Salt Drainage Efficiency and Anti-Clogging Effects of Subsurface Pipes Wrapped with Geotextiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Tested Soils

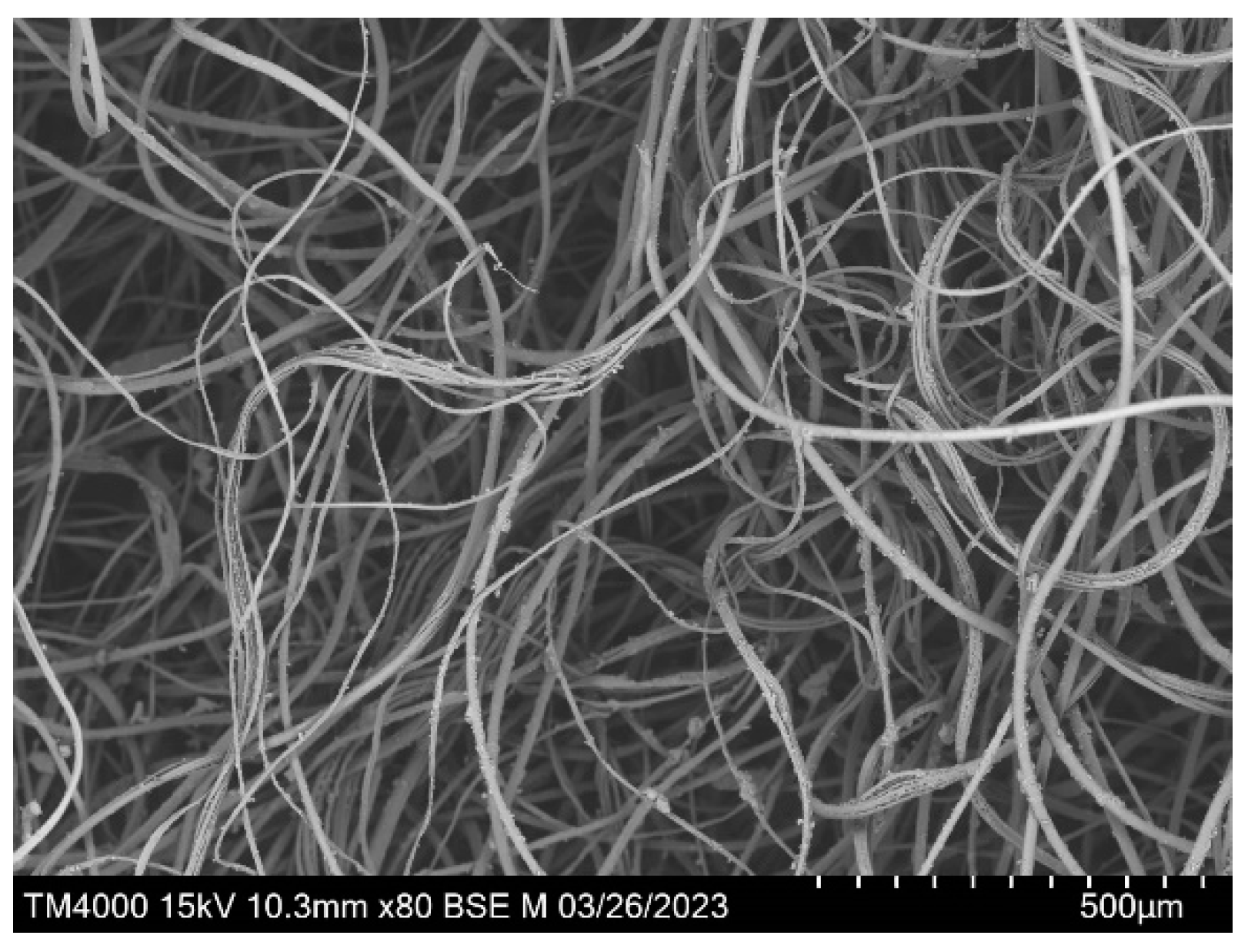

2.2. Simulation Device for Subsurface Pipe Drainage

2.3. Experiment Design and Process

2.4. Sample Collection and Measurement

2.5. Measurement and Methods

2.6. Calculation Formulae

2.7. Data Processing and Analysis

3. Results

3.1. Soil Moisture Distribution under Different Scenarios

3.2. Soil Salt Distribution under Different Scenarios

3.3. Analysis of the Effect of Soil Salt Leaching and Alkali Reduction under Different Scenarios

3.4. Analysis of Salt Leaching Efficiency under Different Scenarios

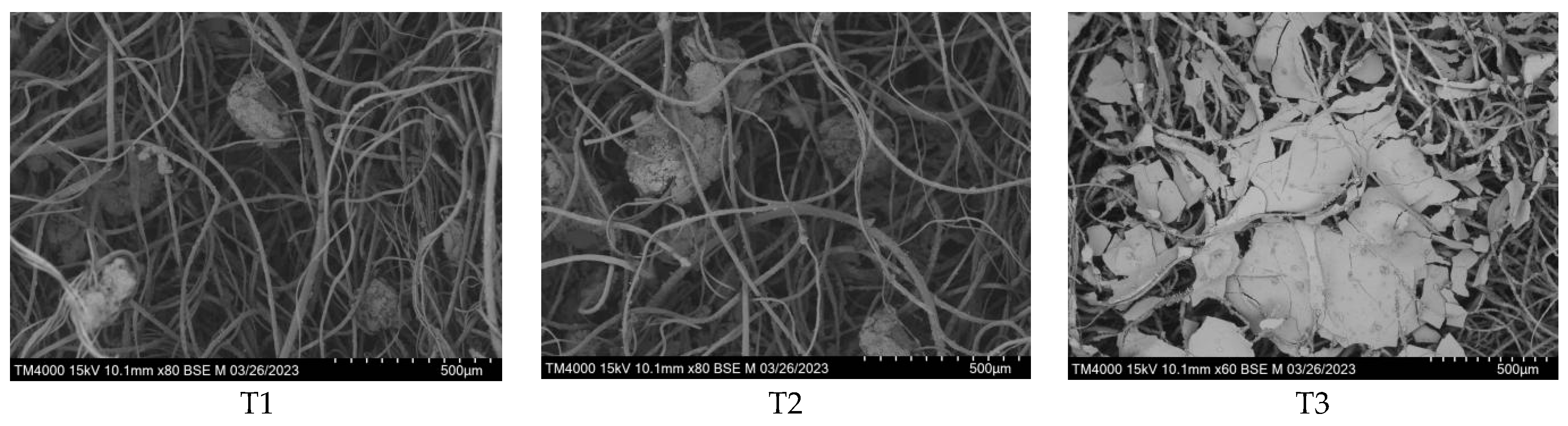

3.5. Geotextile Clogging and Soil Retention Effect

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tarolli, P.; Luo, J.; Park, E.; Barcaccia, G.; Masin, R. Soil salinization in agriculture: Mitigation and adaptation strategies combining nature-based solutions and bioengineering. iScience 2024, 27, 108830. [Google Scholar] [CrossRef] [PubMed]

- Cuevas, J.; Daliakopoulos, I.; Moral, F.; Hueso, J.; Tsanis, I. A review of soil-improving cropping systems for soil salinization. Agronomy 2019, 9, 295. [Google Scholar] [CrossRef]

- Minhas, P.; Ramos, T.; Ben, A.; Pereira, L. Coping with salinity in irrigated agriculture: Crop evapotranspiration and water management issues. Agric. Water Manag. 2020, 227, 105832. [Google Scholar] [CrossRef]

- James, O. History of the roles of gypsum in soil reclamation and establishment of SAR/EC water quality guidelines. In Proceedings of the First IUSS Conference on Sodic Soil Reclamation, Changchun, China, 10–12 May 2021. [Google Scholar]

- Yang, J.; Yao, R.; Wang, X.; Xie, W.; Zhang, X.; Zhu, W.; Zhang, L.; Sun, R. Research on Salt-affected Soils in China: History, Status Quo and Prospect. Acta Pedol. Sin. 2022, 59, 10–27. (In Chinese) [Google Scholar]

- Liu, T.; Wang, B.; Xiao, H.; Wang, R.; Yang, B.; Cao, Q.; Cao, Y. Differentially improved soil microenvironment and seedling growth of Amorpha fruticosa by plastic, sand and straw mulching in a saline wasteland in northwest China. Ecol. Eng. 2018, 122, 126–134. [Google Scholar] [CrossRef]

- Askri, B.; Khodmi, S.; Bouhlila, R. Impact of subsurface drainage system on waterlogged and saline soils in a Saharan palm grove. Catena 2022, 212, 106070. [Google Scholar] [CrossRef]

- Askar, M.; Youssef, M.; Chescheir, G.; Negm, L.; King, K.; Hesterberg, D.; Amoozegar, A.; Skaggs, R. DRAINMOD simulation of macropore flow at subsurface drained agricultural fields: Model modification and field testing. Agric. Water Manag. 2020, 242, 106401. [Google Scholar] [CrossRef]

- Ritzema, H.; Abdel-Dayem, S.; El-Atfy, H.; Nasralla, M.; Shaheen, H. Challenges in modernizing the subsurface drainage systems in Egypt. Agric. Water Manag. 2023, 288, 108484. [Google Scholar] [CrossRef]

- Soe, Y.; Shinogi, Y.; Taniguchi, T. Changes in Certain Paddy Soil Properties under Perforated Sheet Pipe as Subsurface Shallow Drainage. Jpn. Agric. Res. Q. JARQ 2022, 56, 59–66. [Google Scholar] [CrossRef]

- Heng, T.; Feng, G.; Yang, L.; He, X.; Yang, G.; Li, F.; Xu, X.; Feng, Y. Soil salt balance in a cotton field under drip irrigation and subsurface pipe drainage systems. Agron. J. 2021, 113, 4875–4888. [Google Scholar] [CrossRef]

- Acharya, U.; Chatterjee, A.; Daigh, A. Effect of Subsurface Drainage Spacing and Depth on Crop Yield. Agron. J. 2019, 111, 1675–1681. [Google Scholar] [CrossRef]

- Chen, G.; Wei, Z.; Liu, H. Study on Soil Desalination Process of Saline-Alkaline Grassland along the Yellow River in Western Inner Mongolia under Subsurface Drainage. Sustainability 2022, 14, 14494. [Google Scholar] [CrossRef]

- Rong, Z.; Wang, S.; Hao, R.; Hao, R.; Tao, Y. Permeability and anti-clogging performance of geotextile envelope material around subsurface drainage pipe in Yinbei Irrigation District in Ningxia. Trans. Chin. Soc. Agric. Eng. 2021, 37, 68–75. (In Chinese) [Google Scholar]

- Talukolaee, M.; Naftchali, A.; Parvariji, L.; Ahmadi, M. Investigating long-term effects of subsurface drainage on soil structure in paddy fields. Soil Tillage Res. 2018, 177, 155–160. [Google Scholar] [CrossRef]

- Mante, A.; Ranjan, R.; Bullock, P. Subsurface drainage for promoting soil strength for field operations in southern Manitoba. Soil Tillage Res. 2018, 184, 261–268. [Google Scholar] [CrossRef]

- Han, D.; Chen, C.; Wang, F.; Li, W.; Peng, H.; Jin, Q.; Bi, B.; Shaghaleh, H.; Hamoud, Y.A. Effects of Subsurface Pipe Drainage Spacing on Soil Salinity Movement in Jiangsu Coastal Reclamation Area. Sustainability 2023, 15, 13932. [Google Scholar] [CrossRef]

- Tian, F.; Miao, Q.; Shi, H.; Li, R.; Dou, X.; Duan, J.; Liu, J.; Feng, W. Study on Water and Salt Transport under Different Subsurface Pipe Arrangement Conditions in Severe Saline–Alkali Land in Hetao Irrigation District with DRAINMOD Model. Water 2023, 15, 3001. [Google Scholar] [CrossRef]

- Liu, W.; Luo, W.; Jia, Z.; Pan, Y.; Tang, S.; Yuan, H.; Li, S. Experimental study on geotextile envelope for subsurface drainage in Yellow River Delta. Trans. Chin. Soc. Agric. Eng. 2013, 29, 109–116. (In Chinese) [Google Scholar]

- Tian, F.; Shi, H.; Miao, Q.; Li, R.; Duan, J.; Dou, X.; Feng, W. Soil Water and Salt Transport in Severe Saline–Alkali Soil after Ditching under Subsurface Pipe Drainage Conditions. Agriculture 2023, 13, 2196. [Google Scholar] [CrossRef]

- Guo, C.; Wu, J.; Zhu, Y.; Lin, Z.; He, S.; Qian, Y.; Yang, H.; Li, H.; Wei, M. Influence of clogging substances on pore characteristics and permeability of geotextile envelopes of subsurface drainage pipes in arid areas. Geotext. Geomembr. 2020, 48, 735–746. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, S.; Xu, D.; Zhai, X. Effect of Structure-type on Improved Subsurface Drainage Performance. Trans. Chin. Soc. Agric. Mach. 2016, 47, 113–118. (In Chinese) [Google Scholar]

- Hu, S.; Tian, C.; Song, Y. Calculation of salinity leaching quota based on saturated infiltration theroy. Acta Pedol. Sin. 2010, 47, 563–567. (In Chinese) [Google Scholar]

- Wang, X.; Sun, Z.; Liu, X.; Bao, Z.; Jiao, B.; Li, X.; Zeng, Y.; Sameh, E. Amelioration of Alkalized Solonchak Soils by Subsurface Gravel Blind Ditches and Desulfurized Gypsum. Appl. Ecol. Environ. Res. 2019, 17, 7865–7879. [Google Scholar] [CrossRef]

- Chen, M.; Huang, J.; Zeng, W.; Ao, C.; Liu, D.; Liu, Y. Water-salt transport law of subsurface pipes with geotextiles under the condition of salt discharge. Trans. Chin. Soc. Agric. Eng. 2020, 36, 130–139. (In Chinese) [Google Scholar]

- Alavi, S.; Naseri, A.; Bazaz, A.; Ritzema, H.; Hellegers, P. Performance evaluation of the Hydroluis drainpipe-envelope system in a saline-sodic soil. Agric. Water Manag. 2021, 243, 106486. [Google Scholar] [CrossRef]

- Lu, P.; Yang, Y.; Luo, W.; Zhang, Y.; Jia, Z. Numerical Simulation of Soil Water-Salt Dynamics and Agricultural Production in Reclaiming Coastal Areas Using Subsurface Pipe Drainage. Agronomy 2023, 13, 588. [Google Scholar] [CrossRef]

- Zhang, D.; Jia, Z.; He, Y.; Zhang, Y.; Luo, K. Experimental study on hydraulic performance of subsurface drainage geotextile envelope in Yangzhou Yanyun Irrigation District. J. Drain. Irrig. Mach. Eng. 2023, 41, 38–43. (In Chinese) [Google Scholar]

- Elzoghby, M.; Jia, Z.; Luo, W. Experimental study on the hydraulic performance of nonwoven geotextile as subsurface drain filter in a silty loam area. Ain Shams Eng. J. 2021, 12, 3461–3469. [Google Scholar] [CrossRef]

- Tan, P.; Wang, S.; Fu, T.; Liu, J.; Han, L. Development history, present situation and prospect of the subsurface drainage technology in China. Chin. J. Eco-Agric. 2021, 29, 633–639. (In Chinese) [Google Scholar]

- Xu, Y.; Liu, H.; Gong, P.; Li, P.; Li, L.; Xu, Q.; Xue, B.; Guo, Y.; Zhang, Y.; Tian, R. Model-Based Optimization of Design Parameters of Subsurface Drain in Cotton Field under Mulch Drip Irrigation. Water 2022, 14, 3369. [Google Scholar] [CrossRef]

- Heng, T.; He, X.; Yang, L.; Xu, X.; Feng, Y. Mechanism of Saline–Alkali land improvement using subsurface pipe and vertical well drainage measures and its response to agricultural soil ecosystem. Environ. Pollut. 2022, 293, 118583. [Google Scholar] [CrossRef]

| Soil Depth/(cm) | Soil Texture | pH | Soil Salinity/(g∙kg−1) | Dry Density/(g∙cm−3) | Porosity/ (%) | Field Capacity/ (%) |

|---|---|---|---|---|---|---|

| 0−20 | Loam soil | 8.43 ± 0.01 | 99.86 ± 6.04 | 1.47 ± 0.05 | 44.53 ± 0.71 | 19.0 ± 0.50 |

| 20−40 | Loam soil | 8.42 ± 0.01 | 54.98 ± 3.13 | 1.53 ± 0.06 | 42.26 ± 0.68 | 19.1 ± 0.35 |

| 40−60 | Loam soil | 8.42 ± 0.01 | 71.17 ± 5.39 | 1.56 ± 0.04 | 41.13 ± 0.74 | 20.3 ± 0.80 |

| Soil Depth | Original Soil | T1 | T2 | T3 | ||||

|---|---|---|---|---|---|---|---|---|

| Salinity (g∙kg−1) | pH | Salinity (g∙kg−1) | pH | Salinity (g∙kg−1) | pH | Salinity (g∙kg−1) | pH | |

| 0–20 cm | 99.86 ± 6.04 | 8.43 ± 0.01 | 1.8 ± 0.16 b | 8.36 ± 0.02 a | 2.3 ± 0.14 b | 8.35 ± 0.02 a | 3.6 ± 0.11 a | 8.35 ± 0.01 a |

| 20–40 cm | 54.98 ± 3.13 | 8.42 ± 0.01 | 2.1 ± 0.37 b | 8.29 ± 0.08 a | 2.4 ± 0.24 b | 8.30 ± 0.02 a | 3.7 ± 0.10 a | 8.35 ± 0.01 a |

| 40–60 cm | 71.17 ± 5.39 | 8.42 ± 0.01 | 3.1 ± 0.83 b | 8.36 ± 0.01 a | 3.0 ± 0.19 b | 8.36 ± 0.03 a | 4.1 ± 0.10 a | 8.39 ± 0.02 a |

| Total salinity (kg) | 33.22 ± 10.02 | / | 1.2 ± 0.06 b | / | 1.1 ± 0.06 b | / | 1.6 ± 0.02 a | / |

| Scenario | Drainage Rate/v (cm∙h−1) | Drainage Efficiency/Rw (%) | Salt Discharge Rate/Rs (%) | Desalination Rate/LR (%) | (Rs/LR) |

|---|---|---|---|---|---|

| T1 | 0.037 ± 0.002 a | 49.78 ± 0.80 b | 83.40 ± 2.65 b | 96.39 ± 4.39 a | 0.87 ± 0.02 b |

| T2 | 0.034 ± 0.002 a | 54.92 ± 1.74 a | 95.00 ± 2.34 a | 96.69 ± 3.94 a | 0.98 ± 0.07 a |

| T3 | 0.023 ± 0.003 b | 54.01 ± 4.23 a | 74.38 ± 1.49 c | 95.18 ± 2.99 a | 0.78 ± 0.04 c |

| Scenario | Weight of Soil Loss/(g) | Initial Weight of Geotextile/(g) | Weight of Clogged Geotextile/(g) | Clogging Rate/(%) |

|---|---|---|---|---|

| T1 | 182.73 ± 6.62 a | 9.16 ± 0.11 c | 12.58 ± 0.68 c | 37.33 ± 6.54 c |

| T2 | 142.37 ± 3.70 b | 18.41 ± 0.58 b | 25.80 ± 1.16 b | 40.12 ± 5.24 b |

| T3 | 118.17 ± 5.60 c | 27.96 ± 1.44 a | 40.78 ± 2.42 a | 45.81 ± 1.65 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhang, Y.; Fan, L.; Shen, J. Salt Drainage Efficiency and Anti-Clogging Effects of Subsurface Pipes Wrapped with Geotextiles. Water 2024, 16, 1392. https://doi.org/10.3390/w16101392

Wang X, Zhang Y, Fan L, Shen J. Salt Drainage Efficiency and Anti-Clogging Effects of Subsurface Pipes Wrapped with Geotextiles. Water. 2024; 16(10):1392. https://doi.org/10.3390/w16101392

Chicago/Turabian StyleWang, Xu, Yonghong Zhang, Liqin Fan, and Jingli Shen. 2024. "Salt Drainage Efficiency and Anti-Clogging Effects of Subsurface Pipes Wrapped with Geotextiles" Water 16, no. 10: 1392. https://doi.org/10.3390/w16101392

APA StyleWang, X., Zhang, Y., Fan, L., & Shen, J. (2024). Salt Drainage Efficiency and Anti-Clogging Effects of Subsurface Pipes Wrapped with Geotextiles. Water, 16(10), 1392. https://doi.org/10.3390/w16101392