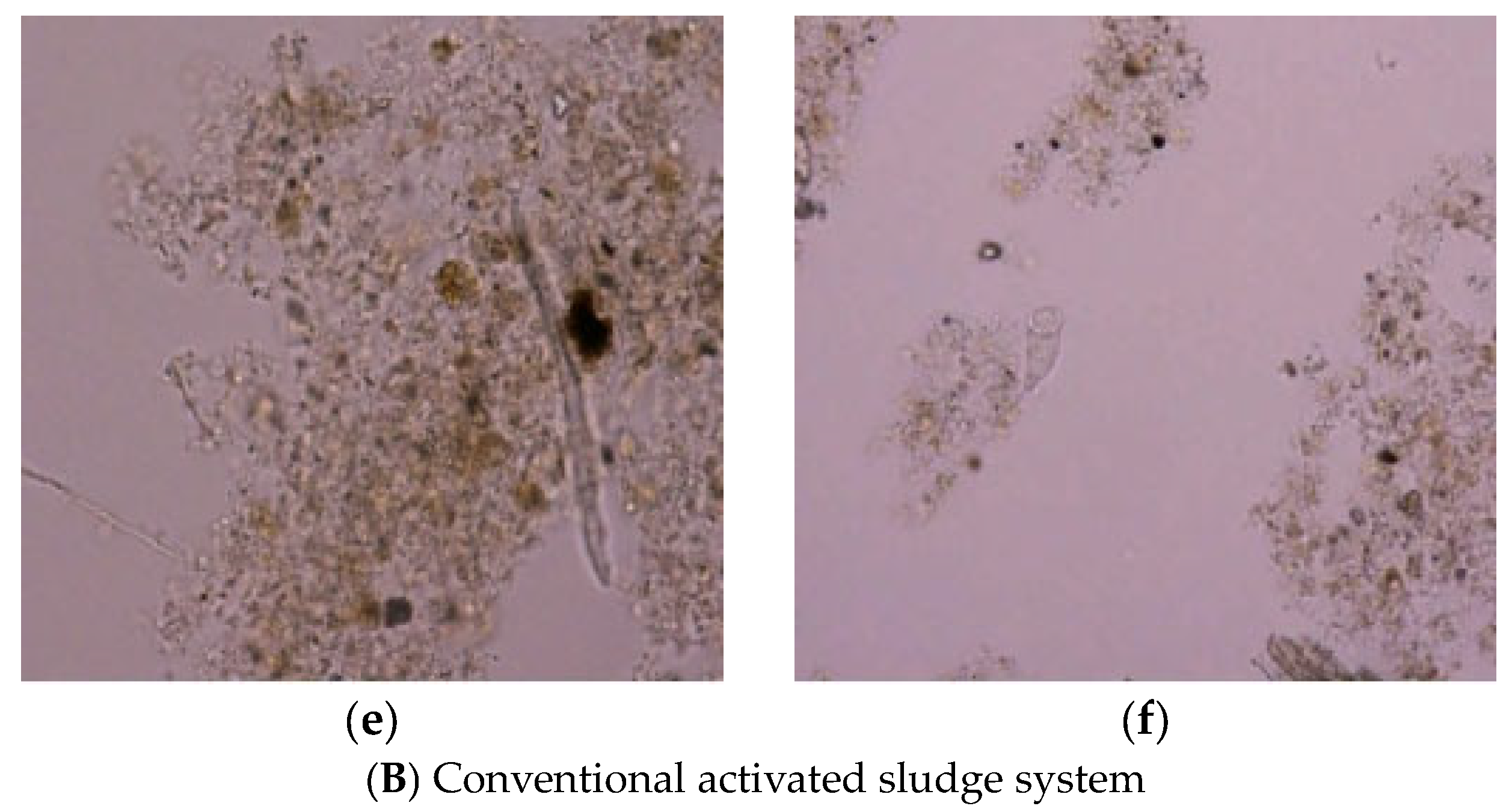

3.3.3. Comparison of Microorganisms in Two Systems

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishima, K.; Nakamura, M. Self-immobilization of aerobicactivated sludge-a pilot study of the aerobic upflow sludge blanket process in municipal sewage treatment. Water Sci. Technol. 1991, 23, 981–990. [Google Scholar] [CrossRef]

- McSwain, B.S.; Irvine, R.L.; Hausner, M.; Wilderer, P. Composition and distribution of extracellular polymeric substances in aerobic flocs and granular sludge. Appl. Environ. Microbiol. 2005, 71, 1051–1057. [Google Scholar] [CrossRef]

- Lee, D.J.; Chen, Y.Y.; Show, K.Y.; Whiteley, C.G.; Tay, J.H. Advances in aerobic granule formation and granule stability in the course of storage and reactor operation. Biotechnol. Adv. 2010, 28, 919–934. [Google Scholar] [CrossRef] [PubMed]

- de Bruin, L.M.M.; van der Roest, H.F.; van Loosdrecht, M.C.M. Overview of Applied Research with Nereda-Technology in the Netherlands. Proc. Water Environ. Fed. 2010, 2010, 103–113. [Google Scholar] [CrossRef]

- Feng, L.; Zheng, H.; Gao, B.; Zhang, S.; Zhao, C.; Zhou, Y.; Xu, B. Fabricating an anionic polyacrylamide (APAM) with an anionic block structure for high turbidity water separation and purification. RSC Adv. 2017, 7, 28918–28930. [Google Scholar] [CrossRef]

- Pronk, M.; De Kreuk, M.K.; De Bruin, B.; Kamminga, P.; Kleerebezem, R.V.; Van Loosdrecht, M.C.M. Full scale performance of the aerobic granular sludge process for sewage treatment. Water Res. 2015, 84, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zheng, H.; Gao, B.; Sun, Y.; Liu, B.; Zhao, C. UV-initiated template copolymerization of AM and MAPTAC: Microblock structure, copolymerization mechanism, and flocculation performance. Chemosphere 2017, 167, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ding, L.B.; Cai, A.; Huang, G.X.; Horn, H. Aerobic Sludge Granulation in a Full-Scale Sequencing Batch Reactor. Biomed Res. Int. 2014, 2014, 268789. [Google Scholar] [CrossRef] [PubMed]

- Bassin, J.P.; Kleerebezem, R.; Dezotti, M.; Van Loosdrecht, M.C.M. Measuring biomass specific ammonium, nitrite and phosphate uptake rates in aerobic granular sludge—ScienceDirect. Chemosphere 2012, 89, 1161–1168. [Google Scholar] [CrossRef]

- Ni, B.J.; Xie, W.M.; Liu, S.G.; Yu, H.Q.; Wang, Y.Z.; Wang, G.; Dai, X.L. Granulation of activated sludge in a pilot-scale sequencing batch reactor for the treatment of low-strength municipal wastewater. Water Res. 2009, 43, 751–761. [Google Scholar] [CrossRef]

- Yang, H.G.; Li, J.; Liu, J.; Ding, L.B.; Chen, T.; Huang, G.X.; Shen, J.Y. A case for aerobic sludge granulation: From pilot to full scale. J. Water Reuse Desalination 2016, 6, 188–194. [Google Scholar] [CrossRef]

- Sumiyati, S.; Sitinjak, R. Removal of Ammonia Nitrogen by Activated Sludge Process Using Simultaneous Nitrification Denitrification Method. In Proceedings of the E3S Web of Conferences, 5th International Conference on Energy, Environmental and Information System (ICENIS 2020), Semarang, Indonesia, 12–13 August 2020; Volume 202. [Google Scholar]

- Zeng, D.; Wu, J.; Kennedy, J.F. Application of a chitosan flocculant to water treatment. Carbohydr. Polym. 2008, 71, 135–139. [Google Scholar] [CrossRef]

- Owodunni, A.A.; Ismail, S.; Kurniawan, S.B.; Ahmad, A.; Imron, M.F.; Abdullah, S.R.S. A review on revolutionary technique for phosphate removal in wastewater using green coagulant. J. Water Process Eng. 2023, 52, 103573. [Google Scholar] [CrossRef]

- Abidli, A.; Huang, Y.; Rejeb, Z.B.; Zaoui, A.; Park, C.B. Sustainable and efficient technologies for removal and recovery of toxic and valuable metals from wastewater: Recent progress, challenges, and future perspectives. Chemosphere 2022, 292, 133102. [Google Scholar]

- Du, Y.; Cao, B.; Zhang, W.; Yang, P.; Xu, Q.; Wang, D.; Shen, X. Improvement of wastewater sludge dewatering properties using polymeric aluminum-silicon complex flocculants conditioning: Importance of aluminum/silicon ratio. Colloids Surf. A Physicochem. Eng. Asp. 2017, 530, 134–145. [Google Scholar] [CrossRef]

- Villaseñor-Basulto, D.L.; Astudillo-Sánchez, P.D.; del Real-Olvera, J.; Bandala, E.R. Wastewater treatment using Moringa oleifera Lam seeds: A review. J. Water Process Eng. 2018, 23, 151–164. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, J.; Yan, Y.; Yang, L.; Xing, G.; Li, H.; Wu, P.; Wang, M.; Zheng, H. Application of coagulation/flocculation in oily wastewater treatment: A review. Sci. Total Environ. 2021, 765, 142795. [Google Scholar] [CrossRef] [PubMed]

- Boulaadjoul, S.; Zemmouri, H.; Bendjama, Z.; Drouiche, N. A novel use of Moringa oleifera seed powder in enhancing the primary treatment of paper mill effluent. Chemosphere 2018, 206, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Tomasi, I.T.; Machado, C.A.; Boaventura, R.A.; Botelho, C.M.; Santos, S.C. Tannin-based coagulants: Current development and prospects on synthesis and uses. Sci. Total Environ. 2022, 822, 153454. [Google Scholar] [CrossRef]

- Lekniute-Kyzike, E.; Bendoraitiene, J.; Navikaite-Snipaitiene, V.; Peciulyte, L.; Rutkaite, R. Production of Cationic Starch-Based Flocculants and Their Application in Thickening and Dewatering of the Municipal Sewage Sludge. Materials 2023, 16, 2621. [Google Scholar] [CrossRef]

- Ozun, S.; Ulus, D.A. An Investigation on the Turbidity Removal from Natural Stone Processing Plant Wastewater by Flocculation. Inz. Miner. J. Pol. Miner. Eng. Soc. 2020, 2, 157–162. [Google Scholar] [CrossRef]

- Hu, P.; Shen, S.; Yang, H. Evaluation of hydrophobically associating cationic starch-based flocculants in sludge dewatering. Sci. Rep. 2021, 11, 13. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.M.; Zhang, M.X.; Zheng, H.H.; Yi, F. Sedimentation Behavior of Flocculant-Treated Dredged Slurry under Filtration of Woven Geotextiles. Water 2023, 15, 4158. [Google Scholar] [CrossRef]

- Tsilo, P.H.; Basson, A.K.; Ntombela, Z.G.; Maliehe, T.S.; Pullabhotla, V. Production and Characterization of a Bioflocculant from Pichia kudriavzevii MH545928.1 and Its Application in Wastewater Treatment. Int. J. Environ. Res. Public Health 2022, 19, 3148. [Google Scholar] [CrossRef]

- Barros, A.; Vecino, X.; Reig, M.; Cortina, J.L. Coagulation and Flocculation Optimization Process Applied to the Sidestream of an Urban Wastewater Treatment Plant. Water 2022, 14, 4024. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, S.Q.; Ren, Z.Y.; Wang, Q.; Zhang, Y.; Zuo, Y.J.; Zhou, J.; Jia, H.T.; Wang, T.C. Potential of non-thermal discharge plasmas for activated sludge settling: Effects and underlying mechanisms. RSC Adv. 2023, 13, 19869–19880. [Google Scholar] [CrossRef]

- Ren, G.P.; Zhang, J.; Feng, T.G.; Liang, Y.; Yin, Y.H. Mechanism and Influence of Dispersants on the Action of Polymer Flocculants Used in Slurry Separation. Polymers 2023, 15, 4073. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.C.; Fan, L.; Ni, S.B.; Wei, J.H.; Huang, Y.P. Study on the matching rules and control mechanisms between flocculants and slurry settlement characteristics. Environ. Res. Commun. 2023, 5, 11. [Google Scholar] [CrossRef]

- Jia, X.F.; Fan, H.X.; Liang, J.W.; Dai, J.H.; Sun, Y.; Mai, W.N. Performance Analysis of Anaerobic Digestion Coupled with Simultaneous Nitrification and Denitrification Process for Treating Alcohol Precipitation Wastewater of Chinese Patent Medicine. Water 2023, 15, 1939. [Google Scholar] [CrossRef]

| Ordinal Number | Basic Control Items | Minimum to Maximum | Average Value |

|---|---|---|---|

| 1 | BOD5 (mg/L) | 15.3~124 | 55.5 |

| 2 | CODcr (mg/L) | 25.1~315 | 128 |

| 3 | SS (mg/L) | 21~117 | 66 |

| 4 | NH3-N (mg/L) | 7.94~58.3 | 25.8 |

| 5 | TN (mg/L) | 13.60~74.69 | 36.1 |

| 6 | TP (mg/L) | 0.64~7.13 | 2.64 |

| 7 | PH | 6.64~8.17 | 7.52 |

| Types of Flocculants | Affiliated Categories | Dosage (mg/L) | ||||

|---|---|---|---|---|---|---|

| PAC | Inorganic polymer flocculant | 25 | 50 | 100 | 300 | 500 |

| FeCl3 | Traditional inorganic flocculants | 25 | 50 | 100 | 300 | 500 |

| Al2(SO4)3 | Traditional inorganic flocculants | 25 | 50 | 100 | 300 | 500 |

| APAM | Anionic organic synthetic flocculants | 2 | 5 | 10 | 15 | 20 |

| CPAM | Cationic organic synthetic flocculants | 2 | 5 | 10 | 15 | 20 |

| Sports Event | Speedy | Medium Speed | Slow Speed |

|---|---|---|---|

| Number of revolutions per minute (r/min) | 1000 | 120 | 60 |

| Mixing time (min) | 2 | 10 | 10 |

| PAC Dosage (mL) | SV30 (100%) | V60 (mL/min) | Sludge Volume after Settling for 60 min (mL) | Turbidity of Supernatant (NTU) | MLSS (g/L) | SVI (mL/g) |

|---|---|---|---|---|---|---|

| 0 | 90.5 | 3.0 | 820 | 10.5 | 10.112 | 90 |

| 25 | 72 | 6.67 | 600 | 4.63 | 9.676 | 74 |

| 50 | 70 | 6.83 | 590 | 3.83 | 9.656 | 72 |

| 100 | 65.5 | 7.08 | 575 | 3.00 | 9.336 | 70 |

| 300 | 72 | 6.58 | 605 | 5.45 | 9.84 | 73 |

| 500 | 75 | 6.50 | 610 | 7.86 | 9.952 | 77 |

| FeCl3 Dosage (mL) | SV30 (100%) | V60 (mL/min) | Sludge Volume after Settling for 60 min (mL) | Turbidity of supernatant (NTU) | MLSS (g/L) | SVI (mL/g) |

|---|---|---|---|---|---|---|

| 0 | 90.5 | 2.83 | 830 | 13.44 | 8.466 | 106 |

| 25 | 72.5 | 6.17 | 630 | 6.58 | 9.462 | 77 |

| 50 | 71 | 6.33 | 620 | 5.76 | 9.370 | 76 |

| 100 | 68 | 6.50 | 610 | 4.20 | 9.336 | 73 |

| 300 | 73 | 6.08 | 635 | 5.52 | 9.822 | 74 |

| 500 | 74 | 6.00 | 640 | 8.63 | 9.626 | 75 |

| Al2(SO4)3 Dosage (mL) | SV30 (100%) | V60 (mL/min) | Sludge Volume after Settling for 60 min (mL) | Turbidity of Supernatant (NTU) | MLSS (g/L) | SVI (mL/g) |

|---|---|---|---|---|---|---|

| 0 | 92.5 | 2.17 | 870 | 9.51 | 10.230 | 90 |

| 25 | 85 | 4.00 | 760 | 6.92 | 10.734 | 79 |

| 50 | 85 | 4.00 | 760 | 6.35 | 10.086 | 84 |

| 100 | 84 | 4.17 | 750 | 5.76 | 11.246 | 75 |

| 300 | 83 | 4.33 | 740 | 5.06 | 10.976 | 76 |

| 500 | 82 | 4.33 | 740 | 6.48 | 10.686 | 77 |

| APAM Dosing Rate (mL) | SV30 (100%) | V60 (mL/min) | Sludge Volume after Settling for 60 min (mL) | Turbidity of Supernatant (NTU) | MLSS (g/L) | SVI (mL/g) |

|---|---|---|---|---|---|---|

| 0 | 87 | 2.92 | 825 | 13.68 | 10.92 | 80 |

| 2 | 80 | 5.25 | 685 | 7.06 | 12.376 | 65 |

| 5 | 79 | 5.33 | 680 | 6.29 | 11.392 | 69 |

| 10 | 79 | 5.42 | 675 | 5.19 | 11.352 | 70 |

| 15 | 79 | 5.42 | 675 | 5.42 | 10.734 | 74 |

| 20 | 79 | 5.5 | 670 | 4.16 | 12.116 | 65 |

| CPAM Dosage (mL) | SV30 (100%) | V60 (L/min) | Sludge Volume after Settling for 60 min (mL) | Turbidity of Supernatant (NTU) | MLSS (g/L) | SVI (mL/g) |

|---|---|---|---|---|---|---|

| 0 | 88 | 3.00 | 820 | 12.48 | 10.56 | 83 |

| 2 | 80 | 6.67 | 600 | 6.75 | 10.858 | 74 |

| 5 | 78 | 7.00 | 580 | 5.49 | 10.789 | 72 |

| 10 | 66 | 8.16 | 510 | 5.17 | 10.892 | 61 |

| 15 | 64 | 8.50 | 490 | 4.72 | 10.529 | 61 |

| 20 | 62.5 | 8.83 | 470 | 4.16 | 10.762 | 58 |

| Flocculant | Dosage (mg/L) | SV30 (100%) | V60 min (mL/min) | Sludge Volume after 60 min of Settling (mL) | Turbidity of Supernatant (NTU) | MLSS (g/L) | SVI (mL/g) |

|---|---|---|---|---|---|---|---|

| PAC | 100 | 65.5 | 7.08 | 575 | 3.00 | 9.336 | 70 |

| FeCl3 | 100 | 68 | 6.50 | 610 | 4.20 | 9.336 | 73 |

| Al2(SO4)3 | 100 | 84 | 4.17 | 750 | 5.76 | 11.246 | 75 |

| APAM | 2 | 80 | 5.25 | 685 | 7.06 | 12.376 | 65 |

| CPAM | 10 | 66 | 8.16 | 510 | 5.17 | 10.892 | 61 |

| Considerations | Mixing Section Hydraulic Retention Time (s) | Hydraulic Retention Time of Flocculation Section (min) | Mixing Intensity of Mixing Section (r min−1) | Flocculation 1# Section Mixing Intensity (r min−1) | Flocculation 2# Section Mixing Intensity (r min−1) |

|---|---|---|---|---|---|

| 1 | 30 | 5 | 600 | 60 | 20 |

| 2 | 60 | 10 | 800 | 90 | 40 |

| 3 | 120 | 15 | 1000 | 120 | 60 |

| 4 | 300 | 20 | 1200 | 150 | 80 |

| Considerations | Mixing Section Hydraulic Retention Time (s) | Hydraulic Retention Time of Flocculation Section (min) | Mixing Intensity of Mixing Section (r min−1) | Flocculation 1# Section Mixing Intensity (r min−1) | Flocculation 2# Section Mixing Intensity (r min−1) | SVI (mL/g) |

|---|---|---|---|---|---|---|

| 1 | 30 | 5 | 600 | 60 | 20 | 99 |

| 2 | 30 | 10 | 800 | 90 | 40 | 97 |

| 3 | 30 | 15 | 1000 | 120 | 60 | 86 |

| 4 | 30 | 20 | 1200 | 150 | 80 | 88 |

| 5 | 60 | 5 | 800 | 120 | 80 | 94 |

| 6 | 60 | 10 | 600 | 120 | 60 | 95 |

| 7 | 60 | 15 | 1200 | 60 | 40 | 87 |

| 8 | 60 | 20 | 1000 | 90 | 20 | 85 |

| 9 | 120 | 5 | 1000 | 150 | 40 | 86 |

| 10 | 120 | 10 | 1200 | 120 | 20 | 85 |

| 11 | 120 | 15 | 600 | 90 | 80 | 84 |

| 12 | 120 | 20 | 800 | 60 | 60 | 82 |

| 13 | 300 | 5 | 1200 | 90 | 60 | 96 |

| 14 | 300 | 10 | 1000 | 60 | 80 | 97 |

| 15 | 300 | 15 | 800 | 150 | 20 | 100 |

| 16 | 300 | 20 | 600 | 120 | 40 | 93 |

| Considerations | Mixing Section Hydraulic Retention Time (s) | Hydraulic Retention Time of Flocculation Section (min) | Mixing Intensity of Mixing Section (r min−1) | Flocculation 1# Section Mixing Intensity (r min−1) | Flocculation 2# Section Mixing Intensity (r min−1) |

|---|---|---|---|---|---|

| Mean value 1 | 92.50 | 93.77 | 92.91 | 91.25 | 92.04 |

| Mean value 2 | 90.23 | 93.53 | 90.55 | 90.55 | 90.77 |

| Mean value 3 | 84.37 | 89.24 | 89.48 | 89.48 | 89.80 |

| Mean value 4 | 96.38 | 86.93 | 92.20 | 90.86 | 90.86 |

| Range error | 2.88 | 2.65 | 4.67 | 3.72 | 3.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, B.; He, H.; Yan, Y.; Wang, Y.; Yang, X.; Liu, Y.; Xu, J.; Huang, W. Flocculants for the High-Concentration Activated Sludge Method and the Effectiveness of Urban Wastewater Treatment. Water 2024, 16, 2281. https://doi.org/10.3390/w16162281

Luo B, He H, Yan Y, Wang Y, Yang X, Liu Y, Xu J, Huang W. Flocculants for the High-Concentration Activated Sludge Method and the Effectiveness of Urban Wastewater Treatment. Water. 2024; 16(16):2281. https://doi.org/10.3390/w16162281

Chicago/Turabian StyleLuo, Benfu, Haixin He, Yujing Yan, Yin Wang, Xi Yang, Yuhang Liu, Jiaran Xu, and Weiheng Huang. 2024. "Flocculants for the High-Concentration Activated Sludge Method and the Effectiveness of Urban Wastewater Treatment" Water 16, no. 16: 2281. https://doi.org/10.3390/w16162281

APA StyleLuo, B., He, H., Yan, Y., Wang, Y., Yang, X., Liu, Y., Xu, J., & Huang, W. (2024). Flocculants for the High-Concentration Activated Sludge Method and the Effectiveness of Urban Wastewater Treatment. Water, 16(16), 2281. https://doi.org/10.3390/w16162281