An Assessment of the Embedding of Francis Turbines for Pumped Hydraulic Energy Storage

Abstract

:1. Introduction

- -

- placing inside the spiral casing of internal support that will prevent deformation because of the pressure of the surrounding concrete;

- -

- the spiral casing is placed on a pre-prepared foundation;

- -

- the casing is surrounded by reinforced concrete on several layers;

- -

- the internal support is removed, and the other parts of the turbine are mounted.

2. Materials and Methods

2.1. Design Geometry

2.2. Structural Loads and Operating Modes

- -

- p1 = 6.96 MPa—applied on the internal surfaces of the spiral casing;

- -

- p2 = 6.26 MPa—applied on the internal surfaces of the lower and upper rings;

- -

- p3 = 5.57 MPa—applied on the upper and lower sealing rings.

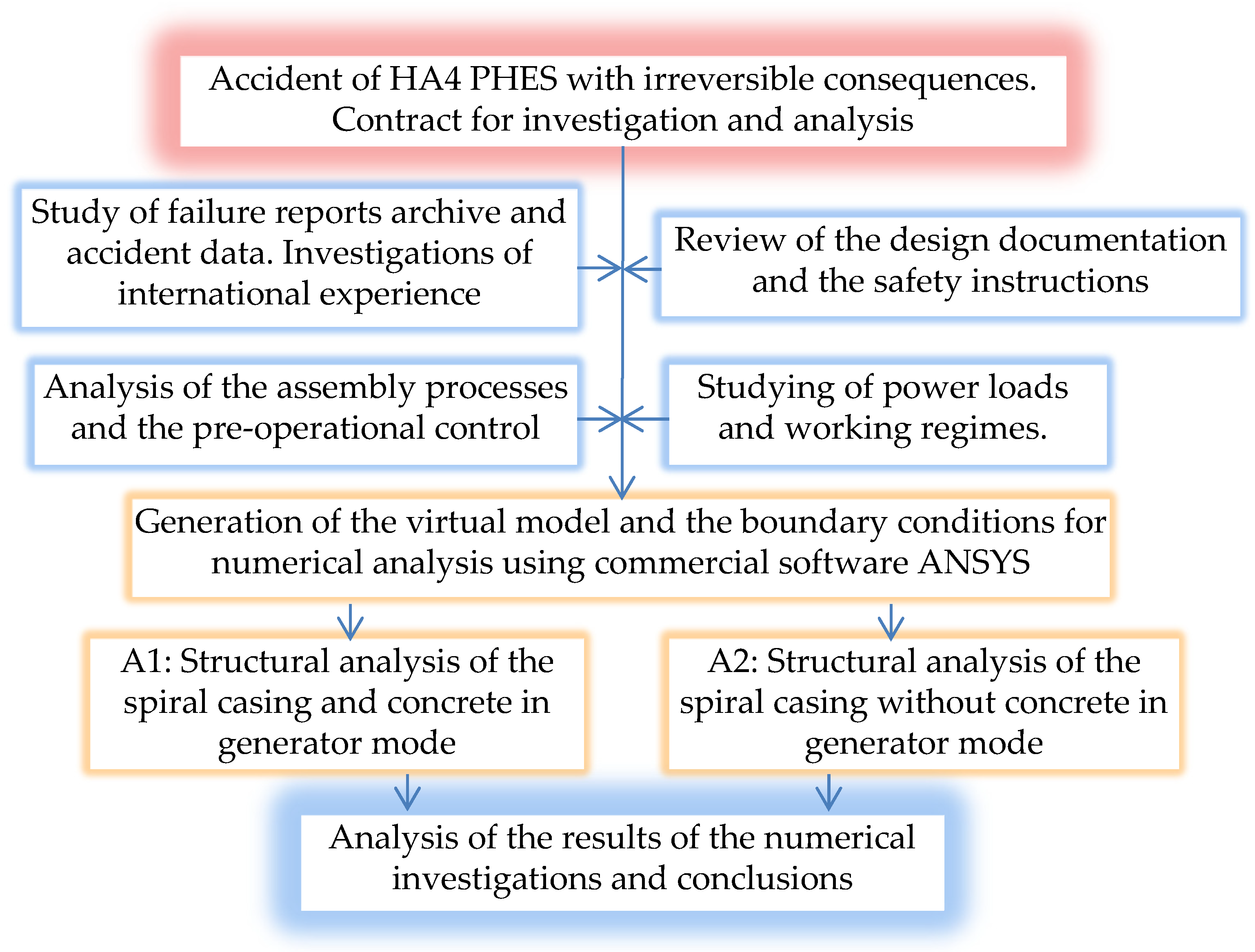

2.3. Aim and Stages of the Investigations

- A1: Complete structural analysis of the spiral casing and concrete under loads in generator mode;

- A2: Complete structural analysis of the spiral casing under loads in generator mode but without concrete.

3. Results

3.1. A1: Structural and Mechanical Simulation of Spiral Casing and Concrete Enclosure

3.2. A2: Structural and Mechanical Analysis of Spiral Casing, without Concrete Enclosure

3.3. Analysis of the Numerical Simulation Results

4. Discussion

- -

- the influence of the concrete structure support over the maximal stress values is insignificant, as the structure is experiencing plastic deformations in both examined casings;

- -

- the displacements are increased nearly twice, i.e., due to the decreased rigidity of the structure;

- -

- the plastic strains are increased by nearly 40%, leading to a definitive possibility for crack initiation;

- -

- the subject of the investigations is a critically damaged structure, and only numerical experiments and simulation could be conducted.

5. Conclusions

- -

- -

- -

- investigation A2 shows that if the gap between the turbine and the concrete embedding is significant (no contact), the main loading as a result of the extremely high pressure is on the stay vanes;

- -

- -

- it is proven that the contact surfaces between the support ring, the stay vanes, and the cover ring are the places with extremely high plastic stresses;

- -

- concentration of unacceptable stresses in the cross sections of the stay vanes along the sections of the welding are observed;

- -

- realization of the embedding method P (discussed in Introduction Section 1) could not be found in the scientific literature for more than 30–50 years, although some disadvantages could be observed with the other methods of embedding.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Javier, F.; Christian, B. Aging of European power plant infrastructure as an opportunity to evolve towards sustainability. Int. J. Hydrogen Energy 2017, 42, 18081–18091. [Google Scholar]

- Kougias, I.; Aggidis, G.; Avellan, F.; Deniz, S.; Lundin, U.; Moro, A.; Muntean, S.; Novara, D.; Pérez-Díaz, J.I.; Quaranta, E.; et al. Analysis of emerging technologies in the hydropower sector. Renew. Sustain. Energy Rev. 2019, 113, 109257. [Google Scholar] [CrossRef]

- Toufani, P.; Nadar, E.; Kocaman, A.S. Operational benefit of transforming cascade hydropower stations into pumped hydro energy storage systems. J. Energy Storage 2022, 51, 104444. [Google Scholar] [CrossRef]

- Punys, S.; Baublys, R.; Kasiulis, E.; Vaisvila, A.; Pelikan, B.; Steller, J. Assessment of renewable electricity generation by pumped storage power plants in EU Member State. Renew. Sustain. Energy Rev. 2013, 26, 190–200. [Google Scholar] [CrossRef]

- Yang, J.; Robert, B.; Jackson, R.B. Opportunities and barriers to pumped-hydro energy storage in the United States. Renew. Sustain. Energy Rev. 2011, 15, 839–844. [Google Scholar] [CrossRef]

- Manikas, K.; Skroufouta, S.; Baltas, E. Simulation and evaluation of pumped hydropower storage (PHPS) system at Kastraki reservoir. Renew. Energy 2024, 222, 119888. [Google Scholar] [CrossRef]

- Amirante, R.; Cassone, E.; Distaso, E.; Tamburrano, P. Overview on recent developments in energy storage: Mechanical, electrochemical and hydrogen technologies. Energy Convers. Manag. 2017, 132, 372–387. [Google Scholar] [CrossRef]

- Kucukali, S. Finding the most suitable existing hydropower reservoirs for the development of pumped-storage schemes: An integrated approach. Renew. Sustain. Energy Rev. 2014, 37, 502–508. [Google Scholar] [CrossRef]

- Wilson, I.A.G.; Barbour, E.; Ketelaer, T.; Kuckshinrichs, W. An analysis of storage revenues from the time-shifting of electrical energy in Germany and Great Britain from 2010 to 2016. J. Energy Storage 2018, 17, 446–456. [Google Scholar] [CrossRef]

- Favrel, A.; Müller, A.; Landry, C.; Yamamoto, K.; Avellan, F. Study of the Vortex-Induced Pressure Excitation Source in a Francis Turbine Draft Tube by Particle Image Velocimetry. Exp. Fluids 2015, 56, 215. [Google Scholar] [CrossRef]

- Favrel, A.; Müller, A.; Landry, C.; Yamamoto, K.; Avellan, F. LDV Survey of Cavitation and Resonance Effect on the Precessing Vortex Rope Dynamics in the Draft Tube of Francis Turbines. Exp. Fluids 2016, 57, 168. [Google Scholar] [CrossRef]

- Alligné, S.; Nicolet, C.; Tsujimoto, Y.; Avellan, F. Cavitation Surge Model ling in Francis Turbine Draft Tube. J. Hydraul. Res. 2014, 52, 399–411. [Google Scholar] [CrossRef]

- Müller, A.; Favrel, A.; Landry, C.; Avellan, F. Fluid-Structure Interaction Mechanisms Leading to Dangerous Power Swings in Francis Turbines at Full Load. J. Fluids Struct. 2017, 69, 56–71. [Google Scholar] [CrossRef]

- Panov, L.; Chirkov, D.; Cherny, S.; Pylev, I.; Sotnikov, A. Numerical Simulation of Steady Cavitating Flow of Viscous Fluid in a Francis Hydroturbine. Thermophys. Aeromech. 2012, 19, 415–427. [Google Scholar] [CrossRef]

- Susan-Resiga, R.; Ciocan, G.; Anton, I.; Avellan, F. Analysis of the Swirling Flow Downstream a Francis Turbine Runner. ASME J. Fluids Eng. 2006, 128, 177–189. [Google Scholar] [CrossRef]

- Rudolf, P.; Štefan, D. Decomposition of the Swirling Flow Field Downstream of Francis Turbine Runner. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 062008. [Google Scholar] [CrossRef]

- Dörfler, P.; Keller, M.; Braun, O. Francis Full-Load Surge Mechanism Identified by Unsteady 2-Phase CFD. IOP Conf. Ser. Earth Environ. Sci. 2010, 12, 012026. [Google Scholar] [CrossRef]

- Mössinger, P.; Conrad, P.; Jung, A. Transient Two-Phase CFD Simulation of Overload Pressure Pulsation in a Prototype Sized Francis Turbine Considering the Waterway Dynamics. IOP Conf. Ser. Earth Environ. Sci. 2014, 22, 032033. [Google Scholar] [CrossRef]

- Chirkov, D.; Panov, L.; Cherny, S.; Pylev, I. Numerical Simulation of Full Load Surge in Francis Turbines Based on Three-Dimensional Cavitating Flow Model. IOP Conf. Ser. Earth Environ. Sci. 2014, 22, 032036. [Google Scholar] [CrossRef]

- Wack, J.; Riedelbauch, S. Numerical Simulations of the Cavitation Phenomena in a Francis Turbine at Deep Part Load Conditions. J. Phys. Conf. Ser. 2015, 656, 012074. [Google Scholar] [CrossRef]

- Trivedi, C.; Cervantes, M.J. State of the Art in Numerical Simulation of High Head Francis Turbines. Renew. Energy Environ. Sustain. 2016, 1, 20. [Google Scholar] [CrossRef]

- Yasuda, M.; Watanabe, S. How to Avoid Severe Incidents at Hydropower Plants. Int. J. Fluid Mach. Syst. 2017, 10, 296–306. [Google Scholar] [CrossRef]

- Price, J.W.H. The failure of the Dartmouth turbine casing. Int. J. Press. Vessels Pip. 1998, 75, 559–566. [Google Scholar] [CrossRef]

- Rabbat, B.G.; Russell, H.G. Friction Coefficient of Steel on Concrete or Grout. J. Struct. Eng. 1985, 111, 505–515. [Google Scholar] [CrossRef]

- Baltay, P.; Gjelsvik, A. Coefficient of Friction for Steel on Concrete at High Normal Stress. J. Mater. Civ. Eng. 1990, 2, 46–49. [Google Scholar] [CrossRef]

- Available online: https://en.wikipedia.org/wiki/Sayano-Shushenskaya_power_station_accident (accessed on 4 July 2024).

- Itabashi, S.; Yamazaki, M. Francis Turbine Assembly. Patent No, EP0786504B2, 2 March 2005. [Google Scholar]

- Gao, X.; Fu, D.; Wu, H. Embedment of Steel Spiral Casings in Concrete: Lessons from a Structural Deformation Accident in China. Appl. Sci. 2022, 12, 8395. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, Y.; Ma, Z.; Chen, J. Effect of concrete cracks on dynamic characteristics of powerhouse for giant-scale hydrostation. Trans. Tianjin Univ. 2008, 14, 307–312. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, Q.L.; Wu, H.G. Reinforcement calculation for spiral casing embedded with cushion layer of hydropower station. Tianjin Daxue Xuebao (Ziran Kexue yu Gongcheng Jishu Ban). J. Tianjin Univ. Sci. Technol. 2009, 42, 673–677. [Google Scholar]

- Xu, X.; Li, M.; Ma, Z.; Zhang, H.; He, P. Simulation and analysis of the constant internal pressure spiral casing with non-uniform gap. Shuili Fadian Xuebao. J. Hydroelectr. Eng. 2009, 28, 75–80. [Google Scholar]

- Ma, Z.; Zhang, C. Static and dynamic damage analysis of mass concrete in hydropower house of Three Gorges Project. Trans. Tianjin Univ. 2010, 16, 433–440. [Google Scholar] [CrossRef]

- Panda, S.; Jena, J.; Basa, B. Stress analysis around spiral casing of Francis turbine of a Hydel power house by finite element method. In Proceedings of the International Conference on Structural Engineering and Mechanics, Rourkela, India, 20–22 December 2013. [Google Scholar]

- Chen, W.; Xian, L. Analysis and treatment of a raising deformation accident of the No.9 spiral casing structure in Xiluodu hydroelectric power plant. Shaanxi Water Resour. 2012, 5, 41–43. [Google Scholar]

- Zhang, Q.-L.; Wu, H.-G. Advance in research and application of spiral casing structure with a membrane in hydroelectric power plant. Shuili Xuebao. J. Hydraul. Eng. 2012, 43, 869–876. [Google Scholar]

- Zhang, Q.L.; Wu, H.G. Effect of compressible membrane’s nonlinear stress-strain behavior on spiral casing structure. Struct. Eng. Mech. 2012, 42, 73–93. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Wu, H.G. Using softened contact relationship describing compressible membrane in FEA of spiral casing structure. Arch. Civ. Mech. Eng. 2013, 13, 506–517. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Wu, H.G. Sliding behaviour of steel liners on surrounding concrete in c-cross-sections of spiral casing structures. Struct. Eng. Int. 2016, 26, 333–340. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Wu, H.G. Embedment of steel spiral casings in concrete: China’s experience. Renew. Sustain. Energy Rev. 2017, 72, 1271–1281. [Google Scholar] [CrossRef]

- Wu, H.; Shen, Y.; Jiang, K.; Shi, J. Structural Analysis of the Embedded Spiral Casing in the Three Gorges Hydropower Station. Pract. Period. Struct. Des. Constr. 2012, 17, 41–47. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, L.; Li, S. Research on three-dimensional simulation algorithm of preloaded filling spiral casing with non-uniform gap, Shuili Xuebao. J. Hydraul. Eng. 2015, 46, 1434–1443. [Google Scholar]

- Zhang, Q.-L.; Hu, C.; Hu, L.; Wu, H.-G. Compression-Resilience Responses of Commonly Used Membrane Materials in Spiral Casing Structures of Hydroelectric Power Plants: Experimental Investigation. J. Mater. Civ. Eng. 2018, 30, 06018005. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, H.; Shi, C.; Zhang, Q.; Su, K.; Hu, L. Numerical modeling of preloaded filling spiral casing structure. Lat. Am. J. Solids Struct. 2018, 15, 110. [Google Scholar] [CrossRef]

- Qi, Y.; Chen, Q.; Gong, Y.; Xie, Z. Optimization analysis of giant spiral casing with combined embedding method. IOP Conf. Ser. Earth Environ. Sci. 2019, 304, 032064. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, L.; Li, S. Influences of boundary conditions on the initial gap of preloading water-filled spiral casing. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2020, 36, 40–47. [Google Scholar]

- Birtarescu, E.; Constantin Câmpian, V.; Nedelcu, N. Strength Calculations Performed on the Spiral Casing of a Francis Turbine Operating in Secondary Control Regime. Sci. Bull. Mech. Eng. 2021, 83, 261–272. [Google Scholar]

- Gao, X.; Wu, H.; Fu, D. Effect of Temporary Internal Water Pressure on Structural Performance of Spiral Casing Structure in Pumped-Storage Power Plants. Energies 2022, 15, 2463. [Google Scholar] [CrossRef]

- Xu, W.; Wang, G.; Ma, Z.; Kang, F. Analysis of the Joint Bearing Capacity of Composite Cushion-Spiral Casing Structures for Hydropower Stations Considering the Damage Mechanisms of Surrounding Concrete. Water 2024, 16, 112. [Google Scholar] [CrossRef]

- Todorov, G.D.; Kamberov, K.H. Black box/white box hybrid method for virtual prototyping validation of multiphysics simulations and testing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 878, 012051. [Google Scholar] [CrossRef]

- Malakov, I.; Zv, V.; Tzeaharinonov, V. Size Ranges Optimization. Proc. Eng. 2015, 100, 791–800. [Google Scholar] [CrossRef]

- Vacheva, G.; Hinov, N. Modeling and simulation of hybrid electric vehicles. In Proceedings of the 46th International Conference on Applications of Mathematics in Engineering and Economics, Sofia, Bulgaria, 7–13 June 2021. [Google Scholar]

| Parameter | HT60 | JIS G 3106 SM 50 A | Concrete 25 |

|---|---|---|---|

| Modulus of elasticity, E, GPa | 209 | 200 | 30 |

| Coefficient of Poisson, μ | 0.29 | 0.28 | 0.18 |

| Density, ρ, kg/m3 | 7850 | 7700 | 2400 |

| Yield strength Rp0,2, MPa | 461 | 334 | - |

| Tensile strength, Rm, MPa | 620 | 520 | - |

| Tangent modulus, MPa | 3300 | 3640 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Todorov, G.; Kralov, I.; Kamberov, K.; Zahariev, E.; Sofronov, Y.; Zlatev, B. An Assessment of the Embedding of Francis Turbines for Pumped Hydraulic Energy Storage. Water 2024, 16, 2252. https://doi.org/10.3390/w16162252

Todorov G, Kralov I, Kamberov K, Zahariev E, Sofronov Y, Zlatev B. An Assessment of the Embedding of Francis Turbines for Pumped Hydraulic Energy Storage. Water. 2024; 16(16):2252. https://doi.org/10.3390/w16162252

Chicago/Turabian StyleTodorov, Georgi, Ivan Kralov, Konstantin Kamberov, Evtim Zahariev, Yavor Sofronov, and Blagovest Zlatev. 2024. "An Assessment of the Embedding of Francis Turbines for Pumped Hydraulic Energy Storage" Water 16, no. 16: 2252. https://doi.org/10.3390/w16162252

APA StyleTodorov, G., Kralov, I., Kamberov, K., Zahariev, E., Sofronov, Y., & Zlatev, B. (2024). An Assessment of the Embedding of Francis Turbines for Pumped Hydraulic Energy Storage. Water, 16(16), 2252. https://doi.org/10.3390/w16162252